Abstract

Vanilla, a quintessential flavoring agent, experiences burgeoning demand globally, particularly for natural variants. In response, Taiwan has ventured into vanilla cultivation, aiming to reduce the energy consumption associated with international transportation by fostering domestic production. This study investigates the sensory attributes of Taiwan and Madagascar vanilla beans amid increasing global demand for natural vanilla. We extended our sensory evaluations to vanilla ice cream products to assess their quality. Employing sensory evaluation questionnaires and experimental techniques, we utilized purposive and snowball sampling methodologies for participant recruitment. Our primary aim is to discern the edible disparities between Taiwan and Madagascar vanilla beans by scrutinizing variations in consumer sensory preferences. Our findings reveal statistically significant disparities between Taiwan and Madagascar vanilla beans concerning product texture and overall aroma in sensory evaluations, while other attributes do not exhibit notable differences. This suggests that the sensory experience of vanilla ice cream products derived from Taiwan and Madagascar vanilla beans primarily diverges in terms of product texture and overall aroma, with negligible disparities elsewhere. Remarkably, Taiwan vanilla beans consistently outperform Madagascar vanilla beans across many evaluation criteria, underscoring the superior quality and competitive edge of Taiwan’s vanilla beans. This empirical evidence highlights the exceptional quality and value proposition of Taiwan vanilla beans, offering insights for the expansion and deepening of sensory evaluations pertaining to vanilla beans. Furthermore, our study contributes to environmental sustainability by promoting local production and presents new avenues for Taiwan’s vanilla processing industry.

1. Introduction

Vanilla is one of the most prevalent condiments and the most popular raw flavoring material globally, with extensive applications in the food, beverage, spice, and pharmaceutical industries [1,2,3,4]. Particularly within the baking industry, vanilla is a common ingredient in cakes, cookies, puddings, ice cream, and other related products, leading to a significant surge in demand. The high consumption of ice cream in countries such as the United States and Canada has further driven the growth of this market [5]. Vanilla beans were initially added to food products, with ice cream being one of the first to showcase the complete flavor profile of vanilla. The ice cream-making process deliberately avoids heating steps to prevent the loss of aroma, ensuring the full expression of the vanilla flavor. Additionally, ice cream holds significant economic importance in the food industry. According to the Global Industry Insight (GII) report on the global ice cream market [6], the market reached USD 73.2 billion in 2022, with projected lucrative growth to USD 108.9 billion by 2030. The market is anticipated to achieve a robust compound annual growth rate (CAGR) of 5.1% during the forecast period of 2023–2030. Therefore, ice cream serves as the material for sensory evaluation in this project.

According to Mordor Intelligence’s [7] forecast, the vanilla market size is projected to grow from USD 958.57 million in 2023 to USD 1.41695 billion by 2028, reflecting a compound annual growth rate (CAGR) of 8.13% during the forecast period (2023–2028). Owing to its extensive applications in the food and related industries, vanilla remains one of the most expensive spices traded internationally and continues to be a highly popular flavor across various sectors. It holds a particularly significant share in the ice cream and chocolate industries. As consumer awareness about health and the environmental impact of regulatory standards increases, major market players such as Nestlé, General Mills, and Hershey’s have announced intentions to incorporate natural colors and flavors in their products, thereby driving global demand for vanilla. Additionally, Mazhar and Taghadomi-Saberi [8] reported that the Australian vanilla industry is expected to surpass a total output value of USD 10 million by 2028.

However, the production of vanilla beans is notably challenging. The five major countries where vanilla cultivation is prevalent include Madagascar, Indonesia, China, Mexico, and Papua New Guinea [9]. Approximately 80% of the world’s vanilla is grown in Madagascar, which boasts an optimal climate for vanilla cultivation. This climate features a temperature range of 21–32 °C, an evenly distributed annual precipitation of 1500 mm or more, and an average relative humidity of 80% [10]. Due to reduced production and increased international demand, the average price of vanilla beans has risen sharply since 2013. In 2017, Madagascar, the world’s largest vanilla producer, was struck by Hurricane Enawo. The storm left more than 20,000 people homeless and destroyed 70% of the country’s vanilla crops, leading to a significant decline in production and a subsequent rise in prices. By 2018, the price of vanilla beans had soared to USD 600 per kilogram, making vanilla the most expensive spice in the world after saffron [5,11].

The global market has been enduring a prolonged “vanilla crisis,” characterized by an uncontrolled surge in the price of natural vanilla. This crisis stems from significant volatility in the vanilla market, where global demand for natural vanilla is rising while supply is diminishing [12]. In Taiwan, the Taoyuan District Agricultural Research and Extension Station, part of the Ministry of Agriculture, initiated the trial cultivation of Bourbon vanilla orchid in 2007 [13]. By 2012, following the transfer of cultivation technology to local farmers, an increasing number of Taiwanese farmers began planting Bourbon vanilla orchid.

The vanilla orchid is a heliophilous plant, typically cultivated in net chambers within Taiwan. Significant production of vanilla beans does not commence until the third year post-planting. The harvested pods undergo a meticulous process involving four stages—cyanide treatment, fermentation, drying, and ripening—over a period of 5 to 6 months before they become market-ready. Despite these advancements, Taiwan’s vanilla industry remains nascent and continues to face numerous challenges. Madagascar’s vanilla beans are internationally recognized as the benchmark for vanilla quality, while Indonesia is emerging as a promising alternative in terms of both quantity and quality. The escalating demand for vanilla, particularly in the ultra-luxury ice cream sector, has prompted expanding vanilla exports from producing nations such as Madagascar and Indonesia, notably to European and American markets [14]. Based on the high-quality grading standards of most stores like Cooks Vanilla [15], Native Vanilla [16], and Vanilla Pura [17], Grade-A beans, often referred to as “gourmet vanilla beans,” are visually more appealing. They are plump, pliable, and full of fresh vanilla bean caviar. Their color is dark and chocolate-like, sometimes with hints of red. The moisture content in vanilla beans is a crucial physical property, with good vanilla beans ranging between 20% and 35% water. The most important quality of vanilla beans is their vanillin content, which ranges between 0.75% and 1.5% per weight. Good vanilla beans typically measure between 15 and 20 cm.

Hence, vanilla beans represent a commodity of considerable economic value in the global agricultural landscape, with significant industrial implications. Notably, Taiwan’s vanilla bean market is heavily reliant on imports, with Madagascar standing out as a primary exporter in the international arena [18]. Madagascar’s vanilla not only enjoys a reputation for superior quality but also commands approximately 80% of the global market share. Vanilla beans undergo harvesting while still green and devoid of any discernible aroma. This initial stage marks the commencement of a prolonged transformation process necessary for the development of the characteristic aroma associated with vanilla. Vanilla extract, a derivative of vanilla beans, comprises various compounds, with vanillin being the most prevalent [4]. Sinha, Sharma, and Sharma [3] emphasize that vanillin significantly influences the flavor profile of vanilla.

As a species of vanilla plant, the vanilla bean encompasses over 270 distinct fragrance compounds, including notes of milk, fruitiness, tea, sweetness, acidity, woodiness, oiliness, vinous tones, spiciness, and smokiness [19]. Takahashi et al. [20] estimate that vanilla beans contain approximately 250 to 500 different flavoring constituents. Januszewska et al. [9] categorize the perceived odor description of vanilla extract into six main categories: fruity, creamy, fermented, floral, phenolic, and spicy.

Research conducted by da Silva et al. [21] underscores the diverse attributes associated with vanilla flavor. Notably, respondents commonly mention sweetness (71.1%), caramel notes (43.20%), floral hints (32.20%), fruity undertones (28.7%), woody nuances (23.9%), honeyed accents (20.9%), and creamy qualities (20.6%). Evidently, vanilla beans exhibit a rich and multifaceted flavor profile, with sweetness, caramel, floral, and fruity notes being among the most prevalent and recognizable to the majority of individuals. The market success of a product hinges not only on initial consumer preference but also on subsequent repeat purchases, as underscored by Drake, Watson, and Liu [22]. To foster repeat purchases, products must consistently meet consumer preferences, highlighting the importance of sensory and hedonic considerations from the consumer’s standpoint. Sensory science has evolved into a comprehensive field of study over the past century, serving as a valuable tool for practical applications.

Methods for sensory evaluation of food can be broadly categorized into two types. The first type is affective testing, which involves consumer tests. This method employs consumers or untrained individuals as panelists to directly measure the degree of liking or acceptance of a food product. Affective tests are commonly used in new product development or to gauge consumer evaluations of existing products. The second type is analytical testing, which includes sensitivity tests and difference and descriptive analyses. Difference analysis focuses on understanding whether and to what extent differences exist between products. Descriptive analysis qualitatively or quantitatively assesses the characteristic attributes of food substances. Analytical sensory evaluations typically require trained panelists, especially for descriptive analysis, which necessitates rigorously trained evaluators [23].

Sidel et al. [24] proposed that the number of panelists for sensory tests should range between 25 to 50. For consumer-oriented sensory evaluations, panelists should come from various industries, age groups, and genders, with a minimum number of 30 and preferably more than 50 for optimal results. The evaluation questionnaires should be simple and concise. Additionally, Lawless [25] mentioned that human perceptions are easily influenced by environmental factors, leading to varying judgments. Factors such as conversation, noise interference, sample order, color, and appearance can induce psychological biases in panelists. These elements must be controlled to ensure scientific rigor in sensory evaluation processes.

Therefore, the process of human flavor perception is highly complex. To understand people’s views on food through sensory evaluation, it is necessary to explore from multiple perspectives. Particularly in the design of sensory evaluation experiments, it is essential to consider various factors and provide a well-designed experimental environment, appropriate tools, and thorough procedures to obtain the most effective evaluation data.

The aim of this study is to understand the sensory differences between vanilla beans produced in Taiwan and those from Madagascar, as Madagascar’s vanilla beans are considered the gold standard worldwide. Therefore, we will measure the flavors of vanilla beans from both Taiwan and Madagascar to assess whether Taiwanese vanilla beans can meet the quality of the Madagascar gold standard. This assessment will particularly focus on consumer sensory evaluations, preference, and acceptance differences through the processing of vanilla into ice cream.

2. Materials and Methods

2.1. Materials

The vanilla beans used in the experiment consisted of domestically produced vanilla beans from Taiwan and vanilla beans originating from Madagascar. The vanilla beans used in this study were sourced from the Taoyuan District Agricultural Research and Extension Station, Ministry of Agriculture, in Taiwan, in September 2023, and measured 18 to 20 cm in length. The vanilla beans from Madagascar were purchased from TEHMAG FOODS CORPORATION (Taipei City, Taiwan) in September 2023. To ensure consistency, researchers also selected vanilla beans measuring 18 to 20 cm in length from Madagascar, thereby ensuring fairness in the study. The extraction of vanilla beans was performed using a modified method based on the recommendations of Jadhav et al. [26], Dong et al. [27], Delgado et al. [28], and Yeh et al. [29] to suit the objectives of this study.

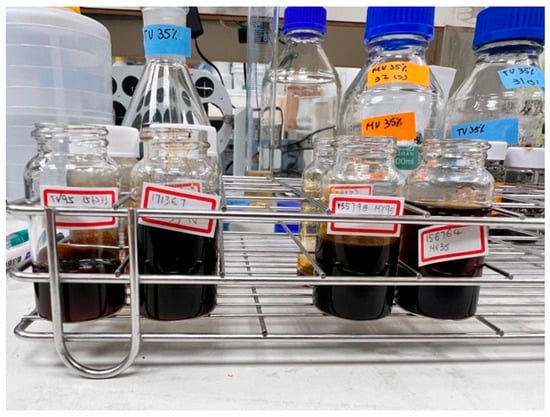

2.2. Extraction of Vanilla Beans: Plant Sources and Methods

In this study, 90 g of vanilla beans from both Taiwan and Madagascar were ground. The sample-to-solvent ratio was 1:10 (w/v), with 900 mL of different concentrations of ethanol (35%, 95%) added [29]. Ultrasonic agitation (Delta® DC300H, Taipei City, Taiwan) was conducted for 60 min (Figure A1), and this process was repeated three times. The samples were then filtered, and the extract was transferred to a rotary evaporator (Büchi Rotavapor® R-100, Uster, Switzerland) (Figure A2) to remove the solvent and obtain the vanilla extract (Figure A3). Subsequently, the extraction efficiency for different varieties and solvents was calculated.

After three rounds of ultrasonic extraction of 90 g of vanilla beans, the highest extraction yields with 35% ethanol solvent were obtained for Taiwan vanilla beans at 20.3% and Madagascar vanilla beans at 21.8% (Table A1). Subsequently, 4-hydroxybenzoic acid, vanillic acid, 4-hydroxybenzaldehyde, and vanillin were analyzed using High Performance Liquid Chromatography (HPLC) with the vanilla concentrate extract samples. It was found that Taiwan vanilla beans and Madagascar vanilla beans extracted the highest amounts of vanillin when using 35% ethanol solvent (Table A1). Therefore, subsequent sensory evaluation experiments will utilize extracts obtained with 35% ethanol solvent.

2.3. Vanilla Ice Cream

In the production of the ice cream samples (Table 1), the vanilla flavor is derived from the extract of vanilla beans obtained through scientific instrumentation. To preserve the purity of flavor and avoid interference, the formulation deliberately excludes materials such as eggs, gelatin, stabilizers, emulsifiers, and flavorings. Instead, the ice cream is made using only fresh milk, animal cream, seaweed sugar, and condensed milk.

Table 1.

Vanilla ice cream recipe.

2.4. Sensory Evaluation

2.4.1. Study Subjects and Sampling Method

This study obtained approval from the Taoyuan District Agricultural Research and Extension Station (Approval No. 1120502-S). The research procedures adhere to the ethical guidelines outlined by our institution’s ethics committee, which are based on the ethical principles outlined in the “Ethical Committee of Fu Jen Catholic University” and the “Declaration of Helsinki”. According to Sidel et al. [24], studies suggest that the number of participants can range from 25 to 50. Therefore, this study recruited 55 participants through snowball sampling and purposive sampling. Researchers introduced the nature of the study and the composition of the samples to the participants, inquired about any food allergies beforehand, and ensured that participation was voluntary and that participants understood they could withdraw from the experiment at any time. Oral consent was obtained in the presence of at least two research team members acting as witnesses. All participants have had the experience of consuming vanilla ice cream, with each individual consuming it at least once a month. Furthermore, all participants are enthusiasts of vanilla ice cream. The demographic characteristics of the participants are detailed in Table 2. All participants self-reported no significant illnesses or conditions that could potentially affect their taste or smell, confirming their physiological health. Sensory evaluations were conducted in a professional sensory evaluation laboratory, with participants tasting vanilla ice cream under room temperature and white fluorescent lighting. Participants were instructed to rinse their mouths with water both before and after tasting to minimize residual flavors. The order in which participants tasted the samples was randomized. Upon completion of sensory evaluation of the samples, participants received gift cards as compensation to acknowledge their participation.

Table 2.

Distribution of basic consumer demographics (n = 55).

2.4.2. Sensory Evaluation Questionnaire

The preference evaluation conducted in this study belongs to the category of consumer sensory evaluation methods [30]. Participants do not require prior training to conduct the evaluation. The questionnaire in this stage is divided into three main categories: basic information, terminology explanation, and rating selection. The items in the preference evaluation questionnaire of this study were adapted and revised from the studies of Świąder, K., and Marczewska [31]; Ker et al. [32]; Lee et al. [33]; Short et al. [34]; Craine et al. [35]; and Thompson et al. [36], to better fit the research theme (see Table 3). The sensory assessment questionnaire consists of 11 items, using a 7-point scale. A score of 7 indicates “extremely liked”, while a score of 1 indicates “extremely disliked”. Participants select their rating based on their actual experience, with higher scores indicating higher preference or intensity for the item.

Table 3.

Sensory evaluation questionnaire for vanilla ice cream consumers.

2.5. Statistical Analysis

The statistical analysis software SPSS 25.0 for Windows was used for the data analysis. “First, group the participants’ evaluations of the two origins, then analyze the data related to sensory evaluation, including mean, standard deviation, and Independent Samples t-Test.”

3. Results

3.1. Sensory Evaluation Analysis of Vanilla Ice Cream

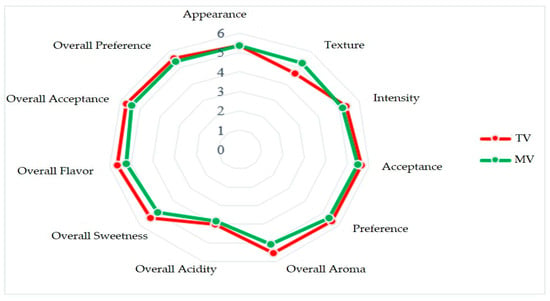

According to Table 4, participants compared the sensory evaluation of domestically produced vanilla beans and Madagascar-produced vanilla beans in vanilla ice cream. There was no significant difference observed in product color (t = 0.077, p > 0.05), indicating that participants perceived no distinction between the two in terms of product color. However, there was a significant difference in product texture (t = −2.664, p < 0.01), indicating that participants perceived a noticeable difference in product texture between the two. No significant differences were found in vanilla richness (t = 0.720, p > 0.05), vanilla acceptance (t = 0.873, p > 0.05), and vanilla preference (t = 0.972, p > 0.05), indicating that participants perceived no difference in vanilla richness, acceptance, and preference between the two.

Table 4.

Sensory evaluation analysis of vanilla ice cream (n = 55).

A significant difference was observed in overall aroma (t = 2.135, p < 0.05), indicating that participants perceived a noticeable difference in overall aroma between the two. However, no significant differences were found in overall acidity (t = 0.626, p > 0.05), overall sweetness (t = 1.943, p > 0.05), overall flavor (t = 1.896, p > 0.05), overall acceptance (t = 1.180, p > 0.05), and overall preference (t = 0.950, p > 0.05), indicating that participants perceived no difference in overall acidity, sweetness, flavor, acceptance, and preference between the two.

Overall, vanilla ice cream made from Taiwanese and Madagascar vanilla bean extracts showed significant differences in product texture and overall aroma in the sensory evaluation by participants. However, there were no significant differences observed in other aspects, indicating that participants perceived differences in product texture and overall aroma between the ice creams made from vanilla beans of the two origins, while other aspects showed no distinction.

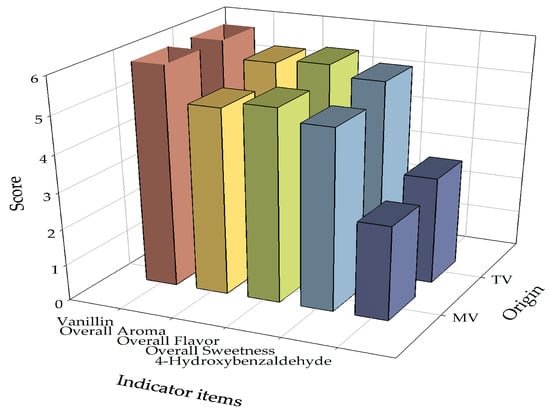

Additionally, as shown in Figure 1, participants had a positive perception of the TV vanilla ice cream, particularly in terms of product color, vanilla richness, vanilla acceptance, vanilla preference, overall aroma, overall acidity, overall sweetness, overall flavor, overall acceptance, and overall preference, with average scores higher than those for MV. As shown in Figure 2, by compiling the values of vanillin, 4-Hydroxybenzaldehyde, overall aroma, overall sweetness, and overall flavor, it can be observed that the average scores for TV in these three categories are significantly higher than those for MV. This finding is consistent with the results of the HPLC analysis (refer to Table A1). Therefore, the results of this study contribute to the sensory evaluation of Taiwanese vanilla beans, filling a gap in this field.

Figure 1.

Participant ice cream sensory evaluation radar chart.

Figure 2.

Three-dimensional relationship map of vanilla flavor, origin, and components.

3.2. Single Factor Covariate Analysis

In this study, we conducted a Single Factor Covariate Analysis (ANCOVA) to compare the overall flavor satisfaction of Madagascan vanilla beans (MV) and Taiwanese vanilla beans (TV). The overall flavor satisfaction of MV was used as a covariate, while the overall flavor satisfaction of TV was the dependent variable. The results, as shown in Table 5, indicate that after controlling for the impact of MV’s overall flavor satisfaction, there were significant differences in the overall flavor satisfaction of TV.

Table 5.

Single factor ANCOVA results for overall flavor satisfaction of TV.

The ANCOVA results revealed an F-value of 7.182 with a p-value of 0.009, which is less than 0.01, reaching a significance level of 0.01. This indicates a significant difference in overall flavor satisfaction for TV. The partial eta squared (η2) was 0.099, indicating a substantial effect size.

These results demonstrate that after controlling for the influence of MV’s overall flavor satisfaction, there is a significant variance in overall flavor satisfaction based on the different origins of the vanilla beans.

4. Discussion

According to experimental results, participants perceived a statistically significant difference in product texture and overall aroma between vanilla beans from different regions. Specifically, participants rated the overall flavor, sweetness, and aroma of Taiwanese vanilla significantly higher than that of Madagascan vanilla. Additionally, Taiwanese vanilla beans received slightly higher scores in terms of overall acceptance, overall liking, vanilla liking, vanilla acceptance, and vanilla richness. However, the texture of the Taiwanese product was rated lower than that of the Madagascan vanilla.

Due to the differences in vanilla pod varieties, soil composition, climate, and cultivation practices, the aroma components between different vanilla varieties and origins vary [37]. In sensory studies of vanilla pods, researchers have explored different origins [38,39,40], harvest periods [41], curing procedures [42], and bean quality [43]. Most studies on vanilla pods focus on comparisons between different origins. Our study compares two origins and finds that Taiwanese vanilla pods are of exceptionally high quality. This competitiveness can be attributed to the vanillin content, which is 2.2% for Taiwanese beans and 1.8% for Madagascan beans—an important quality indicator for vanilla [3,4]. As identified in our study, the vanillin content is higher in Taiwanese vanilla beans. Overall, Taiwanese vanilla beans demonstrate considerable competitiveness [13,29].

The study also evaluated the sensory properties of the most popular processed product, vanilla ice cream, following the vanilla bean production process. Similar sensory evaluation methods have been used in various studies [36,44,45,46]. The research team conducted sensory evaluations with consumers experienced in consuming vanilla ice cream to determine preferences for Taiwanese vanilla beans. As highlighted by Drake, Watson, and Liu [22], products that align with consumer preferences are more likely to become repeat purchases.

The ice cream used for evaluation was made with vanilla extract derived from vanilla beans of a fixed weight. Given the same unit weight, Taiwanese vanilla beans contain a higher proportion of vanillin, resulting in ice cream with a richer vanilla flavor. The results confirmed that participants perceived the overall flavor, sweetness, and aroma of ice cream made from Taiwanese vanilla beans to be significantly higher than those made from Madagascan beans. This finding underscores the high quality and competitiveness of Taiwanese vanilla beans.

Additionally, sensory evaluations of vanilla ice cream made from Taiwanese beans indicate that these beans provide richer and more favorable flavor characteristics. This enhances the competitive advantage of Taiwanese vanilla beans in both local and international markets. The results suggest that vanilla products derived from Taiwanese vanilla beans are highly favored by consumers. In addition to local cultivation and sales, these products reduce energy consumption associated with import transportation, promote sustainable agricultural practices, and enhance local economic development, particularly revitalizing rural areas, thus providing overall environmental sustainability benefits [47,48]. Taiwanese vanilla beans are thus comparable in quality to Madagascan vanilla beans. For Taiwanese consumers, choosing locally produced vanilla is conducive to sustainable development, maintaining high-quality standards, and supporting the local production economy [48]. The benefits of this approach are substantial.

In summary, we conducted a sensory evaluation of vanilla beans produced in Taiwan and Madagascar, inviting participants with experience in consuming vanilla ice cream. The results indicate that Taiwanese vanilla beans are superior to Madagascan vanilla beans in terms of overall flavor, sweetness, and aroma. These findings are consistent with our HPLC analysis results. This demonstrates that the quality of Taiwanese vanilla beans is exceptionally high, leading to a superior final product quality.

5. Conclusions

This study conducted an in-depth investigation of vanilla beans produced in Taiwan and Madagascar, providing valuable insights into various extraction methods and vanillin content. Vanilla extracts from both sources were used to create vanilla ice cream, which was then subjected to a comprehensive sensory evaluation. The evaluation assessed multiple attributes such as product color, texture, vanilla richness, and overall flavor characteristics, including sweetness, acidity, and aroma.

The experimental methods meticulously documented the selection criteria for the vanilla beans and detailed the production process of the vanilla ice cream. Fifty-five healthy consumers with a preference for vanilla ice cream participated in the sensory evaluation. The research aimed to address the following questions: (1) How do the sensory profiles of Taiwan and Madagascar vanilla beans differ? (2) What are the impacts of these differences on ice cream quality and consumer preferences?

The findings revealed that the quality of Taiwanese vanilla beans is exceptionally good, as evidenced by their superior performance across multiple sensory attributes compared to Madagascan vanilla beans, potentially matching or even exceeding the traditional quality standards associated with Madagascan vanilla. Taiwan’s unique geological environment, including rich soil conditions and suitable climate, provides ideal growing conditions, significantly enhancing the aroma and quality of the vanilla beans.

Further, through a one-way ANCOVA, we explored the significant differences in overall flavor satisfaction between vanilla beans from different origins. In this study, the overall flavor satisfaction of Madagascan vanilla beans (MV) served as a covariate, and that of Taiwanese vanilla beans (TV) as the dependent variable. The analysis showed that after controlling for the influence of MV, the F-value for TV was 7.182, with a p-value of 0.009, achieving a significance level of 0.01, indicating a significant difference in overall flavor satisfaction between Taiwanese and Madagascan vanilla beans. This finding further confirms the unique sensory advantages of Taiwanese vanilla beans.

Madagascar, being the largest producer of vanilla beans globally, possesses the most suitable climatic conditions for vanilla cultivation, including a temperature range of 21–32 °C, an annual average rainfall of over 1500 mm, and an average relative humidity of around 80%. These conditions provide an ideal natural environment for the growth of vanilla, making Madagascan vanilla beans the gold standard in quality on the global market. However, the study also found significant sensory attributes in Taiwanese vanilla beans, suggesting that Taiwan’s unique agricultural practices and climatic conditions contribute to its superior quality.

The differences in sensory evaluation between vanilla beans may be attributed to several key factors. Climatic conditions play a crucial role, as the unique combination of temperature, humidity, and soil composition in each region can significantly impact the growth and development of vanilla plants, thereby affecting the flavor characteristics of the beans. Moreover, the agricultural practices in both regions, including cultivation, harvesting, and curing methods, are critical in determining the quality and sensory attributes of vanilla beans. Techniques in Taiwan might involve innovative or traditional methods that differ from those used in Madagascar, potentially leading to variations in vanillin content and other aromatic compounds. Additionally, genetic differences in the vanilla plants cultivated in each region may contribute to subtle differences in flavor and sensory attributes. Different species or cultivars, each with their specific genetic makeup, can yield beans with varying qualities and sensory profiles.

This study’s findings contribute significantly to the field of vanilla bean research, particularly in highlighting the unique advantages of Taiwanese vanilla beans. However, the study also recognizes the necessity for further research to refine the quality assessment metrics, especially for Taiwanese vanilla beans. Such research could explore additional sensory dimensions and potentially involve a larger and more diverse sample population to validate the findings. This pioneering investigation marks a significant step in the sensory analysis of vanilla ice cream made from Taiwanese vanilla beans, setting the groundwork for future studies in this field.

6. Practical Contribution

The findings of this study make a significant contribution to the field of vanilla bean research in Taiwan. While there have been numerous discussions in the literature regarding vanilla beans, research specifically focused on those grown and produced in Taiwan remains scarce. This study expands the scope and depth of research topics in this area. Our team is the first to conduct a sensory evaluation of Taiwanese vanilla beans, using vanilla beans from Madagascar as the control standard due to their reputation as the gold standard for quality. By conducting sensory evaluations of vanilla ice cream, we aimed to capture consumers’ genuine sensory experiences and preferences, which is the greatest contribution of this study. The results provide a valuable foundation for promoting Taiwanese vanilla beans. These findings have the potential to drive innovation and breakthroughs in Taiwan’s agricultural sector, encouraging industry stakeholders to utilize Taiwanese vanilla beans and thereby enhancing the economic prospects of the industry.

7. Research Limitations and Future Research

This study utilized purposive sampling to recruit participants, focusing on young people, who are the primary consumers of ice cream. However, the age distribution of participants was predominantly between 21 and 30 years old, limiting the generalizability of the results to other age groups. This represents the first limitation of the study. The health of participants was based on self-assessment, without external verification, constituting the second limitation. Although the production and evaluation processes for the ice cream were controlled under unified conditions, the possibility of human operational errors cannot be entirely excluded, marking the third limitation.

Additionally, this study focused exclusively on the sensory evaluation of vanilla ice cream, a specific processed product of vanilla beans, making it challenging to generalize the findings to other vanilla-based products. This is the fourth limitation. Despite these limitations, the potential for further development of Taiwanese vanilla beans remains significant. Future research should explore a broader range of processed products, including direct sensory evaluations of vanilla beans, and employ advanced analytical methods such as electronic tongues and flavor detection instruments. These approaches could provide more comprehensive insights into the qualities and applications of Taiwanese vanilla beans.

Author Contributions

Data curation, C.-H.Y. and Y.-C.H.; formal analysis, Y.-C.C. and M.-C.C.; investigation, Y.-C.C., C.-H.Y. and M.-Y.T.; methodology, Y.-C.C., C.-S.L., M.-C.C. and M.-Y.T.; project administration, Y.-C.H. and C.-H.Y.; resources, W.-H.H. and Y.-J.C.; software, M.-C.C.; supervision, C.-S.L.; validation, C.-H.Y., W.-H.H. and M.-C.C.; visualization, C.-S.L.; writing—original draft, Y.-C.C.; writing—review and editing, C.-S.L. and Y.-C.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Taoyuan District Agricultural Research and Extension Station, Taiwan, grant number 1120502-S.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy and ethical restrictions.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Figure A1.

Ultrasonic agitation process.

Figure A2.

Rotary evaporation process.

Figure A3.

Vanilla extracts obtained by ultrasonic extraction with solvents. From left to right: TV95 (Taiwan vanilla, 95% ethanol), TV35 (Taiwan vanilla, 35% ethanol), MV95 (Madagascar vanilla, 95% ethanol), MV35 (Madagascar vanilla, 35% ethanol).

Table A1.

HPLC Analysis Results of Vanilla Concentrate Extract Samples (unit: mg/g).

Table A1.

HPLC Analysis Results of Vanilla Concentrate Extract Samples (unit: mg/g).

| Sample | Sample W (g) | Yield (%) | 4-Hydroxybenzoic Acid (mg/g) | Vanillic Acid (mg/g) | 4-Hydroxybenzaldehyde (mg/g) | Vanillin (mg/g) |

|---|---|---|---|---|---|---|

| TV95 | 16.92 | 18.8 | 0.14 ± 0.03 | 0.83 ± 0.10 | 2.45 ± 0.16 | 44.08 ± 2.38 |

| TV35 | 18.27 | 20.3 | 0.42 ± 0.03 | 2.41 ± 0.07 | 2.96 ± 0.17 | 47.59 ± 4.73 |

| MV95 | 18.18 | 20.2 | 1.41 ± 0.14 | 4.96 ± 0.49 | 1.84 ± 0.11 | 27.13 ± 1.66 |

| MV35 | 19.62 | 21.8 | 1.88 ± 0.04 | 6.64 ± 0.26 | 2.60 ± 0.15 | 35.40 ± 2.69 |

Note: TV represents Taiwan vanilla beans, MV represents Madagascar vanilla beans, 95 represents 95% ethanol, and 35 represents 35% ethanol.

References

- Grisoni, M.; Nany, F. The beautiful hills: Half a century of vanilla (Vanilla planifolia Jacks. ex Andrews) breeding in Madagascar. Genet. Resour. Crop Evol. 2021, 68, 1691–1708. [Google Scholar] [CrossRef]

- Gallage, N.J.; Møller, B.L. Biotechnology of Natural Products; Schwab, W., Lange, B., Wüst, M., Eds.; Springer: Cham, Switzerland, 2018; pp. 3–24. [Google Scholar]

- Sinha, A.K.; Sharma, U.K.; Sharma, N. A comprehensive review on vanilla flavor: Extraction, isolation and quantification of vanillin and others constituents. Int. J. Food. Sci. Nutr. 2008, 59, 299–326. [Google Scholar] [CrossRef]

- Pitman, C.N.; LaCourse, W.R. Rapid characterization of vanilla with Molecular Ionization Desorption Analysis Source (MIDAS) for mass spectrometry. Int. J. Mass. Spectrom. 2022, 479, 116888. [Google Scholar] [CrossRef]

- Fortune Business Insights. Available online: https://www.fortunebusinessinsights.com/vanilla-market-104180 (accessed on 3 June 2024).

- GII. Available online: https://www.gii.tw/report/dmin1325306-global-ice-cream-market.html (accessed on 22 April 2024).

- Mordor Intelligence. Available online: https://www.mordorintelligence.com/industry-reports/global-vanilla-industry (accessed on 3 June 2024).

- AgriFutures Australia. Australian Vanilla RD&E Plan (2023–2028). Available online: https://agrifutures.com.au/product/australian-vanilla-rde-plan-2023-2028/ (accessed on 3 June 2024).

- Januszewska, R.; Giret, E.; Clement, F.; Van Leuven, I.; Goncalves, C.; Vladislavleva, E.; Pradal, P.; Nåbo, R.; Landuyt, A.; D’Heer, G.; et al. Impact of vanilla origins on sensory characteristics of chocolate. Food Res. Int. 2020, 137, 109313. [Google Scholar] [CrossRef]

- FAO. Available online: https://www.fao.org/fileadmin/user_upload/inpho/docs/Post_Harvest_Compendium_-_Vanilla.pdf (accessed on 3 June 2024).

- KTCHNrebel. Available online: https://www.ktchnrebel.com/bourbon-vanilla-madagascar-crime/ (accessed on 3 June 2024).

- da Silva Oliveira, J.P.; Garrett, R.; Koblitz, M.G.B.; Macedo, A.F. Vanilla flavor: Species from the Atlantic forest as natural alternatives. Food Chem. 2022, 375, 131891. [Google Scholar] [CrossRef] [PubMed]

- Yeh, C.H.; Chen, K.Y.; Chou, C.Y.; Liao, H.Y.; Chen, H.C. New insights on volatile components of Vanilla planifolia cultivated in Taiwan. Molecules 2021, 26, 3608. [Google Scholar] [CrossRef]

- GII. Available online: https://www.gii.tw/report/ksi1410245-vanilla-market-forecasts-from.html (accessed on 22 April 2024).

- Cooks Vanilla. Available online: https://cooksvanilla.com/blogs/news/how-are-madagascar-vanilla-beans-graded (accessed on 28 June 2024).

- Native Vanilla. Available online: https://nativevanilla.com/collections/gourmet-beans (accessed on 28 June 2024).

- Vanilla Pura. Available online: https://www.vanillapura.com/pages/grade-a-vanilla-beans-vs-grade-b-vanilla-beans (accessed on 28 June 2024).

- Ministry of Agriculture. Available online: https://kmweb.moa.gov.tw/subject/subject.php?id=48083&print=Y (accessed on 9 August 2024).

- Pérez-Silva, A.; Odoux, E.; Brat, P.; Ribeyre, F.; Rodriguez-Jimenes, G.; Robles-Olvera, V.; García-Alvarado, M.A.; Günata, Z. GC–MS and GC–olfactometry analysis of aroma compounds in a representative organic aroma extract from cured vanilla (Vanilla planifolia G. Jackson) beans. Food Chem. 2006, 99, 728–735. [Google Scholar] [CrossRef]

- Takahashi, M.; Inai, Y.; Miyazawa, N.; Kurobayashi, Y.; Fujita, A. Identification of the key odorants in Tahitian cured vanilla beans (Vanilla tahitensis) by GC-MS and an aroma extract dilution analysis. Biosci. Biotechnol. Biochem. 2013, 77, 601–605. [Google Scholar] [CrossRef]

- da Silva, F.N.; Brumano, C.N.; Vieira, R.F.; Vidigal, M.C.T.R.; Minim, V.P.R. Market research: Characterization of the vanilla consumer and non-consumer market. Res. Soc. Dev. 2022, 11, e57911730505. [Google Scholar] [CrossRef]

- Drake, M.A.; Watson, M.E.; Liu, Y. Sensory analysis and consumer preference: Best practices. Annu. Rev. Food Sci. Technol. 2023, 14, 427–448. [Google Scholar] [CrossRef] [PubMed]

- Gillette, M. Sensory evaluation: Analytical and affective testing. Perfum. flavor. 1990, 15, 33–40. [Google Scholar]

- Sidel, J.L.; Stone, H.; Bloomquist, J. Use and misuse of sensory evaluation in research and quality control. J. Dairy Sci. 1981, 64, 2296–2302. [Google Scholar] [CrossRef]

- Lawless, H. The sense of smell in food quality and sensory evaluation. J. Food Qual. 1991, 14, 33–60. [Google Scholar] [CrossRef]

- Jadhav, D.; Rekha, B.N.; Gogate, P.R.; Rathod, V.K. Extraction of vanillin from vanilla pods: A comparison study of conventional soxhlet and ultrasound assisted extraction. J. Food Eng. 2009, 93, 421–426. [Google Scholar] [CrossRef]

- Dong, Z.; Gu, F.; Xu, F.; Wang, Q. Comparison of four kinds of extraction techniques and kinetics of microwave-assisted extraction of vanillin from Vanilla planifolia Andrews. Food Chem. 2014, 149, 54–61. [Google Scholar] [CrossRef] [PubMed]

- Delgado, L.; Heckmann, C.M.; De Benedetti, S.; Nardini, M.; Gourlay, L.J.; Paradisi, F. Producing natural vanilla extract from green vanilla beans using a β-glucosidase from Alicyclobacillus acidiphilus. J. Biotechnol. 2021, 329, 21–28. [Google Scholar] [CrossRef]

- Yeh, C.H.; Chou, C.Y.; Wu, C.S.; Chu, L.P.; Huang, W.J.; Chen, H.C. Effects of Different Extraction Methods on Vanilla Aroma. Molecules 2022, 27, 4593. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Toro-Gipson, R.S.D.; Drake, M. Sensory properties and consumer acceptance of ready-to-drink vanilla protein beverages. J. Sens. Stud. 2021, 36, e12704. [Google Scholar] [CrossRef]

- Świąder, K.; Marczewska, M. Trends of using sensory evaluation in new product development in the food industry in countries that belong to the EIT regional innovation scheme. Foods 2021, 10, 446. [Google Scholar] [CrossRef]

- Ker, J.K.; Lee, C.S.; Chen, Y.C.; Chiang, M.C. Exploring Taiwanese Consumer Dietary Preferences for Various Vinegar Condiments: Novel Dietary Patterns across Diverse Cultural Contexts. Nutrients 2023, 15, 3845. [Google Scholar] [CrossRef]

- Lee, Y.J.; Kim, I.A.; van Hout, D.; Lee, H.S. Investigating effects of cognitively evoked situational context on consumer expectations and subsequent consumer satisfaction and sensory evaluation. Food Qual. Prefer. 2021, 94, 104330. [Google Scholar] [CrossRef]

- Short, E.C.; Kinchla, A.J.; Nolden, A.A. Plant-based cheeses: A systematic review of sensory evaluation studies and strategies to increase consumer acceptance. Foods 2021, 10, 725. [Google Scholar] [CrossRef] [PubMed]

- Craine, E.B.; Bramwell, S.; Ross, C.F.; Fisk, S.; Murphy, K.M. Strategic malting barley improvement for craft brewers through consumer sensory evaluation of malt and beer. J. Food Sci. 2021, 86, 3628–3644. [Google Scholar] [CrossRef] [PubMed]

- Thompson, K.R.; Chambers, D.H.; Chambers Iv, E.D.G.A.R. Sensory characteristics of ice cream produced in the USA and Italy. J. Sens. Stud. 2009, 24, 396–414. [Google Scholar] [CrossRef]

- Brunschwig, C.; Collard, F.X.; Bianchini, J.P.; Raharivelomanana, P. Evaluation of chemical variability of cured vanilla beans (Vanilla tahitensis and Vanilla planifolia). Nat. Prod. Commun. 2009, 4, 1393–1400. [Google Scholar] [PubMed]

- Franco, J.L.; Ayres, E.M.M.; de Oliveira, D.; Martins, I.B.A.; Macedo, A.F.; Deliza, R.; Koblitz, M.G.B. Exploring the potential of the Vanilla species from the Brazilian Atlantic Forest: Sensory description and consumer acceptance. J. Sens. Stud. 2024, 39, e12896. [Google Scholar] [CrossRef]

- Cai, Y.; Gu, F.; Hong, Y.; Chen, Y.; Xu, F.; An, K. Metabolite transformation and enzyme activities of Hainan vanilla beans during curing to improve flavor formation. Molecules 2019, 24, 2781. [Google Scholar] [CrossRef]

- Brunschwig, C.; Rochard, S.; Pierrat, A.; Rouger, A.; Senger-Emonnot, P.; George, G.; Raharivelomanana, P. Volatile composition and sensory properties of Vanilla× tahitensis bring new insights for vanilla quality control. J. Sci. Food Agric. 2016, 96, 848–858. [Google Scholar] [CrossRef]

- Ravier, A.; Chalut, P.; Belarbi, S.; Santerre, C.; Vallet, N.; Nhouchi, Z. Impact of the Post-Harvest Period on the Chemical and Sensorial Properties of planifolia and pompona Vanillas. Molecules 2024, 29, 839. [Google Scholar] [CrossRef]

- Van Dyk, S.; McGlasson, W.B.; Williams, M.; Gair, C. Influence of curing procedures on sensory quality of vanilla beans. Fruits 2010, 65, 387–399. [Google Scholar] [CrossRef]

- Takahashi, M.; Inai, Y.; Miyazawa, N.; Kurobayashi, Y.; Fujita, A. Key odorants in cured Madagascar vanilla beans (Vanilla planiforia) of differing bean quality. Biosci. Biotechnol. Biochem. 2013, 77, 606–611. [Google Scholar] [CrossRef] [PubMed]

- Hyvönen, L.; Linna, M.; Tuorila, H.; Dijksterhuis, G. Perception of melting and flavor release of ice cream containing different types and contents of fat. J. Dairy Sci. 2003, 86, 1130–1138. [Google Scholar] [CrossRef] [PubMed]

- Kantono, K.; Hamid, N.; Shepherd, D.; Lin, Y.H.T.; Brard, C.; Grazioli, G.; Carr, B.T. The effect of music on gelato perception in different eating contexts. Food Res. Int. 2018, 113, 43–56. [Google Scholar] [CrossRef] [PubMed]

- Genovese, A.; Balivo, A.; Salvati, A.; Sacchi, R. Functional ice cream health benefits and sensory implications. Food Res. Int. 2022, 161, 111858. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Bravo, P.; Chambers, E.; Noguera-Artiaga, L.; Sendra, E.; Chambers, E., IV; Carbonell-Barrachina, Á.A. Consumer understanding of sustainability concept in agricultural products. Food Qual. Prefer. 2021, 89, 104136. [Google Scholar] [CrossRef]

- Stein, A.J.; Santini, F. The sustainability of “local” food: A review for policy-makers. Rev. Agric. Food Environ. Stud. 2022, 103, 77–89. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).