Nonlinear Logistic Model for Describing Strawberry Fruit Production

Abstract

:1. Introduction

2. Material and Methods

2.1. Experiment I

2.2. Experiment II

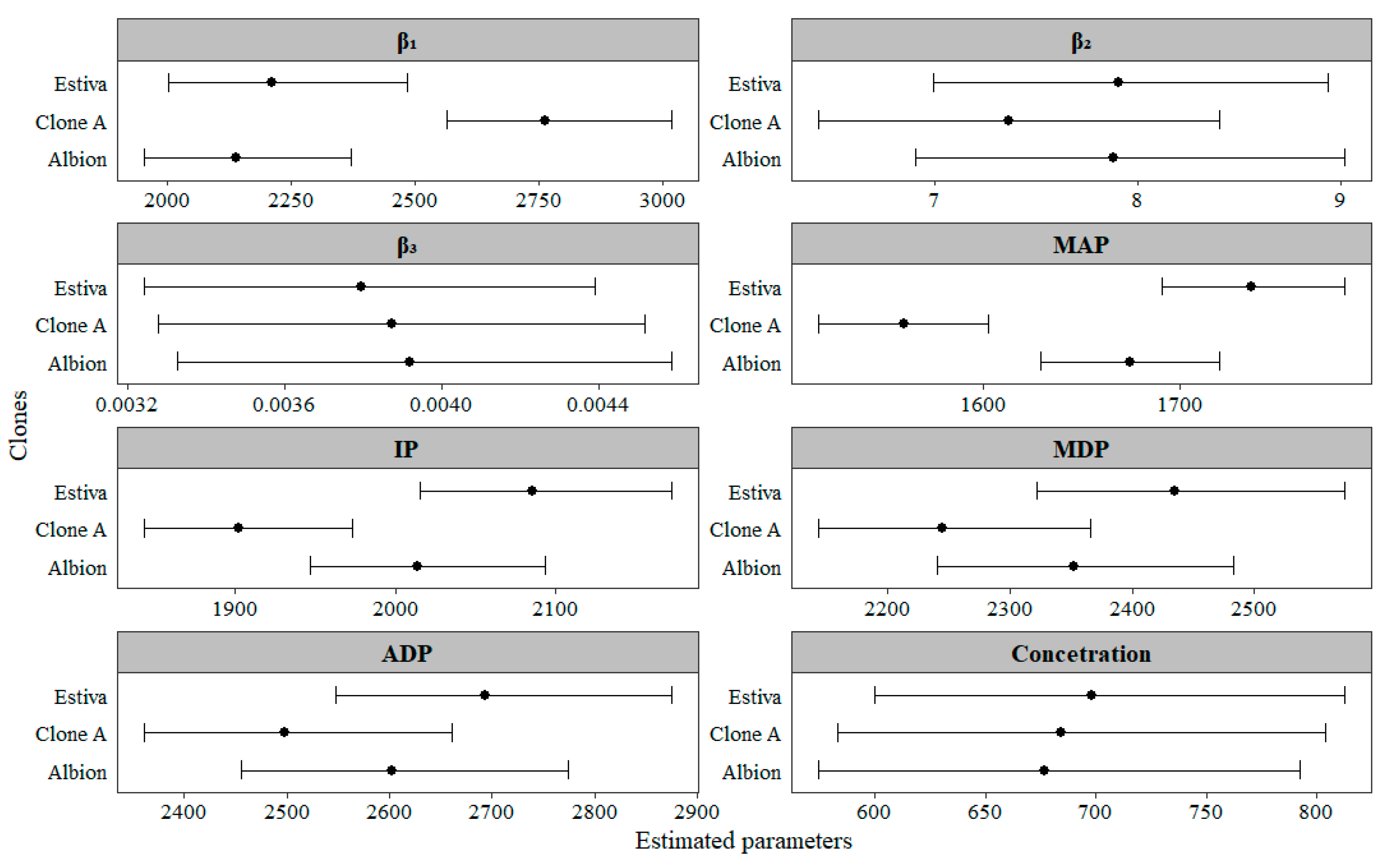

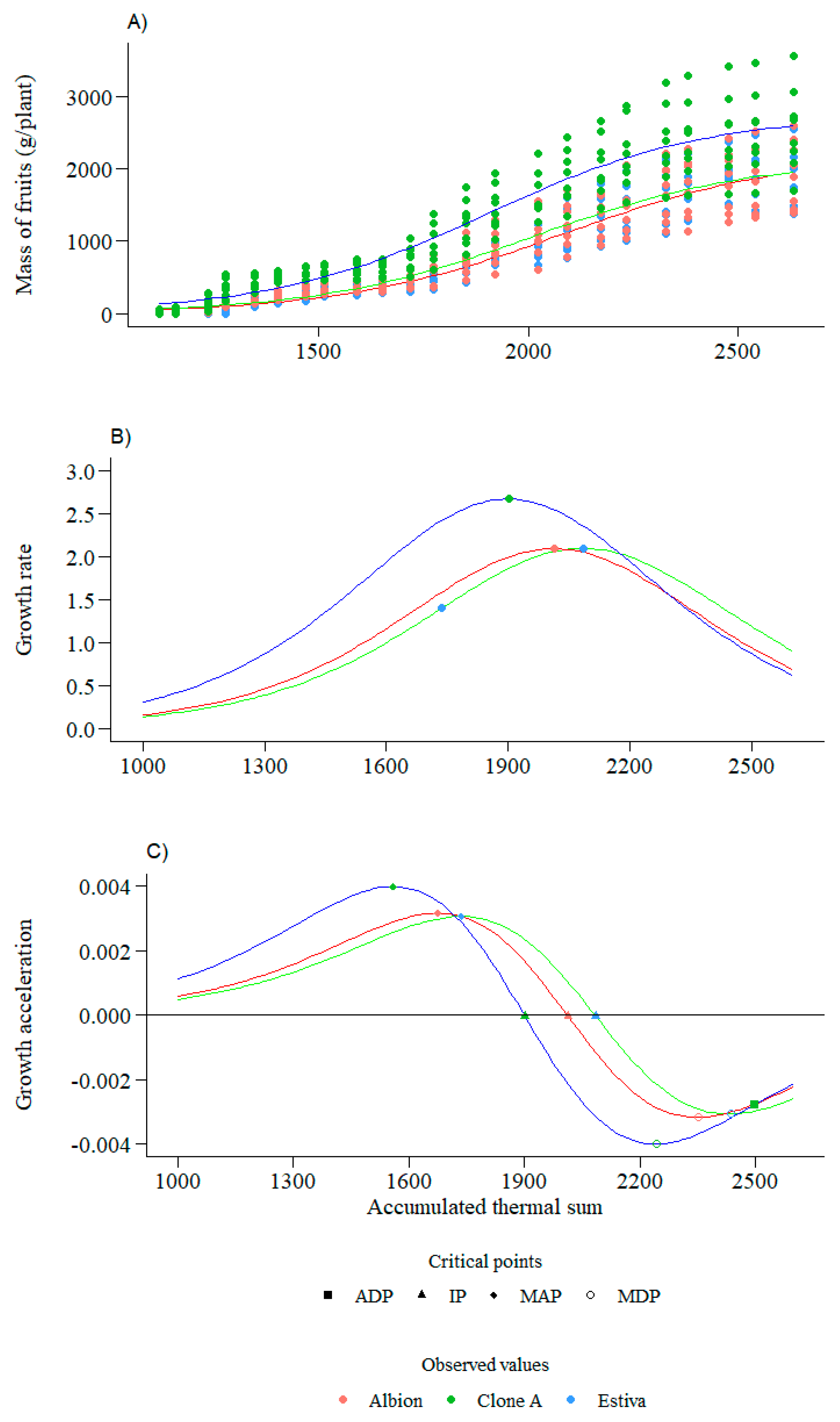

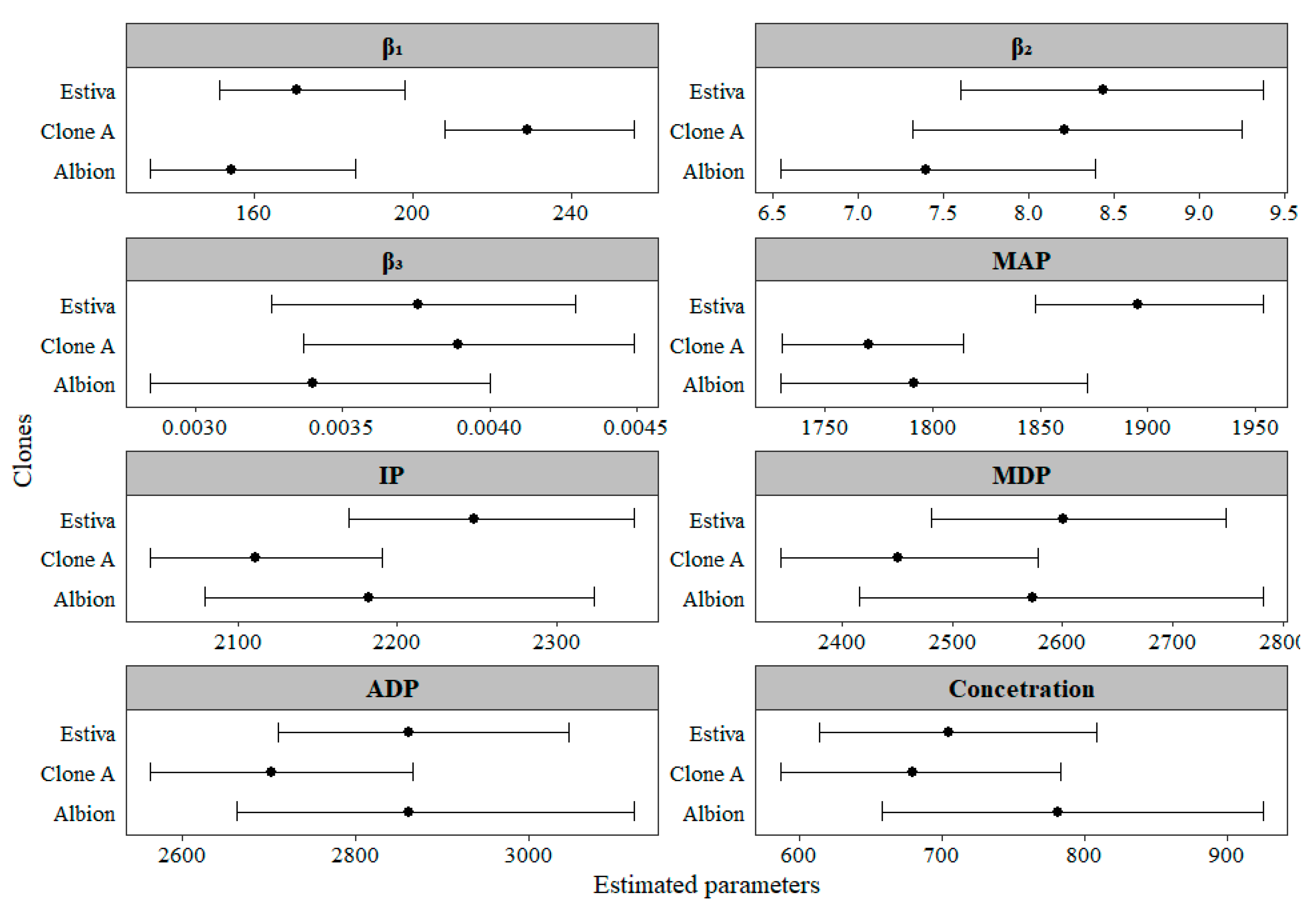

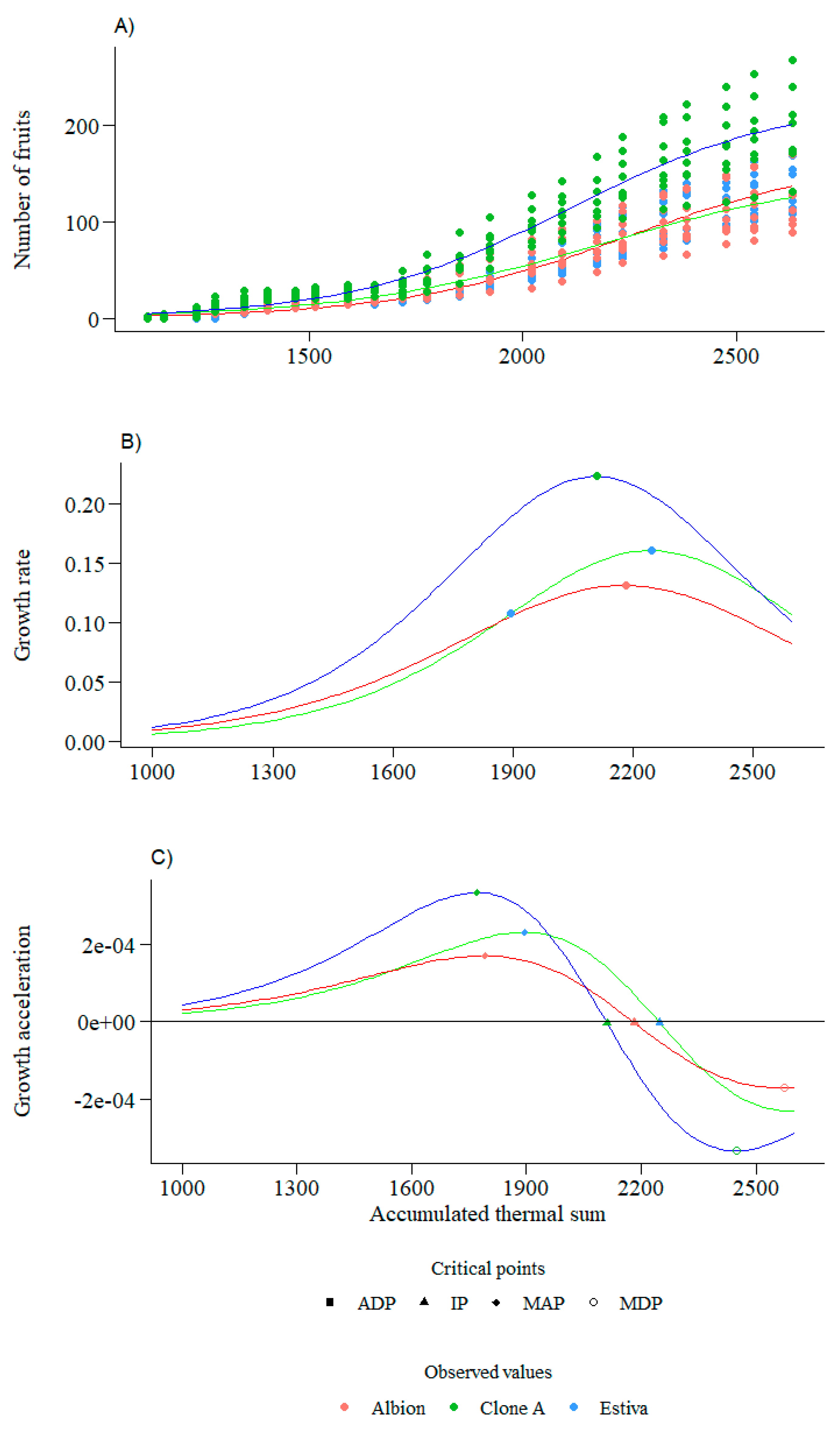

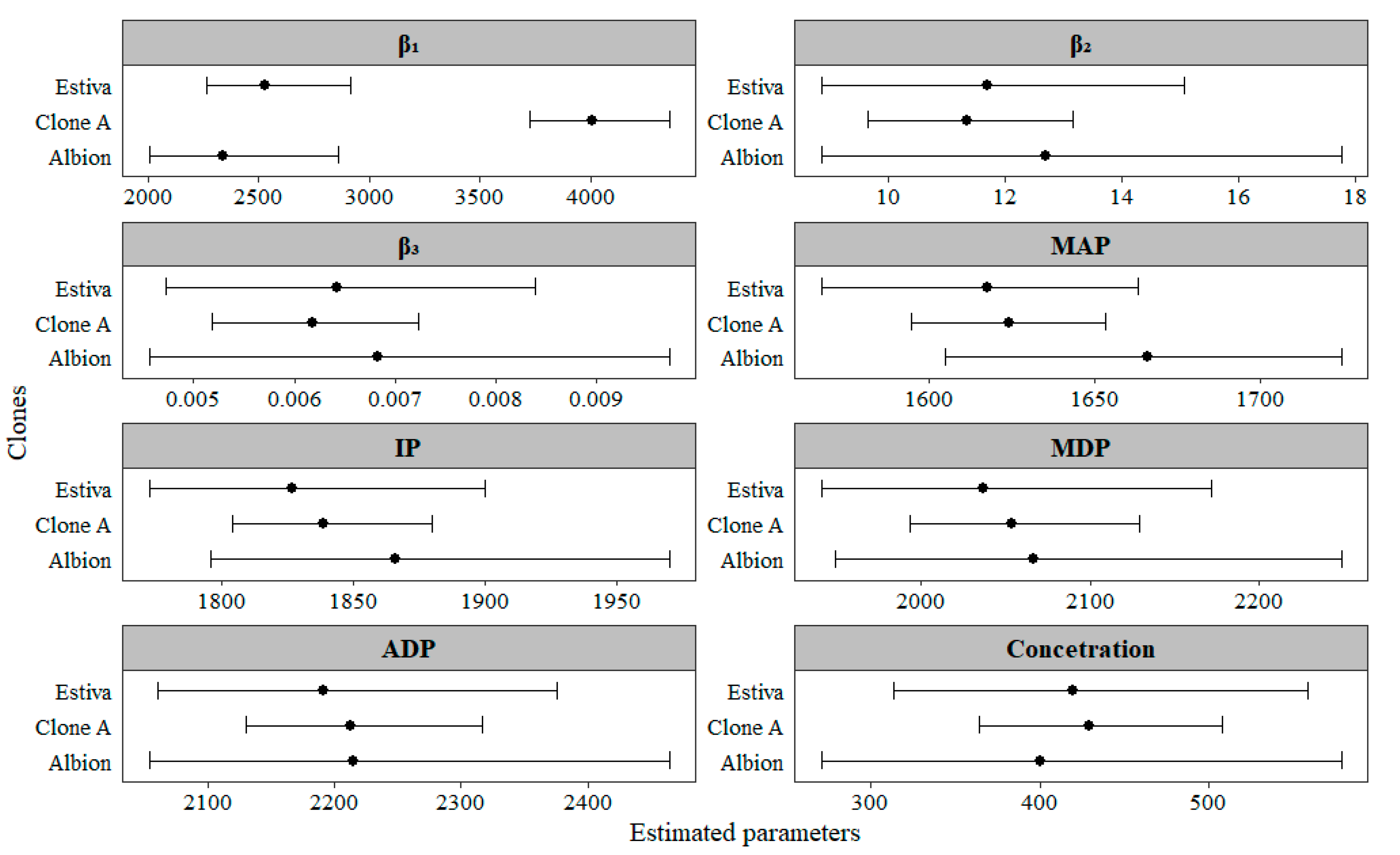

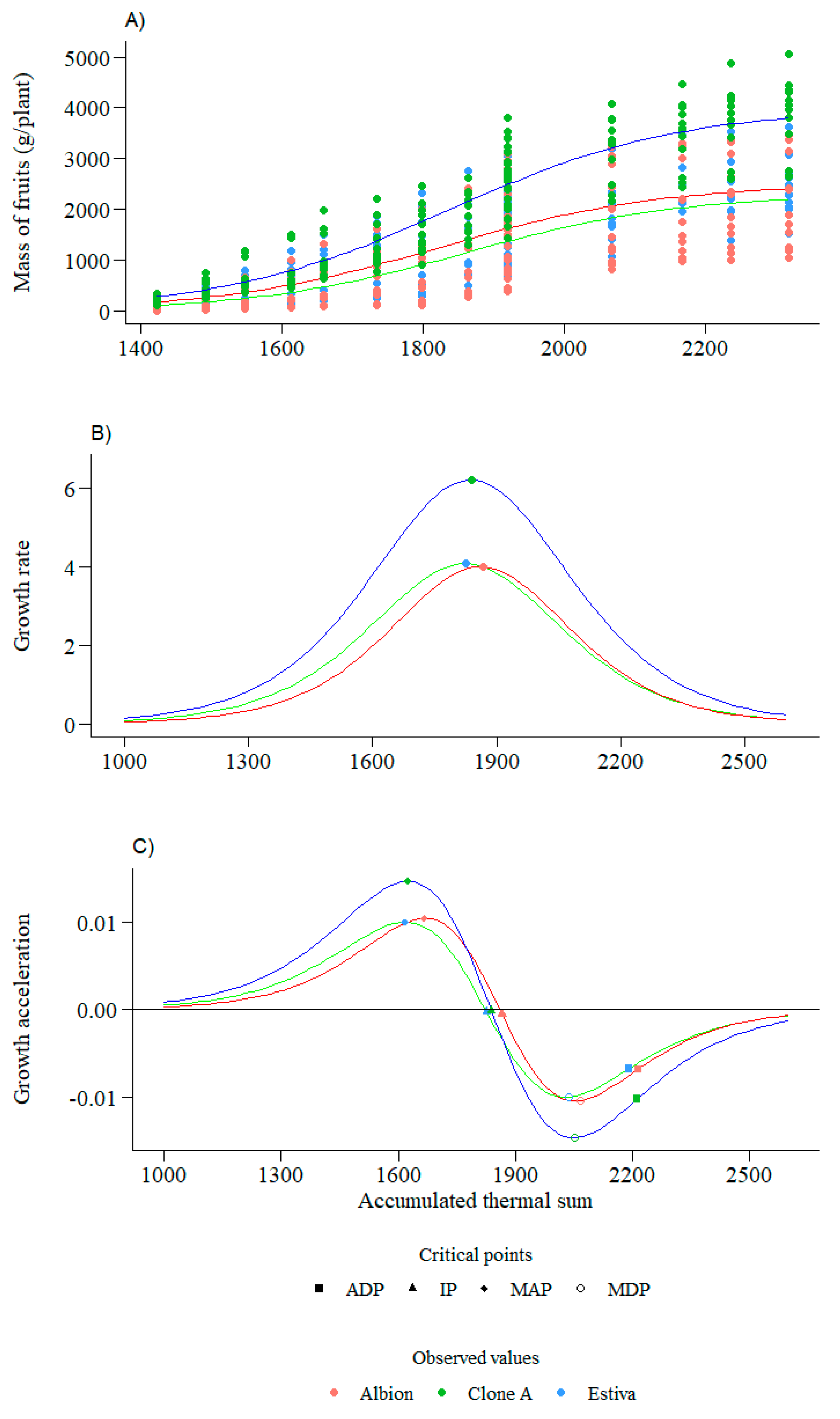

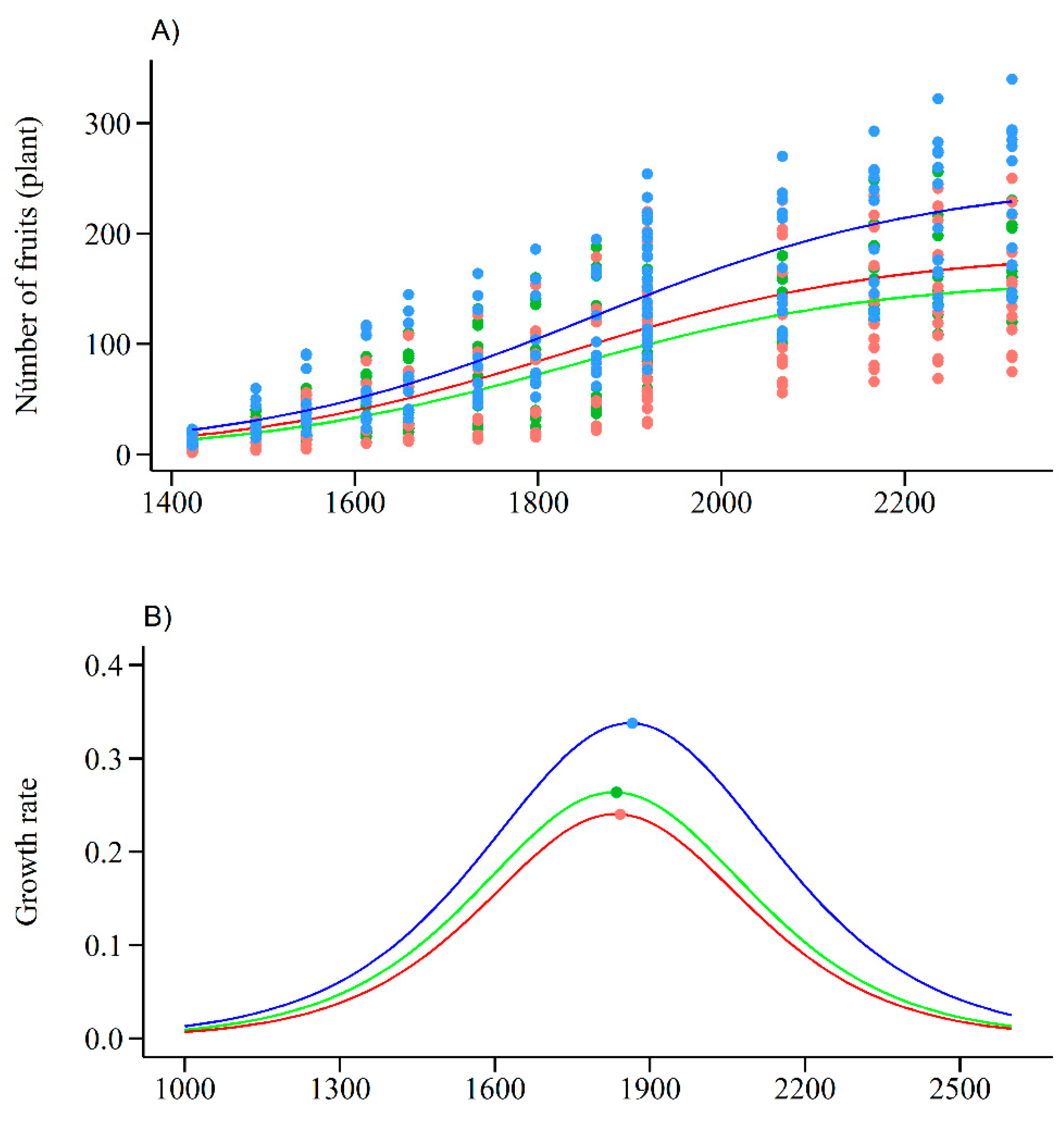

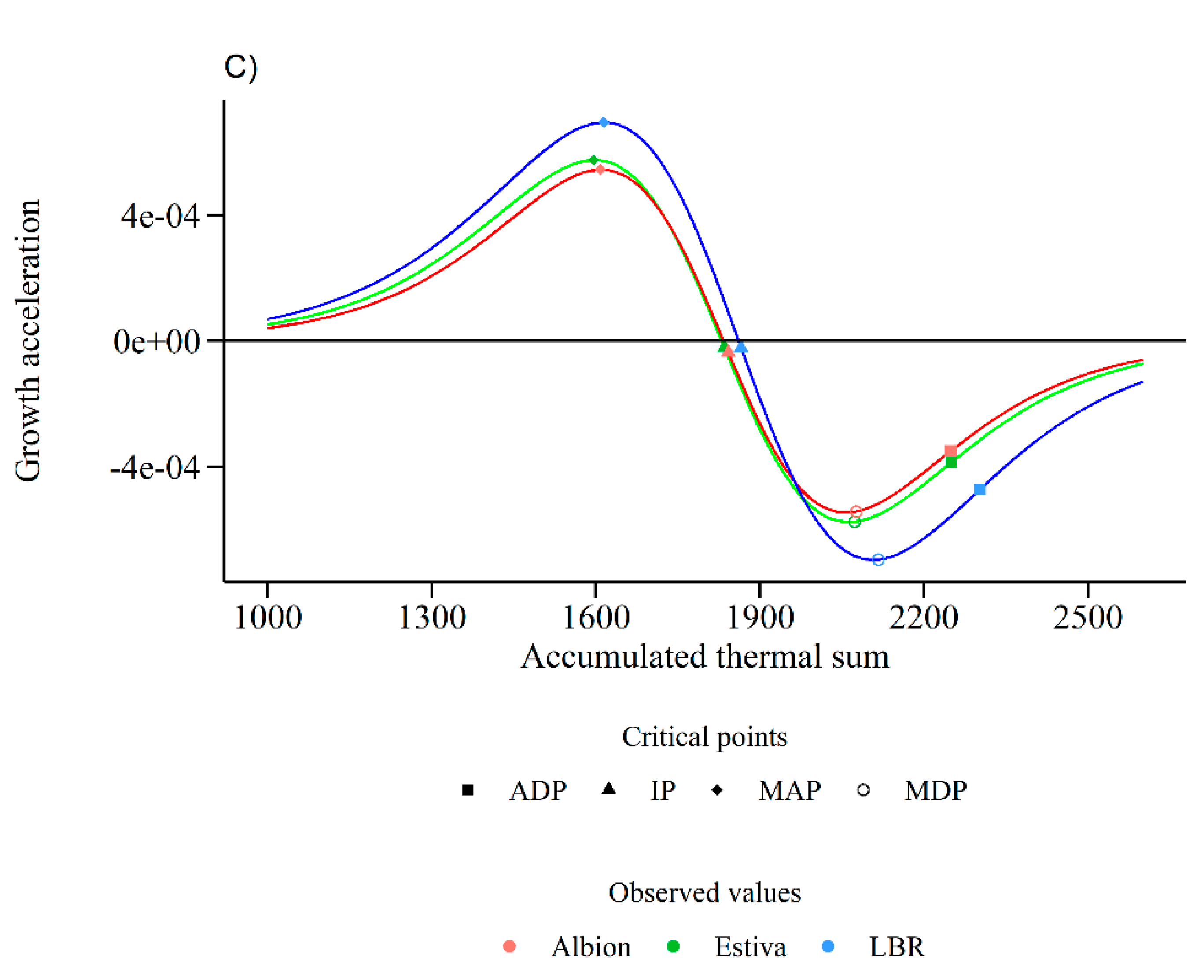

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Whitaker, V.M.; Knapp, S.J.; Hardigan, M.A.; Edger, P.P.; Slovin, J.P.; Bassil, N.V.; Hytönen, T.; Mackenzie, K.K.; Lee, S.; Jung, S.; et al. A Roadmap for Research in Octoploid Strawberry. Hortic. Res. 2020, 7, 1–17. [Google Scholar] [CrossRef]

- Negi, Y.K.; Sajwan, P.; Uniyal, S.; Mishra, A.C. Enhancement in Yield and Nutritive Qualities of Strawberry Fruits by the Application of Organic Manures and Biofertilizers. Sci. Hortic. 2021, 283, 110038. [Google Scholar] [CrossRef]

- Ameri, A.; Tehranifar, A.; Davarynejad, G.; Shoor, M. Flowering Times and Some Growth Indicators of Strawberry Were Affected by Physical Properties of the Growing Media. Sci. Hortic. 2020, 272, 109601. [Google Scholar] [CrossRef]

- Liston, A.; Cronn, R.; Ashman, T.L. Fragaria: A Genus with Deep Historical Roots and Ripe for Evolutionary and Ecological Insights. Am. J. Bot. 2014, 101, 1686–1699. [Google Scholar] [CrossRef] [PubMed]

- Faostat FAO: Food and Agriculture Organization of the United Nations Statistics Division. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 15 July 2024).

- Zeist, A.R.; Resende, J.T.V. de Strawberry Breeding in Brazil: Current Momentum and Perspectives. Hortic. Bras. 2019, 37, 7–16. [Google Scholar] [CrossRef]

- Barth, E.; de Resende, J.T.V.; Mariguele, K.H.; de Resende, M.D.V.; da Silva, A.L.B.R.; Ru, S. Multivariate Analysis Methods Improve the Selection of Strawberry Genotypes with Low Cold Requirement. Sci. Rep. 2022, 12, 11458. [Google Scholar] [CrossRef]

- Alves, M.C.; Matoso, E.S.; Peil, R.M. What Is the Profile of Strawberry Producers in the South Brazilian Region and What Do They Think about Substrate Cultivation? Hortic. Bras. 2020, 38, 428–433. [Google Scholar] [CrossRef]

- Gonçalves, M.A.; Vignolo, G.K.; Antunes, L.E.C.; Reisser Junior, C. Produção de Morango Fora Do Solo; Embrapa Cl.: Pelotas, Brazil, 2016. [Google Scholar]

- Antunes, L.E.C.; Peres, N.A. Strawberry Production in Brazil and South America. Int. J. Fruit Sci. 2013, 13, 156–161. [Google Scholar] [CrossRef]

- Lin, Y.; Hou, G.; Jiang, Y.; Liu, X.; Yang, M.; Wang, L.; Long, Y.; Li, M.; Zhang, Y.; Wang, Y.; et al. Joint Transcriptomic and Metabolomic Analysis Reveals Differential Flavonoid Biosynthesis in a High-Flavonoid Strawberry Mutant. Front. Plant Sci. 2022, 13, e-919619. [Google Scholar] [CrossRef]

- Claire, D.; Watters, N.; Gendron, L.; Boily, C.; Pépin, S.; Caron, J. High Productivity of Soilless Strawberry Cultivation under Rain Shelters. Sci. Hortic. 2018, 232, 127–138. [Google Scholar] [CrossRef]

- Singh, A.; Syndor, A.; Deka, B.C.; Singh, R.K.; Patel, R.K. The Effect of Microclimate inside Low Tunnels on Off-Season Production of Strawberry (Fragaria × Ananassa Duch.). Sci. Hortic. 2012, 144, 36–41. [Google Scholar] [CrossRef]

- Diel, M.I.; Pinheiro, M.V.M.; Cocco, C.; Fontana, D.C.; Caron, B.O.; de Paula, G.M.; Pretto, M.M.; Thiesen, L.A.; Schmidt, D. Phyllochron and Phenology of Strawberry Cultivars from Different Origins Cultivated in Organic Substracts. Sci. Hortic. 2017, 220, 226–232. [Google Scholar] [CrossRef]

- Antunes, L.E.C.; Bonow, P.; de Lima, R.H.; Costa, H.; Paulus, G.; Ries, J. Morango: Produção Aumenta Ano a Ano. Campo Negócio-Anuário HF 2021, 1, 88–92. [Google Scholar]

- Fagherazzi, A.F.; Suek Zanin, D.; Soares Dos Santos, M.F.; Martins de Lima, J.; Welter, P.D.; Francis Richter, A.; Regianini Nerbass, F.; Anneliese Kretzschmar, A.; Rufato, L.; Baruzzi, G. Initial Crown Diameter Influences on the Fruit Yield and Quality of Strawberry Pircinque. Agronomy 2021, 11, 184. [Google Scholar] [CrossRef]

- Schiavon, A.V.; Becker, T.B.; Delazeri, E.E.; Vignolo, G.K.; Mello-Farias, P.; Antunes, L.E.C. Production and Quality of Strawberry Plants Produced from Different Nutrient Solutions in Soilless Cultivation. Rev. Ceres 2022, 69, 348–357. [Google Scholar] [CrossRef]

- Bisognin, D.A.; Pivetta, C.R.; Janisch, D.I.; Fischer, H.; Dalpicio, M. Método de Propagação de Plantas. Rev. Propr. Ind. 2019, 2511, 644–690. [Google Scholar]

- Lúcio, A.D.; Sari, B.G.; Rodrigues, M.; Bevilaqua, L.M.; Voss, H.M.G.; Copetti, D.; Faé, M. Modelos Não-Lineares Para a Estimativa Da Produção de Tomate Do Tipo Cereja. Ciênc. Rural 2015, 46, 233–241. [Google Scholar] [CrossRef]

- Lucio, A.D.; Nunes, L.F.; Rego, F. Nonlinear Regression and Plot Size to Estimate Green Beans Production. Hortic. Bras. 2016, 34, 507–513. [Google Scholar] [CrossRef]

- Diel, M.I.; Sari, B.G.; Krysczun, D.K.; Vinícius, M.; Pinheiro, M.; Meira, D.; Schmidt, D.; Dal, A.; Lúcio, C.; Vinícius, M.; et al. Nonlinear Regression for Description of Strawberry (Fragaria × Ananassa) Production. J. Hortic. Sci. Biotechnol. 2019, 94, 259–273. [Google Scholar] [CrossRef]

- Diel, M.I.; Lúcio, A.D.; Sari, B.G.; Olivoto, T.; Pinheiro, M.V.M.; Krysczum, D.K.; De Melo, P.J.; Schmidt, D. Behavior of Strawberry Production with Growth Models: A Multivariate Approach. Acta Sci. Agron. 2020, 43, e47812. [Google Scholar] [CrossRef]

- Mischan, M.M.; de Pinho, S.Z.; de Carvalho, L.R. Determination of a Point Sufficiently Close to the Asymptote in Nonlinear Growth Functions. Sci. Agric. 2011, 68, 109–114. [Google Scholar] [CrossRef]

- Diel, M.I.; Lúcio, A.D.; Schmidt, D.; de Lima Tartaglia, F.; Tischler, A.L.; Lambrecht, D.M. Using Nonlinear Models to Define Production, Production Rate, and Precocity of Strawberry Cultivars. Rev. Ceres 2022, 69, 55–61. [Google Scholar] [CrossRef]

- Sari, B.G.; Lúcio, A.D.; Santana, C.S.; Savian, T.V. Describing Tomato Plant Production Using Growth Models. Sci. Hortic. 2019, 246, 146–154. [Google Scholar] [CrossRef]

- Sari, B.G.; Lúcio, A.D.; Souza Santana, C.; Olivoto, T.; Diel, M.I.; Krysczun, D.K. Nonlinear Growth Models: An Alternative to ANOVA in Tomato Trials Evaluation. Eur. J. Agron. 2019, 104, 21–36. [Google Scholar] [CrossRef]

- Alvares, C.A.; Stape, J.L.; Sentelhas, P.C.; De Moraes Gonçalves, J.L.; Sparovek, G. Koppen’s Climate Classification Map for Brazil. Meteorol. Z. 2013, 22, 711–728. [Google Scholar] [CrossRef]

- Burin, C.; Antônio Bisognin, D.; Haygert Lencina, K.; Salvatierra Gimenes, E. Early Selection of Cabralea Canjerana for Propagation by Mini-Cutting. Pesqui. Agropecu. Bras. 2018, 53, 1018–1024. [Google Scholar] [CrossRef]

- Rosa, H.T.; Walter, L.C.; Streck, N.A.; Andriolo, J.L.; da Silva, M.R.; Langner, J.A. Base Temperature for Leaf Appearance and Phyllochron of Selected Strawberry Cultivars in a Subtropical Environment. Bragantia 2011, 70, 939–945. [Google Scholar] [CrossRef]

- Bates, D.M.; Watts, D.G. Nonlinear Regression Analysis and Its Applications, 2nd ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1988; Volume 85, ISBN 9780470316757. [Google Scholar]

- Sari, B.G.; Olivoto, T.; Diel, M.I.; Krysczun, D.K.; Lúcio, A.D. Nonlinear Modeling for Analyzing Data from Multiple Harvest Crops. Agron. J. 2018, 110, 2331–2342. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2024. [Google Scholar]

- Casella, G. Statistical Design, 1st ed.; Springer: New York, NY, USA, 2008. [Google Scholar]

- Muniz, J.A.; Nascimento, M.D.S.; Fernandes, T.J.; Muniz, J.A.; Nascimento, M.D.S.; Fernandes, T.J. Nonlinear Models for Description of Cacao Fruit Growth with Assumption Violations. Rev. Caatinga 2017, 30, 250–257. [Google Scholar] [CrossRef]

- Souza, E.M.; Muniz, J.A.; Marchi, G.; Guilherme, L.R.G. Modelagem Não Linear Da Extração de Zinco de Um Solo Tratado Com Lodo de Esgoto. Acta Sci.—Technol. 2010, 32, 193–199. [Google Scholar] [CrossRef]

- Ratkowski, D. Nonlinear Regression Modeling; M. Dekker: New York, NY, USA, 1983; 276p. [Google Scholar]

- Seber, G.A.F.; Wild, C.J. Nonlinear Regression; Sons, J.W.: Hoboken, NJ, USA, 2003. [Google Scholar]

- Rosa, H.T.; Streck, N.A.; Walter, L.C.; Andriolo, J.L.; da Silva, M.R. Crescimento Vegetativo e Produtivo de Duas Cultivares de Morango Sob Épocas de Plantio Em Ambiente Subtropical. Rev. Cienc. Agron. 2013, 44, 604–613. [Google Scholar] [CrossRef]

- Conti, J.H.; Minami, K.; Tavares, F.C.A. Produção e Qualidade de Frutos de Diferentes Cultivares de Morangueiro Em Ensaios Conduzidos Em Atibaia e Piracicaba. Hortic. Bras. 2002, 20, 10–17. [Google Scholar] [CrossRef]

- Hazarika, T.K.; Lalrinfeli, L.; Lalthlamuani, L.; Lalchhanmawia, J.; Nautiyal, B.P. Effect of Planting Density on Growth, Yield and Quality of Strawberry (Fragaria × Ananassa) Cv. Camarosa. Indian J. Agric. Sci. 2019, 89, 489–493. [Google Scholar] [CrossRef]

- de Lima, J.M.; Welter, P.D.; Dos Santos, M.F.S.; Kavcic, W.; Costa, B.M.; Fagherazzi, A.F.; Nerbass, F.R.; Kretzschmar, A.A.; Rufato, L.; Baruzzi, G. Planting Density Interferes with Strawberry Production Efficiency in Southern Brazil. Agronomy 2021, 11, 408. [Google Scholar] [CrossRef]

- Rahman, M.M.; Rahman, M.M.; Hossain, M.M.; Khaliq, Q.A.; Moniruzzaman, M. Effect of Planting Time and Genotypes Growth, Yield and Quality of Strawberry (Fragaria × ananassa Duch.). Sci. Hortic. 2014, 167, 56–62. [Google Scholar] [CrossRef]

- Moreira, A.F.P.; de Resende, J.T.V.; Shimizu, G.D.; Hata, F.T.; do Nascimento, D.; Oliveira, L.V.B.; Zanin, D.S.; Mariguele, K.H. Characterization of Strawberry Genotypes with Low Chilling Requirement for Cultivation in Tropical Regions. Sci. Hortic. 2022, 292, 110629. [Google Scholar] [CrossRef]

- Hancock, J. Strawberries; Springer: Wallingford, CT, USA, 1999. [Google Scholar]

- Durner, E.F. Photoperiod Affects Floral Ontogeny in Strawberry (Fragaria × ananassa Duch.) Plug Plants. Sci. Hortic. 2015, 194, 154–159. [Google Scholar] [CrossRef]

| Experiment I | |||||||

| Clones | SW | BP | DW | ci | cθ | R2aj | |

| Mass of fruit | Estiva | 5.03 × 10−6 | 2.10 × 10−15 | 0.45 | 0.08 | 0.86 | 0.91 |

| Albion | 6.02 × 10−7 | 1.22 × 10−17 | 0.57 | 0.09 | 0.77 | 0.89 | |

| A | 2.41 × 10−4 | 1.48 × 10−11 | 0.43 | 0.09 | 0.63 | 0.88 | |

| Experiment II | |||||||

| Estiva | 0.00252 | 9.33 × 10−6 | 0 | 0.14 | 0.83 | 0.69 | |

| Albion | 0.00053 | 9.35 × 10−10 | 0 | 0.20 | 1.14 | 0.58 | |

| A | 0.06473 | 1.87 × 10−6 | 0 | 0.08 | 0.54 | 0.85 | |

| Experiment I | |||||||

| Number of fruits | Estiva | 3.66 × 10−5 | 4.00 × 10−22 | 0.75 | 0.08 | 1.19 | 0.93 |

| Albion | 1.48 × 10−7 | 1.75 × 10−16 | 0.98 | 0.09 | 1.4 | 0.88 | |

| A | 9.23 × 10−8 | 9.79 × 10−13 | 0.09 | 0.08 | 0.82 | 0.92 | |

| Experiment II | |||||||

| Estiva | 2.54 × 10−4 | 5.50 × 10−8 | 0 | 0.14 | 1.11 | 0.65 | |

| Albion | 8.56 × 10−4 | 1.80 × 10−9 | 0 | 0.18 | 1.37 | 0.53 | |

| A | 8.13 × 10−4 | 2.74 × 10−9 | 0 | 0.12 | 1.14 | 0.70 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diel, M.I.; Lucio, A.D.C.; Bisognin, D.A.; de Araujo Lopes, G.; dos Santos, V.J. Nonlinear Logistic Model for Describing Strawberry Fruit Production. Agronomy 2024, 14, 1884. https://doi.org/10.3390/agronomy14091884

Diel MI, Lucio ADC, Bisognin DA, de Araujo Lopes G, dos Santos VJ. Nonlinear Logistic Model for Describing Strawberry Fruit Production. Agronomy. 2024; 14(9):1884. https://doi.org/10.3390/agronomy14091884

Chicago/Turabian StyleDiel, Maria Inês, Alessandro Dal Col Lucio, Dilson Antonio Bisognin, Gabriel de Araujo Lopes, and Valdeci Jose dos Santos. 2024. "Nonlinear Logistic Model for Describing Strawberry Fruit Production" Agronomy 14, no. 9: 1884. https://doi.org/10.3390/agronomy14091884