Optimal Application of Biogas Slurry in Paddy Fields under the Dual Constraints of Agronomy and Environment in the Yangtze River Delta Region

Abstract

:1. Introduction

2. Materials and Methods

2.1. Field Experiment Description

2.2. Experiment Design and Management

2.3. Sampling and Measurements

2.3.1. Yield, Yield Components, and Harvest Index

2.3.2. Nitrogen Content Determination

2.3.3. Ammonium (–N) Content in Surface Water

2.3.4. Rice Quality Determination

2.4. Data Analysis

2.5. Statistical Analysis

3. Results

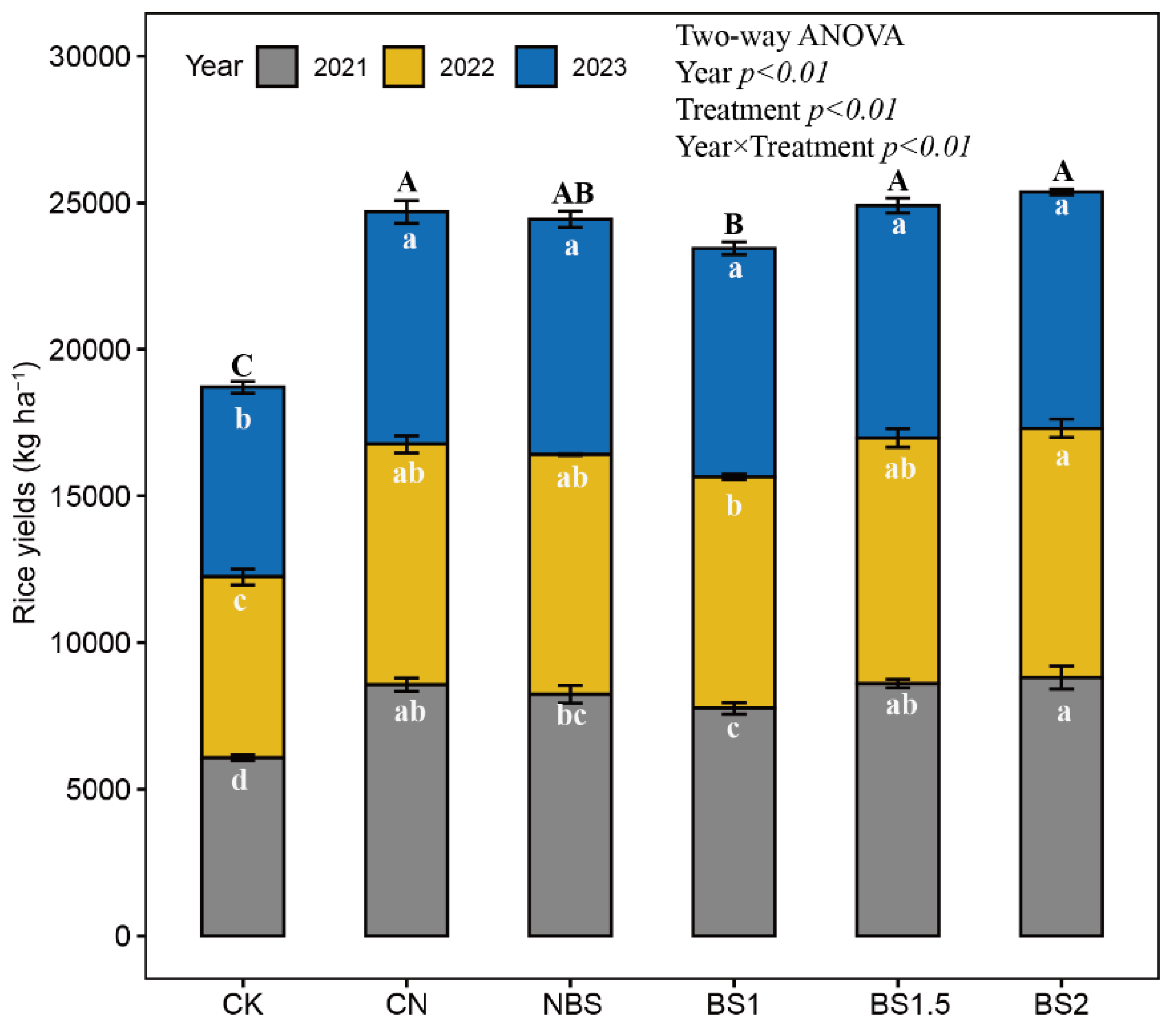

3.1. Rice Yields, Yield Components, and Harvest Index

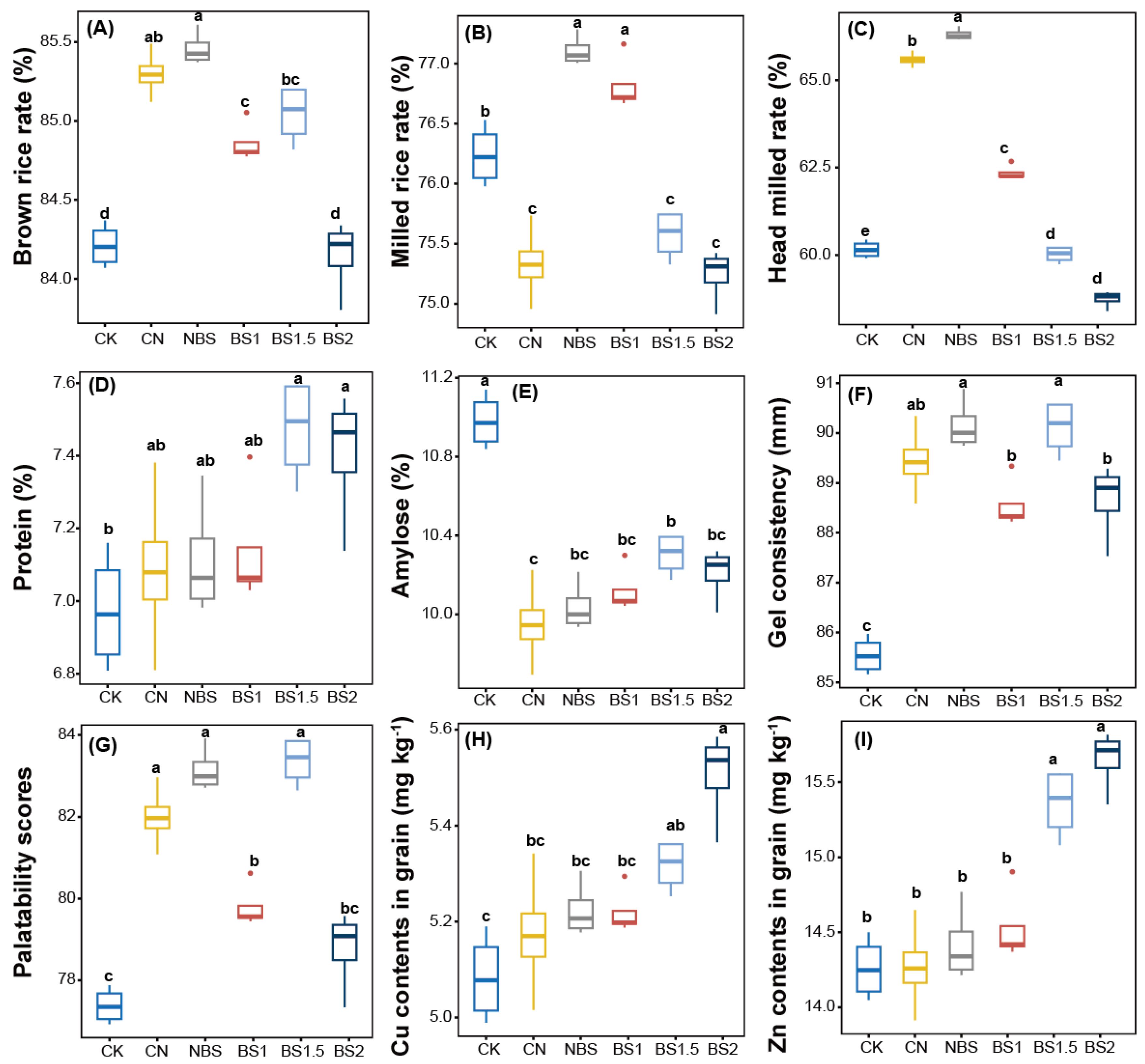

3.2. Rice Quality

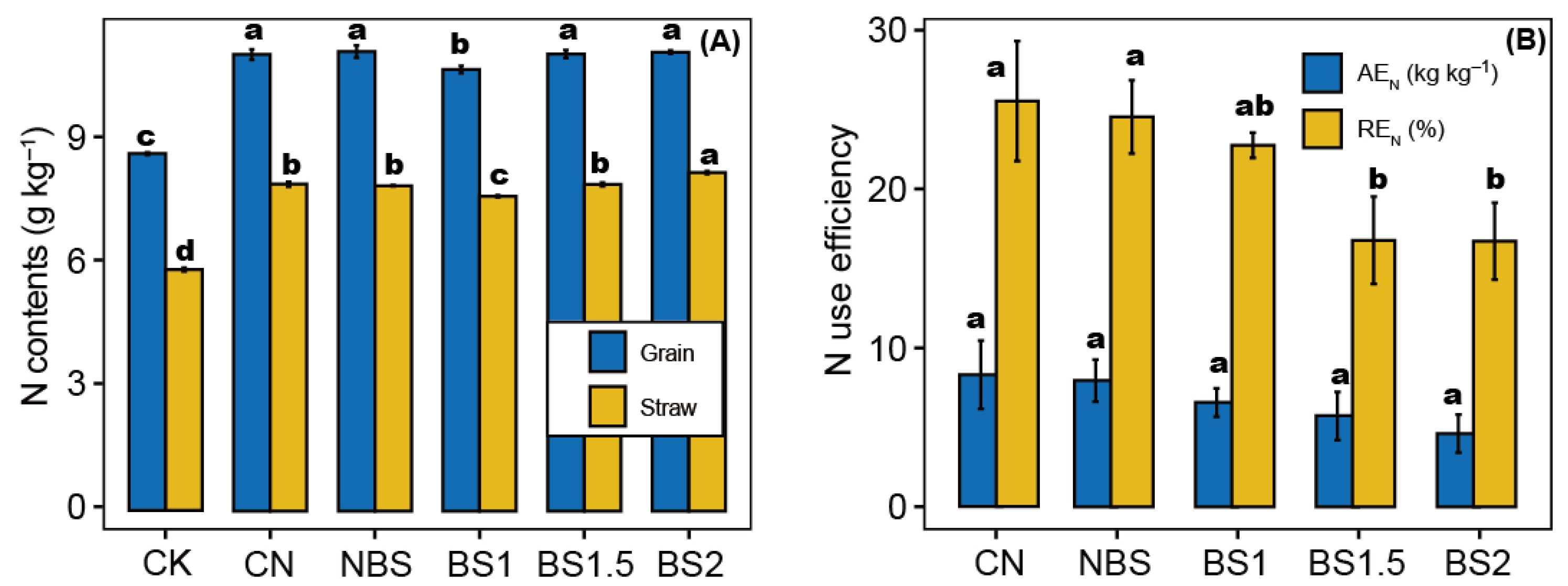

3.3. Nitrogen-Use Efficiency

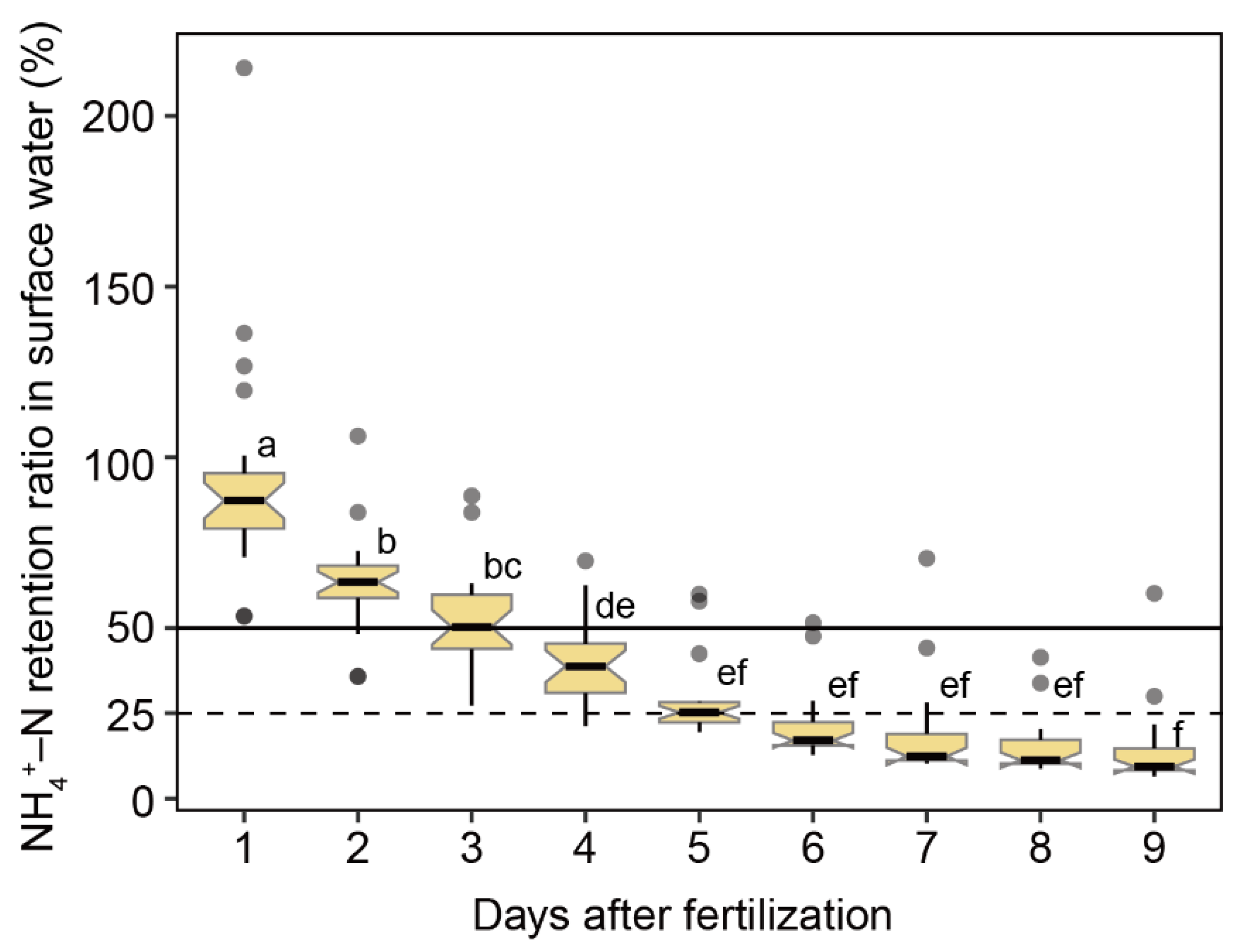

3.4. –N Concentrations in Surface Water

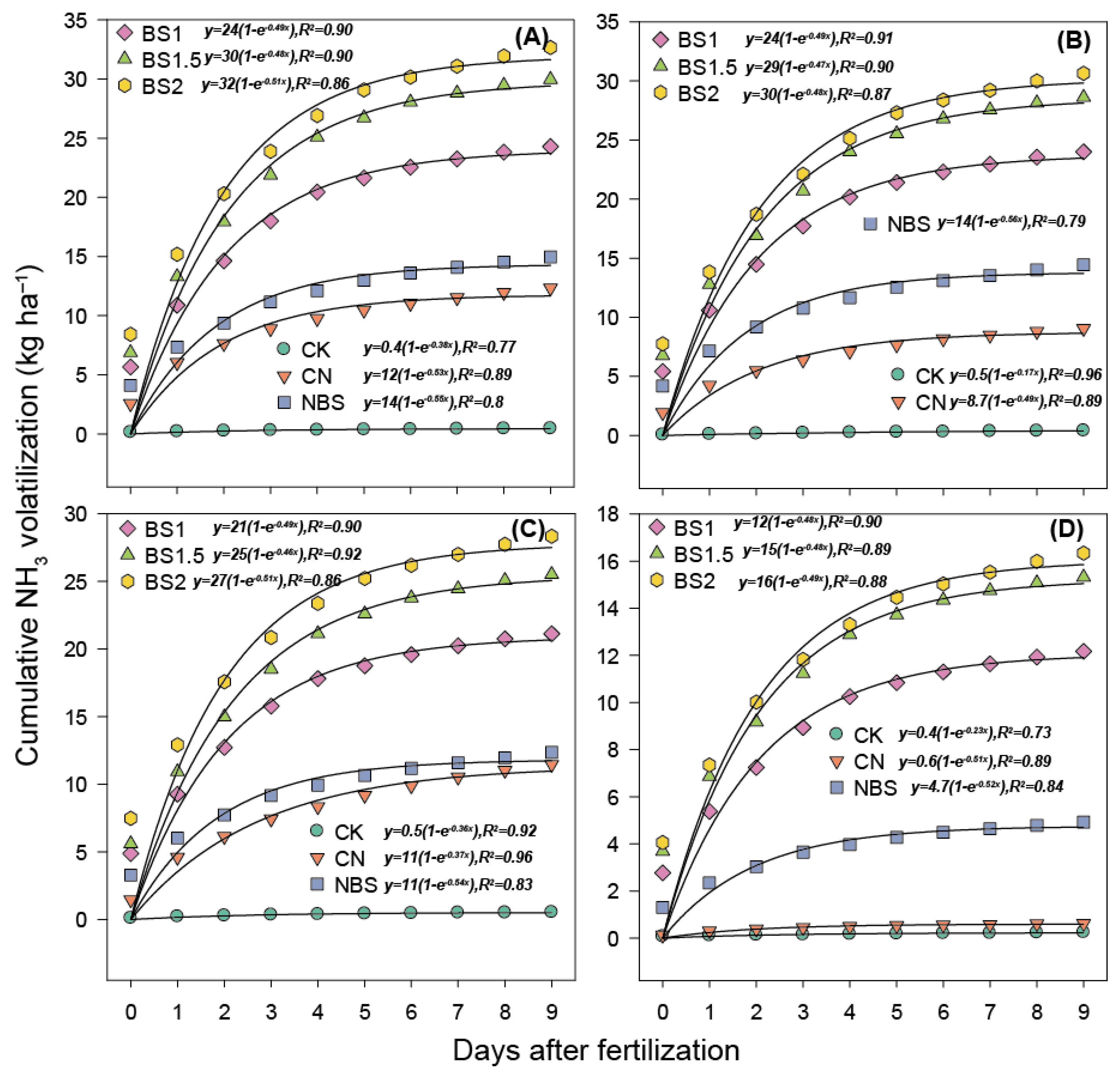

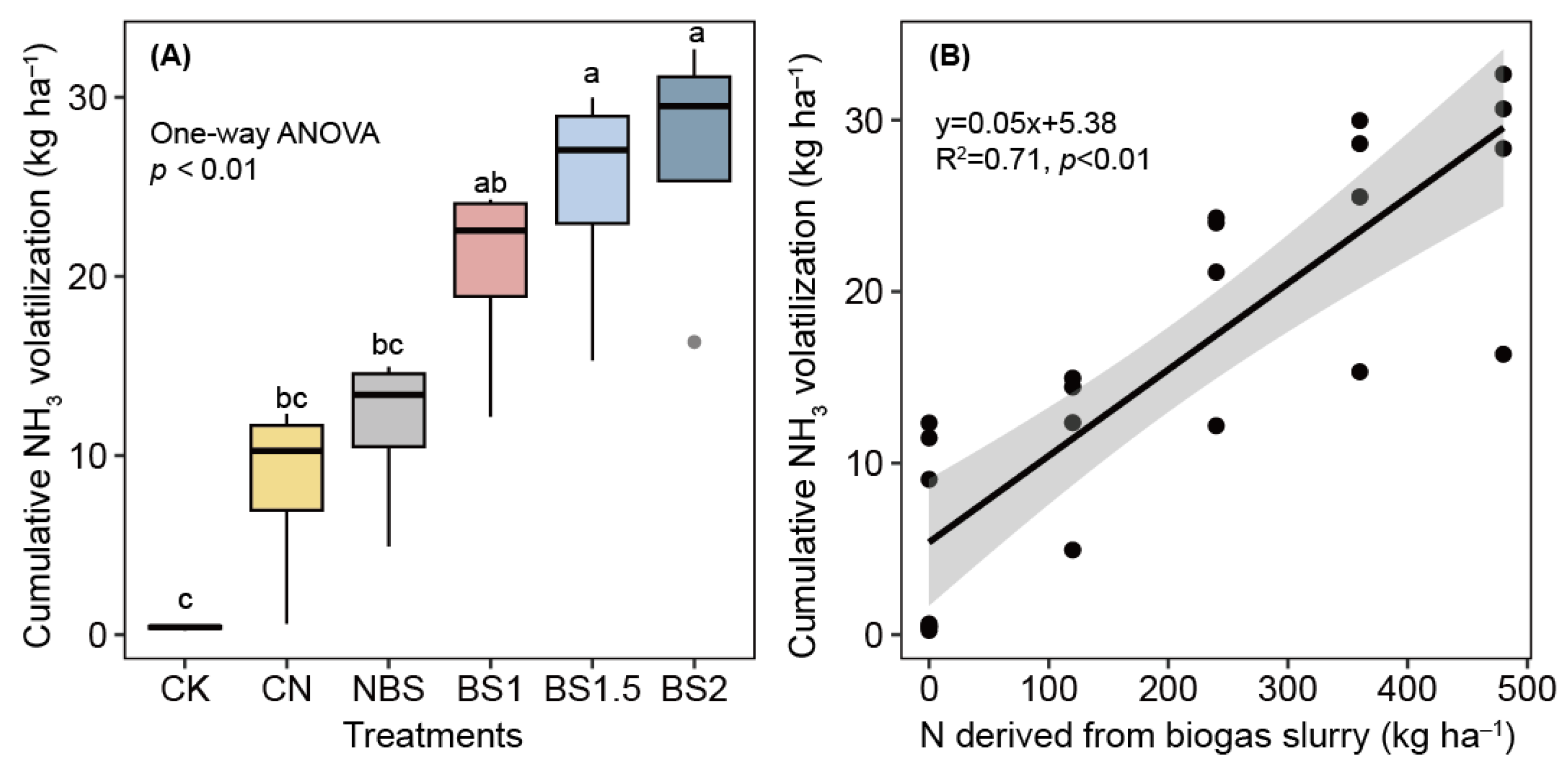

3.5. Characteristics of NH3 Volatilization

4. Discussion

4.1. Rice Yields, Quality, and Potential Safety Risks

4.2. Nitrogen-Use Efficiency and Loss

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mottet, A.; de Haan, C.; Falcucci, A.; Tempio, G.; Opio, C.; Gerber, P. Livestock: On Our Plates or Eating at Our Table? A New Analysis of the Feed/Food Debate. Glob. Food Secur. 2017, 14, 1–8. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). FAO Statistical Yearbook 2021-World Food and Agriculture; FAO: Rome, Italy, 2021. [Google Scholar]

- Hagos, K.; Zong, J.; Li, D.; Liu, C.; Lu, X. Anaerobic Co-Digestion Process for Biogas Production: Progress, Challenges and Perspectives. Renew. Sustain. Energy Rev. 2017, 76, 1485–1496. [Google Scholar] [CrossRef]

- Chen, G.; Zhao, G.; Zhang, H.; Shen, Y.; Fei, H.; Cheng, W. Biogas Slurry Use as N Fertilizer for Two-Season Zizania Aquatica Turcz. in China. Nutr. Cycl. Agroecosystems 2017, 107, 303–320. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). The Global Status of Biogas Production; FAO: Rome, Italy, 2019. [Google Scholar]

- International Energy Agency (IEA). Outlook for Biogas and Biomethane: Prospects for Organic Growth; OECD Publishing: Paris, France, 2020. [Google Scholar]

- Paolini, V.; Petracchini, F.; Segreto, M.; Tomassetti, L.; Naja, N.; Cecinato, A. Environmental Impact of Biogas: A Short Review of Current Knowledge. J. Environ. Sci. Health Part A 2018, 53, 899–906. [Google Scholar] [CrossRef] [PubMed]

- Nie, L.; Peng, S. Rice Production in China. In Rice Production Worldwide; Chauhan, B.S., Jabran, K., Mahajan, G., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 33–52. ISBN 978-3-319-47516-5. [Google Scholar]

- National Bureau of Statistics of China (NBS). China Statistical Yearbook; National Bureau of Statistics of China (NBS): Beijing, China, 2023.

- Naher, U.A.; Ahmed, M.N.; Sarkar, M.I.U.; Biswas, J.C.; Panhwar, Q.A. Chapter 8-Fertilizer Management Strategies for Sustainable Rice Production. In Organic Farming; Chandran, S., Unni, M.R., Thomas, S., Eds.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Cambridge, UK, 2019; pp. 251–267. ISBN 978-0-12-813272-2. [Google Scholar]

- Ding, W.; Xu, X.; He, P.; Ullah, S.; Zhang, J.; Cui, Z.; Zhou, W. Improving Yield and Nitrogen Use Efficiency through Alternative Fertilization Options for Rice in China: A Meta-Analysis. Field Crop. Res. 2018, 227, 11–18. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Z.; Zhao, J.; Ma, J.; Yu, Q.; Zou, P.; Lin, H.; Ma, J. Fate of Heavy Metals and Bacterial Community Composition Following Biogas Slurry Application in a Single Rice Cropping System. J. Soils Sediments 2022, 22, 968–981. [Google Scholar] [CrossRef]

- Lu, Y.; Xiao, Q.; Wu, S.; Yuan, H.; Gao, T.; Cai, T.; Wu, X.; Ma, Y.; Liao, X. Partial Substitution of Nitrogen Fertilizer with Biogas Slurry Increases Rice Yield and Fertilizer Utilization Efficiency, Enhancing Soil Fertility in the Chaohu Lake Basin. Plants 2024, 13, 2024. [Google Scholar] [CrossRef]

- Xu, M.; Xian, Y.; Wu, J.; Gu, Y.; Yang, G.; Zhang, X.; Peng, H.; Yu, X.; Xiao, Y.; Li, L. Effect of Biogas Slurry Addition on Soil Properties, Yields, and Bacterial Composition in the Rice-Rape Rotation Ecosystem over 3 Years. J. Soils Sediments 2019, 19, 2534–2542. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, M.; Ouwerkerk, P.B.F. Molecular and environmental factors determining grain quality in rice. Food Energy Secur. 2012, 1, 111–132. [Google Scholar] [CrossRef]

- Butardo, V.M.; Sreenivasulu, N.; Juliano, B.O. Improving Rice Grain Quality: State-of-the-Art and Future Prospects. In Rice Grain Quality: Methods and Protocols; Sreenivasulu, N., Ed.; Springer: New York, NY, USA, 2019; pp. 19–55. ISBN 978-1-4939-8914-0. [Google Scholar]

- Yu, L.; Turner, M.S.; Fitzgerald, M.; Stokes, J.R.; Witt, T. Review of the Effects of Different Processing Technologies on Cooked and Convenience Rice Quality. Trends Food Sci. Technol. 2017, 59, 124–138. [Google Scholar] [CrossRef]

- Xu, Y.; Ying, Y.; Ouyang, S.; Duan, X.; Sun, H.; Jiang, S.; Sun, S.; Bao, J. Factors Affecting Sensory Quality of Cooked Japonica Rice. Rice Sci. 2018, 25, 330–339. [Google Scholar] [CrossRef]

- Balindong, J.L.; Ward, R.M.; Liu, L.; Rose, T.J.; Pallas, L.A.; Ovenden, B.W.; Snell, P.J.; Waters, D.L.E. Rice Grain Protein Composition Influences Instrumental Measures of Rice Cooking and Eating Quality. J. Cereal Sci. 2018, 79, 35–42. [Google Scholar] [CrossRef]

- Wang, G.; Kou, X.; Zhang, J.; Wang, S.; Xu, R.; Han, G.; Tang, H.; Zhu, L.; Bi, J.; Wu, L. Effect of chemical fertilzer nitrogen substitution by biogas slurry on the growth and quality of rice. Chin. J. Ecol. 2018, 37, 2672–2679. [Google Scholar] [CrossRef]

- Wang, Q.; Huang, Q.; Wang, J.; Li, H.; Qin, J.; Li, X.; Gouda, S.G.; Liu, Y.; Liu, Q.; Guo, G.; et al. Ecological Circular Agriculture: A Case Study Evaluating Biogas Slurry Applied to Rice in Two Soils. Chemosphere 2022, 301, 134628. [Google Scholar] [CrossRef] [PubMed]

- Hou, F.; Yang, Z.; Chen, Y.; Jin, C.; Shi, K.; Chen, C.; Feng, G. Effects of biogas slurry produced from swine manure substituing for urea applied on growth traits, yield and forage quality of indica rice. J. South. Agric. 2019, 50, 1197–1203. (In Chinese) [Google Scholar]

- Mao, X.; Wu, J.; Meng, X.; Wei, K.; Zhang, Z.; Tian, D.; Xian, Y. Effects of three-year continuous application of digested biogas slurry on yield and quality of rice. ACTA Agric. Boreali-Sin. 2016, 31, 218–224. [Google Scholar]

- Hou, F.; Chen, Y.; Yang, Z.; Jin, C.; Shi, K.; Chen, C.; Feng, G.; Li, H. Effects of digested pig slurry application on agronomic trait, yield and forage quality of indica rice. J. Zhejiang Univ. Agric. Life Sci. 2019, 45, 325–331. (In Chinese) [Google Scholar]

- Li, J.; Xu, Y.; Wang, L.; Li, F. Heavy Metal Occurrence and Risk Assessment in Dairy Feeds and Manures from the Typical Intensive Dairy Farms in China. Environ. Sci. Pollut. Res. 2019, 26, 6348–6358. [Google Scholar] [CrossRef]

- Win, A.T.; Toyota, K.; Ito, D.; Chikamatsu, S.; Motobayashi, T.; Takahashi, N.; Ookawa, T.; Hirasawa, T. Effect of Two Whole-Crop Rice (Oryza sativa L.) Cultivars on Methane Emission and Cu and Zn Uptake in a Paddy Field Fertilized with Biogas Slurry. Soil Sci. Plant Nutr. 2016, 62, 99–105. [Google Scholar] [CrossRef]

- Win, A.T.; Toyota, K.; Win, K.T.; Motobayashi, T.; Ookawa, T.; Hirasawa, T.; Chen, D.; Lu, J. Effect of Biogas Slurry Application on CH4 and N2O Emissions, Cu and Zn Uptakes by Whole Crop Rice in a Paddy Field in Japan. Soil Sci. Plant Nutr. 2014, 60, 411–422. [Google Scholar] [CrossRef]

- Huijsmans, J.F.M.; Hol, J.M.G.; Hendriks, M.M.W.B. Effect of Application Technique, Manure Characteristics, Weather and Field Conditions on Ammonia Volatilization from Manure Applied to Grassland. NJAS Wagening. J. Life Sci. 2001, 49, 323–342. [Google Scholar] [CrossRef]

- Kang, Q.; Zhang, Z. Overview of Main Nutrient and Heavy Metal Concentrations in Current Large-Scale Pig Farm Biogas Slurry. Int. J. Ecol. 2019, 08, 310–316. [Google Scholar] [CrossRef]

- Shaheb, M.R.; Nazrul, M.I.; Khan, A.M. Agro Economic Performance of Bio-Slurry on Boro Rice Cultivation in Some Sites of Moulvibazar District. Bangladesh J. Agric. Res. 2017, 42, 363–371. [Google Scholar] [CrossRef]

- Insam, H.; Gómez-Brandón, M.; Ascher, J. Manure-Based Biogas Fermentation Residues–Friend or Foe of Soil Fertility? Soil Biol. Biochem. 2015, 84, 1–14. [Google Scholar] [CrossRef]

- Möller, K. Effects of Anaerobic Digestion on Soil Carbon and Nitrogen Turnover, N Emissions, and Soil Biological Activity. A Review. Agron. Sustain. Dev. 2015, 35, 1021–1041. [Google Scholar] [CrossRef]

- Zhou, S.; Nishiyama, K.; Watanabe, Y.; Hosomi, M. Nitrogen Budget and Ammonia Volatilization in Paddy Fields Fertilized with Liquid Cattle Waste. Water. Air. Soil Pollut. 2009, 201, 135–147. [Google Scholar] [CrossRef]

- Chen, D.; Jiang, L.; Huang, H.; Toyota, K.; Dahlgren, R.A.; Lu, J. Nitrogen Dynamics of Anaerobically Digested Slurry Used to Fertilize Paddy Fields. Biol. Fertil. Soils 2013, 49, 647–659. [Google Scholar] [CrossRef]

- Cruz, L.P.S.; Alves, R.S.; da Rocha, F.O.C.; Moreira, M.S.; dos Santos Júnior, A. Atmospheric Levels, Multivariate Statistical Study, and Health Risk Assessment of Odorous Compounds (H2S and NH3) in Areas near Polluted Urban Rivers in the City of Salvador, in Northeastern Brazil. Air Qual. Atmos. Health 2022, 15, 159–176. [Google Scholar] [CrossRef]

- IUSS Working Group WRB World Reference Base for Soil Resources. International Soil Classification System for Naming Soils and Creating Legends for Soil Maps, 4th ed.; International Union of Soil Sciences (IUSS): Vienna, Austria, 2022. [Google Scholar]

- Boo, H.-K.; Ma, T.S. A Simple Method for Determining Ammonia in Water at the Ppm Level. Microchim. Acta 1976, 66, 515–523. [Google Scholar] [CrossRef]

- ISO 6647-2; Rice—Determination of Amylose Content—Part 2: Spectrophotometric Routine Method without Defatting Procedure and with Calibration from Rice Standards. ISO: Vernier, Geneva, 2020.

- GB/T 17891—2017; High Quality Paddy. Standards Press of China: Beijing, China, 2018.

- Shi, L.; Shen, M.; Wu, H.; Lu, C.; Mei, L.; Zhu, X.L.; Wang, H.; Song, Y.-S. Using Sowing Date Management to Promote Micronutrient Quality and Alleviate Cadmium Accumulation in Rice Grains. Cereal Res. Commun. 2020, 48, 575–583. [Google Scholar] [CrossRef]

- Roelle, P.A.; Aneja, V.P. Modeling of Ammonia Emissions from Soils. Environ. Eng. Sci. 2005, 22, 58–72. [Google Scholar] [CrossRef]

- NY 861—2004; Limits of Eight Elements in Cereals, Legume, Tubes and Its Products. Standards Press of China: Beijing, China, 2005.

- Jiang, L.; Wang, Q.; Chen, D.; Li, A.; Qian, S.; Fu, J.; Wang, S. The ecological effects of fallow paddy field disposal biogas slurry and tis impact on the following rice safety production. J. Agro-Environ. Sci. 2011, 30, 1328–1336. (In Chinese) [Google Scholar]

- Wang, Y.; Ren, T.; Lu, J.; Ming, R.; Li, P.; Hussain, S.; Cong, R.; Li, X. Heterogeneity in Rice Tillers Yield Associated with Tillers Formation and Nitrogen Fertilizer. Agron. J. 2016, 108, 1717–1725. [Google Scholar] [CrossRef]

- Zhu, D.; Zhang, H.; Guo, B.; Xu, K.; Dai, Q.; Wei, H.; Gao, H.; Hu, Y.; Cui, P.; Huo, Z. Effects of Nitrogen Level on Yield and Quality of Japonica Soft Super Rice. J. Integr. Agric. 2017, 16, 1018–1027. [Google Scholar] [CrossRef]

- Ye, T.; Li, Y.; Zhang, J.; Hou, W.; Zhou, W.; Lu, J.; Xing, Y.; Li, X. Nitrogen, Phosphorus, and Potassium Fertilization Affects the Flowering Time of Rice (Oryza sativa L.). Glob. Ecol. Conserv. 2019, 20, e00753. [Google Scholar] [CrossRef]

- Li, X.; Wu, L.; Geng, X.; Xia, X.; Wang, X.; Xu, Z.; Xu, Q. Deciphering the Environmental Impacts on Rice Quality for Different Rice Cultivated Areas. Rice 2018, 11, 7. [Google Scholar] [CrossRef]

- Zhou, C.; Huang, Y.; Jia, B.; Wang, Y.; Wang, Y.; Xu, Q.; Li, R.; Wang, S.; Dou, F. Effects of Cultivar, Nitrogen Rate, and Planting Density on Rice-Grain Quality. Agronomy 2018, 8, 246. [Google Scholar] [CrossRef]

- Fan, Y.; Zhang, Y.; Wang, Y.; Li, J.; Du, Y.; Sun, H.; Ting, P.; Zhao, Z.; Zhang, J. Effects of temperature and light conditions on yield and quality of Indica rice under different sowing dates. J. Henan Agric. Sci. 2024, 53, 17–27. (In Chinese) [Google Scholar] [CrossRef]

- Ata-Ul-Karim, S.T.; Zhu, Y.; Cao, Q.; Rehmani, M.I.A.; Cao, W.; Tang, L. In-Season Assessment of Grain Protein and Amylose Content in Rice Using Critical Nitrogen Dilution Curve. Eur. J. Agron. 2017, 90, 139–151. [Google Scholar] [CrossRef]

- Kaur, A.; Ghumman, A.; Singh, N.; Kaur, S.; Virdi, A.S.; Riar, G.S.; Mahajan, G. Effect of Different Doses of Nitrogen on Protein Profiling, Pasting and Quality Attributes of Rice from Different Cultivars. J. Food Sci. Technol. 2016, 53, 2452–2462. [Google Scholar] [CrossRef]

- Atapattu, A.J.; Prasantha, B.D.R.; Amaratunga, K.S.P.; Marambe, B. Increased Rate of Potassium Fertilizer at the Time of Heading Enhances the Quality of Direct Seeded Rice. Chem. Biol. Technol. Agric. 2018, 5, 22. [Google Scholar] [CrossRef]

- Zhou, T.-Y.; Li, Z.-K.; Li, E.-P.; Wang, W.-L.; Yuan, L.-M.; Zhang, H.; Liu, L.-J.; Wang, Z.-Q.; Gu, J.-F.; Yang, J.-C. Optimization of Nitrogen Fertilization Improves Rice Quality by Affecting the Structure and Physicochemical Properties of Starch at High Yield Levels. J. Integr. Agric. 2022, 21, 1576–1592. [Google Scholar] [CrossRef]

- GB 2762—2012; National Food Safety Standard—Limits of Contaminants in Food. Standards Press of China: Beijing, China, 2013.

- Wang, H.; Dong, Y.; Yang, Y.; Toor, G.S.; Zhang, X. Changes in Heavy Metal Contents in Animal Feeds and Manures in an Intensive Animal Production Region of China. J. Environ. Sci. 2013, 25, 2435–2442. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Wang, L.; Wu, D.; Dai, C.; Han, J. Assessment of heavy metal pollution and bearing capacity estimation of continuous biogas slurry application on cropland: A case study of the coastal rice-wheat rotated farmland in Jiangsu, China. China Environ. Sci. 2019, 39, 1687–1695. (In Chinese) [Google Scholar]

- Linquist, B.A.; Liu, L.; van Kessel, C.; van Groenigen, K.J. Enhanced Efficiency Nitrogen Fertilizers for Rice Systems: Meta-Analysis of Yield and Nitrogen Uptake. Field Crop. Res. 2013, 154, 246–254. [Google Scholar] [CrossRef]

- Xia, Y. Recent Advances in Control Technologies for Non-Point Source Pollution with Nitrogen and Phosphorous from Agricultural Runoff: Current Practices and Future Prospects. Appl. Biol. Chem. 2020, 63, 8. [Google Scholar] [CrossRef]

- Hayashi, K.; Nishimura, S.; Yagi, K. Ammonia Volatilization from the Surface of a Japanese Paddy Field during Rice Cultivation. Soil Sci. Plant Nutr. 2006, 52, 545–555. [Google Scholar] [CrossRef]

- Starr, J.L.; DeRoo, H.C.; Frink, C.R.; Parlange, J.-Y. Leaching Characteristics of a Layered Field Soil. Soil Sci. Soc. Am. J. 1978, 42, 386–391. [Google Scholar] [CrossRef]

- Xiao, Q.; Dong, Z.; Han, Y.; Hu, L.; Hu, D.; Zhu, B. Impact of Soil Thickness on Productivity and Nitrate Leaching from Sloping Cropland in the Upper Yangtze River Basin. Agric. Ecosyst. Environ. 2021, 311, 107266. [Google Scholar] [CrossRef]

- GB/T 14848—2017; Standard for Groundwater Quality. Press of China: Beijing, China, 2018.

- Senbayram, M.; Chen, R.; Budai, A.; Bakken, L.; Dittert, K. N2O Emission and the N2O/(N2O+N2) Product Ratio of Denitrification as Controlled by Available Carbon Substrates and Nitrate Concentrations. Agric. Ecosyst. Environ. 2012, 147, 4–12. [Google Scholar] [CrossRef]

| Treatment | Nitrogen Source | Basal (kg N ha−1) | Tillering (kg N ha−1) | Jointing (kg N ha−1) | Booting (kg N ha−1) |

|---|---|---|---|---|---|

| CK | - | - | - | - | - |

| CN | Urea | 72 | 72 | 96 | - |

| NBS | Urea/biogas slurry | 36/30 | 36/30 | 48/30 | -/30 |

| BS1 | Biogas slurry | 60 | 60 | 60 | 60 |

| BS1.5 | Biogas slurry | 90 | 90 | 90 | 90 |

| BS2 | Biogas slurry | 120 | 120 | 120 | 120 |

| Year | Treat | Panicle Numbers (106 ha−1) | Spikelet Numbers (per Panicle) | Seed-Setting Rate (%) | 1000-Grain Weight (g) |

|---|---|---|---|---|---|

| 2021 | CK | 2.55 e | 110.25 d | 92.53 b | 25.23 c |

| CN | 2.84 c | 128.92 b | 92.18 c | 26.36 a | |

| NBS | 2.70 d | 122.81 c | 94.28 a | 26.47 a | |

| BS1 | 2.70 d | 119.59 c | 92.16 c | 25.96 b | |

| BS1.5 | 2.95 b | 129.89 b | 90.19 d | 25.69 b | |

| BS2 | 2.99 a | 135.06 a | 88.90 e | 25.21 c | |

| 2022 | CK | 2.58 e | 109.57 e | 90.06 d | 25.03 c |

| CN | 2.90 b | 116.09 d | 95.61 a | 26.11 ab | |

| NBS | 2.78 c | 122.99 bc | 94.69 b | 26.52 a | |

| BS1 | 2.74 d | 120.94 c | 92.39 c | 26.19 ab | |

| BS1.5 | 2.94 a | 126.00 b | 90.10 d | 25.80 b | |

| BS2 | 2.94 a | 129.55 a | 89.57 e | 25.24 c | |

| 2023 | CK | 2.58 f | 108.23 d | 92.53 f | 25.23 c |

| CN | 2.79 e | 115.31 bc | 95.33 a | 26.33 a | |

| NBS | 2.93 c | 113.12 c | 94.21 b | 26.42 a | |

| BS1 | 2.87 d | 116.57 b | 93.45 c | 26.15 a | |

| BS1.5 | 2.94 b | 122.66 a | 89.16 d | 25.63 b | |

| BS2 | 3.22 a | 122.16 a | 85.49 e | 25.09 c | |

| Two-way ANOVA | |||||

| Year | ** | ** | ** | ns | |

| Treatment | ** | ** | ** | ** | |

| Year × Treatment | ** | ** | ** | ns | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, L.; Jiang, H.; Liu, T.; Shen, Y.; Dong, L.; Lu, C.; Wang, H.; Li, R. Optimal Application of Biogas Slurry in Paddy Fields under the Dual Constraints of Agronomy and Environment in the Yangtze River Delta Region. Agronomy 2024, 14, 2142. https://doi.org/10.3390/agronomy14092142

Shi L, Jiang H, Liu T, Shen Y, Dong L, Lu C, Wang H, Li R. Optimal Application of Biogas Slurry in Paddy Fields under the Dual Constraints of Agronomy and Environment in the Yangtze River Delta Region. Agronomy. 2024; 14(9):2142. https://doi.org/10.3390/agronomy14092142

Chicago/Turabian StyleShi, Linlin, Huawei Jiang, Tengfei Liu, Yuan Shen, Linlin Dong, Changying Lu, Haihou Wang, and Ruirong Li. 2024. "Optimal Application of Biogas Slurry in Paddy Fields under the Dual Constraints of Agronomy and Environment in the Yangtze River Delta Region" Agronomy 14, no. 9: 2142. https://doi.org/10.3390/agronomy14092142