Optimizing Unmanned Aerial Vehicle Operational Parameters to Improve Pest Control Efficacy and Decrease Pesticide Dosage in Tea Gardens

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Sites and Crop Characteristics

2.2. Spray Equipment and Chemicals

2.3. Basic Operational Process of CP-UAVs

2.4. Experimental Design

2.4.1. Effect of Operational Parameters on the Spraying Performance of T30 and T40

2.4.2. Comparison of Spraying Quality Between T30 and T40

2.4.3. Control Effect of T40 Under Optimal Application Parameters

3. Results

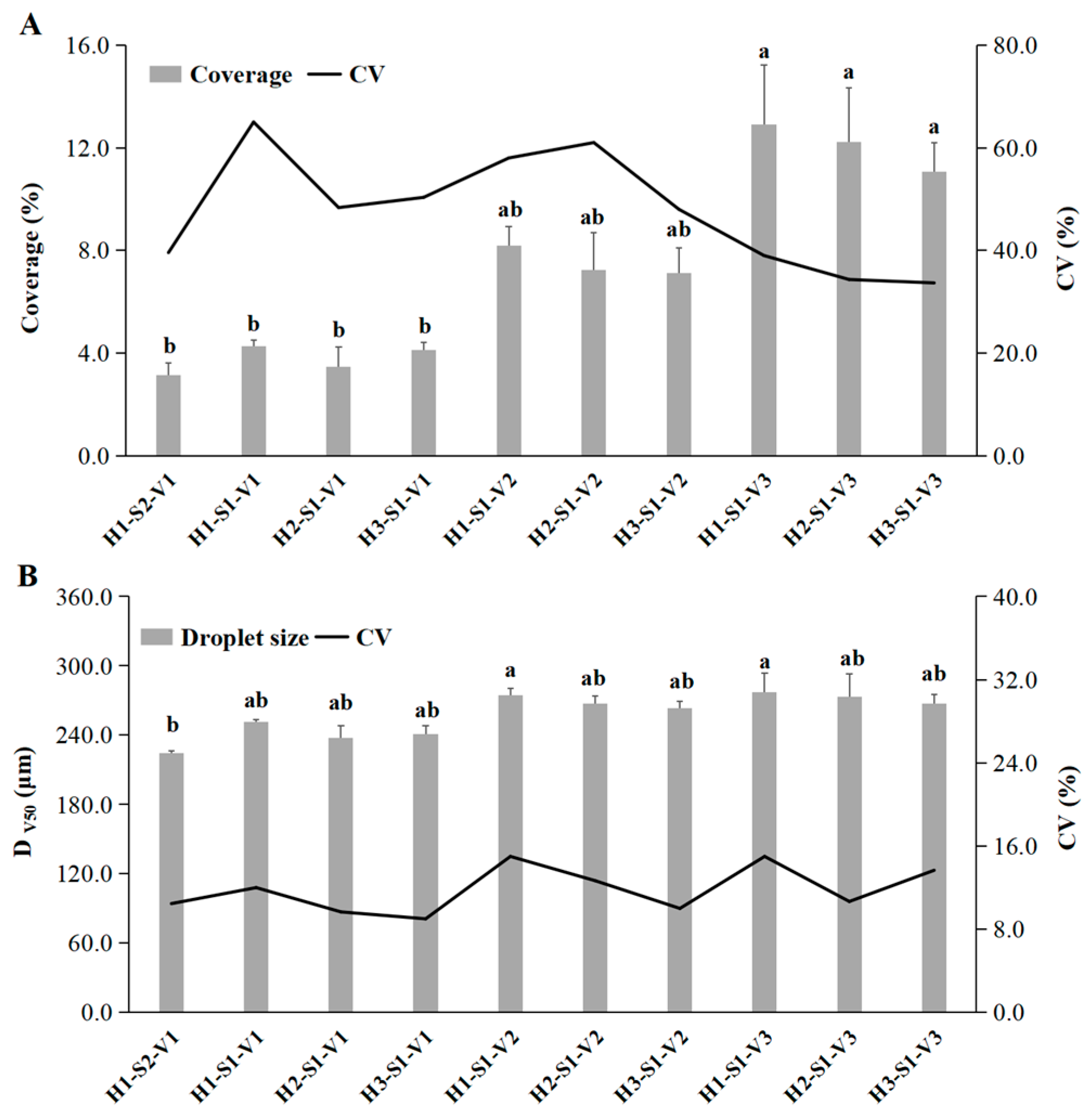

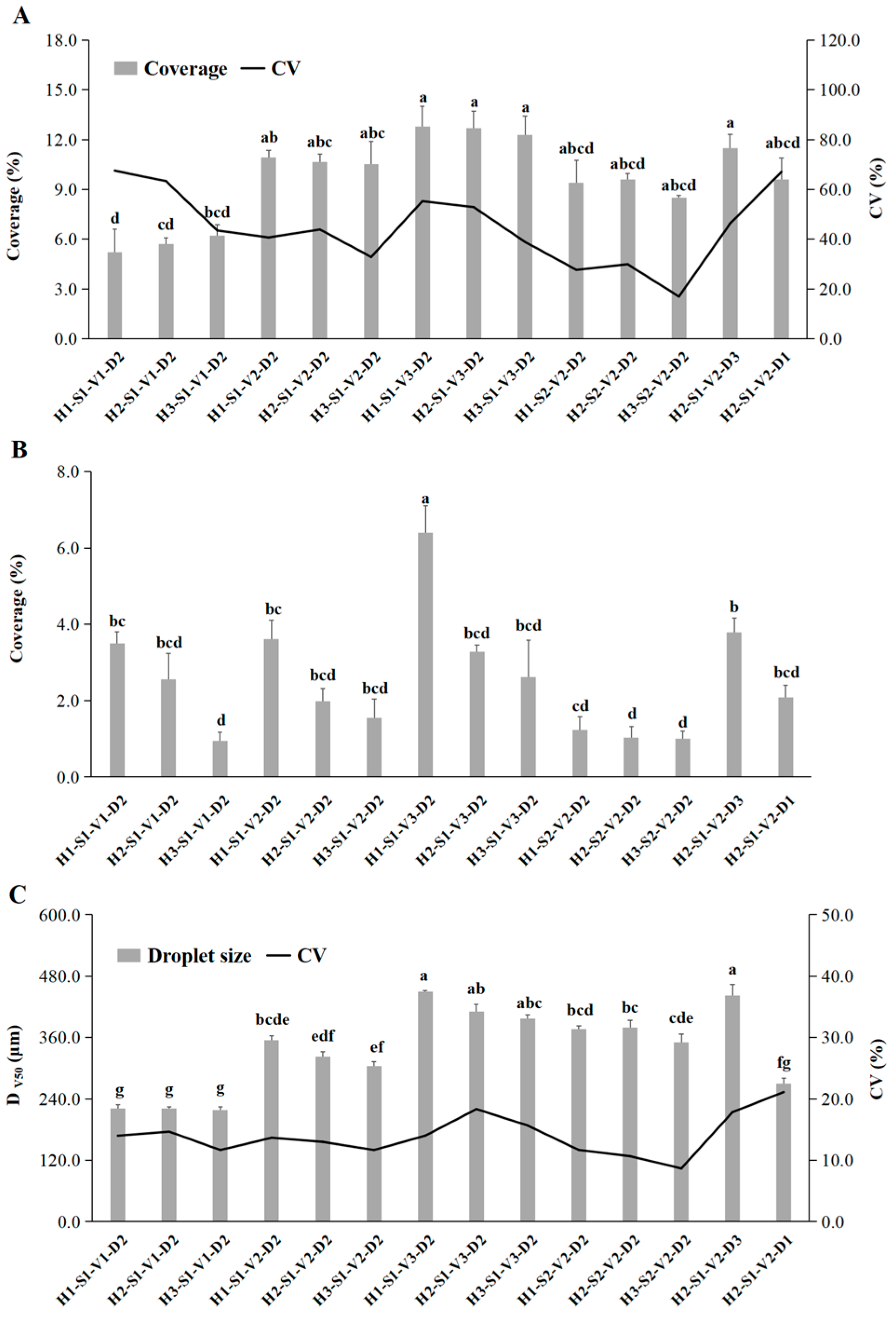

3.1. Effects of Operational Parameters on the Spraying Performance of T30 and T40

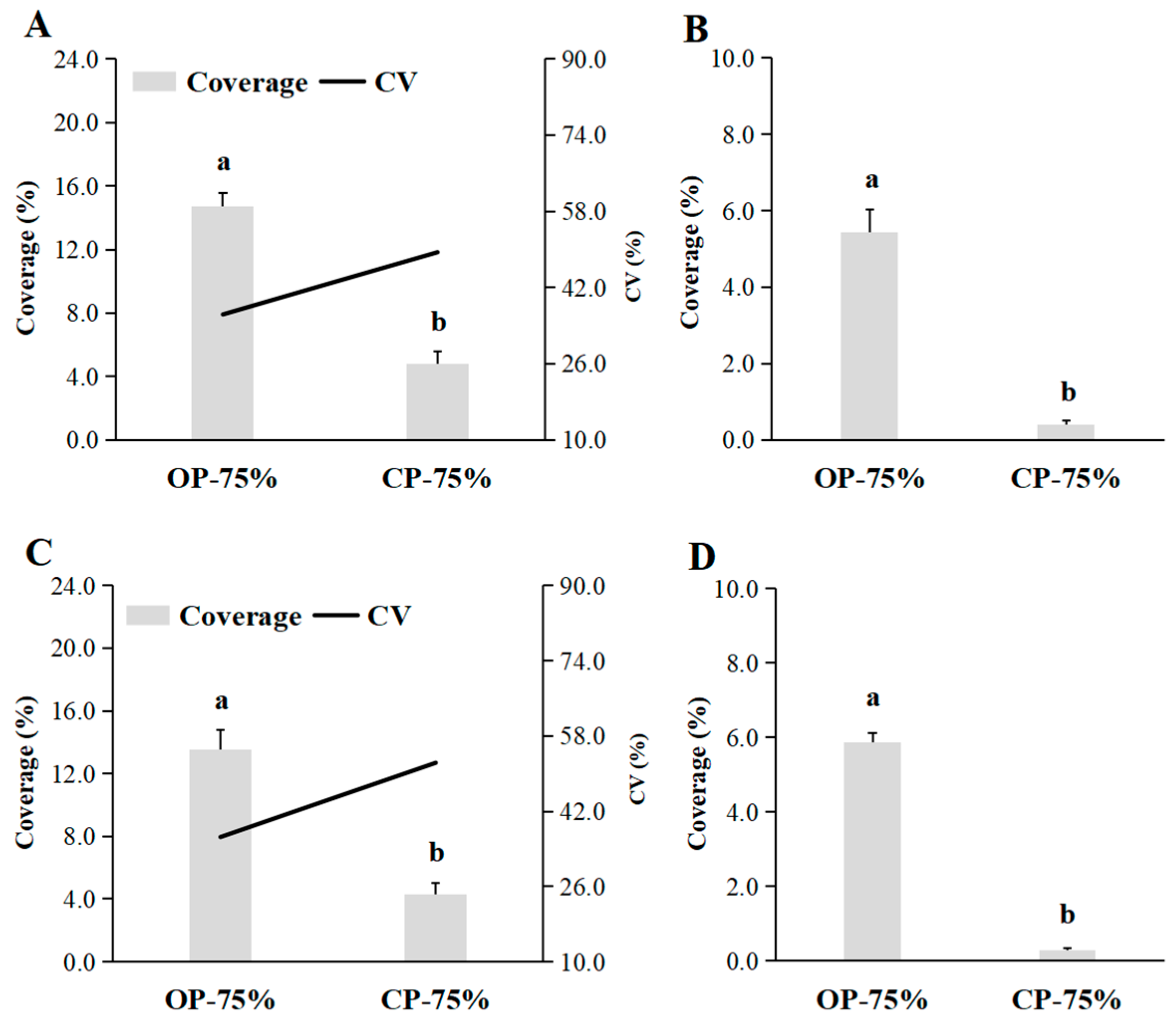

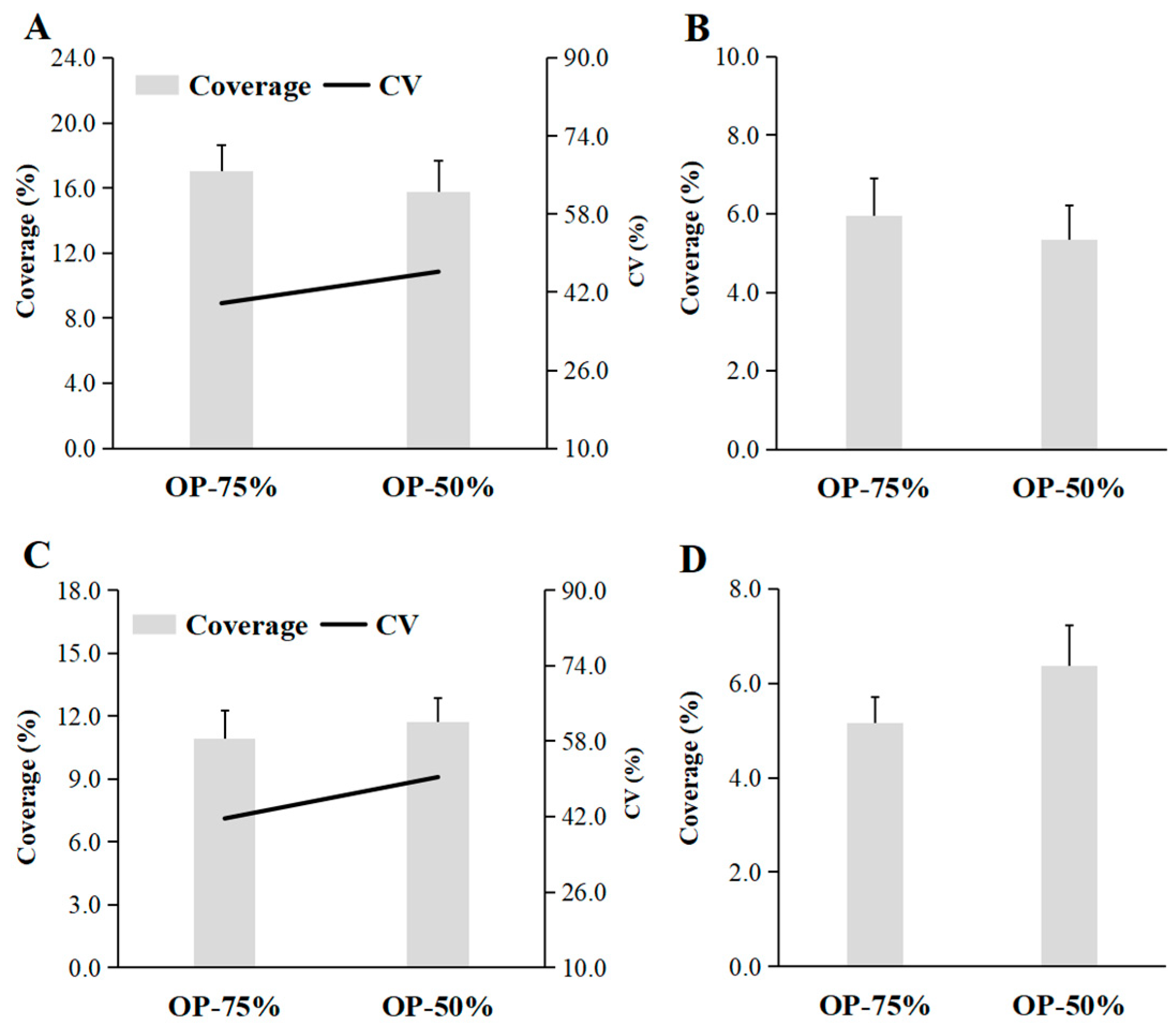

3.2. Comparison of Spraying Quality Between T30 and T40

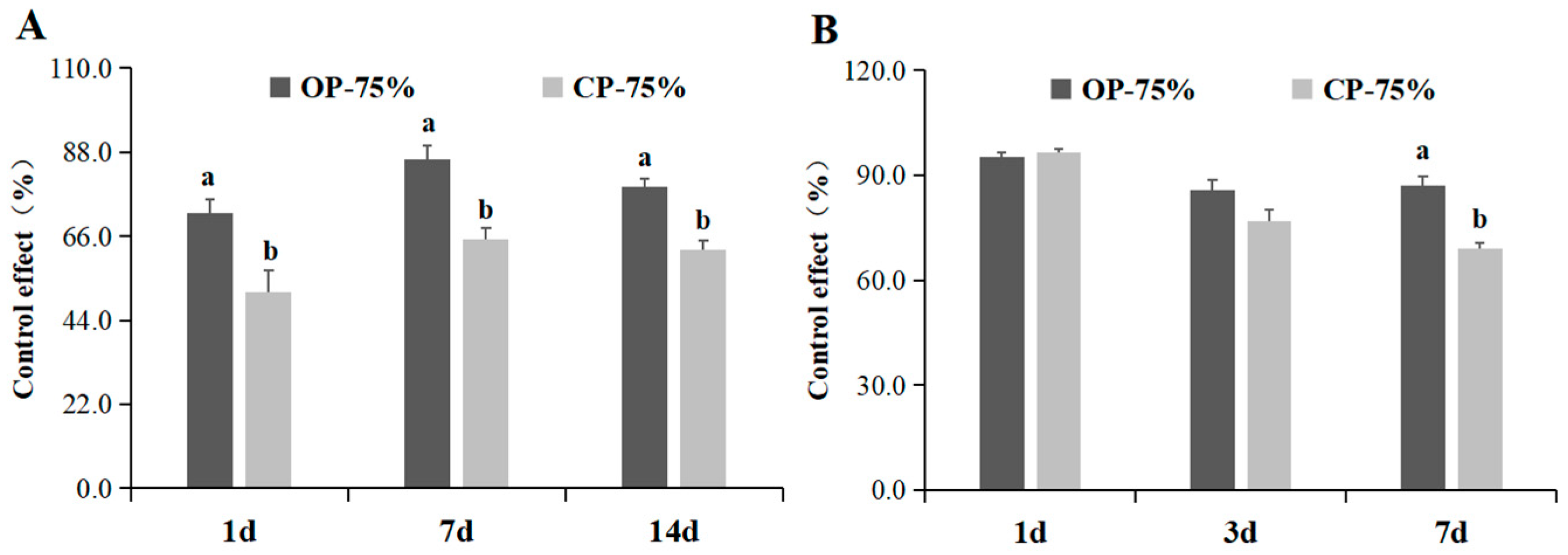

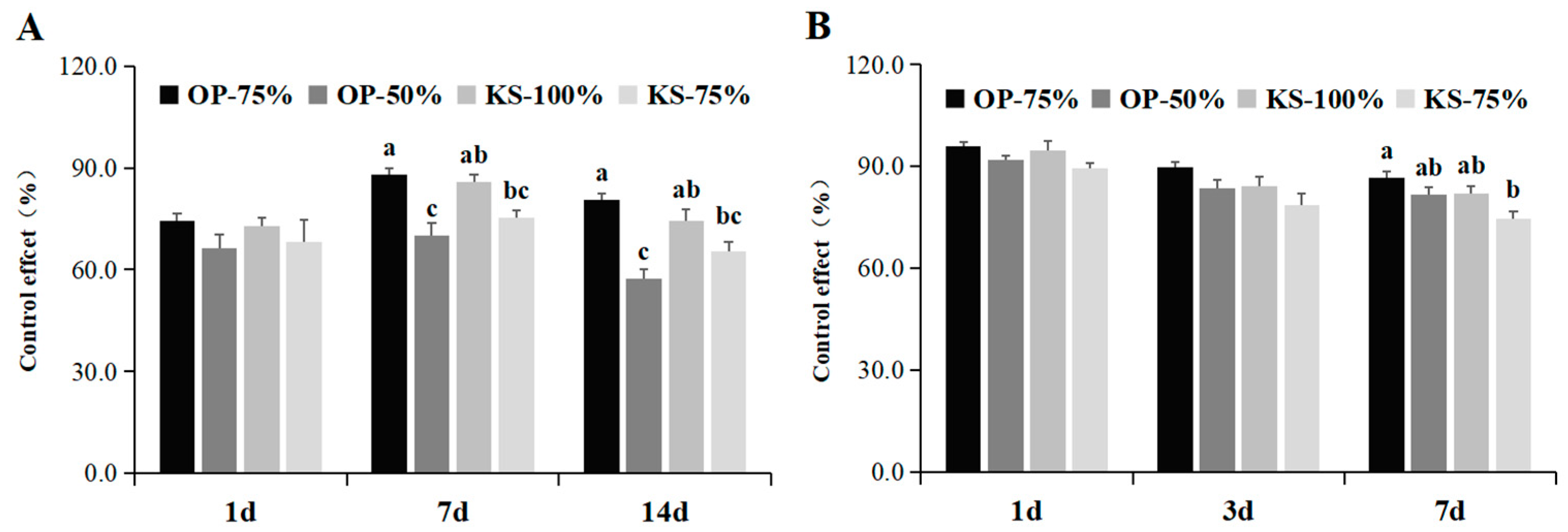

3.3. Control Effect of T40 Under Optimal Application Parameters

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, C.S.; Hong, J. Prevention of chronic diseases by tea: Possible mechanisms and human relevance. Annu. Rev. Nutr. 2013, 33, 161–181. [Google Scholar] [CrossRef] [PubMed]

- Hazzrika, L.K.; Bhuyan, M.; Hazarika, B.N. Insect pests of tea and their management. Annu. Rev. Entomol. 2009, 54, 267–286. [Google Scholar] [CrossRef] [PubMed]

- Mogili, U.M.R.; Deepak, B.B.V.L. Review on application of drone systems in precision agriculture. Procedia Comput. Sci. 2018, 133, 502–509. [Google Scholar] [CrossRef]

- Delavarpour, N.; Koparan, C.; Zhang, Y.; Steele, D.D.; Betitame, K.; Bajwa, S.G.; Sun, X. A review of the current unmanned aerial vehicle sprayer applications in precision agriculture. J. ASABE 2023, 66, 703–721. [Google Scholar] [CrossRef]

- Hanif, A.S.; Han, X.; Yu, S.H. Independent control spraying system for UAV-based precise variable sprayer: A review. Drones 2022, 6, 383. [Google Scholar] [CrossRef]

- Zhang, R.R.; Hewitt, A.J.; Chen, L.P.; Li, L.L.; Tang, Q. Challenges and opportunities of unmanned aerial vehicles as a new tool for crop pest control. Pest Manag. Sci. 2023, 79, 4123–4131. [Google Scholar] [CrossRef]

- Martinez-Guanter, J.; Agüera, P.; Agüera, J.; Perez-Ruiz, M. Spray and economics assessment of a UAV-based ultra-low-volume application in olive and citrus orchards. Precis. Agric. 2020, 21, 226–243. [Google Scholar] [CrossRef]

- Subramanian, K.S.; Pazhanivelan, S.; Srinivasan, G.; Santhi, R.; Sathiah, N. Drones in insect pest management. Front Agron. 2021, 3, 640885. [Google Scholar] [CrossRef]

- Biglia, A.; Grella, M.; Bloise, N.; Comba, L.; Mozzanini, E.; Sopegno, A.; Pittarello, M.; Dicembrini, E.; Alcatrao, L.E.; Guglieri, G. UAV-spray application in vineyards: Flight modes and spray system adjustment effects on canopy deposit, coverage, and off-target losses. Sci. Total Environ. 2022, 845, 157292. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, C.L.; Wongsuk, S.; Qi, P.; Liu, L.M.; Qiao, B.Y.; Zhong, L.; He, X.K. Field evaluation of a six-rotor unmanned agricultural aerial sprayer: Effects of application parameters on spray deposition and control efficacy against rice planthopper. Pest Manag. Sci. 2023, 79, 4664–4678. [Google Scholar] [CrossRef]

- Hu, H.; Kaizu, Y.; Huang, J.; Furuhashi, K.; Zhang, H.; Li, M.; Imou, K. Research on methods decreasing pesticide waste based on plant protection unmanned aerial vehicles: A review. Front Plant Sci. 2022, 13, 811256. [Google Scholar] [CrossRef] [PubMed]

- Ebert, T.A.; Taylor, R.A.; Downer, R.A.; Hall, F.R. Deposit structure and efficacy of pesticide application. 1: Interactions between deposit size, toxicant concentration and deposit number. Pest Sci. 1999, 55, 783–792. [Google Scholar]

- Wang, J.; Lan, Y.; Zhang, H.; Zhang, Y.; Wen, S.; Yao, W.; Deng, J. Drift and deposition of pesticide applied by UAV on pineapple plants under different meteorological conditions. Int. J. Agric. Biol. Eng. 2018, 11, 5–12. [Google Scholar] [CrossRef]

- Hou, C.; Tang, Y.; Luo, S.; Lin, J.; He, Y.; Zhuang, J.; Huang, W. Optimization of control parameters of droplet density in citrus trees using UAVs and the Taguchi method. Int. J. Agric. Biol. Eng. 2019, 12, 1–9. [Google Scholar] [CrossRef]

- Martin, D.E.; Woldt, W.E.; Latheef, M.A. Effect of application height and ground speed on spray pattern and droplet spectra from remotely piloted aerial application systems. Sensors 2019, 3, 83. [Google Scholar] [CrossRef]

- Li, X.; Giles, D.K.; Niederholzer, F.J.; Andaloro, J.T.; Lang, E.B.; Watson, L.J. Evaluation of an unmanned aerial vehicle as a new method of pesticide application for almond crop protection. Pest Manag. Sci. 2021, 77, 527–537. [Google Scholar] [CrossRef]

- Li, L.; Hu, Z.; Liu, Q.; Yi, T.; Han, P.; Zhang, R.; Pan, L. Effect of flight velocity on droplet deposition and drift of combined pesticides sprayed using an unmanned aerial vehicle sprayer in a peach orchard. Front. Plant Sci. 2022, 13, 981494. [Google Scholar] [CrossRef]

- da Vitória, E.L.; de Oliveira, R.F.; Crause, D.H.; Ribeiro, L.F.O. Effect of flight operative height and genotypes on conilon coffee spraying using an unmanned aerial vehicle. Coffee Sci. 2022, 17, e172003. [Google Scholar]

- Dengeru, Y.; Ramasamy, K.; Allimuthu, S.; Balakrishnan, S.; Kumar, A.P.M.; Kannan, B.; Karuppasami, K.M. Study on spray deposition and drift characteristics of UAV agricultural sprayer for application of insecticide in redgram crop (Cajanus cajan L. Millsp.). Agronomy 2022, 12, 3196. [Google Scholar] [CrossRef]

- Ribeiro, L.F.O.; Vitória, E.L.D.; Soprani Júnior, G.G.; Chen, P.; Lan, Y. Impact of operational parameters on droplet distribution using an unmanned aerial vehicle in a papaya orchard. Agronomy 2023, 13, 1138. [Google Scholar] [CrossRef]

- Qi, P.; Zhang, L.; Wang, Z.; Han, H.; Müller, J.; Li, T.; Wang, C.L.; Huang, Z.; He, M.; Liu, Y.J.; et al. Effect of operational parameters of unmanned aerial vehicle (UAV) on droplet deposition in trellised pear orchard. Drones 2023, 7, 57. [Google Scholar] [CrossRef]

- Hua, D.K.; Zheng, X.B.; Zhang, K.; Zhang, Z.; Wan, Y.R.; Zhou, X.G.; Zhang, Y.J.; Wu, Q.J. Assessing pesticide residue and spray deposition in greenhouse eggplant canopies to improve residue analysis. J. Agric. Food Chem. 2020, 68, 11920–11927. [Google Scholar] [CrossRef] [PubMed]

- Guo, M.M.; Qin, Y.J.; Sun, H.Z.; Li, Z.Q.; Zhang, X.Z.; Wang, X.R.; Yang, M.; Luo, F.J.; Chen, Z.M.; Zhou, L. Method validation for detection of afidopyropen and M440I007 in tea. J. Sci. Food Agric. 2023, 103, 5738–5746. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.H.; Wang, X.R.; Wang, M.; Li, Z.Q.; Zhang, X.Z.; Zhou, L.; Sun, H.Z.; Yang, M.; Lou, Z.Y.; Chen, Z.M.; et al. Establishment of a QuEChERS-UPLC-MS/MS method for simultaneously detecting tolfenpyrad and its metabolites in tea. Agronomy 2022, 12, 2324. [Google Scholar] [CrossRef]

- Wang, G.B.; Lan, Y.B.; Yuan, H.Z.; Qi, H.X.; Chen, P.C.; Ouyang, F.; Han, Y.X. Comparison of spray deposition, control efficacy on wheat aphids and working efficiency in the wheat field of the unmanned aerial vehicle with boom sprayer and two conventional knapsack sprayers. Appl. Sci. 2019, 9, 218. [Google Scholar] [CrossRef]

- Giles, D.; Billing, R. Unmanned aerial platforms for spraying: Deployment and performance. Asp. Appl. Biol. 2014, 122, 63–69. [Google Scholar]

- Chen, P.; Douzals, J.P.; Lan, Y.; Cotteux, E.; Delpuech, X.; Pouxviel, G.; Zhan, Y.L. Characteristics of unmanned aerial spraying systems and related spray drift: A review. Front Plant Sci. 2022, 13, 870956. [Google Scholar] [CrossRef]

- Ferguson, J.C.; Chechetto, R.G.; Hewitt, A.J.; Chauhan, B.S.; Adkins, S.W.; Kruger, G.R.; O’Donnell, C.C. Assessing the deposition and canopy penetration of nozzles with different spray qualities in an oat (Avena sativa L.) canopy. Crop Prot. 2016, 81, 14–19. [Google Scholar] [CrossRef]

- De, C.S.; Bin, L.Y.; Li, J.Y.; Zhou, Z.Y.; Liu, A.M.; Mao, Y.D. Effect of wind field below unmanned helicopter on droplet deposition distribution of aerial spraying. Int. J. Agric. Biol. Eng. 2017, 10, 67–77. [Google Scholar]

- Shi, Q.; Liu, D.; Mao, H.; Shen, B.; Li, M. Wind-induced response of rice under the action of the downwash flow field of a multi-rotor UAV. Biosyst. Eng. 2021, 203, 60–69. [Google Scholar] [CrossRef]

- Zhan, Y.L.; Chen, P.C.; Xu, W.C.; Chen, S.D.; Han, Y.F.; Lan, Y.B.; Wang, G.B. Influence of the downwash airflow distribution characteristics of a plant protection UAV on spray deposit distribution. Biosyst. Eng. 2022, 216, 32–45. [Google Scholar] [CrossRef]

- Qin, W.C.; Qiu, B.J.; Xue, X.Y.; Chen, C.; Xu, Z.F.; Zhou, Q.Q. Droplet deposition and control effect of insecticides sprayed with an unmanned aerial vehicle against plant hoppers. Crop Prot. 2016, 85, 79–88. [Google Scholar] [CrossRef]

- Wongsuk, S.; Qi, P.; Wang, C.L.; Zeng, A.J.; Sun, F.Y.; Yu, F.Q.; Zhao, X.; He, X.K. Spray performance and control efficacy against pests in paddy rice by UAV-based pesticide application: Effects of atomization, UAV configuration and flight velocity. Pest Manag. Sci. 2024, 80, 2072–2084. [Google Scholar] [CrossRef]

- Kharim, M.N.A.; Wayayok, A.; Shariff, A.R.M.; Abdullah, A.F.; Husin, E.M. Droplet deposition density of organic liquid fertilizer at low altitude UAV aerial spraying in rice cultivation. Comput. Electron. Agric. 2019, 167, 105045. [Google Scholar] [CrossRef]

- Tang, Y.; Hou, C.J.; Luo, S.M.; Lin, J.T.; Yang, Z.; Huang, W.F. Effects of operation height and tree shape on droplet deposition in citrus trees using an unmanned aerial vehicle. Comput. Electron. Agric. 2018, 148, 1–7. [Google Scholar] [CrossRef]

- Zhang, X.Q.; Song, X.P.; Liang, Y.J.; Qin, Z.Q.; Zhang, B.Q.; Wei, J.J.; Li, Y.R.; Wu, J.M. Effects of spray parameters of drone on the droplet deposition in sugarcane canopy. Sugar Tech. 2020, 22, 583–588. [Google Scholar] [CrossRef]

- Lou, Z.X.; Xin, F.; Han, X.Q.; Lan, Y.B.; Duan, T.Z.; Fu, W. Effect of unmanned aerial vehicle flight height on droplet distribution, drift and control of cotton aphids and spider mites. Agronomy 2018, 8, 187. [Google Scholar] [CrossRef]

- Miranda, M.P.; Eduardo, W.I.; Scapin, M.D.S.; Volpe, H.X.L.; Rodriguez, G.M.; Vizoni, M.C.; Hakvoort, R.B.J. Insecticide application using an unmanned aerial vehicle for Diaphorina citri control in citrus orchards. J. Appl. Entomol. 2023, 147, 716–727. [Google Scholar] [CrossRef]

- Ochieng’, V.; Rwomushana, I.; Ongamo, G.; Ndegwa, P.; Kamau, S.; Makale, F.; Chacha, D.; Gadhia, K.; Akiri, M. Optimum flight height for the control of desert locusts using unmanned aerial vehicles (UAV). Drones 2023, 7, 233. [Google Scholar] [CrossRef]

- Arakawa, T.; Kamio, S. Control efficacy of UAV-based ultra-low-volume application of pesticide in chestnut orchards. Plants 2023, 12, 2597. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.Q.; Liang, Y.J.; Qin, Z.Q.; Li, D.W.; Wei, C.Y.; Wei, J.J.; Li, Y.R.; Song, X.P. Application of multi-rotor unmanned aerial vehicle application in management of stem borer (Lepidoptera) in Sugarcane. Sugar Technol. 2019, 21, 847–852. [Google Scholar] [CrossRef]

- Xiao, Q.G.; Du, R.; Yang, L.; Han, X.Q.; Zhao, S.F.; Zhang, G.Q.; Fu, W.; Wang, G.B.; Lan, Y.B. Comparison of droplet deposition control efficacy on Phytophthora capsica and aphids in the processing pepper field of the unmanned aerial vehicle and knapsack sprayer. Agronomy 2020, 10, 215. [Google Scholar] [CrossRef]

- Munthali, D.C.; Wyatt, I.J. Factors affecting the biological efficiency of small pesticide droplets against Tetranychus urticae eggs. Pest Manag. Sci. 1986, 17, 155–164. [Google Scholar] [CrossRef]

- Bryant, J.E.; Yendol, W.G. Evaluation of the influence of droplet size and density of Bacillus thuringiensis against gypsy moth larvae (Lepidoptera: Lymantriidae). J. Econ. Entomol. 1988, 81, 130–134. [Google Scholar] [CrossRef]

- Yuan, H.Z.; Wang, G.B. Effects of droplet size and deposition density on field efficacy of pesticides. Plant Prot. 2015, 41, 9–16. [Google Scholar]

| Parameters | T30 | T40 |

|---|---|---|

| Total weight (kg) | 36.5 | 50 |

| Dimensions (arms and propellers unfolded, m) | 2.9 × 2.7 × 0.8 | 2.8 × 3.2 × 0.8 |

| Tank volume (L) | 30 | 40 |

| Maximum power (W) | 3600 W/rotor | 3600 W/rotor |

| Number of rotors | 6 | 8 |

| Type of nozzles | SX11001VS | LX8060SZ |

| Number of nozzles | 16 | 2 |

| Particle diameter (μm) | 130–250 | 50–300 |

| Maximum effective swath width (m) | 4–9 | 11 |

| Type of water pump | plunger pump | magnetic drive impeller pump |

| Max flow rate of water pump (L·min−1) | 4 | 6 |

| Number of water pump | 1 | 2 |

| T30 | WH (m) | DS (m·s−1) | SV (L·ha−1) | T40 | WH (m) | DS (m·s−1) | SV (L·ha−1) | AD |

|---|---|---|---|---|---|---|---|---|

| H1-S2-V1 | 2 | 7 | 30 | H1-S1-V1-D2 | 2 | 3 | 60 | medium |

| H1-S1-V1 | 2 | 3 | 30 | H2-S1-V1-D2 | 3.5 | 3 | 60 | medium |

| H2-S1-V1 | 3.5 | 3 | 30 | H3-S1-V1-D2 | 5 | 3 | 60 | medium |

| H3-S1-V1 | 5 | 3 | 30 | H1-S1-V2-D2 | 2 | 3 | 105 | medium |

| H1-S1-V2 | 2 | 3 | 60 | H2-S1-V2-D2 | 3.5 | 3 | 105 | medium |

| H2-S1-V2 | 3.5 | 3 | 60 | H3-S1-V2-D2 | 5 | 3 | 105 | medium |

| H3-S1-V2 | 5 | 3 | 60 | H1-S1-V3-D2 | 2 | 3 | 150 | medium |

| H1-S1-V3 | 2 | 3 | 90 | H2-S1-V3-D2 | 3.5 | 3 | 150 | medium |

| H2-S1-V3 | 3.5 | 3 | 90 | H3-S1-V3-D2 | 5 | 3 | 150 | medium |

| H3-S1-V3 | 5 | 3 | 90 | H1-S2-V2-D2 | 2 | 5 | 105 | medium |

| H2-S2-V2-D2 | 3.5 | 5 | 105 | medium | ||||

| H3-S2-V2-D2 | 5 | 5 | 105 | medium | ||||

| H2-S1-V2-D3 | 3.5 | 3 | 105 | coarse | ||||

| H2-S1-V2-D1 | 3.5 | 3 | 105 | fine | ||||

| Operational Parameters | T30 | T40 | |||||

|---|---|---|---|---|---|---|---|

| df | DC-S | DZ-S | df | DC-S | DC-I | DZ-S | |

| WH | 2 | 0.5730 | 0.4235 | 2 | 0.8831 | 0.0017 | 0.1035 |

| DS | 1 | 0.5287 | 0.0731 | 1 | 0.0594 | 0.0023 | <0.0001 |

| SV | 2 | <0.0001 | 0.0035 | 2 | <0.0001 | <0.0001 | <0.0001 |

| AD | / | / | / | 2 | 0.3901 | 0.0190 | <0.0001 |

| WH × SV | 4 | 0.9518 | 0.9887 | 4 | 0.9439 | 0.1533 | 0.1605 |

| WH × DS | / | / | / | 2 | 0.8800 | 0.1477 | 0.2464 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, M.; Li, Z.; Yang, Y.; Meng, X.; Luo, Z.; Bian, L.; Xiu, C.; Fu, N.; Chen, Z.; Wang, G.; et al. Optimizing Unmanned Aerial Vehicle Operational Parameters to Improve Pest Control Efficacy and Decrease Pesticide Dosage in Tea Gardens. Agronomy 2025, 15, 431. https://doi.org/10.3390/agronomy15020431

Wu M, Li Z, Yang Y, Meng X, Luo Z, Bian L, Xiu C, Fu N, Chen Z, Wang G, et al. Optimizing Unmanned Aerial Vehicle Operational Parameters to Improve Pest Control Efficacy and Decrease Pesticide Dosage in Tea Gardens. Agronomy. 2025; 15(2):431. https://doi.org/10.3390/agronomy15020431

Chicago/Turabian StyleWu, Mengtao, Zhaoqun Li, Yuzhou Yang, Xiangfei Meng, Zongxiu Luo, Lei Bian, Chunli Xiu, Nanxia Fu, Zongmao Chen, Guochang Wang, and et al. 2025. "Optimizing Unmanned Aerial Vehicle Operational Parameters to Improve Pest Control Efficacy and Decrease Pesticide Dosage in Tea Gardens" Agronomy 15, no. 2: 431. https://doi.org/10.3390/agronomy15020431

APA StyleWu, M., Li, Z., Yang, Y., Meng, X., Luo, Z., Bian, L., Xiu, C., Fu, N., Chen, Z., Wang, G., & Cai, X. (2025). Optimizing Unmanned Aerial Vehicle Operational Parameters to Improve Pest Control Efficacy and Decrease Pesticide Dosage in Tea Gardens. Agronomy, 15(2), 431. https://doi.org/10.3390/agronomy15020431