Design and Test of the Outside-Filling Chinese Chive Adjustable-Capacity Precision Seed-Metering Device

Abstract

1. Introduction

2. Materials and Methods

2.1. Structural Components

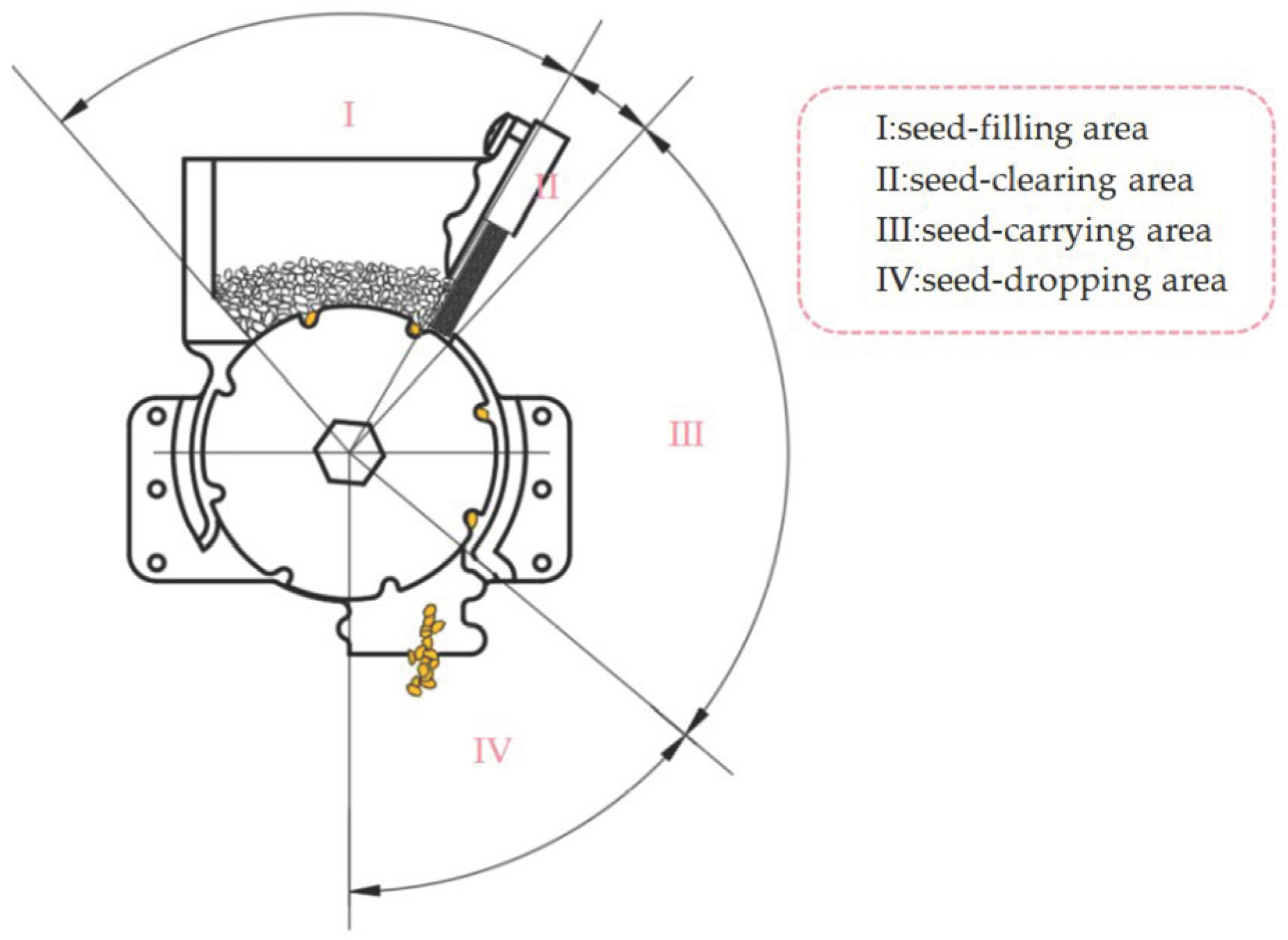

2.2. Work Principle

2.3. Agronomic Requirements for Growing Chinese Chive

2.4. Basic Parameters Chinese Chive

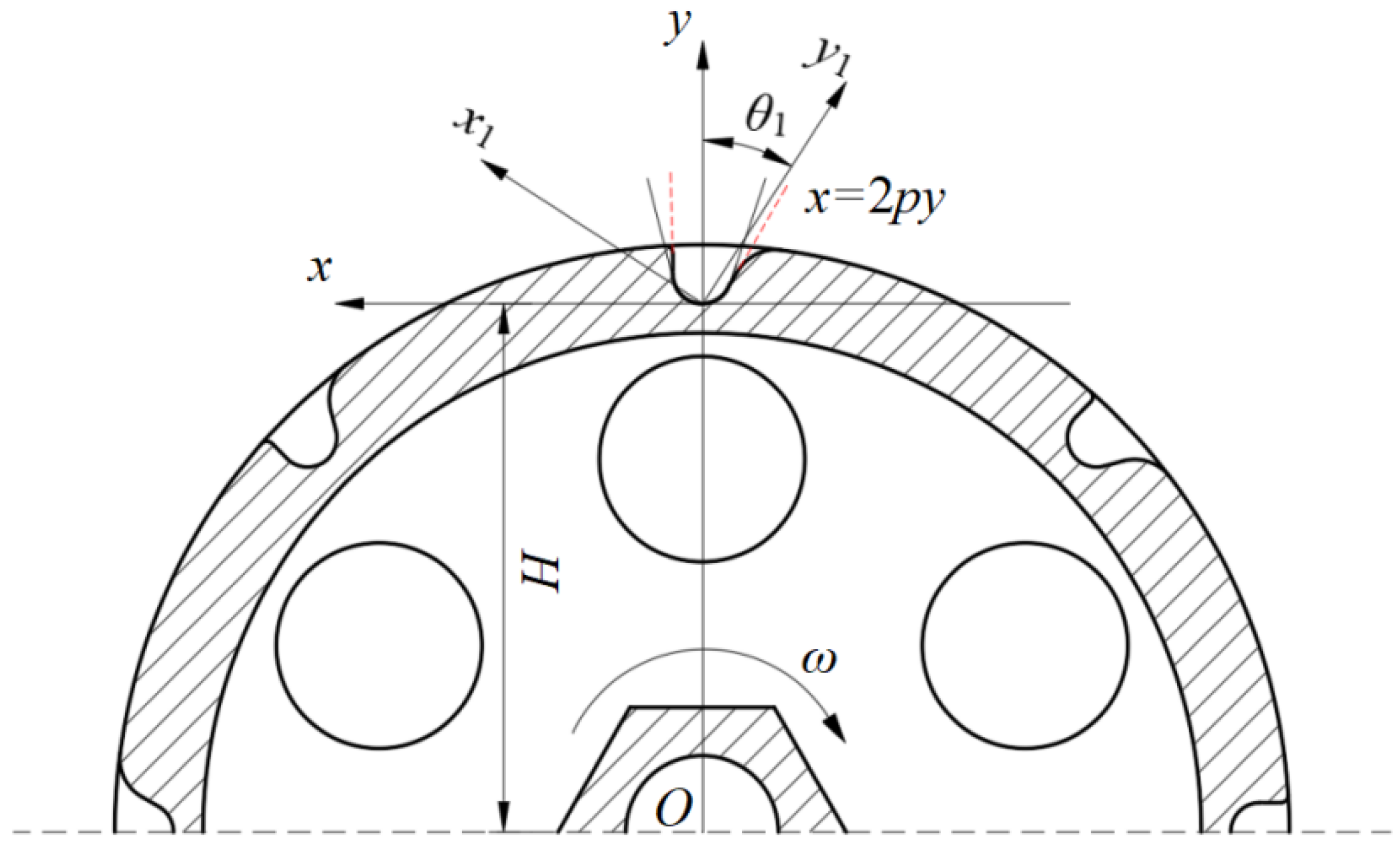

2.5. Design of Seeding Plate Diameter and Shaped Hole

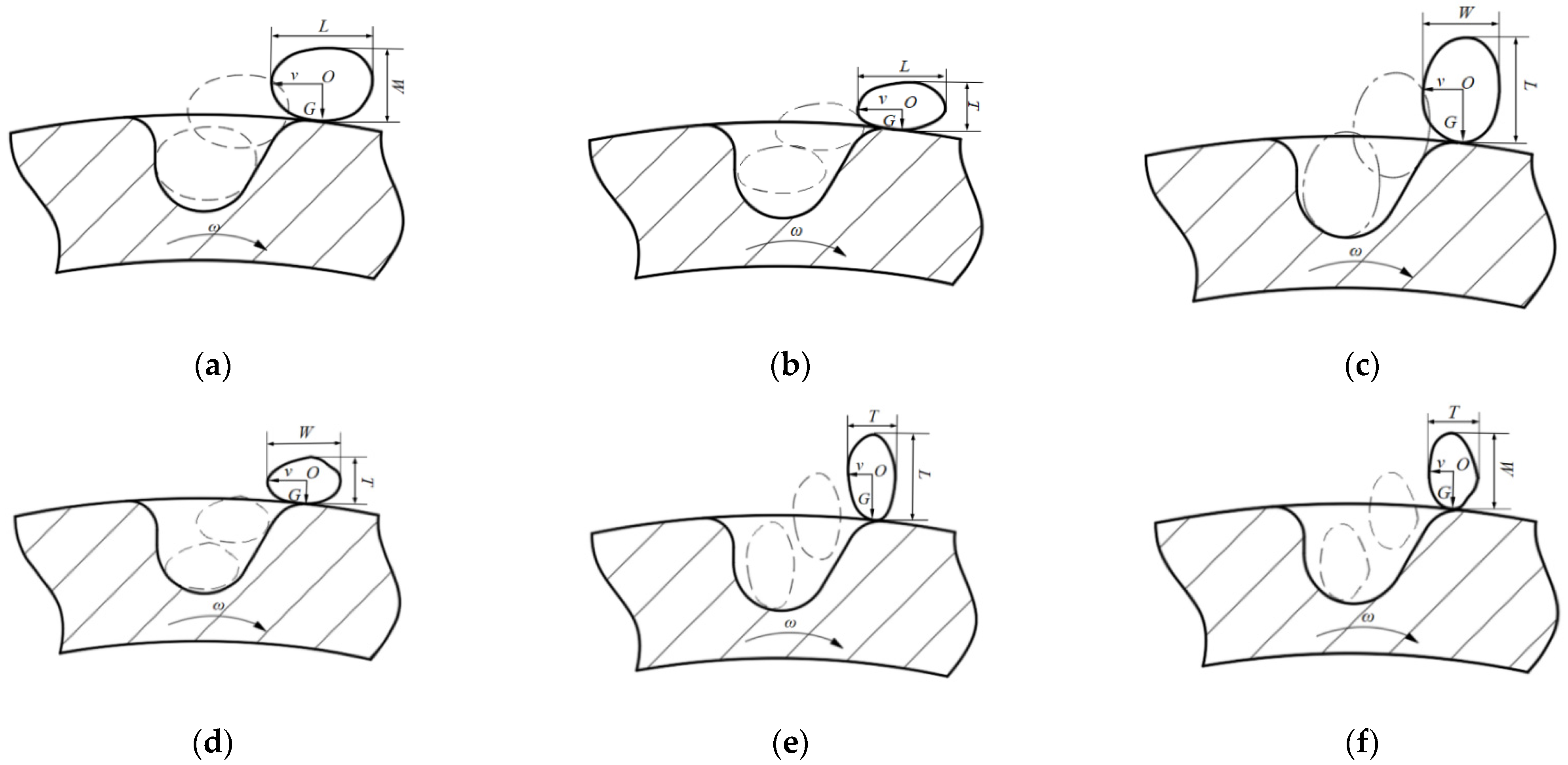

2.6. Design of Seed Slot

3. Results

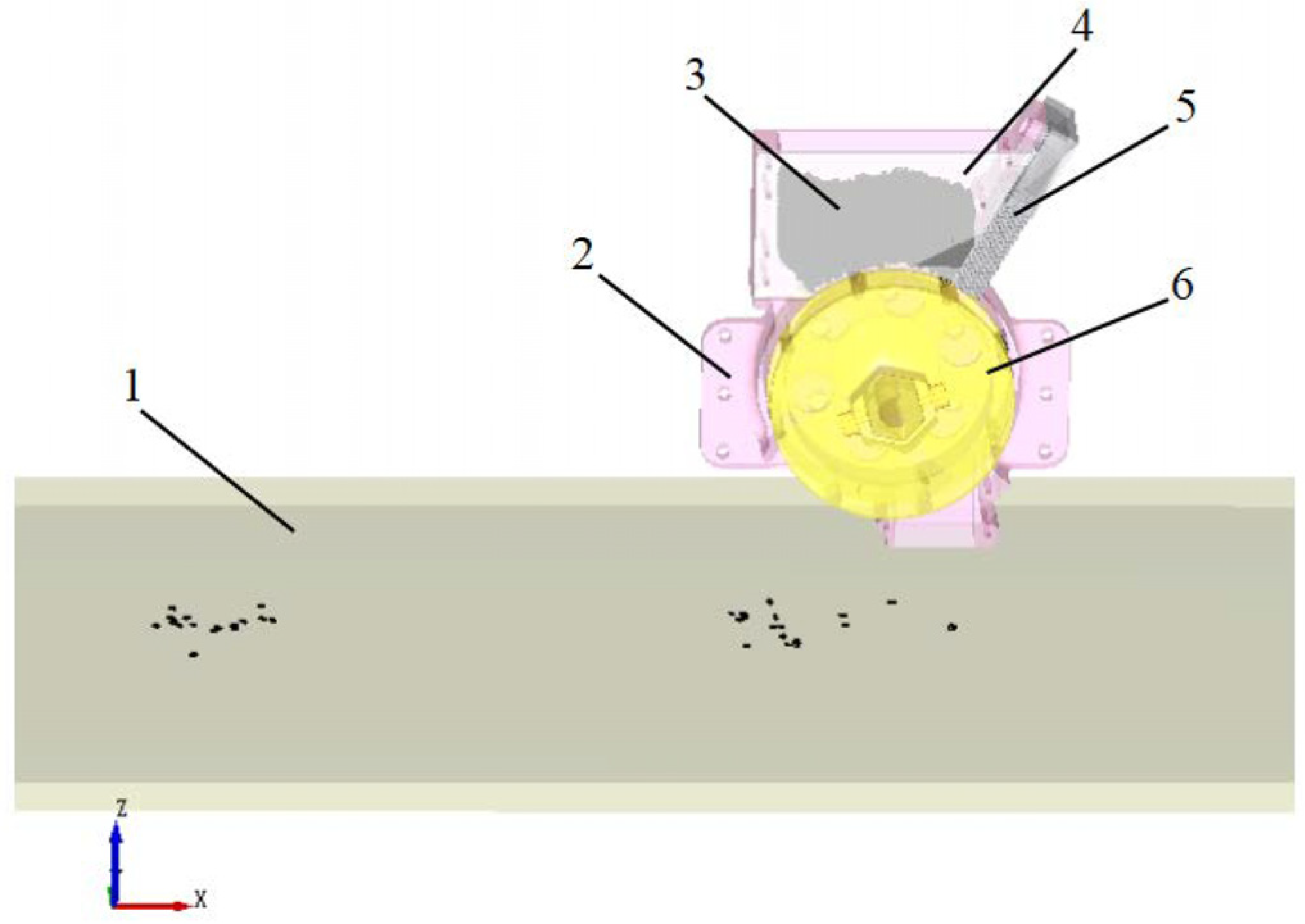

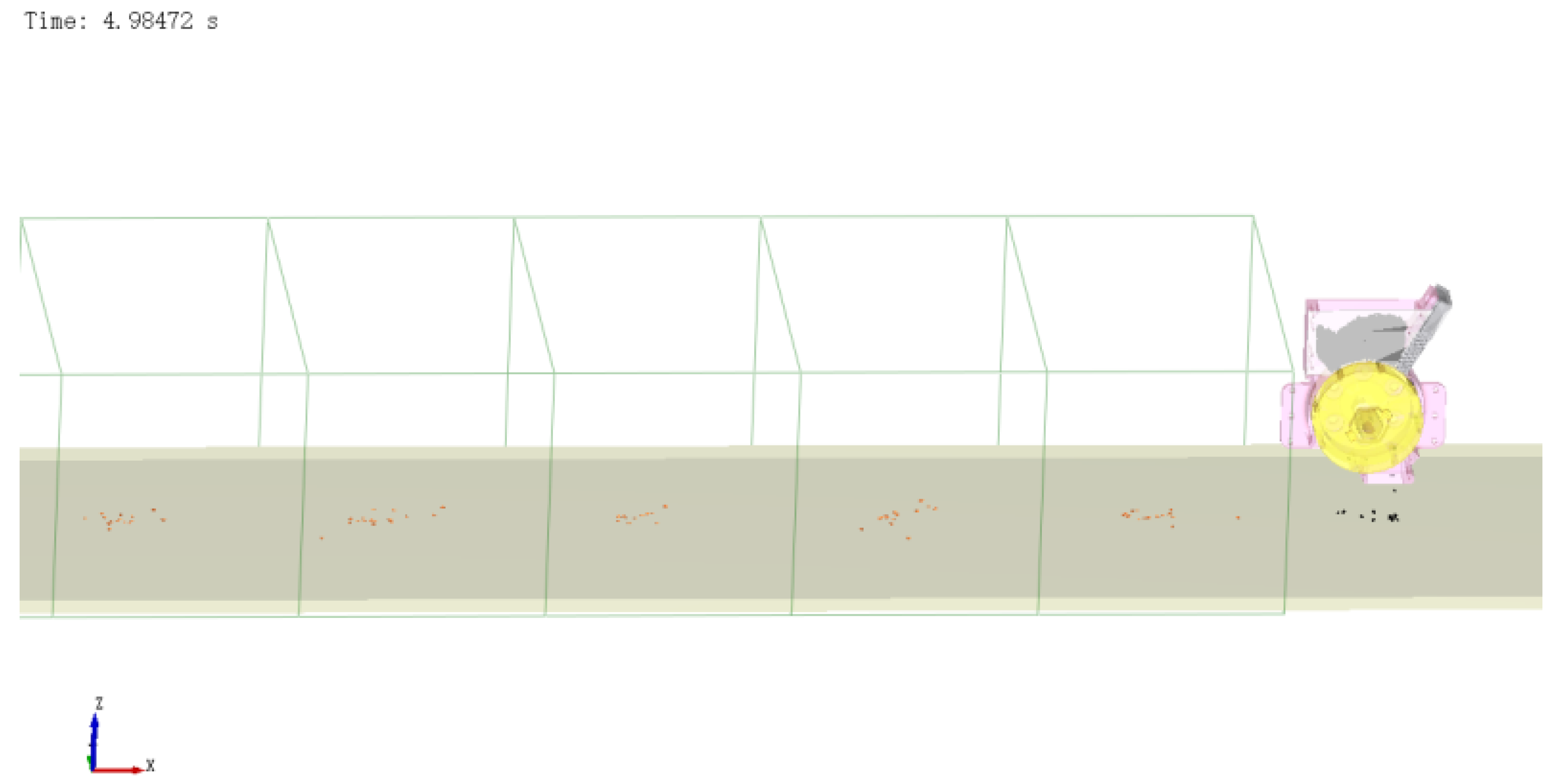

3.1. EDEM Discrete Element Simulation Test

3.2. Sowing Performance Evaluation

3.3. Single-Factor Experiment

3.4. Response Surface Test

3.4.1. Experimental Design

3.4.2. Experimental Results and Analysis of Variance

3.4.3. Response Surface Analysis

3.4.4. Simulation Parameter Optimization

3.5. Bench and Field Tests

3.5.1. Test Condition

3.5.2. Verification Test

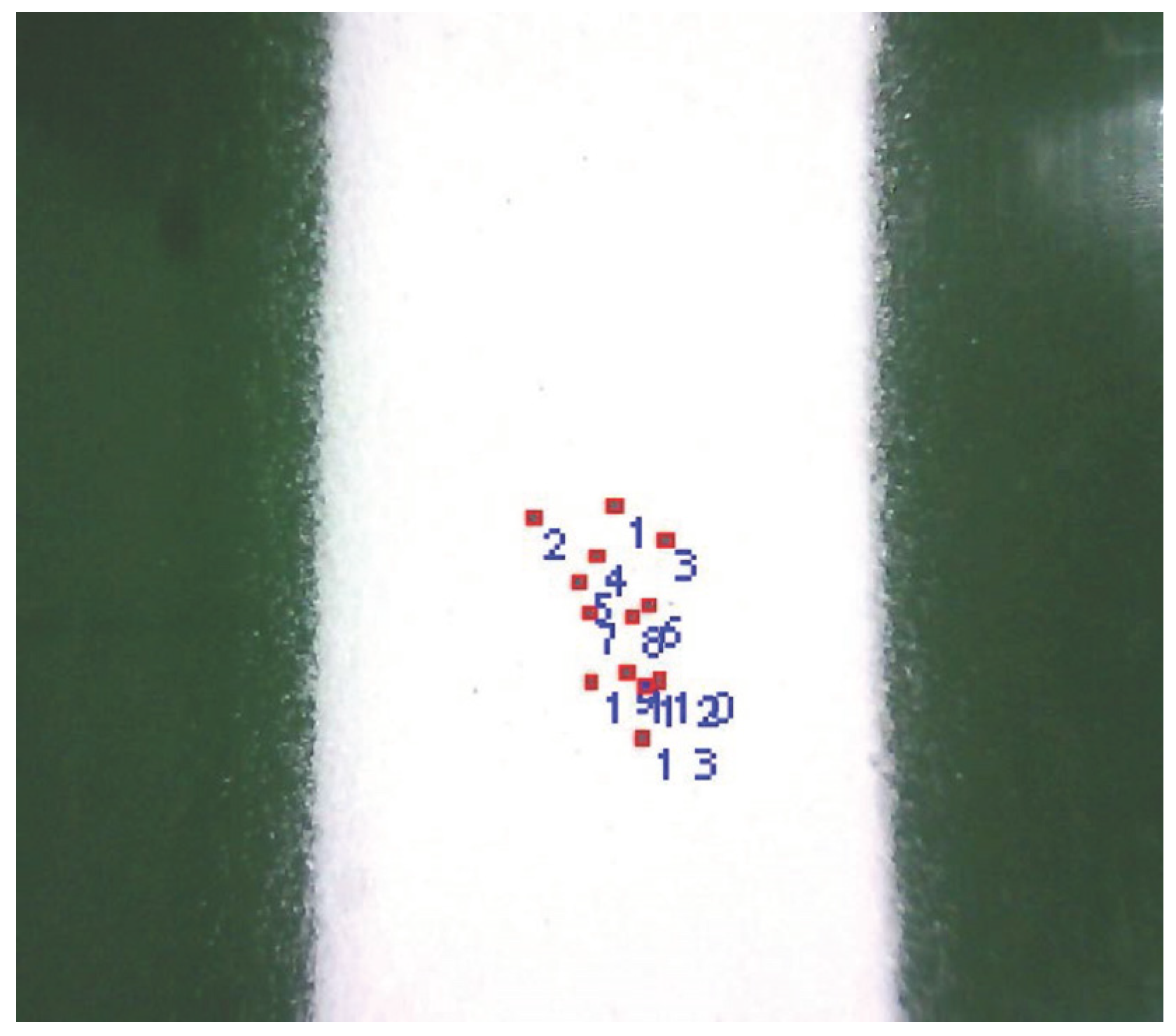

3.5.3. Seed Slot Volume-Adjustment Tests and Field Trials

4. Discussion

5. Conclusions

- (1)

- The seed-metering device was designed and trial-produced to realize Chinese chive precision hole sowing and improve the concentration of Chinese chive hole sowing. The overall structure and working principle of the seed-metering device are described, the material characteristics of Chinese chive seeds are measured, the probability of seed filling is analyzed, and the diameter of the seeding plate and the seed slot are designed to realize the precise adjustment of the number of seeds.

- (2)

- By constructing an EDEM discrete-element simulation model of Chinese chive seeds and seed displacer, a single-factor experiment was first used to determine the best seeding effect when the seed slot length was 17.9 mm. A quadratic general rotary combination design experiment was also designed to obtain regression equations for vertical concentration and horizontal concentration. The analysis of variance showed that the factors affecting vertical concentration were seed slot depth and seed slot diameter, in that order of priority, and the factors affecting horizontal concentration were seed slot diameter and seed slot depth, in that order of priority. The smaller the coefficient of variation, the more concentrated the hole sowing. The optimal combination of parameters was obtained using the minimum longitudinal and transverse concentrations as the optimization objectives. The longitudinal concentration was 0.563, the transverse concentration was 0.634 when the seed slot diameter was 3.075 mm, and the seed slot depth was 3.323 mm.

- (3)

- The simulation test optimization results for the optimal parameter combinations were experimentally verified. The results of the bench test show that the longitudinal concentration is 0.559, the transverse concentration is 0.642, the relative error of the longitudinal concentration is 3.20%, and the relative error of the transverse concentration is 2.47%, which is close to the results of the bench test and the simulation test. A seed slot adjustment test was also designed to count the number of seeds sown in five horizontal lengths of seed slots. The number of seeds planted per hole and the length of the seed slots were linearly correlated. It shows that the outside-filling Chinese chive adjustable-capacity precision seed-metering device can meet the challenge of having different grain numbers in sowing by adjusting the length of the seed slot, improving sowing centralization.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ku, H.-H.; Lee, S.G.; Chiang, M.-H.; Choi, J.-L.; Lee, S.E. Effects of pH of soil medium on the growth and nutrient absorption of cultivated and native Chinese chives plants. Korean J. Environ. Biol. 2019, 37, 42–47. [Google Scholar] [CrossRef]

- Nomura, K.; Wada, E.; Saito, M.; Itokawa, S.; Mizobuchi, K.; Yamasaki, H.; Tada, I.; Iwao, T.; Yamazaki, T.; Kitano, M. Effect of different fertigation scheduling methods on the yields and photosynthetic parameters of drip-fertigated Chinese chive (Allium tuberosum) grown in a horticultural greenhouse. Horticulturae 2024, 10, 794. [Google Scholar] [CrossRef]

- Feng, Y.; Yin, X.; Jin, H.; Tong, W.; Ning, X. Sugarcane, single-bud sugarcane seed, disc-type seeding device, seeding uniformity. Int. J. Agric. Biol. Eng. 2023, 16, 125–131. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Ma, P.; Chen, J.; Lv, A.; Zhang, G.; Li, K.; Yin, S.; Chen, Z. Analysis of Chinese chive field mechanized live cultivation technology and advantages. China Veg. 2020, 12, 107–109. [Google Scholar]

- Ding, L.; Yuan, Y.; Dou, Y.; Li, C.; He, Z.; Guo, G.; Zhang, Y.; Chen, B.; Li, H. Design and experiment of air-suction maize seed-metering device with auxiliary guide. Agriculture 2024, 14, 169. [Google Scholar] [CrossRef]

- Pareek, C.; Tewari, V.; Machavaram, R. Multi-objective optimization of seeding performance of a pneumatic precision seed metering device using integrated ann-mopso approach. Eng. Appl. Artif. Intell. 2023, 117, 105559. [Google Scholar] [CrossRef]

- Karayel, D.; Güngör, O.; Šarauskis, E. Estimation of optimum vacuum pressure of air-suction seed-metering device of precision seeders using artificial neural network models. Agronomy 2022, 12, 1600. [Google Scholar] [CrossRef]

- Van Loon, J.; Krupnik, T.J.; López-Gómez, J.A.; Timsina, J.; Govaerts, B. A standard methodology for evaluation of mechanical maize seed meters for smallholder farmers comparing devices from Latin America, Sub-Saharan Africa, and Asia. Agronomy 2020, 10, 1091. [Google Scholar] [CrossRef]

- Virk, S.S.; Fulton, J.P.; Porter, W.M.; Pate, G.L. Row-crop planter performance to support variable-rate seeding of maize. Precis. Agric. 2020, 21, 603–619. [Google Scholar] [CrossRef]

- Li, H.; Ma, Y.; Yu, H.; Wang, Y.; Sun, J.; Yi, J. Design and experiment of group air-suction type celery seed metering device. Trans. Chin. Soc. Agric. Mach. 2023, 54, 87–95. [Google Scholar]

- Liu, H.; Yi, S.; Chen, T.; Tao, G.; Mao, X. Design and experiment of duckbill millet seed metering device. J. Agric. Mech. Res. 2024, 46, 111–119. [Google Scholar]

- Li, H.; Zhao, W.; Shi, L.; Dai, F.; Rao, G.; Wang, Z. Design and test of seed ladle tongue type flax precision burrow planter. Trans. Chin. Soc. Agric. Mach. 2024, 55, 85–95. [Google Scholar]

- Ding, L.; Guo, H.; Wang, W.; Lv, Z.; Lv, Y.; Zhang, R. Design and test of Cyperus esculentus cell-wheel seed-metering device with low-position seeding and cavitation function. Trans. Chin. Soc. Agric. Mach. 2022, 53, 86–97. [Google Scholar]

- Modi, R.U.; Manes, G.S.; Mahal, J.S.; Dixit, A.K.; Singh, M. Design of an innovative tractor-operated seeder for mat type paddy nursery. J. Sci. Ind. Res. 2022, 81, 683–694. [Google Scholar]

- Kumar, D.; Tripathi, A.; Prakash, O.; Joshi, P.; Khan, K.; Kumar, M. Seed metering device evaluation by grease belt method. Indian J. Agric. Sci. 2021, 91, 1443–1446. [Google Scholar] [CrossRef]

- Tang, H.; Xu, F.; Guan, T.; Xu, C.; Wang, J. Design and test of a pneumatic type of high-speed maize precision seed metering device. Comput. Electron. Agric. 2023, 211, 107997. [Google Scholar] [CrossRef]

- Jiang, X.; Zhang, J.; Liu, S.; Fu, L.; Huang, D. Development and evaluation of a universal seed discharger for precision planting in corn-soybean cropping system. Processes 2024, 12, 1595. [Google Scholar] [CrossRef]

- Sharaby, N.; Doroshenko, A.; Butovchenko, A. Modelling and verification of sesame seed particles using the discrete element method. J. Agric. Eng. 2022, 53, 1286. [Google Scholar] [CrossRef]

- Li, H.; Zhao, C.; Yan, B.; Ling, L.; Meng, Z. Design and verification of the variable capacity roller-wheel precision rice direct seed-metering device. Agronomy 2022, 12, 1798. [Google Scholar] [CrossRef]

- Gao, X.; Xie, G.; Li, J.; Shi, G.; Lai, Q.; Huang, Y. Design and validation of a centrifugal variable-diameter pneumatic high-speed precision seed-metering device for maize. Biosyst. Eng. 2023, 227, 161–181. [Google Scholar] [CrossRef]

- Ospanova, S.; Aduov, M.; Kapov, S.; Orlyansky, A.; Volodya, K. The results of experimental research of a rotor seed-metering unit for sowing non-free-flowing seeds. J. Agric. Eng. 2024, 55, 1556. [Google Scholar] [CrossRef]

- Xiong, D.; Wu, M.; Xie, W.; Liu, R.; Luo, H. Design and experimental study of the general mechanical pneumatic combined seed metering device. Appl. Sci. 2021, 11, 7223. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, J.; Zhang, X.; Shi, Z.; Wang, M.; Wu, H.; Fu, H. Design and experiment of pressure-holding precision seed-metering device for maize. INMATEH Agric. Eng. 2023, 69, 159–169. [Google Scholar] [CrossRef]

- Zheng, G.; Qi, B.; Zhang, W.; Shao, W.; Zhang, L.; Wang, Y.; Ding, Y. Engineering discrete element method-based design and optimization of the key components of a spoon-wheel spinach seed-metering device. Agronomy 2024, 14, 2096. [Google Scholar] [CrossRef]

- Wang, H.; Sun, X.; Li, H.; Fu, J.; Zeng, X.; Xu, Y.; Wang, Y.; Liu, H.; Lü, Z. Design and parameter optimization of a finger clip plate garlic seed-metering device based on EDEM. Agronomy 2022, 12, 1543. [Google Scholar] [CrossRef]

- Shang, Y.; Zhou, B.; Yang, J.; Zhang, S. Design and experiment of impeller seed guide device for rice internal suction hole direct seeding device. Sci. Rep. 2024, 14, 13300. [Google Scholar] [CrossRef]

- Qiao, Y.; Huang, S.; Yang, C.; Liu, S.; Wang, K.; Lu, Y.; Wang, J. Calibration and testing of discrete element simulation parameters for ultrasonic vibration-cutter-soil interaction model. Agriculture 2024, 15, 20. [Google Scholar] [CrossRef]

- Zhou, H.; Li, K.; Qin, Z.; Wang, S.; Wang, X.; Sun, F. Discrete element model of oil peony seeds and the calibration of its parameters. Agriculture 2024, 14, 1092. [Google Scholar] [CrossRef]

- Li, Z.; Zhong, J.; Gu, X.; Zhang, H.; Chen, Y.; Wang, W.; Zhang, T.; Chen, L. DEM study of seed motion model-hole-wheel variable seed metering device for wheat. Agriculture 2023, 13, 23. [Google Scholar] [CrossRef]

- Melika, B.; Hossein, K.S.; Hadi, A.-N.; Mahdi, K.-J.; Hossein, B.; Farhang, S. DEM simulation for seeding performance of a slotted roller seed-metering device for planting maize in laboratory condition. J. Biosyst. Eng. 2023, 48, 428–436. [Google Scholar]

- Jahanbakhshi, A.; Nadooshan, A.A.; Bayareh, M. Multi-objective optimization of microchannel heatsink with wavy microtube by combining response surface method and genetic algorithm. Eng. Anal. Bound. Elem. 2022, 140, 12–31. [Google Scholar] [CrossRef]

- Tang, H.; Xu, F.; Xu, C.; Zhao, J.; Wang, Y.-J. The influence of a seed drop tube of the inside-filling air-blowing precision seed-metering device on seeding quality. Comput. Electron. Agric. 2023, 204, 107555. [Google Scholar] [CrossRef]

- Chen, K.; Gao, S.; Wang, C.; Yuan, Y.; Zhao, B.; Zhou, L.; Niu, K.; Wang, H.; Zheng, Y. Design and analysis of a high-precision dynamic compensation system for seed dropping position in corn sowing operations. Appl. Sci. 2023, 13, 7741. [Google Scholar] [CrossRef]

- Xie, C.; Zhang, D.; Yang, L.; Cui, T.; He, X.; Du, Z.; Xiao, T. Research and analysis on the influence of different speed measurement methods on the monitoring accuracy of seed spacing. Agriculture 2023, 13, 128. [Google Scholar] [CrossRef]

- Zhao, P.; Gao, X.; Su, Y.; Xu, Y.; Huang, Y. Investigation of seeding performance of a novel high-speed precision seed metering device based on numerical simulation and high-speed camera. Comput. Electron. Agric. 2024, 217, 108563. [Google Scholar] [CrossRef]

- Shah, K.; Alam, M.S.; Nasir, F.E.; Qadir, M.U.; Haq, I.U.; Khan, M.T. Design and performance evaluation of a novel variable rate multi-crop seed metering unit for precision agriculture. IEEE Access 2022, 10, 133152–133163. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Density of Chinese chive seeds/kg·m−3 | 1274 |

| Shear modulus of Chinese chive seeds/Pa | 1.36 × 107 |

| Poisson’s ratio of Chinese chive seeds | 0.26 |

| Density of PLA plastics/kg·m−3 | 1290 |

| Shear modulus of PLA plastics/Pa | 1.04 × 107 |

| Poisson’s ratio of PLA plastics | 0.30 |

| Density of seed-clearing brush/kg·m−3 | 1150 |

| Shear modulus of seed-clearing brush/Pa | 1.1 × 108 |

| Poisson’s ratio of seed-clearing brush | 0.4 |

| Density of ground plastics/kg·m−3 | 1400 |

| Shear modulus of ground/Pa | 1.06 × 106 |

| Poisson’s ratio of ground | 0.37 |

| Coefficient of restitution between seeds and seeds | 0.16 |

| Coefficient of static friction between seeds and seeds | 0.87 |

| Coefficient of rolling friction between seeds and seeds | 0.08 |

| Coefficient of restitution between seeds and PLA plastics | 0.29 |

| Coefficient of static friction between seeds and PLA plastics | 0.56 |

| Coefficient of rolling friction between seeds and PLA plastics | 0.04 |

| Coefficient of restitution between seeds and seed-clearing brush | 0.40 |

| Coefficient of static friction between seeds and seed-clearing brush | 0.40 |

| Coefficient of rolling friction between seeds and seed-clearing brush | 0.01 |

| Coefficient of restitution between seeds and seed-clearing brush | 0.01 |

| Coefficient of static friction between seeds and seed-clearing brush | 0.05 |

| Coefficient of rolling friction between seeds and seed-clearing brush | 0.5 |

| Coding | Factors | |

|---|---|---|

| Diameter of Seed Slot (mm) | Depth of Seed Slot (mm) | |

| 1.414 | 3.30 | 3.90 |

| 1 | 3.21 | 3.61 |

| 0 | 3.00 | 2.90 |

| −1 | 2.79 | 2.19 |

| −1.414 | 2.70 | 1.90 |

| Test Number | Factors | Vertical Concentration | Horizontal Concentration | |

|---|---|---|---|---|

| X1 | X2 | |||

| 1 | −1 | −1 | 0.746 | 0.915 |

| 2 | 1 | −1 | 0.685 | 0.898 |

| 3 | −1 | 1 | 0.667 | 0.843 |

| 4 | 1 | 1 | 0.561 | 0.632 |

| 5 | −1.414 | 0 | 0.697 | 0.768 |

| 6 | 1.414 | 0 | 0.684 | 0.749 |

| 7 | 0 | −1.414 | 0.725 | 0.937 |

| 8 | 0 | 1.414 | 0.591 | 0.722 |

| 9 | 0 | 0 | 0.566 | 0.664 |

| 10 | 0 | 0 | 0.574 | 0.676 |

| 11 | 0 | 0 | 0.569 | 0.652 |

| 12 | 0 | 0 | 0.614 | 0.701 |

| 13 | 0 | 0 | 0.582 | 0.628 |

| Source of Variance | Vertical Concentration | Horizontal Concentration | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sum of Squares | Degrees of Freedom | The Mean Square | F-Value | p-Value | Sum of Squares | Degrees of Freedom | The Mean Square | F-Value | p-Value | |

| Model | 0.0492 | 5 | 0.0098 | 15.41 | 0.0012 ** | 0.1377 | 5 | 0.0275 | 59.46 | 0.0005 ** |

| X1 | 0.0043 | 1 | 0.0043 | 6.72 | 0.0358 * | 0.0081 | 1 | 0.0081 | 95.24 | 0.0462 * |

| X2 | 0.0193 | 1 | 0.0193 | 30.14 | 0.0009 ** | 0.0515 | 1 | 0.0515 | 0.0768 | 0.0005 ** |

| X1X2 | 0.0005 | 1 | 0.0005 | 0.7924 | 0.4029 | 0.0094 | 1 | 0.0094 | 4.39 | 0.0353 * |

| X12 | 0.0191 | 1 | 0.0191 | 29.87 | 0.0009 ** | 0.0204 | 1 | 0.0204 | 17.08 | 0.0064 ** |

| X22 | 0.0091 | 1 | 0.0091 | 14.21 | 0.0070 ** | 0.0559 | 1 | 0.0559 | 192.11 | 0.0004 ** |

| Residual | 0.0045 | 7 | 0.0006 | 0.0097 | 7 | 0.0014 | ||||

| Lack of fit | 0.003 | 3 | 0.001 | 2.62 | 0.1875 | 0.0068 | 3 | 0.0023 | 3.06 | 0.1543 |

| Error | 0.0015 | 5 | 0.0004 | 0.0030 | 4 | 0.0007 | ||||

| Cor total | 0.0537 | 12 | 0.1474 | 12 | ||||||

| Number | Vertical Concentration | Horizontal Concentration | Relative Error in Vertical Concentration (%) | Relative Error in Horizontal Concentration (%) |

|---|---|---|---|---|

| 1 | 0.584 | 0.655 | 3.73 | 3.31 |

| 2 | 0.552 | 0.623 | 1.95 | 1.73 |

| 3 | 0.541 | 0.649 | 3.91 | 2.37 |

| Average | 0.559 | 0.642 | 3.20 | 2.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dun, G.; Wei, Y.; Ji, X.; Gao, S.; Pei, Y.; He, Y.; Ma, C. Design and Test of the Outside-Filling Chinese Chive Adjustable-Capacity Precision Seed-Metering Device. Agronomy 2025, 15, 622. https://doi.org/10.3390/agronomy15030622

Dun G, Wei Y, Ji X, Gao S, Pei Y, He Y, Ma C. Design and Test of the Outside-Filling Chinese Chive Adjustable-Capacity Precision Seed-Metering Device. Agronomy. 2025; 15(3):622. https://doi.org/10.3390/agronomy15030622

Chicago/Turabian StyleDun, Guoqiang, Yuhan Wei, Xinxin Ji, Shang Gao, Yingyi Pei, Yang He, and Chao Ma. 2025. "Design and Test of the Outside-Filling Chinese Chive Adjustable-Capacity Precision Seed-Metering Device" Agronomy 15, no. 3: 622. https://doi.org/10.3390/agronomy15030622

APA StyleDun, G., Wei, Y., Ji, X., Gao, S., Pei, Y., He, Y., & Ma, C. (2025). Design and Test of the Outside-Filling Chinese Chive Adjustable-Capacity Precision Seed-Metering Device. Agronomy, 15(3), 622. https://doi.org/10.3390/agronomy15030622