Analysis of the Resistance to Teeth During the Picking Process Based on DEM-MBD Coupling Simulation

Abstract

:1. Introduction

2. Materials and Methods

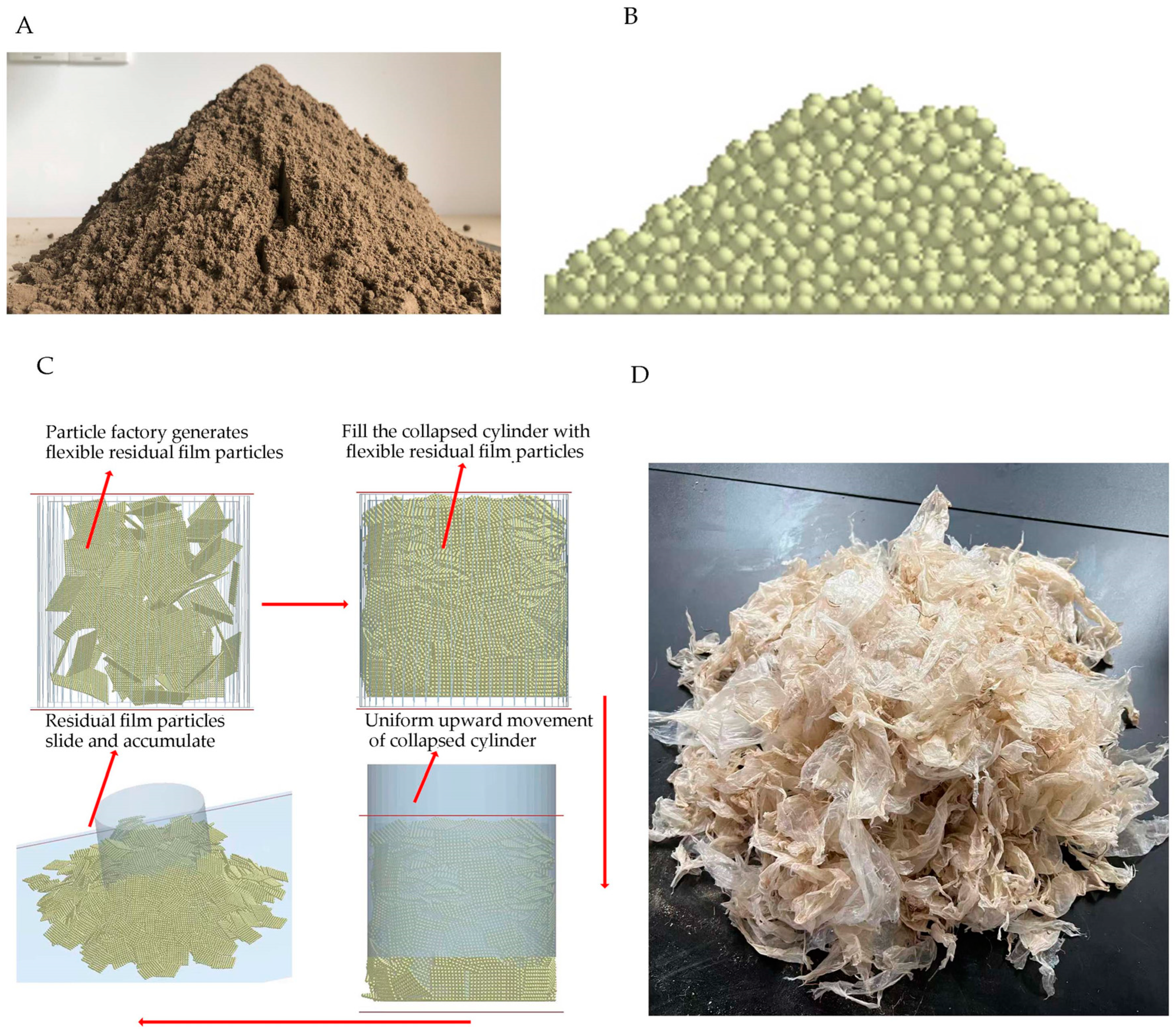

2.1. Determination of the Mechanical Properties of Residual Film and Analysis of the Impact of Key Parameters on Simulation Accuracy

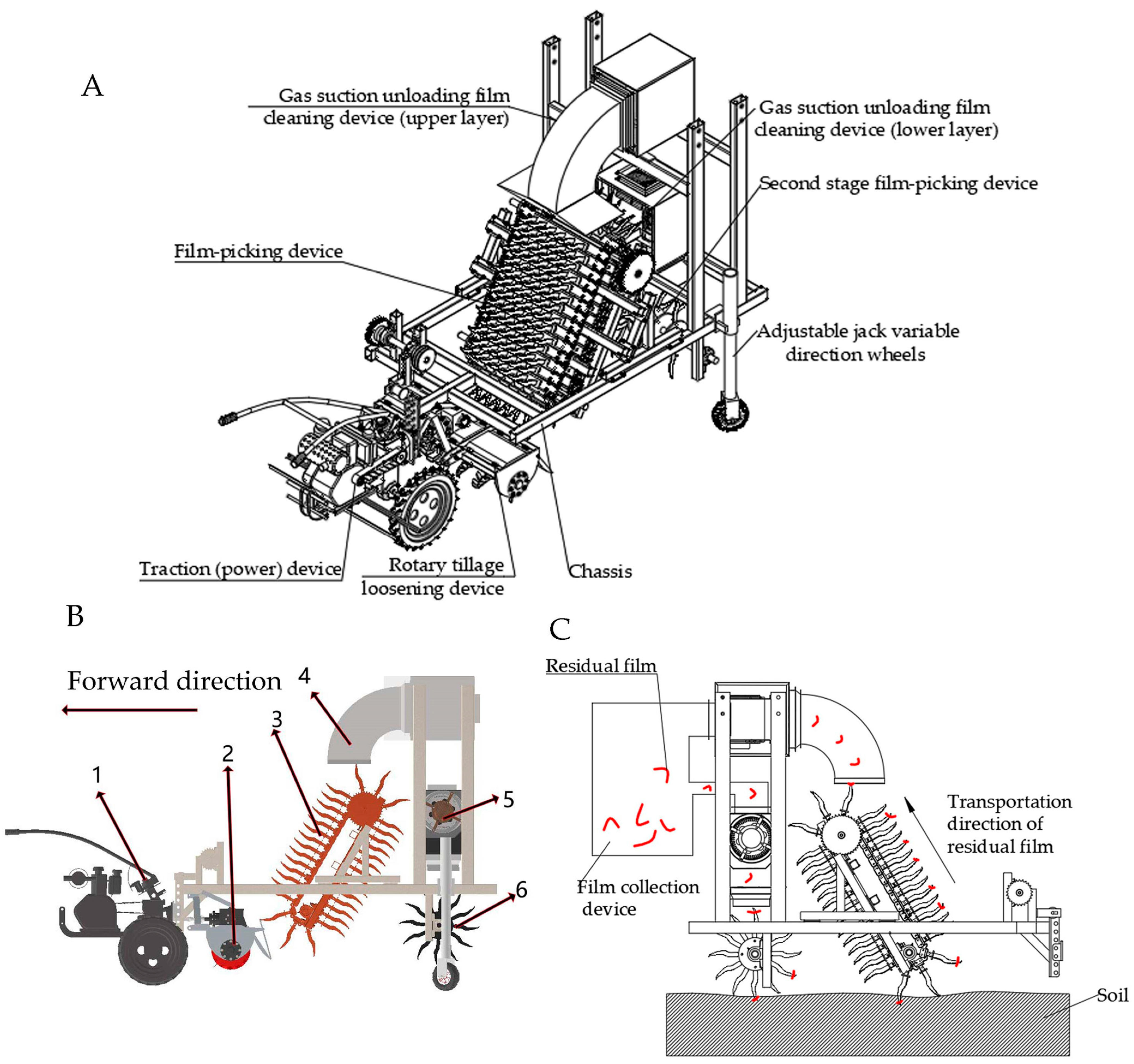

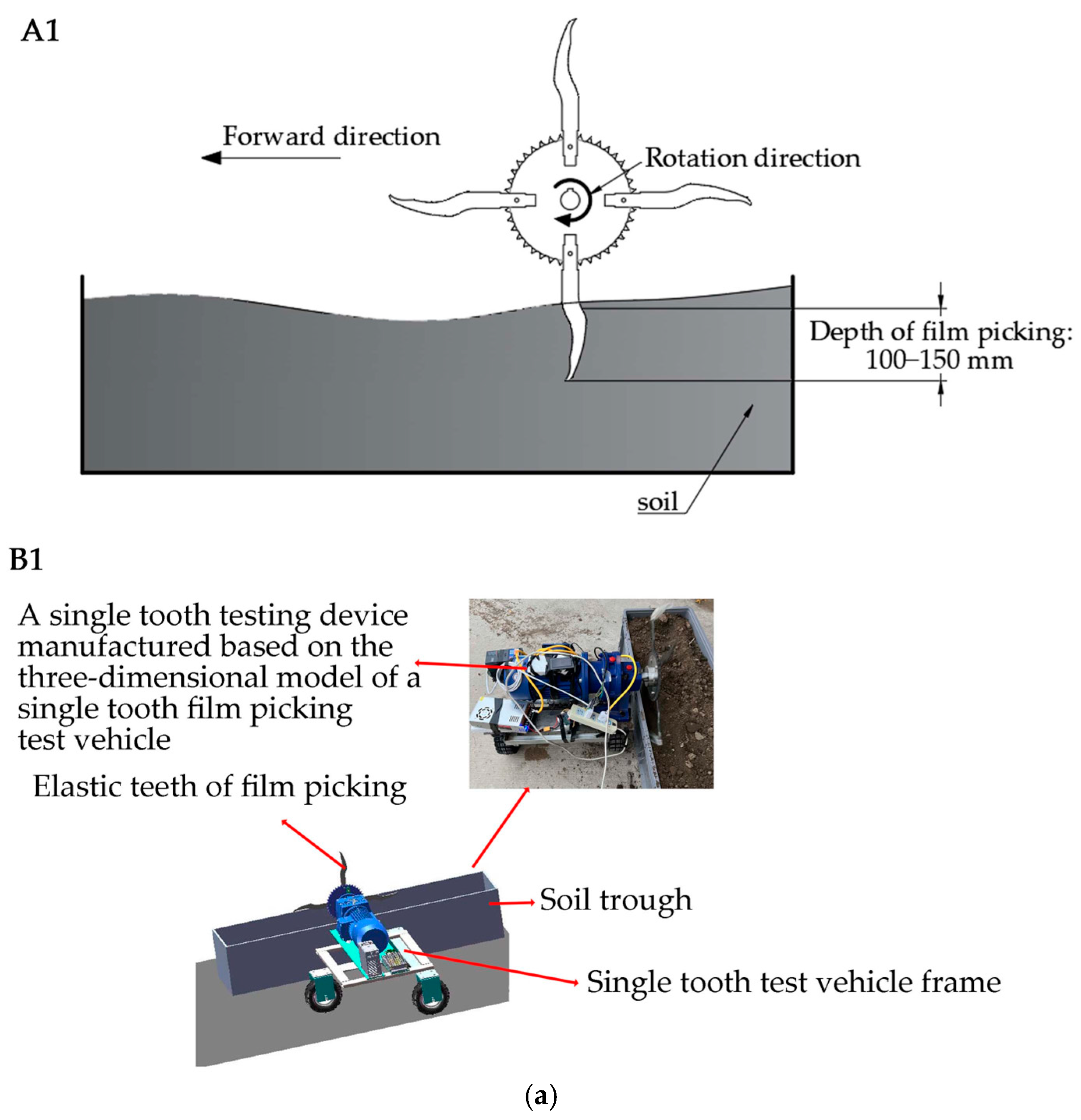

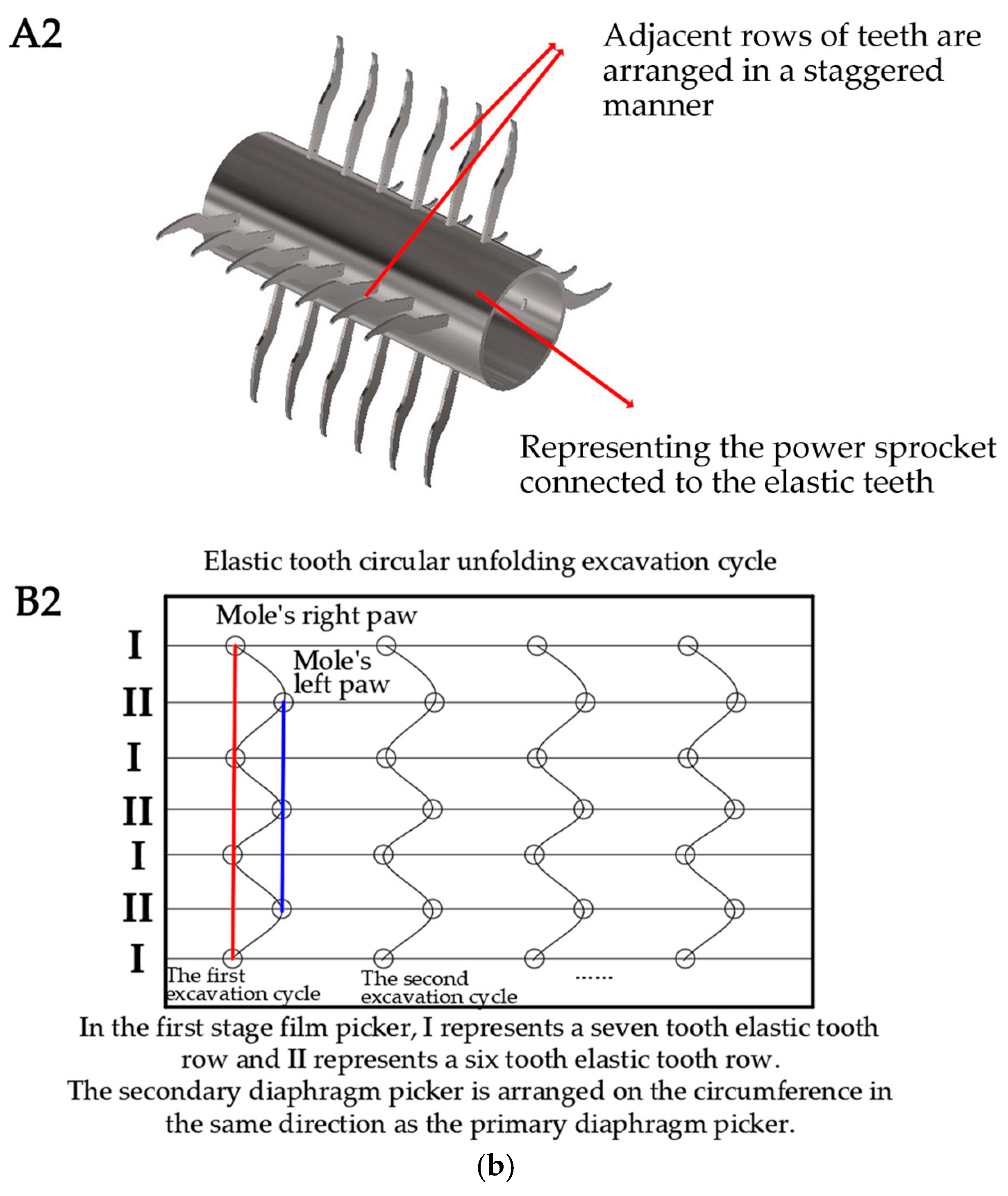

2.2. The Overall Design Scheme of the Residual Film Recycling Machine

2.3. Theoretical Analysis and Simulation of the Film-Picking Process

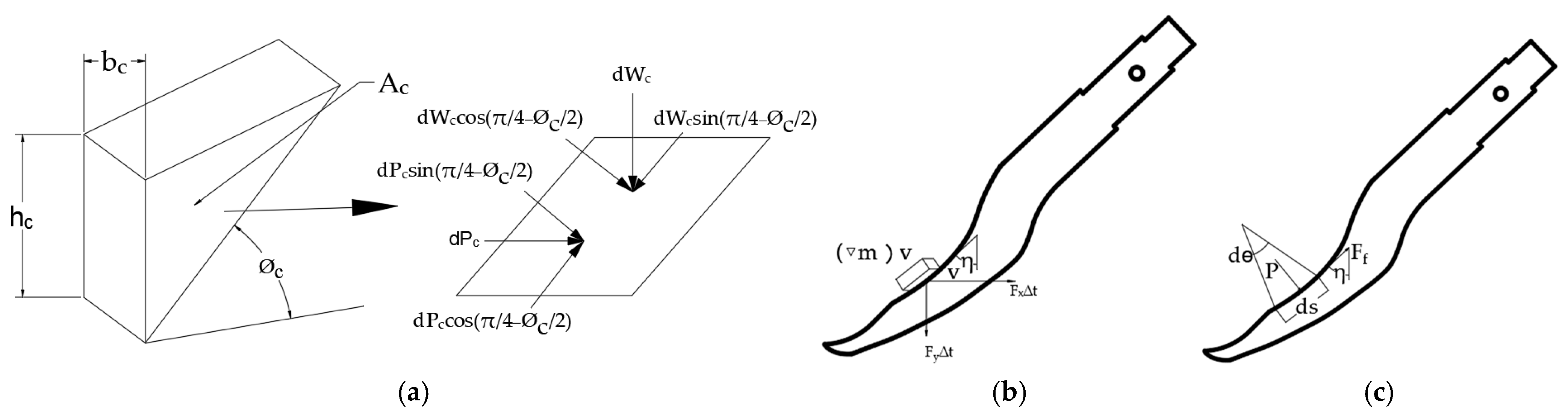

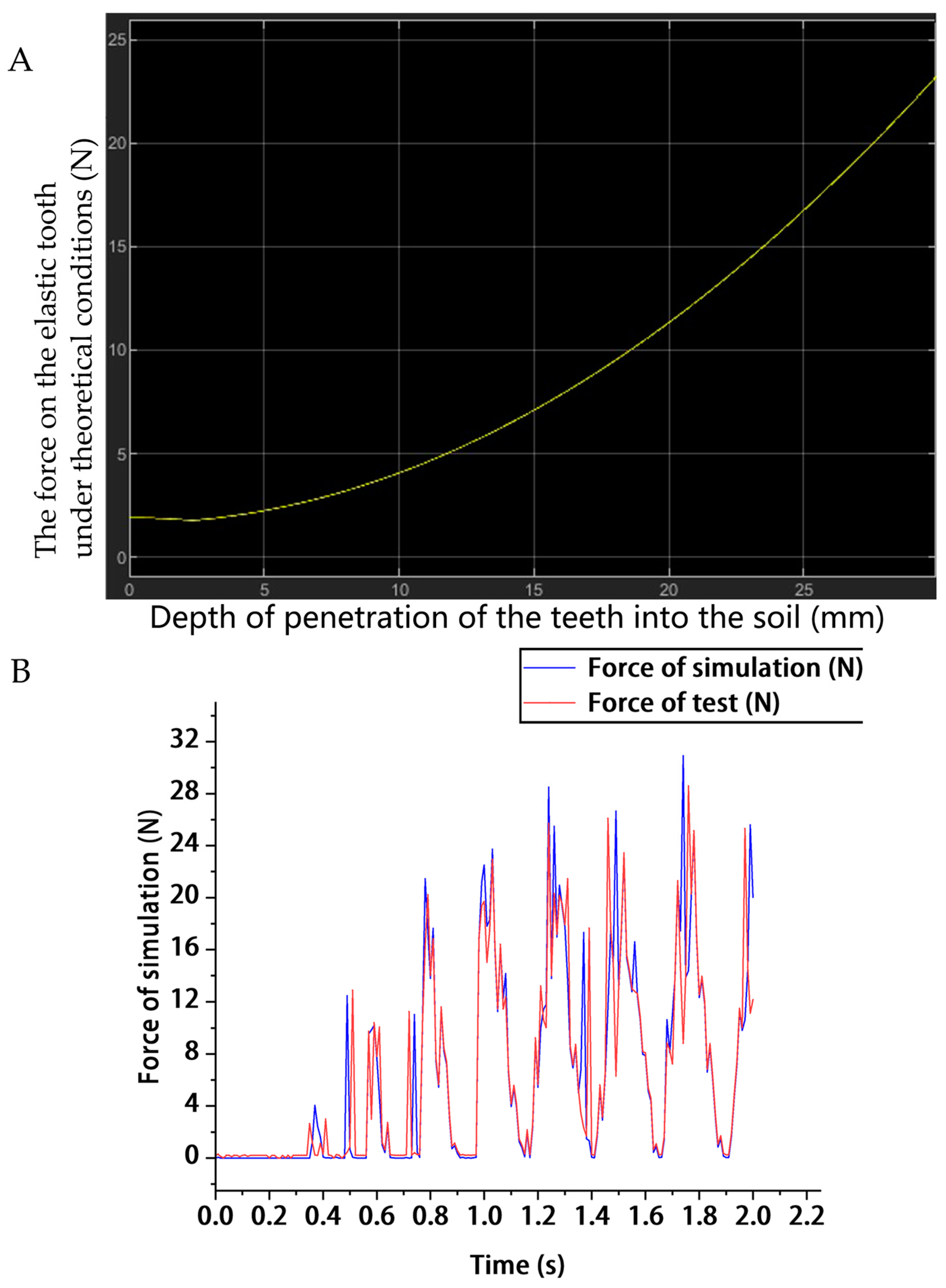

2.3.1. Mathematical Modeling and Simulation Analysis of the Resistance of Tooth Penetration into Soil

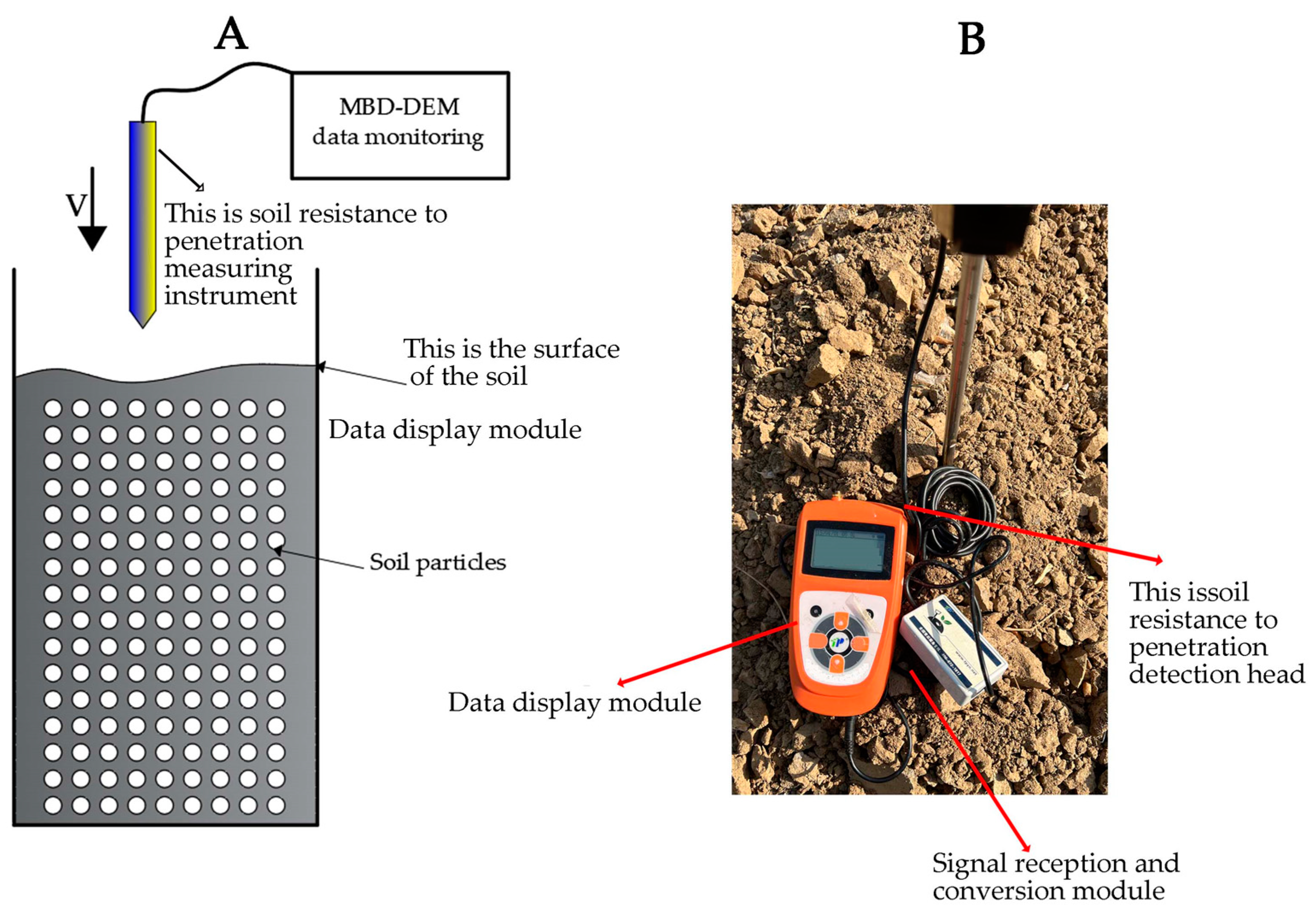

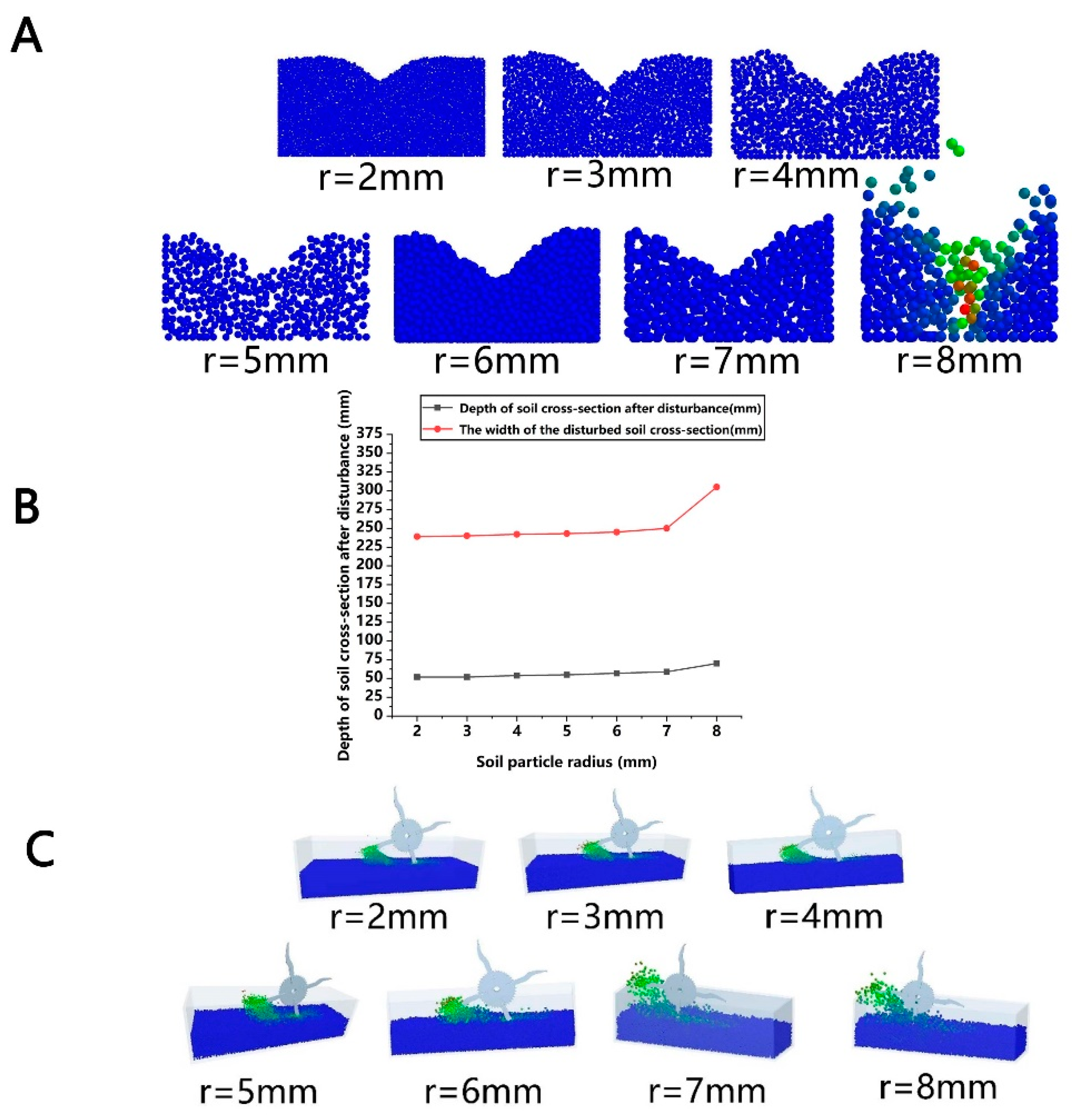

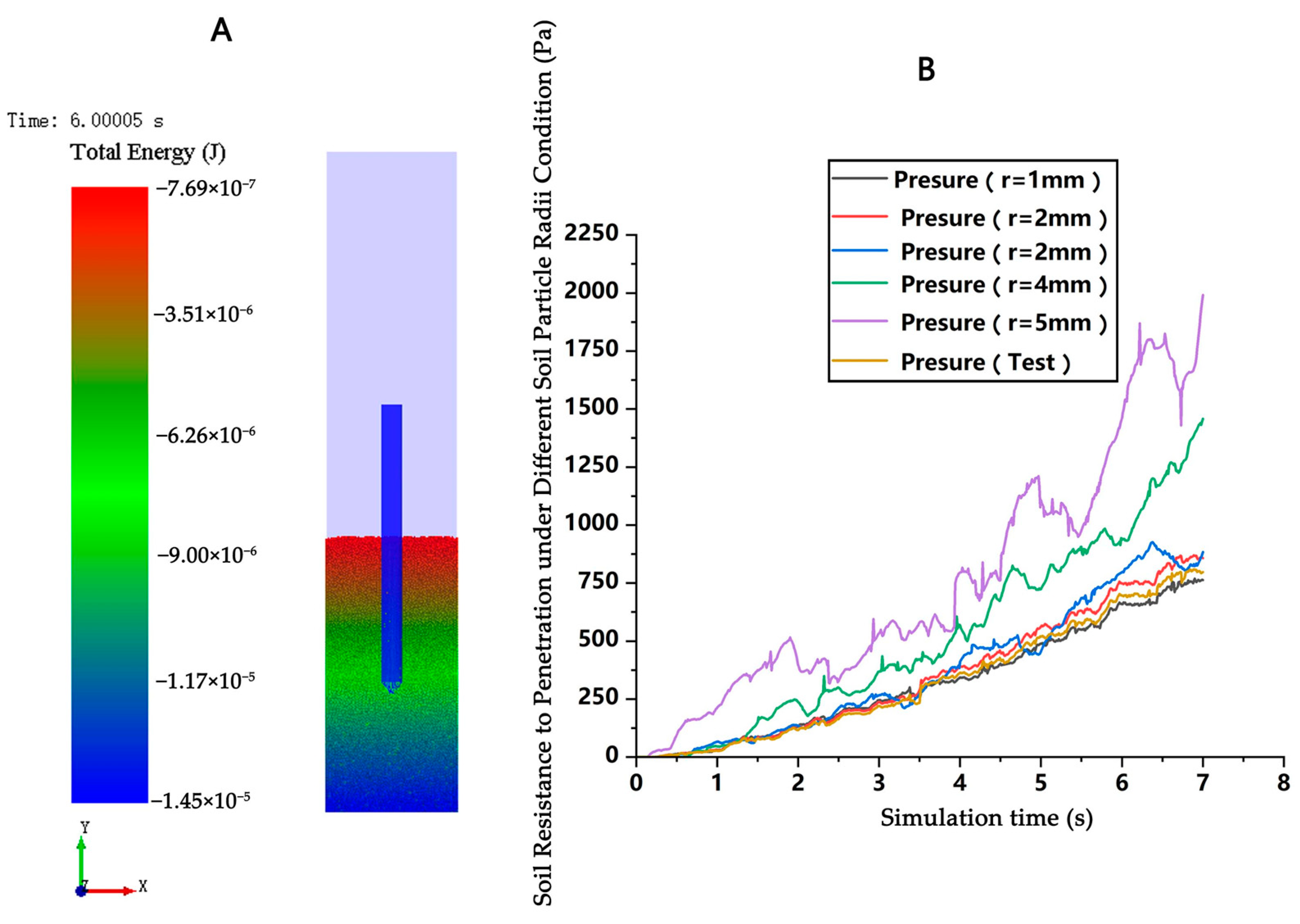

2.3.2. Analysis of the Impact of Particle Size on Soil Resistance to Penetration During Simulation Using the DEM Method

2.3.3. The Influence of Particle Size on the Accuracy of Resistance Prediction Using the DEM Method

2.4. Optimization Plan for the Parameters of a Toothed Chain Tillage-Layer Residual Film Recycling Machine

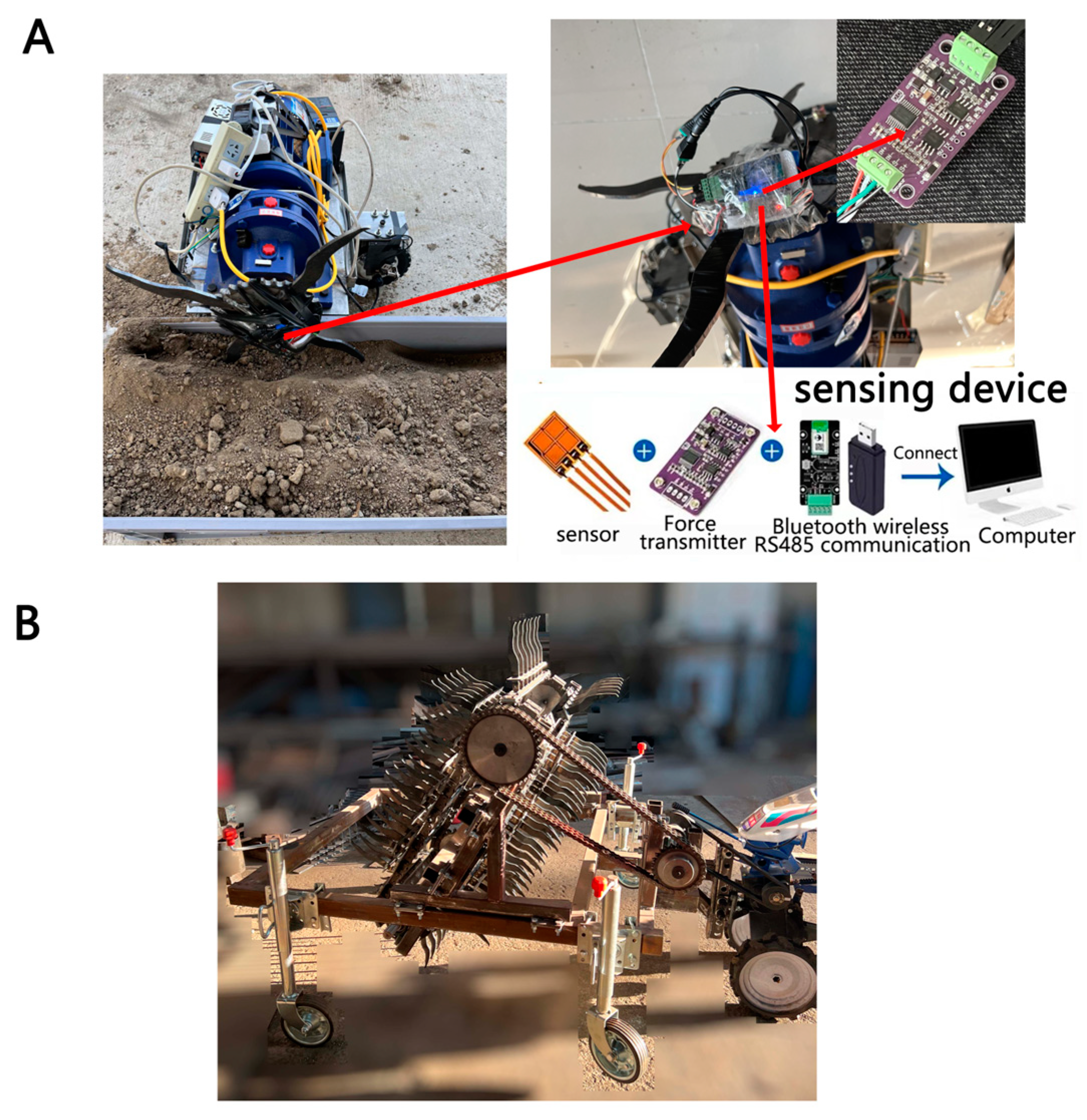

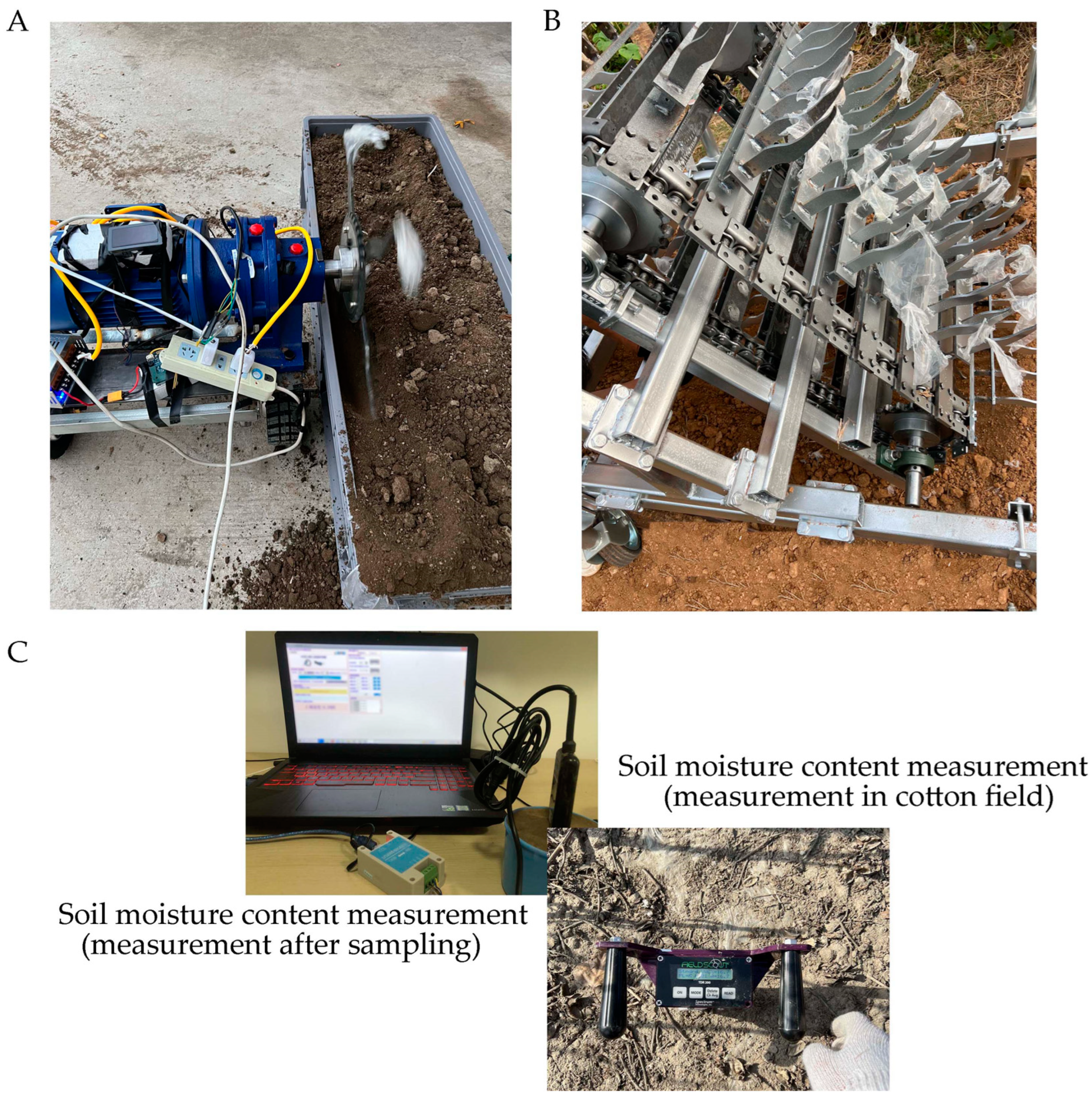

2.5. Stress Collection Tester for the Process of Tooth Film Picking

3. Results

3.1. Analysis of the Influence of the Soil Particle Radius on Simulation Accuracy

3.1.1. Simulation Disturbance Cross-Section Analysis of Elastic Teeth on Soil with the Soil Particle Size as the Variable Factor

3.1.2. The Influence of Particle Size on Soil Resistance to Penetration and Comparative Analysis of the Simulation and Experimental Results of Soil Resistance to Penetration

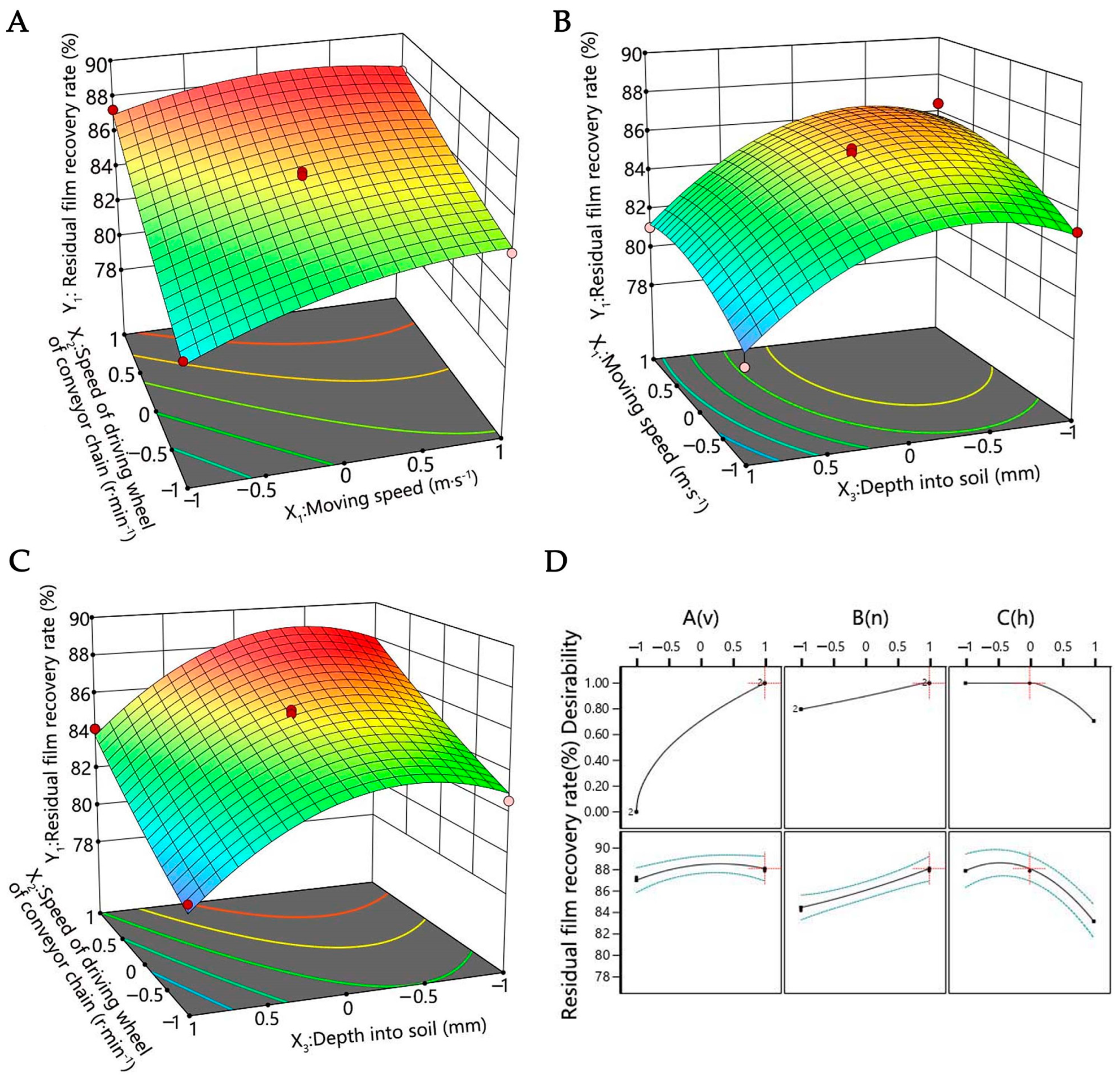

3.2. Analysis of the Results of the Optimization of the Working Parameters

3.2.1. Analysis of the Results of Parameter Optimization

3.2.2. Regression Model Establishment and Significance Analysis

3.2.3. Parameter Optimization and Validation

3.3. Experimental Study on the Force Analysis of Film-Picking Teeth

3.3.1. Simulation and Experimental Comparative Analysis of the Torque Acting on the Elastic Teeth During the Film-Picking Process

3.3.2. Analysis of the Film-Lifting Force Results of the Simulation and Experiment

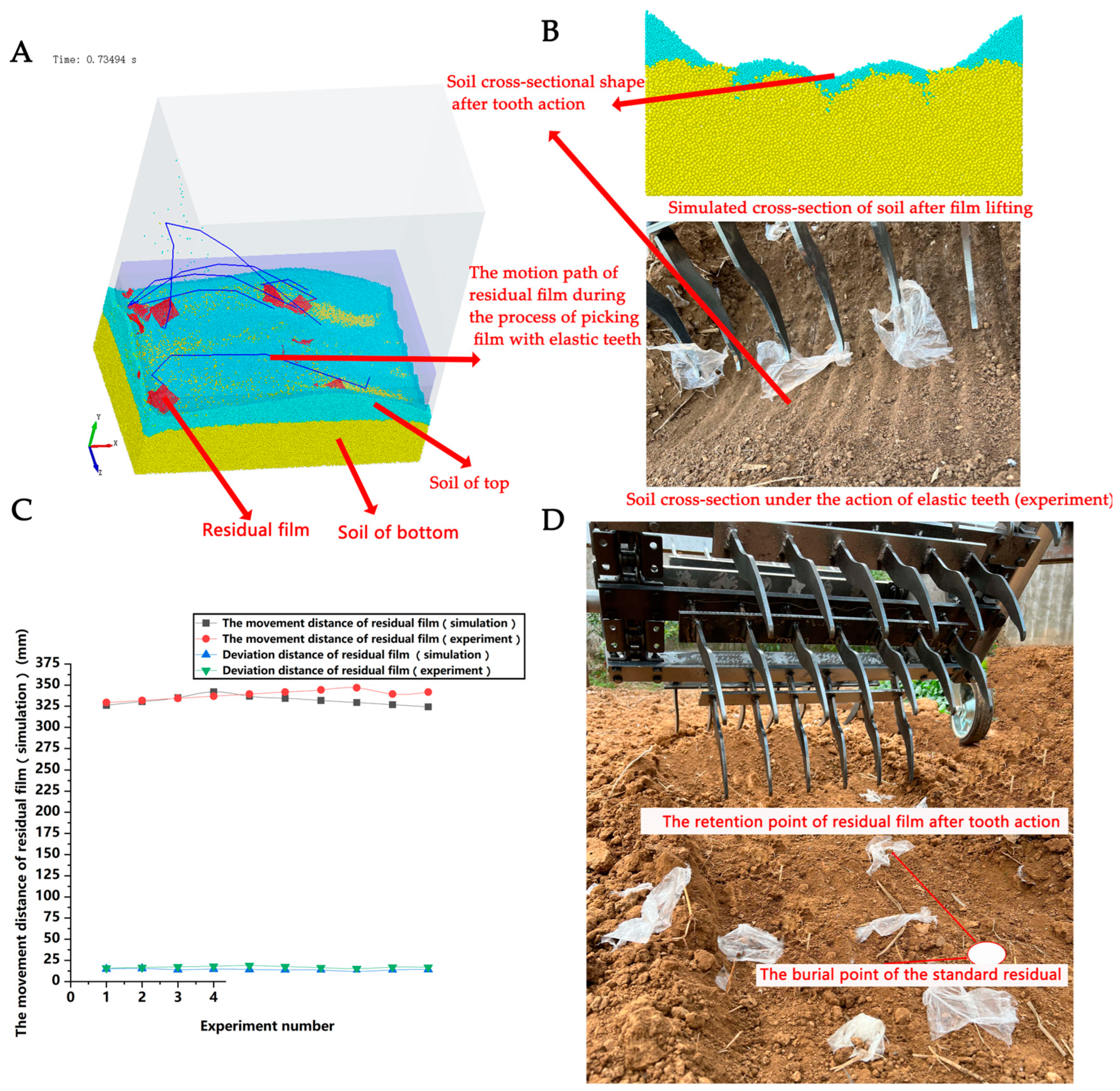

3.4. Simulation and Comparative Analysis of the Experimental Results on the Interaction and Movement Trend of the Soil and Residual Film Under the Action of Elastic Teeth

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, X.; Fan, W.; Wu, J.; Lv, Y.; Zhu, W.; Cai, H. Temporal and Spatial Distribution of Residual Film in Soil Profile under Continuous Film Mulching. Sustainability 2023, 15, 15534. [Google Scholar] [CrossRef]

- Jiang, D.; Yan, L.; Chen, X.; Mo, Y.; Yang, J. Design and experiment of nail tooth picking up device for strip type residual film recycling and baling machine. Int. J. Agric. Biol. Eng. 2023, 16, 85–96. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, X.; Wang, X.; Xue, S.; Li, J. Design and test of the arc-shaped nail-tooth roller residual film recovery machine from the sowing layer. Int. J. Agric. Biol. Eng. 2024, 17, 90–98. [Google Scholar] [CrossRef]

- Shi, Z.; Zhang, X.; Yan, J.; Jiang, Y.; Yao, J. Experiment and Analysis of Film-Soil Separation Motion Characteristics of a Chain Drive Residual Film Recovery Mechanism for the Tillage Layer. Appl. Sci. 2022, 12, 5884. [Google Scholar] [CrossRef]

- Yang, S.; Chen, X.; Yan, L.; Jiang, D. Performance of three different spades for residual plastic film recycling machine. Appl. Eng. Agric. 2020, 36, 187–195. [Google Scholar] [CrossRef]

- Shi, Z.; Zhang, X.; Liu, X.; Kang, M.; Yao, J.; Guo, L. Analysis and Test of the Tillage Layer Roll-Type Residual Film Recovery Mechanism. Appl. Sci. 2023, 13, 7598. [Google Scholar] [CrossRef]

- Guo, W.; Hu, C.; He, X.; Wang, L.; Hou, S.; Wang, X. Construction of virtual mulch film model based on discrete element method and simulation of its physical mechanical properties. Int. J. Agric. Biol. Eng. 2020, 13, 211–218. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Z.; Li, X.; Xue, Z.; Jin, M.; Deng, B. Near-Infrared-Based Measurement Method of Mass Flow Rate in Grain Vibration Feeding System. Agriculture 2024, 14, 1476. [Google Scholar] [CrossRef]

- Ma, Z.; Wu, Z.; Li, Y.; Song, Z.; Yu, J.; Li, Y.; Xu, L. Study of the grain particle-conveying performance of a bionic non-smooth-structure screw conveyor. Biosyst. Eng. 2024, 238, 94–104. [Google Scholar] [CrossRef]

- Wang, H.; Li, Y.; Wang, Y.; Zhang, Z.; Chen, H.; Wang, L. Design and field simulation test of throwing film nail tooth arc picking up device for residual film. Agric. Res. Arid Areas 2021, 39, 209–218. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, L.; Yan, J.; Shi, Z.; Kang, M.; Yao, J. Simulation Analysis and Parameter Optimization of Residual Film Pickup Process Based on Finite Element Method. Agriculture 2024, 14, 524. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Wang, X.; Zhao, Y.; Xue, S.; Su, Z. Parameters Optimization and Test of an Arc-Shaped Nail-Tooth Roller-Type Recovery Machine for Sowing Layer Residual Film. Agriculture 2022, 12, 660. [Google Scholar] [CrossRef]

- Dong, J.; Li, S.; Bi, X.; Wang, G.; Wang, J.; Wang, W.; Tong, N. Design and Experimental Research of a New Film-Picking Mulch Film Recovery Machine with Impurity Separation Function. Processes 2022, 10, 455. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, W.; Ji, M.; Miao, H.; Jin, Z. Numerical simulation and parameter optimization of earth auger in hilly area using EDEM software. Sci. Rep. 2022, 12, 19526. [Google Scholar] [CrossRef] [PubMed]

- Liang, Z.; Huang, Y.; Li, D.; Wada, M.E. Parameter determination of a viscoelastic-plastic contact model for potatoes during transient collisions. Biosyst. Eng. 2023, 234, 156–171. [Google Scholar] [CrossRef]

- El Salem, A.; Wang, H.; Gao, Y.; Zha, X.; Abdeen, M.A.; Zhang, G. Effect of Biomimetic Surface Geometry, Soil Texture, and Soil Moisture Content on the Drag Force of Soil-Touching Parts. Appl. Sci. 2021, 11, 8927. [Google Scholar] [CrossRef]

- Zhou, D.; Hou, P.; Xin, Y.; Wu, B.; Tong, J.; Yu, H.; Qi, J.; Zhang, J.; Zhang, Q. Resistance and Consumption Reduction Mechanism of Bionic Vibration and Verification of Field Subsoiling Experiment. Appl. Sci. 2021, 11, 10480. [Google Scholar] [CrossRef]

- Kesner, A.; Choteborsky, R.; Linda, M.; Hromasova, M.; Katinas, E.; Sutanto, H. Stress distribution on a soil tillage machine frame segment with a chisel shank simulated using discrete element and finite element methods and validate by experiment. Biosyst. Eng. 2021, 209, 125–138. [Google Scholar] [CrossRef]

- Yang, Q.; Shi, L.; Shi, A.; He, M.; Zhao, X.; Zhang, L.; Addy, M. Determination of key soil characteristic parameters using angle of repose and direct shear stress test. Int. J. Agric. Biol. Eng. 2023, 16, 143–150. [Google Scholar] [CrossRef]

- Zhang, L.; Zhai, Y.; Wu, C.; Huang, S.; Zhang, Z. Modeling the interaction between a new four-bar subsoiling mechanism and red soil using the improved differential evolution algorithm and DEM. Comput. Electron. Agric. 2023, 208, 107783. [Google Scholar] [CrossRef]

- Li, X.; Luo, Z.; Hao, Z.; Zheng, E.; Yao, H.; Zhu, Y.; Wang, X. Investigation on tillage resistance and soil disturbance in wet adhesive soil using discrete element method with three-layer soil-plough coupling model. Powder Technol. 2024, 436, 193. [Google Scholar] [CrossRef]

- Zhu, D.; Shi, M.; Yu, C.; Yu, Z.; Kuang, F.; Xiong, W.; Xue, K. Tool-straw-paddy soil coupling model of mechanical rotary-tillage process based on DEM-FEM. Comput. Electron. Agric. 2023, 215, 108420. [Google Scholar] [CrossRef]

- Fang, W.; Wang, X.; Han, D.; Chen, X. Review of Material Parameter Calibration Method. Agriculture 2022, 12, 706. [Google Scholar] [CrossRef]

- Tamas, K.; Bernon, L. Role of particle shape and plant roots in the discrete element model of soil-sweep interaction. Biosyst. Eng. 2021, 211, 77–96. [Google Scholar] [CrossRef]

- Kim, Y.S.; Lee, S.D.; Baek, S.M.; Baek, S.Y.; Jeon, H.H.; Lee, J.H.; Siddique, M.A.; Kim, Y.J.; Kim, W.S.; Sim, T.; et al. Development of DEM-MBD coupling model for draft force prediction of agricultural tractor with plowing depth. Comput. Electron. Agric. 2022, 202, 107405. [Google Scholar] [CrossRef]

- Bahrami, M.; Naderi-Boldaji, M.; Ghanbarian, D.; Keller, T. Discrete element modelling of stress propagation in soil under a rigid wheel in a soil bin: A simulation of probe inducing stress deviation and wheel speed. Biosyst. Eng. 2023, 230, 159–170. [Google Scholar] [CrossRef]

- Liu, L.; Wang, X.; Zhang, X.; Cheng, X.; Wei, Z.; Zhou, H.; Zhao, K. The impact of ‘T’-shaped furrow opener of no-tillage seeder on straw and soil based on discrete element method. Comput. Electron. Agric. 2023, 213, 108278. [Google Scholar] [CrossRef]

- Liu, W.; Zeng, S.; Chen, X. Design and Experiment of Adaptive Profiling Header Based on Multi-Body Dynamics-Discrete Element Method Coupling. Agriculture 2024, 14, 105. [Google Scholar] [CrossRef]

- Li, S.; Hu, M.; Liu, Y.; Li, Y. DEM parameters of slope cultivated purple soil in Southwest China and interaction mechanism between very narrow tine. Sci. Rep. 2024, 14, 18089. [Google Scholar] [CrossRef]

- Ma, C.; Meng, H.W.; Zhang, J.; Zhang, C.; Zhao, Y.; Wang, L.H. Research and experiment on the trenching performance of orchard trenching device. Sci. Rep. 2023, 13, 18941. [Google Scholar] [CrossRef]

- Yuan, H.; Liang, S.; Wang, J.; Lu, Y. Numerical Simulation and Analysis of Vibrating Rice Filling Based on EDEM Software. Agriculture 2022, 12, 2013. [Google Scholar] [CrossRef]

- Liu, L.; Wang, X.; Zhang, X.; Zhong, X.; Wei, Z.; Geng, Y.; Cheng, X.; Zhao, K.; Bai, M. Determination and verification of parameters for the discrete element modelling of single disc covering of flexible straw with soil. Biosyst. Eng. 2023, 233, 151–167. [Google Scholar] [CrossRef]

- Shi, Y.; Jiang, Y.; Wang, X.; Thuy, N.T.D.; Yu, H. A mechanical model of single wheat straw with failure characteristics based on discrete element method. Biosyst. Eng. 2023, 230, 1–15. [Google Scholar] [CrossRef]

- Tang, H.; Xu, C.; Zhao, J.; Wang, J. Stripping mechanism and loss characteristics of a stripping-prior-to-cutting header for rice harvesting based on CFD-DEM simulations and bench experiments. Biosyst. Eng. 2023, 229, 116–136. [Google Scholar] [CrossRef]

- Du, C.; Han, D.; Song, Z.; Chen, Y.; Chen, X.; Wang, X. Calibration of contact parameters for complex shaped fruits based on discrete element method: The case of pod pepper (Capsicum annuum). Biosyst. Eng. 2023, 226, 43–54. [Google Scholar] [CrossRef]

- Wang, X.; Gao, P.; Yue, B.; Shen, H.; Fu, Z.; Zheng, Z.; Huang, Y. Optimization of installation parameters of subsoiler’ wing using the discrete element method. Comput. Electron. Agric. 2019, 162, 523–530. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, Q.; Muhammad, S.M.; Ji, C.; Zhao, Z. Design and experiment of bionic mole’s toe arrangement serrated blade for soil-rototilling and straw-shattering. Trans. Chin. Soc. Agric. Eng. 2017, 33, 43–50. [Google Scholar] [CrossRef]

- Hu, G.; Quan, L.; Zou, Y.; Shen, H. Establishment and simulation test of membrane-soil separation model for mechanical recycling of agricultural residual film. J. Hunan Agric. Univ. 2021, 287, 344–350. [Google Scholar] [CrossRef]

- Fang, W.; Wang, X.; Han, D.; Zang, N.; Xue, G.; Israel, E.O. Parameter Optimization and Disturbance Analysis of the Film Picking Device of the Chain-Type Plough Layer Residual Film Recovery Machine Based on DEM-MBD Coupling. Comput. Electron. Agric. 2024, 222, 109041. [Google Scholar] [CrossRef]

- Meng, F. Biomimetic Design and Experiment of Sliding Trench Device. Chang. Jilin Univ. 2021, 16–21. [Google Scholar] [CrossRef]

- Jin, W.; Liu, J.; Xu, C.; Zhang, X.; Bai, S. Design, Simulation and Experimentation of a Polythene Film Debris Recovery Machine in Soil. Appl. Sci. 2022, 12, 1366. [Google Scholar] [CrossRef]

- Guo, W.; He, X.; Wang, L.; Zhao, P.; Hu, C.; Hou, S.; Wang, X. Development of a comb tooth loosening and pneumatic stripping plough layer residual film recovery machine. Trans. Chin. Soc. Agric. Eng. 2020, 36, 1–10. [Google Scholar] [CrossRef]

- Huang, W.; Wang, H.; Dai, W.; Zhang, M.; Ren, D.; Wang, W. Study on the throwing device of residual film recycling machine for the plough layer. Comput. Electron. Agric. 2024, 227, 109679. [Google Scholar] [CrossRef]

- Shi, Z.; Zhang, X.; Liu, X.; Guo, L.; Zhang, C.; Liu, L. Design and Test of Roll-type Tillage Layer Residual Film Recovery Machine. Trans. Chin. Soc. Agric. Mach. 2024, 55, 128–137. [Google Scholar]

- Peng, Q.; Li, K.; Wang, X.; Zhang, G.; Kang, J. Design and Test of Stripping and Impurity Removal Device for Spring-Tooth Residual Plastic Film Collector. Agriculture 2023, 13, 42. [Google Scholar] [CrossRef]

- Fang, W.; Wang, X.; Zhu, C.; Han, D.; Zang, N.; Chen, X. Analysis of Film Unloading Mechanism and Parameter Optimization of Air Suction-Type Cotton Plough Residual Film Recovery Machine Based on CFD-DEM Coupling. Agriculture 2024, 14, 1021. [Google Scholar] [CrossRef]

- Jin, W.; Zhang, X.; Ding, Y.; Bai, S.; Liu, W.; Zhou, X. Experiment on Suspension Separation of Residual Film and Impurity Based on EDEM-Fluent Coupling. Trans. Chin. Soc. Agric. Mach. 2022, 53, 89–98. [Google Scholar]

- Zhang, S.; Jia, X.; Dong, J.; Wang, X.; Zhao, H.; Chen, X.; Zhang, Z.; Huang, Y.; Shi, J. Optimization of operating angles of disc coulters for maize residue management using discrete element method. Comput. Electron. Agric. 2024, 218, 108691. [Google Scholar] [CrossRef]

- Deng, H.; Dai, F.; Shi, R.; Song, X.; Zhao, W.; Pan, H. Simulation of full-film double-row furrow roller hole fertiliser application based on DEM-MBD coupling and research on its water and fertiliser transport law. Biosyst. Eng. 2024, 239, 190–206. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Q.; Huang, Y.; Ji, J. An efficient method for determining DEM parameters of a loose cohesive soil modelled using hysteretic spring and linear cohesion contact models. Biosyst. Eng. 2022, 215, 283–294. [Google Scholar] [CrossRef]

| Parameter | Soil | 65 Mn Steel | Residual Plastic Film | ||

|---|---|---|---|---|---|

| Poisson’s ratio | 0.36 | 0.35 | 0.21 | ||

| Shear modulus (Pa) | 1 × 106 | 7.27 × 1010 | 1.12 × 106 | ||

| Density (kg·m−3) | 1.610 × 103 | 7.830 × 103 | 0.915 × 103 | ||

| Soil-65Mn steel | Soil–Residual film | Soil–Soil | Residual film–Residual film | Residual film–65Mn steel | |

| coefficient of static friction | 0.50 | 0.55 | 0.74 | 0.52 | 0.45 |

| coefficient of rolling friction | 0.31 | 0.46 | 0.22 | 0.4 | 0.4 |

| coefficient of collision recovery | 0.43 | 0.5 | 0.52 | 0.57 | 0.5 |

| Levels | Moving Speed v () | Speed of Driving Wheel of Conveyor Chain n | Depth into Soil h (mm) |

|---|---|---|---|

| −1 | 0.83 | 6.28 | 100 |

| 0 | 1.39 | 8.37 | 125 |

| 1 | 1.94 | 10.47 | 150 |

| No. | % | |||

|---|---|---|---|---|

| 1 | −1 | 1 | 0 | 87.29 |

| 2 | 0 | 0 | 0 | 85.39 |

| 3 | 0 | −1 | 1 | 79.28 |

| 4 | −1 | 0 | −1 | 83.09 |

| 5 | 0 | 0 | 0 | 85.84 |

| 6 | −1 | 0 | 1 | 78.51 |

| 7 | 0 | 1 | −1 | 87.61 |

| 8 | 1 | 0 | 1 | 81.04 |

| 9 | 0 | 0 | 0 | 86.01 |

| 10 | −1 | 1 | 0 | 87.29 |

| 11 | 0 | 0 | 0 | 85.38 |

| 12 | 0 | 0 | 0 | 86.07 |

| 13 | 1 | 1 | 0 | 87.88 |

| 14 | 0 | 1 | 1 | 84.13 |

| 15 | 1 | −1 | 0 | 84.19 |

| 16 | 0 | −1 | −1 | 82.59 |

| 17 | 1 | 0 | −1 | 86.46 |

| Source | /% | |||

|---|---|---|---|---|

| Sum of Squares | Degree of Freedom | F | Significance Level | |

| Model | 131.42 | 9 | 45.84 | <0.0001 ** |

| A-v | 12.05 | 1 | 37.84 | 0.0005 ** |

| B-n | 49.95 | 1 | 156.81 | <0.0001 ** |

| C-h | 35.24 | 1 | 110.62 | <0.0001 ** |

| AB | 1.88 | 1 | 5.89 | 0.0456 * |

| AC | 0.1764 | 1 | 0.5538 | 0.4810 |

| BC | 0.0072 | 1 | 0.0227 | 0.8845 |

| A2 | 3.45 | 1 | 10.83 | 0.0133 * |

| B2 | 0.2080 | 1 | 0.6529 | 0.4457 |

| C2 | 27.55 | 1 | 86.48 | <0.0001 ** |

| Residual | 14.17 | 5 | ||

| Lack of Fit | 9.50 | 3 | 5.36 | 0.0692 |

| Pure Error | 4.67 | 2 | ||

| Cor Total | 226.00 | 14 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, W.; Wang, X.; Han, D.; Enema Ohiemi, I. Analysis of the Resistance to Teeth During the Picking Process Based on DEM-MBD Coupling Simulation. Agronomy 2025, 15, 1002. https://doi.org/10.3390/agronomy15051002

Fang W, Wang X, Han D, Enema Ohiemi I. Analysis of the Resistance to Teeth During the Picking Process Based on DEM-MBD Coupling Simulation. Agronomy. 2025; 15(5):1002. https://doi.org/10.3390/agronomy15051002

Chicago/Turabian StyleFang, Weiquan, Xinzhong Wang, Dianlei Han, and Israel Enema Ohiemi. 2025. "Analysis of the Resistance to Teeth During the Picking Process Based on DEM-MBD Coupling Simulation" Agronomy 15, no. 5: 1002. https://doi.org/10.3390/agronomy15051002

APA StyleFang, W., Wang, X., Han, D., & Enema Ohiemi, I. (2025). Analysis of the Resistance to Teeth During the Picking Process Based on DEM-MBD Coupling Simulation. Agronomy, 15(5), 1002. https://doi.org/10.3390/agronomy15051002