Design, Development, and Performance Evaluation of a Trash-Board Moldboard Plow for the Interaction between Soil and Straw with Two Different Water Content Levels

Abstract

:1. Introduction

2. Results

2.1. Soil Water Content

2.2. Soil Forces on the Trash-Board Moldboard Plow at 30% Water Content and Tool Parameters

2.3. Soil Forces on the Trash-Board Moldboard Plow at 24% Water Content and Tool Parameters

2.4. Soil Displacement and Clod Size

2.5. Straw Displacement

3. Discussion

4. Materials and Methods

4.1. Site

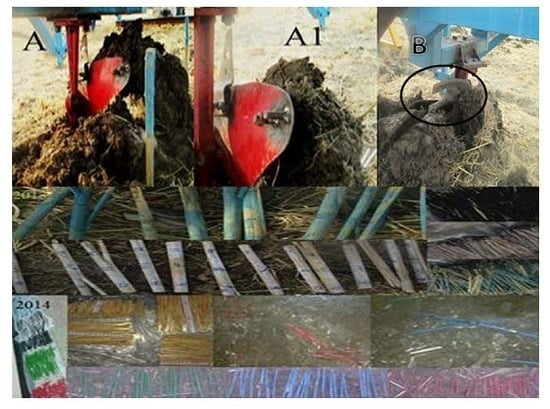

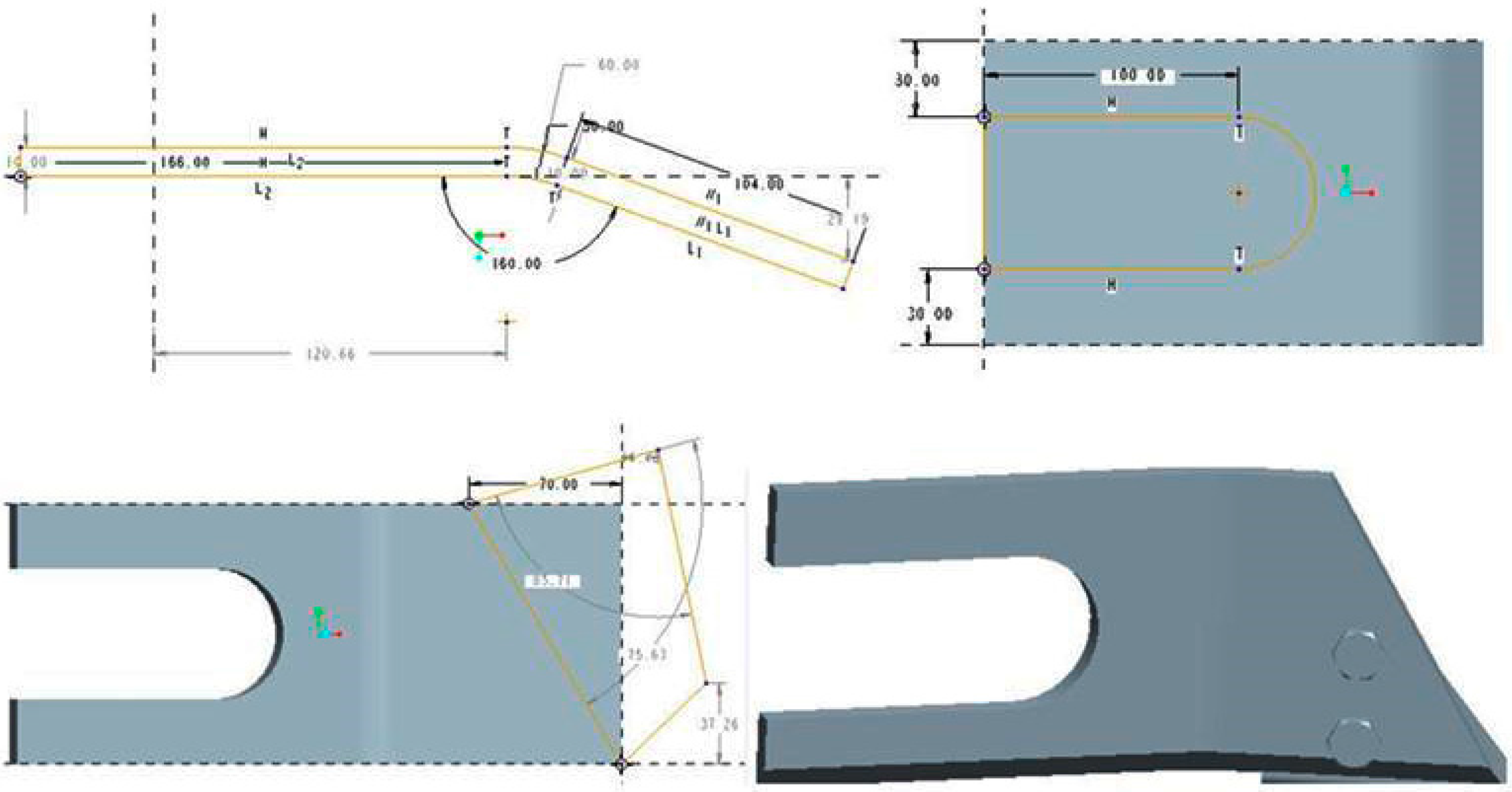

4.2. Trash-Board Description

4.3. Design and Development of the Trash-Board for the Moldboard Plow

4.4. Experiment Layout

4.5. Measurements

4.6. Field Testing Platform

4.7. Statistical Analysis

5. Conclusions

- The draft was generally the highest without a trash-board and lowest when attaching a trash-board, and only the straw stem had high water content.

- Draft requirement decreased with the installation of a trash-board and increased water content. The trash-board was also closely related to soil cohesion derived from vane shear measurements.

- The trash-board has the largest effect for soil fragmentation at different water content levels, but this may be attributed to the benefit of a trash-board, as shown in the result.

- Both straw length and soil water content impact straw displacement. Thus, it is recommended for farm operators that a trash-board be used with more than 30% water content according to the percentage of straw to be displaced.

- The results indicate that straw nearby shear significantly increased the displacement for all treatments, at variance of that nearby moldboard.

- The present study introduced new experimental methods, which will facilitate research in this area.

- Displacement of soil by moldboard plowing is a severe land degradation process for hilly agricultural land. Reduced soil displacement with a trash-board attachment was also found in other soil conditions, both in bare soil and with standing stubbles. Similar effects of reduced soil displacement were also true for working depths.

- It is better to set a trash-board as high as possible, making sure the front point remains against the shin. This allows the trash-board to turn trash quicker and provide a lighter draft.

- If more trash coverage is desired, then the rear of the trash-board should be lowered; (a) remove and retain nuts from plow bolts, and (b) attach the supporting bracket using existing hardware.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Arvidsson, J.; Keller, T.; Gustafsson, K. Specific draught for mouldboard plow, chisel plow and disc harrow at different water contents. Soil Tillage Res. 2004, 79, 221–231. [Google Scholar] [CrossRef]

- Arvidsson, J.; Hillerström, O. Specific draught, soil fragmentation and straw incorporation for different tine and share types. Soil Tillage Res. 2010, 110, 154–160. [Google Scholar] [CrossRef]

- Shirneshan, A. The effect of different types of tillage on soil’s physical, mechanical and biological properties. Researcher 2011, 3, 25–29. [Google Scholar]

- Chen, Y.; Monero, F.; Lobb, D.A.; Tessier, S.; Cavers, C. Effects of six tillage methods on residue incorporation and crop performance under a heavy clay soil condition. Trans. ASAE. 2004, 47, 1003–1010. [Google Scholar] [CrossRef]

- Chen, Y.; McLaughlin, N.B.; Tessier, S. Double extended octagonal ring (DEOR) drawbar dynamometer. Soil Tillage Res. 2007, 93, 462–471. [Google Scholar] [CrossRef]

- Doan, V.; Chen, Y.; Irvine, B. Effect of oat stubble height on the performance of no-till seeder openers. J. Can. Biosyst. Eng. 2005, 47, 37–44. [Google Scholar]

- Fox, F.; Wagner, L. A laser distance-based method for measuring standing residue. In Soil Erosion Research for the 21st Century; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2001; pp. 143–146. [Google Scholar]

- Godwin, R.J. An extended octagonal ring transducer for use in tillage studies. J. Agric. Eng. Res. 1975, 20, 347–352. [Google Scholar] [CrossRef]

- Godwin, R.J.; Reynolds, A.J.; O’Dogherty, M.J.; Al-Ghazal, A.A. A triaxial dynamometer for force and management measurement on tillage implements. J. Agric. Eng. Res. 1993, 55, 189–205. [Google Scholar] [CrossRef]

- Shinde, G.U.; Badgujar, P.D.; Kajale, S.R. Experimental Analysis of Tillage Tool Shovel Geometry on Soil Disruption by Speed and Depth of Operation. In International Conference on Environmental and Agriculture Engineering, IPCBEE 2011; ACSIT Press: Singapore, Singapore, 2011. [Google Scholar]

- Hanna, H.; Melvin, S.; POPE, R. Tillage implements operational effects on residue cover. Appl. Eng. 1995, 11, 205–210. [Google Scholar] [CrossRef]

- Ding, Y.Z.; Jin, J.H.; Guo, X.L.; Tang, H.; Yang, H.J. Study on 3-D Numerical Simulation for Soil Cutting with Large Deformation. Trans. Chin. Soc. Agric. Mach. 2012, 4, 30. [Google Scholar]

- Wang, J.S.; Yang, R.B.; Shang, S.Q. Analysis of influencing factors on operating resistance of machine-soil system. Adv. Mater. Res. 2013, 422, 596–600. (In Chinese) [Google Scholar] [CrossRef]

- Ming, Z.; Zhang, G.Z.; Yao, X.L. Applications of Finite Element Analysis in Soil Cutting. J. Agric. Mech. Res. 2015, 9, 57. (In Chinese) [Google Scholar]

- Heckrath, G.; Djurhuusa, J.; Goversc, G. The effect of tillage direction on soil redistribution by mouldboard plowing on complex slopes. Soil Tillage Res. 2006, 88, 225–241. [Google Scholar] [CrossRef]

- Kirisci, V.; Blackmore, B.S.; Godwin, R.J.; Blake, J. Design and Calibration of Three Different Three-Point Linkage Dynamometers; ASAE/CSAE Paper No. 93-1009; ASAE: St. Joseph, MI, USA, 1993. [Google Scholar]

- Kosmas, C.; Gerontidisa, S.; Marathianoua, M.; Detsisa, B.; Zafirioua, T.; Nan Muysenb, W.; Goversb, G.; Quinec, T.; Quinec, K. The effects of tillage displaced soil on soil properties and wheat biomass. Soil Tillage Res. 2001, 58, 31–44. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Y.; Kushwaha, R. Effect of tillage speed and straw length on soil and straw movement by a sweep. Soil Tillage Res. 2010, 109, 9–17. [Google Scholar] [CrossRef]

- Nielsen, D.C. Optimum wheat stubble height to reduce erosion and evaporation. In Conservation Tillage Factsheet; USDA-ARS, NRCS, and Colorado Conservation Tillage Association: Akron, OH, USA, 2003; pp. 4–97. [Google Scholar]

- Shelton, D.P.; Dickey, E.C.; Kachman, S.D.; Fairbanks, K.T. Corn residue cover on the soil surface after planting for various tillage and planting systems. Soil Water Conserv. 1995, 50, 399–494. [Google Scholar]

- Manuwa, S.; Ademosun, O.C. Draught and Soil Disturbance of Model Tillage Tines under Varying Soil Parameters. Agric. Eng. Int. CIGR J. 2007, 9, 1–18. [Google Scholar]

- Špokas, L.; Steponavičius, D. Impact of wheat stubble height on combine technological parameters. Food Agric. Environ. 2010, 8, 464–468. [Google Scholar]

- Taniguchi, T.; Makanga, J.T.; Kishimoto, K. Draft and manipulation by a moldboard plow under different forward speed and body attachments. Trans. ASAE 1999, 99, 1517–1521. [Google Scholar] [CrossRef]

- Zhai, L.; Ji, C.; Ding, Q.; Yu, Y. Analysis of Distribution of Displacement on Soil Surface in Front of Plow with FEM. Trans. Chin. Soc. Agric. Mach. 2011, 10, 10. (In Chinese) [Google Scholar]

- Farid Eltom, A.E.; Ding, W.; Ding, Q.; Tagar, A.A.; Talha, Z.; Gamareldawla. Field investigation of a trash-board, tillage depth and low speed effect on the displacement and burial of straw. Catena 2015, 133, 385–393. [Google Scholar] [CrossRef]

- Farid Eltom, A.E.; Ding, W.; Ding, Q.; Ali, A.B.B.; Adam, B.E. Effect of trash-board on moldboard plow performance at low speed and under two straw conditions. J. Terramech. 2015, 59, 27–34. [Google Scholar] [CrossRef]

- Rahman, S.; Chen, Y.; Lobb, D.A. Soil movement resulting from sweep type manure injection tools. J. Biosyst. Eng. 2005, 91, 379–392. [Google Scholar] [CrossRef]

- Olatunji, O.M.; Davies, R.M. Effect of Weight and Draught on the Performance of Disc on Sandy-loam Soil. Res. J. Appl. Sci. Eng. Technol. 2009, 1, 22–26. [Google Scholar]

- Abbaspour, Y.; Alimardani1, R.; Khalilian, A.; Keyhani, A.; Sadati, S.A.H. Energy Requirement of Site-specific and Conventional Tillage as Affected by Tractor Speed and Soil Parameters. Int. J. Agric. Biol. 2006, 8, 499–503. [Google Scholar]

- Zoerb, G.C.; Musonda, N.G.; Kushwaha, R.L. A combined drawbar pins and force transducer. Can. Agric. Eng. 1983, 25, 157–162. [Google Scholar]

| Layers mm | 2013 | 2014 | ||||

|---|---|---|---|---|---|---|

| Normal | Dry Bulk | Wet Bulk | Normal | Dry Bulk | Wet Bulk | |

| Stress (kPa) | Density g/cm3 | Density g/cm3 | Stress (kPa) | Density g/cm3 | Density g/cm3 | |

| 20 | 0 | 1.07 | 1.49 | 0.00 | 0.26 | 1.05 |

| 40 | 83 | 1.22 | 1.51 | 30 | 0.30 | 1.20 |

| 60 | 75 | 1.96 | 1.42 | 60 | 0.28 | 1.14 |

| 80 | 68 | 1.10 | 1.55 | 60 | 0.32 | 1.27 |

| 100 | 144 | 1.13 | 1.83 | 68 | 0.35 | 1.39 |

| 120 | 386 | 1.14 | 1.81 | 212 | 0.40 | 1.58 |

| 140 | 651 | 1.22 | 1.85 | 204 | 0.45 | 1.81 |

| 160 | 606 | 1.84 | 1.98 | 333 | 0.44 | 1.76 |

| 180 | 545 | 1.97 | 2.03 | 568 | 0.47 | 1.86 |

| 200 | 727 | 2.27 | 2.020 | 569 | 0.51 | 2.03 |

| Soil Treatments Moisture | Soil Displacement | Clods Width cm | Clods Length cm | Blank Space | |

|---|---|---|---|---|---|

| 30% | WTNS | 48.89 | 21.33 | 27.22 | 6.55 |

| WTONS | 64.22 | 29.78 | 45.33 | 9.56 | |

| WTHS | 46.44 | 20.44 | 48.11 | 10.78 | |

| WTOHS | 49.78 | 34.78 | 67.78 | 11.56 | |

| 24% | WTNS | 31.22 | 20.89 | 19.33 | 4.89 |

| WTONS | 39.56 | 24.78 | 25.33 | 7.22 | |

| WTHS | 38.78 | 26.2 | 32.11 | 9.44 | |

| WTOHS | 41.44 | 32.11 | 41.56 | 12.56 | |

| Straw Length mm | Forward Straw Displacement mm | Lateral Straw Displacement mm | ||||||

|---|---|---|---|---|---|---|---|---|

| with a Trash-Board | without a Trash-Board | with a Trash-Board | without a Trash-Board | |||||

| Nearby Shear | Nearby Moldboard | Nearby Shear | Nearby Moldboard | Nearby Shear | Nearby Moldboard | Nearby Shear | Nearby Moldboard | |

| 2013 | ||||||||

| 100 | 65.5 (453.3) a | 30.8 (198.1) c | 75.2 (353.7) a | 38.1 (258.1A) b | 38.1 (353.7) a | 70.1 (232A) c | 45.8 (175A) a | 80.5 (353.7) a |

| 150 | 70.3 (165.5) a | 45.7 (245.1) b | 79.6 (542.8) a | 49.2 (303.1) b | 49.2 (198.1) c | 75.6 (278.4) c | 50.8 (326.2) c | 87.2 (222.2) b |

| 250 | 73.4 (275.7) b | 50.9 (349.4) a | 83.2 (324.1) a | 55.3 (220.0) c | 55.3 (124.1) b | 80.5 (419.7) a | 68.7 (295.4) c | 99.7 (218.5) a |

| 2014 | ||||||||

| 75 | 60 (4272.0) b | 28.8 (353.7) b | 35.4 (415.2) a | 30.2 (353.7) a | 30.2 (471.5) a | 65.4 (298.1) c | 39.5 (398.1) c | 50.6 (353.7) a |

| 125 | 69.5 (353.7) a | 33.2 (214.1) c | 48.2 (198.1) c | 39.5 (254.7) a | 39.5 (353.7) b | 71.9 (325.7) a | 45.1 (321.0) a | 58.8 (353.7) a |

| 175 | 87.3 (213.7) a | 45 (198.1) c | 49.4 (353.7) a | 50.6 (198.1) c | 50.6 (153.7) a | 89.2 (353.7) b | 56.5 (251.7) b | 66.6 (214.3) c |

| 225 | 93.5 (353.7) a | 57.2 (353.7) b | 63.4 (251.7) c | 66.1 (145.4) a | 66.1 (325.3) b | 112.8 (323.8) b | 74.2 (453.0) c | 77.8 (353.7A) a |

| Items | 2013 | 2014 |

|---|---|---|

| Soil water content (%) | 30 | 24 |

| Soil cohesion (mPa) | 51.39 | 46.284 |

| Friction angle (Φ) | 12.85° | 7.81° |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdallah, F.E.; Ding, W.; Ding, Q.; Pan, G. Design, Development, and Performance Evaluation of a Trash-Board Moldboard Plow for the Interaction between Soil and Straw with Two Different Water Content Levels. Agronomy 2016, 6, 30. https://doi.org/10.3390/agronomy6020030

Abdallah FE, Ding W, Ding Q, Pan G. Design, Development, and Performance Evaluation of a Trash-Board Moldboard Plow for the Interaction between Soil and Straw with Two Different Water Content Levels. Agronomy. 2016; 6(2):30. https://doi.org/10.3390/agronomy6020030

Chicago/Turabian StyleAbdallah, Farid E., Weimin Ding, Qishuo Ding, and Genxing Pan. 2016. "Design, Development, and Performance Evaluation of a Trash-Board Moldboard Plow for the Interaction between Soil and Straw with Two Different Water Content Levels" Agronomy 6, no. 2: 30. https://doi.org/10.3390/agronomy6020030

APA StyleAbdallah, F. E., Ding, W., Ding, Q., & Pan, G. (2016). Design, Development, and Performance Evaluation of a Trash-Board Moldboard Plow for the Interaction between Soil and Straw with Two Different Water Content Levels. Agronomy, 6(2), 30. https://doi.org/10.3390/agronomy6020030