Simulation Analysis of a Ventilation System in a Smart Broiler Chamber Based on Computational Fluid Dynamics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Research Objects and Measurement Methods

2.1.1. Layout of Experimental Site

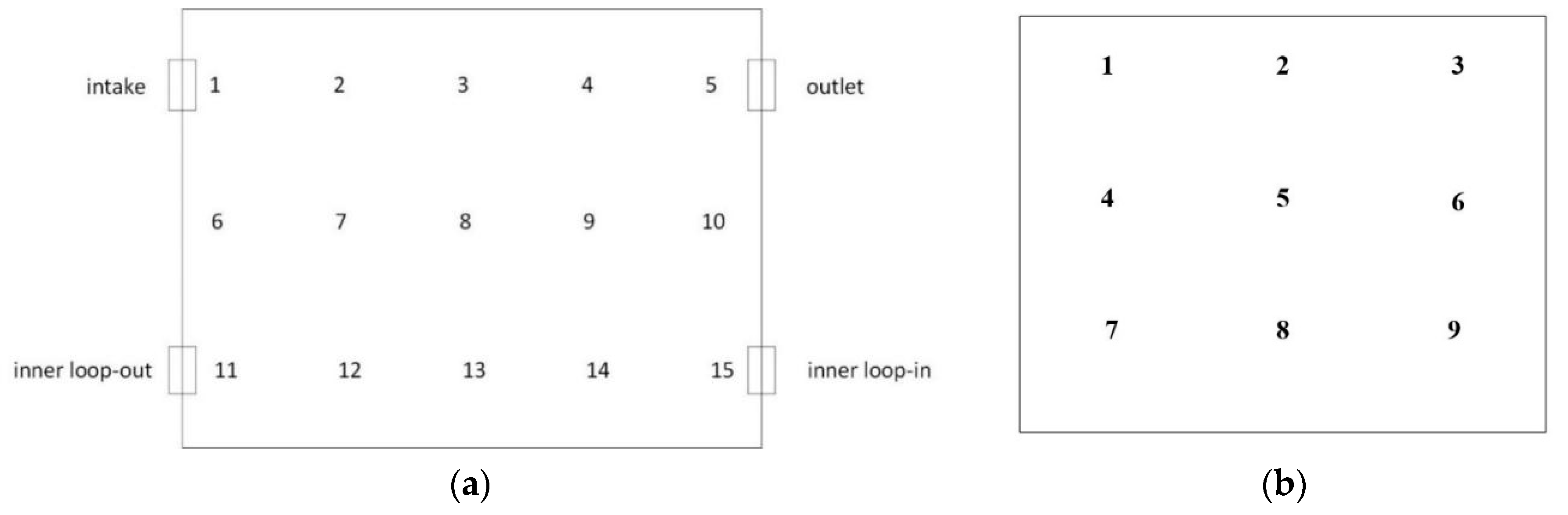

2.1.2. Selection of Measurement Points

2.1.3. Ventilation System

2.2. CFD Model

2.2.1. CFD Control Equations

2.2.2. Mesh Division of the Broiler Chamber

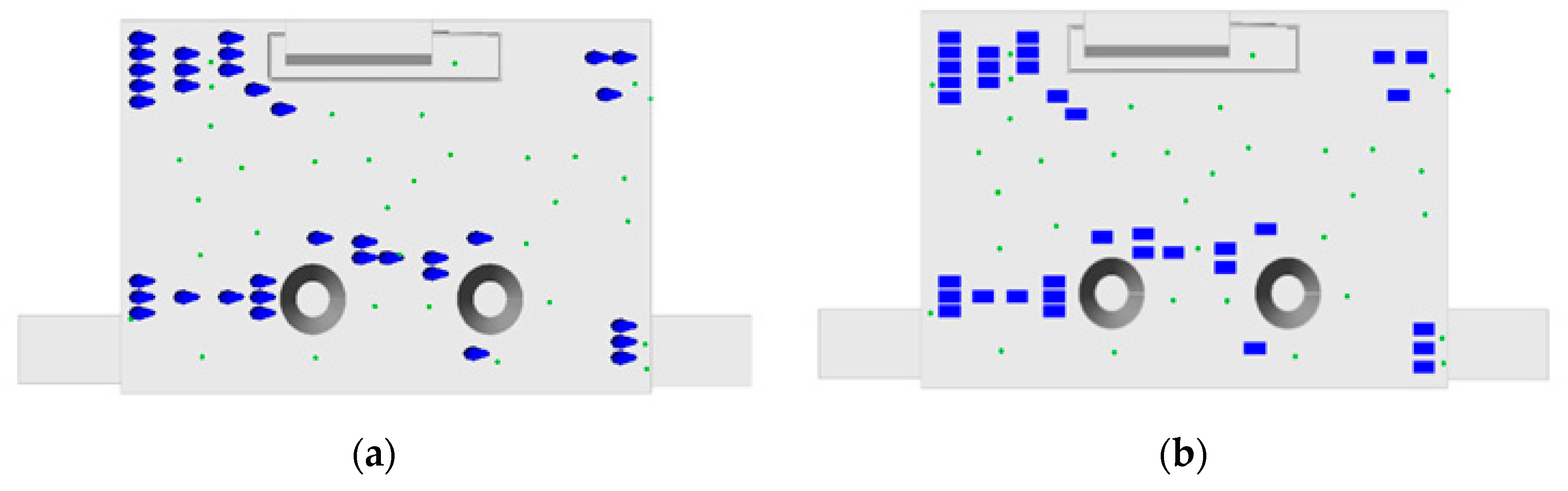

2.2.3. Broiler Model

Simplification of Broiler

Efficiency Calculation and Selection

2.3. Solver Parameter Settings

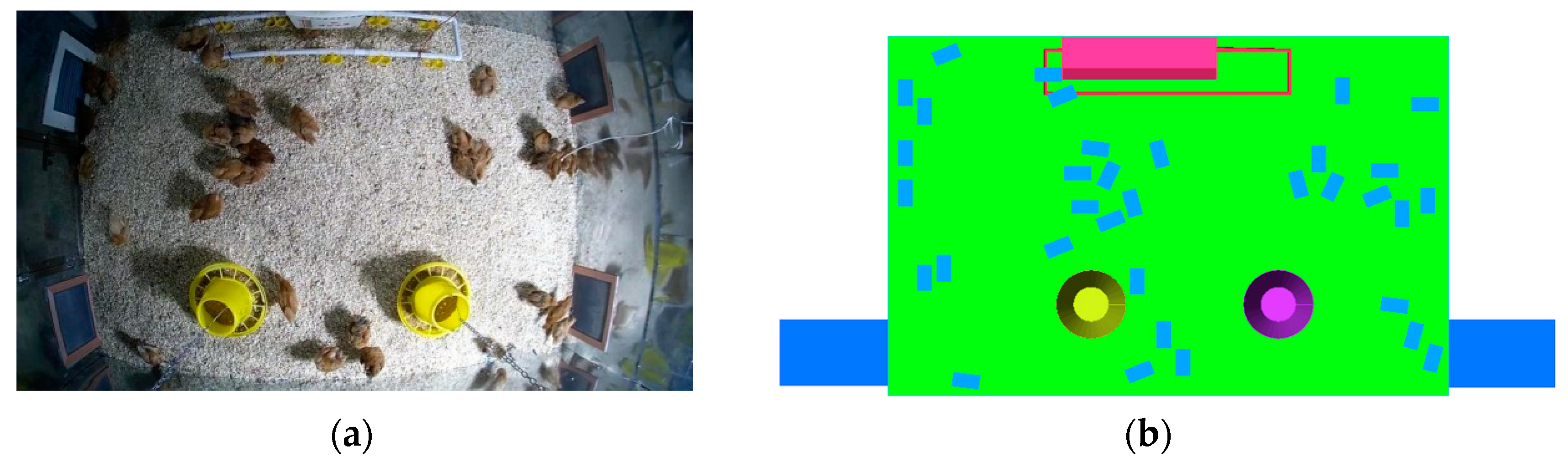

2.4. Broiler Chambers

2.5. RMS Error

2.6. Control Equation of Age of Air

3. Results and Discussion

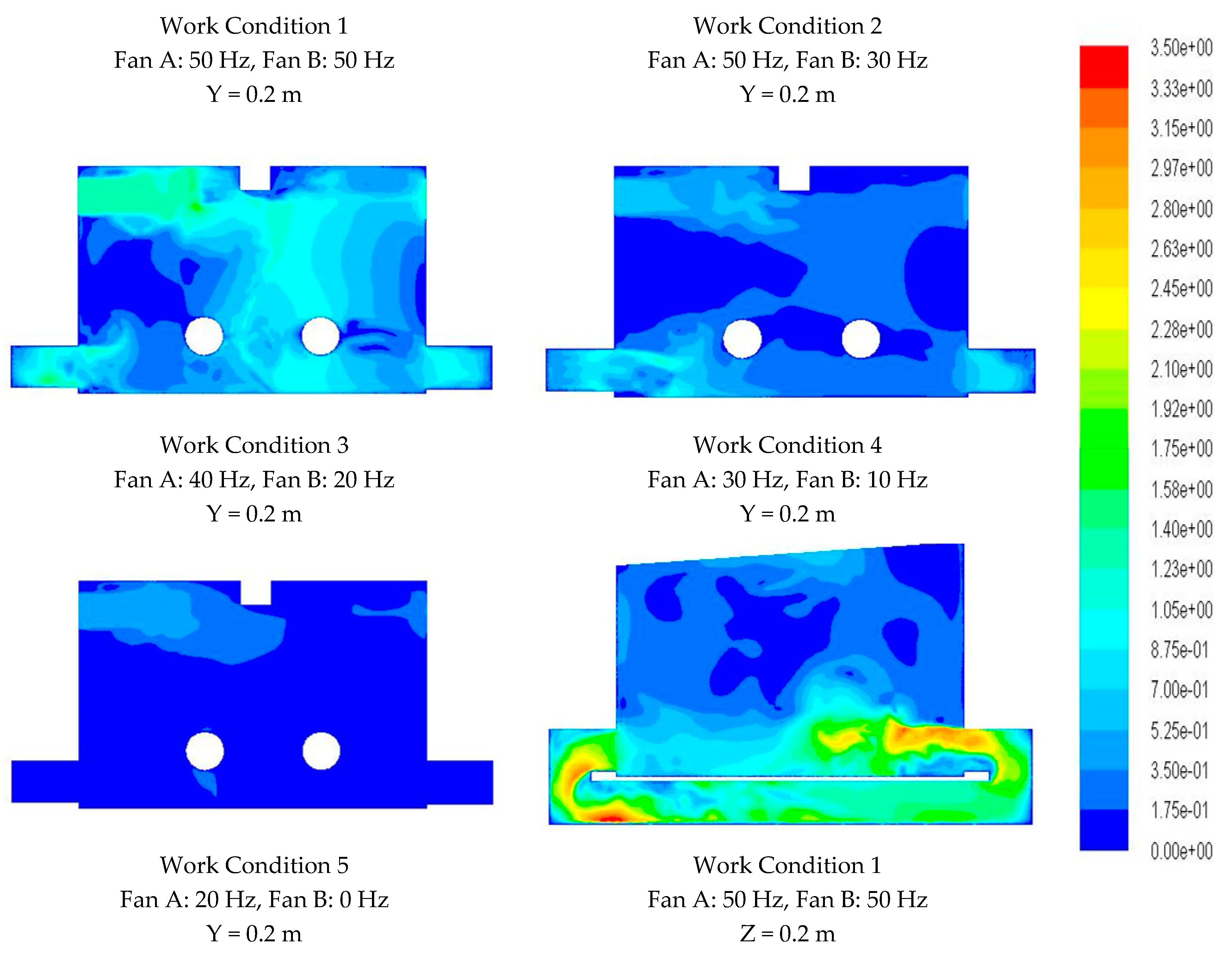

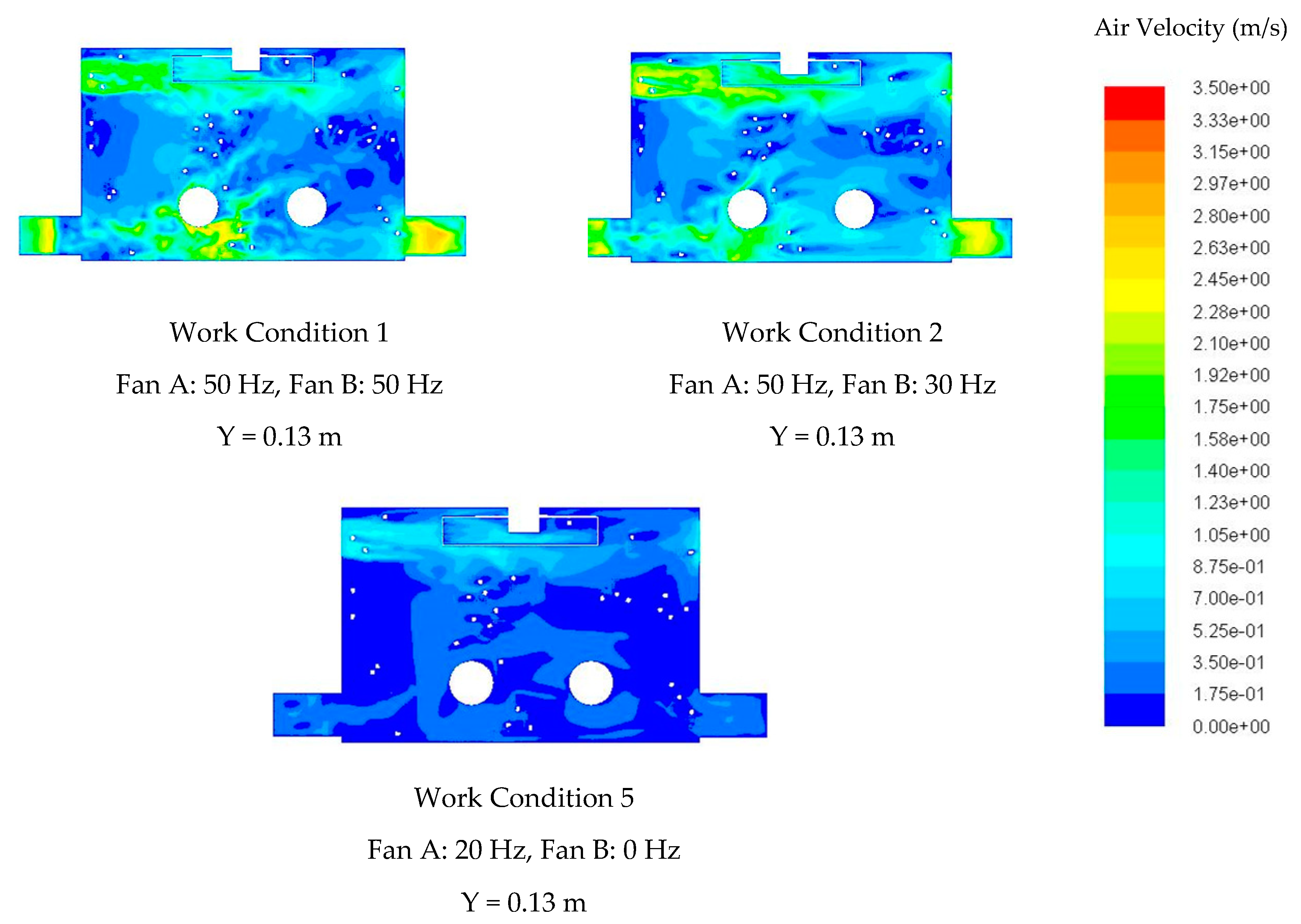

3.1. Wind Velocity Simulation of Empty Broiler Chamber under Different Working Conditions

3.1.1. Numerical Comparison of Monitoring Points

3.1.2. Analysis of Velocity Contours

3.2. Simulation of the Broiler Chamber with Broilers under Three Common Working Conditions

3.3. Simulation of the Age of Air

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Park, G.; Lee, I.; Yeo, U.; Ha, T.; Kim, R.; Lee, S. Ventilation rate formula for mechanically ventilated broiler houses considering aerodynamics and ventilation operating conditions. Biosyst. Eng. 2018, 175, 82–95. [Google Scholar] [CrossRef]

- Yao, H.; Sun, Q.; Zou, X.; Wang, S.; Zhang, S.; Zhang, S.; Zhang, S. Research of yellow-feather chicken breeding model based on small chicken chamber. Agric. Eng. 2018, 56, 91–100. [Google Scholar]

- Du, L.; Yang, C.; Dominy, R.; Yang, L.; Hu, C.; Du, H.; Li, Q.; Yu, C.; Xie, L.; Jiang, X. Computational fluid dynamics aided investigation and optimization of a tunnel-ventilated poultry house in china. Comput. Electron. Agric. 2019, 159, 1–15. [Google Scholar] [CrossRef]

- LEE, I.-B.; SASE, S.; SUNG, S.-H. Evaluation of CFD accuracy for the ventilation study of a naturally ventilated broiler house. Jpn Agric. Res. Q. 2007, 41, 53–64. [Google Scholar] [CrossRef]

- Seo, I.H.; Lee, I.B.; Moon, O.K.; Kim, H.T.; Hwang, H.S.; Hong, S.W.; Bitog, J.P.; Yoo, J.I.; Kwon, K.S.; Kim, Y.H.; et al. Improvement of the ventilation system of a naturally ventilated broiler house in the cold season using computational simulations. Biosyst. Eng. 2009, 104, 106–117. [Google Scholar] [CrossRef]

- Cheng, Q.; Li, H.; Rong, L.; Feng, X.; Zhang, G.; Li, B. Using CFD to assess the influence of ceiling deflector design on airflow distribution in hen house with tunnel ventilation. Comput. Electron. Agric. 2018, 151, 165–174. [Google Scholar] [CrossRef]

- Kic, P.; Zajicek, M. A numerical cfd method for the broiler house ventilation analysis. J. Inf. Technology in Agric. 2011, 1, 1–7. [Google Scholar]

- Bjerg, B.; Svidt, K.; Zhang, G.; Morsing, S.; Johnsen, J.O. Modeling of air inlets in cfd prediction of airflow in ventilated animal houses. Comput. Electron. Agric. 2002, 34, 223–235. [Google Scholar] [CrossRef]

- Norton, T.; Grant, J.; Fallon, R.; Sun, D. Improving the representation of thermal boundary conditions of livestock during CFD modelling of the indoor environment. Comput. Electron. Agric. 2010, 73, 17–36. [Google Scholar] [CrossRef]

- Mostafa, E.; Lee, I.; Song, S.; Kwon, K.; Seo, I.; Hong, S.; Hwang, H.-S.; Bitog, J.P.; Han, H.-T. Computational fluid dynamics simulation of air temperature distribution inside broiler building fitted with duct ventilation system. Biosyst. Eng. 2012, 112, 293–303. [Google Scholar] [CrossRef]

- Yao, J.; Guo, B.; Ding, W.; Shao, X.; Shi, Z. Structure optimization and validation of goose house ventilation system based on airflow field simulation by CFD. Trans. Chin. Soc. Agric. Eng. 2017, 33, 214–220. [Google Scholar]

- Li, W.; Shi, Z.; Wang, C. Numerical simulation of tunnel ventilation system of plane-raising enclosed henhouse. J. China Agric. Univ. 2007, 12, 80–84. [Google Scholar]

- Coradi, P.C.; Costa, D.R.D.; Visser, E.M.; Martins, M.A.; Tinôco, I.D.F.F. Thermal comfort evaluation in a broiler house utilizing computational fluid dynamics (CFD) software. In Proceedings of the CIGR International Conference of Agricultural Engineering, Viçosa, Brazil, 3 August 2008. [Google Scholar]

- Blanes-Vidal, V.; Guijarro, E.; Balasch, S.; Torres, A.G. Application of computational fluid dynamics to the prediction of airflow in a mechanically ventilated commercial poultry building. Biosyst. Eng. 2008, 100, 105–116. [Google Scholar] [CrossRef]

- Cheng, Q.; Wu, W.; Li, H.; Zhang, G.; Li, B. CFD study of the influence of laying hen geometry, distribution and weight on airflow resistance. Comput. Electron. Agric. 2018, 144, 181–189. [Google Scholar] [CrossRef]

- Sun, H.; Zhao, L.; Zhang, Y. Evaluating RNGk-εmodels using PIV data for airflow in animal buildings at different ventilation rates. ASHRAE 2007, 113, 358–365. [Google Scholar]

- Seo, I.; Lee, I.; Moon, O.; Hong, S.; Hwang, H.; Bitog, J.P.; Kwon, K.; Ye, Z.; Lee, J. Modelling of internal environmental conditions in a full-scale commercial pig house containing animals. Biosyst. Eng. 2012, 111, 91–106. [Google Scholar] [CrossRef]

- Zajicek, M.; Kic, P. Improvement of the broiler house ventilation using the CFD simulation. Agron. Res. 2012, 1, 235–242. [Google Scholar]

- Khosravi Nikou, M.R.; Ehsani, M.R. Turbulence models application on CFD simulation of hydrodynamics, heat and mass transfer in a structured packing. Int.Commun. Heat Mass Transf. 2008, 35, 1211–1219. [Google Scholar] [CrossRef]

- Jinru, C. Study of Indoor Environment Dynamic Simulation of Layer-House Based on the Model of Caged Pens of Porous Media. Master’s Thesis, Hebei University of Technology, Wuhan, China, 2015. [Google Scholar]

- Damin, Z.; Xiugan, Y. Numerical solution of age of air. J. Beijing Univ. Aeronaut. Astronaut. 1997, 23, 565–570. [Google Scholar]

- Shaoshuai, Z.; Huajie, D.; Minhong, Z.; Jinghai, F.; Ying, Z.; Meng, L.; Xiumei, L. Effects of air velocity and moderate ambient temperatures on physiological, endocrine and immune indices of broilers. Chin. J. Anim.Nutr. 2017, 29, 69–79. [Google Scholar]

- Yu, N. Numerical simulation of the air distribution of typical ship kitchen ventilation system. Ship Ocean Eng. 2018, 47, 89–92. [Google Scholar]

| Measuring Point Number | Measuring Velocity Values (m/s) | ||

|---|---|---|---|

| Fan A = 50 HZ | Fan A = 30 HZ | Fan A = 20 HZ | |

| 1 | 1.67 | 0.81 | 0.27 |

| 2 | 1.74 | 0.83 | 0.34 |

| 3 | 1.64 | 0.79 | 0.31 |

| 4 | 1.69 | 0.93 | 0.37 |

| 5 | 1.97 | 1.15 | 0.47 |

| 6 | 1.73 | 1.07 | 0.39 |

| 7 | 1.78 | 0.87 | 0.29 |

| 8 | 1.80 | 0.94 | 0.32 |

| 9 | 1.79 | 0.92 | 0.30 |

| Average value | 1.76 | 0.92 | 0.34 |

| Standard deviation | 0.091 | 0.11 | 0.05 |

| Number of Work Condition | Temperature | Fan A | RPM (Fan A) | Fan B | RPM (Fan B) | Air Conditioner |

|---|---|---|---|---|---|---|

| >34 °C | 0 | 0 | 30 Hz | 840 | On (set 30 °C) | |

| 1 | 32~34 °C | 50Hz | 1400 | 50 Hz | 1400 | Off |

| 2 | 30~32 °C | 50Hz | 1400 | 30 Hz | 840 | Off |

| 3 | 28~30 °C | 40Hz | 1120 | 20 Hz | 560 | Off |

| 4 | 26~28 °C | 30Hz | 840 | 10 Hz | 280 | Off |

| 5 | 24~26 °C | 20Hz | 560 | 0 | 0 | Off |

| <24 °C | 10Hz | 280 | 0 | 0 | Off |

| Selected Model | Time (Unit: s) | Number of Cells | Quality of Meshes | Time to Achieve Convergence (Unit: h) |

|---|---|---|---|---|

| Empty chamber | 803 | 7,494,859 | >0.35 | 1.35 |

| Block model | 993 | 8,310,070 | >0.34 | 2 |

| Body only model | 4381 | 40,120,931 | >0.2 | 7.5 |

| Parameters | Values |

|---|---|

| Simulated state | Steady state |

| Turbulence model | RNG (the renormalization group) k-ε |

| Air density/(kg/m3) | 1.225 |

| Aerodynamic viscosity/(Pa·s) Dynamic mesh | 1.83 × 10−5 Smoothing |

| ErrorType | Fan A 20 Hz Fan B 0 Hz | Fan A 30Hz Fan B 10Hz | Fan A 40Hz Fan B 20Hz | Fan A 50Hz Fan B 30Hz | Fan A 50Hz Fan B 50Hz |

|---|---|---|---|---|---|

| Maximum Absolute Error (Unit: m/s) | 0.1 | 0.15 | 0.24 | 0.24 | 0.27 |

| Root Mean Square Error (Unit: m/s) | 4.9 | 17.6 | 18.2 | 19.1 | 16.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Ding, A.; Zou, X.; Feng, B.; Qiu, X.; Wang, S.; Zhang, S.; Qian, Y.; Yao, H.; Wei, Y. Simulation Analysis of a Ventilation System in a Smart Broiler Chamber Based on Computational Fluid Dynamics. Atmosphere 2019, 10, 315. https://doi.org/10.3390/atmos10060315

Zhang S, Ding A, Zou X, Feng B, Qiu X, Wang S, Zhang S, Qian Y, Yao H, Wei Y. Simulation Analysis of a Ventilation System in a Smart Broiler Chamber Based on Computational Fluid Dynamics. Atmosphere. 2019; 10(6):315. https://doi.org/10.3390/atmos10060315

Chicago/Turabian StyleZhang, Shikai, Anlan Ding, Xiuguo Zou, Bo Feng, Xinfa Qiu, Siyu Wang, Shixiu Zhang, Yan Qian, Heyang Yao, and Yuning Wei. 2019. "Simulation Analysis of a Ventilation System in a Smart Broiler Chamber Based on Computational Fluid Dynamics" Atmosphere 10, no. 6: 315. https://doi.org/10.3390/atmos10060315

APA StyleZhang, S., Ding, A., Zou, X., Feng, B., Qiu, X., Wang, S., Zhang, S., Qian, Y., Yao, H., & Wei, Y. (2019). Simulation Analysis of a Ventilation System in a Smart Broiler Chamber Based on Computational Fluid Dynamics. Atmosphere, 10(6), 315. https://doi.org/10.3390/atmos10060315