Improved Pulsed-Jet Cleaning of Cone Filter Cartridges Using an Annular-Slit Nozzle

Abstract

:1. Introduction

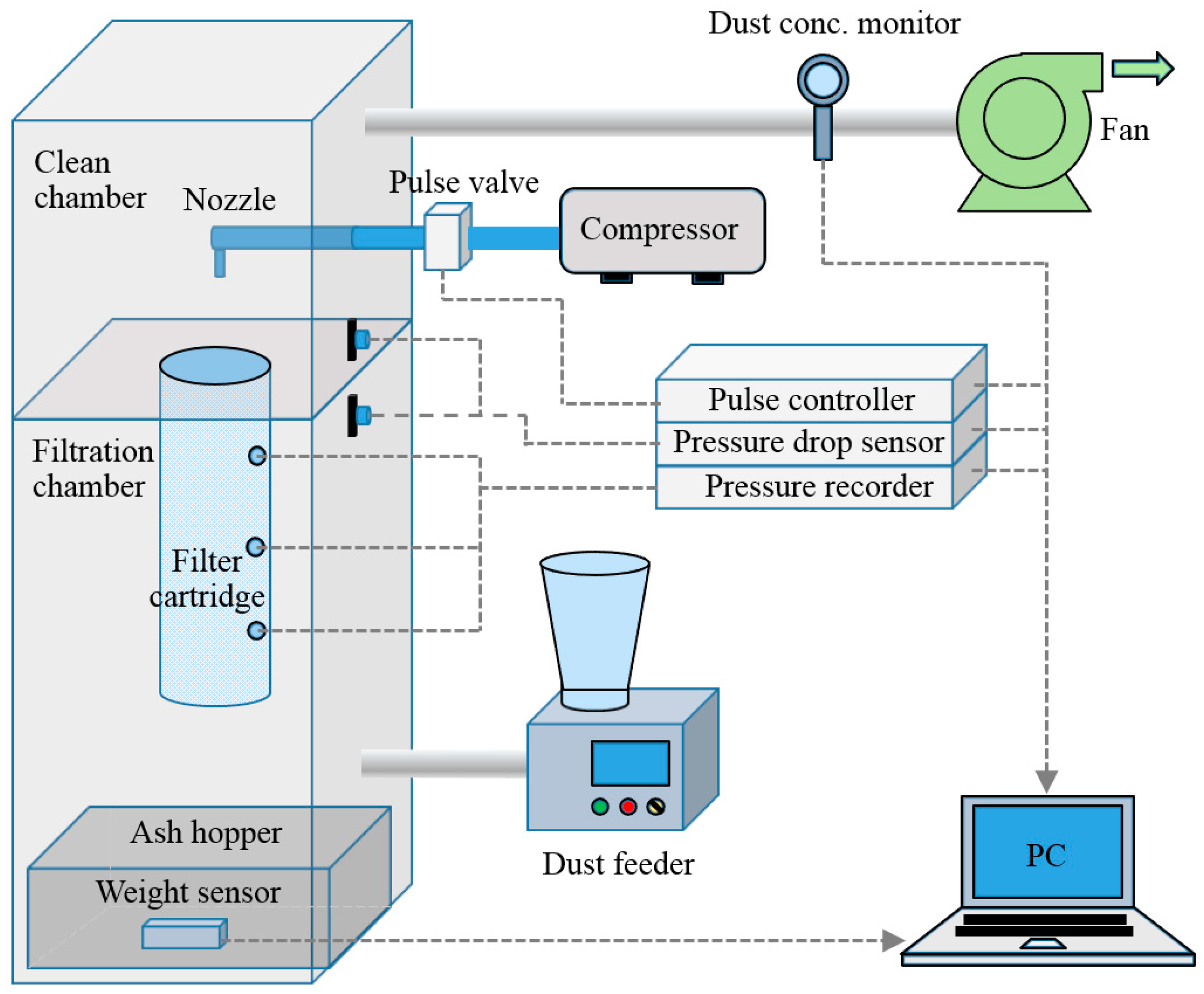

2. Experimental and Materials

2.1. Experimental System

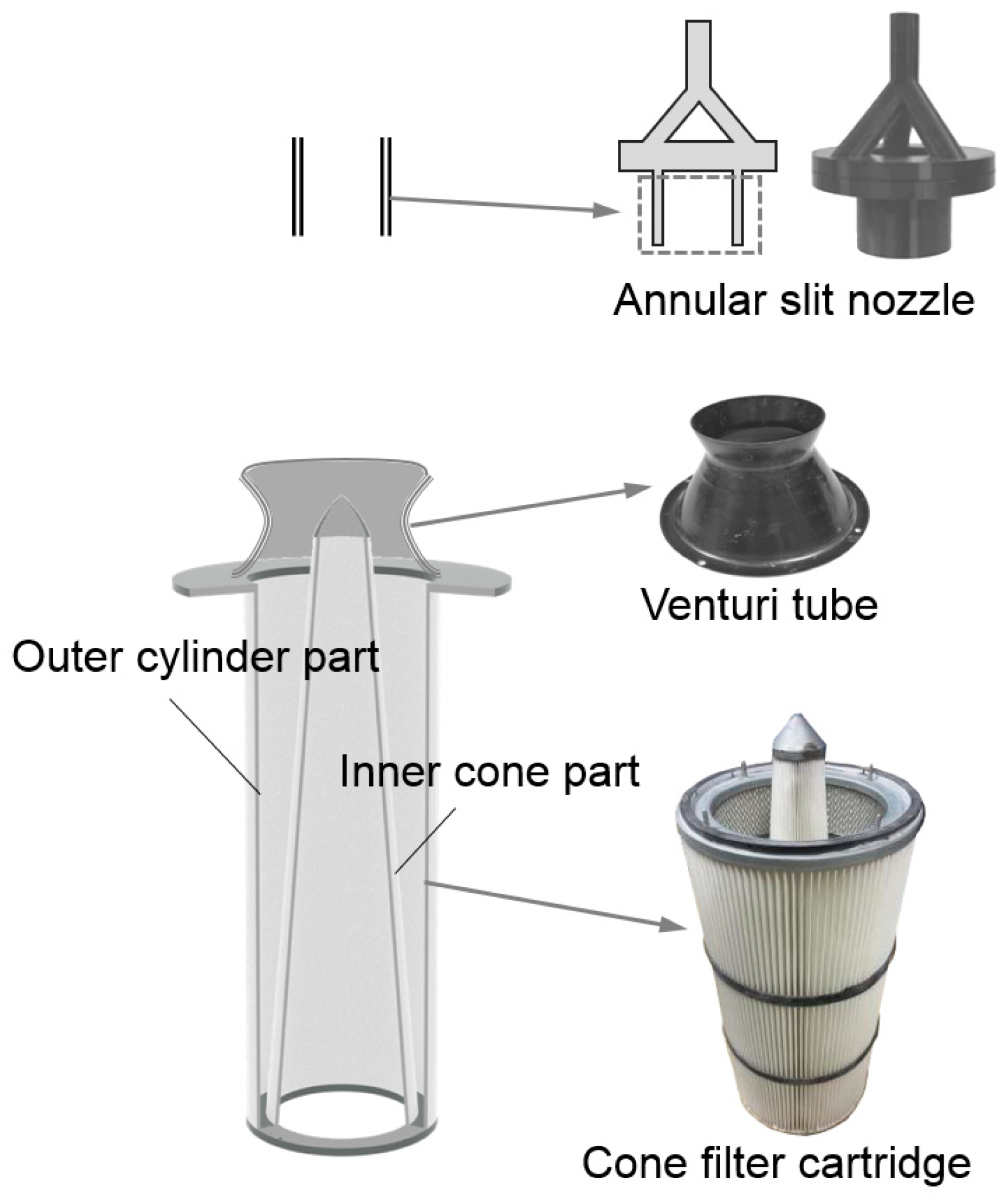

2.2. Filter Cartridge, Nozzle, and Dust

2.3. Experimental Procedures

- (1)

- Off-line pulse jet cleaning procedure

- (2)

- Online dust filtration and filter cleaning

3. Results and Discussion

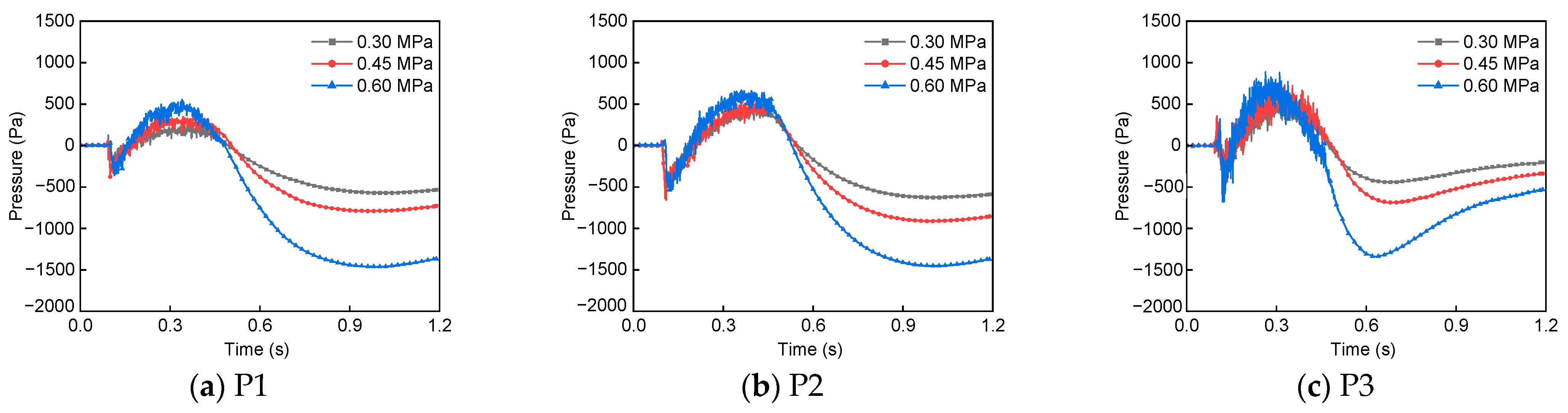

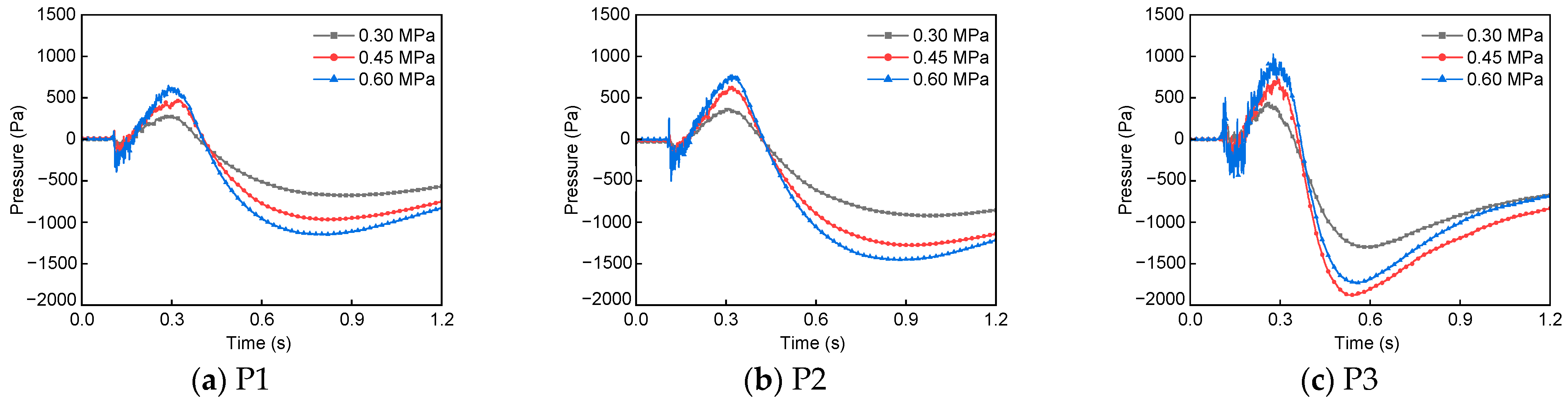

3.1. Comparison of Pulsed-Jet Pressure between the Annular-Slit Nozzle and the Common Nozzle Cases

3.2. Effect of Venturi on Pulsed-Jet Pressure and Performance

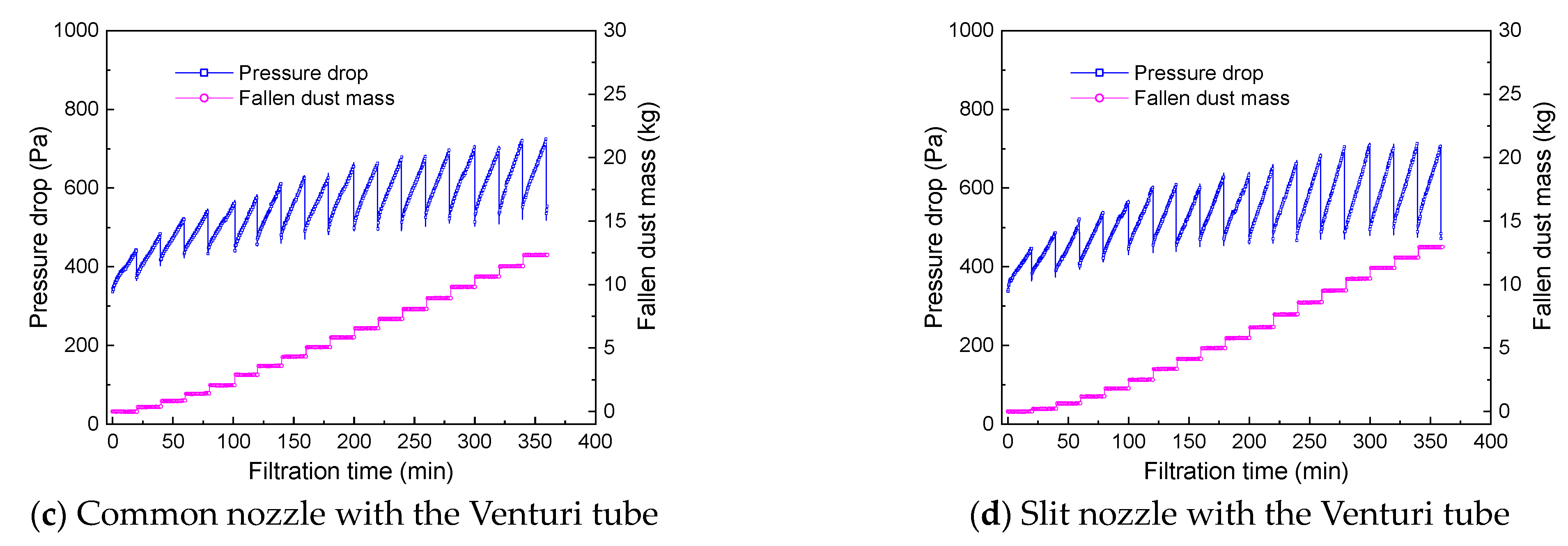

3.3. Online Dust Filtration and Filter Cleaning Experiment

4. Conclusions

- (1)

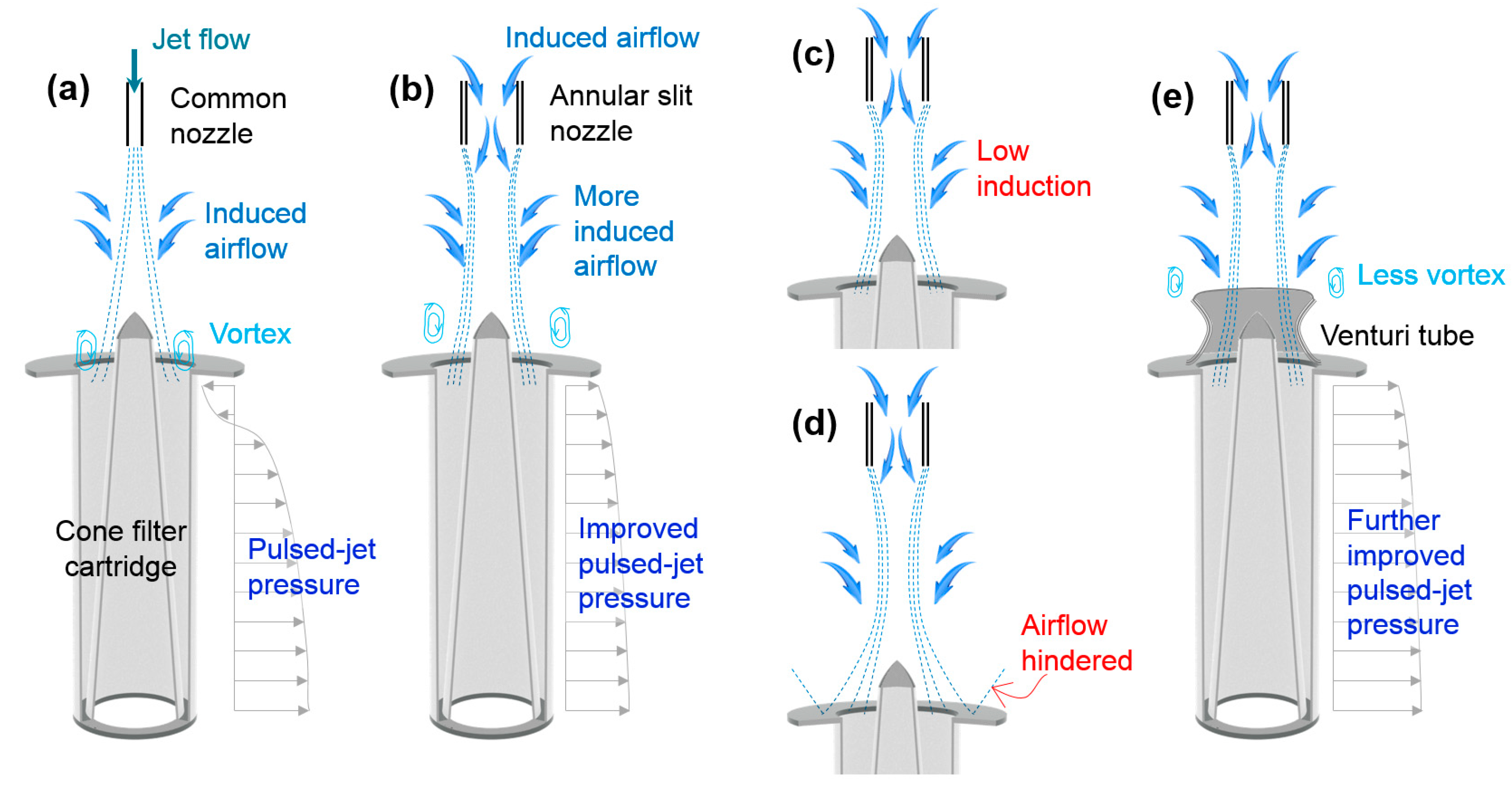

- For both the common and slit nozzle cases, five stages of the pulse jet process were summarized, which included the generation of a static pressure pulse wave when the jet starts, the entrainment of surrounding air by the jet, the formation of negative pressure in the filter cartridge, the accumulation of the rebound jet, and finally the ending with negative pressure. The static pressure in the fourth stage played a vital role in the filter cleaning through the pulse jet. Compared to the common nozzle, the jet generated by the slit nozzle had a significantly larger contact area with the surrounding air. This enhancement led to an improved entrainment effect, increased overall pulsed-jet pressure and significantly enhanced pressure in the upper and middle sections of the filter cartridge, especially the upper one.

- (2)

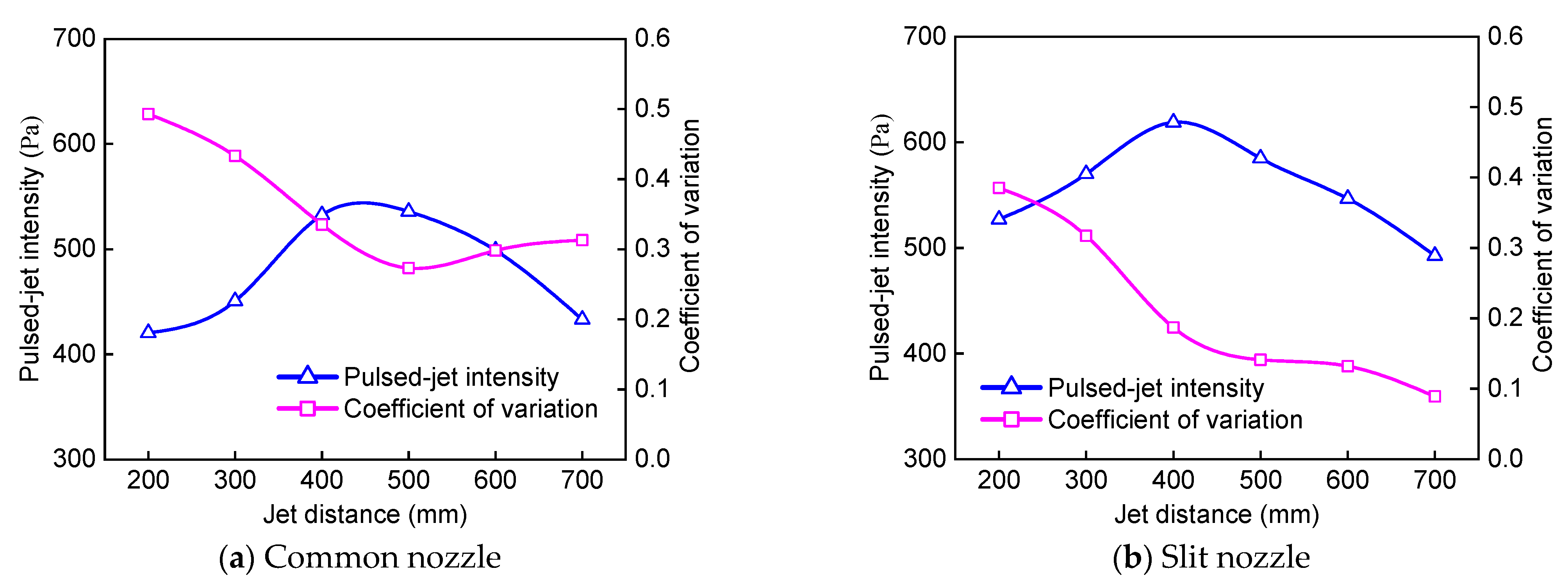

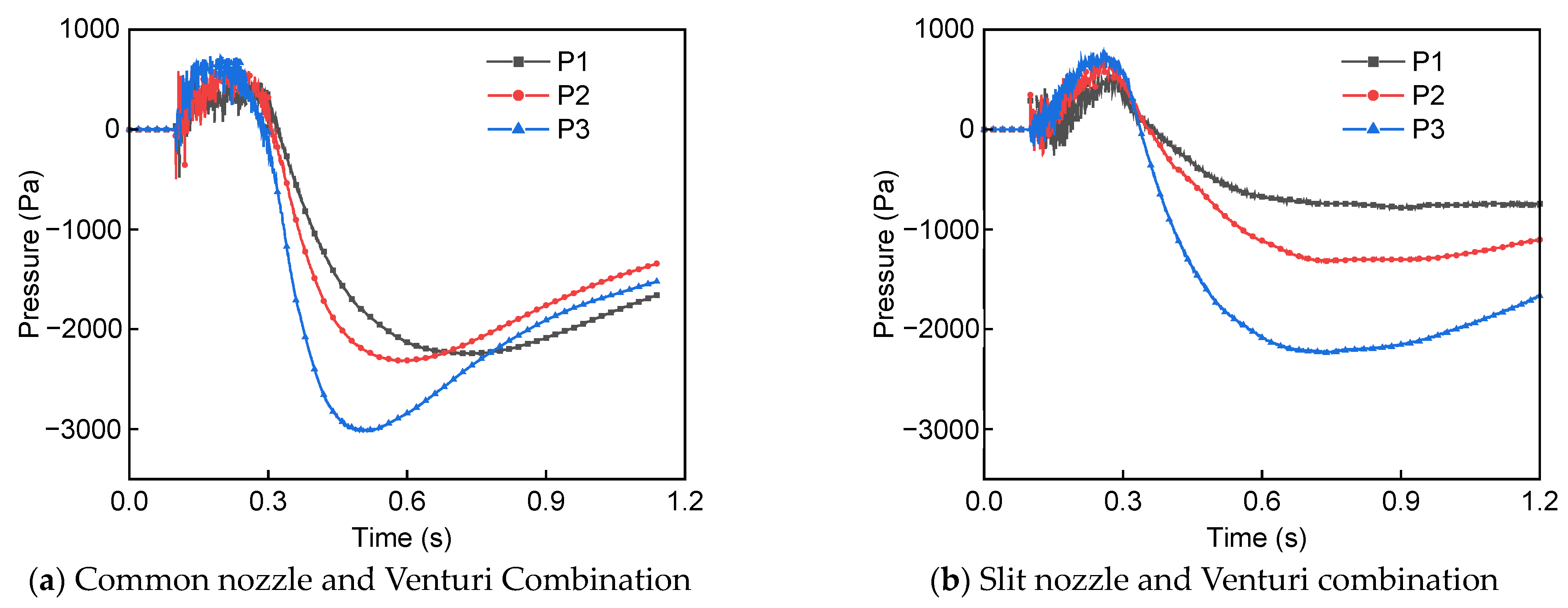

- The pulsed-jet intensity initially increased and then decreased with the increase in jet distance in both the common and the slit nozzles. The entrainment decreased with the decrease in the jet distance, while an excessive jet distance caused some of the jet airflow to fail to enter the filter cartridge. The optimal jet distance for the common nozzle and slit nozzle were 500 mm and 400 mm, respectively. At the optimal jet distance, the pulsed-jet intensity with the slit nozzle was increased by 16% (the pressure in the upper region is increased by 23%), and the pulsed-jet uniformity was increased by 44% compared with the common nozzle. For the slit nozzle, the pulsed-jet intensity was further increased by 6% after adding a Venturi tube, and pulsed-jet uniformity also improved.

- (3)

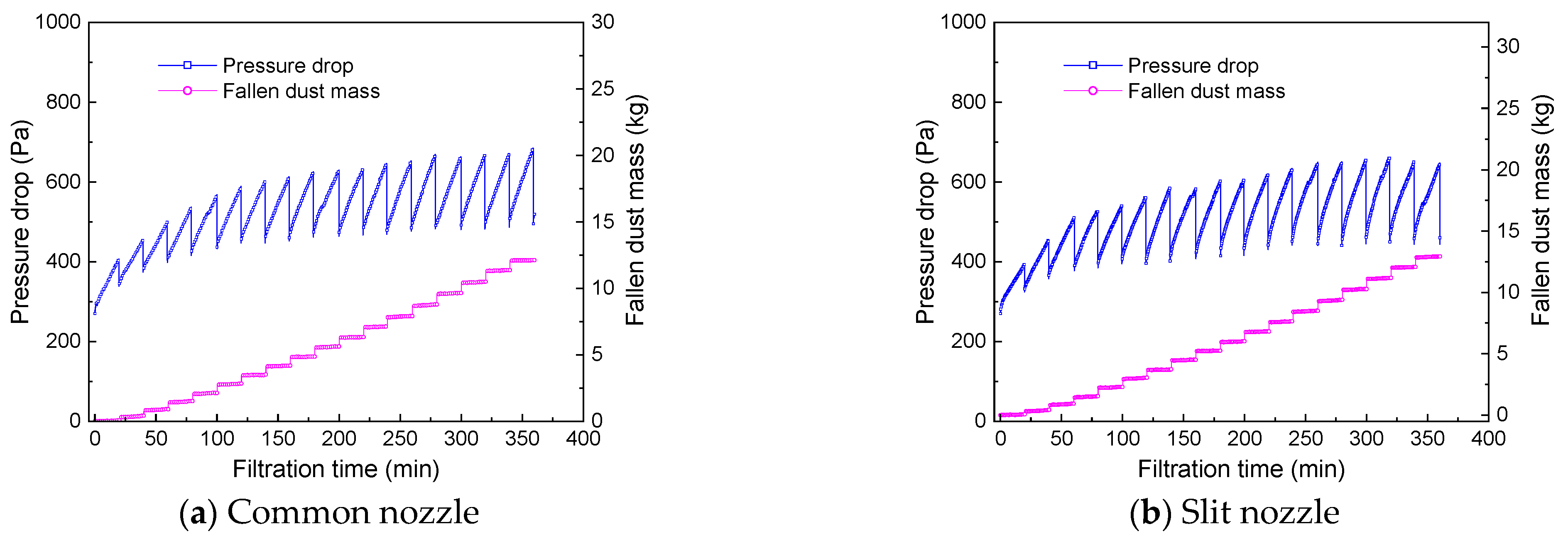

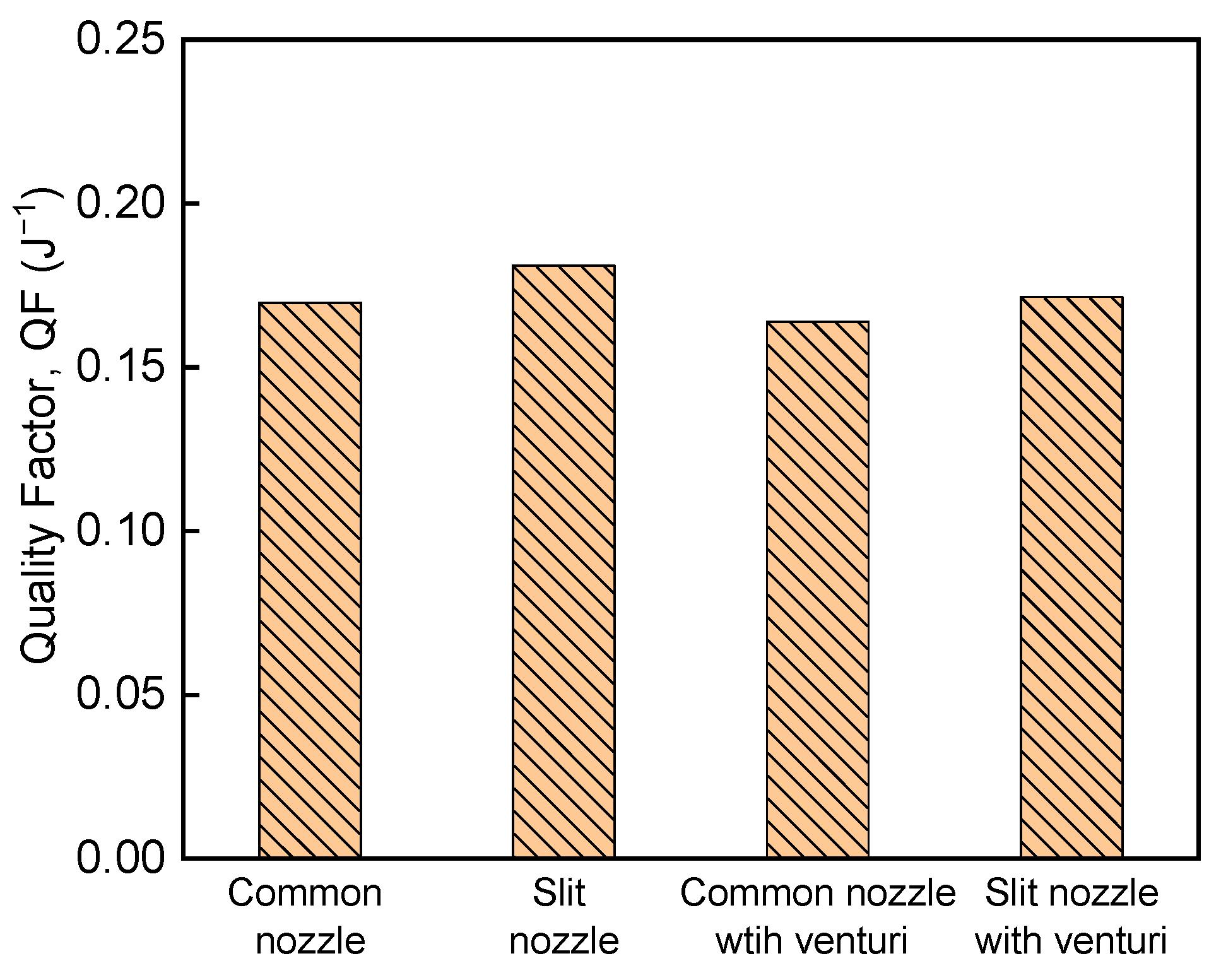

- Compared with the common nozzle, the slit nozzle could reduce the residual pressure drop of the dust collector and increase the fallen dust mass. The fallen dust mass produced by a single cleaning of the slit nozzle was 0.64 kg. The average residual pressure drop decreased by 8% (to 413 Pa), while the dust quality and the comprehensive filtration performance increased by 6% and 7% (to 0.18), respectively. When using a slit nozzle, the addition of a Venturi tube improved the cleaning effect of the filter cartridge. However, this also resulted in an increase in the filtration pressure drop of the dust collector, leading to a reduction in the comprehensive filtration performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lelieveld, J.; Evans, J.S.; Fnais, M.; Giannadaki, D.; Pozzer, A. The contribution of outdoor air pollution sources to premature mortality on a global scale. Nature 2015, 525, 367–371. [Google Scholar] [CrossRef]

- Tu, X.; Fang, X.; Fang, H.; Ye, C.; Liu, Z.; Jia, X.; He, D.; Wang, J.; Huang, H.; Zou, C.; et al. Chemical composition characteristics and source apportionment of PM2.5 in ceramic industrial base during winter. Aerosol Air Qual. Res. 2022, 22, 210390. [Google Scholar] [CrossRef]

- McDuffie, E.E.; Martin, R.V.; Spadaro, J.V.; Burnett, R.; Smith, S.J.; O’Rourke, P.; Hammer, M.S.; van Donkelaar, A.; Bindle, L.; Shah, V.; et al. Source sector and fuel contributions to ambient PM(2.5) and attributable mortality across multiple spatial scales. Nat. Commun. 2021, 12, 3594. [Google Scholar] [CrossRef] [PubMed]

- Wang, D. Mine Dusts; Science Press: Beijing, China, 2015. (In Chinese) [Google Scholar]

- Zhang, M.; Qin, W.; Ma, X.; Liu, A.; Yan, C.; Li, P.; Huang, M.; He, C. An environmentally friendly technology of metal fiber bag filter to purify dust-laden airflow. Atmosphere 2022, 13, 485. [Google Scholar] [CrossRef]

- Li, S.; Wen, G.; Lv, W.; Liu, H.; Lin, Y.; Yuan, L.; Zhou, F. Effects of various humid environments on the filtration and dust cleaning performance of filter media. Sep. Purif. Technol. 2022, 309, 122940. [Google Scholar] [CrossRef]

- Li, J.L.; Chen, Y.Z.; Lin, Z.J.; Wu, Q.Q.; Wu, D.S. Study progress and outlook of pulsed-jet cleaning technology for filter cartridge of dust collector. Metal Mine 2022, 557, 23–35. (In Chinese) [Google Scholar]

- Zhang, Q.; Qian, Y.L.; Liu, D.; Zhang, Y.Y. Experimental study on the influence of venturi on filter cartridge cleaning of a pulse-jet filtration system. Environ. Sci. Technol. 2015, 38, 133–137. (In Chinese) [Google Scholar]

- Feng, X.; Geng, F.; Teng, H.; Li, S.; An, J.; Gui, C. Dust dispersion during the pulse-jet cleaning process with the diffuser effect of the cartridge filter. Environ. Sci. Pollut. Res. Int. 2023, 30, 41486–41504. [Google Scholar] [CrossRef]

- Liu, X.; Shen, H. Effect of venturi structures on the cleaning performance of a pulse jet baghouse. Appl. Sci. 2019, 9, 3687. [Google Scholar] [CrossRef]

- Bi, Y.X.; Zhang, M.X.; Chen, J.D.; Chen, H.Y.; Qian, Y.L.; Zhou, R. Influence of venturis on bag cleaning of a pulse-jet filtration system. Chin. J. Environ. Eng. 2013, 7, 4481–4485. (In Chinese) [Google Scholar]

- Qiu, J.; Wu, D.; Chen, D.; Li, J. Reverse pulsed-flow cleaning of pleated filter cartridges having an inner pleated filter cone. Process Saf. Environ. 2021, 146, 481–489. [Google Scholar] [CrossRef]

- Chen, S.; Chen, D. Annular-slit nozzles for reverse flow cleaning of pleated filter cartridges. Sep. Purif. Technol. 2017, 177, 182–191. [Google Scholar] [CrossRef]

- Shuo, Z.; Zhihong, T.; Libing, L.; Guilong, X. The influence of the pulse jet flow on the dust cleaning characteristics of filter cartridges with double Laval nozzles. Environ. Pollut. Control. 2021, 43, 411–415. (In Chinese) [Google Scholar]

- Xi, Y.; Jiang, W.W.; Dai, Y.; Wang, G.J.; Yan, Z.G.; Ren, F.L.; Niu, F.J. Numerical simulation and optimal of conical diffuser for ash removal characteristics based on CFD. Light Ind. Mach. 2021, 39, 98–103. (In Chinese) [Google Scholar]

- Xue, F.; Li, P.; Huang, W.; Hu, M.; Yan, C.; Chen, H.; Yang, G. Effect of nozzle form to filter cartridge pulse-jet cleaning performance in clean-on-demand mode. China Powder Sci. Technol. 2022, 28, 48–56. (In Chinese) [Google Scholar]

- Zhu, Y.; Zuo, D.; Yang, X.G.; Yan, H.F.; Long, X.P.; Ji, B. Numerical simulation of the pulsejet backblow ash removal process of a combined cartridge filter. Fluid Mach. 2020, 48, 23–28. (In Chinese) [Google Scholar]

- Su, Z.; Lin, Z.; Li, J.; Qiu, J.; Wu, Q.; Wu, D. Numerical simulation of the performance of pulse jet dust cleaning of venturi nozzle improved golden cone filter. Chin. J. Environ. Eng. 2022, 16, 220–229. (In Chinese) [Google Scholar]

- Li, J.; Wang, P.; Wu, D.; Chen, D. Numerical study of opposing pulsed-jet cleaning for pleated filter cartridges. Sep. Purif. Technol. 2020, 234, 116086. [Google Scholar] [CrossRef]

- Li, J.; Li, S.; Zhou, F. Effect of cone installation in a pleated filter cartridge during pulse-jet cleaning. Powder Technol. 2015, 284, 245–252. [Google Scholar] [CrossRef]

- Li, J.; Wu, D.; Wu, Q.; Luo, M.; Li, J. Design and performance evaluation of novel colliding pulse jet for dust filter cleaning. Sep. Purif. Technol. 2019, 213, 101–113. [Google Scholar] [CrossRef]

- Li, J.; Zhao, Y.; Sun, Z.; Wu, Q.; Zhong, Y.; Wu, Q.; Ma, Z.; Wu, D. Numerical simulation of improved pulse jet performance by annular slit nozzle for the filter cartridge with an inner cone deflector. J. Nanchang Univ. (Eng. Technol.) 2023, 45, 9–15. (In Chinese) [Google Scholar]

- Li, J.; Zhou, F.; Li, S. Experimental study on the dust filtration performance with participation of water mist. Process Saf. Environ. 2017, 109, 357–364. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, Z.; Wang, G.; Guo, J.; Lu, W.; Zhao, Y.; Wu, Q.; Li, J. Improved Pulsed-Jet Cleaning of Cone Filter Cartridges Using an Annular-Slit Nozzle. Atmosphere 2023, 14, 1332. https://doi.org/10.3390/atmos14091332

Xing Z, Wang G, Guo J, Lu W, Zhao Y, Wu Q, Li J. Improved Pulsed-Jet Cleaning of Cone Filter Cartridges Using an Annular-Slit Nozzle. Atmosphere. 2023; 14(9):1332. https://doi.org/10.3390/atmos14091332

Chicago/Turabian StyleXing, Zhenqiang, Gang Wang, Jiace Guo, Wenyong Lu, Yi Zhao, Quanquan Wu, and Jianlong Li. 2023. "Improved Pulsed-Jet Cleaning of Cone Filter Cartridges Using an Annular-Slit Nozzle" Atmosphere 14, no. 9: 1332. https://doi.org/10.3390/atmos14091332

APA StyleXing, Z., Wang, G., Guo, J., Lu, W., Zhao, Y., Wu, Q., & Li, J. (2023). Improved Pulsed-Jet Cleaning of Cone Filter Cartridges Using an Annular-Slit Nozzle. Atmosphere, 14(9), 1332. https://doi.org/10.3390/atmos14091332