Particle Counter Design Upgrade for Euro 7

Abstract

:1. Introduction

2. Materials and Methods

2.1. Original Layout

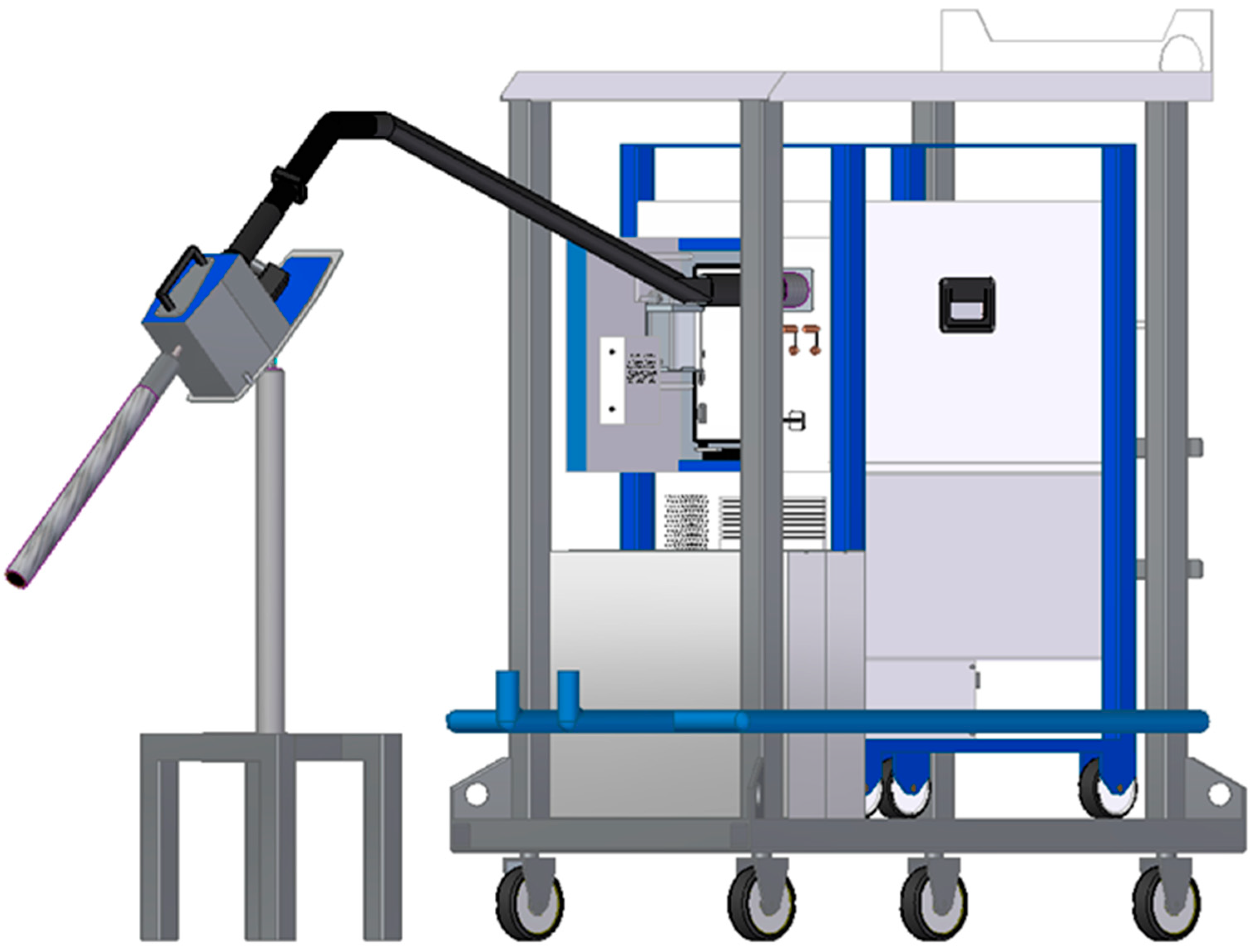

2.2. N-Layout

2.2.1. Condensate Drain Unit

2.2.2. High-Efficiency Particulate Air (HEPA) Filter

2.2.3. Diaphragm Pump

2.2.4. Adjustable Power Supply

2.2.5. External Condensation Particle Counter (CPC)

2.3. Measurement Layout for Verification

3. Results

3.1. Measurement Layout for Verification

3.2. Comparative Test Results

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| APC | AVL Particle Counter |

| EEPS | Engine exhaust particle sizer |

| DMS | Differential mobility spectrometer |

| ELPI | Electrical low-pressure impactor |

| SPN | Solid particle number |

| NMVOC | Non-methane volatile organic compound |

| VOC | Volatile organic compound |

| DPF | Diesel particle filter |

| PM | Particle matter |

| THCs | Total hydrocarbons |

| RDE | Real-driving emissions |

| WHSC | World harmonized stationary cycle |

| CPC | Condensation particle counters |

| CS | Catalytic stripper |

| ET | Evaporation tube |

| PN | Particle number |

| UNECE | United Nations Economic Commission for Europe |

| CVS | Constant volume sampling |

| CoP | Conformity of Production |

| HEPA | High-efficiency particulate air filter |

| GTR | Global technical regulation |

| WHDC | Harmonized heavy-duty certification |

| DOC | Diesel oxidation catalyst |

| EVF | Exhaust volume flow |

| P | Work done by test engine |

| GRPE | Group of Rapporteurs on Pollution and Energy |

| AGES | Aerosol gas exchange system |

References

- Xie, L.-J.; Jiang, J.-C.; Huang, A.-C.; Tang, Y.; Liu, Y.-C.; Zhou, H.-L.; Xing, Z.-X. Calorimetric Evaluation of Thermal Stability of Organic Liquid Hydrogen Storage Materials and Metal Oxide Additives. Energies 2022, 15, 2236. [Google Scholar] [CrossRef]

- Zhang, C.-Z.; Xie, L.-J.; Tang, Y.; Li, Y.; Jiang, J.-C.; Huang, A.-C. Thermal Safety Evaluation of Silane Polymer Compounds as Electrolyte Additives for Silicon-Based Anode Lithium-Ion Batteries. Processes 2022, 10, 1581. [Google Scholar] [CrossRef]

- Berg, W. Legislation for the Reduction of Exhaust Gas Emissions. In Traffic and Environment; Gruden, D., Ed.; Springer: Berlin/Heidelberg, Germany, 2003; Volume 3T, pp. 175–253. ISBN 978-3-540-00050-1. [Google Scholar]

- Giechaskiel, B.; Joshi, A.; Ntziachristos, L.; Dilara, P. European Regulatory Framework and Particulate Matter Emissions of Gasoline Light-Duty Vehicles: A Review. Catalysts 2019, 9, 586. [Google Scholar] [CrossRef]

- European Environment Agency. Air Quality in Europe: 2020 Report; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Valverde, V.; Mora, B.; Clairotte, M.; Pavlovic, J.; Suarez-Bertoa, R.; Giechaskiel, B.; Astorga-Llorens, C.; Fontaras, G. Emission Factors Derived from 13 Euro 6b Light-Duty Vehicles Based on Laboratory and on-Road Measurements. Atmosphere 2019, 10, 243. [Google Scholar] [CrossRef]

- Park, G.; Mun, S.; Hong, H.; Chung, T.; Jung, S.; Kim, S.; Seo, S.; Kim, J.; Lee, J.; Kim, K.; et al. Characterization of Emission Factors Concerning Gasoline, LPG, and Diesel Vehicles via Transient Chassis-Dynamometer Tests. Appl. Sci. 2019, 9, 1573. [Google Scholar] [CrossRef]

- Ro, S.; Park, J.; Shin, M.; Lee, J. Developing on-Road NOx Emission Factors for Euro 6b Light-Duty Diesel Trucks in Korean Driving Conditions. Energies 2021, 14, 1041. [Google Scholar] [CrossRef]

- Crosignani, P.; Nanni, A.; Pepe, N.; Pozzi, C.; Silibello, C.; Poggio, A.; Conte, M. The Effect of Non-Compliance of Diesel Vehicle Emissions with Euro Limits on Mortality in the City of Milan. Atmosphere 2021, 12, 342. [Google Scholar] [CrossRef]

- Mei, H.; Wang, L.; Wang, M.; Zhu, R.; Wang, Y.; Li, Y.; Zhang, R.; Wang, B.; Bao, X. Characterization of Exhaust CO, HC and NOx Emissions from Light-Duty Vehicles under Real Driving Conditions. Atmosphere 2021, 12, 1125. [Google Scholar] [CrossRef]

- Valverde, V.; Giechaskiel, B. Assessment of Gaseous and Particulate Emissions of a Euro 6d-Temp Diesel Vehicle Driven >1300 km Including Six Diesel Particulate Filter Regenerations. Atmosphere 2020, 11, 645. [Google Scholar] [CrossRef]

- Morales, V.V.; Clairotte, M.; Pavlovic, J.; Giechaskiel, B.; Bonnel, P. On-Road Emissions of Euro 6d-TEMP Vehicles: Consequences of the Entry into Force of the RDE Regulation in Europe; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- European Comission. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_22_6495 (accessed on 2 December 2022).

- Biró, N.; Kiss, P. Euro VI-d Compliant Diesel Engine’s Sub-23 nm Particle Emission. Sensors 2023, 23, 590. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Mamakos, A.; Andersson, J.; Dilara, P.; Martini, G.; Schindler, W.; Bergmann, A. Measurement of Automotive Nonvolatile Particle Number Emissions within the European Legislative Framework: A Review. Aerosol Sci. Technol. 2012, 46, 719–749. [Google Scholar] [CrossRef]

- EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32016R1628&from=HR (accessed on 27 August 2023).

- Giechaskiel, B.; Schwelberger, M.; Delacroix, C.; Marchetti, M.; Feijen, M.; Prieger, K.; Andersson, S.; Karlsson, H. Experimental assessment of solid particle number Portable Emissions Measurement Systems (PEMS) for heavy-duty vehicles applications. J. Aerosol Sci. 2018, 123, 161–170. [Google Scholar] [CrossRef]

- Wei, Q.; Akard, M.; Asano, I.; Rahman, M. Penetration, calibration and verification for the solid particle counting system with polydisperse and monodisperse particles. SAE Int. J. Fuels Lubr. 2009, 1, 593–602. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Wang, X.; Horn, H.-G.; Spielvogel, J.; Gerhart, C.; Southgate, J.; Jing, L.; Kasper, M.; Drossinos, Y.; Krasenbrink, A. Calibration of condensation particle counters for legislated vehicle number. Emission measurements. Aerosol Sci. Technol. 2009, 43, 1164–1173. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Bergman, A. Validation of 14 used, re-calibrated and new TSI 3790 condensation particle counters according to the UN-ECE Regulation 83. J. Aerosol Sci. 2011, 42, 195–203. [Google Scholar] [CrossRef]

- Kangasluoma, J.; Attoui, M. Review of sub-3 nm condensation particle counters, calibrations, and cluster generation methods. Aerosol Sci. Technol. 2019, 53, 1277–1310. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Melas, A. Comparison of Particle Sizers and Counters with Soot-like, Salt, and Silver Particles. Atmosphere 2022, 13, 1675. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Mamakos, A.; Woodburn, J.; Szczotka, A.; Bielaczyc, P. Evaluation of a 10 nm Particle Number Portable Emissions Measurement System (PEMS). Sensors 2019, 19, 5531. [Google Scholar] [CrossRef] [PubMed]

- Amanatidis, S.; Ntziachristos, L.; Giechaskiel, B.; Katsaounis, D.; Samaras, Z.; Bergmann, A. Evaluation of an oxidation catalyst (“catalytic stripper”) in eliminating volatile material from combustion aerosol. J. Aerosol Sci. 2013, 57, 130–145. [Google Scholar] [CrossRef]

- UNECE. Available online: https://unece.org/sites/default/files/2021-12/GRPE-85-28e.pdf (accessed on 6 August 2023).

- Khan, M.Y.; Sharma, S.; Liew, C.M.; Joshi, A.; Barnes, D.; Scott, N.; Mensen, B.; Cao, T.; Li, Y.; Shimpi, S.A.; et al. Comparison of Full Flow Dilution, Partial Flow Dilution, and Raw Exhaust Particle Number Measurements. Emiss. Control Sci. Technol. 2018, 4, 103–112. [Google Scholar] [CrossRef]

- Biró, N.; Kiss, P. Emission Quantification for Sustainable Heavy-Duty Transportation. Sustainability 2023, 15, 7483. [Google Scholar] [CrossRef]

- Pamminger, M.; Wang, B.; Hall, C.M.; Vojtech, R.; Wallner, T. The impact of water injection and exhaust gas recirculation on combustion and emissions in a heavyduty compression ignition engine operated on diesel and gasoline. Int. J. Engine Res. 2020, 21, 1555–1573. [Google Scholar] [CrossRef]

- Harrison, R.M.; MacKenzie, A.R.; Xu, H.; Alam, M.S.; Nikolova, I.; Zhong, J.; Singh, A.; Zeraati-Rezaei, S.; Stark, C.; Beddows, D.; et al. Diesel exhaust nanoparticles and their behaviour in the atmosphere. Proc. R. Soc. A Math. Phys. Eng. Sci. 2018, 474, 20180492. [Google Scholar] [CrossRef] [PubMed]

- Bourrous, S.; Bouilloux, L.; Ouf, F.X.; Lemaitre, P.; Nerisson, P.; Thomas, D.; Appert-Collin, J.C. Measurement and modeling of pressure drop of HEPA filters clogged with ultrafine particles. Powder Technol. 2016, 289, 109–117. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Melas, A.D.; Lähde, T.; Martini, G. Non-Volatile Particle Number Emission Measurements with Catalytic Strippers: A Review. Vehicles 2020, 2, 342–364. [Google Scholar] [CrossRef]

- Kandlhofer, C.; (AVL List GmbH Headquarters, Graz, Austria). Particle Number 10 vs. 23 nm Cut Off Comparison: Influence of Catalytic Stripper. Personal communication, 2020. [Google Scholar]

- UNECE. Amendment 4 to UN GTR No. 4. Available online: https://unece.org/transport/documents/2021/09/standards/amendment-4-un-gtr-no-4 (accessed on 7 August 2023).

- UNECE. Working Party on Pollution and Energy—Introduction. Available online: https://unece.org/transport/vehicle-regulations/working-party-pollution-and-energy-introduction (accessed on 6 August 2023).

- Peng, Y.; Nix, A.; Li, H.; Johnson, D.; Heltzel, R. Derivation of a Representative Engine Duty Cycle from on-Road Heavy-Duty Vehicle Driving Data. J. Transp. Technol. 2017, 7, 376–389. [Google Scholar] [CrossRef]

- Dieselnet. Available online: https://dieselnet.com/standards/cycles/whsc.php (accessed on 5 August 2023).

- EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32007R0715 (accessed on 8 August 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biró, N.; Szőllősi, D.; Kiss, P. Particle Counter Design Upgrade for Euro 7. Atmosphere 2023, 14, 1411. https://doi.org/10.3390/atmos14091411

Biró N, Szőllősi D, Kiss P. Particle Counter Design Upgrade for Euro 7. Atmosphere. 2023; 14(9):1411. https://doi.org/10.3390/atmos14091411

Chicago/Turabian StyleBiró, Norbert, Dániel Szőllősi, and Péter Kiss. 2023. "Particle Counter Design Upgrade for Euro 7" Atmosphere 14, no. 9: 1411. https://doi.org/10.3390/atmos14091411

APA StyleBiró, N., Szőllősi, D., & Kiss, P. (2023). Particle Counter Design Upgrade for Euro 7. Atmosphere, 14(9), 1411. https://doi.org/10.3390/atmos14091411