Factors That Limit the Adoption of Biofloc Technology in Aquaculture Production in Mexico

Abstract

:1. Introduction

1.1. Biofloc Technology: Origins

1.2. Biofloc Technology: Definitions

2. Materials and Methods

2.1. Study Region: Mexico

2.2. Data Collection

3. Results

3.1. General Features

3.2. Socioeconomic Information

3.3. Production Information

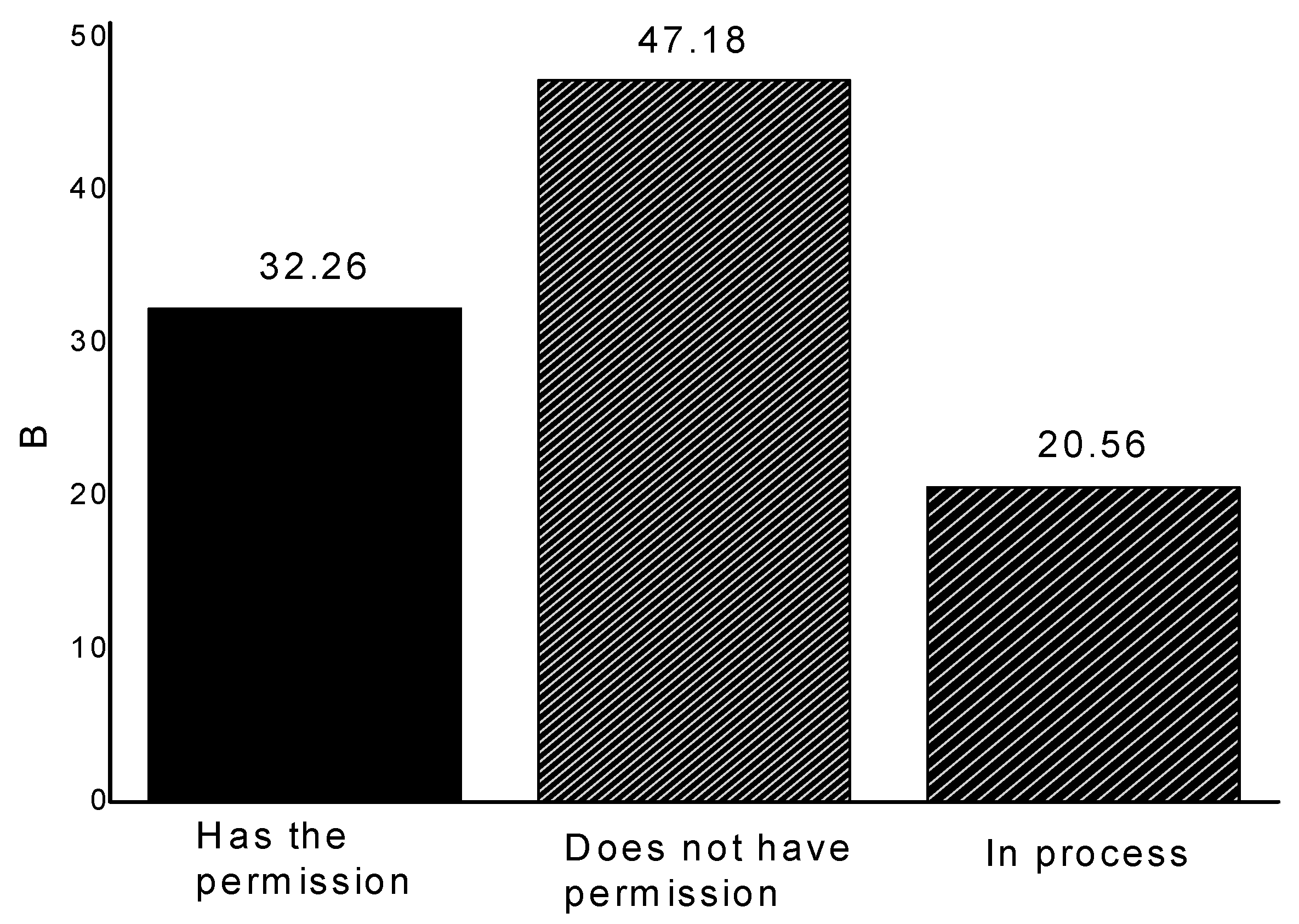

3.4. Regulatory Aspects

3.5. Technological Information and System Management

3.6. Marketing

3.7. Training, Organization, and Production Support

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- DOF. Diario Oficial de la Federación. Ley General de Pesca y Acuacultura Sustentable. Cámara de Diputados del H. Congreso de la Unión. México. 2015. Available online: https://www.gob.mx/cms/uploads/attachment/file/103535/Ley_General_de_Pesca_y_Acuacultura_Sustentables_DOF-04-06-2015.pdf (accessed on 15 August 2020).

- Arnason, R.; Kobayashi, M.; de Fontaubert, C. The Sunken Billions Revisit: Progress and Challenges in Global Marine Fisheries; Banco Mundial: Washington, DC, USA, 2017. [Google Scholar] [CrossRef]

- SAGARPA (Secretaría de Agricultura, Ganadería, Desarrollo Rural, Pesca y Alimentación). Anuario Estadístico de Acuacultura y Pesca; SAGARPA: Mexico City, Mexico, 2013.

- SAGARPA. Panorama Económico 2008–2018, Unidades Representativas de Producción Acuícola y Pesquera. Resumen Ejecutivo. AGROPROSPECTA, Red Mexicana de Investigación en Política Agroalimentaria 2010, 1–78. Available online: https://www.researchgate.net/profile/Luis_Almendarez_Hernandez/publication/263426318_Camaron_pesca/links/0a85e53acd1cfba6c1000000.pdf (accessed on 1 January 2020).

- FAO. El estado Mundial de la Pesca y la Acuicultura. Contribución a la Seguridad Alimentaria y la Nutrición para Todos 2016, 244. Available online: http://www.fao.org/3/a-i5555s.pdf (accessed on 3 August 2019).

- FAO. Organización de las Naciones Unidas para la Alimentación y la Agricultura. México. National Aquaculture Sector Overview Fact Sheets (2005–2018). In Departamento de Pesca y Acuicultura; Montero Rodríguez, M., Ed.; 2018; Available online: http://www.fao.org/fishery/countrysector/naso_mexico/es (accessed on 3 September 2019).

- FAO. Organización de las Naciones Unidas para la Alimentación y la Agricultura. In El Estado Mundial de la Pesca y la Acuicultura; FAO: Rome, Italy, 2018; Available online: http://www.fao.org/docrep/fao/007/y5600s/y5600s00.pdf (accessed on 25 September 2019).

- SAGARPA (Secretaría de Agricultura, Ganadería, Desarrollo Rural, Pesca y Alimentación). Avanza México Como una Potencia de Producción Acuícola. Comunicado de Prensa 15-04-2017; SAGARPA: Mexico City, Mexico, 2017.

- CONAPESCA (Comisión Nacional de Acuacultura y Pesca). La Acuacultura en México, Retos y Oportunidades. In XII Foro Internacional de Acuicultura (FIACUI); CONAPESCA: Mexico city, Mexico, 2017. Available online: https://fiacui.com/2017 (accessed on 21 September 2019).

- Luo, G.; Gao, Q.; Wang, C.; Liu, W.; Sun, D.; Li, L.; Tan, H. Growth, digestive activity, welfare, and partial cost-effectiveness of genetically improved farmed tilapia (Oreochromis niloticus) cultured in a recirculating aquaculture system and an indoor biofloc system. Aquaculture 2014, 422–423, 1–7. [Google Scholar] [CrossRef]

- Braga, A.; Magalhães, V.; Hanson, T.; Morris, T.C.; Samocha, T.M. The effects of feeding commercial feed formulated for semi-intensive systems on Litopenaeus vannamei production and its profitability in a hyper-intensive biofloc-dominated system. Aquac. Rep. 2016, 3, 172–177. [Google Scholar] [CrossRef] [Green Version]

- Avnimelech, Y. Biofloc Technology: Fifteen Years of Progress. Hatch. Int. 2015, 1. Available online: https://www.hatcheryinternational.com/recirc/biofloc-technology-fifteen-years-of-progress_1-1177 (accessed on 4 October 2020).

- Avnimelech, Y. Biolfocs Tehcnology Practical Guide Book, 3rd ed.; The World Aquaculture Society: Sorrento, LA, USA, 2015. [Google Scholar]

- Avnimelech, Y. Biofloc Technology. A Practical Guide Book, 1st ed.; The World Aquaculture Society: Sorrento, LA, USA, 2009. [Google Scholar]

- Avnimelech, Y. Carbon nitrogen ratio as a control element in aquaculture systems. Aquaculture 1999, 176, 227–235. [Google Scholar] [CrossRef]

- Emerenciano, M.; Gaxiola, G.; Cuzon, G. Biofloc technology (BFT): A review for aquaculture application and animal food industry. In Biomass Now—Cultivation and Utilization; IntechOpen: Rijeka, Croatia, 2013; pp. 301–328. [Google Scholar]

- Gonzalez, E.M.B.; Ruales, C.A.D.; Gutiérrez, L.A. Diversidad del perifiton presente en un sistema de producción de tilapia en biofloc. Rev. Lasallista Investig. 2016, 13, 163–177. [Google Scholar] [CrossRef] [Green Version]

- CEDRSSA (Centro de Estudios para el Desarrollo Rural Sustentable y la Soberanía Alimentaria). El Sector Agropecuario en el PIB. CEDRSSA: Mexico. 2019. Available online: http://www.cedrssa.gob.mx/post_el_-n-sector_agropecuario_en_el_pib-n-_-segundo_trimestre_de_2019-_.htm (accessed on 3 July 2020).

- CONAGUA (Comisión Nacional del Agua). Estadísticas del Agua en México; CONAGUA: Mexico City, Mexico, 2017. Available online: http://sina.conagua.gob.mx/publicaciones/EAM_2017.pdf (accessed on 1 June 2019).

- Zamora, S.; Marín-Muñiz, J.L.; Nakase-Rodríguez, C.; Fernández-Lambert, G.; Sandoval, L. Wastewater treatment by constructed wetland eco-technology: Influence of mineral and plastic materials as filter media and tropical ornamental plants. Water 2019, 11, 2344. [Google Scholar] [CrossRef] [Green Version]

- CONAGUA (Comisión Nacional del Agua. Portal de Transparencia). Concesiones de Descarga de Aguas Residuales; CONAGUA: Mexico City, Mexico, 2018. Available online: https://app.conagua.gob.mx/transparencia/Contenido.aspx?n1=8 (accessed on 13 June 2020).

- Buschmann, H.; Fortt, A. Efectos ambientales de la acuicultura intensiva y alternativas para un desarrollo sustentable. Rev. Ambiente Desarro. 2005, 21, 58–64. [Google Scholar]

- Martínez-Córdova, L.R.; Martínez Porchas, R.; Cortés-Jacinto, E. Camaronicultura mexicana y mundial: ¿actividad sustentable o Industria contaminante? Rev. Int. Contam. Ambient. 2009, 25, 181–196. [Google Scholar]

- Amaro, V.; Martínez, C.; Flores, P.; Sandoval, A.; Rosas, C. Problemática ambiental de la actividad piscícola en el Estado de Hidalgo, México. Ingeniería 2012, 16, 165–174. [Google Scholar]

- Sosa-Villalobos, C.; Castañeda-Chávez, M.; Amaro-Espejo, I.; Galaviz-Villa, I.; Lango-Reynoso, F. Diagnosis of the current state of aquaculture production systems with regard to the environment in Mexico. Lat. Am. J. Aquat. Res. 2016, 44, 193–201. [Google Scholar] [CrossRef]

- Folke, C.; Kautsky, N. Aquaculture with its environment: Prospects for sustainability. Ocean. Coast. Manag. 1992, 17, 5–24. [Google Scholar] [CrossRef]

- Boyd, C.E.; Clay, J.W. Shrimp aquaculture and the environment. Sci. Am. 1998, 278, 58–65. [Google Scholar] [CrossRef]

- Costa-Pierce, B.A. Ecology as the paradigm for the future of aquaculture. In Ecological Aquaculture: The Evolution of the Blue Revolution; Blackwell Science: Hoboken, NJ, USA, 2002. [Google Scholar] [CrossRef]

- Grigorakis, K.; Rigos, G. Aquaculture effects on environmental and public welfare—The case of Mediterranean mariculture. Chemosphere 2011, 85, 899–919. [Google Scholar] [CrossRef] [PubMed]

- Aldecoa, J. Desarrollan Cultivo Hiperintensivo de Camarón. In Agencia Informativa Prensa; CONACYT: Mexico City, Mexico, 2017. Available online: www.conacytprensa.mx/index.php/tecnologia/16194-cultivo-hiperintensivo-camar (accessed on 12 August 2019).

- Molnar, N.; Marchand, C.; Deborde, J.; Patrona, L.D.; Meziane, T. Seasonal pattern of the biogeochemical properties of mangrove sediments receiving shrimp farm effluents (New Caledonia). J. Aquac. Res. Dev. 2014, 5, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Nóbrega, G.N.; Otero, X.L.; Macías, F.; Ferreira, T.O. Phosphorus geochemistry in a Brazilian semiarid mangrove soil affected by shrimp farm effluents. Environ. Monitor. Assess. 2014, 186, 5749–5762. [Google Scholar] [CrossRef] [PubMed]

- Suárez-Abelenda, M.; Ferreira, T.O.; Camps-Arbestain, M.; Rivera-Monroy, V.H.; Macías, F.; Nuto Nóbrega, G.; Otero, X.L. The effect of nutrient-rich effluents from shrimp farming on mangrove soil carbon storage and geochemistry under semi-arid climate conditions in northern Brazil. Geoderma 2014, 213, 551–559. [Google Scholar] [CrossRef]

- Edwards, P. Aquaculture environment interactions: Past, present and likely future trends. Aquaculture 2015, 447, 2–14. [Google Scholar] [CrossRef]

- Sandoval-Herazo, M.; Nani, G.; Sandoval, L.; Rivera, S.; Fernández-Lambert, G.; Alvarado-Lassman, A. Evaluation of the performance of vertical partially saturated constructed wetlands for sewage treatment swine. Trop Subtrop. Agroecosyst. 2020, 23, 3138. [Google Scholar]

- Sandoval, H.L.C.; Zurita, F.; Del Ángel-Coronel, O.A.; Adame-García, J.; Marín-Muñiz, J.L. Influence of a new ornamental species (Spathiphyllum blandum) on the removal of COD, nitrogen, phosphorus and fecal coliforms: A mesocosm wetland study with PET and tezontle substrates. Water Sci. Technol. 2020, 81, 961–970. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiménez-Sáenz, A.J. Sistemas de Recirculación para la Acuicultura: Una Visión y Retos Diversos para Latinoamérica. 2007, pp. 1–5. Available online: http://www.industriaacuicola.com/PDFs/Sistemas_de_recirculacion.pdf (accessed on 15 November 2019).

- Duran, P.C.E. Gasto Hídrico en la Producción de Tilapia Roja en la Granja Experimental de la Universidad Francisco de Paula Santander OcañA; Universidad Francisco de Paula: Santander, Spain, 2012. [Google Scholar]

- De Silva, S.S.; Anderson, T.A. Fish Nutrition in Aquaculture; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1994; Volume 1. [Google Scholar]

- Naylor, R.L.; Goldburg, R.J.; Primavera, J.H.; Kautsky, N.; Beveridge, M.C.; Clay, J.; Folke, C.; Lubchenco, J.; Mooney, H.; Troell, M. Effect of aquaculture on world fish supplies. Nature 2000, 405, 1017–1024. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- CONACYT (Consejo Nacional de Ciencia y Tecnología). Baja California en la Perspectiva Global de la Acuicultura; CONACYT: Mexico City, Mexico, 2016. Available online: http://www.conacytprensa.mx/index.php/ciencia/ambiente/5106-baja-california-acuacultura-perspectiva-global (accessed on 5 August 2019).

- Beveridge, M.C. Cage Aquaculture; John Wiley & Sons: Hoboken, NJ, USA, 2008; Volume 5. [Google Scholar]

- Betanzo-Torres, E.A.; Marín-Muñiz, J.L.; Piñar-Álvarez, M.A.; Celdrán-Sabater, D.; Mata-Alejandro, H. Desarrollo de la acuacultura con tecnología biofloc para producción de tilapia (Oreochromis niloticus) en regiones rurales de México. Rinderesu 2019, 4, 42–58. [Google Scholar]

- Ekasari, J.; Suprayudi, M.A.; Wiyoto, W.; Hazanah, R.F.; Lenggara, G.S.; Sulistiani, R.; Zairin, M., Jr. Biofloc technology application in African catfish fingerling production: The effects on the reproductive performance of broodstock and the quality of eggs and larvae. Aquaculture 2016, 464, 349–356. [Google Scholar] [CrossRef]

- Pérez-Fuentes, J.A.; Pérez-Rostro, C.I.; Hernández-Vergara, M.P. Pond-reared Malaysian prawn Macrobrachium rosenbergii with the biofloc system. Aquaculture 2013, 400, 105–110. [Google Scholar] [CrossRef]

- Bostock, J.; McAndrew, B.; Richards, R.; Jauncey, K.; Telfer, T.; Lorenzen, K.; Little, D.; Ross, L.; Handisyde, N.; Gatward, I.; et al. Aquaculture: Global status and trends. Philos. Trans. R. Soc. B Biol. Sci. 2010, 365, 2897–2912. [Google Scholar] [CrossRef]

- Burford, M.A.; Thompson, P.J.; McIntosh, R.P.; Bauman, R.H.; Pearson, D.C. Nutrient and microbial dynamics in high-intensity, zero-exchange shrimp ponds in Belize. Aquaculture 2003, 219, 393–411. [Google Scholar] [CrossRef] [Green Version]

- Boyd, C.E.; Tucker, C.S. Pond Aquaculture Water Quality Management; Springer Science Business Media: New York, NY, USA, 1998. [Google Scholar] [CrossRef]

- McNeil, R. ZEAH, Zero exchange, aerobic, heterotrophic system: Key considerations. Glob. Aquac. Advocate 2000, 3, 72–76. [Google Scholar]

- Wasielesky, W.; Atwood, H.; Stokes, A.; Browdy, C.L. Effect of natural production in a zero exchange suspended microbial floc based super-intensive culture system for white shrimp Litopenaeus vannamei. Aquaculture 2006, 258, 396–403. [Google Scholar] [CrossRef]

- Luo, G.Z.; Avnimelech, Y.; Pan, Y.F.; Tan, H.X. Inorganic nitrogen dynamics in sequencing batch reactors using biofloc technology to treat aquaculture sludge. Aquac. Eng. 2013, 52, 73–79. [Google Scholar] [CrossRef]

- Ahmad, I.; Rani, A.B.; Verma, A.K.; Maqsood, M. Biofloc technology: An emerging avenue in aquatic animal healthcare and nutrition. Aquac. Int. 2017, 25, 1215–1226. [Google Scholar] [CrossRef] [Green Version]

- Avnimelech, Y. Tilapia production using biofloc technology (BFT). In Proceedings of the 9th International Symposium on Tilapia in Aquaculture, Shanghai, China, 21–24 April 2011; pp. 362–366. [Google Scholar]

- Collazos-Lasso, L.F.; Arias-Castellanos, J.A. Fundamentos de la tecnología biofloc (BFT). Una alternativa para la piscicultura en Colombia. Revisión Orinoquia 2015, 19, 77–86. [Google Scholar] [CrossRef]

- Hari, B.; Kurup, M.B.; Varghese, J.T.; Sharma, J.W.; Verdegem, M.C.J. Effects of carbohydrate addition on production in extensive shrimp culture systems. Aquaculture 2004, 241, 179–194. [Google Scholar] [CrossRef]

- Azim, M.E.; Little, D.C. The Biofloc technology (BFT) in indoor tanks: Water quality, biofloc composition, and growth and welfare of Nile tilapia (Oreochromis niloticus). Aquaculture 2008, 283, 29–35. [Google Scholar] [CrossRef]

- De Schryver, P.; Crab, R.; Defoirdt, T.; Boon, N.; Verstraete, W. The basics of bio-flocs technology: The added value for aquaculture. Aquaculture 2008, 277, 125–137. [Google Scholar] [CrossRef]

- Kubitza, F. Criação de tilápias em a presença de microalgas sobre os detritos orgânicos sistema com bioflocos sem renovação de água. Panor Aquicultura 2011, 21, 1–68. [Google Scholar]

- Monroy-Dosta, M.C.; De Lara-Andrade, R.; Castro-Mejía, J.; Castro-Mejía, G.; Coelho-Emerenciano, M.G. Composición y abundancia de comunidades microbianas asociadas al biofloc en un cultivo de tilapia. Rev. Biol. Mar. Oceanogr. 2013, 48, 511–520. [Google Scholar] [CrossRef] [Green Version]

- Castro-Nieto, L.; Castro-Barrera, T.; De Lara-Andrade, R.; Castro-Mejía, J.; Castro-Mejía, G. Sistemas biofloc: Un avance tecnológico en acuicultura. Rev. Digit. Dep. Hombre Ambiente 2012, 1, 1–6. [Google Scholar]

- Ekasari, J.; Angela, D.; Waluyo, S.H.; Bachtiar, T.; Surawidjaja, E.H.; Bossier, P.; De Schryver, P. The size of biofloc determines the nutritional composition and the nitrogen recovery by aquaculture animals. Aquaculture 2014, 426–427, 105–111. [Google Scholar] [CrossRef]

- Martínez-Córdova, L.R.; Martínez-Porchas, M.; Córdova, L.R.M.; López, J.A.E.; Campaña, A.T.; Miranda, A.B.; Ballester, E.; Porchas Cornejo, M.A. Alimento natural en acuacultura: Una revisión actualizada. Memorias Simp. Int. Nutr. Acuícola 2010, 10, 668–699. [Google Scholar]

- Vivanco Aranda, M.; Martínez Cordero, F.J.; Taddei Bringas, I.C. Análisis de competitividad de cuatro sistema-producto estatales de tilapia en México. Estud. Soc. (Hermosillo Son.) 2010, 18, 165–207. [Google Scholar]

- Ray, A.J.; Seaborn, G.; Leffler, J.W.; Wilde, S.B.; Lawson, A.; Browdy, C.L. Characterization of microbial communities in minimal-exchange, intensive aquaculture systems and the effects of suspended solids management. Aquaculture 2010, 310, 130–138. [Google Scholar] [CrossRef]

- Celdrán-Sabater, D. ¿Qué es la tecnología Biofloc? Divulg. Acuícola 2017, 1–24. Available online: http://divulgacionacuicola.com.mx/revistanoviembre2017/ (accessed on 12 August 2019).

- Hargreaves, J. Biofloc Production Systems for Aquaculture. Sourthern Regional AquaCulture Center. SRAC Publication, 2013, No.4503, 1–12. Available online: https://srac.tamu.edu/index.cfm/event/getFactSheet/whichfactsheet/259/ (accessed on 2 August 2019).

- Wu, L.; Peng, C.; Peng, Y.; Li, L.; Wang, S.; Ma, Y. Effect of wastewater COD/N ratio on aerobic nitrifying sludge granulation and microbial population shift. J. Environ. Sci. 2012, 24, 234–241. [Google Scholar] [CrossRef]

- Hargreaves, J. Photosynthetic suspended-growth systems in aquaculture. Aquac. Eng. 2006, 34, 344–363. [Google Scholar] [CrossRef]

- Avnimelech, Y. Bio-filters: The need for a new comprehensive approach. Aquac. Eng. 2006, 34, 172–178. [Google Scholar] [CrossRef]

- Crab, R.; Defoirdt, T.; Bossier, P.; Verstraete, W. Biofloc technology in aquaculture: Beneficial effects and future challenges. Aquaculture 2012, 356, 351–356. [Google Scholar] [CrossRef]

- Avnimelech, Y. Tilapia Production Using Biofloc Technology: Saving Water, Waste Recycling Improves Economics. Global Aquac. Advocate 2012, 5/6, 66–68. Available online: http://pdf.gaalliance.org/pdf/GAA-Avnimelech-May11.p (accessed on 1 August 2019).

- Widanarni, J.; Ekasari Maryam, S. Evaluation of Biofloc Technology application on water quality and production performance of red tilapia Oreochromis sp. cultured at different stocking densities. Hayati J. Biosci. 2012, 19, 7380. [Google Scholar] [CrossRef] [Green Version]

- Ogello, E.O.; Musa, S.M.; Aura, C.M.; Abwao, J.O.; Munguti, J.M. An appraisal of the feasibility of tilapia production in ponds using Biofloc Technology: A review. Int. J. Aquat. Sci. 2014, 5, 21–39. [Google Scholar]

- Rauniyar, G.P.; Goode, F.M. Technology adoption on small farms. World Dev. 1992, 20, 275–282. [Google Scholar] [CrossRef]

- Kumar, G.; Engle, C.; Tucker, C. Factors driving aquaculture technology adoption. J. World Aquac. Soc. 2018, 49, 447–476. [Google Scholar] [CrossRef]

- Jaramillo-Villanueva, J.L.; Morales-Jiménez, J.; Domínguez-Torres, V. Importancia económica del traspatio y su relación con la seguridad alimentaria en comunidades de alta marginación en Puebla, México. Agroproductividad 2017, 10, 27–32. [Google Scholar]

- Amador-del Ángel, L.E.; Wakida-Kusunoki, A.T.; Guevara, E.; Brito, R.; Cabrera-Rodríguez, P. Peces invasores de agua dulce en la región de la Laguna de Términos, Campeche. U. Tecnociencia 2009, 3, 11–28. [Google Scholar]

- Jiménez-Ojeda, Y.K.; Collazos-Lasso, L.F.; Arias-Castellanos, J.A. Dynamics and use of nitrogen in Biofloc Technology-BFT. AACL Bioflux 2018, 11, 1107–1129. [Google Scholar]

- Feder, G.; Just, R.E.; Zilberman, D. Adoption of agricultural innovations in developing countries: A survey. Econ. Dev. Cult. Chang. 1985, 33, 255–298. [Google Scholar] [CrossRef] [Green Version]

- APROMAR. Asociación empresarial de Productores de cultivos Marinos de España. La Acuicultura en España 2014. Available online: http://www.apromar.es/content/publicado-el-informe-la-acuicultura-en-españa-2014 (accessed on 1 November 2019).

- Cifuentes-Lemus, J.L.; Cupul-Magaña, F.G.; Germán, F. Un vistazo a la historia de la pesca en México. Administración, legislación y esfuerzos para su investigación. Cienc. Ergo-Sum 2002, 9, 112–118. Available online: https://cienciaergosum.uaemex.mx/article/view/8107. (accessed on 1 January 2020).

- Lango-Reynoso, V.; Reta-Mendiola, J.L.; López, F.G.; Lango-Reynoso, F.; Figueroa-Rodríguez, K.A.; Asiain-Hoyos, A. The Tilapia Agrifood-chain from a Sociopolitical Territorial Approach: A Theoretical Proposal. J. Agric. Sci. 2017, 9. [Google Scholar] [CrossRef] [Green Version]

- Lango-Reynoso, V.; Reta-Mendiola, J.L.; Asiain-Hoyos, A.; Figueroa-Rodríguez, K.A.; Lango-Reynoso, F. “Live Tilapia”: Diversifying Livelihoods for Rural Communities in Mexico. J. Agric. Sci. 2015, 7, 101–112. [Google Scholar] [CrossRef] [Green Version]

- Lango-Reynoso, V. Comercialización de Tilapia Viva: Propuesta de Innovación y Crecimiento Económico en la Cadena Agroalimentaria. Ph.D. Thesis, Colegio de Posgraduados-Campus, Veracruz, Mexico, 2016. [Google Scholar]

- García-Mondragón, D.; Gallego-Alarcón, I.; Espinoza-Ortega, A.; García- Martínez, A.; Arriaga-Jordán, C.M. Desarrollo de la producción de trucha arcoíris (Oncorhynchus mykiss) en el Centro de México. Rev. AquaTIC 2013, 38, 46–56. [Google Scholar]

- García, M.L.; León, B.J.I. La capacidad de absorción del conocimiento y sus dimensiones en Pymes Acuícolas: El caso Sonora, México. Rev. AquaTIC 2015, 43, 14–22. [Google Scholar]

- Barraza-Guardado, H.R.; Martínez-Córdova, L.R.; Enríquez-Ocaña, L.F.; Martínez-Porchas, M.M.; Miranda-Baeza, A.; Porchas-Cornejo, M.A. Effect of shrimp farm effluent on water and sediment quality parameters off the coast of Sonora, México. Cienc. Mar. 2014, 40, 221–235. [Google Scholar] [CrossRef] [Green Version]

- Salas, M.D.R.; Durazo, A.M.; Enrique, J.M.M. La acuicultura y su impacto en la zona costera del golfo de California. Biotecnia 2016, 18, 37–46. [Google Scholar] [CrossRef]

- Palafox, J.P.; Ceja, E.S.; Ramos, E.M.; Zepeda, F.J.R. La etapa de crecimiento lento de la acuicultura en Nayarit: Aspectos económicos y sostenibilidad. Rev. Mex. Desarro. Local 2018, 2, 1–12. [Google Scholar]

- Boyd, C.E. Feed efficiency indicators for responsible aquaculture. Glob. Aquac. Advocate 2005, 5, 73–74. [Google Scholar]

- SNIIM. Sistema Nacional de Información de Mercados. Clasificación de las Tallas de Venta. Secretaria de Economía—Sistema Nacional de Información de Mercados: Mexico. 2018. Available online: http://www.economia-sniim.gob.mx/nuevo/ (accessed on 4 October 2020).

- Ortega, S.C. Veterinary medical education and veterinary involvement in aquatic animal health and aquaculture in Mexico. J. Vet. Med Educ. 2012, 39, 195–199. [Google Scholar] [CrossRef]

- Platas-Rosado, D.E.; Hernández-Arzaba, J.C.; González-Reynoso, L. Importancia económica y social del sector acuícola en México. Agro Product. 2017, 10, 19–24. [Google Scholar]

- Instituto Nacional de Pesca. Acuacultura: Camarón Blanco del Pacífico. Instituto Nacional de Pesca: México. 2020. Available online: https://www.gob.mx/inapesca/acciones-y-programas/acuacultura-camaron-blanco-del-pacifico (accessed on 4 October 2020).

- Ponce-Palafox, J.T.; Romero-Cruz, O.; Castillo-Vargas, S.; Arteaga-Nochebuena, P.; Ulloa-García, M.; González-Sala, R.; Esparza-Leal, H. El desarrollo sostenible de la acuicultura en América Latina. Rev. Electrónica Vet. 2006, 7, 1–16. [Google Scholar]

- Zimmermann, S.; Fitzsimmons, K. Tilapicultura intensiva. Tópicos especiais em piscicultura de agua doce tropical. São Paulo, SP. TecArt 2004, 1, 239–266. [Google Scholar]

- Jover, C.M. Ingeniería de Sistemas Acuícolas. Sistemas de Producción Acuícola en Tierra. Universidad Politécnica de Valencia: Valencia. 2013. Available online: https://www.cfp.upv.es/formacion-permanente/curso/ingenieria-sistemas-acuicolas_31785.html (accessed on 4 October 2020).

- Ferreira, D.S. Aprovechamiento integral de la tilapia: Producción (uso de la tecnología bft) y procesamiento (curtido de piel y harina para consumo humano). In Proceedings of the 12 Foro Internacional de Acuicultura, Guadalajara, Jalisco, Mexico, 27–29 September 2017. [Google Scholar]

- Platas-Rosado, D.E.; Vilaboa-Arróniz, J. La acuacultura mexicana: Potencialidad, retos y áreas de oportunidad. Rev. Mex. Agronegocios 2014, 18, 1065–1071. [Google Scholar]

- Comisión Nacional de Pesca y Acuacultura. Estadística de Producción Pesquera; CONAPESCA: Mexico City, Mexico, 2018. Available online: https://www.conapesca.gob.mx/wb/cona/estadisticas_de_produccion_pesquera (accessed on 25 July 2019).

- CFE. Comisión Federal de Electricidad Tarifa Agrícola Vigente Con Subsidio; Comisión Federal de Electricidad: Mexico City, Mexico, 2018; Available online: https://app.cfe.mx/Aplicaciones/CCFE/Tarifas/TarifasCRECasa/Tarifas/AgricolaNocturna.aspx (accessed on 25 August 2019).

- Vega-Villasante, F.; Cortés-Lara, M.; Zúñiga-Medina, L.M.; Jaime-Ceballos, B.; Galindo-López, J.; Basto-Rosales, M.E.R.; Nolasco-Soria, H. Cultivo de tilapia (Oreochromis niloticus) a pequeña escala ¿alternativa alimentaria para familias rurales y periurbanas de México? Rev. Electrónica Vet. 2010, 11, 1–15. [Google Scholar]

- Wang, M.; Lu, M. Tilapia polyculture: A global review. Aquac. Res. 2016, 47, 2363–2374. [Google Scholar] [CrossRef]

- Meza, E.Z. Crecimiento del robalo y el chucumite en agua dulce en el estado de Veracruz, México/Growth of the snook and chucumite in fresh water in the state of Veracruz, Mexico. CIBA Rev. Iberoam. Ciencias Biológicas Agropecu. 2018, 7, 1–12. [Google Scholar]

- Reyes, S.L.D. Densidades idóneas para sistemas de policultivo de especies comerciales Tilapia Roja (Oreochromis spp.) y Carpa Roja (Ciprynus carpio) en sistemas de confinamiento artesanal en lagos artificiales en Santiago de Cali (Valle del Cauca, Colombia). Idesia 2018, 36, 73–82. [Google Scholar] [CrossRef]

- Hernández-Vergara, M.P.; Cruz-Ordóñez, S.B.; Pérez-Rostro, C.I.; Pérez-Legaspi, I.A. Policultivo del acocil (Procambarus acanthophorus) y tilapia del Nilo (Oreochromis niloticus) como estrategia de uso sustentable del agua. Hidrobiológica 2018, 28, 11–15. [Google Scholar]

- García-Vega, D.; García-Rojas, H.R.G.; Maldonado-Villalpando, E. El Aprovechamiento Irracional del Agua en la Industria Mexicana: Análisis Comparativo de los Principales Sectores Industriales por RHA. 2018. Available online: https://www.researchgate.net/publication/326624060 (accessed on 15 August 2020).

- Aguilar-Siguenza, D.A. Control de buenas prácticas de manejo de los insumos en el cultivo semi intensivo de Litopenaeus vannamei (Tesis de Maestría). Unidad Académica de Ciencias Agropecuarias. Ing. Acuícola: Utmach. Universidad Técnica de Machala, Ecuador 2018, 1, 1–23. Available online: http://repositorio.utmachala.edu.ec/bitstream/48000/12902/1/DE00005_EXAMENCOMPLEXIVO.pdf (accessed on 12 July 2020).

- Perea-Román, C.; Garcés-Caicedo, Y.J.; Muñoz-Arboleda, L.S.; Hoyos-Concha, J.L.; Gómez-Peñaranda, J.A. Valoración económica del uso de ensilaje de residuos piscícolas en la alimentación de Oreochromis spp. Biotecnol. Sect. Agropecu. Agroind. 2018, 16, 43–51. [Google Scholar] [CrossRef]

- Shields, M.L.; Rauniyar, G.P.; Goode, F.M. A longitudinal analysis of factors influencing increased technology adoption in Swaziland, 1985–1991. J. Dev. Areas 1993, 27, 469–484. [Google Scholar]

- Rogers, E.M. Diffusion of Innovations, 4th ed.; Free Press: New York, NY, USA, 1995. [Google Scholar]

- Huerta Mata, J.J. Articulación productiva para la innovación en las pequeñas empresas acuícolas de la región occidente de México. Ágora Usb 2011, 11, 403–422. [Google Scholar]

- Llanes-Cárdenas, O.; Campos, M.N.; Sevilla, P.M.; Guerrero, R.R. Agua subterránea: Alternativa acuícola en el Noroeste de México. Rev. Aquat. 2016, 38, 10–20. [Google Scholar]

- Villamar-Ochoa, C.A. Aguas subterráneas: Acuicultura sustentable y libre de patógenos. Rev. Aquat. 2016, 12, 1–3. Available online: http://revistaaquatic.com/aquatic/html/art1204/subterranea.htm (accessed on 13 July 2019).

- Ghaly, A.E.; Kamal, M.; Mahmoud, N.S. Phytoremediation of aquaculture wastewater for water recycling and production of fish feed. Environ. Int. 2005, 31, 1–13. [Google Scholar] [CrossRef]

- Rangel-López, L.; Lango-Reynoso, F.; Asian-Hoyos, A.; Castañeda-Chávez, M.R. Diagnóstico de la acuacultura en el municipio de Alvarado, Veracruz, México. Ra Ximhai 2014, 10, 75–81. [Google Scholar] [CrossRef]

- Romano, N.; Kumar, V. Vegetarian shrimp: Pellet-free shrimp farming vegetarian shrimp: Pellet-free shrimp farming. World Aquac. Soc. 2017, 12, 36–39. Available online: https://www.researchgate.net/profile/Nicholas_Romano2/publication/321687020_Vegetarian_Shrimp_Pellet-free_Shrimp_Farming/links/5a2b1fafaca2728e05de864c/Vegetarian-Shrimp-Pellet-free-Shrimp-Farming.pdf (accessed on 11 January 2020).

| Category | Quantitative Variables | Qualitative Variables |

|---|---|---|

| General Features | 1. Aquaculture age (EDA) | 2. Federated states surveyed (EFE) 3. Level of Schooling (ESC) |

| Socio-economic Information | 1. Staff attached to the UPA (PAU) | 2. Alternative productive activities (APA) |

| Production | 1. Daily spare rate (TRD) 2. Hours of water pumping (HBA) 3. Production cycle (CPO) 4. Weight organisms at sowing (POS) 5. Sales weight (PEV) 6. Lts of water per kg of product (LKP) 7. Organisms per cubic meter of sowing (OMC) 8. Cost of energy (CEE) 9. Production cost per kilogram (CPK) | 10. Water exchange (RAD) 11. Cultivated species (EPC) 12. Perception of water use (PAU) 13. Use of operation records (URO) 14. Brand of food used (MAU) 15. Physicochemical data on water quality (DFA) |

| Normative | 1. National Register of Fisheries and Aquaculture (RNPA) 2. Federal Taxpayers Registry (RFC) 3. Water concession title (CNA) 4. Water discharge permit (CNA) | |

| Technology and System Management | 1. Experience in aquaculture (EXP) 2. Diameter of discharge pipe (DTS) 3. Number of ponds per unit (NEP) 4. UPAS surface (SUP) | 5. Source of water supply (FAA) 6. Use of discharge water (UAD) 7. Type of culture ponds (TED) 8. Type of aeration system (TSA) 9. Electric power backup systems (SER) |

| Commercialization | 1. Sale price (PRV) | 2. Wholesale sales percentage (VMA) 3. Retail sales percentage (VME) 4. Sales system (SVE) |

| Training | 1. Number of congresses per year (NCA) 2. Cost of technical assistance (CAT) | 3. Technical assistance received (ATR) 4. Knowledge of water technology (CTE) 5. Willingness to learn (DPA) 6. Interest in the efficient use of water (UEA) 7. Sustainability concept (CSU) 8. Results of technical assistance (RAT) |

| Organization and Suppports for Production | 1. Knowledge of associations (CAP) 2. Government and type subsidies (SGT) |

| Quantitative | Qualitative | ||||

|---|---|---|---|---|---|

| (1) EXP | 30.24% | 1 year | (5) FAA | 39.52% | Deep well |

| 33.06% | More than 5 years | 17.34% | River | ||

| 12.90% | Waterhole (Noria) | ||||

| (2) DTD | 40.37% | 4 inches | (6) UAD | 52.02% | No use |

| 23.85% | 2 inches | 22.18% | Agricultural irrigation | ||

| 13.76% | 6 inches | 15.73% | It treats and reuses | ||

| (3) NEP | 33.87% | 6 to 11 ponds | (7) TEC | 40.73% | Circular membranes |

| 28.23% | 1 to 5 ponds | 23.39% | Rustic land | ||

| 12.10% | Floating cages | ||||

| (4) SUP | 47.98% | Less than 1 ha | (8) TSA | 41.48% | Regenerative blower |

| 33.47% | 1 to 5 ha | 27.41% | Pallets | ||

| 21.48% | O2 Air | ||||

| (9) SER | 75.56% | Yes | |||

| Spare Parts Frequency Predominant (76.21%) | Predominant Pumping Hours | Predominant Pipe Diameter | Maximum Flow According to Discharge Diameter | Daily Flow of Water Use of a Mexican UPA | Annual Water Flow of a Mexican UPA |

|---|---|---|---|---|---|

| Once a day | 2 h (26.21%) | 2” (23.85%) | 4 L per second | 28,800 L per day | 10,512 m3 |

| Once a day | 3 h (28.36%) | 4” (40.37%) | 16 L per second | 172,000 L per day | 62,780 m3 |

| Once a day | 4 h (19.35%) | 6” (13.76%) | 36 L per second | 518,400 L per day | 189,216 m3 |

| Annual Discharge of Water from a Mexican UPA | Nutrient Content | Organic Material | Total Nutrients Downloaded per Year | |

|---|---|---|---|---|

| TAN (mg/L) | DQO (mg/L) | DBO (mg/L) | TAN (kg) | |

| 10,512 m3 | 18.3 * | 2760 * | 5510 * | 192.36 |

| 62,780 m3 | 18.3 * | 2760 * | 5510 * | 1148 |

| 189,216 m3 | 18.3 * | 2760 * | 5510 * | 3462 |

| Category | Quantitative | Qualitative | |||

|---|---|---|---|---|---|

| (1) PRV * | 29.63% | Wholesale from 1.62 to 2.02 USD | (2) VMA * | 26.61% | Wholesale |

| 70.37% | Retail 2.52 USD | (3) VME * | 73.39% | Retail | |

| (4) SVE * | 48.80% | Farm Foot | |||

| 21.37% | Local market | ||||

| 9.27% | Dealers | ||||

| Category | Quantitative | Qualitative | ||||

|---|---|---|---|---|---|---|

| Training | (1) NCA (2) CAT | 30.24% 25% 22.58% 45.28% 28.30% | 1 event 3 events 4 events 899.80 to 1,349.71 449.90 to 854.81 | (2) ATR * (3) CTE (4) DPA (5) UEA (6) CSU (7) RAT | 57.26% 37.10% 30.65% 22.58% 93.55% 92.24% 78.63% 31.28% 29.23% ------ 26.06% 35.14% 24.32% 18.92% | Yes RAS Aquaponics Biofloc Yes Yes Yes Be ecological Save natural resources ----- Did not work Not committed He had no experience They did not understand |

| Organization | (1) CAP | 70.97% 47.77% 34.06% | Yes Aquaculture health Product system | |||

| Production Supports | (2) SGT | 56.45% -------- 47.86% 30.00% 12.86% 9.29% -------- 40.11% 59.89% 0% | Yes -------- Electric power Infrastructure Food Genetic material -------- State support Federal support Municipal support | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Betanzo-Torres, E.A.; Piñar-Álvarez, M.d.l.Á.; Sandoval-Herazo, L.C.; Molina-Navarro, A.; Rodríguez-Montoro, I.; González-Moreno, R.H. Factors That Limit the Adoption of Biofloc Technology in Aquaculture Production in Mexico. Water 2020, 12, 2775. https://doi.org/10.3390/w12102775

Betanzo-Torres EA, Piñar-Álvarez MdlÁ, Sandoval-Herazo LC, Molina-Navarro A, Rodríguez-Montoro I, González-Moreno RH. Factors That Limit the Adoption of Biofloc Technology in Aquaculture Production in Mexico. Water. 2020; 12(10):2775. https://doi.org/10.3390/w12102775

Chicago/Turabian StyleBetanzo-Torres, Erick Arturo, María de los Ángeles Piñar-Álvarez, Luis Carlos Sandoval-Herazo, Antonio Molina-Navarro, Isidro Rodríguez-Montoro, and Raymundo Humberto González-Moreno. 2020. "Factors That Limit the Adoption of Biofloc Technology in Aquaculture Production in Mexico" Water 12, no. 10: 2775. https://doi.org/10.3390/w12102775