Performance Study of an Integrated Solar Water Supply System for Isolated Agricultural Areas in Thailand: A Case-Study of the Royal Initiative Project

Abstract

:1. Introduction

2. Government Policy and Decision Making

2.1. Government Policy and the Royal Initiative of His Majesty the King

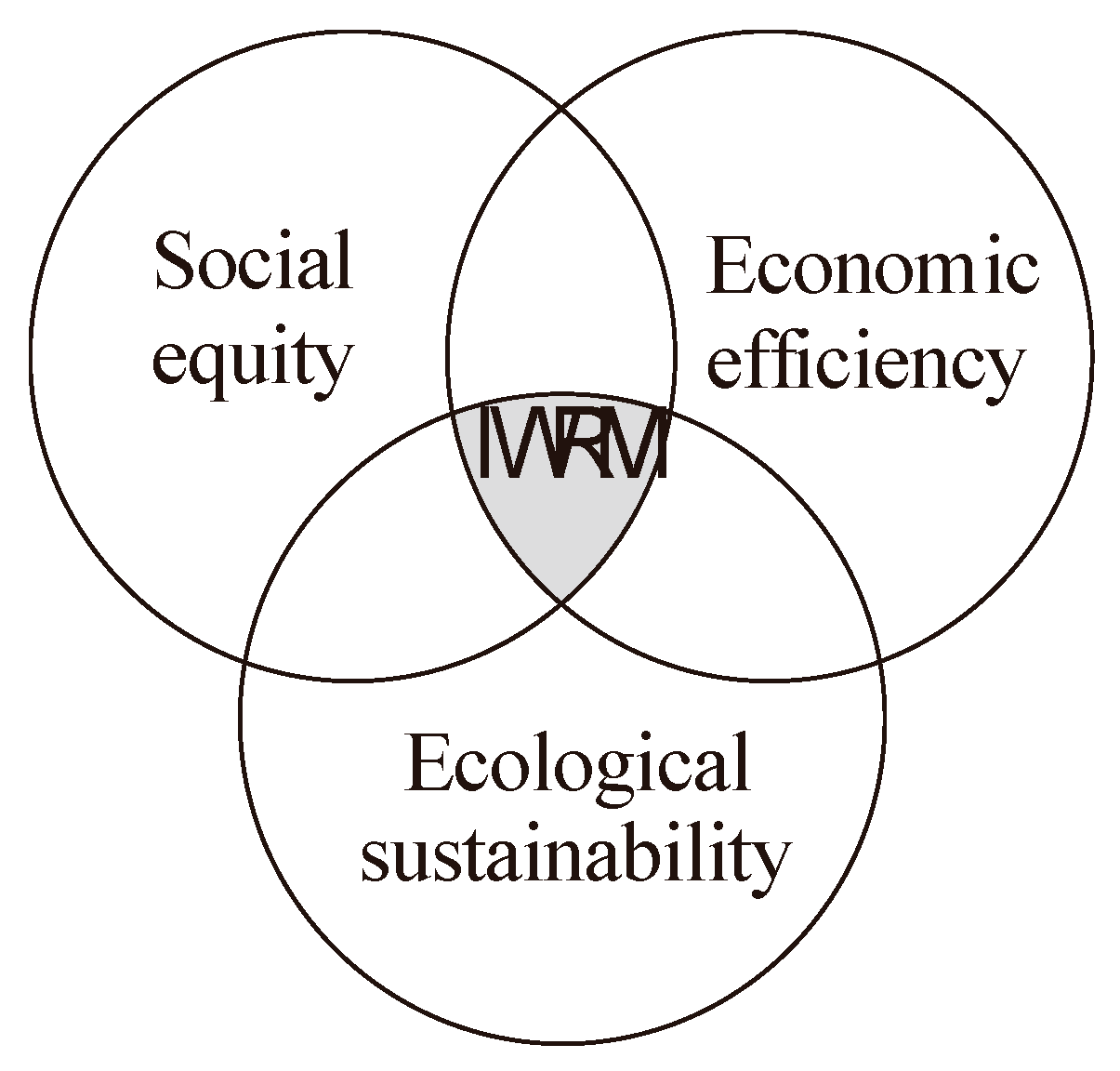

2.2. Decision Making and Integrated Water Management

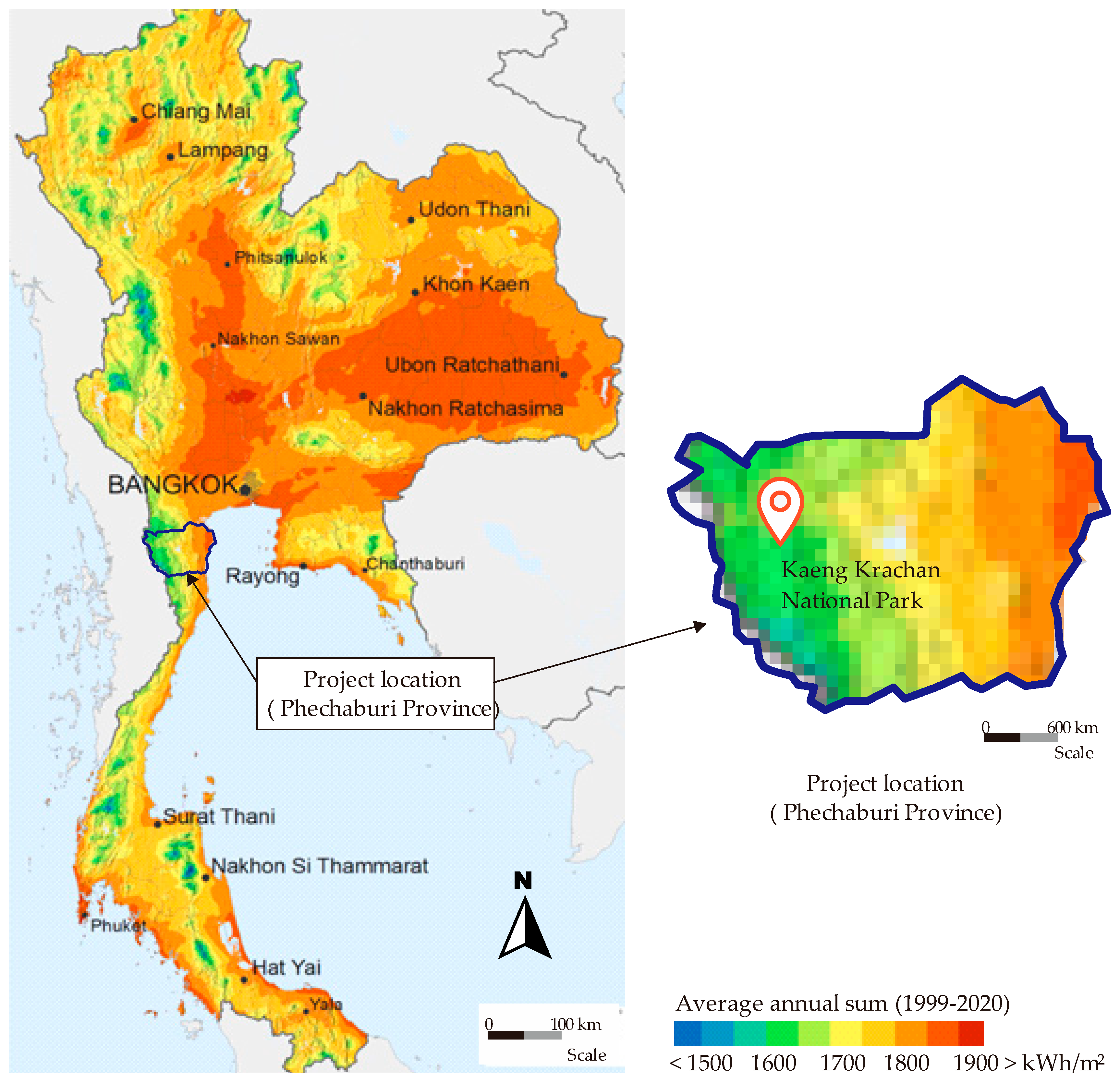

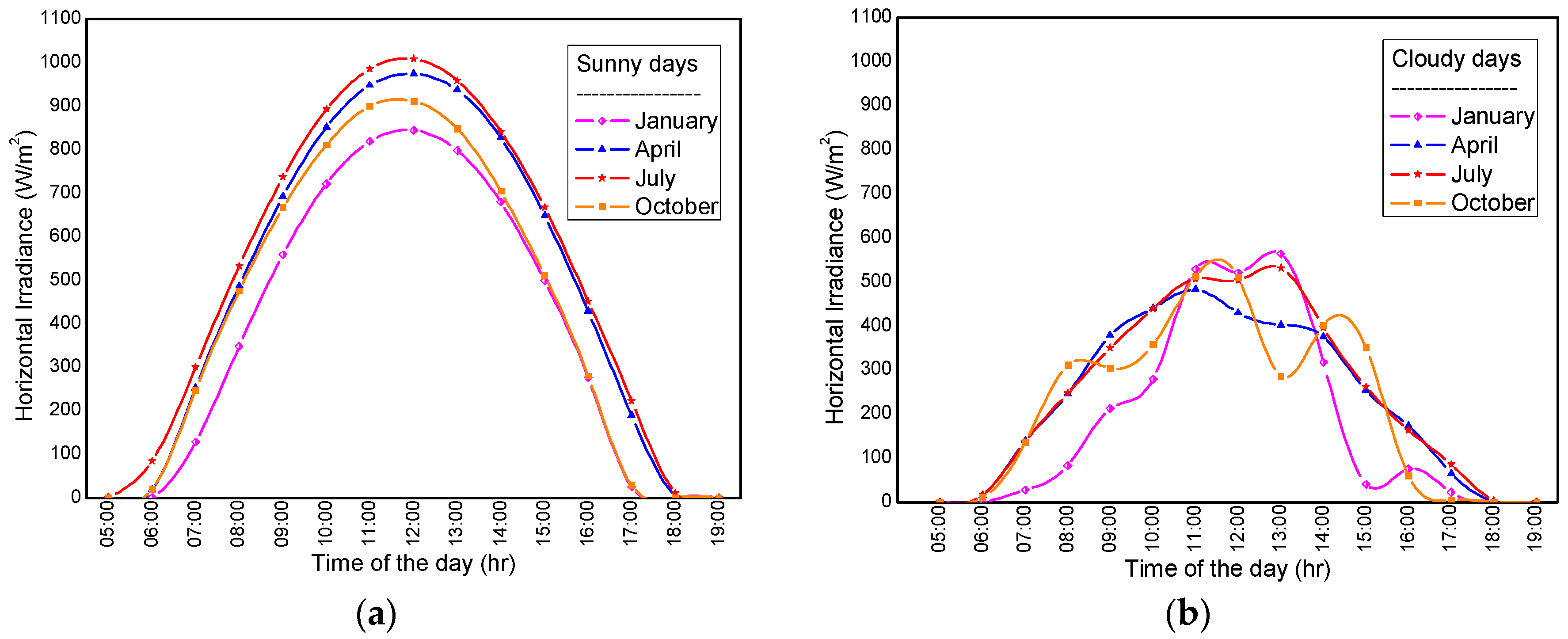

2.3. Horizontal Radiation in Thailand and Tilted Surface Irradiance

3. Project Background

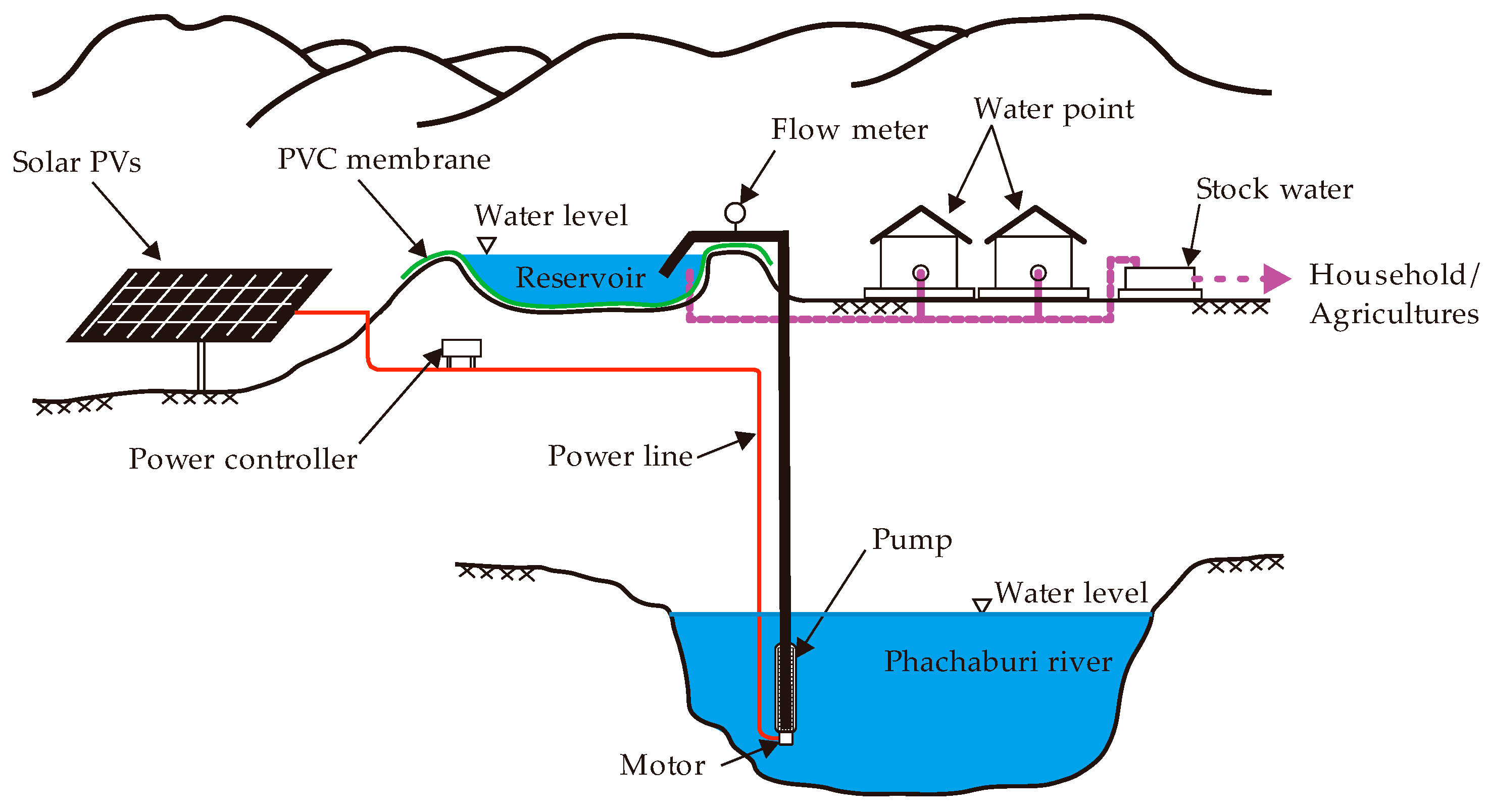

4. Integrated Solar Water Supply System (SWSS) Design

4.1. Design of SWSS for the Project Locations

4.2. Solar PV and Solar Structure Specifications

4.3. Design of the Power Conditioning Unit and Control Station

4.4. Analysis of Water Flow and Design of Piping Alignment

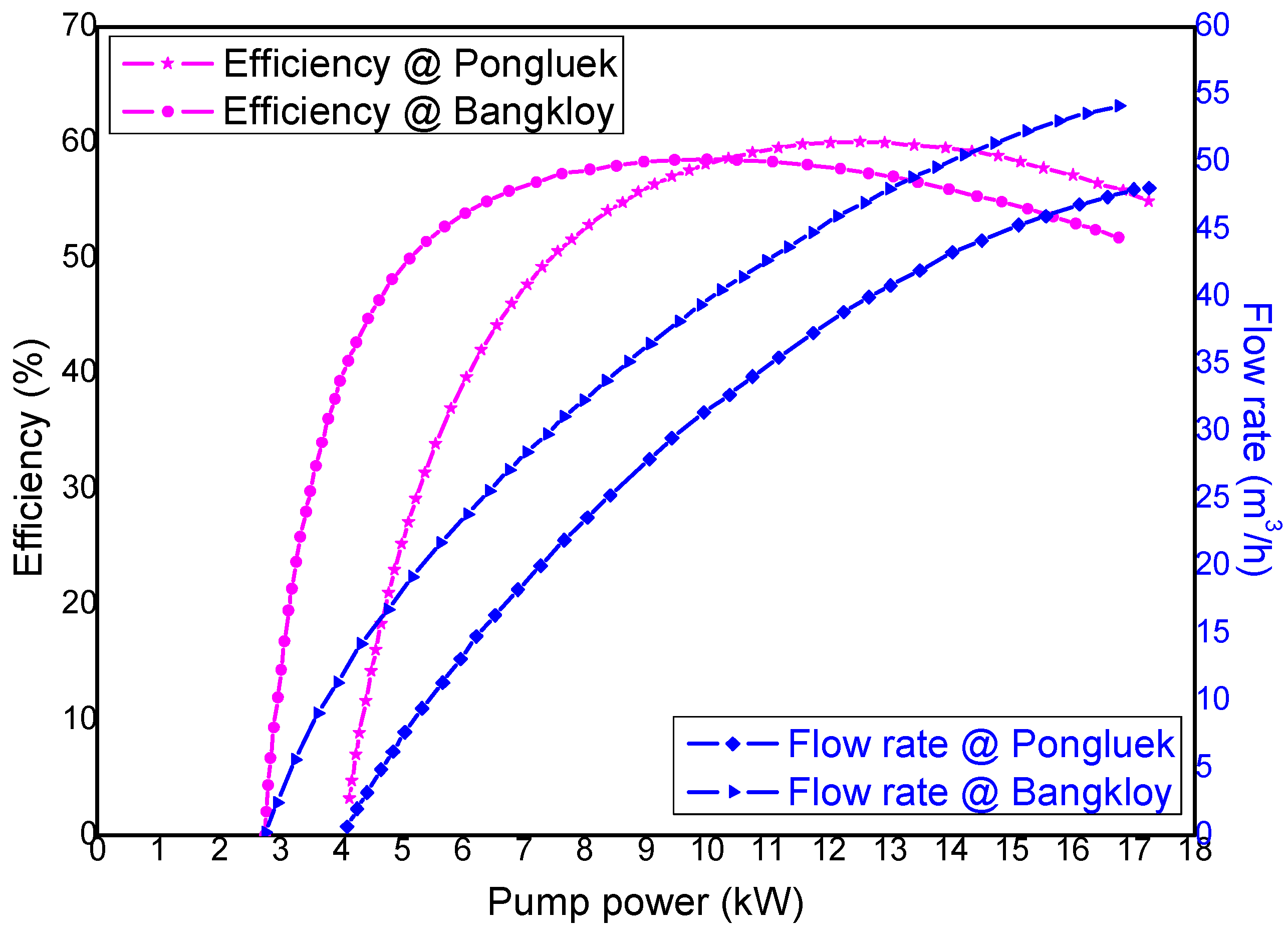

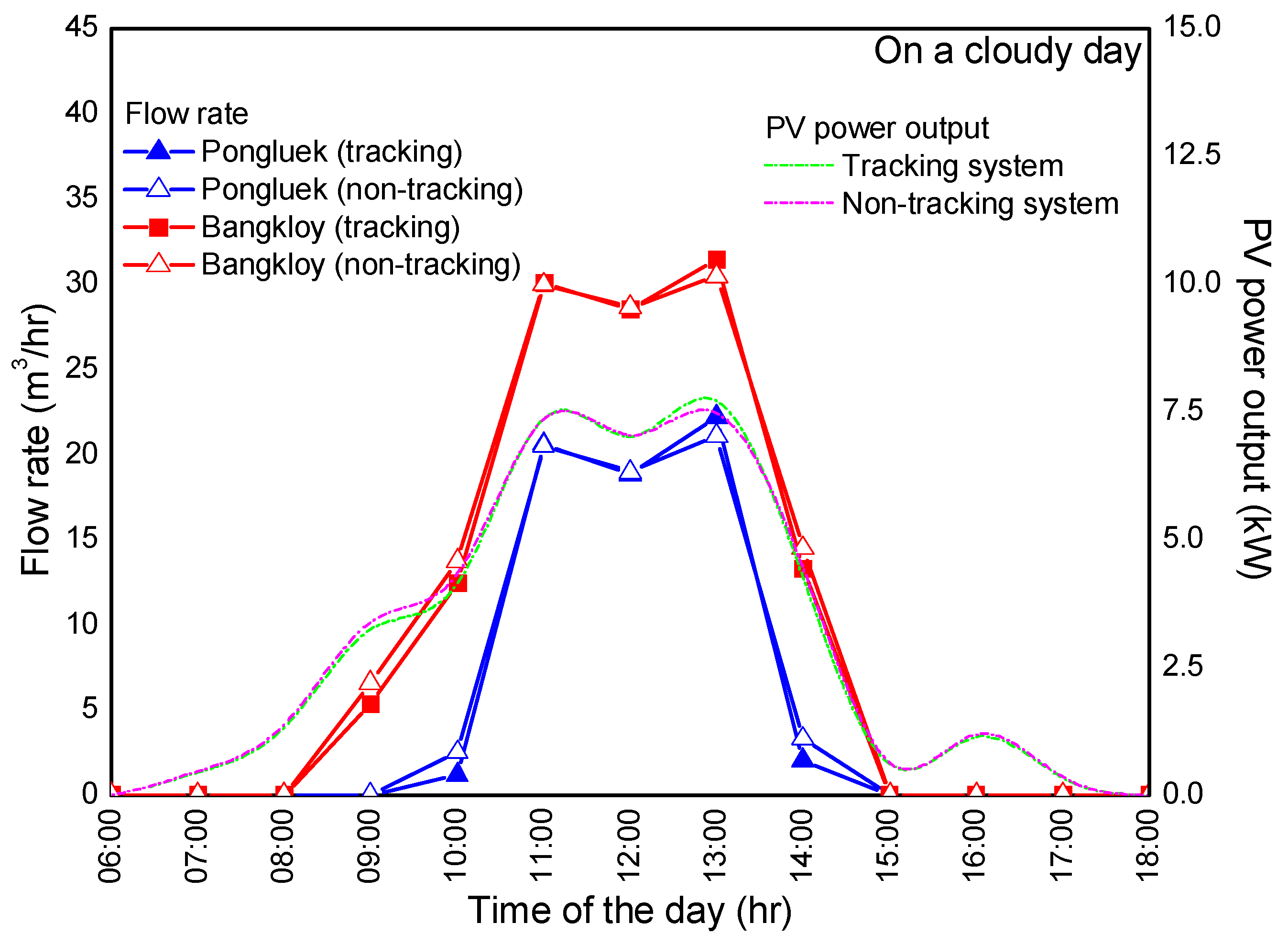

4.5. Pump Performance Corresponding to Intermittent Solar Irradiance

5. Results and Discussion

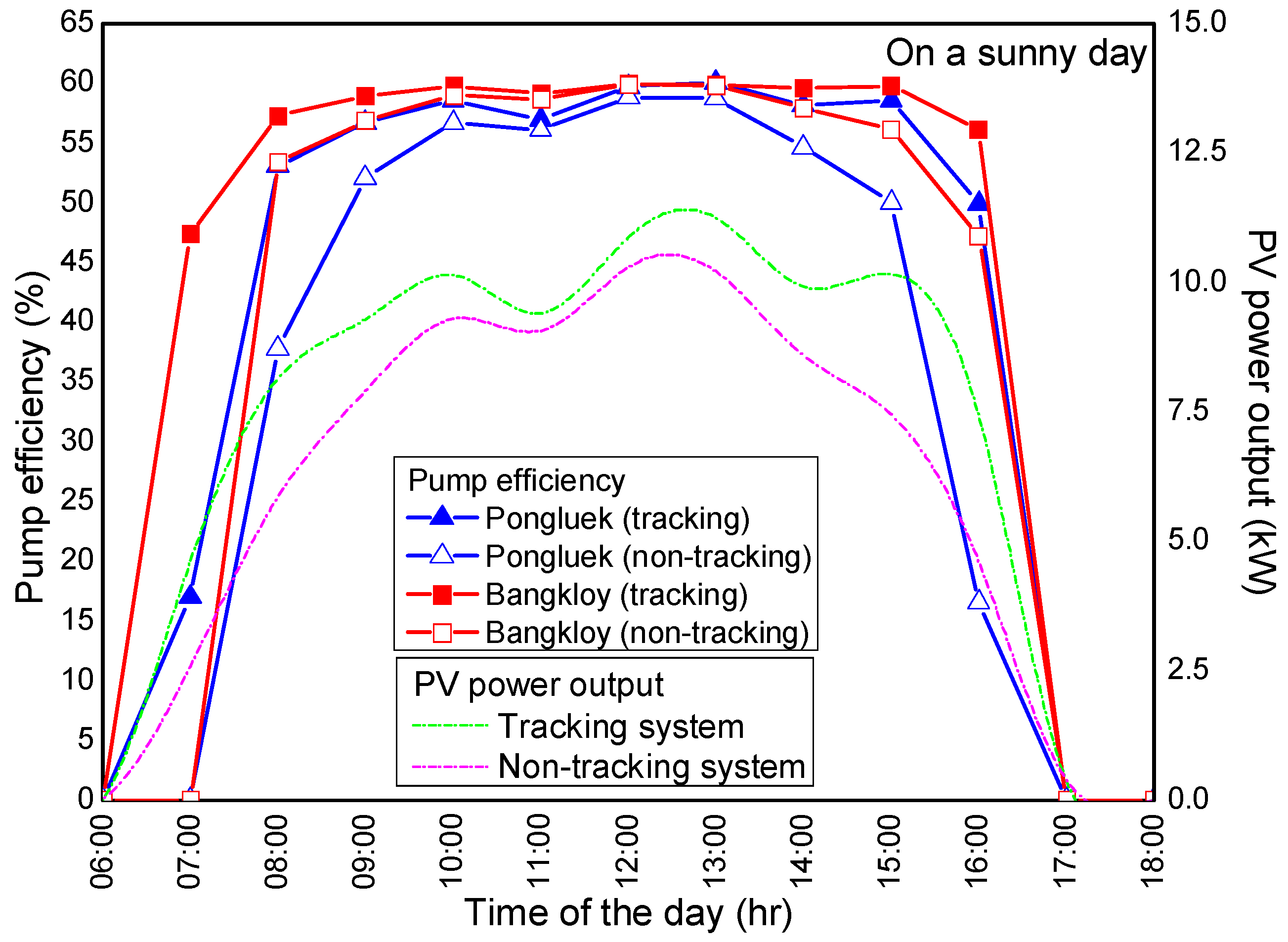

5.1. Manufactured Pump Performance

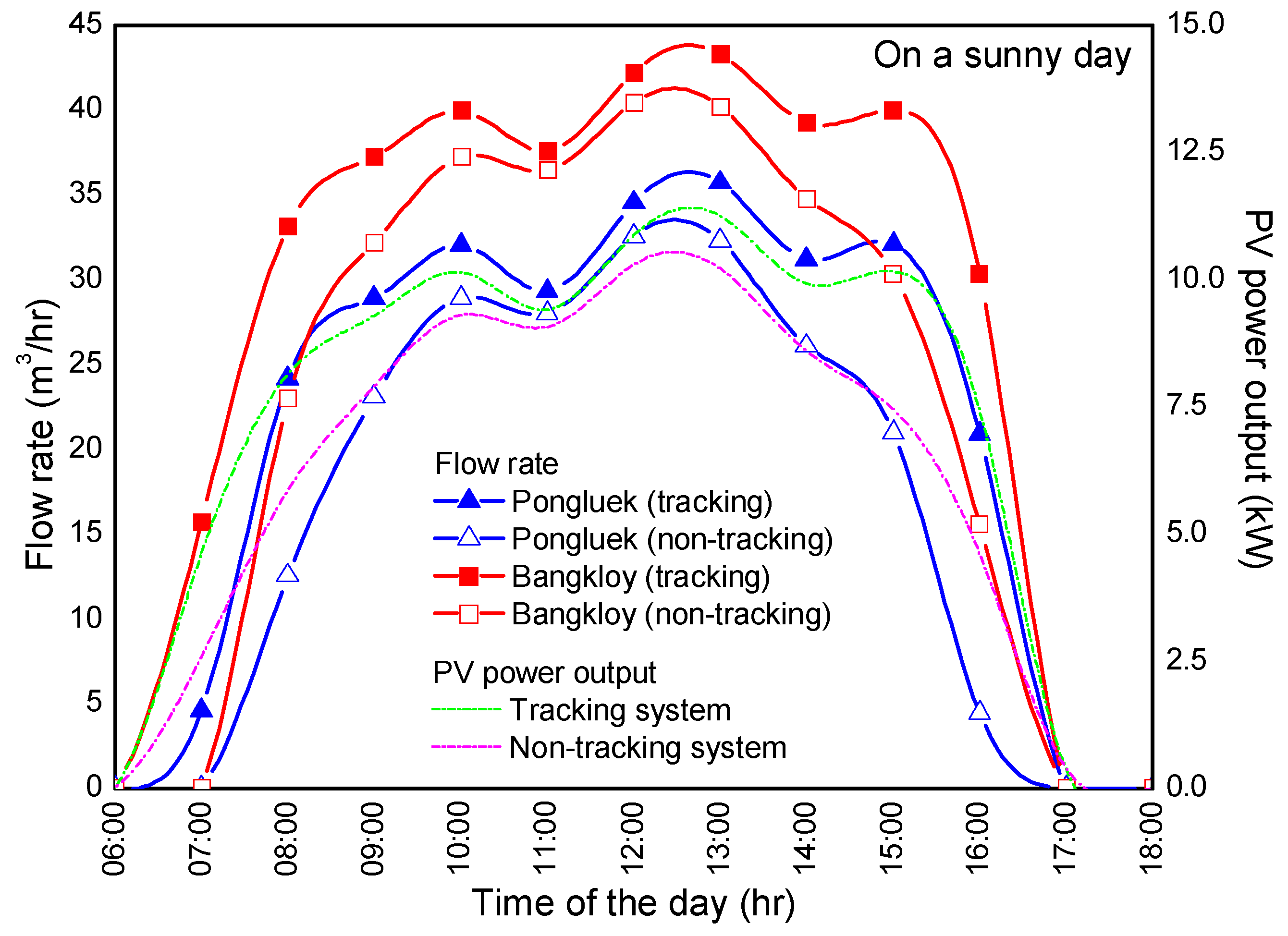

5.2. Electrical Power Output From Non-Tracked and Tracked PV Arrays

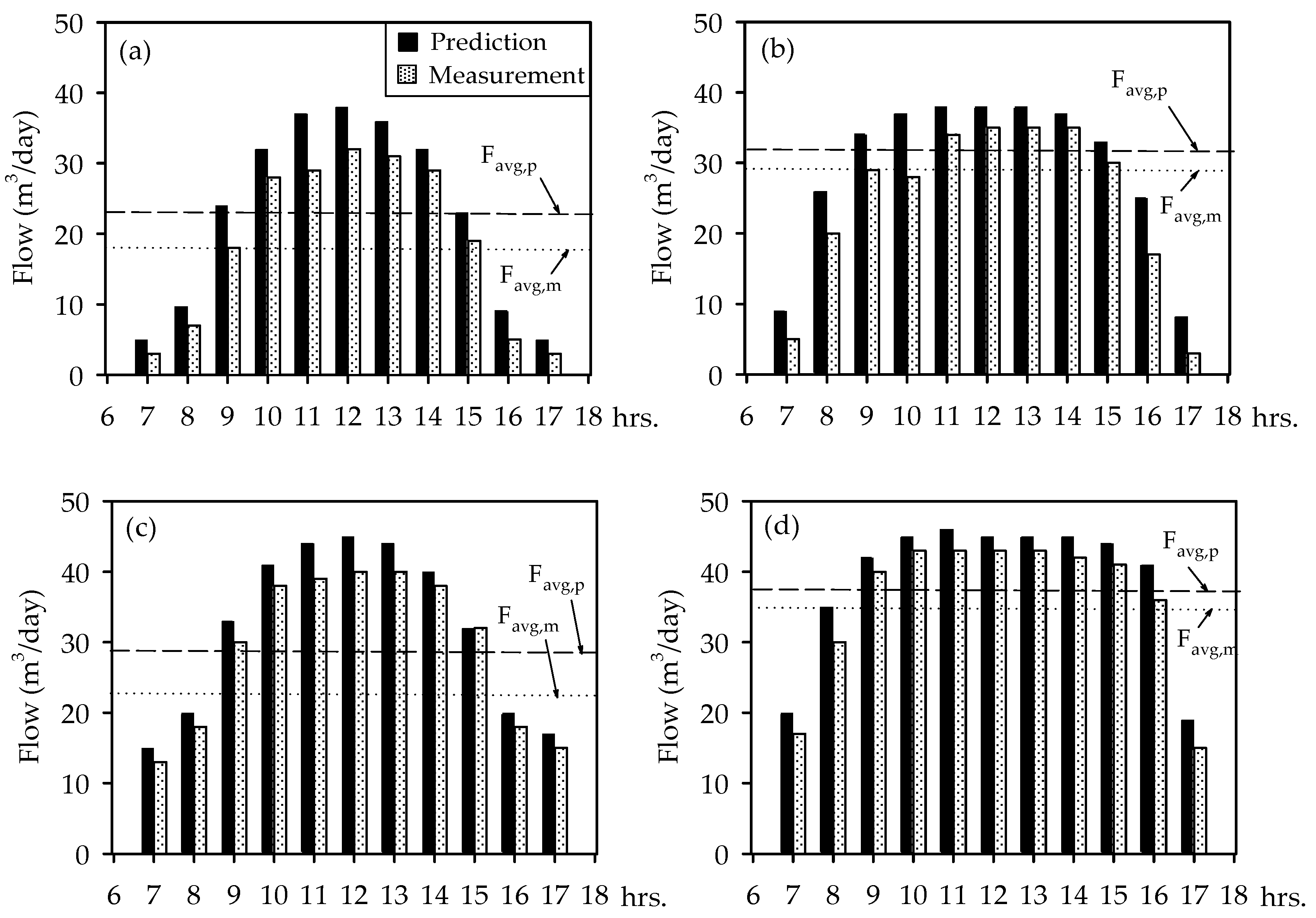

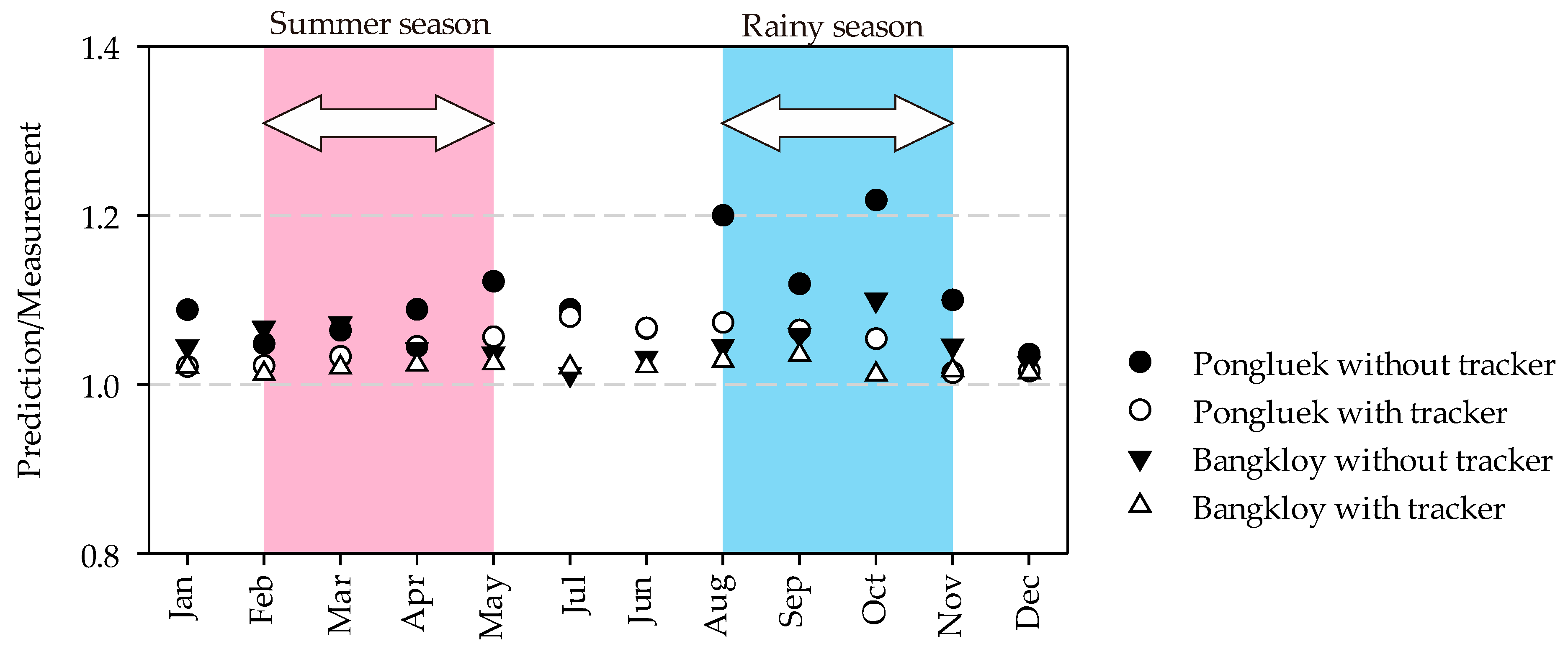

5.3. Prediction of Water Flow vs. Annual Forecast

6. Summary

7. Practical Implications

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Goal 2. Department of Economic and Social Affairs. Available online: https://sdgs.un.org/goals/goal2 (accessed on 29 July 2020).

- Qoaider, L.; Steinbrecht, D. Photovoltaic systems: A cost competitive option to supply energy to off-grid agricultural communities in arid regions. Appl. Energy 2010, 87, 427–435. [Google Scholar] [CrossRef]

- Chandel, S.S.; Naik, M.N.; Chandel, R. Review of solar photovoltaic water pumping system technology for irrigation and community drinking water supplies. Renew. Sustain. Energy Rev. 2015, 49, 1084–1099. [Google Scholar] [CrossRef]

- Meah, K.; Fletcher, S.; Ula, S. Solar photovoltaic water pumping for remote locations. Renew. Sustain. Energy Rev. 2008, 12, 472–487. [Google Scholar] [CrossRef]

- Solarbuzz. Annual World PV Market Review, Solar-Buzz; Solarbuzz: Port Washington, NY, USA, 2011. [Google Scholar]

- Aliyu, M.; Hassan, G.; Said, S.A.; Siddiqui, M.U.; Alawami, A.T.; Elamin, I.M. A review of solar-powered water pumping systems. Renew. Sustain. Energy Rev. 2018, 87, 61–76. [Google Scholar] [CrossRef]

- Li, G.; Jin, Y.; Akram, M.W.; Chen, X. Research and current status of the solar photovoltaic water pumping system—A review. Renew. Sustain. Energy Rev. 2017, 79, 440–458. [Google Scholar] [CrossRef]

- Caton, P. Design of rural photovoltaic water pumping systems and the potential of manual array tracking for a West-African village. Sol. Energy 2014, 103, 288–302. [Google Scholar] [CrossRef]

- Sontake, V.C.; Kalamkar, V.R. Solar photovoltaic water pumping system—A comprehensive review. Renew. Sustain. Energy Rev. 2016, 59, 1038–1067. [Google Scholar] [CrossRef]

- Korpale, V.S.; Kokate, D.H.; Deshmukh, S.P. Performance Assessment of Solar Agricultural Water Pumping System. Energy Procedia 2016, 90, 518–524. [Google Scholar] [CrossRef]

- Benghanem, M.; Daffallah, K.O.; Alamri, S.N.; Joraid, A.A. Effect of pumping head on solar water pumping system. Energy Convers. Manag. 2014, 77, 334–339. [Google Scholar] [CrossRef]

- Al-Smairan, M. Application of photovoltaic array for pumping water as an alternative to diesel engines in Jordan Badia, Tall Hassan station: Case study. Renew. Sustain. Energy Rev. 2012, 16, 4500–4507. [Google Scholar] [CrossRef]

- Meah, K.; Ula, S.; Barrett, S. Solar photovoltaic water pumping-opportunities and challenges. Renew. Sustain. Energy Rev. 2008, 12, 1162–1175. [Google Scholar] [CrossRef]

- Campana, P.E.; Li, H.; Yan, J. Dynamic modelling of a PV pumping system with special consideration on water demand. Appl. Energy 2013, 112, 635–645. [Google Scholar] [CrossRef] [Green Version]

- Gopal, C.; Mohanraj, M.; Chandramohan, P.; Chandrasekar, P. Renewable energy source water pumping systems—A literature review. Renew. Sustain. Energy Rev. 2013, 25, 351–370. [Google Scholar] [CrossRef]

- Belgacem, B.G. Performance of submersible PV water pumping systems in Tunisia. Energy Sustain. Dev. 2012, 16, 415–420. [Google Scholar] [CrossRef]

- Campana, P.E.; Li, H.; Zhang, J.; Zhang, R.; Liu, J.; Yan, J. Economic optimization of photovoltaic water pumping systems for irrigation. Energy Convers. Manag. 2015, 95, 32–41. [Google Scholar] [CrossRef] [Green Version]

- Periasamy, P.; Jain, N.K.; Singh, I.P. A review on development of photovoltaic water pumping system. Renew. Sustain. Energy Rev. 2015, 43, 918–925. [Google Scholar] [CrossRef]

- Thinsurat, K.; Bao, H.; Ma, Z.; Roskilly, A.P. Performance study of solar photovoltaic-thermal collector for domestic hot water use and thermochemical sorption seasonal storage. Energy Convers. Manag. 2019, 180, 1068–1084. [Google Scholar] [CrossRef] [Green Version]

- Fan, K.C.; Chang, K.C.; Chung, K.M. The impact of water quality on the use of solar water heaters in remote Islands of Taiwan. Water 2016, 8, 530. [Google Scholar] [CrossRef] [Green Version]

- Rohit, K.B.; Karve, G.; Khatri, M. Solar water pumping system. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 225–259. [Google Scholar]

- Chakchak, J.; Cetin, N.S. Application of Rural Photovoltaic Water Pumping System Using Immersed Pump and DC Motor. Int. J. Energy Appl. 2017, 4, 164–173. [Google Scholar]

- Qiu, S.; Ruth, M.; Ghosh, S. Evacuated tube collectors: A notable driver behind the solar water heater industry in China. Renew. Sustain. Energy Rev. 2015, 47, 580–588. [Google Scholar] [CrossRef]

- Ma, Z.; Bao, H.; Roskilly, A.P. Feasibility study of seasonal solar thermal energy storage in domestic dwellings in the UK. Sol. Energy. 2018, 162, 489–499. [Google Scholar] [CrossRef]

- Faizal, M.; Saidur, R.; Mekhilef, S.; Alim, M.A. Energy, economic and environmental analysis of metal oxides nanofluid for flat-plate solar collector. Energy Convers. Manag. 2013, 76, 162–168. [Google Scholar] [CrossRef]

- Ehrhart, B.; Gill, D. Evaluation of Annual Efficiencies of High Temperature Central Receiver Concentrated Solar Power Plants with Thermal Energy Storage. Energy Procedia 2013, 49, 752–761. [Google Scholar] [CrossRef] [Green Version]

- Hearps, P.; McConnell, D. Renewable Energy Technology Cost Review; Melbourne Energy Institute: Melbourne, Australia, 2011. [Google Scholar]

- Blake, D.J. King Bhumibol: The symbolic ‘father of water resources management’ and hydraulic development discourse in Thailand. Asian Stud. Rev. 2015, 39, 649–668. [Google Scholar] [CrossRef]

- Imjai, T.; Voravarangkurl, N.; Noisuwan, C.; Locatelli, A. High Efficiency Integrated Solar-Water Supply System for Isolated Agricultural Areas in Thailand: Renewable Energy Development. In Proceedings of the 1st Advances in Civil Engineering for Sustainable Development (ACESD 2014), Nakhon Ratchasima, Thailand, 27–29 August 2014; pp. 1–7. [Google Scholar]

- Philibert, C. Interactions of Policies for Renewable Energy and Climate; Interactions Energy Agency: Paris, France, 2011. [Google Scholar]

- Mekhilef, S.; Faramarzi, S.Z.; Saidur, R.; Salam, Z. The application of solar technologies for sustainable development of agricultural sector. Renew. Sustain. Energy Rev. 2013, 18, 583–594. [Google Scholar] [CrossRef]

- Tyagi, V.V. Progress in Solar PV technology: Research and Achievement. Renew. Sustain. Energy Rev. 2013, 20, 443–461. [Google Scholar] [CrossRef]

- Rahaman, M.M.; Varis, O. Integrated water resources management: Evolution, prospects and future challenges. Sustain. Sci. Pract. Policy 2005, 1, 15–21. [Google Scholar] [CrossRef]

- Suri, R.K.; Al-Marafie, A.M.R.; Al-Homoud, A.A.; Maheshwari, G.P. Cost-effectiveness of solar water production. Desalination 1989, 71, 165–175. [Google Scholar] [CrossRef]

- Bhattacharyya, S.C. Energy access programmes and sustainable development: A critical review and analysis. Energy Sustain. Dev. 2012, 16, 260–271. [Google Scholar] [CrossRef]

- Maxwell, E.L.; Renne, D.S. Measures of Renewable Energy; NREL/MP-463-6254; National Renewable Energy Laboratory: Golden, CO, USA, 1994.

- Solaris. Horizontal Solar Radiation Map of Thailand; Solaris Green Energy: Krabi, Thailand, 2013. [Google Scholar]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 4th ed.; Wiley: New York, NY, USA, 2013. [Google Scholar]

- LORENTZ. 2014. Available online: www.lorentz.de/en/products/submersible-solar-pumps/psk2.html (accessed on 20 May 2020).

- Arunkumar, M.; Mariappan, V.N. Water demand analysis of municipal water supply using epanet software. Int. J. Appl. Bioeng. 2011, 5, 9–16. [Google Scholar]

- Hamidat, A.; Benyoucef, B. Mathematic models of photovoltaic motor-pump systems. Renew. Energy 2008, 33, 933–942. [Google Scholar] [CrossRef]

- Tsai, H.F.; Tsai, H.L. Implementation and verification of integrated thermal and electrical models for commercial PV modules. Sol. Energy 2012, 86, 654–665. [Google Scholar] [CrossRef]

- Skoplaki, E.; Boudouvis, A.G.; Palyvos, J.A. A simple correlation for the operating temperature of photovoltaic modules of arbitrary mounting. Sol. Energy Mater. Sol. Cells 2008, 92, 1393–1402. [Google Scholar] [CrossRef]

| Energy Sources | Year 2012 | Year 2035 |

|---|---|---|

| Solar | 0.3% | 0.7% |

| Wind | 1.8% | 3.2% |

| Geothermal | 0.1% | 0.1% |

| Hydro | 7.6% | 8.8% |

| Nuclear | 5.5% | 6.7% |

| Biofuel | 0.8% | 1.2% |

| Coal | 27.9% | 27.2% |

| Natural gas | 22.2% | 22.7% |

| Conventional | 31.3% | 25.8% |

| Non-conventional | 1.1% | 2.2% |

| Other | 1.4% | 1.4% |

| Month (2012–2013) | Air Temperature | Relative Humidity | Daily Solar Radiation-Horizontal |

|---|---|---|---|

| °C | % | kWh/m2/d | |

| January | 25.7 | 65.1% | 5.12 |

| February | 26.3 | 66.4% | 5.68 |

| March | 26.8 | 70.6% | 5.83 |

| April | 27.2 | 76.2% | 5.86 |

| May | 27.0 | 81.8% | 4.59 |

| June | 26.6 | 83.1% | 3.73 |

| July | 26.4 | 82.4% | 3.70 |

| August | 26.3 | 82.6% | 3.48 |

| September | 26.0 | 83.7% | 3.85 |

| October | 25.7 | 83.2% | 4.09 |

| November | 25.2 | 76.0% | 4.46 |

| December | 25.0 | 65.5% | 4.87 |

| Average | 26.2 | 76.4% | 4.61 |

| Parameter | Value |

|---|---|

| STC Power Rating | 240 W |

| STC Power per unit of area | 146.6 W/m2 |

| Peak efficiency | 14.66% |

| Number of cells | 60 |

| Imp | 7.95 A |

| Vmp | 30.2 V |

| Isc | 8.45 A |

| Voc | 37.3 V |

| NOCT (Nominal Operating Cell Temperature) | 45 °C |

| Temp. coefficient of Isc | 0.05%/K |

| Temp. coefficient of Power | −0.41%/K |

| Temp. coefficient of Voltage | −0.112 V/K |

| Panel area | 1.64 m2 |

| Month | No. of Sunny Days | No. of Partly Cloudy Days | No. of Rainy Days |

|---|---|---|---|

| January | 19 | 10 | 2 |

| February | 19 | 8 | 1 |

| March | 19 | 10 | 2 |

| April | 17 | 10 | 3 |

| May | 10 | 13 | 8 |

| June | 9 | 14 | 7 |

| July | 9 | 15 | 7 |

| August | 9 | 13 | 9 |

| September | 9 | 14 | 7 |

| October | 9 | 14 | 8 |

| November | 15 | 11 | 4 |

| December | 22 | 7 | 2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Imjai, T.; Thinsurat, K.; Ditthakit, P.; Wipulanusat, W.; Setkit, M.; Garcia, R. Performance Study of an Integrated Solar Water Supply System for Isolated Agricultural Areas in Thailand: A Case-Study of the Royal Initiative Project. Water 2020, 12, 2438. https://doi.org/10.3390/w12092438

Imjai T, Thinsurat K, Ditthakit P, Wipulanusat W, Setkit M, Garcia R. Performance Study of an Integrated Solar Water Supply System for Isolated Agricultural Areas in Thailand: A Case-Study of the Royal Initiative Project. Water. 2020; 12(9):2438. https://doi.org/10.3390/w12092438

Chicago/Turabian StyleImjai, Thanongsak, Kamon Thinsurat, Pakorn Ditthakit, Warit Wipulanusat, Monthian Setkit, and Reyes Garcia. 2020. "Performance Study of an Integrated Solar Water Supply System for Isolated Agricultural Areas in Thailand: A Case-Study of the Royal Initiative Project" Water 12, no. 9: 2438. https://doi.org/10.3390/w12092438

APA StyleImjai, T., Thinsurat, K., Ditthakit, P., Wipulanusat, W., Setkit, M., & Garcia, R. (2020). Performance Study of an Integrated Solar Water Supply System for Isolated Agricultural Areas in Thailand: A Case-Study of the Royal Initiative Project. Water, 12(9), 2438. https://doi.org/10.3390/w12092438