A Modelling Framework for the Conceptual Design of Low-Emission Eco-Industrial Parks in the Circular Economy: A Case for Algae-Centered Business Consortia

Abstract

1. Introduction

- Consistent integration of sub-models of different industries capable of matching compatible input and output energy and material streams. This can also be used to build a rich database containing the sub-models of all existing processes and modeled configurations which can be extended with ease.

- Sensitivity analysis of the dynamic network to provide a better understanding of the interdependence among the EIP members. This is critical in EIP planning, as any change in the production or consumption of one member may impact the performances of others and subsequently the balance for the entire EIP system.

- Comparison of economic costs and environmental benefits in different configurations and the extent of tradeoffs among the EIP members. Thus, an optimal EIP design may be realized.

- Use of various IE analytical methods (i.e., MFA, SFA, LCA, etc.) to uncover new insights into the operation of the EIP, particularly how to best realize circular economy principles into the EIP operations and how to develop circular business models.

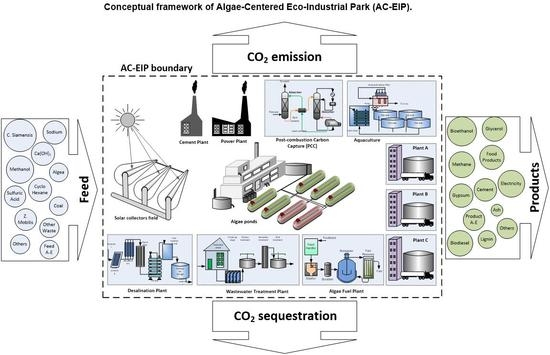

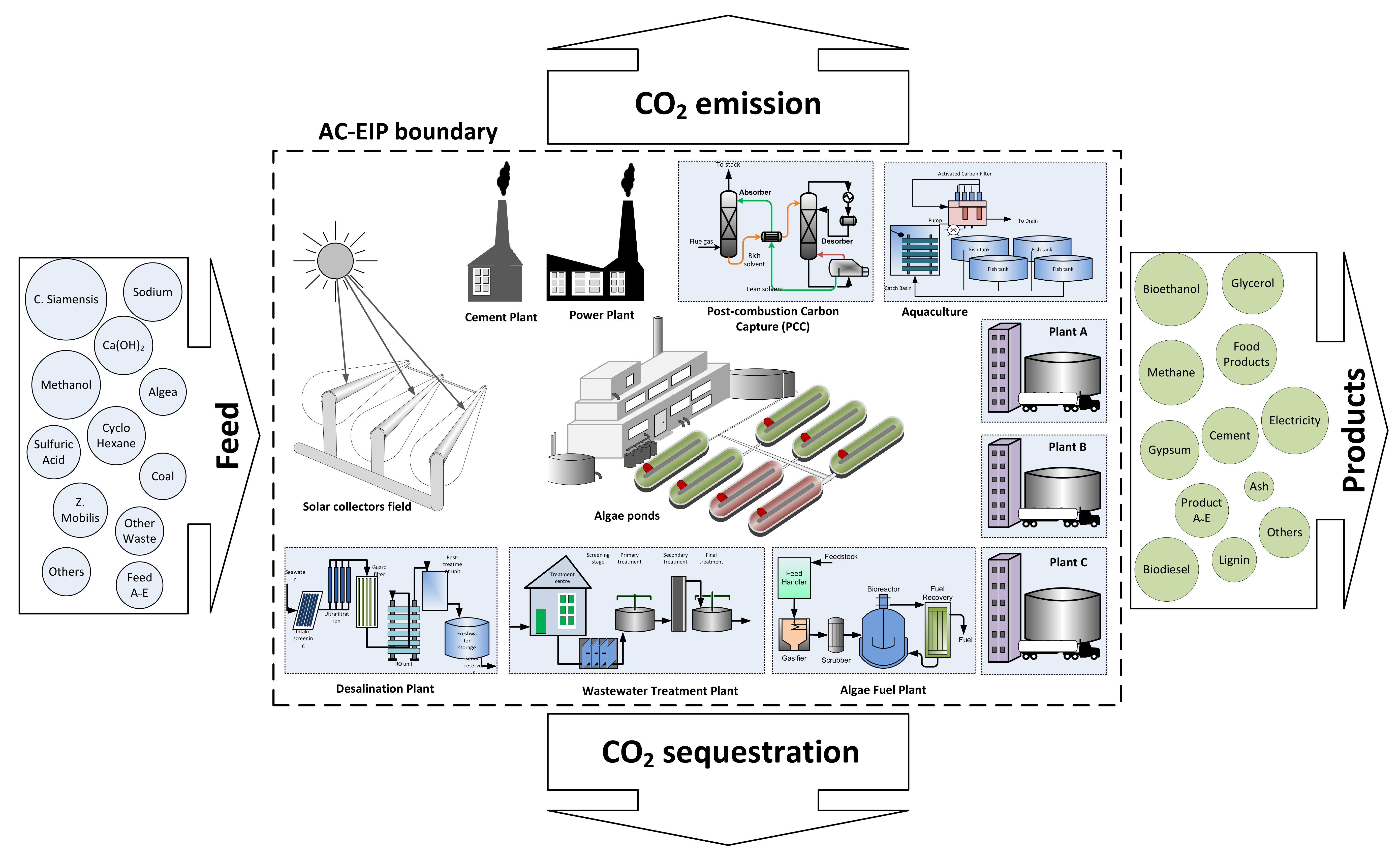

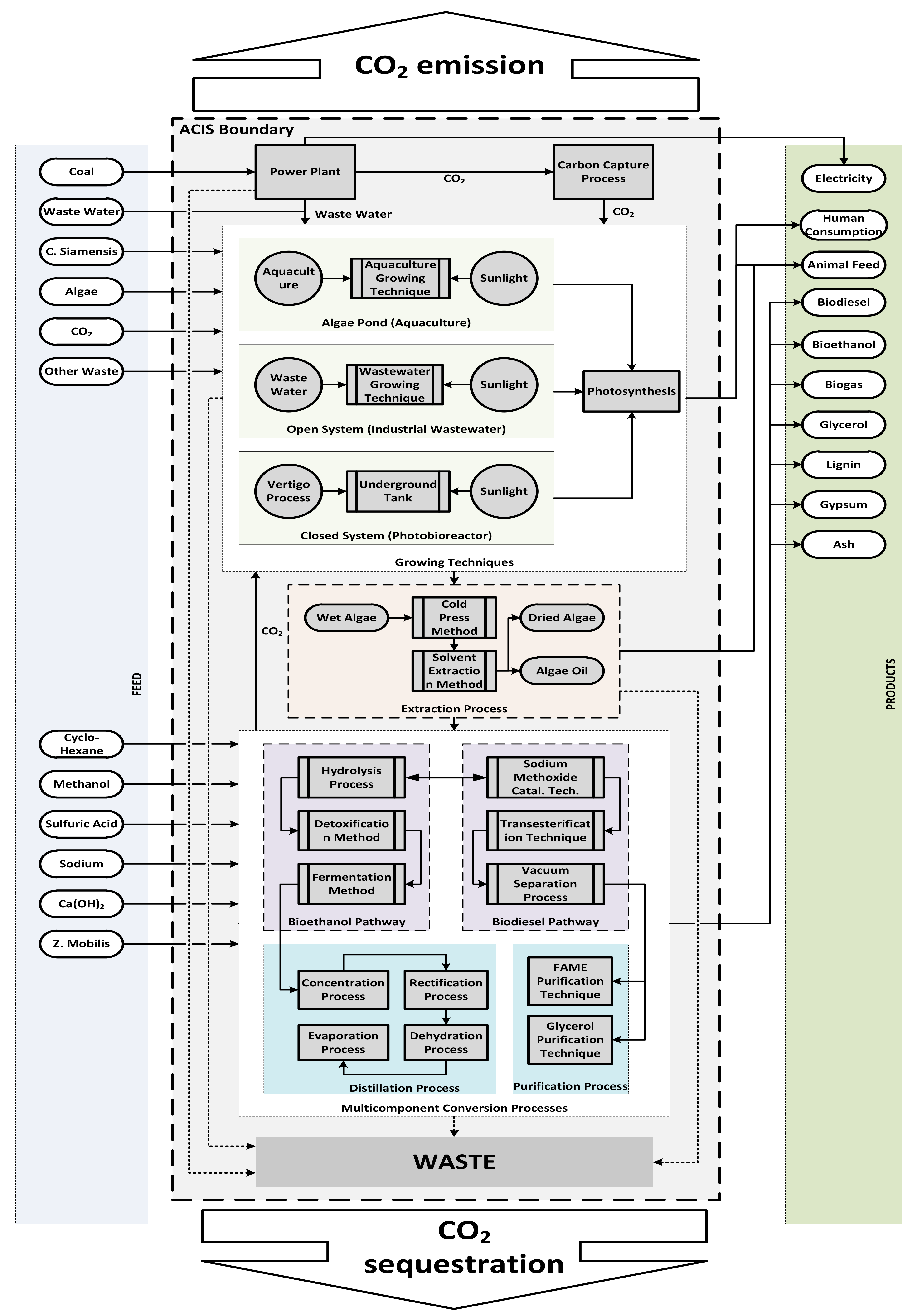

2. A Novel Algae-Centered EIP

2.1. Power Plant and Solar Field

2.2. Carbon Capture and Sequestration (CCS)

2.3. Algae Cultivation Unit (ACU)

- Rapid growth potential and tolerance to harsh conditions in comparison to higher organisms due to their unicellular or simple multicellular structures.

- Compatibility as feedstock for different types of renewable fuels, such as biodiesel, methane, hydrogen and ethanol [64].

- Potential for bioremediation applications and as nitrogen-fixing biofertilizers [66].

- Production of high value products such as omega 3 fatty acids and various phytochemicals [67].

2.4. Aquaculture and Wastewater Treatment with Microalgae

2.5. Algae Biofuel

2.6. Flexibility for Further Process Integrations

3. Calculation Methodology

Case Study

- CO2 sequestered as a result of the carbon capture process.

- CO2 emitted only from the AC-EIP boundary as shown in Figure 6 (i.e., internal-to-boundary and does not include emissions from downstream processes like biodiesel combustion).

- CO2 emission that is external-to-boundary (total CO2 emitted from AC-EIP processes including emissions from the downstream products).

4. Results and Discussion

5. Conclusions and Recommendations

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AC-EIP | Algae-centered eco-industrial park |

| ACU | Algae cultivation unit |

| CCS | Carbon capture and sequestration |

| FSC | Fuel saving scenario |

| IE | Industrial ecology |

| GHG | Greenhouse gases |

| LCA | Lifecycle assessment |

| PBS | Power-boosting scenario |

| Pc | Critical pressure |

| PCC | Post-combustion carbon capture |

| SG | Specific gravity |

| Tb | Boiling temperature |

| Tc | Critical temperature |

| TES | Techno-ecological synergy |

| TMC | Total material consumption |

| TME | Total material emission |

| Vc | Critical volume |

References

- Puga, D. The magnitude and causes of agglomeration economies. J. Reg. Sci. 2010, 50, 203–219. [Google Scholar] [CrossRef]

- Shen, N.; Peng, H. Can industrial agglomeration achieve the emission-reduction effect? Soc. Econ. Plan. Sci. 2020, 100867. [Google Scholar] [CrossRef]

- Butturi, M.; Lolli, F.; Sellitto, M.A.; Balugani, E.; Gamberini, R.; Rimini, B. Renewable energy in eco-industrial parks and urban-industrial symbiosis: A literature review and a conceptual synthesis. Appl. Energy 2019, 255, 113825. [Google Scholar] [CrossRef]

- Zeng, D.Z.; Cheng, L.; She, L.; Luetkenhorst, W. China’s green transformation through eco-industrial parks. World Dev. 2020, 105249. [Google Scholar] [CrossRef]

- Susur, E.; Martin-Carrillo, D.; Chiaroni, D.; Hidalgo, A. Unfolding eco-industrial parks through niche experimentation: Insights from three Italian cases. J. Clean. Prod. 2019, 239, 118069. [Google Scholar] [CrossRef]

- Boix, M.; Montastruc, L.; Ramos, M.; Gentilhomme, O.; Domenech, S. Benefits analysis of optimal design of eco-industrial parks through life cycle indicators. Comput. Aided Chem. Eng. 2017, 40, 1951–1956. [Google Scholar]

- Chertow, M.R. Industrial symbiosis: Literature and taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef]

- Chertow, M.R. “Uncovering” industrial symbiosis. J. Ind. Ecol. 2007, 11, 11–30. [Google Scholar] [CrossRef]

- Belaud, J.-P.; Adoue, C.; Vialle, C.; Chorro, A.; Sablayrolles, C. A circular economy and industrial ecology toolbox for developing an eco-industrial park: Perspectives from French policy. Clean Technol. Environ. Policy 2019, 21, 967–985. [Google Scholar] [CrossRef]

- ElMassah, S. Industrial symbiosis within eco-industrial parks: Sustainable development for Borg El-Arab in Egypt. Bus. Strateg. Environ. 2018, 27, 884–892. [Google Scholar] [CrossRef]

- Saavedra, Y.M.B.; Iritani, D.; Pavan, A.L.R.; Ometto, A.R. Theoretical contribution of industrial ecology to circular economy. J. Clean. Prod. 2018, 170, 1514–1522. [Google Scholar] [CrossRef]

- Lowe, E. Eco-Industrial Park Handbook for Asian Developing Countries: Report to Asian Development Bank; Environment Department, Indigo Development: Oakland, CA, USA, 2001. [Google Scholar]

- Bakshi, B.R.; Ziv, G.; Lepech, M.D. Techno-ecological synergy: A framework for sustainable engineering. Environ. Sci. Technol. 2015, 49, 1752–1760. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Lowe, E.A.; Barnes, D. Industrial symbiosis in China: A case study of the Guitang Group. J. Ind. Ecol. 2007, 11, 31–42. [Google Scholar] [CrossRef]

- Jacobsen, N.B. Industrial symbiosis in Kalundborg, Denmark—A quantitative assessment of economic and environmental aspects. J. Ind. Ecol. 2006, 10, 239–255. [Google Scholar] [CrossRef]

- Gibbs, D.; Deutz, P. Implementing industrial ecology? Planning for eco-industrial parks in the USA. Geoforum 2005, 36, 452–464. [Google Scholar]

- Roberts, B.H. The application of industrial ecology principles and planning guidelines for the development of eco-industrial parks: An Australian case study. J. Clean. Prod. 2004, 12, 997–1010. [Google Scholar] [CrossRef]

- Hoffmann, J.; Rudra, S.; Toor, S.S.; Holm-Nielsen, J.B.; Rosendahl, L.A. Conceptual design of an integrated hydrothermal liquefaction and biogas plant for sustainable bioenergy production. Biores. Technol. 2013, 129, 402–410. [Google Scholar] [CrossRef]

- Ayres, R.U.; Ayres, L.W. A Handbook of Industrial Ecology; Edward Elgar Publishing Limited: Cheltenham, UK, 2002. [Google Scholar]

- Allenby, B. The ontologies of industrial ecology. Int. J. Environ. Pollut. 2006, 3, 13. [Google Scholar] [CrossRef]

- Corder, G.D.; Golev, A. Industrial Ecology in Australia: Barriers and Enablers. Resour. Conserv. Recycl. 2014, 3, 340–361. [Google Scholar] [CrossRef]

- Van Den Bergh, J.C.J.M.; Janssen, M.A. (Eds.) Economics of Industrial Ecology: Materials, Structural Change, and Spatial Scales; MIT Press: London, UK, 2004. [Google Scholar]

- Bourg, D.; Erkman, S. (Eds.) Perspectives on Industrial Ecology; Greenleaf Publishing Ltd.: Austin, TX, USA, 2003. [Google Scholar]

- Graedel, T.E.; Allenby, B.R. (Eds.) Industrial Ecology, 2nd ed.; Prentice Hall: Englewood Cliffs, NJ, USA, 2003; p. 363. [Google Scholar]

- Graedel, T.E. Material flow analysis from origin to evolution. Environ. Sci. Technol. 2019, 53, 12188–12196. [Google Scholar] [CrossRef]

- Rahman, S.; Chowdhury, R.B.; D’Costa, N.G.; Milne, N.; Bhuiyan, M.; Sujauddin, M. Determining the potential role of the waste sector in decoupling of phosphorus: A comprehensive review of national scale substance flow analyses. Resour. Conserv. Recycl. 2019, 144, 144–157. [Google Scholar] [CrossRef]

- Campos-Guzmán, V.; Carcia-Cáscales, M.S.; Espinosa, N.; Urbina, A. Life Cycle Analysis with Multi-Criteria Decision Making: A review of approaches for the sustainability evaluation of renewable energy technologies. Renew. Sustain. Energy Rev. 2019, 104, 343–366. [Google Scholar] [CrossRef]

- Kasbun, N.F.; Ong, T.S.; Muhamad, H.; Said, R.M. Conceptual Framework to Improve Carbon Performance via Carbon Strategies and Carbon Accounting. J. Environ. Manag. Tour. 2019, 10, 1918–1923. [Google Scholar]

- Venkatesh, G. Pinch analysis, as a technique for optimising resource utilisation and promoting environmental sustainability: A review of recent case studies from the developing world and transition economies. Resour. Environ. Inf. Eng. 2019, 1, 1–17. [Google Scholar] [CrossRef]

- Kastner, C.A.; Lau, R.; Kraft, M. Quantitative tools for cultivating symbiosis in industrial parks; a literature review. Appl. Energy 2015, 155, 599–612. [Google Scholar] [CrossRef]

- Yeo, Z.; Masi, D.; Low, J.S.C.; Ng, Y.T.; Tan, P.S.; Barnes, S. Tools for promoting industrial symbiosis: A systematic review. J. Ind. Ecol. 2019, 23, 1087–1108. [Google Scholar] [CrossRef]

- De Bhowmick, G.; Sarmah, A.K.; Sen, R. Zero-waste algal biorefinery for bioenergy and biochar: A green leap towards achieving energy and environmental sustainability. Sci. Total Environ. 2019, 650, 2467–2482. [Google Scholar] [CrossRef]

- Geng, Y.; Liu, Z.; Xue, B.; Dong, H.; Fujita, T.; Chiu, A. Emergy-based assessment on industrial symbiosis: A case of Shenyang Economic and Technological Development Zone. Environ. Sci. Pollut. Res. 2014, 21, 13572–13587. [Google Scholar] [CrossRef]

- Wen, Z.; Meng, X. Quantitative assessment of industrial symbiosis for the promotion of circular economy: A case study of the printed circuit boards industry in China’s Suzhou New District. J. Clean. Prod. 2015, 90, 211–219. [Google Scholar] [CrossRef]

- Walmsley, T.G.; Ong, B.H.Y.; Klemeš, J.J.; Tan, R.R.; Varbanov, P.S. Circular Integration of processes, industries, and economies. Renew. Sustain. Energy Rev. 2019, 107, 507–515. [Google Scholar] [CrossRef]

- Shi, H.; Chertow, M.; Song, Y. Developing country experience with eco-industrial parks: A case study of the Tianjin Economic-Technological Development Area in China. J. Clean. Prod. 2010, 18, 191–199. [Google Scholar] [CrossRef]

- Kim, H.W.; Dong, L.; Choi, A.E.S.; Fugii, M.; Fugii, T.; Park, H.S. Co-benefit potential of industrial and urban symbiosis using waste heat from industrial park in Ulsan, Korea. Resour. Conserv. Recycl. 2018, 135, 225–234. [Google Scholar] [CrossRef]

- Ohnishi, S.; Fujii, M.; Ohata, M.; Rokuta, I.; Fujita, T. Efficient energy recovery through a combination of waste-to-energy systems for a low-carbon city. Resour. Conserv. Recycl. 2018, 128, 394–405. [Google Scholar] [CrossRef]

- Arbolino, R.; Simone, L.D.; Carlucci, F.; Yigitcanlar, T.; Loppolo, G. Towards a sustainable industrial ecology: Implementation of a novel approach in the performance evaluation of Italian regions. J. Clean. Prod. 2018, 178, 220–236. [Google Scholar] [CrossRef]

- Govindan, K.; Hasanagic, M. A systematic review on drivers, barriers, and practices towards circular economy: A supply chain perspective. Int. J. Prod. Res. 2018, 56, 278–311. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Song, X.; Geng, Y.; Dong, H.; Chen, W. Social network analysis on industrial symbiosis: A case of Gujiao eco-industrial park. J. Clean. Prod. 2018, 193, 414–423. [Google Scholar] [CrossRef]

- Geng, Y.; Sarkis, J.; Ulgiati, S.; Zhang, P. Measuring China’s Circular Economy. Science 2013, 339, 1526. [Google Scholar] [CrossRef] [PubMed]

- Kirchherr, J.; Piscielli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Trijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence From the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Prieto-Sandoval, V.; Jaca, C.; Ormazabal, M. Towards a consensus on the circular economy. J. Clean. Prod. 2018, 179, 605–615. [Google Scholar] [CrossRef]

- Qadir, A.; Mokhtar, M.; Khalilpour, R.; Milani, D.; Vassallo, A.; Chiesa, M.; Abbas, A. Potential for solar-assisted post-combustion carbon capture in Australia. Appl. Energy 2013, 111, 175–185. [Google Scholar] [CrossRef]

- Khalilpour, R. Design and Integration of Post-Combustion Carbon Capture Processes: Retrofitting to Coal-Fired power Plants. In School of Chemical &Biomolecular Engineering; University of Sydney: Camperdown, NSW, Australia, 2012. [Google Scholar]

- Australian Energy Statistics. Table O Electricity Generation by Fuel Type 2018-19 and 2019. Available online: https://www.energy.gov.au/publications/australian-energy-statistics-table-o-electricity-generation-fuel-type-2018-19-and-2019 (accessed on 15 June 2020).

- NSW Emissions. Australian Greenhouse Emissions Information System (AGEIS). 2018. Available online: https://climatechange.environment.nsw.gov.au/About-climate-change-in-NSW/NSW-emissions (accessed on 15 June 2020).

- Ebrahimi, A.; Saffari, M.; Milani, D.; Montoya, A.; Valix, M.; Abbas, A. Sustainable transformation of fly ash industrial waste into a construction cement blend via CO2 carbonation. J. Clean. Prod. 2017, 156, 660–669. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Saffari, M.; Hong, Y.; Milani, D.; Montoya, A.; Valix, M.; Minett, A.; Abbas, A. Mineral sequestration of CO2 using saprolite mine tailings in the presence of alkaline industrial wastes. J. Clean. Prod. 2018, 188, 686–697. [Google Scholar] [CrossRef]

- Milani, D.; Khalilpour, R.; Zahedi, G.; Abbas, A. A model-based analysis of CO2 utilization in methanol synthesis plant. J. CO2 Util. 2015, 10, 12–22. [Google Scholar] [CrossRef]

- Luu, M.T.; Milani, D.; Bahadori, A.; Abbas, A. A comparative study of CO2 utilization in methanol synthesis with various syngas production technologies. J. CO2 Util. 2015, 12, 62–76. [Google Scholar] [CrossRef]

- Algae Link. 2014. Available online: www.algaelink.com (accessed on 9 November 2014).

- Li, L.; Zhao, N.; Wei, W.; Sun, Y. A review of research progress on CO2 capture, storage, and utilization in Chinese Academy of Sciences. Fuel 2013, 108, 112–130. [Google Scholar] [CrossRef]

- Hasan, M.F.; Boukouvala, F.; First, E.L.; Floudas, C.A. Nationwide, regional, and statewide CO2 capture, utilization, and sequestration supply chain network optimization. Ind. Eng. Chem. Res. 2014, 53, 7489–7506. [Google Scholar] [CrossRef]

- Parvareh, F.; Sharma, M.; Qadir, A.; Milani, D.; Khalilpour, R.; Chiesa, M.; Abbas, A.L. Integration of solar energy in coal-fired power plants retrofitted with carbon capture: A review. Renew. Sustain. Energy Rev. 2014, 38, 1029–1044. [Google Scholar] [CrossRef]

- Global CCS Institute. The Global Status of CCS: 2011; Global CCS Institute: Canberra, NSW, Australia, 2011; p. 156. [Google Scholar]

- Kadam, K.L. Environmental implications of power generation via coal-microalgae cofiring. Energy 2002, 27, 905–922. [Google Scholar] [CrossRef]

- Brennan, L.; Owende, P. Biofuels from microalgae—A review of technologies for production, processing, and extractions of biofuels and co-products. Renew. Sustain. Energy Rev. 2009, 14, 557–577. [Google Scholar] [CrossRef]

- Chang, W.-T.; Lee, M.; Den, W. Simultaneous carbon capture, biomass production, and diary wastewater purification by Spirulina maxima photobioreaction. Ind. Eng. Chem. Res. 2013, 52, 2046–2055. [Google Scholar] [CrossRef]

- Hirata, S.; Hayashitani, M.; Taya, M.; Tone, S. Carbon dioxide fixation in batch culture of Chlorella sp. using a photobioreactor with a sunlight-cellection device. J. Ferment. Bioeng. 1996, 81, 470–472. [Google Scholar] [CrossRef]

- Mata, T.M.; Martins, A.A.; Caetano, N.S. Microalgae for biodiesel production and other applications: A review. Renew. Sustain. Energy Rev. 2010, 14, 217–232. [Google Scholar] [CrossRef]

- Alaswad, A.; Dassisti, M.; Prescott, M.; Olabi, A.G. Technologies and developments of third generation biofuel production. Renew. Sustain. Energy Rev. 2015, 51, 1446–1460. [Google Scholar] [CrossRef]

- Cristi, Y. Biodiesel from microalgae. Biotechnol. Adv. 2007, 25, 294–306. [Google Scholar]

- Chi, Z.; Zheng, Y.; Jiang, A.; Chen, S. Lipid production by culturing oleaginous yeast and algae with food waste and municipal wastewater in an integrated process. Appl. Biochem. Biotechnol. 2011, 165, 442–453. [Google Scholar] [CrossRef]

- Ververis, C.; Georghiou, K.; Danielidis, D.; Hatzinikolaou, D.G.; Santas, P.; Santas, R.; Corleti, V. Cellulose, hemicelluloses, lignin and ash content of some organic materials and their suitability for use as paper pulp supplements. Bioresour. Technol. 2006, 98, 6. [Google Scholar] [CrossRef]

- Shields, R.J.; Lupatsch, I. Algae for Aquaculture and Animal Feeds. Theor. Praxis 2012, 21, 23–37. [Google Scholar]

- Jayakumar, R.; Abdul Nazar, A.K.; Tamilmani, G.; Sakthivel, M.; Rameshkumar, P.; Antikuttan, K.K.; Johnson, B.; Hanumanta Rao, G. Silver Pompano, Trachinotus blochii—A potential fish for coastal aquaculture in India. Aquac. Spectrum 2019, 2, 9–16. [Google Scholar]

- Hilborn, R.; Kearney, B. Australian Seafood Consumers Mislead by Prophets of Doom and Gloom. Available online: http://damnationfilm.com/uploads/websites/330/wysiwyg/Australian_seafood_consumers_misled_by_prophets_of_doom_and_gloom_Feb_2012.pdf (accessed on 30 December 2020).

- Khan, M.I.; Shin, J.H.; Kim, J.D. The promising future of microalgae: Current status, challenges, and optimization of a sustainable and renewable industry for biofuels, feed, and other products. Microb. Cell Fact. 2018, 17, 36. [Google Scholar] [CrossRef] [PubMed]

- Demirbas, A. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers. Manag. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- McGill, R. Algae as a Feedstock for Transportation Fuels—The Future of Biofuels? Presented to the 35th Executive Committee Meeting, Vienna, Austria, May 2008; A White Paper Prepared for the IEA Advanced Motor Fuels Implementing Agreement. Available online: https://amf-tcp.org/app/webroot/files/file/Annex%20Reports/AMF_Annex_34-2_white%20paper.pdf (accessed on 30 December 2020).

- Hu, Q.; Sommerfeld, M.; Jarvis, E.; Ghirardi, M.; Posewitz, M.; Seibert, M.; Dazins, A. Microalgal triacylglycerols as feedstocks for biofuel production: Perspectives and advances. Plant J. 2008, 54, 621–639. [Google Scholar] [CrossRef] [PubMed]

- McKendry, P. Energy production from biomass (part 2): Conversion technologies. Bioresour. Technol. 2002, 83, 47–54. [Google Scholar] [CrossRef]

- Nisbet, M.A.; VanGeem, M.G.; Gajda, J.; Marceau, M. Environmental Life Cycle Inventory of Portland Cement Concrete; P.C. Association: Skokie, IL, USA, 2000. [Google Scholar]

- Gao, T.; Shen, L.; Shen, M.; Chen, F.; Liu, L.; Gao, L. Analysis on differences of carbon dioxide emission from cement production and their major determinants. J. Clean. Prod. 2015, 103, 160–170. [Google Scholar] [CrossRef]

- Sim, V.S.T.; She, Q.; Chong, T.H.; Tang, C.Y.; Fane, A.G.; Krantz, W.B. Strategic co-location in a Hybrid Process involving desalination and Pressure Retarded Osmosis (PRO). Membranes 2013, 3, 98–125. [Google Scholar] [CrossRef]

- Wang, M.; Wang, K.K.; Jia, Y.X.; Ren, Q.C. The reclamation of brine generated from desalination process by bipolar membrane electrodialysis. J. Membr. Sci. 2014, 452, 54–61. [Google Scholar] [CrossRef]

- Turton, R.; Baillie, R.C.; Whiting, W.B.; Shaeiwiz, J.A. Analysis, Synthesis and Design of Chemical Processes; Pearson Education: New York, NY, USA, 2008. [Google Scholar]

- Sieder, W.; Seader, J.; Lewin, D. Product and Process Design Principles; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Peters, M.S.; Timmerhaus, K.D.; West, R.E. Plant Design and Economics for Chemical Engineers, 5th ed.; McGrawhill: New York, NY, USA, 2003. [Google Scholar]

- Aden, A.; Ruth, M.; Ibsen, K.; Jechura, J.; Neeves, K.; Sheehan, J.; Wallace, B. Lignocellulosic Biomass to Ethanol Process Design and Economics Utilizing Co-Current Dilute Acid Prehydrolysis and Enzymatic Hydrolysis for Corn Stover; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2002; p. 154. [Google Scholar]

- Pienkos, P.T. The Potential for Biofuels from Algae. In Algae Biomass Summit; National Renewable Energy Laboratory (NREL): San Francisco, CA, USA, 2007. [Google Scholar]

- Khalilpour, R.; Abbas, A. HEN optimization for efficient retrofitting of coal-fire power plants with post-combustion carbon capture. Int. J. Greenh. Control 2011, 5, 189–199. [Google Scholar] [CrossRef]

- Pasqualetti, M.J. Decommissioning Nuclear Power Plants. In Controlling the Atom in the 21st Century; O’Very, D.P., Paine, C.E., Reicher, D.W., Eds.; Westview Press: Boulder, CO, USA, 1994. [Google Scholar]

- Pasqualetti, M.J.; Miller, B.A. Land Requirements for the Solar and Coal Options. Geogr. J. 1984, 150, 192–212. [Google Scholar] [CrossRef]

- Florin, N.; Fennel, P. Assessment of the Validity of―Approximate Minimum Land Footprint for Some Types of CO2 Capture Plant; CCR Land Footprint Review; Department of Energy & Climate Change, 2010. Available online: https://www.gov.uk/government/publications/assessment-of-the-validity-of-approximate-minimum-land-footprint-for-some-types-of-co2-capture-plant (accessed on 30 December 2020).

- El Haggar, S. Sustainable Industrial Design and Waste Management: Cradle-to-Cradle for Sustainable Development; Elseiver Academic Press: Oxford, UK, 2007. [Google Scholar]

- Rafiee, A.; Khalilpour, K.R.; Milani, D. CO2 conversion and utilization pathways. In Polygeneration with Polystorage for Chemical and Energy Hubs; Elsevier: Amsterdam, The Netherlands, 2019; pp. 213–245. [Google Scholar]

| Scenario ‘A’ | Scenario ‘B’ | Scenario ‘C’ | Scenario ‘D’ | Scenario ‘E’ | Scenario ‘F’ | |||

|---|---|---|---|---|---|---|---|---|

| Inputs | Coal Feed (t/year) | 3,150,000 | 3,150,000 | 1,575,000 | 3,150,000 | 3,150,000 | - | |

| Power Plant (MW) | 660 | 660 | 330 | 660 | 660 | - | ||

| Solar Plant (MW) | - | - | 330 | 660 | 660 | 660 | ||

| PCC and Sequestration | No | Yes | Yes | No | Yes | No | ||

| Algae Pond (t/year) | - | - | 50,000 | 50,000 | 50,000 | - | ||

| Aquaculture (fishes/year) | - | - | 42,500,000 | 42,500,000 | 42,500,000 | - | ||

| Total Area Needed (km2) | 3.30 | 3.32 | 9.63 | 13.42 | 13.43 | 5.29 | ||

| Outputs | Electricity (MW) | 660 | 660 | 503 | 1132 | 1050 | 660 | |

| Biodiesel (L/year) | - | - | 31,781,709 | 39,092,652 | 39,092,652 | - | ||

| Bioethanol (L/year) | - | - | 5,310,891 | 6,710,567 | 6,710,567 | - | ||

| Methanol (L/year) | - | - | 143,258 | 143,258 | 143,258 | - | ||

| Glycerol (t/year) | - | - | 3570 | 3570 | 3570 | - | ||

| Lignin (t/year) | - | - | 811 | 811 | 811 | - | ||

| Fish Products (t/year) | - | - | 19,550 | 19,550 | 19,550 | - | ||

| CO2 Sequestered (t/year) | - | 2,736,020 | 228 | - | 1,111,894 | - | ||

| CO2 emission | Internal-to-boundary | Absolute (t/year) | 3,040,022 | 304,002 | 19,431 | 1,213,313 | 1,134,019 | - |

| Levelized (t/MW/year) | 4606 | 460.6 | 29.4 | 919 | 859 | - | ||

| External-to-boundary | Absolute (t/year) | 3,040,022 | 304,002 | 1,519,783 | 3,040,022 | 1,928,128 | - | |

| Levelized (t/MW/year) | 4606 | 460.6 | 1003 | 2303 | 1461 | - | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tumilar, A.S.; Milani, D.; Cohn, Z.; Florin, N.; Abbas, A. A Modelling Framework for the Conceptual Design of Low-Emission Eco-Industrial Parks in the Circular Economy: A Case for Algae-Centered Business Consortia. Water 2021, 13, 69. https://doi.org/10.3390/w13010069

Tumilar AS, Milani D, Cohn Z, Florin N, Abbas A. A Modelling Framework for the Conceptual Design of Low-Emission Eco-Industrial Parks in the Circular Economy: A Case for Algae-Centered Business Consortia. Water. 2021; 13(1):69. https://doi.org/10.3390/w13010069

Chicago/Turabian StyleTumilar, Aldric S., Dia Milani, Zachary Cohn, Nick Florin, and Ali Abbas. 2021. "A Modelling Framework for the Conceptual Design of Low-Emission Eco-Industrial Parks in the Circular Economy: A Case for Algae-Centered Business Consortia" Water 13, no. 1: 69. https://doi.org/10.3390/w13010069

APA StyleTumilar, A. S., Milani, D., Cohn, Z., Florin, N., & Abbas, A. (2021). A Modelling Framework for the Conceptual Design of Low-Emission Eco-Industrial Parks in the Circular Economy: A Case for Algae-Centered Business Consortia. Water, 13(1), 69. https://doi.org/10.3390/w13010069