Fluid-Structure Coupling Creep Characteristics of Red-Bed Soft Rock in South China

Abstract

1. Introduction

2. Physical and Mechanical Properties of the Samples

2.1. Physical Property

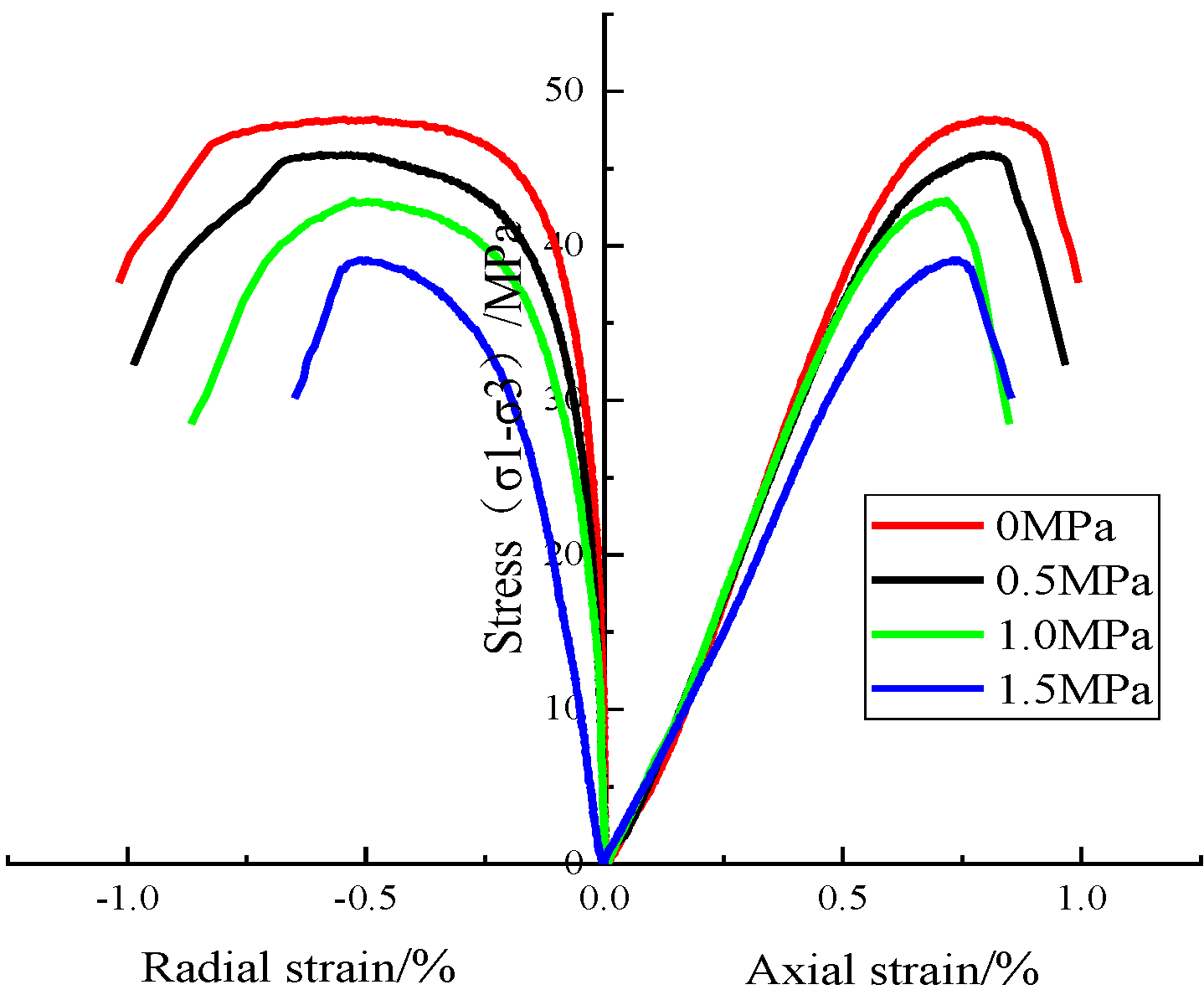

2.2. Strength Properties

3. Creep Experiment and Analysis of Test Results

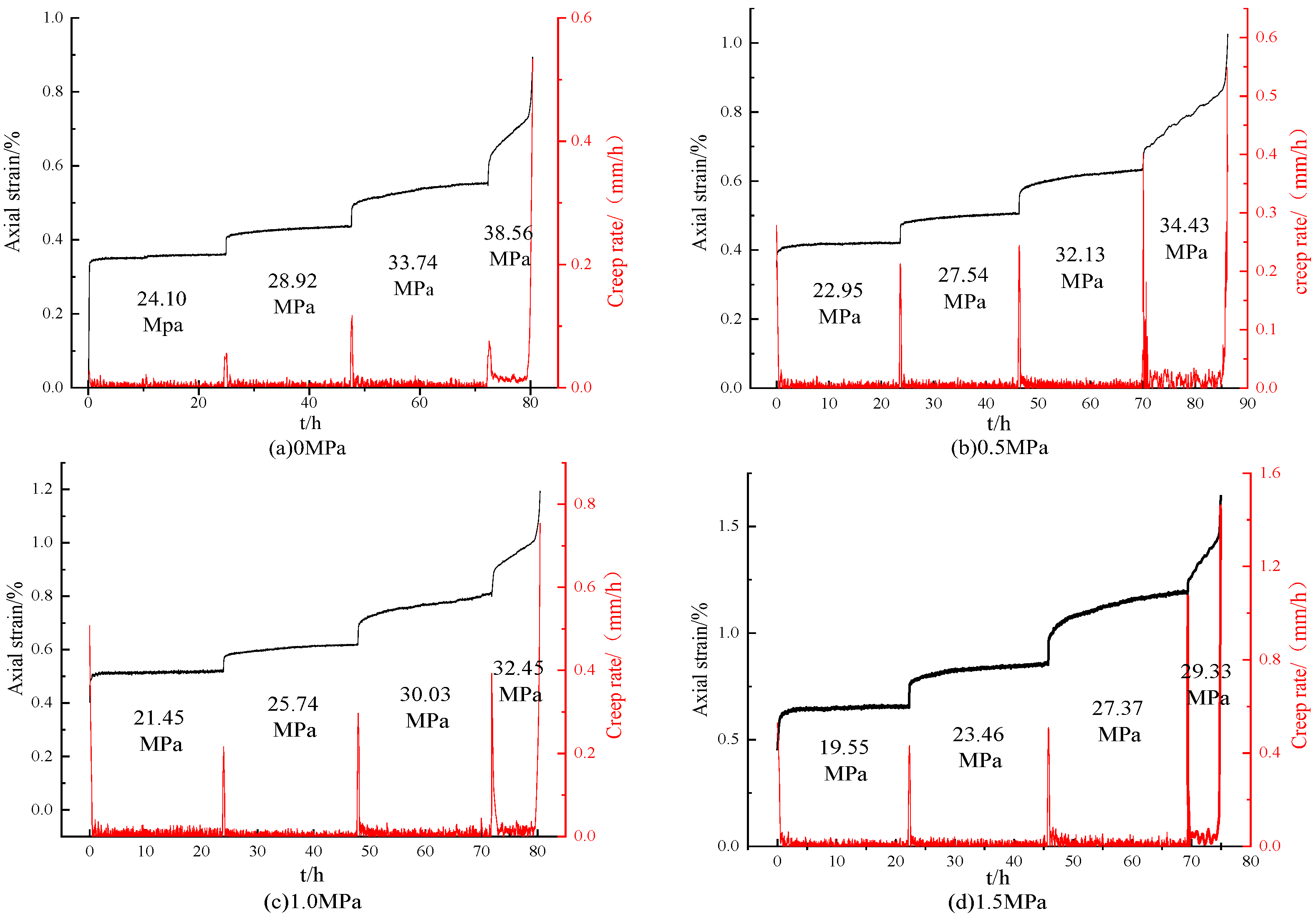

3.1. Creep Strain–Time Curve

- (1)

- The confining pressure remained unchanged at 3 MPa, whereas the seepage pressure was set at 0.5 MPa, 1 MPa, and 1.5 MPa. The liquid used for the seepage is distilled water.

- (2)

- At the loading rate of 0.05 MPa/s, the axial pressure and confining pressure are applied to the predetermined value, and then the axial load is loaded to the predetermined value.

- (3)

- The initial load is 50% of the strength of the rock, then it increases by 10% for each of the grade loads.

- (4)

- For the last grade loads, 80% of the triaxial strength is applied when there is no seepage, and 75% of the triaxial strength is applied when there is seepage.

- (5)

- The duration of each stage of the load is 24 h and so on until the creep failure occurs.

- (6)

- The test data were converted into creep strain–time curves using the Bozltmen superposition method (Figure 6).

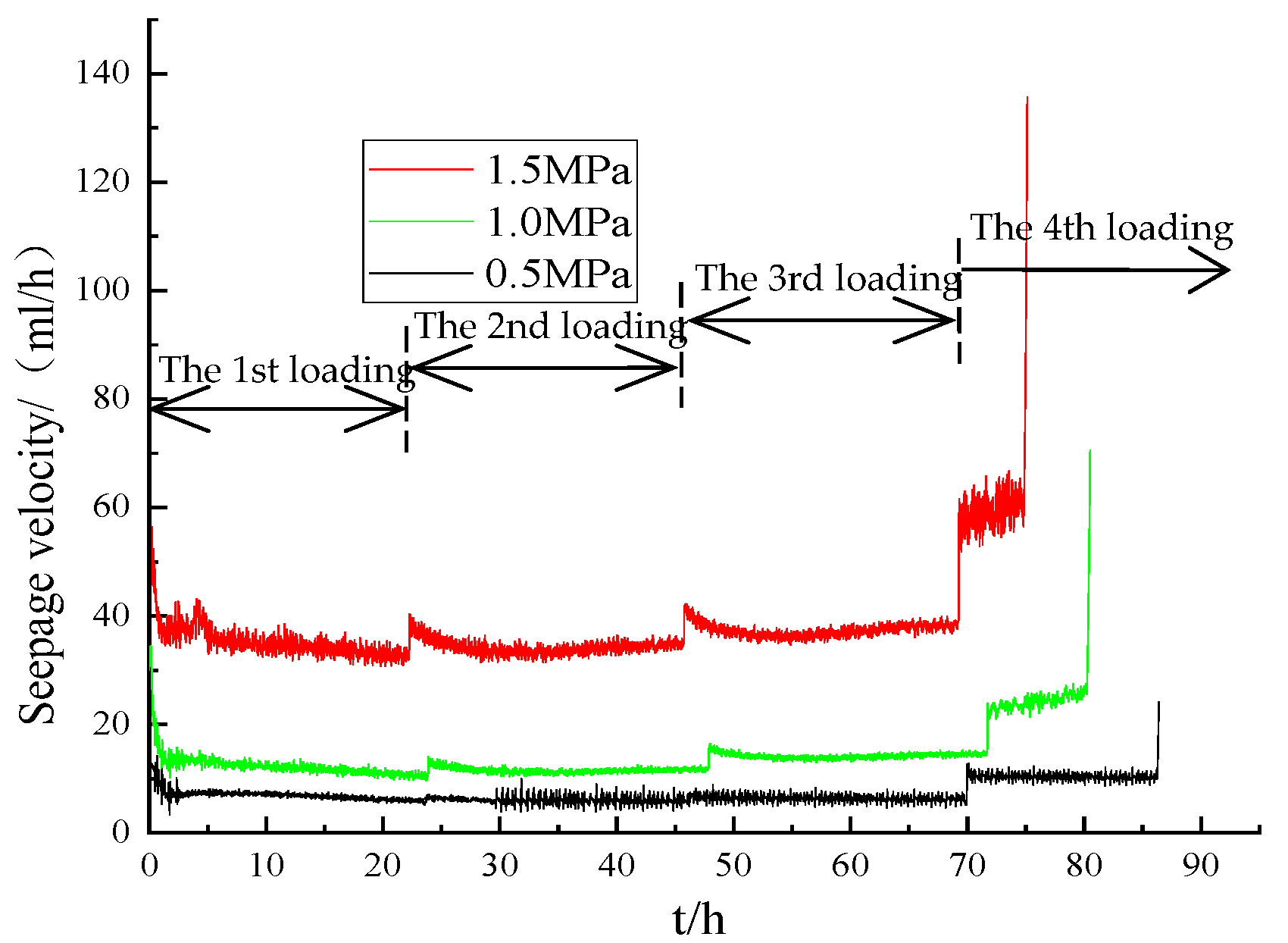

3.2. Creep Rate–Time Curve

- Without seepage, the creep curve is gentle, and the creep velocity is stable under the first- and second-grade loads. Under the third-grade loads, the creep deformation obviously increases, whereas the creep velocity decreases gradually until it drops below 0.0015 mm/h, which indicates that the creep tends to be stable. At the fourth-grade loads, the creep rate increases significantly, and the creep strain increases rapidly, eventually leading to creep failure.

- When the seepage pressure is 0.5 MPa, the creep velocity curve is similar to that without seepage. The creep strain and rate are greater than those without seepage, and the samples were broken after about 16 h.

- When the seepage pressure is 1.0 MPa, the creep deformation of the first- and second-stage loads increases slightly, the curve is relatively gentle, and the creep velocity finally drops to 0.00027 mm/h and 0.00078 mm/h, respectively. After the third-stage loads are applied, the creep curve shows an obvious upward trend, and the final creep rate is 0.0051 mm/h. Failure occurs when the fourth-grade loads last for about 9 h.

- When the seepage pressure is 1.5 MPa, the creep velocity curve is similar to that of 1.0 MPa. The creep rate of the first-, second-, and third-stage loads eventually drop to 0.0007 mm/h, 0.00069 mm/h and 0.0067 mm/h, respectively. Failure occurs when the fourth-grade loads lasts for about 5 h.

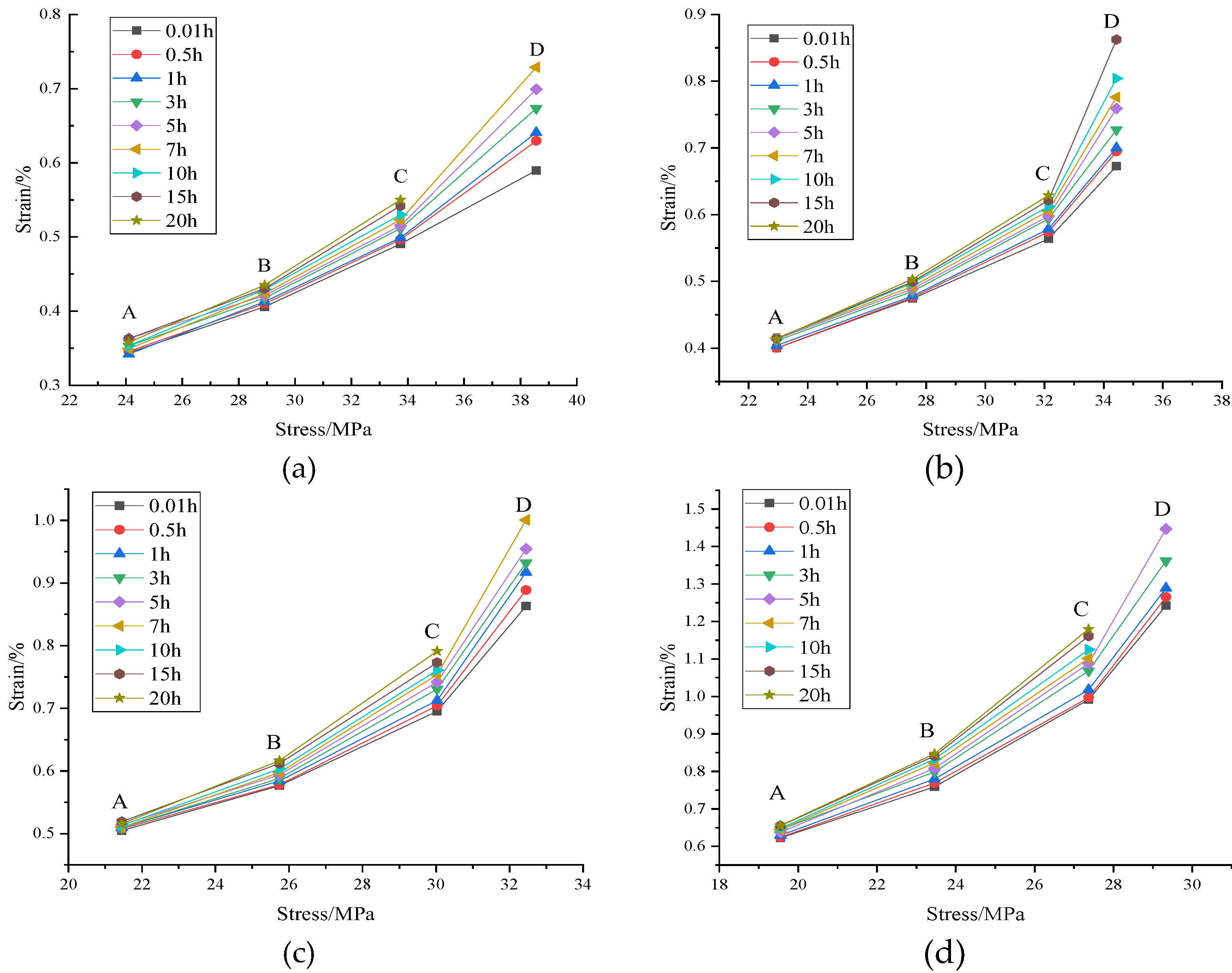

3.3. Long-Term Strength

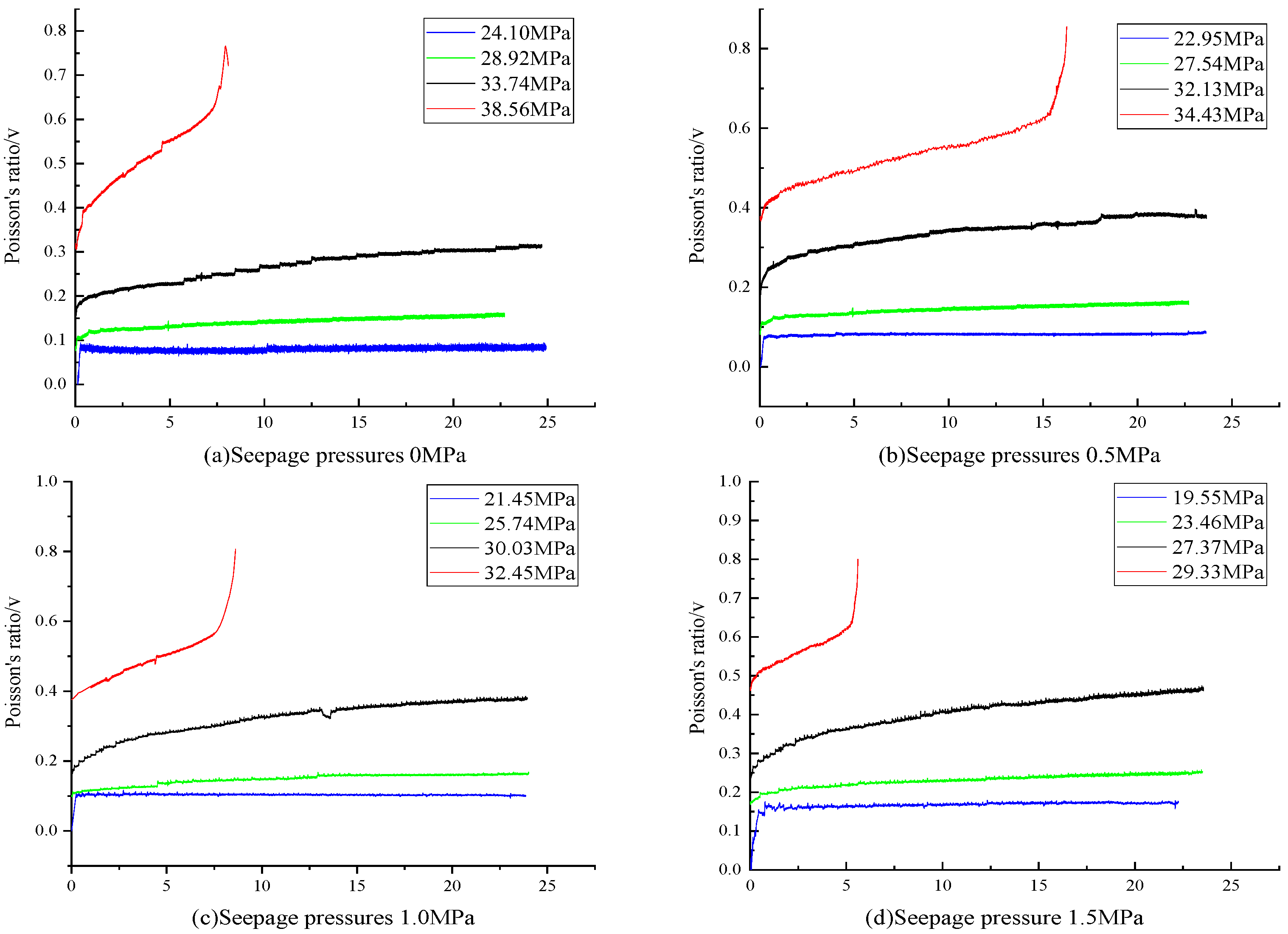

3.4. Creep Poisson’s Ratio Curve

4. Analysis of Seepage Characteristics in the Creep Process

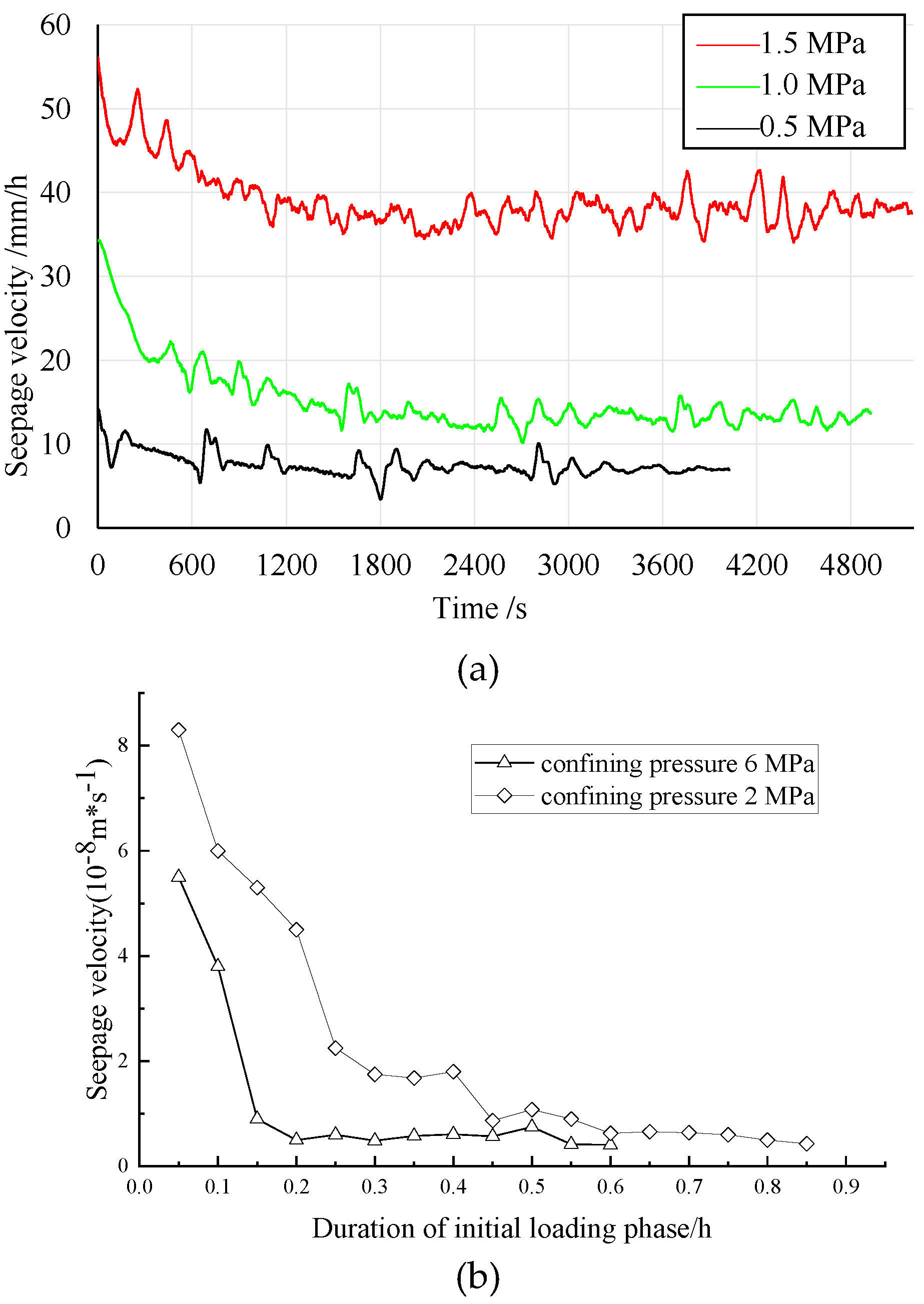

4.1. Instantaneous Deformation Stage

4.2. Steady Creep and Accelerated Creep Stages

4.3. Influence of Seepage Pressure on Velocity

- When the seepage pressure is 0.5 MPa, the seepage velocity decreases rapidly in the first two hours and then slowly at the first-grade loads. This indicates that the pores of the sample are compressed first, and then the porosity decreases slowly. Under the second- and third-grade loads, the seepage velocity is basically constant after some adjustment, indicating no significant change in porosity.

- When the seepage pressure is 1.0 MPa, for the first- and second-grade loads, the characteristics of the curve have no obvious change compared with before, only the seepage velocity increases slightly, which is probably caused by the increase of seepage pressure. After applying the third-grade loads, the seepage velocity increases slowly, but not obviously.

- When the osmotic pressure is 1.5 MPa, the change characteristics of the curve are similar to that of 1.0 MPa, but the seepage velocity increases greatly. This shows that seepage pressure plays a key role in the process of destroying the internal structure of the red-bed soft rock.

- At the fourth stage of loading, the effect of seepage pressure is more obvious, which is mainly reflected in that the slope of the seepage velocity curve increases with the increase of seepage pressure, and the fluctuation of the curve is intensified.

5. Conclusions

- (1)

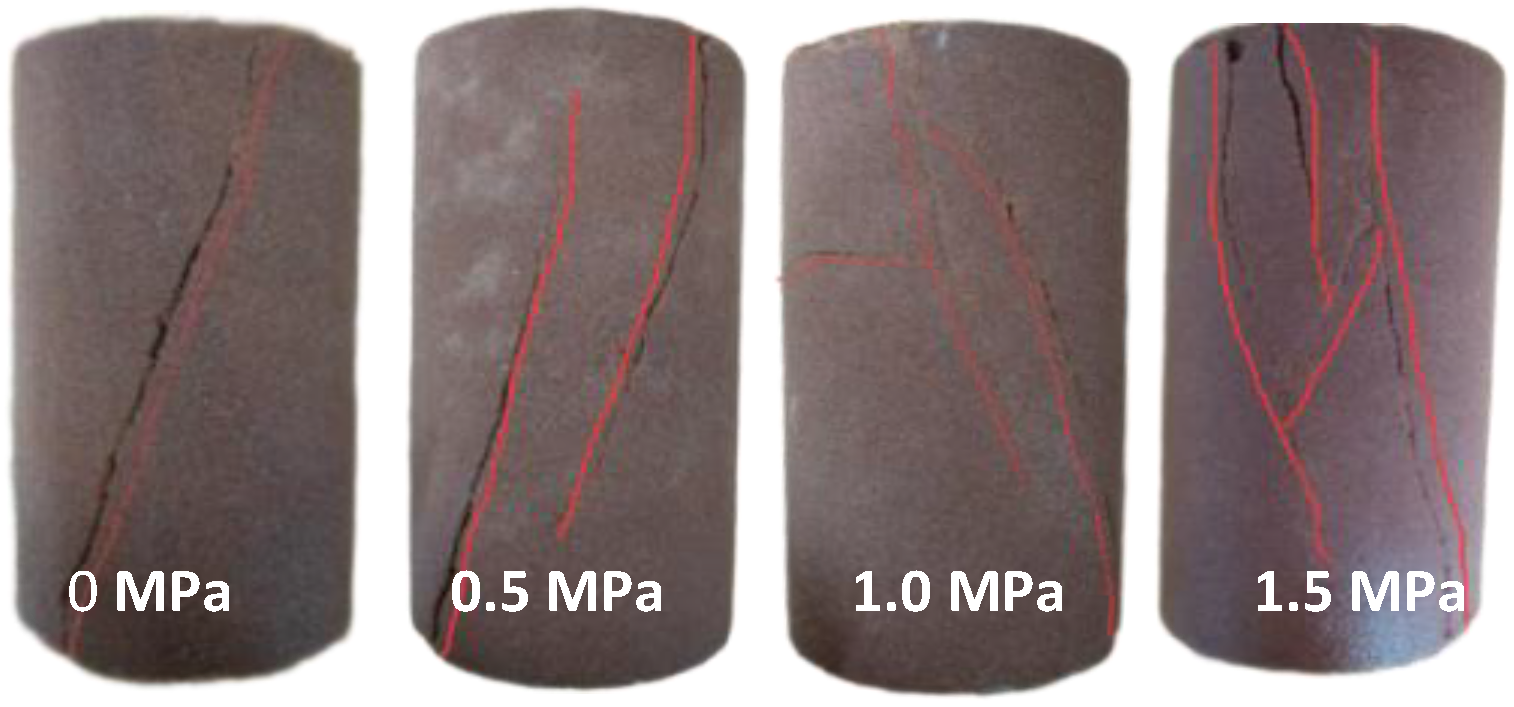

- With the increase of seepage pressure, the failure mode of triaxial compression changes from shear failure to tension–shear conjugate failure. The creep strain increases significantly, and the long-term strength is 60%~70% of the triaxial strength, indicating that seepage pressure and scour have obvious effects on the creep characteristics.

- (2)

- When the stress level and seepage pressure are relatively low, the radial strain response lags behind the axial strain history. However, in the accelerated creep stage, the radial strain is more sensitive than the axial strain, and the duration of creep decreases with the increase of seepage pressure.

- (3)

- The seepage velocity increases significantly with the increase in seepage pressure, indicating that the seepage leads to an increase in porosity and the failure of the internal structure. Especially when the seepage pressure is 1.5 MPa, the seepage velocity increases greatly. Therefore, the influence of the fluid–structure interaction should be fully considered in the long-term stability analysis of engineering.

- (4)

- In the accelerated creep stage, the slope and fluctuation amplitude of the seepage velocity curve increase significantly with the increase in seepage pressure, which can be used as the precursor signal for monitoring the creep instability in the field.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, C.; Yu, L.; You, F.; Liu, Z.; Liang, Y.; Zhang, L. Coupled seepage and stress model and experiment verification for creep behavior of soft rock. Int. J. Geomech. 2020, 20, 04020146. [Google Scholar] [CrossRef]

- Deng, H.; Fang, J.; Li, J.; Xiao, Y.; Zhou, M. Mechanical properties of red-bed soft rock on saturated state. J. China Coal Soc. 2017, 42, 1994–2002. [Google Scholar]

- Liu, Z.; Zhou, C.Y.; Zhu, F.X.; Zhang, L. Critical criterion for microstructure evolution of soft rocks in softening process. Rock Soil Mech. 2011, 32, 661–666. (In Chinese) [Google Scholar]

- Zhou, C.Y.; Deng, Y.; Tan, X.S.; Liu, Z.Q.; Lin, C.X. Research on the variation regularities of microstructures in the testing of interaction between soft rocks and water. ACTA Sci. Nat. Univ. Sunyatseni 2003, 42, 98–102. (In Chinese) [Google Scholar]

- Yi, P.; Zhen, L.; Cui-yine, Z. Experimental study of disintegration characteristics of red-bed soft rock within water and its interface model. Rock Soil Mech. 2017, 38, 3231–3239. (In Chinese) [Google Scholar]

- Sun, J. Rock rheological mechanics and its advance in engineering applications. Chin. J. Rock Mech. Eng. 2007, 26, 1081–1106. (In Chinese) [Google Scholar]

- Fujii, Y.; Kiyama, T.; Ishijima, Y.; Kodama, J. Circumferential strain behavior during creep tests of brittle rocks. Int. J. Rock Mech. Min. Sci. 1999, 36, 323–337. [Google Scholar] [CrossRef]

- Chen, W.Z.; Tan, X.J.; Lu, S.P.; Yang, J.P.; Wu, G.J.; Yu, H.D. Research on large-scale triaxial compressive rheological test of soft rock in depth and its constitutive model. Chin. J. Rock Mech. Eng. 2009, 28, 1735–1744. (In Chinese) [Google Scholar]

- Han, G.; Hou, J.; Zhou, H.; Zhang, C.Q.; Gao, Y.; Yang, L.; Chen, P.Z. Shear creep experimental study on constitutive model of interlayer shear weakness zones. Chin. J. Rock Mech. Eng. 2021, 40, 958–971. (In Chinese) [Google Scholar]

- Ma, L.; Hu, B.; Chen, Y.; Cui, K.; Ding, J. Shear-seepage properties of intact argillaceous shale under different injection water pressures. Rock Soil Mech. 2022, 43, 2515–2524. (In Chinese) [Google Scholar]

- Montero-Cubillo, N.S.; Galindo, R.A.; Olalla, C.; Muñiz-Menéndez, M. Pull-out creep laboratory test for soft rocks. Int. J. Rock Mech. Min. Sci. 2021, 144, 104811. [Google Scholar] [CrossRef]

- Liu, Q.; Luo, C.; Peng, X.; Liu, H.; Chen, L.; Pan, Y. Research on field rheological test and nonlinear fractional derivative creep model of weak rock mass. J. China Coal Soc. 2020, 45, 1348–1356. (In Chinese) [Google Scholar]

- He, R.P.; Zhang, Q.Y.; Wang, J.H.; Zeng, J.Q.; Huang, Y.K.; Shao, J.D. Study on compressive creep test on diabasic dike at dam site of dagangshan hydropower station. Chin. J. Rock Mech. Eng. 2007, 26, 2495–2503. (In Chinese) [Google Scholar]

- Tomanovic, Z. Rheological model of soft rock creep based on the tests on marl. Mech. Time Depend. Mater. 2006, 10, 135–154. [Google Scholar] [CrossRef]

- Cao, P.; Youdao, W.; Yixian, W.; Haiping, Y.; Bingxiang, Y. Study on nonlinear damage creep constitutive model for high-stress soft rock. Environ. Earth Sci. 2016, 75, 900. [Google Scholar] [CrossRef]

- Chen, F.; Su, R.; Yang, L.; Yang, X.; Jiao, H.; Zhu, C. Study on surrounding rock deformation laws of an argillaceous soft rock roadway based on the creep damage model. Front. Earth Sci. 2022, 10, 914170. [Google Scholar] [CrossRef]

- Xu, W.Y.; Yang, S.Q.; Chu, W.J. Nonlinear viscoelasto-plastic rheological model (Hohai model) of rock and its engineering application. Chin. J. Rock Mech. Eng. 2006, 25, 433–447. (In Chinese) [Google Scholar]

- Zhou, H.W.; Wang, C.P.; Han, B.B.; Duan, Z.Q. A creep constitutive model for salt rock based on fractional derivatives. Int. J. Rock Mech. Min. Sci. 2011, 48, 116–121. [Google Scholar] [CrossRef]

- Ding, J.; Zhou, H.; Chen, Q.; Qiong, L.; Liu, J. Characters of rheological damage and constitutive model of salt rock. Rock Soil Mech. 2015, 36, 769–776. (In Chinese) [Google Scholar]

- Liu, J.; Jing, H.; Meng, B.; Wang, L.; Yang, J.; Zhang, X. A four-element fractional creep model of weakly cemented soft rock. Bull. Eng. Geol. Environ. 2020, 79, 5569–5584. [Google Scholar] [CrossRef]

- Deng, H.F.; Zhou, M.L.; Li, J.L.; Fang, J.C.; Xiao, Y.; Zhang, H.B.; Wang, C.X. Mechanical properties deteriorating change rule research of red-layer soft rock under water-rock interaction. Chin. J. Rock Mech. Eng. 2016, 35, 3481–3491. (In Chinese) [Google Scholar]

- Zhang, F.; Jiang, A.; Yang, X. Effect of pore water pressure on shear creep characteristics of serrate structural plane. Rock Soil Mech. 2020, 41, 2901–2912. (In Chinese) [Google Scholar]

- Xie, X.; Chen, H.; Xiao, X.; Wang, J.; Zhou, J. Micro-structural characteristics and softening mechanism of red-bed soft rock under water-rock interaction condition. J. Eng. Geol. 2019, 27, 966–972. (In Chinese) [Google Scholar]

- Yu, L.; Lai, H.; Zhou, C.; Liu, Z.; Zhang, L. Percolation threshold of red-bed soft rock during damage and destruction. Appl. Sci. 2022, 12, 7615. [Google Scholar] [CrossRef]

- Zhang, Z.-T.; Gao, W.-H. Effect of different test methods on the disintegration behaviour of soft rock and the evolution model of disintegration breakage under cyclic wetting and drying. Eng. Geol. 2020, 279, 105888. [Google Scholar] [CrossRef]

- Huang, K.; Kang, B.; Zha, F.; Li, Y.; Zhang, Q.; Chu, C. Disintegration characteristics and mechanism of red-bed argillaceous siltstone under drying–wetting cycle. Environ. Earth Sci. 2022, 81, 336. [Google Scholar] [CrossRef]

- Li, A.; Deng, H.; Zhang, H.; Liu, H.; Jiang, M. The shear-creep behavior of the weak interlayer mudstone in a red-bed soft rock in acidic environments and its modeling with an improved Burgers model. Mech. Time Depend. Mater. 2021, 1–18. [Google Scholar] [CrossRef]

- Liu, Z.; He, X.; Zhou, C. Influence mechanism of different flow patterns on the softening of red-bed soft rock. J. Mar. Sci. Eng. 2019, 7, 155. [Google Scholar] [CrossRef]

- Zhou, M.; Li, J.; Luo, Z.; Sun, J.; Xu, F.; Jiang, Q.; Deng, H. Impact of water–rock interaction on the pore structures of red-bed soft rock. Sci. Rep. 2021, 11, 7398. [Google Scholar] [CrossRef]

- Hu, D.; Zhou, H.; Shao, J.; Zhang, F. Stress-induced permeability evolutions and erosion damage of porous rocks. In Porous Rock Fracture Mechanics; Woodhead Publishing: Sawston, UK, 2017; pp. 63–92. [Google Scholar]

- Chen, D.; Pan, Z.; Ye, Z.; Hou, B.; Wang, D.; Yuan, L. A unified permeability and effective stress relationship for porous and fractured reservoir rocks. J. Nat. Gas Sci. Eng. 2016, 29, 401–412. [Google Scholar] [CrossRef]

- Ye, Y.; Zeng, Y.; Cheng, S.; Chen, X.; Sun, H. Three-dimensional DEM simulation of the nonlinear crack closure behaviour of rocks. Int. J. Numer. Anal. Methods Geomech. 2022, 46, 1956–1971. [Google Scholar] [CrossRef]

- Fang, Y.; Yao, Z.; Huang, X.; Li, X.; Diao, N.; Hu, K.; Li, H. Permeability evolution characteristics and microanalysis of reactive powder concrete of drilling shaft lining under stress-seepage coupling. Constr. Build. Mater. 2022, 331, 127336. [Google Scholar] [CrossRef]

- Sun, H.; Xiong, F.; Wu, Z.; Ji, J.; Fan, L. An extended numerical manifold method for two-phase seepage–stress coupling process modelling in fractured porous medium. Comput. Methods Appl. Mech. Eng. 2022, 391, 114514. [Google Scholar] [CrossRef]

- Wang, R.; Xu, W.; Wang, W. Experimental investigation on creep behaviors of hard rock in dam foundation and its seepage laws during complete process of rock creep. Chin. J. Rock Mech. Eng. 2010, 29, 960–968. (In Chinese) [Google Scholar]

| Seepage Pressures | 0 MPa | 0.5 MPa | 1.0 MPa | 1.5 MPa |

|---|---|---|---|---|

| Axial deformation/% | 0.123 | 0.134 | 0.192 | 0.347 |

| Axial instantaneous deformation/% | 0.038 | 0.043 | 0.052 | 0.081 |

| Axial creep deformation/% | 0.085 | 0.091 | 0.140 | 0.266 |

| Radial deformation/% | −0.108 | −0.156 | −0.203 | −0.204 |

| Radial instantaneous deformation/% | −0.009 | −0.020 | −0.016 | −0.004 |

| Radial creep deformation/% | −0.099 | −0.137 | −0.188 | −0.201 |

| Seepage Pressures | 0 MPa | 0.5 MPa | 1.0 MPa | 1.5 MPa |

|---|---|---|---|---|

| Maximum deviator stress/Mpa | 48.2 | 45.9 | 42.9 | 39.1 |

| Long-term strength/Mpa | 33.74 | 32.13 | 25.74 | 23.46 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Yun, X.; Song, Y.; Liu, W.; Yang, L. Fluid-Structure Coupling Creep Characteristics of Red-Bed Soft Rock in South China. Water 2022, 14, 4088. https://doi.org/10.3390/w14244088

Zhang S, Yun X, Song Y, Liu W, Yang L. Fluid-Structure Coupling Creep Characteristics of Red-Bed Soft Rock in South China. Water. 2022; 14(24):4088. https://doi.org/10.3390/w14244088

Chicago/Turabian StyleZhang, Shuguang, Xiao Yun, Yu Song, Wenbo Liu, and Li Yang. 2022. "Fluid-Structure Coupling Creep Characteristics of Red-Bed Soft Rock in South China" Water 14, no. 24: 4088. https://doi.org/10.3390/w14244088

APA StyleZhang, S., Yun, X., Song, Y., Liu, W., & Yang, L. (2022). Fluid-Structure Coupling Creep Characteristics of Red-Bed Soft Rock in South China. Water, 14(24), 4088. https://doi.org/10.3390/w14244088