Method for Testing Shear and Tensile Strengths of Freshwater/Seawater Ice

Abstract

:1. Introduction

2. Methods

2.1. Shear Strength Test

2.1.1. Shear Strength Test Principle and Design

2.1.2. Shear Strength Test Equipment and Sample Preparation

2.1.3. Experimental Procedure of Shear Strength Test

- (1)

- Prepare the test, seal the mold and mold base with vaseline, and inject water into the mold to a depth of 60 mm. Then, inject a small amount of water into the heat insulation foam box and freeze the foam box in the corresponding low-temperature environment of the cryogenic test chamber. Install the test device on the test machine, and use the plumb line to calibrate the test device so that the upper and lower indenters are aligned with the side limit sleeve.

- (2)

- Put the mold with water into the low-temperature test chamber, adjust the temperature to −10 °C, and leave the mold in the chamber for 24 h.

- (3)

- Move the ice into the temperature test chamber by using the heat insulation foam box, and place the ice for 12 h at a given low temperature to ensure the stable temperature of the sample.

- (4)

- Take out the ice sample in the low-temperature test chamber, remove the mold, cut off the ice with bubbles, and reshape the ice in the test chamber for low-temperature operation. Then, measure, number, and record the ice sample data according to the test requirements.

- (5)

- Transfer the ice sample into the test box for the shear test, with the heat insulation foam box. Push the ice sample into the side limiting sleeve, and hold the ice sample under the indenter. Start the testing machine to make the upper indenter enter the side limit sleeve. When the side limit sleeve moves downward, the reading value of the force sensor should not change.

- (6)

- Start the test, load at a constant speed until the specimen presents shear failure and the sensor reading value drops rapidly; then, stop loading.

- (7)

- Reset and record the test data, take out the ice sample record, and clean and arrange the test equipment.

2.2. Tensile Strength Test

2.2.1. Tensile Strength Test Principle and Design

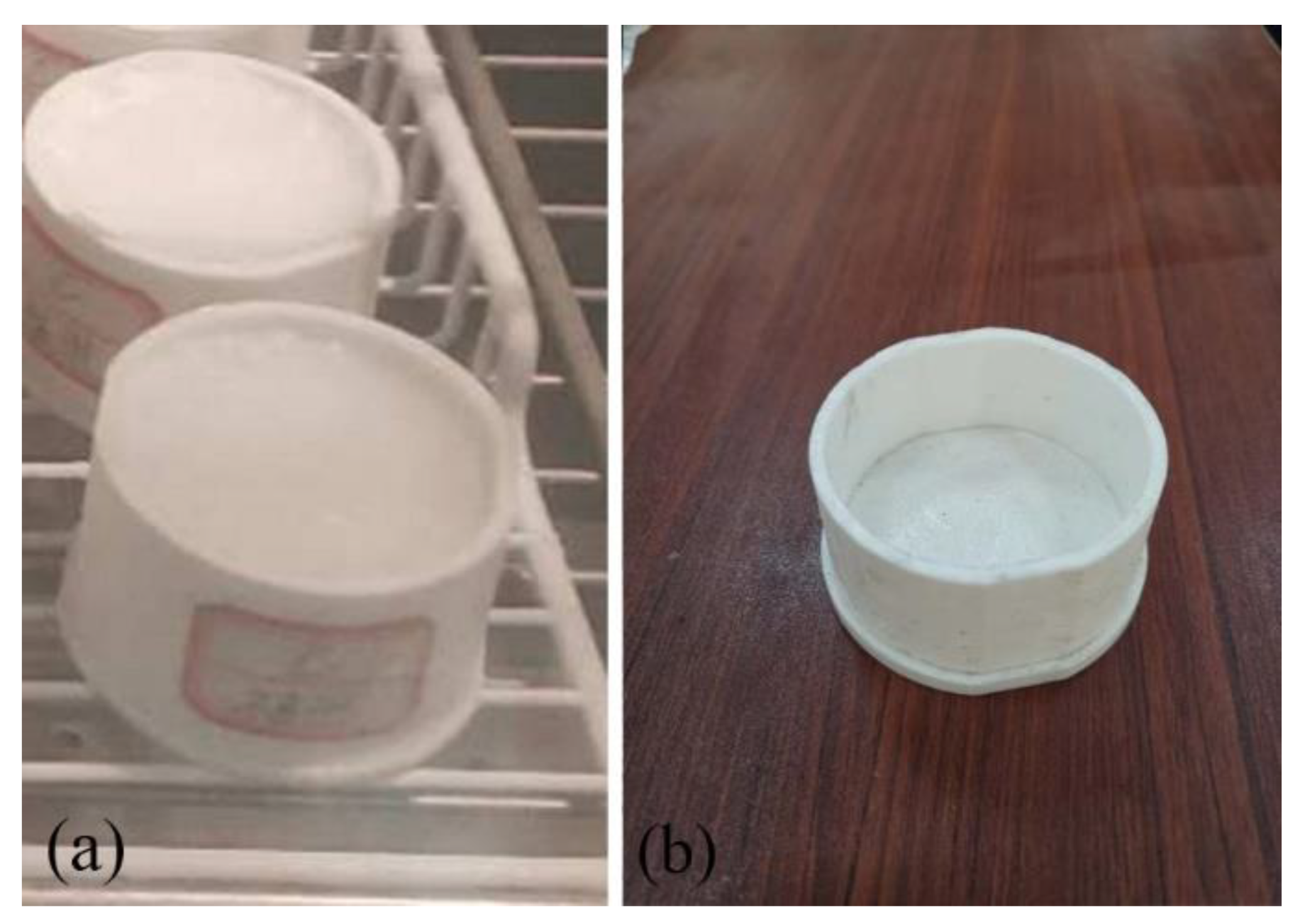

2.2.2. Tensile Strength Test Equipment and Sample Preparation

2.2.3. Experimental Procedure of Tensile Strength Test

- (1)

- Seal the mold and mold base with vaseline, inject water into the mold to a depth of 60 mm, inject a small amount of water in the heat insulation foam box, and then freeze the box in the corresponding low-temperature test chamber.

- (2)

- Freeze, select, and number the ice samples. The procedure is the same as steps (2)–(4) in Section 2.1.3.

- (3)

- Transfer the ice sample into the test box for the disc splitting test, using the heat insulation foam box. Place the ice sample between the upper and lower pressure plates so that the platform of the ice sample is aligned with the pressure plate.

- (4)

- Start the testing machine and calibrate the sensor, start the test, load at a constant speed until the specimen presents shear failure and the sensor reading value drops rapidly, and then stop loading.

- (5)

- Reset and record the test data, take out the ice sample record, and then clean and arrange the test equipment.

3. Results

3.1. Results of Shear Strength Test

3.2. Results of Tensile Strength Test

4. Discussion

4.1. Discussion of Shear Strength Test

4.2. Discussion of Tensile Strength Test

- (1)

- The measurement error of the tension sensor is 1% of the indicated value; the data acquisition instrument has data truncation errors and signal transmission has hysteresis.

- (2)

- In the process of ice making, strict single-sided heat transfer is not realized, which is controlled by using resin with low thermal conductivity (0.08 w/k).

- (3)

- The quality of the ice mold and ice has a great influence on the measurement results. After the ice is frozen, the ice sample with clear crystals and without cracks is selected, and the irregular part of the ice sample is removed and controlled by cutting and trimming.

5. Conclusions

- (1)

- The confined single-sided shear test and Brazilian disc splitting test of freshwater and seawater icing are designed and carried out in a low-temperature environment (from −10 °C to −50 °C).

- (2)

- The relationship between the shear strength of freshwater and seawater ice with the temperature change is studied. After the relationship of the shear strength of different water sources with the change of time is obtained, the appropriate lines are selected for fitting. It is found that the shear strength of freshwater and seawater ice increases at first and then decreases with the decrease in temperature. The strength of seawater ice is lower than that of freshwater ice at around 0 °C, but gradually approaches that of freshwater ice when the temperature decreases.

- (3)

- The relationship between the tensile strength of freshwater and seawater ice with the temperature change is also studied. The appropriate line is selected for fitting after the relationship of the tensile strength of different water sources ice with the change of time is obtained. It is found that with the decrease in temperature, the tensile strength of freshwater ice has a linear relationship with temperature.

- (4)

- In the anti-/de-icing design, since the increase in temperature will reduce the shear strength and tensile strength of the ice, it is possible to adopt local heating methods at the locations where the ice is easy to freeze to reduce the difficulty of de-icing.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thomas, S.K.; Cassoni, R.P.; MacArthur, C.D. Aircraft anti-icing and de-icing techniques and modeling. J. Aircr. 1996, 33, 841–854. [Google Scholar] [CrossRef]

- Parent, O.; Ilinca, A. Anti-icing and de-icing techniques for wind turbines: Critical review. Cold Reg. Sci. Technol. 2011, 65, 88–96. [Google Scholar] [CrossRef]

- Solangi, A.R. Icing Effects on Power Lines and Anti-Icing and De-Icing Methods. Master’s Thesis, UiT The Arctic University of Norway, Tromsø, Norway, 2018; 99p. [Google Scholar]

- Rashid, T.; Khawaja, H.A.; Edvardsen, K. Review of marine icing and anti-/de-icing systems. J. Mar. Eng. Technol. 2016, 15, 79–87. [Google Scholar] [CrossRef]

- Ryerson, C.C. Ice protection of offshore platforms. Cold Reg. Sci. Technol. 2011, 61, 97–110. [Google Scholar] [CrossRef]

- Cammaert, G. Impact of marine icing on Arctic offshore operations. In Arctic Marine Operations Challenges & Recommendations; Ville Miettinen: Mikkeli, Finlan, 2013; p. 5. Available online: https://www.mkc-net.nl/library/documents/613/download (accessed on 15 December 2013).

- Jones, K.F.; Andreas, E.L. Sea spray concentrations and the icing of fixed offshore structures. Q. J. R. Meteorol. Soc. 2012, 138, 131–144. [Google Scholar] [CrossRef]

- Xie, Q.; Chen, H.L.; Zhang, J.F. Research progress of anti-icing/deicing technologies for polar ships and offshore platforms. Chin. J. Ship Res. 2017, 012, 45–53. [Google Scholar]

- Fischel, M. Evaluation of Selected Deicers Based on A Review of the Literature; Report CDOT-DTD-R-2001-15; Colorado Department of Transportation Research Branch: Louisville, CO, USA, 2001; 168p.

- Shi, X.; Akin, M.; Pan, T.; Fay, L.; Liu, Y.; Yang, Z. Deicer impacts on pavement materials: Introduction and recent developments. Open Civ. Eng. J. 2009, 3, 16–27. [Google Scholar] [CrossRef] [Green Version]

- Shi, X.; Veneziano, D.; Xie, N.; Gong, J. Use of chloride-based ice control products for sustainable winter maintenance: A balanced perspective. Cold Reg. Sci. Technol. 2013, 86, 104–112. [Google Scholar] [CrossRef]

- Makkonen, L. Ice adhesion—Theory, measurements and countermeasures. J. Adhes. Sci. Technol. 2012, 26, 413–445. [Google Scholar] [CrossRef]

- Ryerson, C.C. Assessment of Superstructure Ice Protection as Applied to Offshore Oil Operations Safety; U.S. Army Engineer Research and Development Center: Hanover, NH, USA, 2009; 345p.

- Meuler, A.J.; Smith, J.D.; Varanasi, K.K.; Mabry, J.M.; McKinley, G.H.; Cohen, R.E. Relationships between water wettability and ice adhesion. ACS Appl. Mater. Interfaces 2010, 2, 3100–3110. [Google Scholar] [CrossRef]

- Farhadi, S.; Farzaneh, M.; Kulinich, S.A. Anti-icing performance of superhydrophobic surfaces. Appl. Surf. Sci. 2011, 257, 6264–6269. [Google Scholar] [CrossRef]

- Lee, C.; Nam, Y.; Lastakowski, H.; Hur, J.I.; Shin, S.; Biance, A.L.; Pirat, C.; Kim, C.J.; Ybert, C. Two types of Cassie-to-Wenzel wetting transitions on superhydrophobic surfaces during drop impact. Soft Matter 2015, 11, 4592–4599. [Google Scholar] [CrossRef] [PubMed]

- Dou, R.M.; Chen, J.; Zhang, Y.F.; Wang, X.P.; Cui, D.P.; Song, Y.L.; Jiang, L.; Wang, J.J. Anti-icing coating with an aqueous lubricating layer. ACS Appl. Mater. Interfaces 2014, 6, 6998–7003. [Google Scholar] [CrossRef]

- Frankenstein, G.; Garner, R. Equations for determining the brine volume sea ice from 0.5 °C to –22.9 °C. J. Glaciol. 1967, 6, 943–944. [Google Scholar] [CrossRef] [Green Version]

- Assur, A. Composition of Sea Ice and Its Tensile Strength; US Army Snow, Ice and Permafrost Research Establishment: Wilmette, IL, USA, 1960; pp. 106–138.

- Mustafa, T. Cooling of particulate solids and fluid in a moving bed heat exchanger. J. Heat Transf. 2019, 141, 11. [Google Scholar]

- Wang, A.; Ji, S. Flexural Strength of Sea Ice. In Encyclopedia of Ocean Engineering; Cui, W., Fu, S., Hu, Z., Eds.; Springer: Singapore, 2020. [Google Scholar] [CrossRef]

- Mustafa, T. Heat transfer from warm water to a moving foot in a footbath. Appl. Therm. Eng. 2016, 98, 280–287. [Google Scholar]

- Zhang, Y.; Zhang, Y.; Guo, R. Summary of the Test Methods for Icing Strength of Freshwater and Seawater. J. Phys. Conf. Ser. 2021, 1786, 012044. [Google Scholar] [CrossRef]

- Frederking, R.M.W.; Timco, G.W. Measurement of shear strength of granular/ discontinuous-columnar sea ice. Cold Reg. Sci. Technol. 1984, 9, 215–220. [Google Scholar] [CrossRef] [Green Version]

- Gupta, V.; Bergstrom, J.S. A progressive damage model for failure by shear faulting in polycrystalline ice under biaxial compression. Int. J. Plast. 2002, 18, 507–530. [Google Scholar] [CrossRef]

- Repetto-Llamazares, A.H.V.; Høyland, K.V.; Evers, K. Experimental studies on shear failure of freeze-bonds in saline ice: Part I: Set -up, failure mode and freeze -bond strength. Cold Reg. Sci. Technol. 2011, 65, 286–297. [Google Scholar] [CrossRef]

- Saeki, H.; Ono, T.; Zong, N.E.; Nakazawa, N. Experimental study on direct shear strength of sea ice. Ann. Glaciol. 1985, 6, 218–221. [Google Scholar] [CrossRef] [Green Version]

- Timco, G.W.; Weeks, W.F. A review of engineering properties of sea ice. Cold Reg. Sci. Technol. 2010, 60, 107–129. [Google Scholar] [CrossRef]

- Li, Z.J.; Meng, G.L.; Gao, S.G.; Liu, P.L. Experimental study of confined shear strength of S2 ice in Liaodong Gulf. Ocean. Eng. 2002, 20, 20–24. [Google Scholar] [CrossRef]

- Ji, S.Y.; Li, P.F.; Liu, H.L.; Su, H. Experimental studies of the shear strength of sea ice in the Laizhou Bay and around the Yellow River Delta of Bohai Sea. Mar. Sci. Bull. 2013, 32, 241–245. [Google Scholar] [CrossRef]

- Han, H.W.; Huang, W.F.; Jia, Q.; Li, Z.J. Study on the unconfined shear strength of large columnar-grained freshwater ice and its influential factors. South—North Water Transf. Water Sci. Technol. 2016, 14, 62–67. [Google Scholar] [CrossRef]

- Douglass, R.G.; Palacios, J.; Schneeberger, G. Design, fabrication, calibration, and testing of a centrifugal ice adhesion test rig with strain rate control capability. In Proceedings of the 2018 Atmospheric and Space Environments Conference, Atlanta, GA, USA, 25–29 June 2018; p. 3342. [Google Scholar]

- Douglass, R.G.; Palacios, J. Effects of strain rate variation on the shear adhesion strength of impact ice. Cold Reg. Sci. Technol. 2021, 181, 103168. [Google Scholar] [CrossRef]

- Currier, J.H.; Schulson, E.M. The tensile strength of ice as a function of grain size. Acta Metall. 1982, 30, 1511–1514. [Google Scholar] [CrossRef]

- Mohamed, A.M.A.; Farzaneh, M. An experimental study on the tensile properties of atmospheric ice. Cold Reg. Sci. Technol. 2011, 68, 91–98. [Google Scholar] [CrossRef]

- Dempsey, J.P.; Defranco, S.J.; Adamson, R.M.; Mulmule, S.V. Scale effects on the in-situ tensile strength and fracture of ice Part I: Large grained freshwater ice at Spray Lakes Reservoir, Alberta. Int. J. Fract. 1999, 95, 325–345. [Google Scholar] [CrossRef]

- Petrovic, J.J. Review mechanical properties of ice and snow. J. Mater. Sci. 2003, 38, 1–6. [Google Scholar] [CrossRef]

- Dykins, J.E. Tensile properties of sea ice grown in a confined system. Phys. Snow Ice Proc. 1967, 1, 523–537. [Google Scholar]

- Zhang, H.B. Experimental Study on Tensile Strength and Fracture Toughness of Yellow River Ice by Using Split Test. Master’s Thesis, Dalian University of Technology, Dalian, China, 2016; 86p. [Google Scholar]

- Carney, K.S.; Benson, D.J.; DuBois, P.; Lee, R. A phenomenological high strain rate model with failure for ice. Int. J. Solids Struct. 2006, 43, 7820–7839. [Google Scholar] [CrossRef] [Green Version]

- Schulson, E.M. Brittle failure of ice. Eng. Fract. Mech. 2001, 68, 1839–1887. [Google Scholar] [CrossRef]

- Jia, Q.; Li, Z.J.; Han, H.W.; Yu, K.; Gu, X. Experimental study on shear strength of freshwater ice in a reservoir. Math. Pract. Theory 2015, 45, 132–137. [Google Scholar]

- Muskhelishvili, N. Some Basic Problems of the Mathematical Theory of Elasticity; P. Noordhoff Ltd.: Groningen, The Netherlands, 1953. [Google Scholar]

- Wang, Q.Z.; Jia, X.M. Determination of elastic modulus, tensile strength and fracture toughness of brittle rocks by using flattened brazilian disk specimen: Part I: Analytical and numerical results. Chin. J. Rock Mech. Eng. 2002, 21, 1285–1289. [Google Scholar] [CrossRef]

| Seawater | Dalian | Qingdao | Fuzhou | Zhuhai |

|---|---|---|---|---|

| Average salinity | 29.3‰ | 28.1‰ | 26.5‰ | 8.7‰ |

| Seawater Ice | Dalian | Qingdao | Fuzhou | Zhuhai |

|---|---|---|---|---|

| Average salinity | 17.9‰ | 12.5‰ | 14.1‰ | 7.1‰ |

| Ice | Freshwater Ice | Dalian Seawater Ice | Qingdao Seawater Ice | Fuzhou Seawater Ice | Zhuhai Seawater Ice |

|---|---|---|---|---|---|

| R2 | 0.1625 | 0.9530 | 0.8776 | 0.9566 | 0.8827 |

| Ice | Freshwater Ice | Dalian Seawater Ice | Qingdao Seawater Ice | Fuzhou Seawater Ice | Zhuhai Seawater Ice |

|---|---|---|---|---|---|

| R2 | 0.4263 | 0.9598 | 0.9499 | 0.879 | 0.8109 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhang, Y.; Guo, R.; Cui, B. Method for Testing Shear and Tensile Strengths of Freshwater/Seawater Ice. Water 2022, 14, 1363. https://doi.org/10.3390/w14091363

Zhang Y, Zhang Y, Guo R, Cui B. Method for Testing Shear and Tensile Strengths of Freshwater/Seawater Ice. Water. 2022; 14(9):1363. https://doi.org/10.3390/w14091363

Chicago/Turabian StyleZhang, Yongjie, Yunhui Zhang, Renzhong Guo, and Bo Cui. 2022. "Method for Testing Shear and Tensile Strengths of Freshwater/Seawater Ice" Water 14, no. 9: 1363. https://doi.org/10.3390/w14091363