Coffee Industry and Ways of Using By-Products as Bioadsorbents for Removal of Pollutants

Abstract

:1. Introduction

2. Characteristics of Coffee

- Alkaloid caffeine (which has, among other things, properties that stimulate the nervous system);

- Trigonelline (which, under the influence of smoking, is converted into nicotinic acid);

- Theobromine;

- Diterpene alcohols (caffeoyl and caffestol-affecting lipid metabolism);

- Chlorogenic acid (with antioxidant properties);

- Organic acids (malic, citric, phosphoric);

- Phenolacids (caffeic acid and its esters with quinic acid);

- Tannins;

- Carbohydrates (sucrose);

- Proteins;

3. Coffee Beans Processing Technologies

3.1. Dry Coffee Processing Method

3.2. Wet/Semi-Dry Coffee Processing Method

4. By-Products of Coffee Bean Processing

4.1. Coffee Husks and Pulp

4.2. Defective Coffee Beans

4.3. Coffee Silver Skin

4.4. Spent Coffee Grounds

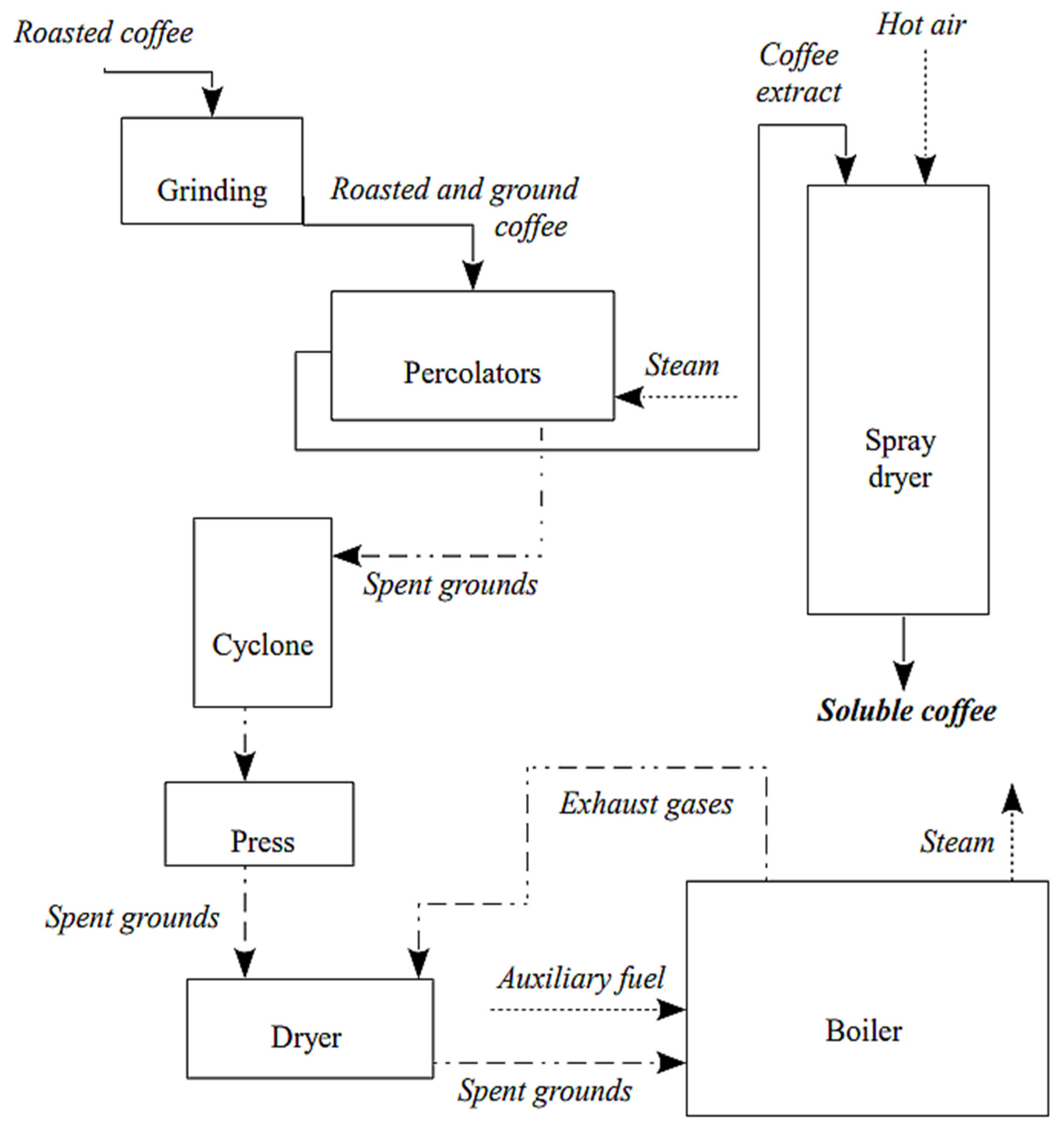

5. Management and Use of By-Products from Coffee Bean Processing

6. Coffee-Processing Waste as Biosorbents

6.1. Spent Coffee Grounds as Biosorbents

6.2. Coffee Beans as Biosorbents

6.3. Other Coffee Waste as Biosorbents

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chudy, S. Development of coffee market and changes in coffee consumption among Poles. J. Agribus. Rural Dev. 2014, 4, 41–51. [Google Scholar]

- Lenart, B. On the coffee trail. With coffee and music through different countries [I]. Przegląd Gastron. 2006, 60, 07–08. [Google Scholar]

- Hrankowski, H. Coffee: Raw Material, Technology; WNT: Warszawa, Poland, 1976. [Google Scholar]

- Fairtrade Polska: Kawa. Available online: https://www.fairtrade.org.pl/fairtrade/produkty-i-producenci/kawa/#:~:text=Warto%C5%9B%C4%87%20%C5%9Bwiatowego%20rynku%20kawy%20szacuje%20si%C4%99%20na%2081,mi%C4%99dzynarodowych%20konsorcj%C3%B3w%20zajmuj%C4%85cych%20si%C4%99%20handlem%20i%20paleniem%20kawy (accessed on 18 October 2022).

- Żukiewicz-Sobczak, W.; Krasowska, E.; Sobczak, P.; Horoch, A.; Wojtyła, A.; Piątek, J. Effect of coffee consumption on the human organism. Med. Ogólna I Nauk. O Zdrowiu 2012, 18, 71–76. [Google Scholar]

- National Coffee Association: History of Coffee—An Ethiopian Legend. Available online: https://www.ncausa.org/About-Coffee/History-of-Coffee (accessed on 18 October 2022).

- International Coffee Organization: World Coffee Consumption. Available online: https://www.ico.org/prices/new-consumption-table.pdf (accessed on 18 October 2022).

- Lewin, B.; Giovannucci, D.; Varangis, P. Coffee markets: New Paradigms in Global Supply and Demand. World Bank Agriculture and Rural Development Discussion Paper No. 3. 2004. Available online: https://ssrn.com/abstract=996111 (accessed on 18 October 2022).

- Andrzejuk, A. The analysis of trends in production and trade of coffee worldwide and in Poland. Ekonomika i Organizacja Gospodarki Żywnościowej 2016, 116, 105–117. [Google Scholar] [CrossRef] [Green Version]

- Coffee Market in Poland Already Worth PLN 5 Billion. The Fastest Growing Premium Category. Available online: https://www.portalspozywczy.pl/drukuj/102129.html (accessed on 20 October 2022).

- Coffee Market in Poland and the World. Available online: https://biznestuba.pl/featured/rynek-kawy-w-polsce-i-na-swiecie/ (accessed on 20 October 2022).

- Vincent, J.C. Green coffee processing. In Coffee Technology; Elsevier Science Publishers: New York, NY, USA, 1987; Chapter 1; pp. 1–33. [Google Scholar]

- Nabais, J.V.; Carrot, P.; Ribeiro Carrot, M.M.L.; Luz, V.; Ortiz, A.L. Influence of preparation conditions in the textural and chemical properties of activated carbons from a novel biomass precursor: The coffee endocarp. Bioresour. Technol. 2008, 99, 7224–7231. [Google Scholar] [CrossRef]

- Sisti, L.; Celli, A.; Totaro, G.; Cinelli, P.; Signori, F.; Lazzeri, A.; Bikaki, M.; Corvini, P.; Ferri, M.; Tassoni, A.; et al. Monomers, Materials and Energy from Coffee By-Products: A Review. Sustainability 2021, 13, 6921. [Google Scholar] [CrossRef]

- International Coffee Organization: Groups of Coffee. Available online: http://www.ico.org/glossary.asp (accessed on 20 October 2022).

- Sharma, H. A Detail Chemistry of Coffee and Its Analysis. In Coffee-Production and Research; IntechOpen: London, UK, 2020; Available online: https://www.intechopen.com/chapters/71528 (accessed on 20 October 2022). [CrossRef] [Green Version]

- Mussatto, S.; Machado, E.M.S.; Martins, S.; Teixeira, J. Production, Composition, and Application of Coffee and Its Industrial Residues. Food Bioprocess Technol. 2011, 4, 661–672. [Google Scholar] [CrossRef] [Green Version]

- Dąbrowska-Molenda, M.; Szwedziak, K.; Zabłudowska, Ż. Analysis of caffeine content in selected types of coffee. Postępy Tech. Przetwórstwa Spożywczego 2019, 2, 68–71. [Google Scholar]

- Fiedoruk, A. Kawa bez Tajemnic; Instytut Wydawniczy Kreator: Białystok, Poland, 2004; Volume 10–50, pp. 105–170. [Google Scholar]

- Matysek-Nawrocka, M.; Cyrankiewicz, P. Biological active substances derived from tea, coffee and cocoa and their application in cosmetics. Post Fitoter. 2016, 2, 139–144. [Google Scholar]

- O’Keefe, J.H.; DiNicolantonio, J.J.; Lavie, C.J. Coffee for Cardioprotection and Longevity. Prog. Cardiovasc. Dis. 2018, 61, 38–42. [Google Scholar] [CrossRef] [Green Version]

- Nieber, K. The Impact of Coffee on Health. Planta Med. 2017, 83, 1256–1263. [Google Scholar] [CrossRef] [Green Version]

- Nehlig, A. Effects of coffee/caffeine on brain health and disease: What should I tell my patients? Pract. Neurol. 2016, 16, 89–95. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Clarke, R.J. Water and Mineral Contents. In Coffee; Chapter 2; Clarke, R.J., Macrae, R., Eds.; Springer: Berlin/Heidelberg, Germany, 1989; pp. 42–82. [Google Scholar]

- Arya, M.; Rao, L.J.M. An impression of coffee carbohydrates. Crit. Rev. Food Sci. Nutr. 2007, 47, 51–67. [Google Scholar] [CrossRef] [PubMed]

- Nabais, J.M.V.; Nunes, P.; Carrott, P.J.M.; Carrott, M.R.; García, A.M.; Diez, M.A.D. Production of activated carbons from coffee endocarp by CO2 and steam activation. Fuel Process. Technol. 2008, 89, 262–268. [Google Scholar] [CrossRef]

- Ladino-Ospina, Y.; Giraldo-Gutierrez, L.; Moreno Piraján, J.C. Calorimetric study of the immersion heats of lead (II) and chromium (VI) from aqueous solutions of Colombian coffee husk. J. Therm. Anal. Calorim. 2005, 81, 435–440. [Google Scholar] [CrossRef]

- Baquero, M.C.; Giraldo, L.; Moreno, J.C.; Suarez Garcia, F.; Martinez Alonso, A.; Tascón, J.M.D. Activated carbons by pyrolysis of coffee bean husk in presence of phosphoric acid. J. Anal. Appl. Pyrolysis 2003, 70, 779–784. [Google Scholar] [CrossRef]

- Boonamnvayvitaya, V.; Sae-Ung, S.; Tanthapanichakoon, W. Preparation of activated carbons from coffee residue for the adsorption of formaldehyde. Sep. Purif. Technol. 2005, 42, 159–168. [Google Scholar] [CrossRef]

- Nakamura, T.; Tokimoro, T.; Tamuro, T.; Kawasaki, N.; Tanada, S. Decolorization of acidic dye by charcoal from coffee grounds. J. Health Sci. 2003, 49, 520–523. [Google Scholar] [CrossRef] [Green Version]

- Hirata, M.; Kawasaki, N.; Nakamura, T.; Matsumoto, K.; Kayayama, M.; Tamuro, T.; Tanada, S. Adsorption of dyes onto carbonaceous materials produced from coffee grounds by microwave treatment. J. Colloid Interface Sci. 2002, 254, 17–22. [Google Scholar] [CrossRef]

- Tsunoda, R.; Ozawa, T.; Ando, J.I. Ozone treatment of coal- and coffee grounds-based active carbons: Water vapor adsorption and surface fractal micropore. J. Colloid Interface Sci. 1998, 205, 265–270. [Google Scholar] [CrossRef]

- Nakamura, T.; Hirata, M.; Kawasaki, N.; Tanada, S.; Tamuro, T.; Nakahori, Y. Decolorization of indigo carmine by charcoal from extracted residue of coffee beans. J. Environ. Sci. Health 2003, 38, 555–562. [Google Scholar] [CrossRef] [PubMed]

- Murthy, P.S.; Naidu, M.M. Sustainable management of coffee industry by-products and value addition—A review. Resour. Conserv. Recycl. 2012, 66, 45–58. [Google Scholar] [CrossRef]

- Cruz, R. Coffee By-Products: Sustainable Agro-Industrial Recovery and Impact on Vegetables Quality; University of Porto: Porto, Portugal, 2014; Available online: https://core.ac.uk/download/pdf/143390706.pdf (accessed on 20 October 2022).

- Dwie Metody Obróbki Kawy—Mokra i Sucha. Available online: https://www.cafesilesia.pl/Dwie-metody-obrobki-kawy-mokra-i-sucha-blog-pol-1538147483.html (accessed on 20 October 2022).

- Nursten, H.E. Coffee Technology; Sivetz, M., Desrosier, N.W., Eds.; AVI Publishing Co. Inc.: Westport, CT, USA, 1982; Volume 9, p. 239. [Google Scholar] [CrossRef]

- Franca, A.S.; Oliveira, L.S. Coffee processing solid wastes: Current uses and future perspectives. Agric. Wastes 2009, 9, 155–189. [Google Scholar]

- Oliveira, L.S.; Franca, A.S.; Camargos, R.R.S.; Ferraz, V.P. Coffee oil as a potential feedstock for biodiesel production. Bioresour. Technol. 2008, 99, 3244–3250. [Google Scholar] [CrossRef] [PubMed]

- Gouvea, B.M.; Torres, C.; Franca, A.S.; Oliveira, L.S.; Oliveira, E.S. Feasibility of ethanol production from coffee husks. Biotechnol. Lett. 2009, 31, 1315–13199. [Google Scholar] [CrossRef]

- Jayachandra, C.; Venugopal, K.A.; Appaiah, K.A. Utilization of phytotoxic agro waste – coffee cherry husk through pretreatment by the ascomycetes fungi Mycotypha for biomethanation. Energy Sustain. Dev. 2011, 15, 104–108. [Google Scholar] [CrossRef]

- Fan, L.; Pandey, A.; Mohan, A.; Soccol, C.R. Use of various coffee industry residues for the cultivation of pleurotus ostreatus in solid state fermentation. Acta Biotechnol. 2000, 20, 41–52. [Google Scholar] [CrossRef]

- da Silva, M.C.S.; Naozuka, J.; da Luz, J.M.R.; de Assunção, L.S.; Oliveira, P.V.; Vanetti, M.C.D.; Bazzolli, D.M.; Kasuya, M.C. Enrichment of Pleurotus ostreatus mushrooms with selenium in coffee husks. Food Chem. 2012, 131, 558–563. [Google Scholar] [CrossRef] [Green Version]

- Kassa, H.; Suliman, H.; Workayew, T. Evaluation of composting process and quality of compost from coffee by-products (coffee husk & pulp). Ethiop. J. Environ. Stud. Manag. 2011, 4, 8–13. [Google Scholar]

- Franca, A.S.; Oliveira, L.S.; Ferreira, M.E. Kinetics and equilibrium studies of methylene blue adsorption by spent coffee grounds. Desalination 2009, 249, 267–272. [Google Scholar] [CrossRef]

- Oliveira, L.S.; Franca, A.S.; Mendonça, J.C.F.; Barros-Júnior, M.C. Proximate composition and fatty acids profile of green and roasted defective coffee beans. LWT-Food Sci. Technol. 2006, 39, 235–239. [Google Scholar]

- Vilela, D.M.; Pereira, G.V.D.M.; Silva, C.F.; Batista, L.R.; Schwan, R.F. Molecular ecology and polyphasic characterization of the microbiota associated with semi-dry processed coffee (Coffea arabica L.). Food Microbiol. 2010, 27, 1128–1135. [Google Scholar] [CrossRef] [PubMed]

- Roussos, S.; de los Angeles Aquiáhuatl, M.; del Refugio Trejo-Hernández, M.; Gaime Perraud, I.; Favela, E.; Ramakrishna, M.; Raimbault, M.; Viniegra-González, G. Biotechnological management of coffee pulp—Isolation, screening, characterization, selection of caffeine-degrading fungi and natural microflora present in coffee pulp and husk. Appl. Microbiol. Biotechnol. 1995, 42, 756–762. [Google Scholar] [CrossRef]

- Rojas, J.B.U.; Verreth, J.A.J.; Amato, S.; Huisman, E.A. Biological treatments affect the chemical composition of coffee pulp. Bioresour. Technol. 2003, 89, 267–274. [Google Scholar] [CrossRef]

- Rodriguez-Duran, L.V.; Ramirez-Coronel, M.A.; Aranda-Delgado, E.; Nampoothiri, K.M.; Favela-Torres, E.; Aguilar, C.N.; Saucedo-Castañeda, G. Soluble and bound hydroxycinnamates in coffee pulp (Coffea arabica) from seven cultivars at three ripening stages. J. Agric. Food Chem. 2014, 62, 7869–7876. [Google Scholar] [CrossRef]

- Oliveira, V.D.; Fialho, E.T.; Lima, J.A.F.; Oliveira, A.I.G.D.; Freitas, R.T.F.D. Coffee husks as a corn substitute in isoenergetic diets for swines: Digestibility and performance. Ciência E Agrotecnologia 2001, 25, 424–436. [Google Scholar]

- Vilela, F.G.; Perez, J.R.O.; Teixeira, J.C.; Reis, S.T. Use of “sticky” coffee husks at several levels for feeding confined steers. Ciência E Agrotecnologia 2001, 25, 198–205. [Google Scholar]

- Souza, A.L.; Garcia, R.; Pereira, O.G.; Cecon, P.R.; Filho, S.C.V.; Paulino, M.F. Proximate and chemical composition of coffee husks treated with amonium and sodium sulfate. Rev. Bras. Zootec. 2001, 30, 983–991. [Google Scholar] [CrossRef]

- Souza, A.L.; Bernardino, F.S.; Garcia, R.; Pereira, O.G.; Rocha, F.C.; Pires, A.J.V. Nutritive value of Pennisetum purpurem Schum sillage with different levels of coffee husks. Rev. Bras. Zootec. 2003, 32, 828–833. [Google Scholar]

- Souza, A.L.; Garcia, R.; Filho, S.C.V.; Rocha, F.C.; Campos, J.M.S.; Cabral, L.S.; Gobbi, K.F. Coffee husks in cows diet: Consumption, digestibility and milk production. Rev. Bras. Zootec. 2005, 34, 2496–2504. [Google Scholar] [CrossRef] [Green Version]

- Rocha, F.C.; Garcia, R.; Bernardino, F.S.; Freitas, A.P.W.; Valadares, R.F.D.; Junqueira, B.A.; Rigueira, J.P.S.; Rocha, G.C. Synthesis of microbial protein in caws fed diets containing coffee husks. Bol. Indústria Anim. 2005, 62, 149–156. [Google Scholar]

- Adams, M.R.; Dougan, J. Waste Products. In Coffee; Clarke, R., Macrae, R., Eds.; Springer: Dordrecht, The Netherlands, 1987; pp. 257–291. [Google Scholar]

- Barcelos, A.F.; Paiva, P.C.; Pérez, J.R.O.; Cardoso, R.M.; Snatos, V.B. Estimate of the carbohydrate fractions of the coffee hulls and dehydrated pulp of coffee (Coffea arabica L.) stored for different periods. Rev. Bras. Zootec. 2001, 30, 1566–1571. [Google Scholar] [CrossRef] [Green Version]

- Pandey, A.; Soccol, C.R.; Nigam, P.; Soccol, V.T. Biotechnological potential of agro-industrial residues. I: Sugarcane bagasse. Bioresour. Technol. 2000, 74, 69–80. [Google Scholar] [CrossRef]

- Clifford, M.N.; Ramirez-Martinez, J.R. Tannins in wet-processed coffee beans and coffee pulp. Food Chem. 1991, 40, 191–200. [Google Scholar] [CrossRef]

- Brand, D.; Pandey, A.; Roussos, S.; Soccol, C.R. Biological detoxification of coffee husk by filamentous fungi using a solid state fermentation system. Enzym. Microb. Technol. 2000, 27, 127–133. [Google Scholar] [CrossRef]

- Matos, A.T. Tratamento de resíduos na pós-colheita do café (Residues disposal in coffee post-processing). In Pós-Colheita do Café (Coffee Post Processing); Borém, F.M., Ed.; Editora UFLA: Lavras, Brazil, 2008; pp. 161–201. [Google Scholar]

- Clarke, R.J. Grading, Stoarge, Pre-treatment and Blending. In Coffee Technology; Clarke, R., Macrae, R., Eds.; Springer: Dordrecht, The Netherlands, 1987; pp. 35–58. [Google Scholar]

- Mazzafera, P. Chemical composition of defective coffee beans. Food Chem. 1999, 64, 547–554. [Google Scholar] [CrossRef]

- Sivetz, M.; Desrosier, N.W. Coffee Technology; Avi Publishing Co.: Westport, CT, USA, 1979. [Google Scholar]

- Nunes, A.A.; Franca, A.S.; Oliveira, L.S. Activated carbons from waste biomass: An alternative use for biodiesel production solid residues. Bioresour. Technol. 2009, 100, 1786–1792. [Google Scholar] [CrossRef]

- Tokimoto, T.; Kawasaki, N.; Nakamura, T.; Akutagawa, J.; Tanada, S. Removal of lead ions in drinking water by coffee grounds as vegetable biomass. J. Colloid Interface Sci. 2005, 281, 56–61. [Google Scholar] [CrossRef]

- Leifa, F.; Pandey, A.; Soccol, C.R. Solid state cultivation—An efficient method to use toxic agro-industrial residues. J. Basic Microbiol. Int. J. Biochem. Physiol. Genet. Morphol. Ecol. Microorg. 2000, 40, 187–197. [Google Scholar] [CrossRef]

- Ramalakshmi, K.; Rao, L.J.M.; Takano-Ishikawa, Y.; Goto, M. Bioactivities of low-grade green coffee and spent coffee in different in vitro model systems. Food Chem. 2009, 115, 79–85. [Google Scholar] [CrossRef]

- Saenger, M.; Hartge, E.U.; Werther, J.; Ogada, T.; Siagi, Z. Combustion of coffee husks. Renew. Energy 2001, 23, 103–121. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Teixeira, J.A. Increase in the fructooligosaccharides yield and productivity by solid-state fermentation with Aspergillus japonicus using agro-industrial residues as support and nutrient source. Biochem. Eng. J. 2010, 53, 154–157. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Machado, E.M.S.; Carneiro, L.M.; Teixeira, J.A. Sugars metabolism and ethanol production by different yeast strains from coffee industry wastes hydrolysates. Appl. Energy 2012, 92, 763–768. [Google Scholar] [CrossRef] [Green Version]

- Bilbao, C.; Ezequiel, M.E.I.; Benavent, M.A.; Calleja, M.H.; del Moral, M.P.; Ariz, M.V. Application of Products of Coffee Silverskin in Anti-Ageing Cosmetics and Functional. Food. Patent EP2730171A1, 14 May 2014. [Google Scholar]

- Martins, S.; Mussatto, S.I.; Martínez-Avila, G.; Montañez-Saenz, J.; Aguilar, C.N.; Teixeira, J.A. Bioactive phenolic compounds: Production and extraction by solid-state fermentation. A review. Biotechnol. Adv. 2011, 29, 365–373. [Google Scholar] [CrossRef] [Green Version]

- Pandey, A. Solid state fermentation. Biochem. Eng. J. 2003, 13, 81–84. [Google Scholar] [CrossRef]

- European Coffee Federation, European Coffee Report 2018/2019. Available online: https://www.ecf-coffee.org/wp-content/uploads/2020/09/European-Coffee-Report-2018–2019.pdf (accessed on 20 October 2022).

- Leifa, F.; Pandey, A.; Soccol, C.R. Production of Flammulina velutipes on coffee husk and coffee spent ground. Braz. Arch. Biol. Technol. 2001, 44, 205–212. [Google Scholar] [CrossRef] [Green Version]

- Kondamudi, N.; Mohapatra, S.K.; Misra, M. Spent coffee grounds as a versatile source of green energy. J. Agric. Food Chem. 2008, 56, 11757–11760. [Google Scholar] [CrossRef]

- Machado, E.M.S.; Rodriguez-Jasso, R.M.; Teixeira, J.A.; Mussatto, S.I. Growth of fungal strains on coffee industry residues with removal of polyphenolic compounds. Biochem. Eng. J. 2012, 60, 87–90. [Google Scholar] [CrossRef] [Green Version]

- Plaza, M.G.; González, A.S.; Pevida, C.; Pis, J.J.; Rubiera, F. Valorisation of spent coffee grounds as CO2 adsorbents for postcombustion capture applications. Appl. Energy 2012, 99, 272–279. [Google Scholar] [CrossRef] [Green Version]

- Limousy, L.; Jeguirim, M.; Dutournié, P.; Kraiem, N.; Lajili, M.; Said, R. Gaseous products and particulate matter emissions of biomass residential boiler fired with spent coffee grounds pellets. Fuel 2013, 107, 323–329. [Google Scholar] [CrossRef]

- Silva, M.A.; Nebra, S.A.; Machado Silva, M.J.; Sanchez, C.G. The use of biomass residues in the Brazilian soluble coffee industry. Biomass Bioenergy 1998, 14, 457–467. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Carneiro, L.M.; Silva, J.P.A.; Roberto, I.C.; Teixeira, J.A. A study on chemical constituents and sugars extraction from spent coffee grounds. Carbohydr. Polym. 2011, 83, 368–374. [Google Scholar] [CrossRef] [Green Version]

- Jaworski, T.; Grochowska, S. Gospodarka Obiegu Zamkniętego–kryteria osiągnięcia i perspektywa wdrożenia w Polsce. Arch. Gospod. Odpad. I Ochr. Środowiska 2017, 19, 4. [Google Scholar]

- Toschi, T.G.; Cardenia, V.; Bonaga, G.; Mandrioli, M.; Rodriguez-Estrada, M.T. Coffee silverskin: Characterization, possible uses, and safety aspects. J. Agric. Food Chem. 2014, 62, 10836–10844. [Google Scholar] [CrossRef] [PubMed]

- Janissen, B.; Huynh, T. Chemical composition and value adding applications of coffee industry by-products: A review. Resour. Conserv. Recycl. 2018, 128, 110–117. [Google Scholar] [CrossRef]

- Bonilla-Hermosa, V.A.; Duarte, W.F.; Schwan, R.F. Utilization of coffee by-products obtained from semi-washed process forproduction of value-added compounds. Bioresour. Technol. 2014, 166, 142–150. [Google Scholar] [CrossRef] [PubMed]

- Sarasini, F.; Luzi, F.; Dominici, F.; Maffei, G.; Iannone, A.; Zuorro, A.; Lavecchia, R.; Torre, L.; Carbonell-Verdu, A.; Balart, R.; et al. Effect of Different Compatibilizers on Sustainable Composites Based on a PHBV/PBAT Matrix Filled with Coffee Silverskin. Polymers 2018, 10, 1256. [Google Scholar] [CrossRef] [Green Version]

- Essabir, H.; Rajia, M.; Ait Laaziza, S.; Rodrique, D.; Bouhfid, R.; el kacem Qaiss, A. Thermo-mechanical performances ofpolypropylene biocomposites based on untreated, treated and compatibilized spent coffee grounds. Compos. Part B Eng. 2018, 149, 1–11. [Google Scholar] [CrossRef]

- Sung, S.H.; Chang, Y.; Han, J. Development of polylactic acid nanocomposite films reinforced with cellulose nanocrystals derivedfrom coffee silverskin. Carbohydr. Polym. 2017, 169, 495–503. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Zuorro, A.; Maffei, G.; Lavecchia, R.; Puglia, D.; Dominici, F.; Luzi, F.; Valente, T.; Torre, L. Recycling coffee silverskin in sustainable composites based on a poly(butylene adipate-co-terephthalate)/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) matrix. Ind. Crops Prod. 2018, 118, 311–320. [Google Scholar] [CrossRef]

- Dadi, D.; Beyene, A.; Simoens, K.; Soares, J.; Demeke, M.M.; Thevelein, J.M.; Bernaerts, K.; Luis, P.; Van der Bruggen, B. Valorization of coffee for bioethanol production using lignocellulosic yeast fermentation and pervaporation. Int. J. Environ. Sci. Technol. 2018, 15, 821–832. [Google Scholar] [CrossRef]

- Procentese, A.; Raganati, F.; Navarini, L.; Olivieri, G.; Russo, M.E.; Marzocchella, A. Coffee silver skin as a renewable resource toproduce butanol and isopropanol. Chem. Eng. Trans. 2018, 64, 139–144. [Google Scholar]

- Carnier, R.; Coscione, A.R.; Delaqua, D.; Puga, A.P.; de Abreu, C.A. Jack Bean Development in Multimetal Contaminated Soil Amended with Coffee Waste-Derived Biochars. Processes 2022, 10, 2157. [Google Scholar] [CrossRef]

- Andrade, C.; Perestrelo, R.; Câmara, J.S. Valorization of Spent Coffee Grounds as a Natural Source of Bioactive Compounds for Several Industrial Applications—A Volatilomic Approach. Foods 2022, 11, 1731. [Google Scholar] [CrossRef]

- Lorenzo, P.; Guilherme, R.; Barbosa, S.; Ferreira, A.J.D.; Galhano, C. Agri-Food Waste as a Method for Weed Control and Soil Amendment in Crops. Agronomy 2022, 12, 1184. [Google Scholar] [CrossRef]

- Budžaki, S.; Velić, N.; Ostojčić, M.; Stjepanović, M.; Rajs, B.B.; Šereš, Z.; Maravić, N.; Stanojev, J.; Hessel, V.; Strelec, I. Waste Management in the Agri-Food Industry: The Conversion of Eggshells, Spent Coffee Grounds, and Brown Onion Skins into Carriers for Lipase Immobilization. Foods 2022, 11, 409. [Google Scholar] [CrossRef]

- Goiri, I.; Díaz de Otálora, X.; Ruiz, R.; Rey, J.; Atxaerandio, R.; Lavín, J.L.; San Martin, D.; Orive, M.; Iñarra, B.; Zufia, J.; et al. Spent Coffee Grounds Alter Bacterial Communities in Latxa Dairy Ewes. Microorganisms 2020, 8, 1961. [Google Scholar] [CrossRef]

- Kim, M.-S.; Kim, J.-G. Adsorption Characteristics of Spent Coffee Grounds as an Alternative Adsorbent for Cadmium in Solution. Environments 2020, 7, 24. [Google Scholar] [CrossRef] [Green Version]

- Minamisawa, M.; Minamisawa, H.; Yoshida, S.; Takai, N. Adsorption behavior of heavy metals on biomaterials. J. Agric. Food Chem. 2004, 52, 5606–5611. [Google Scholar] [CrossRef]

- Zuorro, A.; Lavecchia, R. Adsorption of Pb(II) on spent leaves of green and black tea. Am. J. Appl. Sci. 2010, 7, 153–159. [Google Scholar] [CrossRef] [Green Version]

- Babel, S.; Kurniawan, T.A. Low-cost adsorbents for heavy metals uptake from contaminated water: A review. J. Hazard. Mater. 2003, 97, 219–243. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Liu, X.; Oh, M.; Park, J.B. Oyster shell as a low-cost adsorbent for removing heavy metal ions from wastewater. Pol. J. Environ. Stud. 2019, 28, 2949–2959. [Google Scholar] [CrossRef] [PubMed]

- Wilczyński, T. Sorbenty. Podział i kryteria doboru. Bezpieczeństwo I Tech. Pożarnicza 2006, 2, 155–160. [Google Scholar]

- Demirbas, A. Heavy metal adsorption onto agro-based waste materials: A review. J. Hazard. Mater. 2008, 157, 220–229. [Google Scholar] [CrossRef] [PubMed]

- McNutt, J.; He, Q.S. Spent coffee grounds: A review on current utilization. J. Ind. Eng. Chem. 2019, 71, 78–88. [Google Scholar] [CrossRef]

- Fiol, N.; Escudero, C.; Villaescusa, I. Re-use of exhausted ground coffee waste for Cr(VI) sorption. Sep. Sci. Technol. 2008, 43, 582–596. [Google Scholar] [CrossRef]

- Krishnani, K.K.; Meng, X.; Christodoulatos, C.; Boddu, V.M. Biosorption mechanism of nine different heavy metals onto biomatrix from rice husk. J. Hazard. Mater. 2009, 163, 441–447. [Google Scholar] [CrossRef]

- Azouaou, N.; Sadaoui, Z.; Djaafri, A.; Mokaddem, H. Adsorption of cadmium from aqueous solution onto untreated coffee grounds: Equilibrium, kinetics and thermodynamics. J. Hazard. Mater. 2010, 184, 126–134. [Google Scholar] [CrossRef]

- Azmi, S.N.H.; Al Lawati, W.M.; Al Hoqani, U.H.A.; Al Aufi, E.; Al Hatmi, K.; Al Zadjali, J.S.; Rahman, N.; Nasir, M.; Rahman, H.; Khan, S.A. Development of a Citric-Acid-Modified Cellulose Adsorbent Derived from Moringa peregrina Leaf for Adsorptive Removal of Citalopram HBr in Aqueous Solutions. Pharmaceuticals 2022, 15, 760. [Google Scholar] [CrossRef]

- Martínez, M.; Miralles, N.; Hidalgo, S.; Fiol, N.; Villaescusa, I.; Poch, J. Removal of lead(II) and cadmium(II) from aqueous solutions using grape stalk waste. J. Hazard. Mater. 2006, 133, 203–211. [Google Scholar] [CrossRef] [PubMed]

- Reddad, Z.; Gerente, C.; Andres, Y.; Cloirec, P.L. Adsorption of several metal ions onto a low-cost biosorbent: Kinetic and equilibrium studies. Environ. Sci. Technol. 2002, 36, 2067–2073. [Google Scholar] [CrossRef] [PubMed]

- Mohammad, M.; Maitra, S.; Ahmad, N.; Bustam, A.; Sen, T.K.; Dutta, B.K. Metal ion removal from aqueous solution using physic seed hull. J. Hazard. Mater. 2010, 179, 363–372. [Google Scholar] [CrossRef] [PubMed]

- Brown, P.; Jefcoat, I.A.; Parrish, D.; Gill, S.; Graham, E. Evaluation of the adsorptive capacity of peanut hull pellets for heavy metals in solution. Adv. Environ. Res. 2000, 4, 19–29. [Google Scholar] [CrossRef]

- Utomo, H.D.; Hunter, K.A. Adsorption of heavy metals by exhausted coffee grounds as a potential treatment method for waste waters. E-J. Surf. Sci. Nanotechnol. 2006, 4, 504–506. [Google Scholar] [CrossRef] [Green Version]

- Kaikake, K.; Hoaki, K.; Sunada, H.; Dhakal, R.P.; Baba, Y. Removal characteristics of metal ions using degreased coffee beans: Adsorption equilibrium of cadmium. Biores. Technol. 2007, 98, 2787–2791. [Google Scholar] [CrossRef]

- Oliveira, W.E.; Franca, A.S.; Oliveira, L.S.; Rocha, S.D. Untreated coffee husks as biosorbents for the removal of heavy metals from aqueous solutions. J. Hazard. Mater. 2008, 152, 1073–1081. [Google Scholar] [CrossRef] [PubMed]

- Patterer, M.S.; Bavasso, I.; Sambeth, J.E.; Medici, F. Cadmium removal from acqueous solution by adsorption on spent coffee grounds. Chem. Eng. Trans. 2017, 60, 157–162. [Google Scholar]

- Nam, G.; Kim, M.-S.; Lee, N.; Choi, Y.-H.; Ahn, J.W. An Environmentally Benign Approach for As (V) Absorption from Wastewater Using Untreated Coffee Grounds—Preliminary Results. Water 2017, 9, 867. [Google Scholar] [CrossRef] [Green Version]

- Zungu, V.; Hadebe, L.; Mpungose, P.; Hamza, I.; Amaku, J.; Gumbi, B. Fabrication of Biochar Materials from Biowaste Coffee Grounds and Assessment of Its Adsorbent Efficiency for Remediation of Water-Soluble Pharmaceuticals. Sustainability 2022, 14, 2931. [Google Scholar] [CrossRef]

- Figueroa Campos, G.A.; Perez, J.P.H.; Block, I.; Sagu, S.T.; Saravia Celis, P.; Taubert, A.; Rawel, H.M. Preparation of Activated Carbons from Spent Coffee Grounds and Coffee Parchment and Assessment of Their Adsorbent Efficiency. Processes 2021, 9, 1396. [Google Scholar] [CrossRef]

- Sawalha, H.; Bader, A.; Sarsour, J.; Al-Jabari, M.; Rene, E.R. Removal of Dye (Methylene Blue) from Wastewater Using Bio-Char Derived from Agricultural Residues in Palestine: Performance and Isotherm Analysis. Processes 2022, 10, 2039. [Google Scholar] [CrossRef]

- Gómez-Aguilar, D.L.; Esteban-Muñoz, J.A.; Rodríguez-Miranda, J.P.; Baracaldo-Guzmán, D.; Salcedo-Parra, O.J. Desorption of Coffee Pulp Used as an Adsorbent Material for Cr(III and VI) Ions in Synthetic Wastewater: A Preliminary Study. Molecules 2022, 27, 2170. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Aguilar, D.L.; Rodríguez-Miranda, J.P.; Baracaldo-Guzmán, D.; Salcedo-Parra, O.J.; Esteban-Muñoz, J.A. Biosorption of Pb(II) Using Coffee Pulp as a Sustainable Alternative for Wastewater Treatment. Appl. Sci. 2021, 11, 6066. [Google Scholar] [CrossRef]

- Gómez Aguilar, D.L.; Rodríguez Miranda, J.P.; Astudillo Miller, M.X.; Maldonado Astudillo, R.I.; Esteban Muñoz, J.A. Removal of Zn(II) in Synthetic Wastewater Using Agricultural Wastes. Metals 2020, 10, 1465. [Google Scholar] [CrossRef]

- Frezzini, M.A.; Massimi, L.; Astolfi, M.L.; Canepari, S.; Giuliano, A. Food Waste Materials as Low-Cost Adsorbents for the Removal of Volatile Organic Compounds from Wastewater. Materials 2019, 12, 4242. [Google Scholar] [CrossRef] [PubMed]

| 2017/18 | 2018/19 | 2019/20 | 2020/21 | CAGR (2017/21) | |

|---|---|---|---|---|---|

| World | 161,377 | 168,492 | 164,202 | 166,346 | 1.0% |

| Europe | 53,251 | 55,637 | 53,372 | 54,065 | 0.5% |

| Asia and Oceania | 34,903 | 36,472 | 36,002 | 36,503 | 1.5% |

| North America | 29,941 | 31,779 | 30,580 | 30,993 | 1.2% |

| South America | 26,922 | 27,156 | 26,898 | 27,180 | 0.3% |

| Africa | 11,087 | 12,017 | 12,024 | 12,242 | 3.4% |

| Central America and Mexico | 5273 | 5431 | 5327 | 5364 | 0.6% |

| Coffee Husks (Dry Processed) | Coffee Pulp (Wet Processed) | |

|---|---|---|

| Protein | 8–11 | 4–12 |

| Carbohydrate | 58–85 | 45–89 |

| Lipids | 0.5–3 | 1–2 |

| Minerals | 3–7 | 6–10 |

| Tannins | ~5 | 1–9 |

| Caffeine | ~1 | ~1 |

| Coffee By-Product | Methods | Fuel | Secondary Products |

|---|---|---|---|

| Defatted spent coffee grounds | Pyrolysis | Bio-oil | Biochar |

| Hydrolysis/fermentation | Bioethanol | Fuel pellets | |

| Spent coffee grounds oil | Enzymatic conversion | Biodiesel | Glycerin to bio-hydrogen |

| Chemical conversion/ enzymatic/in situ | Biodiesel | Glycerin to bio-hydrogen | |

| Spent coffee ground | Pyrolysis | Bio-oil | Biochar, syngas |

| Hydrolysis/fermentation | Bioethanol | Fuel pellets |

| Adsorbent | pH | Electrical Conductivity | Loss-On-Ignition | Trace Elements (mg kg−1) | |||||

|---|---|---|---|---|---|---|---|---|---|

| (mS m−1) | (%) | As | Cd | Cu | Ni | Pb | Zn | ||

| Zeolite | 7.3 ± 0.1 | 74 ± 8 | 1.3 ± 0.2 | 4.3 ± 0.1 | 0.39 ± 0.02 | 19.9 ± 0.4 | 17.3 ± 0.7 | 15.6 ± 1.8 | 43 ± 2.3 |

| Spent coffee grounds | 5.2 ± 0.1 | 185 ± 11 | 94.7 ± 0.5 | Not detected | 0.01 ± 0.00 | 12.6 ± 0.3 | 0.4 ± 0.05 | 1.1 ± 0.1 | 6.2 ± 0.2 |

| Langmuir | qe = adsorption capacity determined at equilibrium (mg·g−1); qm = maximum adsorption capacity in mg·g−1; KL = langmuir constant in L·mg−1 | |

| Freundlich | Kf = adsorption capacity; n = intensity of adsorption | |

| Dubinin-Radushkevich | qe = amount of adsorbate adsorbed onto the adsorbent at equilibrium (mg·g−1); qs = theoretical isotherm saturation capacity (mg·g−1); Kad = the Dubinin–Radushkevich isotherm constant (mol2·J−2); ε = the Dubinin–Radushkevich isotherm constant | |

| Temkin | BT (heat of adsorption in J·mol−1) = RT/bT; AT = equilibrium-binding constant of the Temkin isotherm in Lg−1; bT = the Temkin isotherm constant; R = universal gas constant taken as 8.314 J·mol−1 K−1; T = temperature taken as 298 K |

| Freundlich | Langmuir | Dubinin-Radushkevich | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/n | Kf | R2 | qm (mg g−1) | K (L mg−1) | R2 | qm (mg g−1) | E (kJ mol−1) | R2 | |

| Zeolite | 0.39 | 0.10 | 0.87 | 13.91 | <0.01 | 0.92 | 14.48 | 16.44 | 0.81 |

| Spent coffee grounds | 0.32 | 0.85 | 0.95 | 19.32 | <0.01 | 0.96 | 19.79 | 14.08 | 0.96 |

| Type | Biosorbents | Maximum Adsorption Capacity | References |

|---|---|---|---|

| Agro-waste | Rice husk | 14.40 | [108] |

| Grape stalk waste | 13.93 | [111] | |

| Corn starch | 8.88 | [112] | |

| Physic seed hull | 11.89 | [113] | |

| Peanut hull | 5.96 | [114] | |

| Coffee residues | Spent coffee grounds | 19.32 | [99] |

| Coffee | 6.47 | [100] | |

| Exhausted coffee grounds | 11.60 | [115] | |

| Untreated coffee grounds | 15.65 | [109] | |

| Degreased coffee beans | 6.72 | [116] | |

| Coffee husks | 6.85 | [117] | |

| Spent coffee grounds | 4.34 | [118] |

| Adsorbents | Maximum Adsorption Capacity (mg g−1) |

|---|---|

| Olive cores | 12.56 |

| Olive cake | 10.56 |

| S. anthophorbium | 18.90 |

| L. arboresens | 11.50 |

| Olive wastes | 6.56 |

| Degreased coffee beans | 6.72 |

| Bagasse fly ash | 6.19 |

| Commercial activate carbon F.400 | 8.21 |

| Oxidized granular activated carbon | 5.73 |

| Coffee grounds | 15.65 |

| Adsorbent | Total Surface Area (m2/g) | Pore Volume (cm3/g) | Medium Pore Size (Å) |

|---|---|---|---|

| CMK-3 | 1508 | 0.86 | 39 |

| Activated carbon | 1212 | 0.60 | 3 |

| Coffee waste | 0.047 | 0.000935 | 292.92–427.97 |

| Freundlich | Langmuir | Temkin | ||||||

|---|---|---|---|---|---|---|---|---|

| 1/n | Kf | R2 | qm (mg g−1) | K (L mg−1) | R2 | KT (L mg−1) | R2 | |

| Caffeine | 1.98 | 1.41 | 0.975 | 16.46 | −0.03 | 0.915 | 0.03 | 0.9996 |

| Diclofenac | 0.41 | 1.75 | 0.832 | 35.86 | −0.03 | 0.925 | 0.03 | 0.9999 |

| Salicylic acid | 0.90 | 1.60 | 0.990 | 25.80 | −0.03 | 0.964 | 0.03 | 0.9997 |

| Adsorbents | Pb(II) pH 4 | Cd(II) pH 6.7 | ||||||

|---|---|---|---|---|---|---|---|---|

| Parameters | ||||||||

| Langmuir | Freundlich | Langmuir | Freundlich | |||||

| K/L mol−1 | b/mol g−1 | k/mol g−1 | 1/n | K/L mol−1 | b/mol g−1 | k/mol g−1 | 1/n | |

| Coffee | 5.48 × 104 | 5.76 × 10−5 | 1.06 × 10−3 | 0.36 | 4.14 × 104 | 7.98 × 10−5 | 7.45 × 10−3 | 0.53 |

| Tea | 2.61 × 104 | 1.01 × 10−4 | 4.09 × 10−3 | 0.47 | 1.93 × 103 | 8.61 × 10−4 | 3.32 × 10−3 | 0.42 |

| Green tea | 2.92 × 104 | 5.67 × 10−5 | 3.33 × 10−3 | 0.48 | 6.10 × 104 | 1.16 × 10−4 | 3.83 × 10−3 | 0.43 |

| Coarse tea | 3.46 × 104 | 6.55 × 10−5 | 9.46 × 10−3 | 0.34 | 4.52 × 104 | 1.02 × 10−4 | 3.65 × 10−3 | 0.46 |

| Yuzu | 1.62 × 104 | 2.67 × 10−5 | 5.38 × 10−4 | 0.39 | 2.94 × 104 | 6.60 × 10−5 | 2.55 × 10−3 | 0.48 |

| Zeolite | 6.18 × 104 | 4.63 × 10−5 | 3.62 × 10−4 | 0.27 | 6.73 × 103 | 9.96 × 10−4 | 5.79 × 10−2 | 0.61 |

| Aloe | 69.38 | 9.28 × 10−4 | 0.17 | 1.11 | 1.29 × 104 | 8.60 × 10−5 | 3.98 × 10−3 | 0.51 |

| Chitosan | 4.43 × 103 | 3.16 × 10−4 | 5.79 × 10−2 | 0.72 | 1.57 × 104 | 1.16 × 10−4 | 3.76 × 10−2 | 0.71 |

| Activated Carbon | Biochar | |||

|---|---|---|---|---|

| Type of Adsorbent | Removal Efficiency (%) | Rate of Adsorption (L/min) | Removal Efficiency (%) | Rate of Adsorption (L/min) |

| Coffee | 80 | 0.572 | 90 | 0.0865 |

| Almond shells | 100 | 0.8503 | 89 | 0.0836 |

| Peanut hulls | 100 | 0.9911 | 99.6 | 0.0944 |

| Date pits | 100 | 0.951 | 77.2 | 0.084 |

| Pistachio shells | 100 | 0.9956 | 98.6 | 0.0978 |

| Grape vine sticks | 100 | 0.9994 | 99.6 | 0.0988 |

| Sunflower shells | 100 | 0.996 | 99.64 | 0.094 |

| Jute sticks | 100 | 0.9945 | 99.94 | 0.099 |

| Biosorption Characteristics | |||

|---|---|---|---|

| Lignocellulosic Wastes Derived from Coffee Crops | pH | Capacity of Maximum Adsorption (Q Max.) (mg·g−1) | Q Max. Interval |

| Spent coffee powder/coffee grounds | 4.5 | 66.30 | 49.73–159.50 |

| 3.5 | 49.73 | ||

| 3.5 | 159.50 | ||

| 4.0 | 158.70 | ||

| Coffee waste (instant coffee beans) | 5.0 | 9.70 | 9.70 |

| Coffee shell/pulp | 5.0 | 54.05 | 4.80–230.00 |

| N/A | 37.04 | ||

| 4.5 | 4.80 | ||

| 0.5–9.0 | 7.20 | ||

| 0.5–9.0 | 230.00 | ||

| 2.0–9.0 | 50.80 | ||

| 2.0 | 24.10 | ||

| Raw coffee beans | 6.0 | 61.60 | 22.90–61.60 |

| 5.0 | 22.90 | ||

| Spent coffee beans | 3.0–4.0 | 87.02 | 87.02–159.54 |

| 2.0–12.0 | 93.24 | ||

| 2.0–12.0 | 159.54 | ||

| Biosorption Characteristics | |||

|---|---|---|---|

| Lignocellulosic Wastes Derived from Coffee | pH | Q Max. (mg·g−1) | Chemical Modification |

| Spent coffee powder/coffee grounds | 3.5 | 159.50 | Citric acid |

| 4.0 | 158.70 | Citric acid | |

| Coffee waste (instant coffee beans) | 5.0 | 54.05 | Pyrolysis |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skorupa, A.; Worwąg, M.; Kowalczyk, M. Coffee Industry and Ways of Using By-Products as Bioadsorbents for Removal of Pollutants. Water 2023, 15, 112. https://doi.org/10.3390/w15010112

Skorupa A, Worwąg M, Kowalczyk M. Coffee Industry and Ways of Using By-Products as Bioadsorbents for Removal of Pollutants. Water. 2023; 15(1):112. https://doi.org/10.3390/w15010112

Chicago/Turabian StyleSkorupa, Angelika, Małgorzata Worwąg, and Mariusz Kowalczyk. 2023. "Coffee Industry and Ways of Using By-Products as Bioadsorbents for Removal of Pollutants" Water 15, no. 1: 112. https://doi.org/10.3390/w15010112

APA StyleSkorupa, A., Worwąg, M., & Kowalczyk, M. (2023). Coffee Industry and Ways of Using By-Products as Bioadsorbents for Removal of Pollutants. Water, 15(1), 112. https://doi.org/10.3390/w15010112