A Review of Rotating Biological Contactors for Wastewater Treatment

Abstract

:1. Introduction

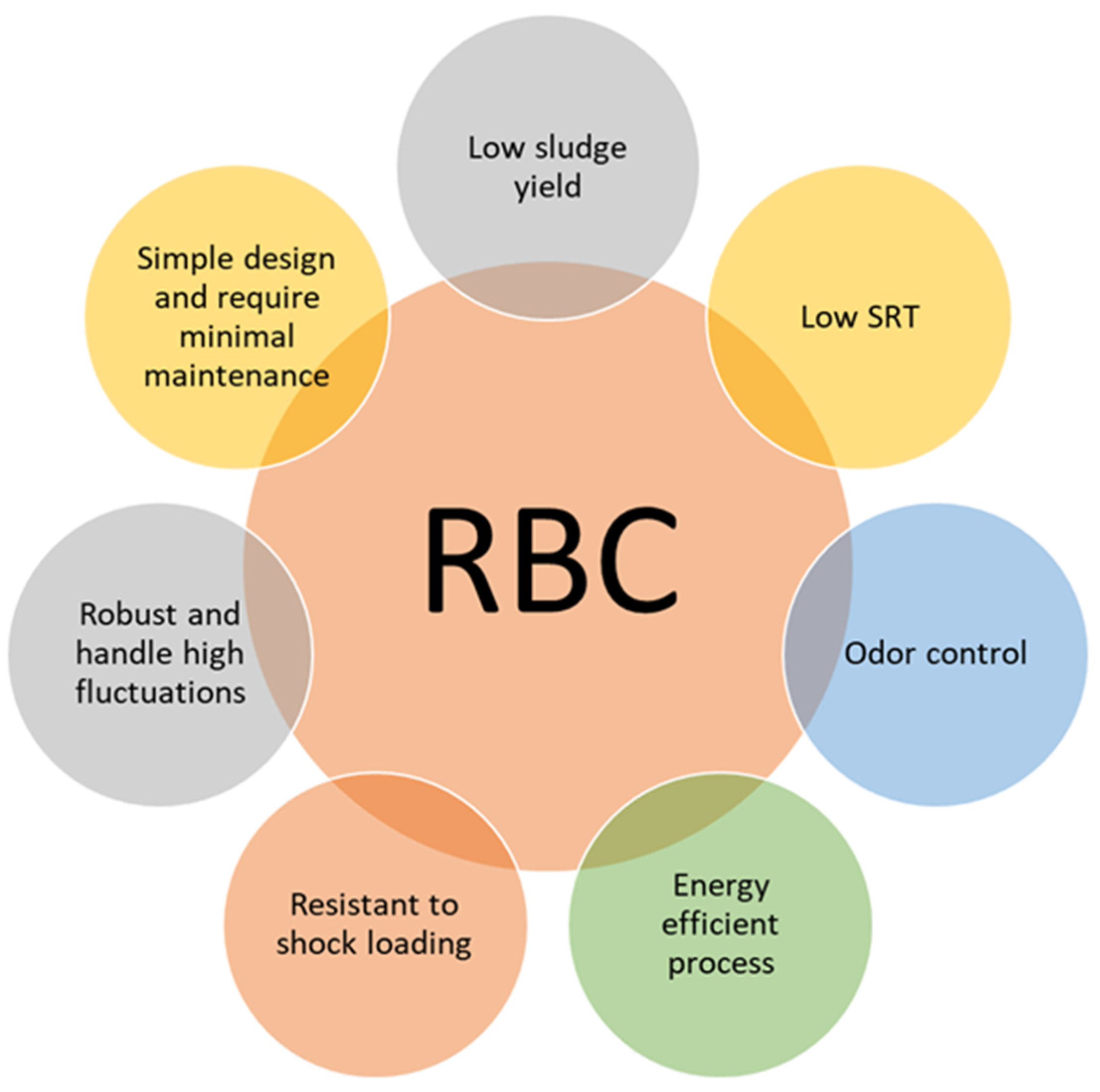

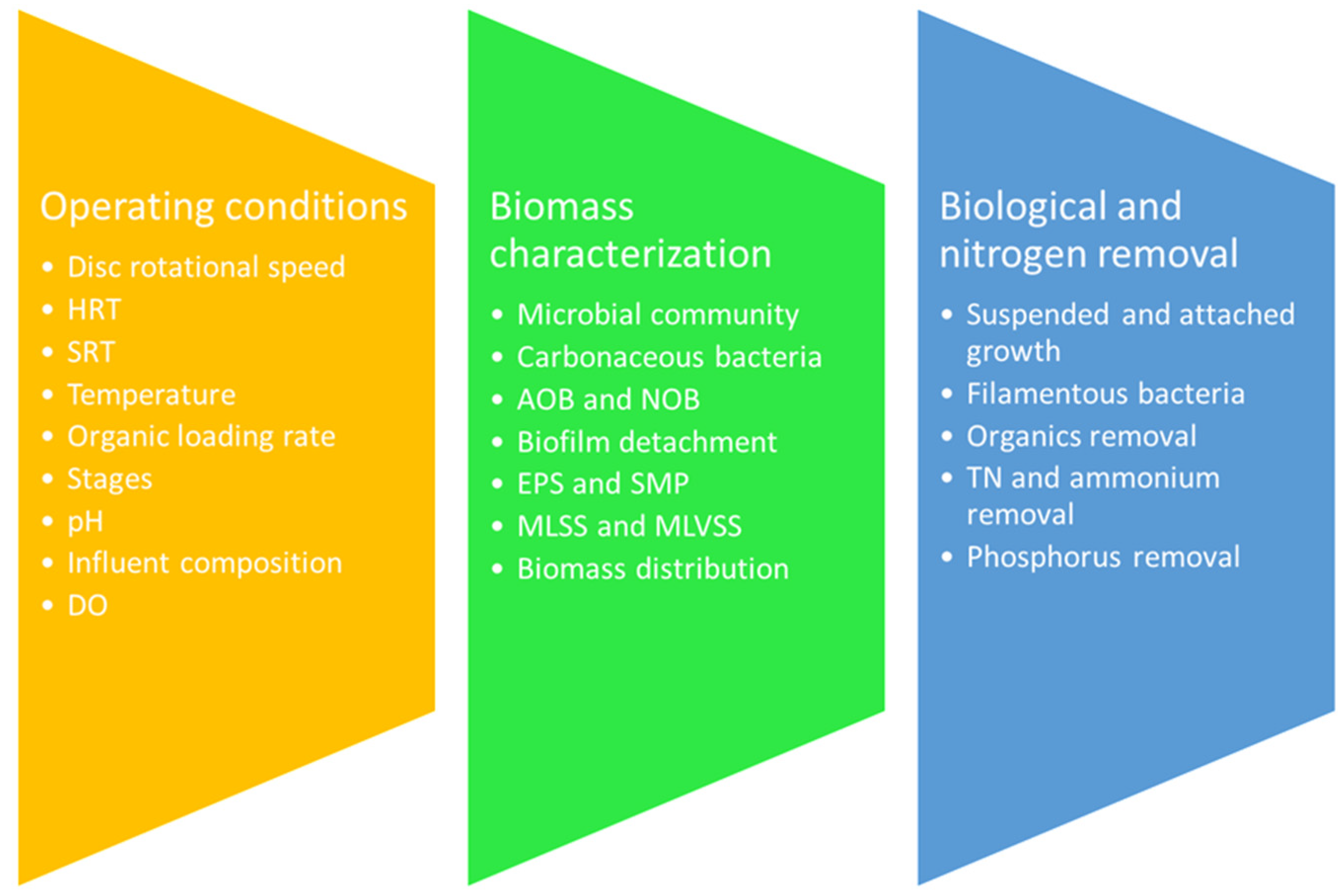

2. Basic Concept of RBC Technology

3. Biofilm Role in RBC

4. Design Considerations

4.1. Disc Rotational Speed

4.2. Hydraulic Retention Time (HRT)

| Type of Bioreactor | Type of Wastewater | Rotational Speed (rpm) | HRT (h) | Disk Submergence (%) | Loading Rate | Reference |

|---|---|---|---|---|---|---|

| Rotating biological contactor | Gold mine wastewater (cyanide removal) | 5, 10 | 10 | 40 | 300 mg cyanide/L | [81] |

| Hybrid anaerobic-activated sludge RBC | Molasses | 30 | 12 | - | 23 g/L d | [77] |

| Anaerobic RBC | Heavy metal removal (Cu, Cd, Pb, Fe, Zn, and Ni) | - | 24, 48 | 40% | Cu 100 mg/L, Cd, Ni, Fe, Pb and Zn 50 mg/L | [82] |

| Non-woven RBC | Municipal sewage via SAND | 2 | 5 | Fully submerged | 50 mg/L ammonia, 65 mg/L nitrite | [83] |

| Packed cage RBC | Mustard tuber wastewater | 8 | 12.2 | 40 | - | [41] |

| Four-stage RBC | Petroleum refinery wastewater | 4.58 optimized (0–14) | - | 40 | 0.005, 0.008, and 0.016 m3/m2d | [43] |

| RBC | Textile dye (colored wastewater) | 6 | 48 | - | - | [84] |

4.3. Solids Retention Time (SRT)

4.4. Organic Loading Rate (OLR)

4.5. Temperature

5. Biological Performance of RBCs

5.1. Organics Removal

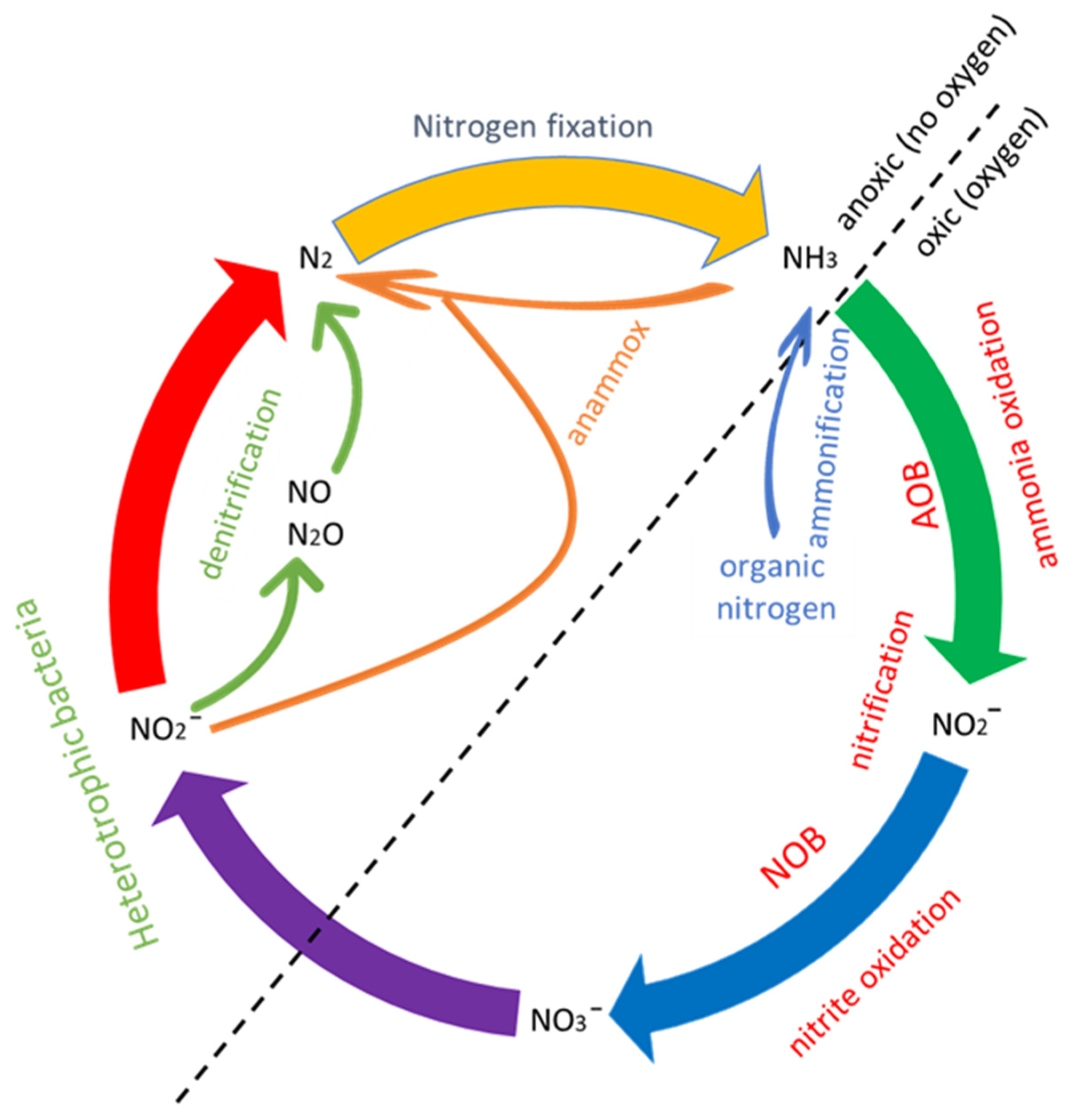

5.2. Nitrogen Removal

5.3. Ammonia Nitrogen Removal

6. Disadvantages of RBC and Solution

7. Future Prospective

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yin, Q.; Sun, Y.; Li, B.; Feng, Z.; Wu, G. The r/K selection theory and its application in biological wastewater treatment processes. Sci. Total Environ. 2022, 824, 153836. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Liu, Y.; Yang, A.; Zhu, Q.; Sun, H.; Sun, P.; Yao, B.; Zang, Y.; Du, X.; Dong, L. Xanthate-Modified Magnetic Fe3O4@ SiO2-based polyvinyl alcohol/chitosan composite material for efficient removal of heavy metal ions from water. Polymers 2022, 14, 1107. [Google Scholar] [CrossRef] [PubMed]

- Chan, S.S.; Khoo, K.S.; Chew, K.W.; Ling, T.C.; Show, P.L. Recent advances biodegradation and biosorption of organic compounds from wastewater: Microalgae-bacteria consortium-A review. Bioresour. Technol. 2022, 344, 126159. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Shan, C.; Liu, Y.; Sun, H.; Yao, B.; Gong, G.; Jin, X.; Wang, S. Characterization and mechanistic study of heavy metal adsorption by facile synthesized magnetic xanthate-modified chitosan/polyacrylic acid hydrogels. Int. J. Environ. Res. Public Health 2022, 19, 11123. [Google Scholar] [CrossRef] [PubMed]

- Obaideen, K.; Shehata, N.; Sayed, E.T.; Abdelkareem, M.A.; Mahmoud, M.S.; Olabi, A. The role of wastewater treatment in achieving sustainable development goals (SDGs) and sustainability guideline. Energy Nexus 2022, 7, 100112. [Google Scholar] [CrossRef]

- Xu, Y.; Li, H.; Li, Y.; Zheng, X.; Zhang, C.; Gao, Y.; Chen, P.; Li, Q.; Tan, L. Systematically assess the advancing and limiting factors of using the multi-soil-layering system for treating rural sewage in China: From the economic, social, and environmental perspectives. J. Environ. Manag. 2022, 312, 114912. [Google Scholar] [CrossRef]

- Weldegebrieal, G.K.; Sibhatu, A.K. 5 Photocatalytic degradation of organic contaminants in wastewater treatment. In Environmental Microbiology; De Gruyter: Berlin, Germany, 2022; pp. 113–136. [Google Scholar]

- Kumar, V.; Bilal, M.; Ferreira, L.F.R. Recent Trends in integrated wastewater treatment for sustainable development. Front. Microbiol. 2022, 13, 1101. [Google Scholar] [CrossRef]

- Sun, Y.; Chang, H.; Zhang, C.; Xie, Y.; Ho, S.-H. Emerging biological wastewater treatment using microalgal-bacterial granules: A review. Bioresour. Technol. 2022, 351, 127089. [Google Scholar] [CrossRef]

- Omer, A.M.; Dey, R.; Eltaweil, A.S.; Abd El-Monaem, E.M.; Ziora, Z.M. Insights into recent advances of chitosan-based adsorbents for sustainable removal of heavy metals and anions. Arab. J. Chem. 2022, 15, 103543. [Google Scholar] [CrossRef]

- Deng, L.; Guo, W.; Ngo, H.H.; Zhang, X.; Chen, C.; Chen, Z.; Cheng, D.; Ni, S.-Q.; Wang, Q. Recent advances in attached growth membrane bioreactor systems for wastewater treatment. Sci. Total Environ. 2022, 808, 152123. [Google Scholar] [CrossRef]

- Boavida-Dias, R.; Silva, J.R.; Santos, A.D.; Martins, R.C.; Castro, L.M.; Quinta-Ferreira, R.M. A Comparison of Biosolids Production and System Efficiency between Activated Sludge, Moving Bed Biofilm Reactor, and Sequencing Batch Moving Bed Biofilm Reactor in the Dairy Wastewater Treatment. Sustainability 2022, 14, 2702. [Google Scholar] [CrossRef]

- Al-dhawi, B.N.S.; Kutty, S.R.M.; Ghaleb, A.A.S.; Almahbashi, N.M.Y.; Saeed, A.A.H.; Al-Mekhlafi, A.-B.A.; Alsaeedi, Y.A.A.; Jagaba, A.H. Pretreated palm oil clinker as an attached growth media for organic matter removal from synthetic domestic wastewater in a sequencing batch reactor. Case Stud. Chem. Environ. Eng. 2023, 7, 100294. [Google Scholar] [CrossRef]

- Chua, S.Y.; Cheng, Y.W.; Lam, M.K.; Dasan, Y.K.; Kadir, W.N.A.; Rosli, S.-S.; Lim, J.W.; Tan, I.S.; Lim, S. Microalgae cultivation for sustainable biofuel production. In Value-Chain of Biofuels; Elsevier: Amsterdam, The Netherlands, 2022; pp. 137–158. [Google Scholar]

- Huang, T.-H.; Tung, F.-T.; Chen, G.-F.; Chen, W.-H. Variations of N concentrations and microbial community in the start-up of anammox using anaerobic heterotrophic sludge: Influence of a long reaction-phase time and comparison of the efficiencies of attached-versus suspended-growth cultures. Chemosphere 2022, 287, 132151. [Google Scholar] [CrossRef] [PubMed]

- Waqas, S.; Bilad, M.R. A review on rotating biological contactors. Indones. J. Sci. Technol. 2019, 4, 241–256. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Aqsha, A.; Harun, N.Y.; Ayoub, M.; Wirzal, M.D.H.; Jaafar, J.; Mulyati, S.; Elma, M. Effect of membrane properties in a membrane rotating biological contactor for wastewater treatment. J. Environ. Chem. Eng. 2021, 9, 104869. [Google Scholar] [CrossRef]

- Padhi, S.K.; Gokhale, S. Biological oxidation of gaseous VOCs–rotating biological contactor a promising and eco-friendly technique. J. Environ. Chem. Eng. 2014, 2, 2085–2102. [Google Scholar] [CrossRef]

- Mizyed, A. Review on Application of Rotating Biological Contactor in Removal of Various Pollutants From Effluent. Tech. BioChemMed 2021, 2, 41–61. [Google Scholar]

- Waqas, S.; Bilad, M.R.; Man, Z.B.; Klaysom, C.; Jaafar, J.; Khan, A.L. An integrated rotating biological contactor and membrane separation process for domestic wastewater treatment. Alex. Eng. J. 2020, 59, 4257–4265. [Google Scholar] [CrossRef]

- Patwardhan, A. Rotating biological contactors: A review. Ind. Eng. Chem. Res. 2003, 42, 2035–2051. [Google Scholar] [CrossRef]

- Han, Y.; Ma, J.; Xiao, B.; Huo, X.; Guo, X. New integrated self-refluxing rotating biological contactor for rural sewage treatment. J. Clean. Prod. 2019, 217, 324–334. [Google Scholar] [CrossRef]

- Rajasulochana, P.; Preethy, V. Comparison on efficiency of various techniques in treatment of waste and sewage water–A comprehensive review. Resour.-Effic. Technol. 2016, 2, 175–184. [Google Scholar]

- Ziembińska-Buczyńska, A.; Ciesielski, S.; Żabczyński, S.; Cema, G. Bacterial community structure in rotating biological contactor treating coke wastewater in relation to medium composition. Environ. Sci. Pollut. Res. 2019, 26, 19171–19179. [Google Scholar] [CrossRef] [PubMed]

- Najafpour, G.; Yieng, H.A.; Younesi, H.; Zinatizadeh, A. Effect of organic loading on performance of rotating biological contactors using palm oil mill effluents. Process Biochem. 2005, 40, 2879–2884. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Q.; Zhu, Y.; Zhao, T. Response of rotating biological contactor started up by heterotrophic nitrification-aerobic denitrification bacteria to various C/N ratios. Chemosphere 2022, 291, 133048. [Google Scholar] [CrossRef]

- Irfan, M.; Waqas, S.; Arshad, U.; Khan, J.A.; Legutko, S.; Kruszelnicka, I.; Ginter-Kramarczyk, D.; Rahman, S.; Skrzypczak, A. Response surface methodology and artificial neural network modelling of membrane rotating biological contactors for wastewater treatment. Materials 2022, 15, 1932. [Google Scholar] [CrossRef]

- Abdel-Kader, A.M. Studying the efficiency of grey water treatment by using rotating biological contactors system. J. King Saud Univ.-Eng. Sci. 2013, 25, 89–95. [Google Scholar] [CrossRef]

- Vasiliadou, I.; Molina, R.; Martínez, F.; Melero, J. Experimental and modeling study on removal of pharmaceutically active compounds in rotating biological contactors. J. Hazard. Mater. 2014, 274, 473–482. [Google Scholar] [CrossRef]

- Egli, K.; Fanger, U.; Alvarez, P.J.; Siegrist, H.; van der Meer, J.R.; Zehnder, A.J. Enrichment and characterization of an anammox bacterium from a rotating biological contactor treating ammonium-rich leachate. Arch. Microbiol. 2001, 175, 198–207. [Google Scholar] [CrossRef]

- Gujer, W.; Boller, M. A mathematical model for rotating biological contactors. Water Sci. Technol. 1990, 22, 53–73. [Google Scholar] [CrossRef]

- Tawfik, A.; Temmink, H.; Zeeman, G.; Klapwijk, B. Sewage treatment in a rotating biological contactor (RBC) system. Water Air Soil Pollut. 2006, 175, 275–289. [Google Scholar] [CrossRef]

- Israni, S.H.; Koli, S.S.; Patwardhan, A.W.; Melo, J.S.; D’souza, S.F. Phenol degradation in rotating biological contactors. J. Chem. Technol. Biotechnol. Int. Res. Process Environ. Clean Technol. 2002, 77, 1050–1057. [Google Scholar] [CrossRef]

- Gopi Kiran, M.; Das, R.; Behera, S.K.; Pakshirajan, K.; Das, G. Modelling a rotating biological contactor treating heavy metal contaminated wastewater using artificial neural network. Water Supply 2021, 21, 1895–1912. [Google Scholar] [CrossRef]

- Madoni, P. Estimates of ciliated protozoa biomass in activated sludge and biofilm. Bioresour. Technol. 1994, 48, 245–249. [Google Scholar] [CrossRef]

- Galil, N.; Rebhun, M. A comparative study of RBC and activated sludge in biotreatment of wastewater from an integrated oil refinery. In Proceedings of the 44th Industrial Waste Conference 9–11 May 1989, Purdue University; CRC Press: Boca Raton, FL, USA, 2018; pp. 711–718. [Google Scholar]

- Mannina, G.; Capodici, M.; Cosenza, A.; Di Trapani, D.; Viviani, G. The influence of solid retention time on IFAS-MBR systems: Analysis of system behavior. Environ. Technol. 2019, 40, 1840–1852. [Google Scholar] [CrossRef] [PubMed]

- Waqas, S.; Bilad, M.R.; Man, Z.B.; Suleman, H.; Nordin, N.A.H.; Jaafar, J.; Othman, M.H.D.; Elma, M. An energy-efficient membrane rotating biological contactor for wastewater treatment. J. Clean. Prod. 2021, 282, 124544. [Google Scholar] [CrossRef]

- Gupta, S.; Bhardwaj, N.K. Advances in the Treatment of Pulp and Paper Mill Wastewater. Environ. Waste Manag. 2016, 33, 47–72. [Google Scholar]

- Radha, K.V. Performance and modeling studies of rotating biological contactor for treatment of vegetable oil wastewater: (Studies on modeling of fabricated rotating biological contactor). Environ. Qual. Manag. 2022, 32, 301–312. [Google Scholar] [CrossRef]

- Dong, Y.; Guo, J.; Zhong, Z.; Wang, J.; Chen, Y. Packed cage rotating biological contactor for mustard tuber wastewater treatment: Performance and microbiome along the axial direction. J. Water Process Eng. 2021, 44, 102384. [Google Scholar] [CrossRef]

- Trikoilidou, E.; Samiotis, G.; Bellos, D.; Amanatidou, E. Sustainable operation of a biological wastewater treatment plant. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016; p. 012093. [Google Scholar]

- Ghalehkhondabi, V.; Fazlali, A.; Fallah, B. Performance analysis of four-stage rotating biological contactor in nitrification and COD removal from petroleum refinery wastewater. Chem. Eng. Process.-Process Intensif. 2021, 159, 108214. [Google Scholar] [CrossRef]

- Safa, M.; Alemzadeh, I.; Vossoughi, M. Biodegradability of oily wastewater using rotating biological contactor combined with an external membrane. J. Environ. Health Sci. 2014, 12, 117. [Google Scholar] [CrossRef]

- Cortez, S.; Teixeira, P.; Oliveira, R.; Mota, M. Rotating biological contactors: A review on main factors affecting performance. Rev. Environ. Sci. Biotechnol. 2008, 7, 155–172. [Google Scholar] [CrossRef]

- Al-Ahmady, K.K. Effect of organic loading on rotating biological contactor efficiency. Int. J. Environ. Res. Public Health 2005, 2, 469–477. [Google Scholar] [CrossRef] [PubMed]

- Hassard, F.; Biddle, J.; Cartmell, E.; Jefferson, B.; Tyrrel, S.; Stephenson, T. Rotating biological contactors for wastewater treatment—A review. Process Saf. Environ. Prot. 2015, 94, 285–306. [Google Scholar] [CrossRef]

- Kapoor, A.; Kuiper, A.; Bedard, P.; Gould, W. Use of a rotating biological contactor for removal of ammonium from mining effluents. Eur. J. Miner. Process. Environ. Prot. 2003, 3, 88–100. [Google Scholar]

- Kesaano, M.; Sims, R.C. Algal biofilm based technology for wastewater treatment. Algal Res. 2014, 5, 231–240. [Google Scholar] [CrossRef]

- Martin, K.J.; Nerenberg, R. The membrane biofilm reactor (MBfR) for water and wastewater treatment: Principles, applications, and recent developments. Bioresour. Technol. 2012, 122, 83–94. [Google Scholar] [CrossRef]

- Egli, K.; Bosshard, F.; Werlen, C.; Lais, P.; Siegrist, H.; Zehnder, A.; van der Meer, J. Microbial composition and structure of a rotating biological contactor biofilm treating ammonium-rich wastewater without organic carbon. Microb. Ecol. 2003, 45, 419–432. [Google Scholar] [CrossRef]

- Blanken, W.; Janssen, M.; Cuaresma, M.; Libor, Z.; Bhaiji, T.; Wijffels, R. Biofilm growth of Chlorella sorokiniana in a rotating biological contactor based photobioreactor. Biotechnol. Bioeng. 2014, 111, 2436–2445. [Google Scholar] [CrossRef]

- Rodgers, M.; Zhan, X.-M. Moving-medium biofilm reactors. Rev. Environ. Sci. Biotechnol. 2003, 2, 213–224. [Google Scholar] [CrossRef]

- Peng, X.; Guo, F.; Ju, F.; Zhang, T. Shifts in the microbial community, nitrifiers and denitrifiers in the biofilm in a full-scale rotating biological contactor. Environ. Sci. Technol. 2014, 48, 8044–8052. [Google Scholar] [CrossRef]

- Najafpour, G.; Zinatizadeh, A.; Lee, L. Performance of a three-stage aerobic RBC reactor in food canning wastewater treatment. Biochem. Eng. J. 2006, 30, 297–302. [Google Scholar] [CrossRef]

- Majumder, P.S.; Gupta, S. Removal of chlorophenols in sequential anaerobic–aerobic reactors. Bioresour. Technol. 2007, 98, 118–129. [Google Scholar] [CrossRef] [PubMed]

- Sauder, L.A.; Peterse, F.; Schouten, S.; Neufeld, J.D. Low-ammonia niche of ammonia-oxidizing archaea in rotating biological contactors of a municipal wastewater treatment plant. Environ. Microbiol. 2012, 14, 2589–2600. [Google Scholar] [CrossRef] [PubMed]

- Griffin, P.; Findlay, G. Process and engineering improvements to rotating biological contactor design. Water Sci. Technol. 2000, 41, 137–144. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.B. Performance and energy consumption evaluation of rotating biological contactor for domestic wastewater treatment. Indones. J. Sci. Technol. 2021, 6, 101–112. [Google Scholar] [CrossRef]

- Del Álamo, A.C.; Pariente, M.; Martínez, F.; Molina, R. Trametes versicolor immobilized on rotating biological contactors as alternative biological treatment for the removal of emerging concern micropollutants. Water Res. 2020, 170, 115313. [Google Scholar] [CrossRef]

- Sayess, R.R.; Saikaly, P.E.; El-Fadel, M.; Li, D.; Semerjian, L. Reactor performance in terms of COD and nitrogen removal and bacterial community structure of a three-stage rotating bioelectrochemical contactor. Water Res. 2013, 47, 881–894. [Google Scholar] [CrossRef]

- Soleimani, A.; Hamedi, S.; Babaeipour, V.; Rouhi, M. Design, construction and optimization a flexible bench-scale rotating biological contactor (RBC) for enhanced production of bacterial cellulose by Acetobacter Xylinium. Bioprocess Biosyst. Eng. 2021, 44, 1071–1080. [Google Scholar] [CrossRef]

- Teixeira, P.; Oliveira, R. Denitrification in a closed rotating biological contactor: Effect of disk submergence. Process Biochem. 2001, 37, 345–349. [Google Scholar] [CrossRef]

- Bicelli, L.G.; Augusto, M.R.; Giordani, A.; Contrera, R.C.; Souza, T.S. Intermittent rotation as an innovative strategy for achieving nitritation in rotating biological contactors. Sci. Total Environ. 2020, 736, 139675. [Google Scholar] [CrossRef]

- Ramsay, J.; Shin, M.; Wong, S.; Goode, C. Amaranth decoloration by Trametes versicolor in a rotating biological contacting reactor. J. Ind. Microbiol. Tbiotechnol. Adv. 2006, 33, 791. [Google Scholar] [CrossRef] [PubMed]

- Di Palma, L.; Verdone, N. The effect of disk rotational speed on oxygen transfer in rotating biological contactors. Bioresour. Technol. 2009, 100, 1467–1470. [Google Scholar] [CrossRef] [PubMed]

- Vairavel, P.; Murty, V.R. Decolorization of Congo red dye in a continuously operated rotating biological contactor reactor. Desalin. Water Treat 2020, 196, 299–314. [Google Scholar] [CrossRef]

- Fuchigami, S.; Hatamoto, M.; Takagi, R.; Watari, T.; Yamaguchi, T. Performance evaluation and microbial community structure of mesh rotating biological reactor treating sewage. J. Water Process. Eng. 2020, 37, 101456. [Google Scholar] [CrossRef]

- Rana, S.; Gupta, N.; Rana, R. Removal of organic pollutant with the use of rotating biological contactor. Mater. Today Proc. 2018, 5, 4218–4224. [Google Scholar] [CrossRef]

- Khondabia, V.G.; Fazlalia, A.; Arjomandzadeganb, M. Biological treatment of phenol from petroleum refinery wastewater using mixed indigenous cultures in a rotating biological contactor: Experimental and statistical studies. Desalination Water Treat. 2019, 1, 1–9. [Google Scholar]

- Tabraiz, S.; Haydar, S.; Hussain, G. Evaluation of a cost-effective and energy-efficient disc material for rotating biological contactors (RBC), and performance evaluation under varying condition of RPM and submergence. Desalination Water Treat. 2016, 57, 20439–20446. [Google Scholar] [CrossRef]

- Popa, M.; Ungureanu, N.; Vlăduţ, V. Applications of rotating biological contactorsin wastewater treatment. Ann. Univ. Craiova-Agric. Mont. Cadastre Ser. 2019, 49, 136–145. [Google Scholar]

- Ebrahimi, M.; Kazemi, H.; Mirbagheri, S.; Rockaway, T.D. Integrated approach to treatment of high-strength organic wastewater by using anaerobic rotating biological contactor. J. Environ. Eng. 2018, 144, 04017102. [Google Scholar] [CrossRef]

- ElHefny, R.M.; Fouad, H.A.; Mohamed, M.A. Reviewing Rotating Biological Contactor’s Different Aspects for Wastewater Treatment with Experiment. J. Homepage Erj. Bu. Edu. Eg 2022, 51, 180–187. [Google Scholar]

- Irfan, M.; Waqas, S.; Khan, J.A.; Rahman, S.; Kruszelnicka, I.; Ginter-Kramarczyk, D.; Legutko, S.; Ochowiak, M.; Włodarczak, S.; Czernek, K. Effect of Operating Parameters and Energy Expenditure on the Biological Performance of Rotating Biological Contactor for Wastewater Treatment. Energies 2022, 15, 3523. [Google Scholar] [CrossRef]

- Ebrahimi, A.; NAjafpour, G.D.; Anazadeh, M.; Ghavami, M. Optimization of whey treatment in rotating biological contactor: Application of Taguchi method. Iran. J. Energy Environ. Carcinog. Ecotoxicol. Rev. 2018, 9, 146–152. [Google Scholar]

- Mohammadi, M.; Mohammadi, P.; Karami, N.; Barzegar, A.; Annuar, M.S.M. Efficient hydrogen gas production from molasses in hybrid anaerobic-activated sludge-rotating biological contactor. Int. J. Hydrog. Energy 2019, 44, 2592–2602. [Google Scholar] [CrossRef]

- Waqas, S.; Harun, N.Y.; Bilad, M.R.; Samsuri, T.; Nordin, N.A.H.M.; Shamsuddin, N.; Nandiyanto, A.B.D.; Huda, N.; Roslan, J. Response surface methodology for optimization of rotating biological contactor combined with external membrane filtration for wastewater treatment. Membranes 2022, 12, 271. [Google Scholar] [CrossRef] [PubMed]

- Daudpoto, M.R.; Talpur, M.G.H.; Shah, F.; Khooharo, A. A residual analysis for the removal of biological oxygen demand through rotating biological contactor. Mehran Univ. Res. J. Eng. Technol. 2021, 40, 459–464. [Google Scholar] [CrossRef]

- Sirianuntapiboon, S.; Chuamkaew, C. Packed cage rotating biological contactor system for treatment of cyanide wastewater. Bioresour. Technol. 2007, 98, 266–272. [Google Scholar] [CrossRef]

- Guadalima, M.P.G.; Monteros, D.A.N. Evaluation of the rotational speed and carbon source on the biological removal of free cyanide present on gold mine wastewater, using a rotating biological contactor. J. Water Process Eng. 2018, 23, 84–90. [Google Scholar] [CrossRef]

- Kiran, M.G.; Pakshirajan, K.; Das, G. A new application of anaerobic rotating biological contactor reactor for heavy metal removal under sulfate reducing condition. Chem. Eng. J. 2017, 321, 67–75. [Google Scholar] [CrossRef]

- Wang, D.; Wang, G.; Yang, F.; Liu, C.; Kong, L.; Liu, Y. Treatment of municipal sewage with low carbon-to-nitrogen ratio via simultaneous partial nitrification, anaerobic ammonia oxidation, and denitrification (SNAD) in a non-woven rotating biological contactor. Chemosphere 2018, 208, 854–861. [Google Scholar] [CrossRef]

- Pakshirajan, K.; Kheria, S. Continuous treatment of coloured industry wastewater using immobilized Phanerochaete chrysosporium in a rotating biological contactor reactor. J. Environ. Manag. 2012, 101, 118–123. [Google Scholar] [CrossRef]

- Hassard, F.; Biddle, J.; Cartmell, E.; Coulon, F.; Stephenson, T. Biosolids recycling impact on biofilm extracellular enzyme activity and performance of hybrid rotating biological reactors. Sci. Total Environ. 2020, 706, 135865. [Google Scholar] [CrossRef] [PubMed]

- Greenham, R.T.; Miller, K.Y.; Tong, A. Removal efficiencies of top-used pharmaceuticals at sewage treatment plants with various technologies. J. Environ. Chem. Eng. 2019, 7, 103294. [Google Scholar] [CrossRef]

- Waqas, S.; Harun, N.Y.; Sambudi, N.S.; Arshad, U.; Nordin, N.A.H.M.; Bilad, M.R.; Saeed, A.A.H.; Malik, A.A. SVM and ANN Modelling Approach for the Optimization of Membrane Permeability of a Membrane Rotating Biological Contactor for Wastewater Treatment. Membranes 2022, 12, 821. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Zhu, B.; Zhao, X.; Wang, Y.; Weng, J.; Liu, F.; Zhao, R.; Lu, J.; Shang, Y. Enhanced treatment effect and universality of novel ARAO coupling process on municipal sewage: A pilot study. Biochem. Eng. J. 2023, 191, 108776. [Google Scholar] [CrossRef]

- Márquez, P.; Gutiérrez, M.; Toledo, M.; Alhama, J.; Michán, C.; Martín, M. Activated sludge process versus rotating biological contactors in WWTPs: Evaluating the influence of operation and sludge bacterial content on their odor impact. Process Saf. Environ. Prot. 2022, 160, 775–785. [Google Scholar] [CrossRef]

- Mohammadi, M.; Mohammadi, P. Developing single-substrate steady-state model for biohydrogen production in continuous anaerobic activated sludge–rotating biological contactor system: Novel insights on the process. Int. J. Energy Res. 2022, 46, 2041–2050. [Google Scholar] [CrossRef]

- Sirianuntapiboon, S. Treatment of wastewater containing Cl2 residue by packed cage rotating biological contactor (RBC) system. Bioresour. Technol. 2006, 97, 1735–1744. [Google Scholar] [CrossRef]

- Lee, J.; Ahn, W.-Y.; Lee, C.-H. Comparison of the filtration characteristics between attached and suspended growth microorganisms in submerged membrane bioreactor. Water Res. 2001, 35, 2435–2445. [Google Scholar] [CrossRef]

- Saikaly, P.; Ayoub, G. Ammonia nitrogen removal in step-feed rotating biological contactors. Water Air Soil Pollut. 2003, 150, 177–191. [Google Scholar] [CrossRef]

- Hoyland, G.; Vale, P.; Rogalla, F.; Jones, M. A new approach to nutrient removal using the HYBACS process. In Proceedings of the Residuals and Biosolids Conference, Savannah, GA, USA, 23–26 May 2010; pp. 81–94. [Google Scholar]

- Waqas, S.; Bilad, M.R.; Huda, N.; Harun, N.Y.; Md Nordin, N.A.H.; Shamsuddin, N.; Wibisono, Y.; Khan, A.L.; Roslan, J. Membrane filtration as post-treatment of rotating biological contactor for wastewater treatment. Sustainability 2021, 13, 7287. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.B. Effect of organic and nitrogen loading rate in a rotating biological contactor for wastewater treatment. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2021; p. 012063. [Google Scholar]

- Phanwilai, S.; Kangwannarakul, N.; Noophan, P.; Kasahara, T.; Terada, A.; Munakata-Marr, J.; Figueroa, L.A. Nitrogen removal efficiencies and microbial communities in full-scale IFAS and MBBR municipal wastewater treatment plants at high COD: N ratio. Front. Environ. Sci. Eng. Min. J. 2020, 14, 115. [Google Scholar] [CrossRef]

- Naghipour, D.; Rouhbakhsh, E.; Jaafari, J. Application of the biological reactor with fixed media (IFAS) for removal of organic matter and nutrients in small communities. Int. J. Environ. Anal. Chem. 2022, 102, 5811–5821. [Google Scholar] [CrossRef]

- Zang, L.; Yang, H.; Wang, J.; Wang, X.; Li, S.; Liu, X. Performance of rotating cage biological contactors based on the partial nitrification of immobilized bioactive fillers. J. Water Process Eng. 2023, 53, 103671. [Google Scholar] [CrossRef]

- Spasov, E.; Tsuji, J.M.; Hug, L.A.; Doxey, A.C.; Sauder, L.A.; Parker, W.J.; Neufeld, J.D. High functional diversity among Nitrospira populations that dominate rotating biological contactor microbial communities in a municipal wastewater treatment plant. ISME J. 2020, 14, 1857–1872. [Google Scholar] [CrossRef] [PubMed]

- Kadu, P.; Badge, A.; Rao, Y. Treatment of Municipal Wastewater by Using Rotating Biological Contactors (RBCs). AJER 2013, 2, 127–132. [Google Scholar]

- Waqas, S.; Bilad, M.R.; Man, Z.; Wibisono, Y.; Jaafar, J.; Mahlia, T.M.I.; Khan, A.L.; Aslam, M. Recent progress in integrated fixed-film activated sludge process for wastewater treatment: A review. J. Environ. Manag. 2020, 268, 110718. [Google Scholar] [CrossRef]

- Delgado, N.; Navarro, A.; Marino, D.; Peñuela, G.A.; Ronco, A. Removal of pharmaceuticals and personal care products from domestic wastewater using rotating biological contactors. Int. J. Environ. Sci. Technol. 2019, 16, 1–10. [Google Scholar] [CrossRef]

| Sr# | Parameter | ASP | RBC |

|---|---|---|---|

| 1 | Ease of operation | Simple operation but requires continuous monitoring [39]. | Simple operation requiring less maintenance and monitoring. No complex process parameter is involved [40]. |

| 2 | Aeration requirement | Oxygen is supplied by mechanical or diffused air aeration, which is about 55% of the total cost. | Oxygen is supplied by contact with a rotating contactor with air [41]. |

| 3 | Total nitrogen (TN) and total phosphorus (TP) | Nitrogen and related compounds are removed by nitrification and denitrification. However, this requires high aeration and a large amount of land. A removal efficiency of 80% has been observed for TN and TP. | The overall removal efficiency was approximately 99% for organics removal and 90% for nitrogen removal [42]. Complete nitrification and denitrification are achievable with an anaerobic RBC [43]. |

| 4 | Sludge production | High sludge production (70–100 g/m3) because of high aeration and microbial activity. | Low sludge production due to high biomass concentration and attached microorganisms [44]. |

| 5 | Land required | A large area is required compared with an RBC and membrane bioreactor (MBR). The requirement for settling the tank requires additional land. | About 1/10th the amount of land is required compared with an ASP [45]. |

| 6 | Organic loading rate (OLR) | Sensitive to OLR due to a lesser amount of microorganisms present. | OLR of 24 g chemical oxygen demand (COD)/m2/day was used [46]. |

| 7 | Energy requirement | High energy consumption (2.4 kWh/m3). | Low energy consumption (1.2 kWh/m3) because no aeration is required in the bioreactor [47]. |

| 8 | Hydraulic retention time | High hydraulic retention time (HRT) (12–48 h) compared with an RBC (6–18 h). | A short HRT of about 4 h was used thanks to the abundant quantity of microorganisms available to digest organic matter [48]. |

| 9 | Solids retention time | High sludge retention time (SRT) range of 10–30 d. The sludge produced is the same as an RBC. | High SRT decreases the amount of sludge, and a large floc size facilitates the settling. |

| 10 | Aeration cost | About 55% of the OPEX. | No aeration is required due to the rotation of the shaft. The oxygen is provided to the microorganisms through shaft movement. |

| 11 | CAPEX and OPEX | High CAPEX and OPEX (2.4 kWh/m3). Compared with trickling filters and RBC (1.2–1.8 kWh/m3). | RBCs are, on average, 35% cheaper per year than trickling filters due to lower land area and running costs [47]. |

| 12 | Primary treatment requirement | Adequate primary treatment is required. | Adequate primary treatment is required. |

| Type of Bioreactor | Type of Wastewater | Performance | Remarks | Reference |

|---|---|---|---|---|

| Rotating biological contactor | Gold mine wastewater (cyanide removal) | Free cyanide biological removal of 96.89% with the addition of a carbon source (3.8 g sucrose/L) at 10 h HRT and 5 rpm. Without a carbon source, the removal efficiency was 83.89% | HRT increase results in an increase in removal efficiency. The selection of appropriate rotational speed is important as it influences the biofilm thickness. | [81] |

| Hybrid anaerobic-activated sludge RBC | Molasses | A maximum amount of hydrogen production rate (4.4 L/L d) was obtained at 30 rpm and 47.5 g /L d OLR | Disk rotational speed and OLR showed a significant effect on process responses. High disk rotational speed improves the system performance. Higher OLR (>47.5 g/L d) causes a reduction in the hydrogen production rate. | [77] |

| Anaerobic RBC | Heavy metal removal (Cu, Cd, Pb, Fe, Zn, and Ni) | Maximum removal of Cu (97%), Cd (90%), and more than 77% for other metals at 48 h HRT | The metal removal values were slightly reduced at 24 h HRT, and the heavy metal removal was in the order: Cu > Cd > Pb > Fe > Zn > Ni | [82] |

| Non-woven RBC | Municipal sewage via SAND | Both COD and TN removal rates are above 70% under optimized conditions. Maximum respective COD and TN removal efficiencies of 83.12% and 79.13% were obtained at DO = 0.2 mg/L and C/N = 2.3 | COD removal rate showed a decreasing trend with an increase in DO and C/N. AOB, anammox bacteria, and BND coefficients in SAND. AOB (65.13%) was dominant in the outer layer, whereas anammox bacteria (47.17%) and DNB (38.91%) were dominant in the inner anaerobic layer. | [83] |

| Packed cage RBC | Mustard tuber wastewater | COD < 100 mg/L effluent concentration while TN removal efficiency was 70.82 ± 3.98% | Under aerobic conditions, the high DO concentration (>1.9 mg/L) results in higher nitrate concentration due to nitritation. High DO concentration is not suitable for stable partial nitritation/anammox. | [41] |

| Four-stage RBC | Petroleum refinery wastewater | The maximum removal efficiency for COD and ammonia was 85.76% and 99.07%, respectively. | At a lower loading rate, a high percentage of nitrates is produced because of the high amount of AOB in the initial stages of the bioreactor. The increase of HLR due to the reduction of HRT seemed to have a negative effect on ammonia removal. | [43] |

| RBC | Textile dye (Colored wastewater) | Sixty-four percent decolorized wastewater was obtained with glucose as a carbon source, while a maximum removal of 83% was obtained with 10 g/L glucose. A maximum COD removal efficiency of 73% was obtained. | The bioreactor performed poorly in the absence of additional glucose in decolorizing wastewater. The addition of glucose increases performance. However, a bioreactor requires a significant amount (1:1) of glucose which is a disadvantage. | [84] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waqas, S.; Harun, N.Y.; Sambudi, N.S.; Bilad, M.R.; Abioye, K.J.; Ali, A.; Abdulrahman, A. A Review of Rotating Biological Contactors for Wastewater Treatment. Water 2023, 15, 1913. https://doi.org/10.3390/w15101913

Waqas S, Harun NY, Sambudi NS, Bilad MR, Abioye KJ, Ali A, Abdulrahman A. A Review of Rotating Biological Contactors for Wastewater Treatment. Water. 2023; 15(10):1913. https://doi.org/10.3390/w15101913

Chicago/Turabian StyleWaqas, Sharjeel, Noorfidza Yub Harun, Nonni Soraya Sambudi, Muhammad Roil Bilad, Kunmi Joshua Abioye, Abulhassan Ali, and Aymn Abdulrahman. 2023. "A Review of Rotating Biological Contactors for Wastewater Treatment" Water 15, no. 10: 1913. https://doi.org/10.3390/w15101913

APA StyleWaqas, S., Harun, N. Y., Sambudi, N. S., Bilad, M. R., Abioye, K. J., Ali, A., & Abdulrahman, A. (2023). A Review of Rotating Biological Contactors for Wastewater Treatment. Water, 15(10), 1913. https://doi.org/10.3390/w15101913