Hydraulic Conductivity Characteristics of a Clayey Soil Incorporating Recycled Rubber and Glass Granules

Abstract

:1. Introduction

2. Materials and Methods

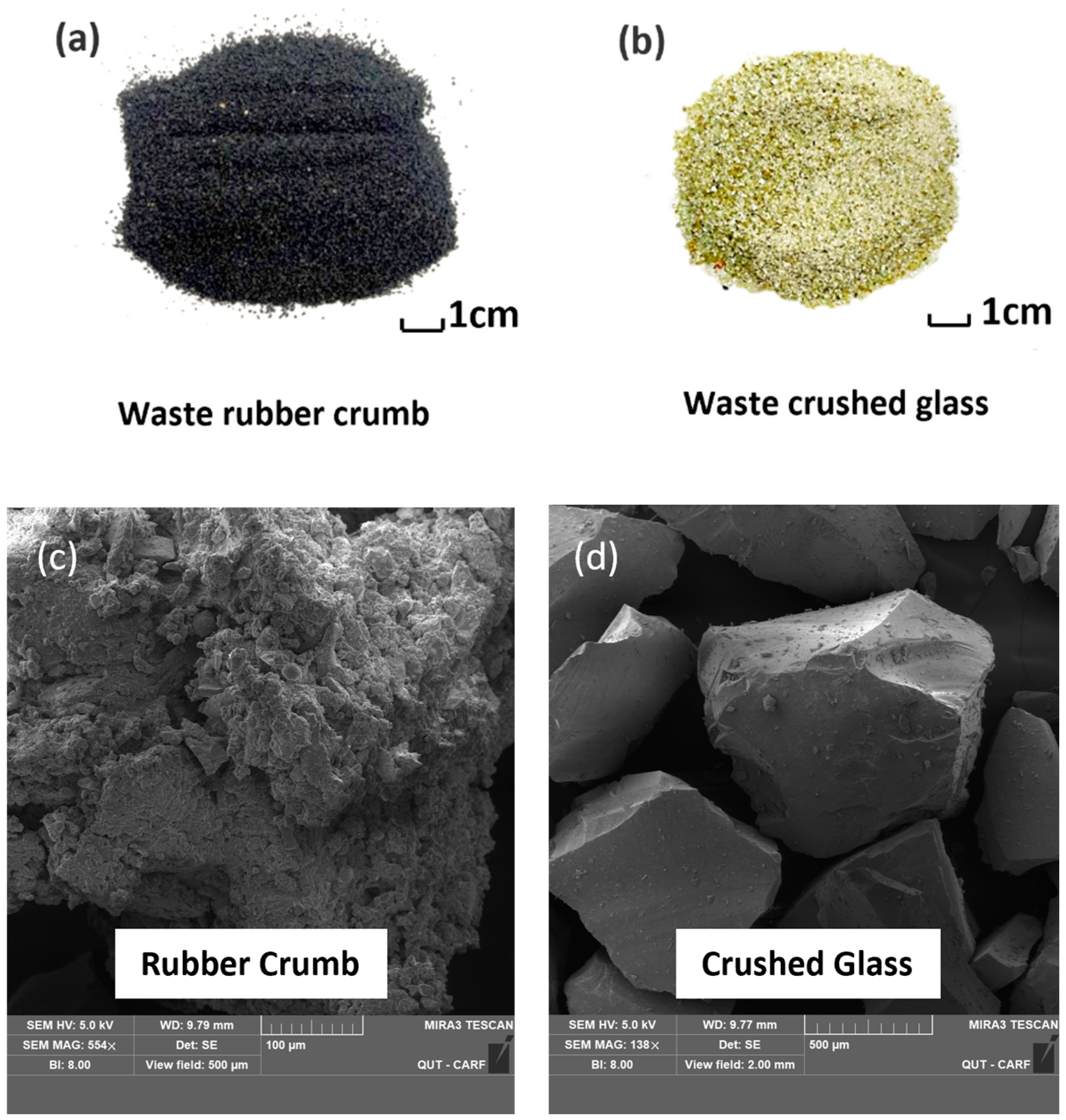

2.1. Materials

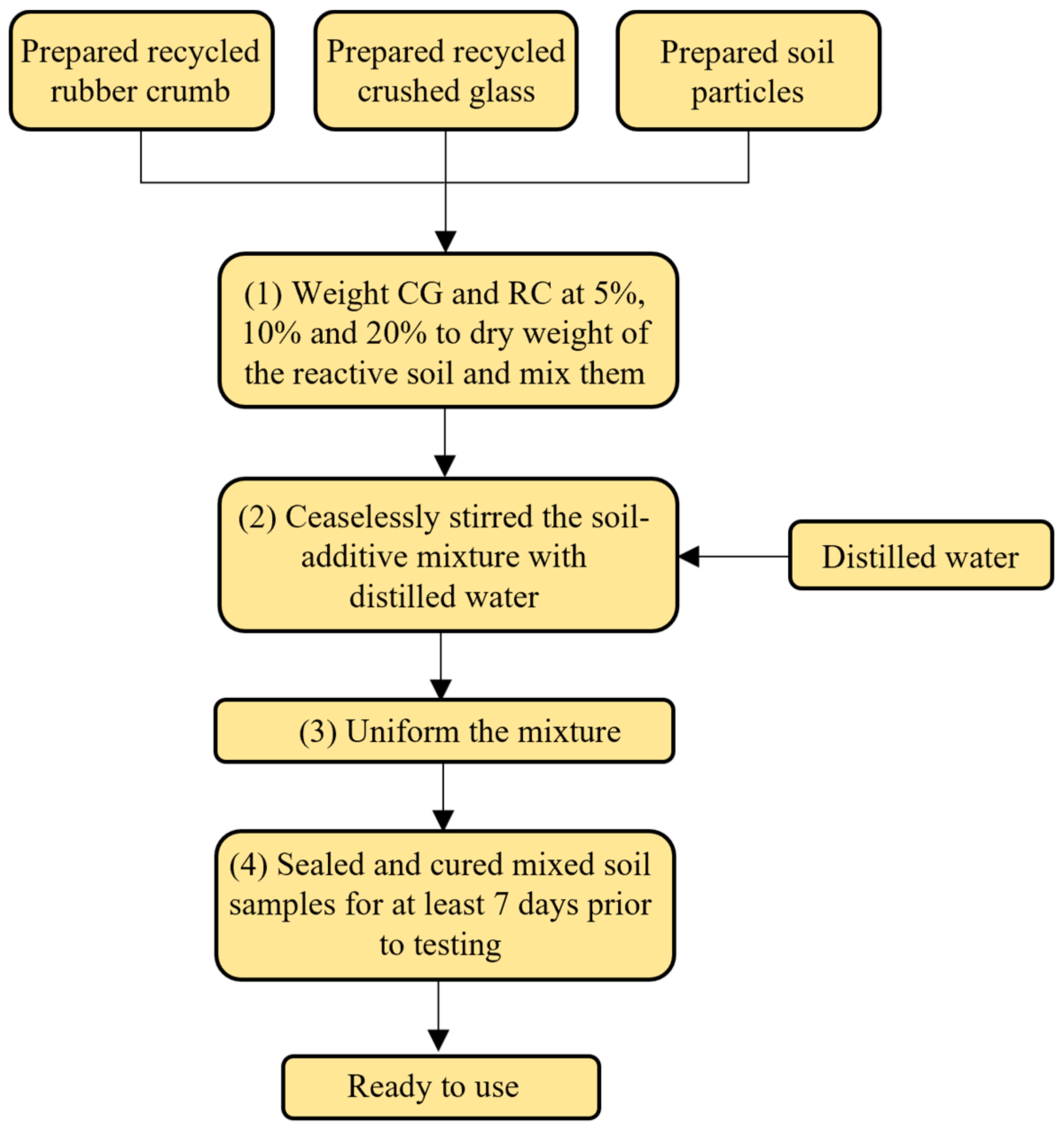

2.2. Preparation of Recycled Waste Treated Soil Samples

2.3. Consolidation Test Procedure

2.4. Analytical Methods

3. Results and Discussion

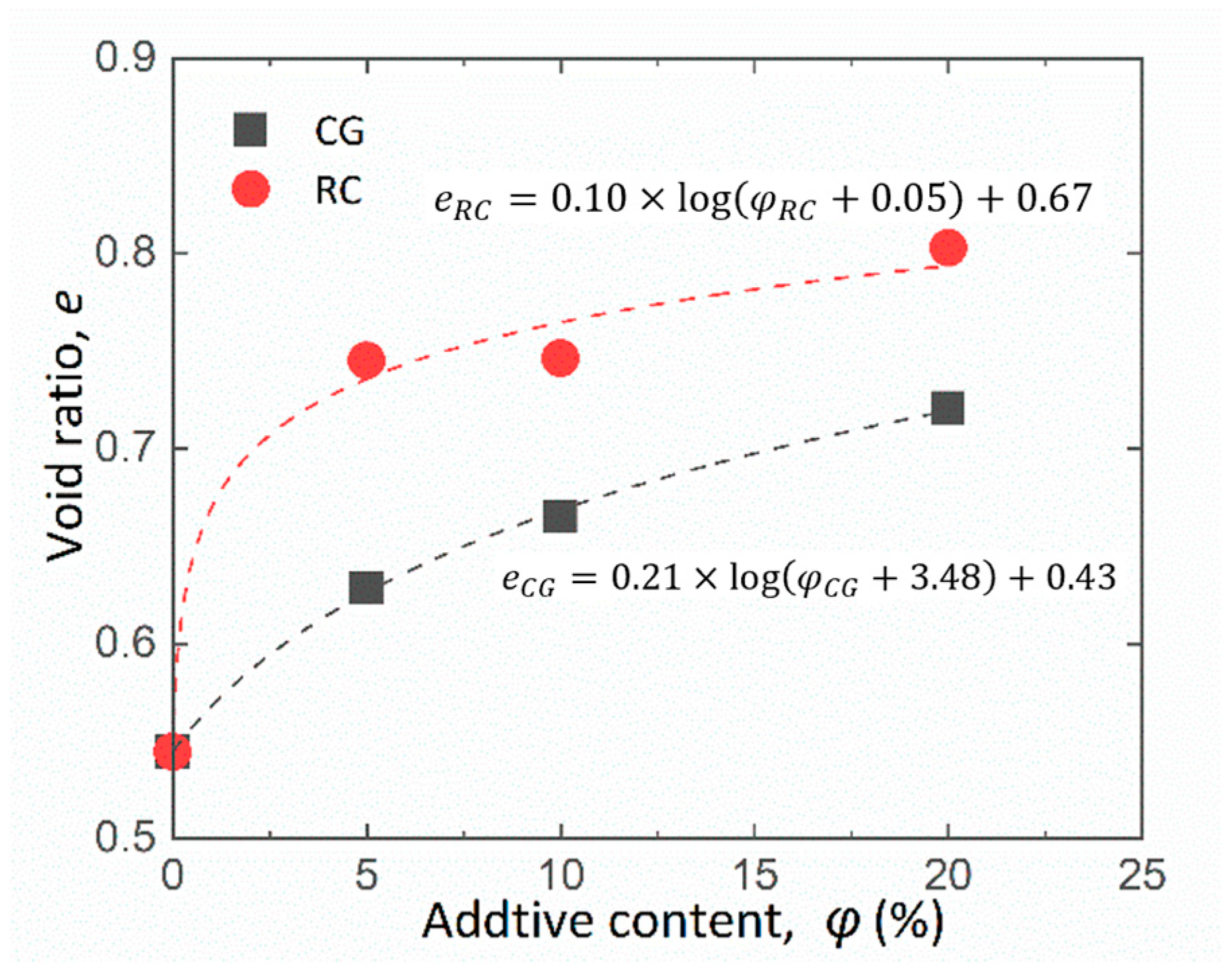

3.1. Impact of RC or CG Inclusion on Compressibility Behavior of Reactive Soil

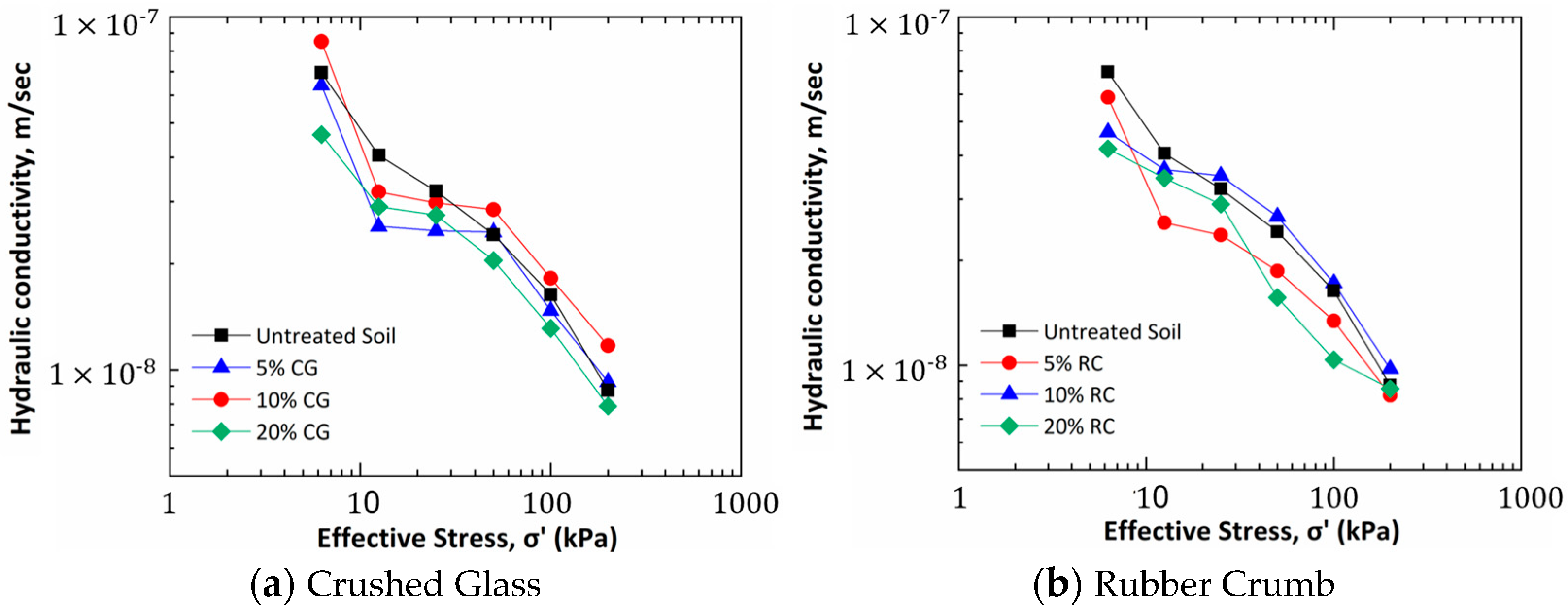

3.2. Impact of In Situ Stress on Hydraulic Conductivity

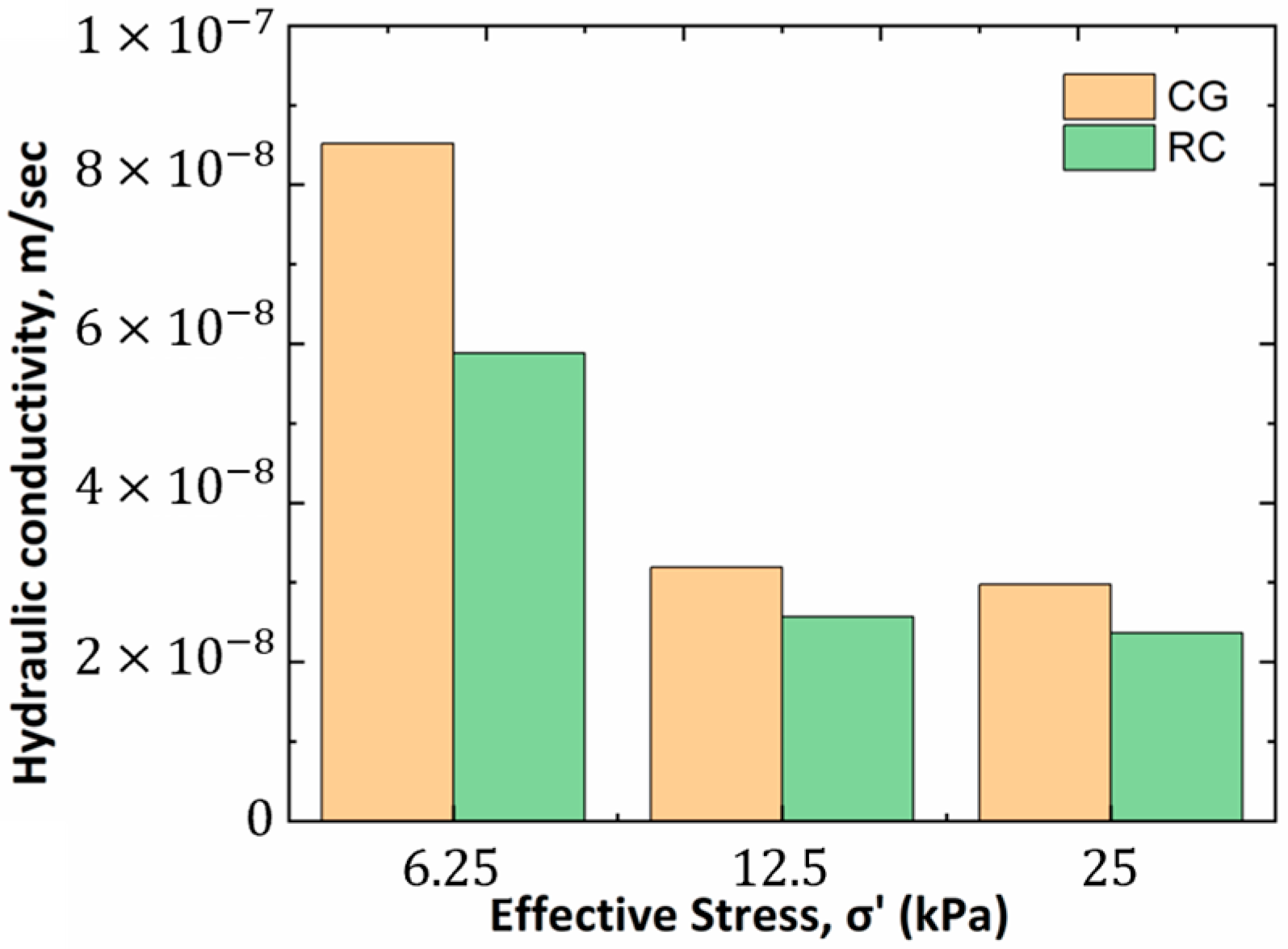

3.3. Impact of RC or CG Inclusion on Hydraulic Conductivity

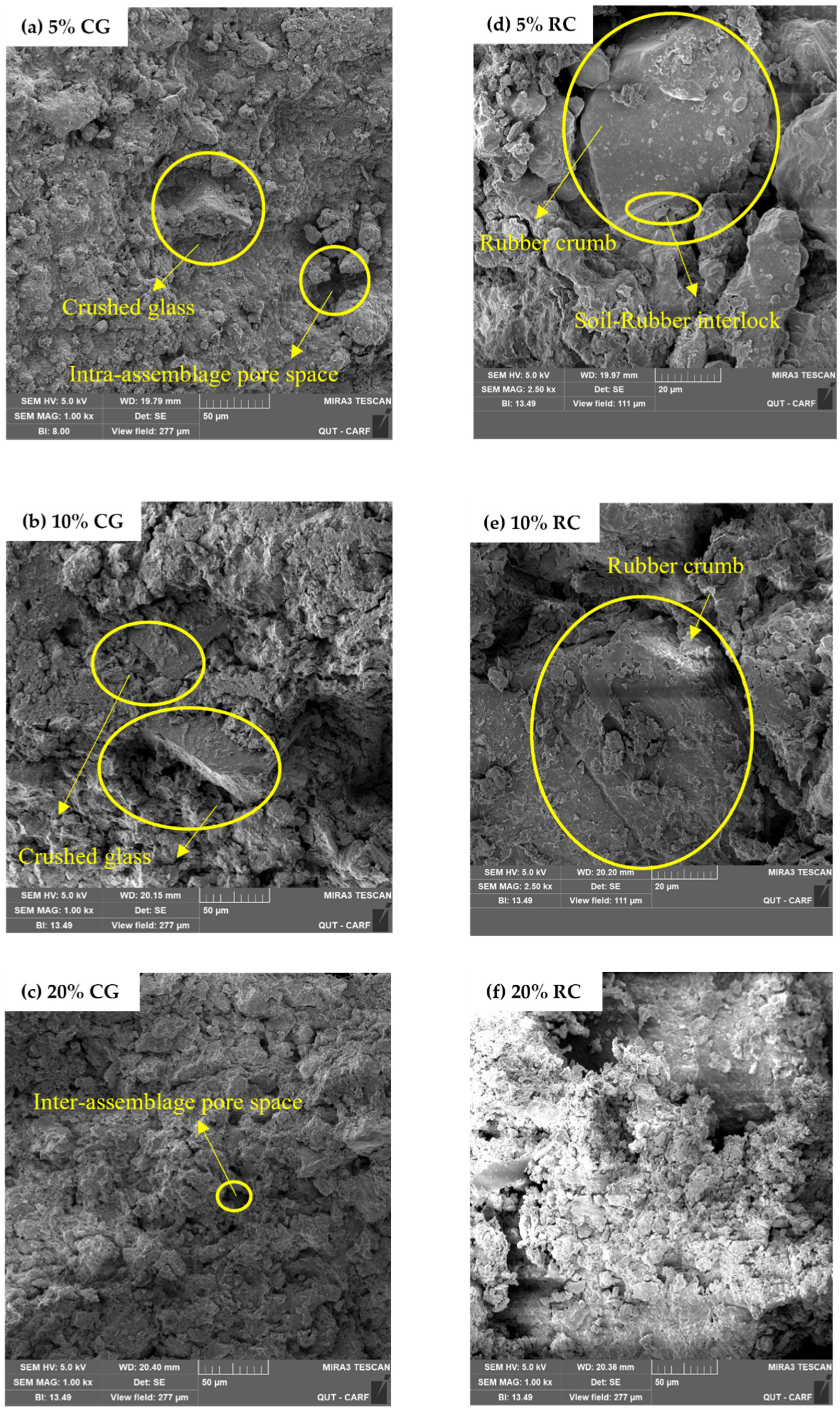

3.4. Microstructure Analysis of Reactive Soil–RC/CG Composites

4. Conclusions

- The alteration in the initial void ratio caused by the incorporation of rubber particles is more pronounced where the increase in void ratio () can be represented as a logarithmic function in relation to the recycled waste content ().

- The hydraulic conductivity of RC– or CG–soil composites consistently declined as the applied stress increases, which indicates a similar trend between applied stress and void ratio. Moreover, the hydraulic conductivity values for CG-treated soil mixtures tend to be stable between 12.5 kPa and 50 kPa applied stress.

- The inclusion of RC and CG can effectively affect the hydraulic conductivity of the soil, regardless of the type of recycled waste. The relationship between the void ratio and hydraulic conductivity is nearly linear: the higher the void ratio, the higher the value of hydraulic conductivity. Meanwhile, the addition of CG initially enhances hydraulic conductivity up to a threshold, beyond which further addition causes a reduction in k, while the addition of RC initially reduces hydraulic conductivity and then increases up to a threshold, beyond which further addition causes a reduction in k.

- Results from SEM indicate that RC and CG inclusion plays an important role in hydraulic conductivity by changing pore size and its distribution on soil morphological structure. When CG was begun to be added, large interaggregate pores were created and caused the formation of smaller pores that were more interconnected, leading to an increase in the effective porosity and hydraulic conductivity of the soil. As for RC-treated soil, soil sample treated with 5% RC experienced a decrease in hydraulic conductivity due to the presence of interlock with nearby soil aggregates. When the content of RC increases, larger rubber crumbs become embedded within soil aggregates. The hydraulic conductivity showed a significant decrease when the amount of CG or RC added was sufficient to fill all interaggregate pores.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gui, Y.; Zhao, G.; Khalili, N. Experimental investigation of desiccation of clayey soils. In From Materials to Structures: Advancement through Innovation; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Gui, Y.L.; Hu, W.; Zhao, Z.Y.; Zhu, X. Numerical modelling of a field soil desiccation test using a cohesive fracture model with Voronoi tessellations. Acta Geotech. 2018, 13, 87–102. [Google Scholar] [CrossRef]

- Tang, C.-S.; Cheng, Q.; Leng, T.; Shi, B.; Zeng, H.; Inyang, H.I. Effects of wetting-drying cycles and desiccation cracks on mechanical behavior of an unsaturated soil. Catena 2020, 194, 104721. [Google Scholar] [CrossRef]

- Vijayan, D.; Parthiban, D. Effect of Solid waste based stabilizing material for strengthening of Expansive soil-A review. Environ. Technol. Innov. 2020, 20, 101108. [Google Scholar] [CrossRef]

- Jones, D.E., Jr.; Holtz, W.G. Expansive soils-the hidden disaster. Civ. Eng. 1973, 43, 49–51. [Google Scholar]

- Chenarboni, H.A.; Lajevardi, S.H.; MolaAbasi, H.; Zeighami, E. The effect of zeolite and cement stabilization on the mechanical behavior of expansive soils. Constr. Build. Mater. 2021, 272, 121630. [Google Scholar] [CrossRef]

- Mahedi, M.; Cetin, B.; White, D.J. Performance evaluation of cement and slag stabilized expansive soils. Transp. Res. Rec. 2018, 2672, 164–173. [Google Scholar] [CrossRef]

- Naseem, A.; Mumtaz, W.; Jalal, F.E.; De Backer, H. Stabilization of expansive soil using tire rubber powder and cement kiln dust. Soil Mech. Found. Eng. 2019, 56, 54–58. [Google Scholar] [CrossRef]

- Ashango, A.A.; Patra, N.R. Behavior of expansive soil treated with steel slag, rice husk ash, and lime. J. Mater. Civ. Eng. 2016, 28, 06016008. [Google Scholar] [CrossRef]

- Ma, J.; Su, Y.; Liu, Y.; Tao, X. Strength and microfabric of expansive soil improved with rice husk ash and lime. Adv. Civ. Eng. 2020, 2020, 9646205. [Google Scholar] [CrossRef]

- Thyagaraj, T.; Rao, S.M.; Suresh, P.S.; Salini, U. Laboratory studies on stabilization of an expansive soil by lime precipitation technique. J. Mater. Civ. Eng. 2012, 24, 1067–1075. [Google Scholar] [CrossRef]

- Dahale, P.; Nagarnaik, P.; Gajbhiye, A. Engineering behavior of remolded expansive soil with lime and flyash. Mater. Today Proc. 2017, 4, 10581–10585. [Google Scholar] [CrossRef]

- Li, M.; Fang, C.; Kawasaki, S.; Achal, V. Fly ash incorporated with biocement to improve strength of expansive soil. Sci. Rep. 2018, 8, 2565. [Google Scholar] [CrossRef]

- Mir, B. Some studies on the effect of fly ash and lime on physical and mechanical properties of expansive clay. Int. J. Civ. Eng. 2015, 13, 203–212. [Google Scholar]

- Sharma, A.K.; Sivapullaiah, P. Ground granulated blast furnace slag amended fly ash as an expansive soil stabilizer. Soils Found. 2016, 56, 205–212. [Google Scholar] [CrossRef]

- Puppala, A.J.; Griffin, J.A.; Hoyos, L.R.; Chomtid, S. Studies on sulfate-resistant cement stabilization methods to address sulfate-induced soil heave. J. Geotech. Geoenviron. Eng. 2004, 130, 391–402. [Google Scholar] [CrossRef]

- Sivapullaiah, P.; Sridharan, A.; Ramesh, H. Strength behaviour of lime-treated soils in the presence of sulphate. Can. Geotech. J. 2000, 37, 1358–1367. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, Q.; Shi, W.; Lv, J.; Lu, Z.; Ling, X. Advances in properties of rubber reinforced soil. Adv. Civ. Eng. 2020, 2020, 6629757. [Google Scholar] [CrossRef]

- Day, R.W. Performance of slab-on-grade foundations on expansive soil. J. Perform. Constr. Facil. 1994, 8, 129–138. [Google Scholar] [CrossRef]

- Yaghoubi, E.; Yaghoubi, M.; Guerrieri, M.; Sudarsanan, N. Improving expansive clay subgrades using recycled glass: Resilient modulus characteristics and pavement performance. Constr. Build. Mater. 2021, 302, 124384. [Google Scholar] [CrossRef]

- Andrews, B.; Rebecchi, J. Guide to Pavement Technology: Part 4E: Recycled Materials; Association of Australasian Road and Transport Agencies: Sydney, Australia, 2009. [Google Scholar]

- Abbaspour, M.; Aflaki, E.; Nejad, F.M. Reuse of waste tire textile fibers as soil reinforcement. J. Clean. Prod. 2019, 207, 1059–1071. [Google Scholar] [CrossRef]

- Bekhiti, M.; Trouzine, H.; Rabehi, M. Influence of waste tire rubber fibers on swelling behavior, unconfined compressive strength and ductility of cement stabilized bentonite clay soil. Constr. Build. Mater. 2019, 208, 304–313. [Google Scholar] [CrossRef]

- Özkul, Z.H.; Baykal, G. Shear Behavior of Compacted Rubber Fiber-Clay Composite in Drained and Undrained Loading. J. Geotech. Geoenviron. Eng. 2007, 133, 767–781. [Google Scholar] [CrossRef]

- Arrieta Baldovino, J.D.J.; dos Santos Izzo, R.L.; da Silva, É.R.; Lundgren Rose, J. Sustainable use of recycled-glass powder in soil stabilization. J. Mater. Civ. Eng. 2020, 32, 04020080. [Google Scholar] [CrossRef]

- Blayi, R.A.; Sherwani, A.F.H.; Ibrahim, H.H.; Faraj, R.H.; Daraei, A. Strength improvement of expansive soil by utilizing waste glass powder. Case Stud. Constr. Mater. 2020, 13, e00427. [Google Scholar] [CrossRef]

- Pham, B.T.; Nguyen, M.D.; Al-Ansari, N.; Tran, Q.A.; Ho, L.S.; Van Le, H.; Prakash, I. A Comparative Study of Soft Computing Models for Prediction of Permeability Coefficient of Soil. Math. Probl. Eng. 2021, 2021, 7631493. [Google Scholar] [CrossRef]

- Quang, N.D.; Chai, J.C. Permeability of lime-and cement-treated clayey soils. Can. Geotech. J. 2015, 52, 1221–1227. [Google Scholar] [CrossRef]

- Taylor, D.W. Fundamentals of soil mechanics. Soil Sci. 1948, 66, 161. [Google Scholar] [CrossRef]

- Jalal, F.E.; Zahid, A.; Iqbal, M.; Naseem, A.; Nabil, M. Sustainable use of soda lime glass powder (SLGP) in expansive soil stabilization. Case Stud. Constr. Mater. 2022, 17, e01559. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A.; Mirzababaei, M. Rubber powder–polymer combined stabilization of South Australian expansive soils. Geosynth. Int. 2018, 25, 304–321. [Google Scholar] [CrossRef]

- Nagaraj, T.; Miura, N. Soft Clay Behaviour Analysis and Assessment; CRC Press: Boca Raton, FL, USA, 2001. [Google Scholar]

- Perera, S.T.A.M.; Saberian, M.; Zhu, J.; Roychand, R.; Li, J. Effect of crushed glass on the mechanical and microstructural behavior of highly expansive clay subgrade. Case Stud. Constr. Mater. 2022, 17, e01244. [Google Scholar] [CrossRef]

| Material Type | Property | Value | Unit | Test Standard |

|---|---|---|---|---|

| Reactive soil | Atterberg limits | ASTM D4318 (ASTM, 2017) | ||

| Liquid limit | 29 | % | ||

| Plastic index | 15 | % | ||

| Linear shrinkage | 6.8 | % | ASTM D854 (ASTM, 2017) | |

| Specific gravity | 2.67 | ASTM D854 (ASTM, 2017) |

| Mineral Compositions | Soil Content (%) |

|---|---|

| Coroudum | 23.17 |

| Quartz | 30.26 |

| Anatase | 1.19 |

| Hematite | 1.53 |

| Geothite | 3.33 |

| Plagioclase (Albite) | 1.97 |

| Plagioclase (Oligoclase, An16) | 7.40 |

| Plagioclase (Oligoclase, An25) | 0.95 |

| Microcline (maximum) | 2.73 |

| Microcline (intermediate) | 0.63 |

| Illite 2M1 | 7.05 |

| Kaolinite (Kga-1b), PONKCS model | 3.64 |

| Smectite 12 Å (SWy-2), PONKCS model | 10.29 |

| Smectite 12 Å (SCa-3), PONKCS model | 5.87 |

| Test Program | Curing Time | RC or CG Added (%) | Applied Stress (kPa) | |||

|---|---|---|---|---|---|---|

| 0 | 5 | 10 | 20 | |||

| Consolidation tests | 7 days | √ | √ | √ | √ | 6.25, 12.5, 25, 50, 100, 200 |

| SEM imaging | 7 days | √ | √ | √ | / | |

| Recycled Waste Type | Content (%) | |

|---|---|---|

| Nontreated | 0 | 0.152 |

| Recycled rubber crumb | 5 | 0.116 |

| 10 | 0.154 | |

| 20 | 0.125 | |

| Recycled crushed glass | 5 | 0.149 |

| 10 | 0.123 | |

| 20 | 0.111 |

| Content, % | Crushed Glass (CG) | Rubber Crumb (RC) |

|---|---|---|

| 0 | 3.09 × 10−6 m/s | 3.09 × 10−6 m/s |

| 5 | 3.08 × 10−8 m/s | 2.12 × 10−8 m/s |

| 10 | 3.21 × 10−8 m/s | 4.36 × 10−8 m/s |

| 20 | 3.03 × 10−8 m/s | 3.60 × 10−8 m/s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, M.; Gui, Y.; Laguna, R. Hydraulic Conductivity Characteristics of a Clayey Soil Incorporating Recycled Rubber and Glass Granules. Water 2023, 15, 2028. https://doi.org/10.3390/w15112028

Yu M, Gui Y, Laguna R. Hydraulic Conductivity Characteristics of a Clayey Soil Incorporating Recycled Rubber and Glass Granules. Water. 2023; 15(11):2028. https://doi.org/10.3390/w15112028

Chicago/Turabian StyleYu, Miao, Yilin Gui, and Ryan Laguna. 2023. "Hydraulic Conductivity Characteristics of a Clayey Soil Incorporating Recycled Rubber and Glass Granules" Water 15, no. 11: 2028. https://doi.org/10.3390/w15112028

APA StyleYu, M., Gui, Y., & Laguna, R. (2023). Hydraulic Conductivity Characteristics of a Clayey Soil Incorporating Recycled Rubber and Glass Granules. Water, 15(11), 2028. https://doi.org/10.3390/w15112028