Abstract

Ceramic membranes have become one of the most rapidly developing and promising membrane materials owing to their excellent properties. Compared with other membrane materials, ceramic membranes are widely used in the wastewater and water treatment fields owing to their advantages, including higher chemical stability, stronger mechanical strength, longer service life, and better water filtration performance. In this paper, the sources of raw materials and their preparation for the production of ceramic membranes are briefly introduced. The methods for preparing ceramic membranes are described in detail, including the role of ceramic membranes in water treatment applications, the preparation methods of the membranes, and the latest progress in this area, along with a review of the applications of ceramic membranes in wastewater and water treatment. Simultaneously, this study also evaluates which preparation method is the most advantageous and the aspects of its advantages. The raw materials used in the ceramic membrane preparation and the types of water treatment suitable for this method were studied. The results showed that the phase-conversion sintering technique has multiple advantages, and the generated asymmetric structure with finger- and sponge-like voids can further improve the flux and separation abilities, which are attractive for scientific researchers. Finally, the development trends in the inorganic ceramic membrane market were surveyed. This work can help beginners understand the preparation procedures employed to produce ceramic membranes for water treatment; compare the porosity, mechanical strength, permeation flux, and chemical and thermal stability of the resulting membranes; and reasonably select the appropriate preparation method for the relevant water treatment type.

1. Introduction

Ceramic membranes have great advantages in the field of separation. Their separation function is based on the “screening” theory. For permeable substances with different permeabilities, the pressure difference is used as the driving force to allow small molecular substances to pass through and intercept large molecular substances to achieve separation [,,]. Compared with polymer membranes, which cannot withstand high temperatures, harsh chemical environments, or other harsh conditions, ceramic membranes are particularly popular because of their superior characteristics with respect to their lifetime. Common ceramic membrane materials include alumina, silica, silicon carbide, titanium dioxide, and inexpensive zeolites [,,]. Ceramic membranes are inorganic materials with excellent performance. They have the advantages of acid and alkali resistance, high heat resistance, excellent chemical stability, high mechanical strength, easy cleaning, and regeneration, and are increasingly being used in petrochemical, medical, biological, environmental, and other fields, especially in applications related to water resources and water environment management [,,]. Table 1 lists the advantages and disadvantages of the ceramic membranes. In the last decade, ceramic membranes have been used in industrial and urban wastewater and drinking water treatments, and rapid development has been achieved []. Ceramic membranes also offer significant advantages over other membrane types. It is not difficult to see from Table 2 that ceramic membranes have obvious advantages over hollow-fiber membranes regarding pore size, water production, acid and alkali resistance, and mechanical strength.

Table 1.

Advantages and disadvantages of ceramic membranes [].

Table 2.

Comparing between ceramic and hollow-fiber membranes.

Internationally, research on ceramic membranes began in the 1940s. Initially, it was used as a membrane material to separate and enrich uranium isotopes in the nuclear industry []. Owing to the unique advantages of ceramic membranes in the context of separation technology, ceramic membrane separation techniques have gradually replaced traditional filtration separation techniques and are widely used in environmental engineering, the processing industry, and other fields. Currently, the preparation of ceramic materials is regarded as the fastest-developing advanced technology worldwide. They have evolved from single-phase ceramics to multiphase composite ceramics, and the research focus has shifted toward achieving low cost and commercialization [].

In China, research on ceramic membranes began in the 1980s, and their application started late, far behind advanced international standards. Therefore, in the early 1990s, the National Natural Science Foundation of China established a special key fund to support basic research on the application of inorganic membranes, hoping to achieve rapid development with a view toward their application as soon as possible. In the 21st century, the application of ceramic membranes has been increasing. The recognition of ceramic membrane technology by the industrial community has gradually improved. The gap between the domestic industrial and advanced foreign technologies has gradually narrowed. The overall penetration rate of domestic applications is still low, but the prospects for future development are wide.

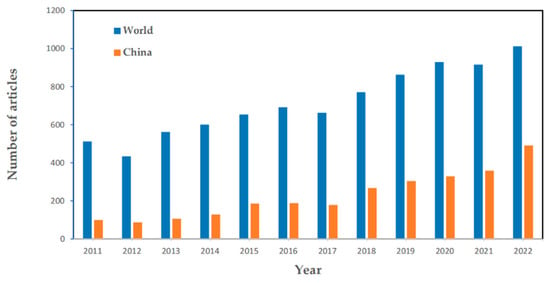

According to the statistics of the ScienceDirect platform, searching with “ceramic membrane” as the subject words, the number of articles related to ceramic membranes published in the last 12 years has fluctuated, but it is still growing steadily, from 513 in 2011, 654 in 2015, and 929 in 2020, with a total of 8610 articles published. Thus, the academic community attaches great importance to ceramic membranes. Among the 120 known scientific journals that have recently published ceramic membrane articles, The Journal of Membrane Science ranked first, accounting for approximately 10% of all source publications. Its research interests were mainly focused on engineering, chemistry, and materials science, accounting for 72, 53, and 49% of the total articles, respectively. As the world’s largest developing market, China has made significant contributions to the commercialization and technical applications of ceramic membranes and related theoretical research (Figure 1). Simultaneously, based on the bibliographic analysis, the application of ceramic membranes in water treatment has attracted much attention.

Figure 1.

The number of articles on ceramic membranes published in China and the world.

Many preparation methods have been used to produce ceramic membranes, and detailed reports have been published on membrane material costs, processing costs, and other manufacturing details []. In the first part of this paper, the preparation of raw materials and ceramic membrane production methods are briefly described, and the advantages and disadvantages of each method are explained and compared. The second section summarizes the application of ceramic membranes in wastewater and water treatment, covering the challenges and future trends in ceramic membrane technology used in wastewater and water treatment. Ceramic membranes are used in many fields and are widely applied in environmental protection in line with future development trends. The final section discusses prospects and the need for research to bring ceramic membranes into their next phase.

2. Preparation of Ceramic Membrane

2.1. Raw Materials for Ceramic Membrane Preparation

The ceramic materials used in membranes manufacturing are critical in determining their function and properties. Ceramic materials for membranes used in wastewater and water treatment are selected based on the physical and chemical properties of the membranes required for their application, such as microstructure (pore and pore size), hydrophilicity, chemical and thermal stability, mechanical strength, and other beneficial properties []. Cost-effectiveness is also a consideration.

2.1.1. Methods of Preparing Ceramic Materials

Ceramic materials used in scientific research and industrial processes include oxides, carbides, nitrides, silicides, and borides, which can be purchased directly or obtained through complex synthetic routes, such as Al2O3 or SiO2, which can be obtained from nonoxide parent materials []. In addition, the ceramic powder must undergo a special treatment process to control its heterogeneity, chemical composition, purity, particle size, particle size distribution, and specific shape []. Various treatment methods are used for different materials and requirements (Table 3).

Table 3.

Descriptions of the characteristics of ceramic material treatment methods.

The sol–gel process involves the production of oxide ceramics by the gelation of metal oxides or hydrolysis of metal salts and the subsequent solidification of colloidal gels []. The sol–gel process is widely used in the special treatment of ceramic materials because ceramics produced by the sol–gel process can reduce the sintering cost and ensure a small grain size.

2.1.2. Low-Cost Ceramic Materials

Most commercial ceramic membranes are expensive to produce because of the raw materials and processing requirements, and it is economical to use low-cost ceramic materials as raw materials in most water treatment applications. Low-cost ceramic membranes have the potential to provide high-volume filtration capabilities, which will help provide clean and safe water to the poorer parts of the world. Achieving structures with appropriate microscale pore structures for contaminant separation while maintaining good mass-transport performance and mechanical robustness is a major challenge in manufacturing low-cost membranes []. Many low-cost materials have been used to achieve this, including clay, zeolites, apatite, ash waste, and cement. Table 4 lists the sources of low-cost materials and powder preparations [].

Table 4.

Sources of low-cost ceramic materials and powder preparation.

2.2. Ceramic Membrane Preparation

In general, the common preparation methods of ceramic films are as follows: extrusion [], pressing [], slip casting [], belt casting [], sol–gel [], reverse rotation sintering [], and chemical vapor deposition (CVD) [] (Table 3). The preparation methods have been described in detail in the literature, and many studies have reported the effects of raw material type, raw material parameters, sintering temperature, pore-forming dose, and sintering aid dose on the properties of the ceramic film flux. In addition, the shape of the support body (flat, hollow fiber, tubular, or multi-channel) was determined by the selected preparation method, which in turn determined the shape of the ceramic membrane. Previously, researchers blindly used powder pressing, extrusion, and other colloidal processing methods to form ceramic membranes. Now that more research has been conducted on the preparation of ceramic membranes, researchers can consider the cost and performance of choosing an appropriate preparation method.

2.2.1. Extrusion Method

Extrusion is a common method for producing bodies in the ceramic industry with the advantages of high production efficiency and good product uniformity []. However, the extrusion process places high demands on slurry materials, requiring the slurry to have sufficient plasticity, fluidity, and uniformity; otherwise, the billet is prone to torsional deformation and cracking []. The extrusion process consists of five steps: mixing, extrusion, compression, cutting, drying, and sintering. During the extrusion process, the ceramic powder is mixed with surfactants, anticoagulants, plasticizers, and additives, stirred, stored for several hours at room temperature and high humidity, and then injected into a chamber where it is compressed. The inside of the chamber has a die opening with a piston that exerts a force on the slurry. The shape, pore size distribution, and porosity of the final product are determined by the applied force (typically 20–180 MPa). The film is then cut to the desired length, dried, and sintered to prevent cracking and bending []. There are two types of extruders to be mentioned here—screw and plunger extruders. The use of a plunger extruder can reduce the possibility of contamination due to wear; however, there is a significant pressure loss that affects the die pressure; the plunger and the die pressure of the screw extruder are similar to that of the plunger.

The extrusion technology was first invented by John Etherington in 1619 for manufacturing bricks. The literature on extrusion was first published in 1990 and applied in the medical field []. In 1999, Rodriguez et al. proposed the use of extrusion technology in producing ceramic tubular supports as carriers for anaerobic reactors []. Hedfi et al. [] used kaolin and alumina as raw materials to produce two types of films by extrusion: plates and tubes. Because of extrusion molding, the orientation of the kaolin plate improved, resulting in a better filling effect of the stencil and a smaller aperture. In addition, the resulting films were compared with those made from kaolin alone or kaolin, and it was found that the extruded films were more permeable and could achieve higher pressures, even with lower porosity. Recent studies on extrusion methods have aimed to use low-cost materials to replace other metal oxides, and studies have been conducted on the use of low-cost membranes to treat oily wastewater and remove heavy metal ions from wastewater [,,,,,,]. In recent years, Kamoun et al. [] have used Tunisian clay as a raw material and graphite as a porogenic agent to obtain low-cost ceramic tubular membranes by extrusion molding. It was found that membranes sintered with graphite additions of 15 wt% and sintering temperatures of 850 °C were the optimal membranes for the treatment of diesel/water emulsions and that the resulting membranes had a porosity of 41% and a diameter compressive strength of 4 MPa [].

2.2.2. Pressing Method

Pressing is the simplest method for ceramic preparation and does not require slurry preparation. In the pressing method, the powder is granulated with a small amount of binder, and the powder obtained after granulation is placed in a mold and compacted directly with a press machine. Dry and isostatic pressing are widely used in pressing processes [,,,]. The particles in the dry-pressing process extrude from each other to produce internal friction, which in turn acts on the powder particles to bond them more closely []. Its technological processes include feeding, compression, molding, billet, and mold cleaning, and it has a relatively simple operation. Because of its simple shape, green is used for substrate products such as plate ceramic films. In the industry’s strong pursuit of economically competitive membranes, in addition to finding alternative low-cost ceramic materials and reducing the sintering temperature, pressing is an environmentally friendly and cost-effective alternative. Manni et al. [] used natural magnesite to obtain low-cost ceramic membranes by a dry uniaxial pressing method with a sintering method and found that a membrane fired at 1100 °C is the best membrane for filtering industrial textile wastewater with a porosity of 48.15%, pore size of 1.12 μm, permeability of 922 Lh−1·m−2·bar−1, and mechanical strength of 6.1 MPa.

2.2.3. Slip-Casting Method

Slip casting is the most widely used technology for preparing metal oxides and ceramic membranes. Alumina, zinc oxide, and silica membranes were prepared using this method []. In the slip-casting process, stably dispersed fine particles were first prepared in a liquid medium (mainly water) and placed in contact with a prefabricated dry porous support. Capillary forces cause liquid to pass through the pores of the support, leaving a layer of concentrated particles on the surface. After controlled drying and heat treatment, the particle layer changed from a semi-solid to a firmly bonded pore network. The thickness of this film was set to approximately 10 µm or less to reduce the pressure drop. Synovial casting is often used to produce active layers, and sometimes, one or more intermediate layers may be required between the membrane and the support to reduce the pore size of the support and provide the membrane with a high rejection rate. This relatively inexpensive and reusable method is suitable for the mass production of environmentally friendly ceramics of any shape []. Zyryanov and Karakchiev [] concluded that slip casting is an attractive process for producing porous ceramic supports with complex shapes for CMR and SOFC. In the same year, Elyassi et al. [] proposed a new method for the preparation of nanoporous silicon carbide films based on the use of sacrificial layers. This refers to the periodic and standby coating of a sacrificial polystyrene layer and silicon carbide preceramic layer on top of a slip-cast tubular silicon carbide bracket. In addition to liquid casting, slip casting is based on additional pressure transmitted by the gas. Boulesteix et al. [] exploited the advantages of pressure slip casting to produce a large number of ceramics and prepared large-sized Nd: YAG transparent ceramics by combining vacuum reactive sintering, static pressure sintering, and other processes; they concluded that the permeability of the mud cake is the key parameter for controlling the casting dynamics. In addition, the selection of low-cost ceramic materials can reduce the cost-effectiveness of ceramic membranes in industry and commerce. Azaman et al. [] obtained low-cost planar rectangular ceramic membranes with a modified slip-casting method using natural Malaysian ball clay as the main precursor with additives (PEG600 and Dispex N40) and a pore-forming dosage. They investigated a sintering temperature of 1000 °C and sintering time of 2 h and found the CM2 ceramic membrane had a porosity of 36–38%, a water permeability of 40,000–70,000 Lh−1·m−2·bar−1, and a compressive strength of 8–12 MPa.

2.2.4. Tape Casting

Tape casting is a manufacturing technique in which a thin ceramic plate is produced from a ceramic slurry, cast into a thin layer onto a flat surface, dried, and sintered. The key to tape casting is the preparation of a slurry consisting of an inorganic powder dispersed in a liquid (water or organic matter). Inorganic powder is used as a solvent for organic additives (dispersants, plasticizers, and adhesives) and a dispersion medium for ceramic particles. The prepared slurry is poured into a container, cast, molded onto the polymer tape, and cut with a “scraper” to control the film thickness. The raw tape was dried and cut into pieces that were laminated to obtain thicker parts and ensure mechanical stability. Finally, the laminate was sintered to remove organic matter and promote densification. During the drying step, the slurry was converted into a semi-rigid flexible tape after removing the solvent. The final step is to burn the raw embryo into a shape []. The pore morphology can be controlled by adjusting the particle size, sacrificial pore-forming agent, sintering conditions, and combined techniques (phase inversion and freeze casting) [].

Glenn Howatt first introduced tape casting in the mid-1940s during the Second World War and produced thin piezoelectric materials. In 1947, Howatt published his first article on the production of thin ceramic plates for capacitors. This process was patented in the USA in 1952 to produce high-dielectric and high-insulation ceramic plates.

The advantages of tape casting are that the ceramic pieces can be cut into desired shapes, and the thickness of the products can be adjusted, which is a key feature in separation applications using membranes or support materials with customizable structures. The main disadvantage is the inaccuracy of the shape owing to the corrosion of the plaster mold. In addition, rubber molding of a slurry with a fine powder takes a long time. Later, scholars tried to solve the problem by repressing it, but this also increased production costs. Kaur et al. [] made different attempts. They used different amounts of two carbonates (calcium and sodium) as pore-forming agents and found that the optimum concentrations of calcium carbonate and sodium carbonate were less than 20 and 10 wt%, respectively. Das et al. [] used activated carbon to improve porosity during sintering and mixed the activated carbon in a slurry containing kaolin, feldspar, quartz, boric acid, sodium metasilicate, titanium dioxide, and water.

2.2.5. Sol–Gel Method

The sol–gel process is an established method of producing ceramic membranes by producing a sol by hydrolysis. The sol–gel process and subsequent heat treatment significantly affect the final pore size of the membrane []. In a short preparation process, the raw materials are solidified by solution (sol) and gel and then heat-treated to form a film []. Capillary forces play an important role in the drying process, and they increase as the capillary radius decreases. This method can be applied to the synthesis of ceramic solids with low molecular weights using elementary organic or inorganic precursors.

Burggraaf et al. [] published the first paper on sol–gel-derived ceramic membranes in 1984, attracting wide attention and accelerating research on inorganic membranes. The sol–gel method is widely used to prepare catalytic materials [] and solid oxide fuel cells []; thin-film ceramic membranes can also be prepared using the sol–gel method []. Using this method, several casting steps must be performed to obtain a suitable film thickness. However, this technology still has shortcomings: that is, the preparation steps are expensive and consume more energy; therefore, tape casting and pressing methods are more commonly used in the preparation of thin-film ceramic membranes. In research on the sol–gel process, it is necessary to overcome its shortcomings and industrialize it. Recently, Coelho et al. [] optimized the key synthesis and process parameters of the sol–gel method and reduced the cost and energy loss by preparing a ZrO2 membrane using the sol–gel method with zirconia and other ceramic materials as supports. The superhydrophilicity and high-flux characteristics of the membrane at low pressures achieved good results for oily wastewater treatment. The development of ZrO2 nanofiltration membranes has promoted the commercialization of ultrafiltration and nanofiltration zirconia membranes.

2.2.6. Phase Inversion/Sintering Technology

Ceramic membranes produced via phase inversion and sintering contain finger- and sponge-like voids. The finger structure is considered a defect caused by the agglomeration of ceramic particles and lack of degassing, which reduces the mechanical strength, and finger-like voids should be avoided []. However, the finger structure exhibited less fluid resistance than the sponge structure. Therefore, the desirability of finger and sponge structures cannot be determined. The void structure can be controlled by changing the manufacturing parameters such as the ceramic content, coagulation bath type, and sintering temperature. Increasing the viscosity of the ceramic suspension reduces the possibility of the finger structure formation. Therefore, the critical value of viscosity was defined as the viscosity at which the finger structure became spongy. The preparation process of the phase inversion and sintering technology can be realized using dry or wet methods. The first step involved preparing a ceramic suspension. In the wet method, the ceramic suspension is immersed in a non-solvent bath for coagulation. The dry method involves exposure to a non-solvent atmosphere for coagulation []. This technology is mainly used to construct hollow fibers with a high surface/volume ratio and has higher performance in membrane module assembly [].

Luyten et al. [] reported the early development of a phase-inversion ceramic membrane used to prepare a LaSrCoFeO3-x membrane for low-cost oxygen production. Wu et al. [] reported for the first time in the field of ceramic membranes an SCFNb0.5-HF membrane made from NMP and water. Drastic changes in the composition and crystal structure of the ceramic materials caused by water helped remove a large amount of Sr and other possible elements from the prepared membrane, thus destroying the excessive structure. According to related studies, a one-step method for the preparation of ceramic membranes has been successfully found, which can convert ceramic powder into hollow fibers or unsupported ceramic membranes with flat structures [].

2.2.7. Chemical Vapor Deposition Method

CVD is an industrial chemical process that uses various deposition techniques to form thin films of various precursors on substrates (typically used for semiconductor materials). Essentially, the CVD process involves exposing the substrate to single- or multi-component volatile precursors in an inert atmosphere at a controlled high temperature and pressure. These volatile precursors react or decompose on the substrate surface to produce the desired thin-film material []. This method has also been used to deposit ionic thin films onto various porous support materials []. CVD is a common membrane surface modification technique that alters the pores of the supporting membrane through the reaction of one or more gas-phase precursors around the near-surface, internal, or mesoporous basal pores. The CVD reaction mechanism involves both gas phase and surface reactions. On the one hand, these reactions between different components can start from the vapor phase by heating the substrate and then depositing a film on the surface. However, the surface layer can also be deposited by a reaction between the surface of the substrate and one or more components of the vapor phase, and the pore size is distributed near the porous support. CVD has the advantages of simple equipment, easy operation, and high yield and is a simple and inexpensive method for preparing uniform ultrathin films on large-aperture ceramic frameworks []. Chen et al. [,] used low-pressure CVD (LPCVD) technology to fabricate ultrathin SiC membranes for the first time. A thin layer of SiC was deposited in the pores of commercial alumina ceramic membranes and the oil emulsion in the water of the SiC membranes was filtered, thereby reducing membrane fouling. Thus, the proposed method is simple and economical. It should be noted that the width of the ceramic channels is very important for the role of the CNTs.

Among these preparation methods, the pressing method can solve the shrinkage problem more easily than the slip-casting method and can also produce a membrane with higher mechanical strength. However, compared with the pressed support, the extruded support has lower porosity and smaller pore size, and the higher the clay content in the initial composition, the more obvious this tendency will be. In addition, the production efficiency and dimensional accuracy of the ceramic membranes produced by the extrusion method are relatively high, and the scope of their application is wider. Slide and tape casting are both low-cost technologies that are easy to operate, but tape casting can easily control the film thickness, while slide casting is difficult to control because of the large time consumption and energy loss. Therefore, the sol–gel method is rarely used in industry and is at a medium level in laboratory research. CVD and phase-inversion technologies have also been favored by scientists. Phase conversion technology has problems with the release of organic solvents into the environment, but it can reduce the production cost to a certain extent, with high mechanical strength and extremely high surface area/volume ratio, and the asymmetric structure with finger-like and spongy voids can further improve the flux and separation ability. (CNIM membranes made with phase conversion technology can increase the water vapor flux by 76% and the total mass transfer coefficient by nearly 1.8 times compared to unmodified membranes [].) Therefore, phase-inversion technology is the most attractive approach.

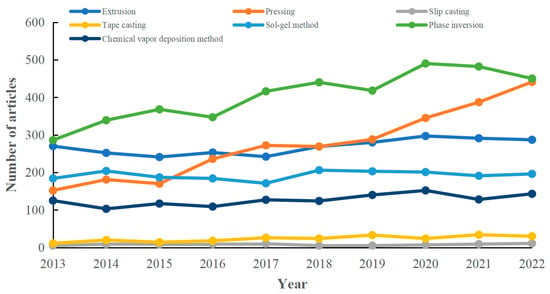

Second, based on a bibliometric analysis, the number of published documents on the seven ceramic membrane preparation methods in the last ten years is shown in Figure 2. The number of articles published in recent years on tape and slip casting as traditional ceramic membrane preparation processes is relatively low (Figure 2); the increase is not obvious, and scientists are not interested in researching those methods. On the contrary, the number of articles on pressing and phase inversion technology is at a high level and is increasing annually because people are pursuing high-performance ceramic membranes. By comparing and analyzing the advantages of different preparation methods in trade and industry, combined with the results of the bibliometric analysis, it is concluded that phase inversion technology has many advantages.

Figure 2.

The number of articles published on the seven preparation methods in the last ten years.

3. Application of Ceramic Membranes in Wastewater and Water Treatment

Based on bibliometric analyses, the application of ceramic membranes in water treatment has attracted increasing attention. Owing to their high stability, ceramic membranes are used in water purification processes, such as oil–water separation, textile wastewater treatment, seawater desalination, and drinking water treatment. The application of ceramic membranes in seawater desalination and wastewater treatment has been the focus of ceramic membrane research [].

3.1. Oil–Water Separation

Oily wastewater is generated by petrochemical, daily chemical, leather, textile, pharmaceutical, and metallurgical industrial processes, and its impact on the ecosystem is long term and deadly [,,,]. During the treatment process, oil droplets easily adhere to the membrane surface, resulting in membrane fouling, which reduces the membrane filtration performance and ultimately shortens the membrane life. To avoid this situation, optimization of the operating conditions and modification of the membrane surface properties are the dominant methods. Oily wastewater can be classified into oily wastewater with and without an emulsion. Among all types of oil–water mixtures, the water emulsions are considered to be the most difficult to separate [,]. There are few reports on the systematic separation of oil droplets from emulsions during oil and protein separation. In recent years, there has been increasing interest in the use of ceramic membranes for oil–water emulsion separation. In oil–water separation, membrane fouling caused by surfactant adsorption and oil droplet blockage is a problem that deserves attention, and changing the hydrophilicity of the ceramic membrane surface or its hydrophobic properties can effectively solve the membrane fouling problem [,].

Generally, surface isolation [], surface coating [], and surface graft polymerization [] are used to improve hydrophilicity. Titanium dioxide has extremely high hydrophobicity, which is beneficial for oil and water separation []. Chang et al. [] modified a commercial ceramic membrane with anodic TiO2 coatings to increase the membrane surface hydrophilicity. The hydrophilic coating prevented oil droplets from adhering to or penetrating through deformation, which reduced membrane fouling. They further improved the flux of the modified membrane by optimizing the operating parameters such as the feed rate, transmembrane pressure, and feed temperature. Gao et al. [] prepared a SWCNT/TiO2 nanocomposite film. Through ultraviolet irradiation, the film exhibited superhydrophobicity and superoleophobic properties and had a stronger ability to separate surfactant-free and surfactant-stable oil-in-water emulsions with large droplet sizes. Jin et al. [] grafted a modified polymer with a low degree of polymerization onto the surface of a ceramic membrane and prepared a PI/CM composite membrane with excellent structural stability, antifouling properties, and separation performance. In the application of edible oil/water separation, the flux recovery rate of the composite membrane is 88.8%, which is higher than that of the ceramic membrane with a flux recovery rate of 32.5%.

Ceramic membranes have strong hydrophilicity, which can provide the membrane surface with hydrophobicity to develop a solid and high-flux membrane material and realize efficient oil–water separation. Grafting imparts hydrophobicity to the ceramic membrane; however, it is still challenging to simultaneously maintain the advantages of the ceramic membrane at the same time. The surface grafting of silane reagents is the most common method for changing ceramic membranes from hydrophilic to hydrophobic. Wei et al. [] used N-octyltrioxicillin as a grafting reagent to deposit ZnO nanospheres on SiC particles and developed superhydrophobic supereosinophilic ceramic membranes. The research shows that the SiC-50 membrane has the best performance with an oil flux of 1000 L·m−2·h−1 (lower than the pressure of 1 bar) and a water rejection rate of 99%. In addition, Wang et al. [] also give excellent separation efficiency to the modified mesh with superhydrophobicity and a water contact angle up to 158° by PANI/TiO2 nanosphere coating, with permeation flux as high as 170 KL·m−2·h−1, oil purity more than 99.7%, and photocatalytic degradation performance, which can reduce oil and organic pollution on the mesh surface.

Traditional membrane materials can produce serious dirt when used, which negates the advantages of using membranes in oil–water separation applications. Membrane surface modification, chemical cleaning, membrane oscillation, pore structure modification, backwashing, and ultrasonic treatment are the most commonly used antifouling methods. However, owing to the emerging bionic interface research, a series of special wettabilities not only gives the membrane surface excellent antifouling properties but also breaks through the long-standing compromise between membrane permeability and surface activity [,].

Traditional membrane separation is limited by the fact that a single membrane cannot separate oil–water and oil–oil mixtures. To solve this problem, researchers have developed a superhydrophilic/superoleophobic shell powder coating that can be used as an advanced separation membrane for separating oil/water mixtures, emulsions, and oil/oil mixtures when used on copper nets and fabrics. Using an ethanol prewetting strategy, oil/water and oil/oil separation can also be achieved using this separation membrane. This has become an emerging technology for treating oil–water emulsions [,].

Oscillating motion is considered an effective process enhancement (PI) technology that can increase the rates of mass and heat transfer in applications, especially those limited by diffusion, such as membrane separation. Compared to other membrane-based separation technologies (ultrafiltration, reverse osmosis, etc.), microfiltration was found to be more effective in treating oil droplets in the produced water. Microfiltration provides a higher permeation flux, which may be attractive to the industry. In addition, through the investigation and calculation of the researchers, it was found that the transmembrane pressure of microfiltration is expected to be lower than that of reverse osmosis, nanofiltration, and ultrafiltration, and it can be used to deal with deformable oil droplets entering the permeate through the membrane at higher pressures. All these technologies contribute to better separation of oil and water [,].

3.2. Seawater Desalination

The application of ceramic membranes in seawater desalination includes membrane distillation and seawater microfiltration pretreatment. Seawater desalination is a new technology used to address freshwater resource shortages. Unlike traditional seawater desalination technologies (such as RO), membrane distillation technology (MD) with ceramic membranes can minimize energy, operation, and maintenance costs []. MD is a membrane separation process based on thermal technology, and ceramic membranes have high cost and thermal conductivity; therefore, the application of ceramic membranes in the MD process is limited, accounting for only 20% of MD-related publications []. To prevent heat loss through the membrane, it is especially important to select materials with low thermal conductivities []. Hydrophobicity is a requirement for membrane distillation, and recent research has focused on modifying hydrophilic ceramic membranes into hydrophobic or superhydrophobic surfaces []. Hydrophobic surface modification alters the physical and chemical properties of ceramic membranes, such as the hydrophobicity, roughness, and surface free energy [].

In 2004, Larbot et al. [] reported the first study on ceramic membranes used in the MD process. The authors used the surface modification of ceramic hollow fiber membranes made of alumina and zirconia and used direct contact membrane distillation to graft fluorine-based Ceylon for seawater desalination. The desalination rate is approximately 100%. Subsequently, many researchers have carried out a series of experiments on the grafting of fluorine groups, and the application prospects of fluorine-modified ceramic membranes in the MD process are wide. Fan et al. [] prepared titanium dioxide nanofiber membranes via fluorine modification, and the desalination performance was good with a desalination rate of 99.92%. There are also some studies in which FAS is grafted on the surface of ceramic membranes such as alumina and zirconia, a g-Al2O3 membrane of FAS is grafted, and the effects of corrosion time, grafting time, and concentration of FAS solution on the hydrophobicity are further investigated. In addition to fluorine-based modifications, silane-based modifications are another important trend [,,,,]. Pagliero et al. [] functionalized an alumina tubular membrane with methyl trichlorosilane (MTS). The results show that the higher the concentration of MTS, the higher the degree of functionalization, which has little influence on the average pore size of the selective and intermediate layers, and the obtained membrane has excellent performance. It is worth mentioning that BinBandar et al. [] realized an uncoated supermodel distillation. Their research work combined inorganic materials and sodium alginate powder to prepare a porous membrane. Sodium alginate powder was used as the pore-forming agent and binder, which not only reduced the cost of the membrane production process but also realized the membrane distillation process without coating. The average pore size of the prepared film was 33 nm and the percentage of salt ions deposited on the film exceeded 80%. The performance of the film was comparable to that of the coating films reported in previous studies.

Membrane fouling and wetting are the primary problems of membrane distillation systems []. The main reason for wetting is the liquid entry pressure (LEP). To reduce the wetting effect caused by LEP, the pore size should be as small as possible to provide a high LEP; however, reducing the pore size may result in a lower permeability.

Tianjin University of Science and Technology has conducted research on the application of ceramic membranes in seawater desalination pretreatment. They used sand filtration and a 0.2 m ceramic membrane for pretreatment in the Tianjin 1000 t/d seawater desalination demonstration project. This experiment not only successfully ensured that the effluent water quality met the water inlet requirements of the GB/T19249-2003 reverse osmosis membrane but also effectively extended the membrane life and reduced membrane fouling. By using sand filtration and a –0.2 NTm ceramic membrane to treat clarified seawater, high-quality pure seawater with an SDI value less than 3 and a turbidity less than 0.3 NTU can be obtained, providing economical and reliable technical support for reverse osmosis seawater desalination technology. Ceramic membranes offer the advantages of good chemical concealment, strong separation ability, acid and alkali resistance, and high mechanical strength. In the experiment, we found that the membrane flux reached more than 600 L/m2·h, and when the backwash cycle was 1.5 h, the backwash effect was good, and the process was simple. This makes the pretreatment process of seawater desalination low-cost and simple to operate, which is conducive to the rapid realization of large-scale seawater desalination. However, there is still scope for improvement. Although periodic backwashing can effectively slow membrane fouling, it cannot completely eliminate it. Chemical cleaning methods must be used to solve this problem when running times are reduced [].

3.3. Textile Wastewater

The textile industry process includes several stages: resizing, printing, dyeing, scouring and screening, washing, rinsing, bleaching, mercerizing, carbonizing, and finishing [,,]. Wastewater is mainly generated from the dyeing, scouring, desizing, mercerizing, and finishing processes. The temperature of thermal wastewater produced by the textile industry can be as high as 90–95 °C, which requires the membrane to be thermally stable. Therefore, the application of inorganic membranes to textile wastewater has attracted the interest of researchers []. Unlike other industrial wastewater treatments, textile wastewater must be cooled before membrane treatment. Agtas et al. [] tested the chemical oxygen demand, total hardness, total organic carbon, color, and electrical conductivity of textile wastewater and monitored the flux and temperature. In the pilot-scale test, the ceramic membrane technology showed good recovery performance for hot wastewater.

Hubadillah et al. [] successfully converted HAp after sintering with WCB and applied the prepared HAp-based bioceramic hollow fiber membrane to the wastewater treatment of a textile mill in Malaysia. The membrane showed high treatment efficiency with color removal (99.9%), COD (80.1%), turbidity (99.4%), and electrical conductivity (30.1). In a similar study, Bhattacharya et al. [] used untreated sulfur black wastewater (COD concentration 3910 mg/L) as a feed solution and investigated the efficiency of tubular multi-channel α-alumina and clay ceramic microfiltration to remove dyes and COD. The dye and COD removal rates were 99 and 80%, respectively. Santra et al. [] studied the microfiltration of a ceramic membrane combined with biosorption; the COD removal rate was 91%. Ciardelli [] studied the influence of mode characteristics on ozone mass transfer and decolorization yield. The metal oxide layer covering the membrane surface significantly improved the ozone transmission, and the decolorization rate of the wastewater was higher after biological treatment.

In recent years, several studies have been conducted to lower costs. Using perlite, drinking water treatment sludge, and kaolin as raw materials for ceramic membrane preparation significantly reduced production costs and led to excellent separation performance when applied to textile wastewater treatment. Idrissi et al. [] successfully prepared low-cost ceramic microfiltration membranes using kaolinite and perlite. It was found that the membrane prepared at a sintering temperature of 1050 °C and perlite content of 50% was the best membrane for removing textile wastewater with an average pore size of 1.25 μm, a permeability of 1779 Lh−1·m−2·bar−1 and a porosity of 30.28%. It can remove 80% of the total organic carbon and turbidity above ninety-seven percent from textile wastewater. In addition, the cost of the membrane is estimated to be $7.7 m−2, which is lower than that of commercial membranes; therefore, the membrane may be produced in large quantities.

3.4. Drinking Water Treatment

Explosive population growth is the main reason for the global shortage of drinking water. The destruction of the ecological environment owing to human activities has caused drinking water pollution to increase at an alarming rate. Reductions in drinking water quantity and quality are two major problems that need to be solved urgently. Traditional water treatment processes have limitations in treating slightly polluted water. The development of ceramic-membrane technology provides an opportunity to solve this problem and improve drinking water safety. Conventional water treatment can include chemical addition (aluminum sulfate, lime, and polymers), coagulation, flocculation, precipitation, filtration, and disinfection, and water is usually treated with chlorine []. These conventional water treatment methods have limitations. Ceramic membranes not only have high thermal, chemical, and mechanical stability but also have higher pathogen tolerance and less membrane fouling [].

Ceramic membrane filtration is an alternative method for drinking water treatment. Werner et al. [] prepared tubular ceramic membranes using yttria-stabilized zirconia via extrusion. The membranes obtained had a wide range of pore sizes (24–146 nm) and could provide a virus retention rate higher than that of four LRV. The existing data show that with an increase in pore size, the retention rate shows a decreasing trend, while the permeation flux shows the opposite trend. Filtration time also affects virus retention because with an increase in filtration time, contaminants will help the membrane retain the virus on its surface. A high virus retention rate for a macroporous membrane can be achieved by functionalizing the membrane surface. Sometimes, the volume of viruses and bacteria is very small; therefore, it is necessary to apply pretreatment steps before membrane filtration to reduce the microbial infection rate in the permeate sample to zero []. Ceramic membranes can also be used as pot filters to intercept viruses in natural waters and obtain high-quality drinking water. Frequent cleaning with deionized water can reduce the filter cake layer formed on the membrane surface, thereby affecting the viral removal efficiency of ceramic pot filters []. Ceramic membranes have a narrow pore-size distribution; therefore, they can effectively intercept viruses in water. Yasui et al. [] were able to achieve virus retention higher than 6.2 LRV with a coagulation and ceramic membrane MF system where the ceramic membrane had a pore size of 0.1 µm and a flux of 2.5 m/day (~100 LMH).

3.5. Industrial Waste Treatment

The discharge of industrial waste is a major economic and environmental problem that has caused some countries to impose stringent regulations to reduce the pollutant content in effluents. Therefore, developing effective effluent treatment methods is of practical importance [].

Application of this Method in Decolorization of Dyeing Wastewater []

The bleaching, dyeing, printing, dyeing, and finishing processes produce a large amount of wastewater containing organic pollutants, which have the following characteristics: large water content, high organic pollutant content, deep color, strong alkalinity, and significant changes in water quality. These factors render printing and dyeing wastewater one of the most difficult wastewaters to treat in the textile industry [,].

Zhao et al. [] used 1.00 mA12O. Reactive dye wastewater was decolorized using magnesium hydroxide adsorption and ceramic membrane microfiltration. This study provides a basis for treating dye wastewater using inorganic ceramic membranes [].

The treatment of printing and dyeing wastewater is a complex problem, and it is often difficult to achieve the ideal effect using a single treatment technology. Therefore, the combination of multiple technologies (such as ceramic membrane filtration and other technologies) has become the development trend for printing and dyeing wastewater treatment. Simultaneously, the reclaimed water reuse rate in the printing and dyeing industry was low (7%), and the reclaimed water reuse rate in the textile industry was less than 10%, which shows the importance of reclaimed water reuse technology in the printing and dyeing industry. Inorganic ceramic membranes have also played a new role [].

The team comprising the Xi Danli Research Group of Donghua University has been committed to research on membrane technology in the field of wastewater treatment and reuse for a long time and has successfully solved the technical problems of printing and dyeing wastewater treatment. They developed a high-tech, flexible combination and patented equipment, which is mainly composed of drug feeding, a ceramic particle tower, and ceramic membrane tower systems. For example, printing and dyeing wastewater is treated by biological methods, such as hydrolytic acidification, contact oxidation, and biological filtering, and the effluent is further treated by ceramsite and ceramic membrane filtration systems. After advanced treatment, wastewater can be used for the pretreatment of printing and dyeing processes. According to the quality analysis of the dyeing products, color fastness and soaping fastness were above Grade 3, which ensured the quality of the products. This treatment method can be used to reuse wastewater, which is of great significance in the reuse of printing and dyeing wastewater [].

3.6. Other Water Treatment Applications

Water is essential for all aspects of the economy. Because available water resources are limited, water and wastewater treatments are two very important processes that can improve water quality and remove most pollutants from wastewater, thus solving the water crisis. Table 5 lists water treatment types other than oil–water separation, textile wastewater, seawater desalination, and drinking water.

Table 5.

Other water treatment applications.

The types of water treated with the membranes made of different ceramic materials differ. For example, MF or UF active layers made of raw clay materials are used to remove suspended particles, oil droplets, dyes, and heavy metals. Zeolite minerals can be used to treat fertilizer-polluted water. Natural volcanic rocks are commonly used to treat textile industry wastewater and have many applications in seawater desalination. Hollow-fiber membranes prepared from rice husk ash can effectively remove heavy metals and can be used for seawater desalination after injection into a hydrophobic surface. Similarly, different preparation methods involve different types of water treatments. For example, the sol–gel method is mainly used in the treatment of pesticide wastewater, oily wastewater, and seawater desalination, whereas tubular ceramic membranes prepared by the extrusion method are widely used in seawater desalination.

4. Prospects

Inorganic ceramic membranes are important components of high-performance membrane materials, and their development prospects are improving. With the development of science and technology, the properties and shapes of existing ceramics and traditional ceramic molding methods can no longer meet the requirements. With the continuous progress in ceramic preparation technology, ceramic materials have been widely used, and their performance requirements are increasing. Different preparation methods have limitations, and the structure and properties of the prepared porous alumina ceramics are different; therefore, it is necessary to choose the appropriate preparation method according to the actual needs. Future research on ceramics can focus on the following points. (1) Combine advanced technologies, such as solid-state filmless molding technology (such as 3D printing), accurately control the phase elements and microstructure of ceramic materials, and optimize the relationship between the mechanical properties and microstructure to meet specific application requirements. (2) Develop ceramic composite materials and expand the application fields of composite ceramics. (3) Break through the preparation technology of low-cost and high-performance inorganic ceramic membranes and carry out systematic research, including ceramic membrane powder preparation, ceramic membrane support preparation, ceramic separation layer preparation, and ceramic membrane sintering process research, to improve the preparation efficiency of the ceramic membrane, reduce the preparation cost, achieve lower cost and higher performance, and realize the commercialization of ceramic membrane products. (4) Low-temperature sintering of ceramic membranes has become a research hotspot, and low-temperature sintering is also an important means to achieve low cost; however, the problem of strength reduction caused by low-temperature sintering has not been solved.

The appearance of new materials, especially metal–organic frameworks and carbon nanostructures such as carbon nanotubes (CNTs), graphene, and their derivatives, provides a new era for membrane technology to achieve complete separation performance. The unique properties of these materials have been exploited to design new inorganic membranes.

There are many new ceramic composite materials with different requirements in various fields, for example molten salt–ceramic, molten salt–graphite, and molten salt–metal. The composite phase change material has good overall thermal properties and is a good thermal storage material for absorbing solar energy. High-entropy metal diborides are a new type of high-entropy material—an ultrahigh-temperature ceramic that has excellent wear resistance and strength and especially excellent high-temperature properties—and they are used as solar receivers in concentrating solar power systems [,,].

Author Contributions

Conceptualization, Y.Z. and W.Z.; methodology, Y.T.; software, R.S.; collection and organization, Y.Z., Y.T. and R.S.; formal analysis, Y.Z.; investigation, Y.T.; resources, R.S.; data curation, Y.Z.; writing—original draft preparation, Y.Z., Y.T. and R.S.; writing—review and editing, W.Z.; visualization, Y.T.; supervision, W.Z.; project administration, R.S.; funding acquisition, W.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Guangxi Natural Science Foundation, grant number 2019GXNSFFA245017.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ahmad, N.A.; Leo, C.P.; Ahmad, A.L.; Ramli, W.K.W. Membranes with great hydrophobicity: A review on preparation and characterization. Sep. Purif. Rev. 2015, 44, 109–134. [Google Scholar] [CrossRef]

- Aissat, M.; Hamouda, S.; Bettahar, N.; Abu Tarboush, B.J.; Bahmani, A. Characterization and application of ceramic membranes prepared from Algerian kaolin. Cerâmica 2019, 65, 554–561. [Google Scholar] [CrossRef]

- Larbot, A.; Gazagnes, L.; Krajewski, S.; Bukowska, M.; Kujawski, W. Water desalination using ceramic membrane distillation. Desalination 2004, 168, 367–372. [Google Scholar] [CrossRef]

- Hubadillah, S.K.; Othman, M.H.D.; Matsuura, T.; Ismail, A.F.; Rahman, M.A.; Harun, Z.; Jaafar, J.; Nomura, M. Fabrications and applications of low cost ceramic membrane from kaolin: A comprehensive review. Ceram. Int. 2018, 44, 4538–4560. [Google Scholar] [CrossRef]

- Lin, Y.S.; Kumakiri, I.; Nair, B.N.; Alsyouri, H. Microporous inorganic membranes. Sep. Purif. Methods 2002, 31, 229–379. [Google Scholar] [CrossRef]

- Das, D.; Baitalik, S.; Haldar, B.; Saha, R.; Kayal, N. Preparation and characterization of macroporous SiC ceramic membrane for treatment of waste water. J. Porous Mater. 2018, 25, 1183–1193. [Google Scholar] [CrossRef]

- Li, C.; Sun, W.J.; Lu, Z.D.; Ao, X.W.; Li, S.M. Ceramic nanocomposite membranes and membrane fouling: A review. Water Res. 2020, 175, 115674. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, N.N.; Ola, O.; Xia, Y.D.; Zhu, Y.Q. Porous ceramics: Light in weight but heavy in energy and environment technologies. Mater. Sci. Eng. Rep. 2021, 143, 100589. [Google Scholar] [CrossRef]

- Otitoju, T.A.; Okoye, P.U.; Chen, G.T.; Li, Y.; Okoye, M.O.; Li, S.X. Advanced ceramic components: Materials, fabrication, and applications. J. Ind. Eng. Chem. 2020, 85, 34–65. [Google Scholar] [CrossRef]

- He, Z.M.; Lyu, Z.Y.; Gu, Q.L.; Zhang, L.; Wang, J. Ceramic-based membranes for water and wastewater treatment. Colloids Surf. A 2019, 578, 123513. [Google Scholar] [CrossRef]

- Hsieh, H.P.; Liu, P.K.T.; Dillman, T.R. Microporous ceramic membranes. Polym. J. 1991, 23, 407–415. [Google Scholar] [CrossRef][Green Version]

- Dong, Y.C.; Wu, H.; Yang, F.L.; Gray, S. Cost and efficiency perspectives of ceramic membranes for water treatment. Water Res. 2022, 220, 118629. [Google Scholar] [CrossRef] [PubMed]

- Fernie, J.A.; Drew, R.A.L.; Knowles, K.M. Joining of engineering ceramics. Int. Mater. Rev. 2009, 54, 283–331. [Google Scholar] [CrossRef]

- Qin, H.; Guo, W.M.; Gao, P.Z.; Xiao, H.N. Spheroidization of low-cost alumina powders for the preparation of high-flux flat-sheet ceramic membranes. Ceram. Int. 2020, 46, 13189–13197. [Google Scholar] [CrossRef]

- Kim, Y.-W.; Eom, J.-H.; Wang, C.M.; Park, C.B. Processing of porous silicon carbide ceramics from carbon-filled polysiloxane by extrusion and carbothermal reduction. J. Am. Ceram. Soc. 2008, 91, 1361–1364. [Google Scholar] [CrossRef]

- Sun, L.Q.; Wang, Z.Y.; Gao, B.Y. Ceramic membranes originated from cost-effective and abundant natural minerals and industrial wastes for broad applications—A review. Desalin. Water Treat. 2020, 201, 121–138. [Google Scholar] [CrossRef]

- Abdullayev, A.; Bekheet, M.F.; Hanaor, D.A.H.; Gurlo, A. Materials and applications for low-cost ceramic membranes. Membranes 2019, 9, 105. [Google Scholar] [CrossRef]

- Hedfi, I.; Hamdi, N.; Rodriguez, M.A.; Srasra, E. Development of a low cost micro-porous ceramic membrane from kaolin and Alumina, using the lignite as porogen agent. Ceram. Int. 2016, 42, 5089–5093. [Google Scholar] [CrossRef]

- Wang, H.Y.; Fu, Y.B.; Xing, P.F. Study on preparation technique of unsymmetrical microporous composite ceramics membranes. Acta Chim. Sin. 2000, 58, 1015–1021. [Google Scholar]

- Fang, J.; Qin, G.T.; Wei, W.; Zhao, X.Q. Preparation and characterization of tubular supported ceramic microfiltration membranes from fly ash. Sep. Purif. Technol. 2011, 80, 585–591. [Google Scholar] [CrossRef]

- Tao, S.; Xu, Y.-D.; Gu, J.-Q.; Abadikhah, H.; Wang, J.-W.; Xu, X. Preparation of high-efficiency ceramic planar membrane and its application for water desalination. J. Adv. Ceram. 2018, 7, 117–123. [Google Scholar] [CrossRef]

- Ward, D.A.; Ho, E.I. Preparing catalytic materials by the sol-gel method. Ind. Eng. Chem. Res. 1995, 34, 421–433. [Google Scholar] [CrossRef]

- Yu, L.; Kanezashi, M.; Nagasawa, H.; Tsuru, T. Phase inversion/sintering-induced porous ceramic microsheet membranes for high-quality separation of oily wastewater. J. Membr. Sci. 2020, 595, 117477. [Google Scholar] [CrossRef]

- Ciora, R.J.; Fayyaz, B.; Liu, P.K.T.; Suwanmethanond, V.; Mallada, R.; Sahimi, M.; Tsotsis, T.T. Preparation and reactive applications of nanoporous silicon carbide membranes. Chem. Eng. Sci. 2004, 59, 4957–4965. [Google Scholar] [CrossRef]

- Ewis, D.; Ismail, N.A.; Hafiz, M.; Benamor, A.; Hawari, A.H. Nanoparticles functionalized ceramic membranes: Fabrication, surface modification, and performance. Environ. Sci. Pollut. Res. 2021, 28, 12256–12281. [Google Scholar] [CrossRef] [PubMed]

- Vitorino, N.; Freitas, C.; Ribeiro, M.J.; Abrantes, J.C.C.; Frade, J.R. Extrusion of ceramic emulsions: Plastic behavior. Appl. Clay Sci. 2014, 101, 315–319. [Google Scholar] [CrossRef]

- Liang, D.H.; Huang, J.G.; Zhang, H.; Fu, H.M.; Zhang, Y.T.; Chen, H.P. Influencing factors on the performance of tubular ceramic membrane supports prepared by extrusion. Ceram. Int. 2021, 47, 10464–10477. [Google Scholar] [CrossRef]

- Grote, J.J. Reconstruction of the middle-ear with hydroxylapatite implants-long-term results. Ann. Otol. Rhinol. Laryngol. 1990, 99, 12–16. [Google Scholar]

- Rodriguez, M.; Hernandez, R.T. Ceramic tubular supports. Rev. Mex. Fis. 1999, 45, 61–63. [Google Scholar]

- Aljlil, S.A. Fabrication of bentonite-silica sand/suspended waste palm leaf composite membrane for water purification. Membranes 2020, 10, 290. [Google Scholar] [CrossRef]

- Ouallal, H.; Azrour, M.; Messaoudi, M.; Moussout, H.; Messaoudi, L.; Tijani, N. Incorporation effect of olive pomace on the properties of tubular membranes. J. Environ. Chem. Eng. 2020, 8, 103668. [Google Scholar] [CrossRef]

- Hubadillah, S.K.; Othman, M.H.D.; Rahman, M.A.; Ismail, A.F.; Jaafar, J. Preparation and characterization of inexpensive kaolin hollow fibre membrane (KHFM) prepared using phase inversion/sintering technique for the efficient separation of real oily wastewater. Arab. J. Chem. 2020, 13, 2349–2367. [Google Scholar] [CrossRef]

- Aloulou, W.; Aloulou, H.; Khemakhem, M.; Duplay, J.; Daramola, M.O.; Ben Amar, R. Synthesis and characterization of clay-based ultrafiltration membranes supported on natural zeolite for removal of heavy metals from wastewater. Environ. Technol. Innov. 2020, 18, 100794. [Google Scholar] [CrossRef]

- Jafari, B.; Abbasi, M.; Hashemifard, S.A.; Sillanpaa, M. Elaboration and characterization of novel two-layer tubular ceramic membranes by coating natural zeolite and activated carbon on mullite-alumina-zeolite support: Application for oily wastewater treatment. J. Asian Ceram. Soc. 2020, 8, 848–861. [Google Scholar] [CrossRef]

- Raji, Y.O.; Othman, M.H.D.; Nordin, N.A.H.S.M.; Zhong, S.T.; Usman, J.; Mamah, S.C.; Ismail, A.F.; Rahman, M.A.; Jaafar, J. Fabrication of magnesium bentonite hollow fibre ceramic membrane for oil-water separation. Arab. J. Chem. 2020, 13, 5996–6008. [Google Scholar] [CrossRef]

- Tai, Z.S.; Othman, M.H.D.; Mustafa, A.; Dzahir, M.I.H.M.; Hubadillah, S.K.; Koo, K.N.; Azali, M.A.; Alias, N.H.; Ooi, B.S.; Kurniawan, T.A. Design and characterization of ceramic hollow fiber membrane derived from waste ash using phase inversion-based extrusion/sintering technique for water filtration. J. Asian Ceram. Soc. 2021, 9, 318–335. [Google Scholar] [CrossRef]

- Kamoun, N.; Jamoussi, F.; Rodríguez, M.A. Development of a ceramic membrane for emulsion water-diesel treatment. Cerâmica 2022, 68, 250–256. [Google Scholar] [CrossRef]

- Anis, S.F.; Lalia, B.S.; Lesimple, A.; Hashaikeh, R.; Hilal, N. Superhydrophilic and underwater superoleophobic nano zeolite membranes for efficient oil-in-water nanoemulsion separation. J. Water Process Eng. 2021, 40, 101802. [Google Scholar] [CrossRef]

- Belgada, A.; Charik, F.Z.; Achiou, B.; Kambuyi, T.N.; Younssi, S.A.; Beniazza, R.; Dani, A.; Benhida, R.; Ouammou, M. Optimization of phosphate/kaolinite microfiltration membrane using Box-Behnken design for treatment of industrial wastewater. J. Environ. Chem. Eng. 2021, 9, 104972. [Google Scholar] [CrossRef]

- Mouratib, R.; Achiou, B.; El Krati, M.; Younssi, S.A.; Tahiri, S. Low-cost ceramic membrane made from alumina- and silica-rich water treatment sludge and its application to wastewater filtration. J. Eur. Ceram. Soc. 2020, 40, 5942–5950. [Google Scholar] [CrossRef]

- Kim, W.-B.; Sukcheol, K.; Cho, S.-H.; Lee, J.-H. Effect of pressing process on the high-temperature stability of yttria-stabilized zirconia ceramic material in molten salt of CaCl2-CaF2-CaO. Korean J. Mater. Res. 2020, 30, 176–183. [Google Scholar] [CrossRef]

- Teng, H.-D.; Wei, Q.; Wang, Y.-L.; Cui, S.-P.; Li, Q.-Y.; Nie, Z.-R. Asymmetric porous cordierite ceramic membranes prepared by phase inversion tape casting and their desalination performance. Ceram. Int. 2020, 46, 23677–23685. [Google Scholar] [CrossRef]

- Manni, A.; Achiou, B.; Karim, A.; Harrati, A.; Sadik, C.; Ouammou, M.; Younssi, S.A.; El Bouari, A. New low-cost ceramic microfiltration membrane made from natural magnesite for industrial wastewater treatment. J. Environ. Chem. Eng. 2020, 8, 103906. [Google Scholar] [CrossRef]

- Queiroga, J.A.; Nunes, E.H.M.; Souza, D.F.; Vasconcelos, D.C.L.; Ciminelli, V.S.T.; Vasconcelos, W.L. Microstructural investigation and performance evaluation of slip-cast alumina supports. Ceram. Int. 2017, 43, 3824–3830. [Google Scholar] [CrossRef]

- Zyryanov, V.V.; Karakchiev, L.G. Porous supports for conducting ceramic membranes. Inorg. Mater. 2008, 44, 429–437. [Google Scholar] [CrossRef]

- Elyassi, B.; Sahimi, M.; Tsotsis, T.T. A novel sacrificial interlayer-based method for the preparation of silicon carbide membranes. J. Membr. Sci. 2008, 316, 73–79. [Google Scholar] [CrossRef]

- Boulesteix, R.; Chevarin, C.; Belon, R.; Maitre, A.; Cochain, L.; Salle, C. Manufacturing of large size and highly transparent Nd:YAG ceramics by pressure slip-casting and post-sintering by HIP: An experimental and simulation study. Materials 2020, 13, 2199. [Google Scholar] [CrossRef]

- Azaman, F.; Nor, M.A.M.; Abdullah, W.R.W.; Razali, M.H.; Adnen, N.A.I.; Zulkifli, R.C.; Ali, A. Fabrication of natural ball clay ceramic membrane using pore former and additive agents based on modified slip casting technique. Desalin. Water Treat. 2021, 223, 290–298. [Google Scholar] [CrossRef]

- Nishihora, R.K.; Rachadel, P.L.; Novy Quadri, M.G.; Hotza, D. Manufacturing porous ceramic materials by tape casting-A review. J. Eur. Ceram. Soc. 2018, 38, 988–1001. [Google Scholar] [CrossRef]

- Ohji, T.; Fukushima, M. Macro-porous ceramics: Processing and properties. Int. Mater. Rev. 2012, 57, 115–131. [Google Scholar] [CrossRef]

- Kaur, H.; Bulasara, V.K.; Gupta, R.K. Preparation of kaolin-based low-cost porous ceramic supports using different amounts of carbonates. Desalin. Water Treat. 2016, 57, 15154–15163. [Google Scholar] [CrossRef]

- Das, B.; Chakrabarty, B.; Barkakati, P. Preparation and characterization of novel ceramic membranes for micro-filtration applications. Ceram. Int. 2016, 42, 14326–14333. [Google Scholar] [CrossRef]

- Tabit, K.; Waqif, M.; Saadi, L. Crystallization behavior and properties of cordierite synthesized by sol-gel technique and hydrothermal treatment. J. Aust. Ceram. Soc. 2019, 55, 469–477. [Google Scholar] [CrossRef]

- Delange, R.S.A.; Hekkink, J.H.A.; Keizer, K.; Burggraaf, A.J. Formation and characterization of supported microporous ceramic membranes prepared by sol-gel modification techniques. J. Membr. Sci. 1995, 99, 57–75. [Google Scholar] [CrossRef]

- Nasani, N.; Gavinola, S.R.; Graca, V.; Allu, A.R.; Reddy, R.C.; Kale, B.B. The effect of nickel doping on the microstructure and conductivity of Ca(Ti,Al)O3-delta for solid oxide fuel cells. J. Am. Ceram. Soc. 2021, 104, 5689–5697. [Google Scholar] [CrossRef]

- Zhu, B.; Rundgren, K.; Mellander, B.E. Ceramic membranes—Potential uses for solid state protonic conductors. Solid State Ion. 1997, 97, 385–391. [Google Scholar] [CrossRef]

- Coelho, F.E.B.; Magnacca, G.; Boffa, V.; Candelario, V.M.; Luiten-Olieman, M.; Zhang, W.J. From ultra to nanofiltration: A review on the fabrication of ZrO2 membranes. Ceram. Int. 2023, 49, 8683–8708. [Google Scholar] [CrossRef]

- Luyten, J.; Buekenhoudt, A.; Adriansens, W.; Cooymans, J.; Weyten, H.; Servaes, F.; Leysen, R. Preparation of LaSrCoFeO3−x membranes. Solid State Ion. 2000, 135, 637–642. [Google Scholar] [CrossRef]

- Rahman, M.A.; Ghazali, M.A.; Abd Aziz, W.M.S.W.; Othman, M.H.D.; Jaafar, J.; Ismail, A.F. Preparation of titanium dioxide hollow fiber membrane using phase inversion and sintering technique for gas separation and water purification. Sains Malays. 2015, 44, 1195–1201. [Google Scholar] [CrossRef]

- Wu, Z.T.; Othman, N.H.; Zhang, G.R.; Liu, Z.K.; Jin, W.Q.; Li, K. Effects of fabrication processes on oxygen permeation of Nb2O5-doped SrCo0.8Fe0.2O3-delta micro-tubular membranes. J. Membr. Sci. 2013, 442, 1–7. [Google Scholar] [CrossRef]

- Kingsbury, B.F.K.; Li, K. A morphological study of ceramic hollow fibre membranes. J. Membr. Sci. 2009, 328, 134–140. [Google Scholar] [CrossRef]

- Li Puma, G.L.; Bono, A.; Krishnaiah, D.; Collin, J.G. Preparation of titanium dioxide photocatalyst loaded onto activated carbon support using chemical vapor deposition: A review paper. J. Hazard. Mater. 2008, 157, 209–219. [Google Scholar] [CrossRef] [PubMed]

- Pandey, P.; Chauhan, R.S. Membranes for gas separation. Prog. Polym. Sci. 2001, 26, 853–893. [Google Scholar] [CrossRef]

- Yuan, K.; Feng, S.S.; Zhang, F.; Zhong, Z.X.; Xing, W.H. Steric configuration-controllable carbon nanotubes-integrated SiC membrane for ultrafine particles filtration. Ind. Eng. Chem. Res. 2020, 59, 19680–19688. [Google Scholar] [CrossRef]

- Chen, M.L.; Shang, R.; Sberna, P.M.; Luiten-Olieman, M.W.J.; Rietveld, L.C.; Heijman, S.G.J. Highly permeable silicon carbide-alumina ultrafiltration membranes for oil-in-water filtration produced with low-pressure chemical vapor deposition. Sep. Purif. Technol. 2020, 253, 117496. [Google Scholar] [CrossRef]

- Ragunath, S.; Roy, S.; Mitra, S. Carbon nanotube immobilized membrane with controlled nanotube incorporation via phase inversion polymerization for membrane distillation based desalination. Sep. Purif. Technol. 2018, 194, 249–255. [Google Scholar] [CrossRef]

- Pendergast, M.M.; Hoek, E.M.V. A review of water treatment membrane nanotechnologies. Energy Environ. Sci. 2011, 4, 1946–1971. [Google Scholar] [CrossRef]

- Zhu, Y.Z.; Wang, D.; Jiang, L.; Jin, J. Recent progress in developing advanced membranes for emulsified oil/water separation. NPG Asia Mater. 2014, 6, e101. [Google Scholar] [CrossRef]

- Chen, W.J.; Peng, J.M.; Su, Y.L.; Zheng, L.L.; Wang, L.J.; Jiang, Z.Y. Separation of oil/water emulsion using Pluronic F127 modified polyethersulfone ultrafiltration membranes. Sep. Purif. Technol. 2009, 66, 591–597. [Google Scholar] [CrossRef]

- Peng, Y.B.; Guo, Z.G. Recent advances in biomimetic thin membranes applied in emulsified oil/water separation. J. Mater. Chem. A 2016, 4, 15749–15770. [Google Scholar] [CrossRef]

- Tanudjaja, H.J.; Hejase, C.A.; Tarabara, V.V.; Fane, A.G.; Chew, J.W. Membrane-based separation for oily wastewater: A practical perspective. Water Res. 2019, 156, 347–365. [Google Scholar] [CrossRef]

- Ding, D.; Mao, H.Y.; Chen, X.F.; Qiu, M.H.; Fan, Y.Q. Underwater superoleophobic-underoil superhydrophobic Janus ceramic membrane with its switchable separation in oil/water emulsions. J. Membr. Sci. 2018, 565, 303–310. [Google Scholar] [CrossRef]

- Karimnezhad, H.; Rajabi, L.; Salehi, E.; Derakhshan, A.A.; Azimi, S. Novel nanocomposite Kevlar fabric membranes: Fabrication characterization, and performance in oil/water separation. Appl. Surf. Sci. 2014, 293, 275–286. [Google Scholar] [CrossRef]

- Zhu, L.; Chen, M.L.; Dong, Y.C.; Tang, C.Y.Y.; Huang, A.S.; Li, L.L. A low-cost mullite-titania composite ceramic hollow fiber microfiltration membrane for highly efficient separation of oil-in-water emulsion. Water Res. 2016, 90, 277–285. [Google Scholar] [CrossRef] [PubMed]

- Lu, D.W.; Zhang, T.; Ma, J. Ceramic membrane fouling during ultrafiltration of oil/water emulsions: Roles played by stabilization surfactants of oil droplets. Environ. Sci. Technol. 2015, 49, 4235–4244. [Google Scholar] [CrossRef]

- Zhou, J.-e.; Chang, Q.B.; Wang, Y.Q.; Wang, J.M.; Meng, G.Y. Separation of stable oil-water emulsion by the hydrophilic nano-sized ZrO2 modified Al2O3 microfiltration membrane. Sep. Purif. Technol. 2010, 75, 243–248. [Google Scholar] [CrossRef]

- Gao, N.W.; Fan, Y.Q.; Quan, X.J.; Cai, Y.W.; Zhou, D.W. Modified ceramic membranes for low fouling separation of water-in-oil emulsions. J. Mater. Sci. 2016, 51, 6379–6388. [Google Scholar] [CrossRef]

- Chang, Q.B.; Zhou, J.-e.; Wang, Y.Q.; Liang, J.; Zhang, X.Z.; Cerneaux, S.; Wang, X.; Zhu, Z.W.; Dong, Y.C. Application of ceramic microfiltration membrane modified by nano-TiO2 coating in separation of a stable oil-in-water emulsion. J. Membr. Sci. 2014, 456, 128–133. [Google Scholar] [CrossRef]

- Gao, S.J.; Shi, Z.; Zhang, W.B.; Zhang, F.; Jin, J. Photoinduced superwetting single-walled carbon nanotube/TiO2 ultrathin network films for ultrafast separation of oil-in-water emulsions. Acs Nano 2014, 8, 6344–6352. [Google Scholar] [CrossRef]

- Jin, X.P.; Peng, S.G.; Chen, Y.M.; Ma, J.Y.; Niu, Q.S. A polymer-ceramic composite membrane for the oil/water separation with enhanced antifouling performance. Ferroelectrics 2020, 565, 137–147. [Google Scholar] [CrossRef]

- Wei, Y.B.; Xie, Z.X.; Qi, H. Superhydrophobic-superoleophilic SiC membranes with micro-nano hierarchical structures for high-efficient water-in-oil emulsion separation. J. Membr. Sci. 2020, 601, 117842. [Google Scholar] [CrossRef]

- Wang, J.R.; Wang, X.F.; Zhao, S.; Sun, B.; Wang, Z.; Wang, J.X. Robust superhydrophobic mesh coated by PANI/TiO2 nanoclusters for oil/water separation with high flux, self-cleaning, photodegradation and anti-corrosion. Sep. Purif. Technol. 2020, 235, 116166. [Google Scholar] [CrossRef]

- Wei, Y.; Qi, H.; Gong, X.; Zhao, S. Specially Wettable Membranes for Oil–Water Separation. Adv. Mater. Interfaces 2018, 5, 1800576. [Google Scholar] [CrossRef]

- Yan, X.H.; Xiao, X.; Au, C.; Mathur, S.; Huang, L.J.; Wang, Y.X.; Zhang, Z.J.; Zhu, Z.J.; Kipper, M.J.; Tang, J.G.; et al. Electrospinning nanofibers and nanomembranes for oil/water separation. J. Mater. Chem. A 2021, 9, 21659–21684. [Google Scholar] [CrossRef]

- Lu, J.W.; Li, F.C.; Miao, G.; Miao, X.; Ren, G.N.; Wang, B.; Song, Y.M.; Li, X.M.; Zhu, X.T. Superhydrophilic/superoleophobic shell powder coating as a versatile platform for both oil/water and oil/oil separation. J. Membr. Sci. 2021, 637, 119624. [Google Scholar] [CrossRef]

- Ullah, A.; Tanudjaja, J.H.; Ouda, M.; Hasan, W.S.; Chew, J.W. Membrane fouling mitigation techniques for oily wastewater: A short review. J. Water Process Eng. 2021, 43, 102293. [Google Scholar] [CrossRef]

- Gomaa, H.G.; Rao, S. Analysis of flux enhancement at oscillating flat surface membranes. J. Membr. Sci. 2011, 374, 59–66. [Google Scholar] [CrossRef]

- Ullah, A. The influence of interfacial tension on rejection and permeation of the oil droplets through a slit pore membrane. Sep. Purif. Technol. 2021, 266, 118581. [Google Scholar] [CrossRef]

- Bin Bandar, K.; Alsubei, M.D.; Aljlil, S.A.; Bin Darwish, N.; Hilal, N. Membrane distillation process application using a novel ceramic membrane for Brackish water desalination. Desalination 2021, 500, 114906. [Google Scholar] [CrossRef]

- Schnittger, J.; McCutcheon, J.; Hoyer, T.; Weyd, M.; Fischer, G.; Puhlfurss, P.; Halisch, M.; Voigt, I.; Lerch, A. Hydrophobic ceramic membranes in MD processes—Impact of material selection and layer characteristics. J. Membr. Sci. 2021, 618, 118678. [Google Scholar] [CrossRef]

- Kujawa, J.; Kujawski, W.; Cerneaux, S.; Li, G.Q.; Al-Gharabli, S. Zirconium dioxide membranes decorated by silanes based-modifiers for membrane distillation—Material chemistry approach. J. Membr. Sci. 2020, 596, 117597. [Google Scholar] [CrossRef]

- Hubadillah, S.K.; Othman, M.H.D.; Jamalludin, M.R.; Naim, R.; Kadir, S.H.S.A.; Puteh, M.H.; Pauzan, M.A.B.; Sobri, F.A.M. Fabrication and characterisation of superhydrophobic bio-ceramic hollow fibre membranes prepared from cow bone waste. Ceram. Int. 2021, 47, 4178–4186. [Google Scholar] [CrossRef]

- Fan, Y.F.; Chen, S.; Zhao, H.M.; Liu, Y.M. Distillation membrane constructed by TiO2 nanofiber followed by fluorination for excellent water desalination performance. Desalination 2017, 405, 51–58. [Google Scholar] [CrossRef]

- Pagliero, M.; Bottino, A.; Comite, A.; Costa, C. Silanization of tubular ceramic membranes for application in membrane distillation. J. Membr. Sci. 2020, 601, 117911. [Google Scholar] [CrossRef]

- Hubadillah, S.K.; Tai, Z.S.; Othman, M.H.D.; Harun, Z.; Jamalludin, M.R.; Rahman, M.A.; Jaafar, J.; Ismail, A.F. Hydrophobic ceramic membrane for membrane distillation: A mini review on preparation, characterization, and applications. Sep. Purif. Technol. 2019, 217, 71–84. [Google Scholar] [CrossRef]

- Gazagnes, L.; Cerneaux, S.; Persin, M.; Prouzet, E.; Larbot, A. Desalination of sodium chloride solutions and seawater with hydrophobic ceramic membranes. Desalination 2007, 217, 260–266. [Google Scholar] [CrossRef]

- Chen, X.F.; Gao, X.Y.; Fu, K.Y.; Qiu, M.H.; Xiong, F.; Ding, D.; Cui, Z.L.; Wang, Z.H.; Fan, Y.Q.; Drioli, E. Tubular hydrophobic ceramic membrane with asymmetric structure for water desalination via vacuum membrane distillation process. Desalination 2018, 443, 212–220. [Google Scholar] [CrossRef]

- Abd Aziz, M.H.; Othman, M.H.D.; Alias, N.H.; Nakayama, T.; Shingaya, Y.; Hashim, N.A.; Kurniawan, T.A.; Matsuura, T.; Rahman, M.A.; Jaafar, J. Enhanced omniphobicity of mullite hollow fiber membrane with organosilane-functionalized TiO2 micro-flowers and nanorods layer deposition for desalination using direct contact membrane distillation. J. Membr. Sci. 2020, 607, 118137. [Google Scholar] [CrossRef]

- Ma, J.H.; Qin, J.R.; Huang, J.Y.; Fang, C. The application of ceramic membranes in the pretreatment of seawater desalinization. Tianjin Chem. Ind. 2007, 21, 26–28. (In Chinese) [Google Scholar]

- Samaei, S.M.; Gato-Trinidad, S.; Altaee, A. The application of pressure-driven ceramic membrane technology for the treatment of industrial wastewaters—A review. Sep. Purif. Technol. 2018, 200, 198–220. [Google Scholar] [CrossRef]

- Dilaver, M.; Hocaoglu, S.M.; Soydemir, G.; Dursun, M.; Keskinler, B.; Koyuncu, I.; Agtas, M. Hot wastewater recovery by using ceramic membrane ultrafiltration and its reusability in textile industry. J. Clean. Prod. 2018, 171, 220–233. [Google Scholar] [CrossRef]

- Avdicevic, M.Z.; Kosutic, K.; Dobrovic, S. Effect of operating conditions on the performances of multichannel ceramic UF membranes for textile mercerization wastewater treatment. Environ. Technol. 2017, 38, 65–77. [Google Scholar] [CrossRef] [PubMed]

- Agtas, M.; Yilmaz, O.; Dilaver, M.; Alp, K.; Koyuncu, I. Hot water recovery and reuse in textile sector with pilot scale ceramic ultrafiltration/nanofiltration membrane system. J. Clean. Prod. 2020, 256, 120359. [Google Scholar] [CrossRef]

- Hubadillah, S.K.; Othman, M.H.D.; Tai, Z.S.; Jamalludin, M.R.; Yusuf, N.K.; Ahmad, A.; Rahman, M.A.; Jaafar, J.; Kadir, S.H.S.A.; Harun, Z. Novel hydroxyapatite-based bio-ceramic hollow fiber membrane derived from waste cow bone for textile wastewater treatment. Chem. Eng. J. 2020, 379, 122396. [Google Scholar] [CrossRef]

- Bhattacharya, P.; Dutta, S.; Ghosh, S.; Vedajnananda, S.; Bandyopadhyay, S. Crossflow microfiltration using ceramic membrane for treatment of sulphur black effluent from garment processing industry. Desalination 2010, 261, 67–72. [Google Scholar] [CrossRef]

- Santra, B.; Ramrakhiani, L.; Kar, S.; Ghosh, S.; Majumdar, S. Ceramic membrane-based ultrafiltration combined with adsorption by waste derived biochar for textile effluent treatment and management of spent biochar. J. Environ. Health Sci. 2020, 18, 973–992. [Google Scholar] [CrossRef]