Research on the Standardized Management System and Operational Indicators of Water Control Dikes Based on GA-BP Artificial Neural Network Model

Abstract

:1. Introduction

2. Materials and Methods

2.1. Standardized Management Indicator System

2.1.1. Management Foundation (B1)

2.1.2. Safety Management (B2)

2.1.3. Operation Management (B3)

2.1.4. Maintenance Management (B4)

2.1.5. Management Assurance (B5)

2.2. AHP-Based Weight Calculation

2.2.1. Construction of Judgment Matrices

2.2.2. Related Weight Calculation of Each Index

- Consistency of the judgment matrix

- 2.

- Calculation of weights

2.3. Evaluation Methods Based on Neural Networks

2.3.1. Criteria for Management Classification

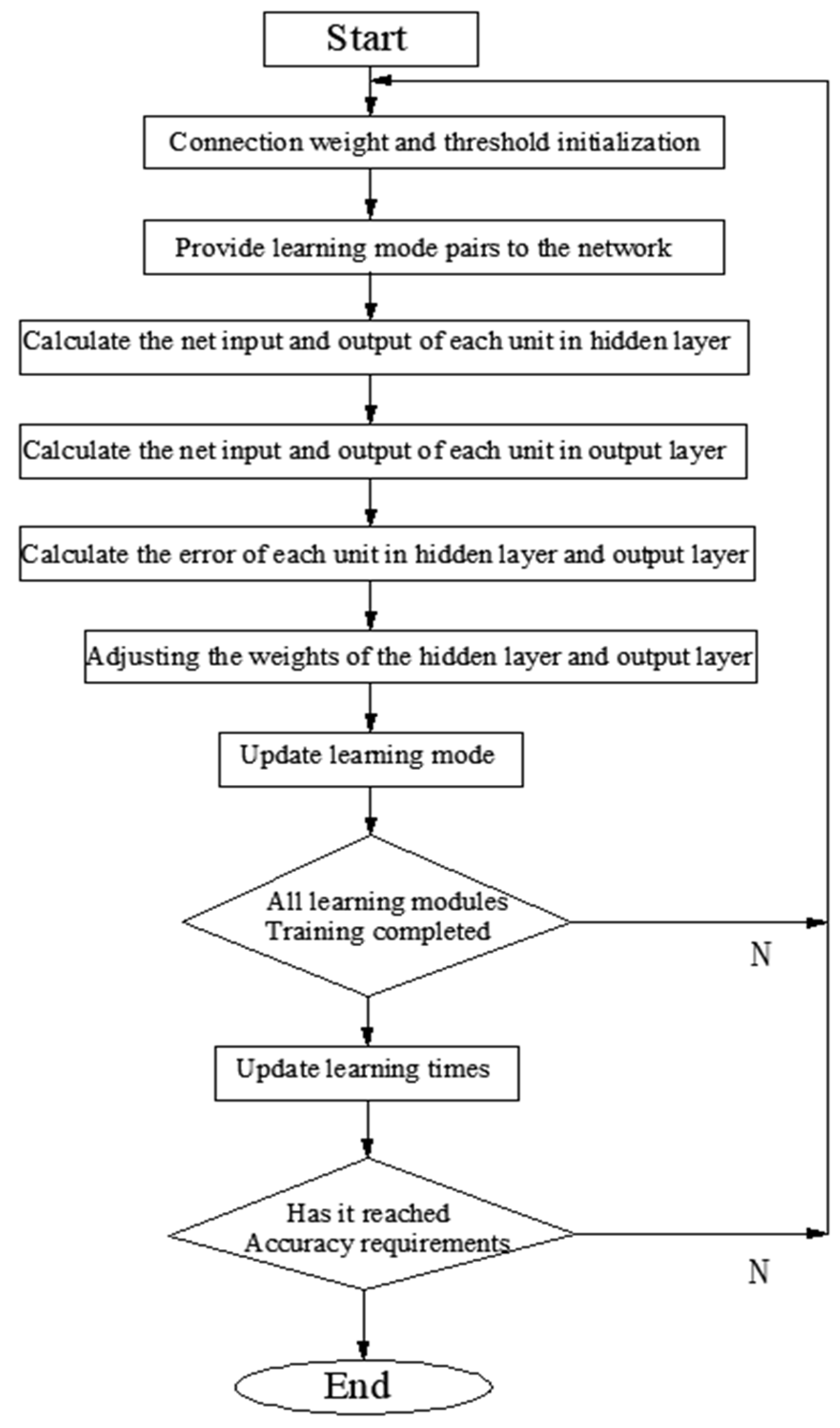

2.3.2. Construction of the Evaluation Model

3. Results

3.1. Training Sample Selection

3.1.1. Preparation of Training Samples from Dike Data

3.1.2. Data Preprocessing

3.2. Determination of Network Topology Structure

3.3. Determination of Network Layers

3.4. Determination of Input Layer Nodes

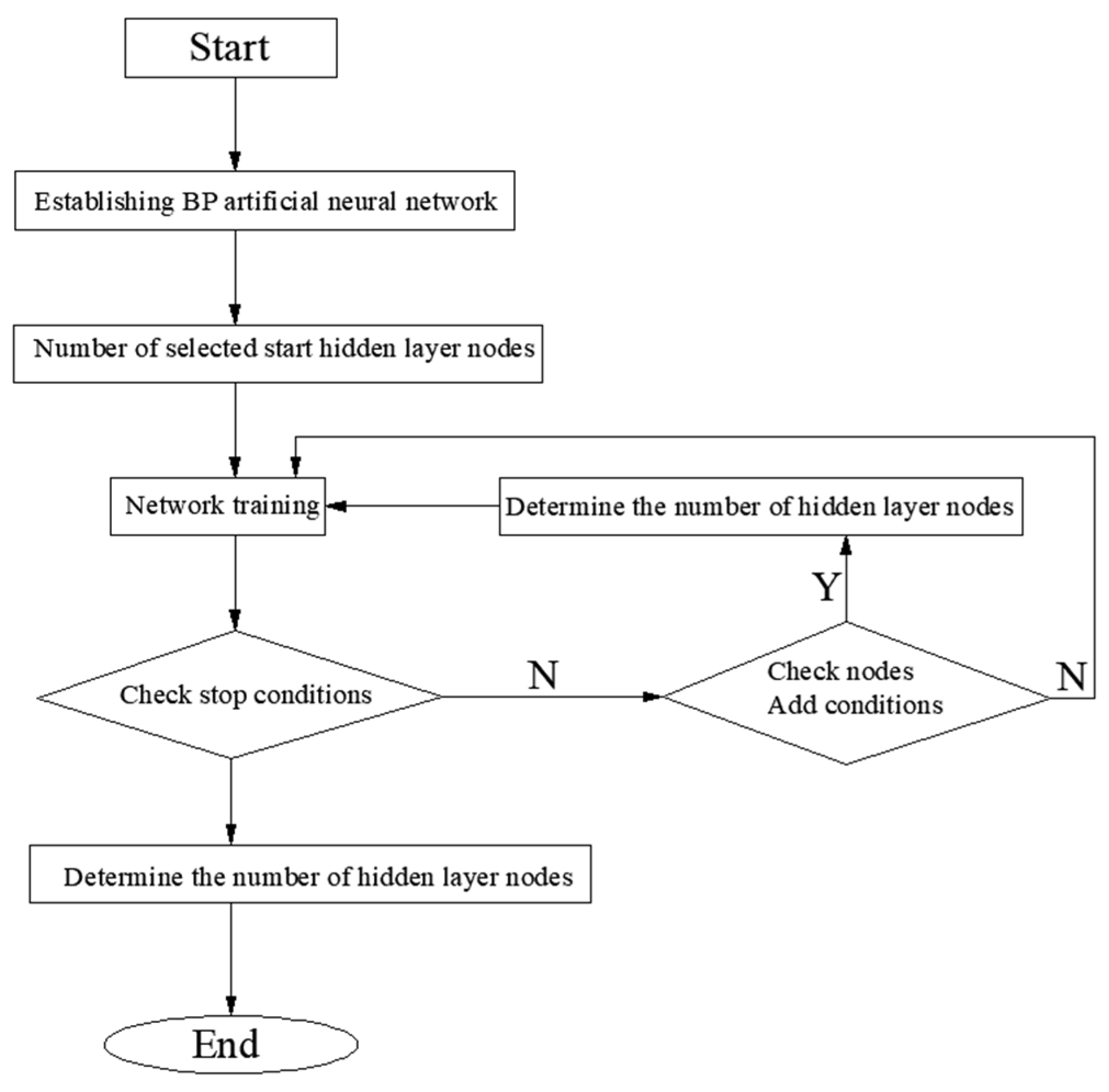

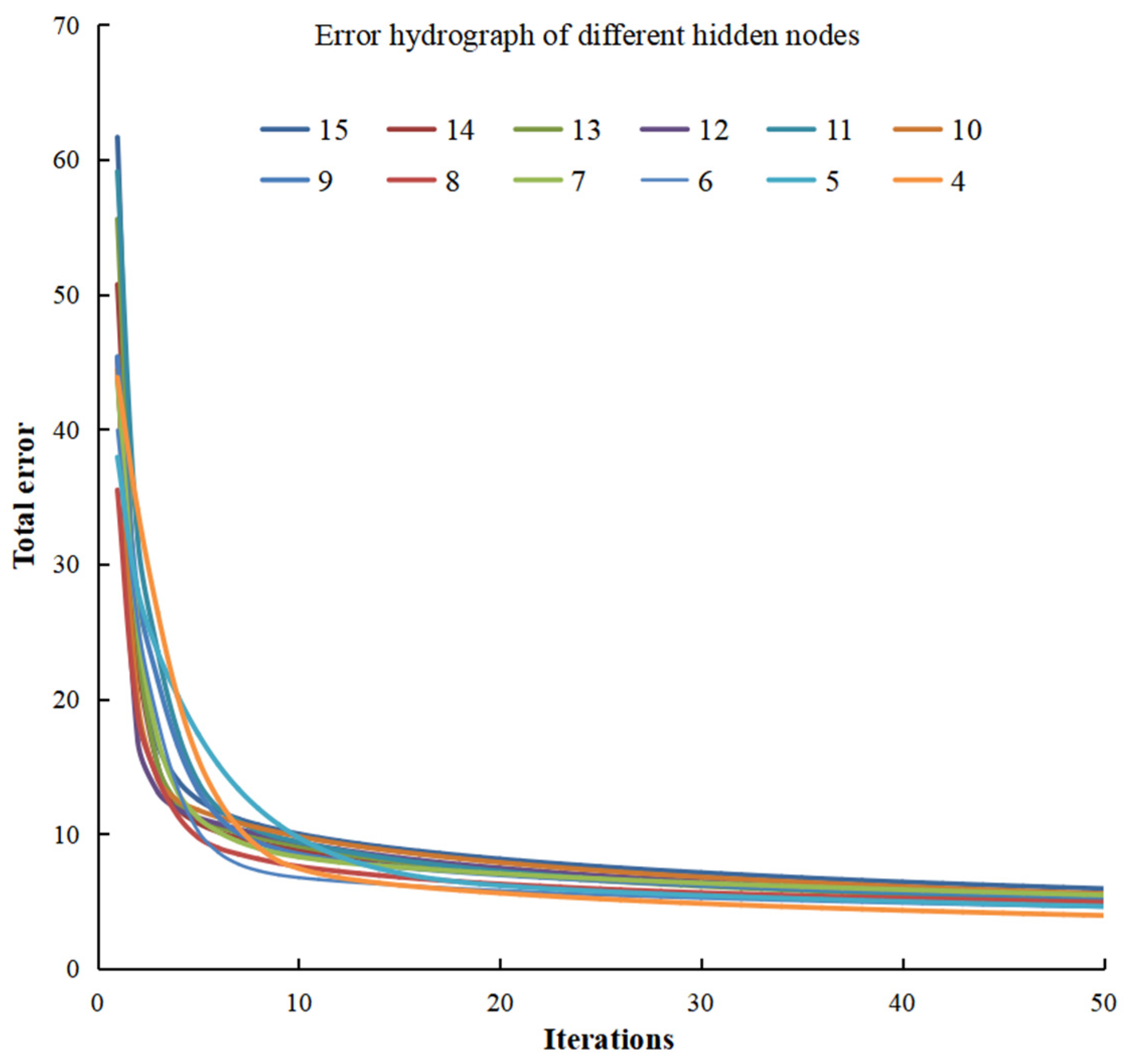

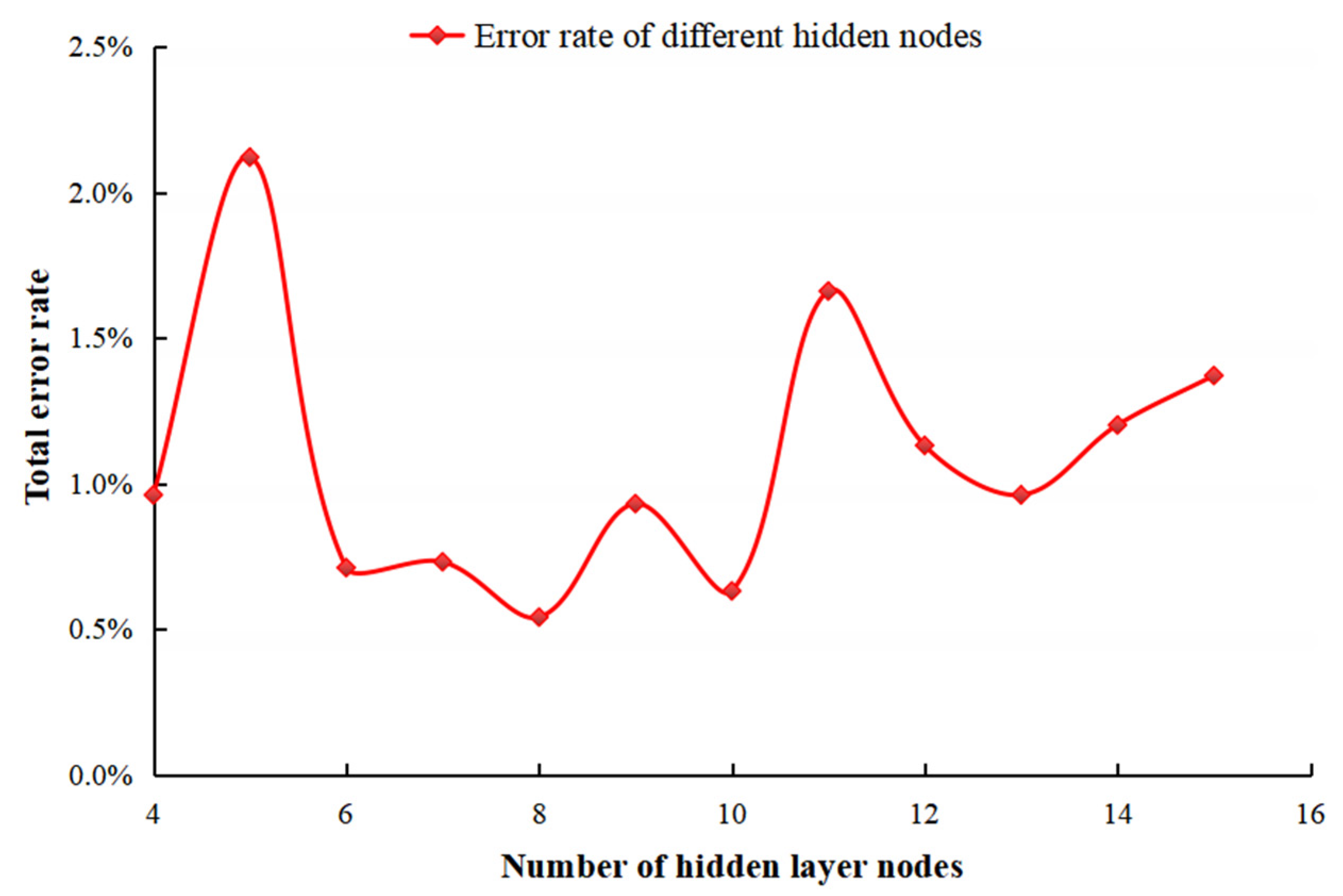

3.5. Determination of Hidden Layer Nodes

3.6. Analysis of the BP Artificial Neural Network Model

4. Discussion

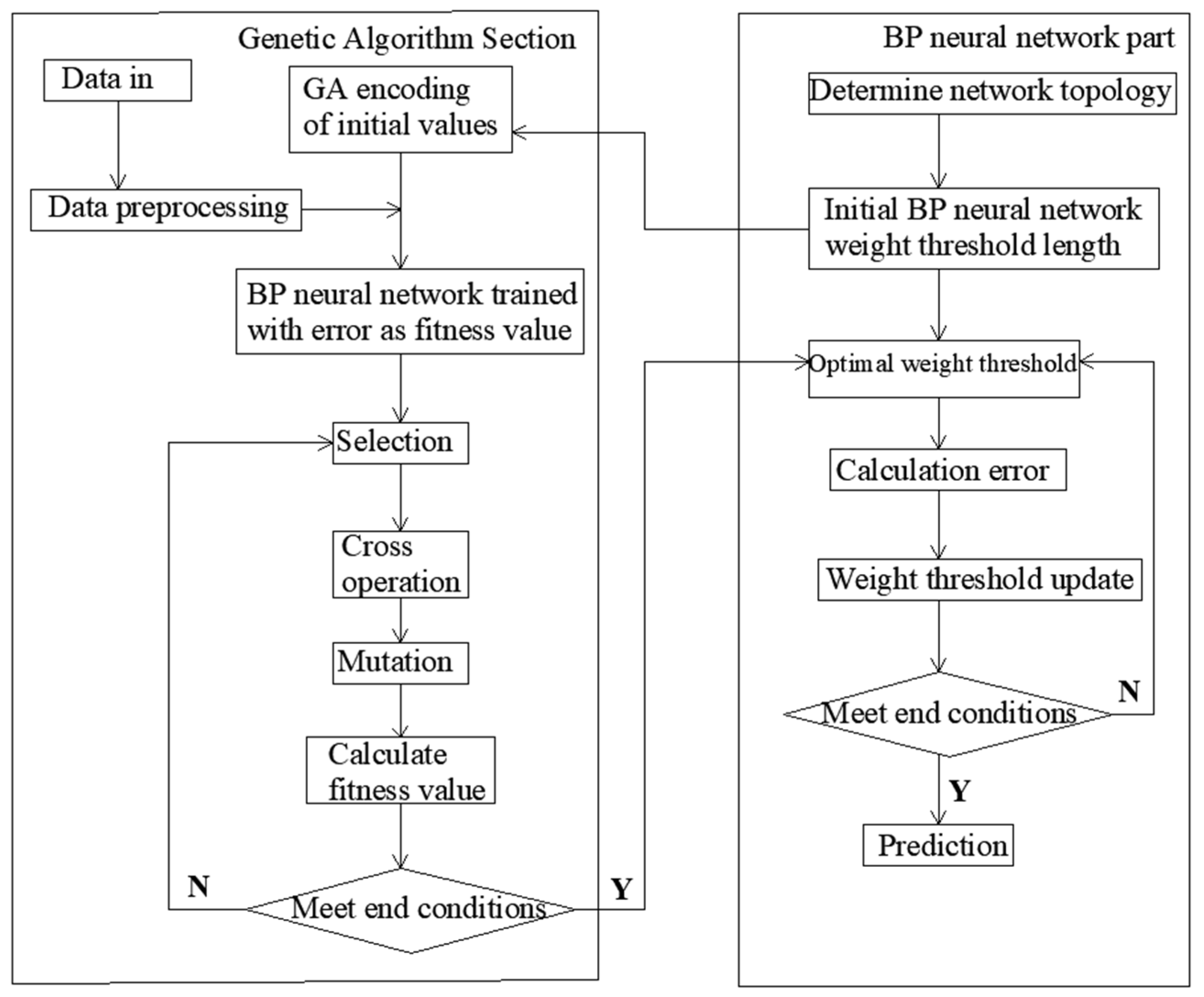

4.1. Optimization of Initial Weights

- Chromosome Encoding and Population Encode the data to determine the chromosome. In this study, real number encoding is used, directly using the connection weights as the chromosome for encoding. For the 3-layer BP artificial neural network established, the chromosome can be represented by a set of weights, denoted as W in Equation (7).In the equation, represents the weights from the input layer to the hidden layer; represents the weights from the hidden layer to the output layer; represents the output threshold of the hidden layer, and represents the output threshold of the output layer.The initial population is generated randomly using the small interval generation method. This involves dividing the range of values for the parameters to be optimized into smaller intervals equal to the total population size. Then, within each interval, a random individual is generated, forming the initial population.

- Fitness Function. The fitness function calculates the absolute difference between the predicted values and the actual values, sums them up, and takes the reciprocal. The formula is as follows in Equation (8):In the equation, yi represents the actual value, ai represents the predicted value, and n represents the number of output nodes.

- Selection Operator. The selection operator utilizes a random sampling method and the best preservation strategy, with the main objective of identifying the best individuals in the population. However, selecting only the best individuals may overlook the diversity of the rest of the population, leading to local optima. To address this, each generation’s population is sorted based on fitness in ascending order. Then, the individuals are divided into segments using the ratios of 0.6, 0.8, and 1. From the end of each segment, individuals are randomly sampled to compensate for the potential loss of diversity. This approach maintains both global convergence characteristics and population diversity.

- Crossover Operation. Crossover involves selecting two individuals from the population and performing crossover at certain positions with a certain probability of generating new individuals. Since real number encoding is used in this study, real number crossover is applied. Specifically, at the i-th position, a crossover is performed between the m-th chromosome (am) and the n-th chromosome (an) in Equation (9):In the equation, b represents a random number between 0 and 1.

- Mutation Operation. Mutation is the process of randomly selecting an individual and applying mutation to its chromosome with a certain probability of generating a new individual. The method is shown in Equation (10):In the equation, the upper bound of the gene amn is amax, and the lower bound is amin. , where g is the current iteration count, Gmax is the maximum evolution count, r is a random number between 0 and 1, and r2 is another random number.

- Apply the chromosome to the neural network, calculate the fitness, and analyze if the set requirements are met. If the requirements are satisfied, decode the optimal individual as the optimal initial weights of the BP artificial neural network and proceed to the next step. Otherwise, go to step 3.

- Set the learning rate n, momentum coefficient m, allowable error c, and maximum training count N for BP artificial neural network as part of the loop step I.

- Input the normalized samples into the network, train the BP artificial neural network by adjusting the network weights, and calculate the network output and total error E.

- If E ≤ e (the desired training accuracy), then training is complete, and proceed to the next step. Otherwise, take the optimized connection weights from this iteration as the initial weights for the next training. Adjust the network weights and biases and go to step 7.

- Output the network connection weights that meet the training accuracy requirement (i.e., E ≤ e).

- Evaluate the standardized management level of the water conservancy project for the evaluated object and calculate the evaluation results. The program flow of the GA-BP artificial neural network evaluation algorithm for improving the modernization of water conservancy project management is shown in Figure 8.

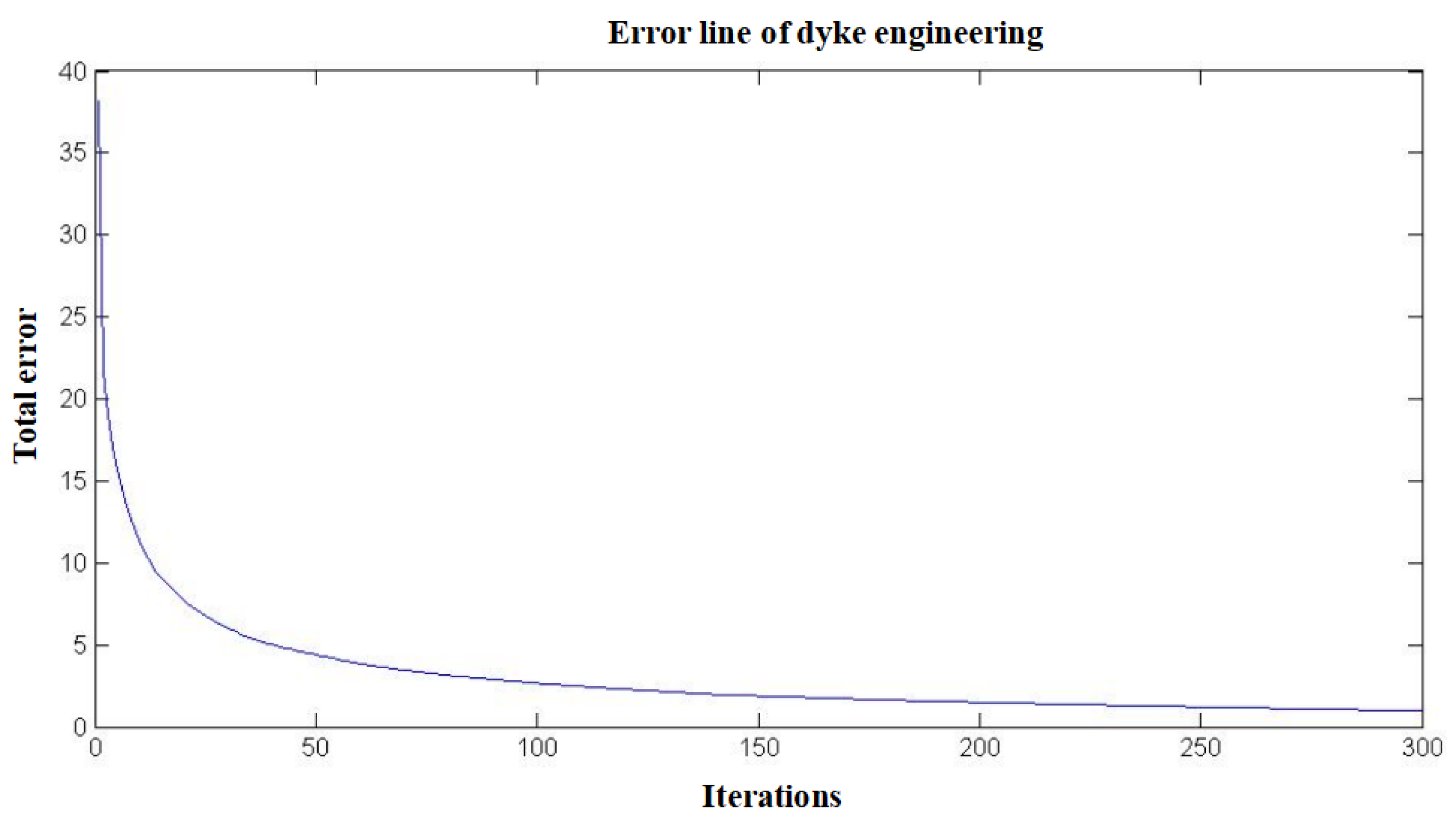

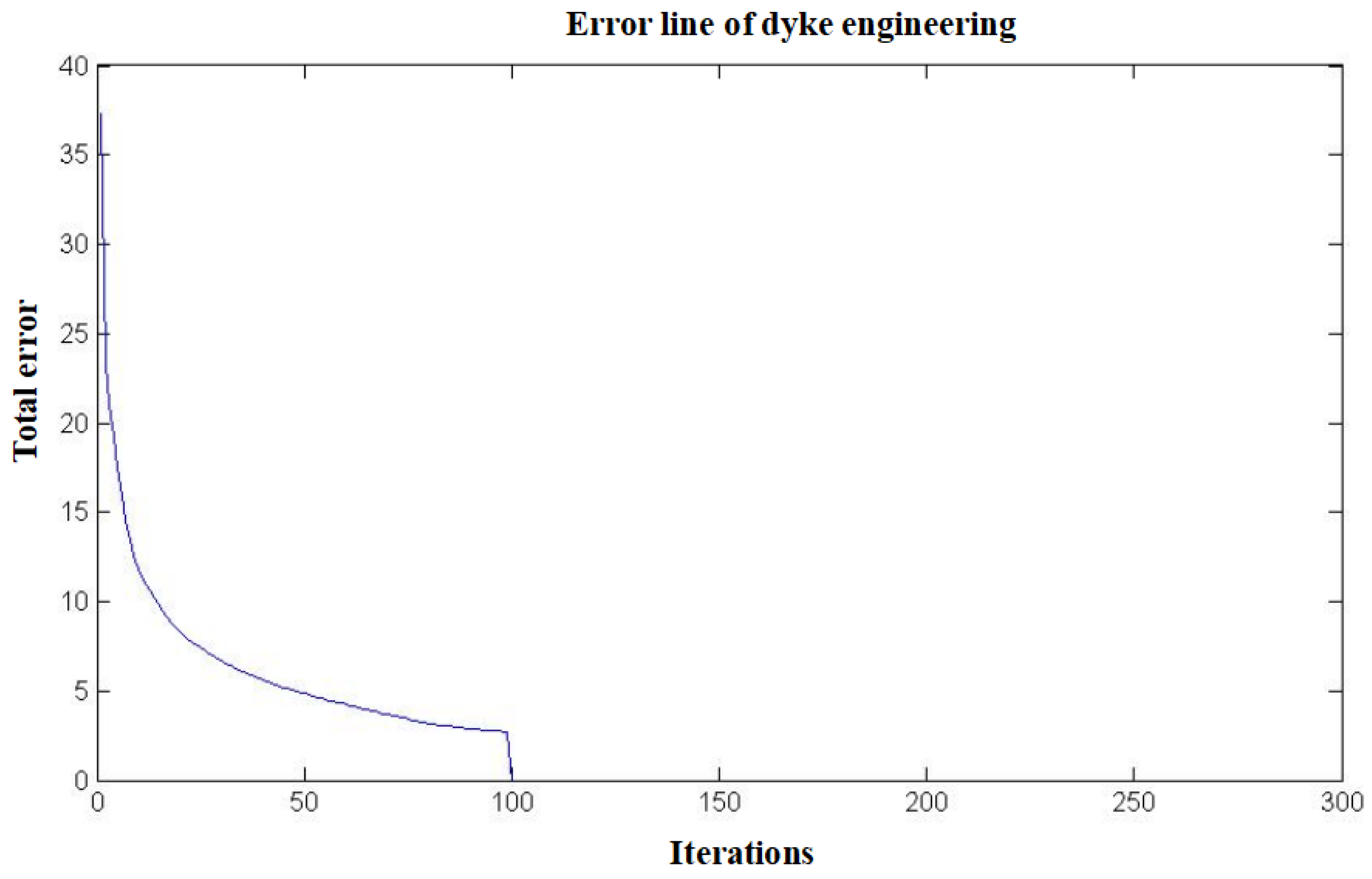

4.2. GA-BP Network Model Computational Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qu, J.; Meng, X.; You, H. Multi-stage ranking of emergency technology alternatives for water source pollution accidents using a fuzzy group decision making tool. J. Hazard. Mater. 2016, 310, 68–81. [Google Scholar] [CrossRef]

- Tu, W.R.; Fang, S.B.; Sun, Z.L. Experimental study and flow analysis on a new design of water-retaining sluice gate. Water Pract. Technol. 2020, 15, 311–320. [Google Scholar] [CrossRef]

- Wang, D.; Li, Y.; Yang, X.; Zhang, Z.; Gao, S.; Zhou, Q.; Zhuo, Y.; Wen, X.; Guo, Z. Evaluating urban ecological civilization and its obstacle factors based on integrated model of PSR-EVW-TOPSIS: A case study of 13 cities in Jiangsu Province, China. Ecol. Indic. 2021, 133, 108431. [Google Scholar] [CrossRef]

- Wang, Q.; Li, S.; Li, R. Evaluating water resource sustainability in Beijing, China: Combining PSR model and matter-element extension method. J. Clean. Prod. 2019, 206, 171–179. [Google Scholar] [CrossRef]

- Lea, D.A.; Löffler, E.; Douglas, I. Review symposium: Our common future: The world commission on environment and development. Aust. Geogr. 1989, 20, 195–201. [Google Scholar] [CrossRef]

- Gunhan, S. Analyzing Sustainable Building Construction Project Delivery Practices: Builders’ Perspective. Pract. Period. Struct. Des. Constr. 2019, 24, 05018003. [Google Scholar] [CrossRef]

- Sharifi, A.; Murayama, A. A critical review of seven selected neighborhood sustainability assessment tools. Environ. Impact Assess. Rev. 2013, 38, 73–87. [Google Scholar] [CrossRef]

- Feng, H.; Hewage, K. Energy saving performance of green vegetation on LEED certified buildings. Energy Build. 2014, 75, 281–289. [Google Scholar] [CrossRef]

- Koskela, L. Lean Productionin Construction. In Lean Construction; Elsevier Science Publishers R.V.: Amsterdam, The Netherlands, 1992; Volume 12, pp. 241–249. [Google Scholar]

- Nahmens, I. From lean to green construction: A natural extension. In Proceedings of the Building a Sustainable Future—Proceedings of the 2009 Construction Research Congress, Seattle, WA, USA, 5–7 April 2009; pp. 1058–1067. [Google Scholar]

- Du Plessis, C. Astrategic framework for sustainable construction in developing countries. Constr. Manag. Econ. 2007, 25, 67–76. [Google Scholar] [CrossRef]

- Marhani, M.A.; Jaapar, A.; Bari, N.A.A. Lean Construction: Towards enhancing sustainable construction in Malaysia. Procedia-Soc. Behav. Sci. 2012, 68, 87–98. [Google Scholar] [CrossRef]

- Circo, C.J. Using Mandatesand Incentivesto Promote Sustainable Construction and Green Building Projects in the Private Sector: A Call for More State Land Use Policy Initiatives. Ph.D. Thesis, University of Arkansas, Faye-Tteville, NC, USA, 2008. [Google Scholar]

- Robichaud, L.B.; Anantatmula, V.S. Greening Project Management Practices for Sustainable Construction. J. Manag. Eng. 2010, 27, 48–57. [Google Scholar] [CrossRef]

- Choi, K.; Lee, H.W. Environmental, Economic, and Social Implications of Highway Concrete Rehabilitation Altematives. J. Constr. Eng. Manag. 2016, 142, 04015079. [Google Scholar] [CrossRef]

- Kokkaew, N.; Rudjanakanoknad, J. A Framework of Green Growth Assessment for Thailand’s Highway Infrastructure Developments. In Computing in Civil and Building Engineering; ASCE: Reston, VA, USA, 2014; pp. 1951–1959. [Google Scholar]

- Wang, S.-J. Bionic (topological) pattern recognition -A new model of pattern recognition theory and its applications. Acta Electron. Sin. 2002, 30, 1417–1420. [Google Scholar]

- Zhou, Z.H.; Jiang, Y.; Chen, S.F. Extracting symbolic rules from trained neural networks ensembles. AI Commun. 2003, 16, 3–15. [Google Scholar]

- Liao, X.F.; Wong, K.W.; Wu, Z.F.; Chen, G.R. Novel robust stability criteria for interval-delayed Hopfield neural networks. IEEE Trans. Circuits Syst. 2001, 48, 1355–1359. [Google Scholar] [CrossRef]

- Liao, X.F.; Chen, G.R.; Sanchez, E.N. LMI-based approach for asymptotically stability analysis of delayed neural networks. IEEE Trans. Circuits Syst. 2002, 49, 1033–1039. [Google Scholar] [CrossRef]

- Liao, X.F.; Wong, K.W.; Yu, J.B. Novel stability condition for cellular networks with time delay. Int. J. Bifurc. Chaos 2001, 11, 1853–1864. [Google Scholar] [CrossRef]

- Ni, S.; Bai, Y. Application of BP neural network model in groundwater water quality evaluation. Syst. Eng. Theory Pract. 2000, 20, 124–127. [Google Scholar]

- Zhu, Q.; Zhang, G. Evaluation model of enterprise knowledge management based on artificial neural network. Stud. Sci. Sci. 2003, 8, 32–34. [Google Scholar]

- Wang, M. Improvement and application of BP neural network algorithm. Comput. Eng. Appl. 2009, 35, 47–48. [Google Scholar]

- Yan, B.; Gao, Z.; Li, D. Application of RBF neural network in comprehensive safety evaluation of dams. Chin. J. Rock Mech. Eng. 2008, 23, 3991–3997. [Google Scholar]

- Wang, A.; Sun, J. Application of BP neural network in engineering project management. Mod. Build. Manag. 2009, 23, 306–309. [Google Scholar]

- Bashiri, M.; Badri, H.; Hejazi, T.H. Selecting optimum maintenance strategy by fuzzy interactive linear assignment method. Appl. Math. Model. 2011, 35, 152–164. [Google Scholar] [CrossRef]

- Ali, A.; Zhu, Y.; Zakarya, M.J.N. Exploiting dynamic spatio-temporal graph convolutional neural networks for citywide traffic flows prediction. Neural Netw. 2022, 145, 233–247. [Google Scholar] [CrossRef] [PubMed]

- Yan, D.; Zhang, H.; Li, G.; Li, X. Improved method to detect the tailings ponds from multispectral remote sensing images based on faster R-CNN and transfer learning. Remote Sens. 2022, 14, 103. [Google Scholar] [CrossRef]

- Li, Y.; Bao, T.; Gao, Z.; Shu, X.; Zhang, K.; Xie, L.; Zhang, Z. A new dam structural response estimation paradigm powered by deep learning and transfer learning techniques. Struct. Health Monit.-Int. J. 2022, 21, 770–787. [Google Scholar] [CrossRef]

- Dong, L.; Deng, S.; Wang, F. Some developments and new insights for environmental sustainability and disaster control of tailings dam. J. Clean. Prod. 2020, 269, 122270. [Google Scholar] [CrossRef]

- Jia, T.; Wang, R.; Chai, B. Effects of heavy metal pollution on soil physicochemical properties and microbial diversity over different reclamation years in a copper tailings dam. J. Soil Water Conserv. 2019, 74, 439–448. [Google Scholar] [CrossRef]

- Cheng, M.Y.; Cao, M.T.; Huang, I.F. Hybrid artificial intelligence-based inference models for accurately predicting dam body displacements: A case study of the Fei Tsui dam. Struct. Health Monit.-Int. J. 2022, 21, 1738–1756. [Google Scholar] [CrossRef]

- Chen, H.; Li, H.; Wang, Y.; Cheng, B. A Comprehensive Assessment Approach for Water-Soil Environmental Risk during Railway Construction in Ecological Fragile Region Based on AHP and MEA. Sustainability 2020, 12, 7910. [Google Scholar] [CrossRef]

- Ikram, M.; Sroufe, R.; Zhang, Q. Prioritizing and overcoming barriers to integrated management system (IMS) implementation using AHP and G-TOPSIS. J. Clean. Prod. 2020, 254, 120121. [Google Scholar] [CrossRef]

- Darko, A.; Chan AP, C.; Ameyaw, E.E.; Owusu, E.K.; Pärn, E.; Edwards, D.J. Review of application of analytic hierarchy process (AHP) in construction. Int. J. Construct. Manag. 2019, 19, 436–452. [Google Scholar] [CrossRef]

- Barcelos, D.A.; Pontes, F.V.; da Silva, F.A.; Castro, D.C.; Dos Anjos, N.O.; Castilhos, Z.C. Gold mining tailing: Environmental availability of metals and human health risk assessment. J. Hazard. Mater. 2020, 397, 122721. [Google Scholar] [CrossRef] [PubMed]

- Belmokre, A.; Mihoubi, M.K.; Santillan, D.J. Seepage and dam deformation analyses with statistical models: Support vector regression machine and random forest. Procedia Struct. Integr. 2019, 17, 698–703. [Google Scholar] [CrossRef]

| Level 1 Indicator (B) | Secondary Indicator (C) |

|---|---|

| Management Foundation (B1) | Management Manual (C1) |

| Engineering delimitation (C2) | |

| Management Facilities (C3) | |

| Archive Management (C4) | |

| Safety Management (B2) | Responsible person (C5) |

| Safety Production (C6) | |

| Emergency Management (C7) | |

| Flood prevention and control (C8) | |

| Operation Management (B3) | Engineering Inspection (C9) |

| Engineering Observation (C10) | |

| Operation (C11) | |

| Maintenance Management (B4) | Repair and maintenance (C12) |

| Equipment maintenance (C13) | |

| Engineering Image (C14) | |

| Management Assurance (B5) | Position personnel (C15) |

| Informatization level (C16) | |

| Evaluation incentive (C17) | |

| Management and protection funds (C18) |

| Secondary Indicator (C) | Three-Level Indicator (D) | Index Content |

|---|---|---|

| Management Manual (C1) | Pocket Book (D1) Management and Operations Manual (D2) | Prepare system manuals and operating procedures as required. Key systems and operating procedures are clearly stated on the wall. |

| Engineering delimitation (C2) | Scope delineation (D3) Boundary Pile Embedding (D4) | Define the scope of engineering management and protection according to regulations. Setting up enough boundary stakes within the scope of engineering management. |

| Management Facilities (C3) | Number of identification plates (D5) Identification and Signage Category (D6) | The number of identification signs is complete. Complete categories of identification signs. |

| Archive Management (C4) | Archive facilities (D7) Data storage (D8) | There is a dedicated archive room or cabinet. Engineering archives and operational management data are clearly classified and stored in an orderly manner. |

| Secondary Indicator (C) | Three-Level Indicator (D) | Index Content |

|---|---|---|

| Responsible person (C5) | Responsible person implementation (D9) | Clarify the person responsible for safety and make it public. |

| Safety Production (C6) | Safety inspection (D10) Safety equipment (D11) Work with certificate (D12) | Conduct regular safety inspections. Equip necessary safety production facilities and maintain safety and reliability. Key positions must be certified according to regulations. |

| Emergency Management (C7) | Emergency Plan (D13) Emergency drill (D14) | Prepare and approve emergency plans for flood prevention and safety management. Organize and carry out contingency plan drills. |

| Flood prevention and control (C8) | Flood control materials (D15) Flood Control Traffic (D16) Flood Control Team (D17) Flood Control Duty (D18) | Reserve necessary flood control materials and standardize management. Smooth flood control roads. Clarify the personnel and contact information of the flood prevention and rescue team. Report any abnormalities or dangerous situations promptly. |

| Secondary Indicator (C) | Three-Level Indicator (D) | Index Content |

|---|---|---|

| Engineering Inspection (C9) | Inspection frequency (D19) Inspection content (D20) Inspection Record (D21) | Whether the assessment meets the inspection frequency specified in the “Operation Manual”. Comprehensive inspection content. Record detailed specifications. |

| Engineering Observation (C10) | Observation facility integrity rate (D22) Observation content and frequency (D23) Observation Record (D24) | Intactness rate of observation facilities. Whether the assessment meets the observation frequency specified in the “Operation Manual”. Standardized recording of observation data, timely compilation, and analysis. |

| Operation (C11) | Operate according to chapter (D25) Operation Record (D26) | Operate according to operating procedures and instructions. Normative records. |

| Secondary Indicator (C) | Three-Level Indicator (D) | Index Content |

|---|---|---|

| Repair and maintenance (C12) | Dike maintenance (D27) Piercing structures (D28) Prevention and control measures (D29) Maintenance Record (D30) | The embankment is smooth, without leakage, caves, and the slope protection is not damaged or collapsed. The structure of the building passing through the embankment is intact and meets the requirements for safe operation. Prevention and control measures for harmful animals on embankments, without indiscriminate cultivation, excavation, or occupation. Timely carry out maintenance and repair, with standardized records. |

| Equipment maintenance (C13) | Metal structure (D31) Mechanical and Electrical Equipment (D32) Maintenance Record (D33) | Normal use of metal structures and lifting equipment. The use of electromechanical equipment and auxiliary facilities is normal. Maintenance Record Specification. |

| Engineering Image (C14) | Embankment Appearance (D34) Office area (D35) | Keep the appearance of buildings, facilities, and equipment in the engineering area clean and tidy. Keep the office area clean and tidy. |

| Secondary Indicator (C) | Three-Level Indicator (D) | Index Content |

|---|---|---|

| Position personnel (C15) | Job Setting (D36) Education and Training (D37) | Position-Personnel-Task List. Regular education and training for professional and technical personnel. |

| Informatization level (C16) | Video surveillance (D38) Platform Construction (D39) Platform Operation and Maintenance (D40) | Construction project operation management platform with complete functions. The management platform is in normal use and well maintained. Conduct video surveillance in important areas and maintain normal operation of facilities. |

| Evaluation incentive (C17) | Management self-assessment (D41) Reward and Punishment Hook (D42) | Conduct self-evaluation according to regulations and link the evaluation results with personnel rewards and punishments. Rectify any issues found during inspections and inspections by superiors. |

| Management and protection funds (C18) | Budget (D43) Fund availability rate (D44) | Calculate maintenance expenses. Maintenance funds included in the financial budget and fully implemented. |

| Quantified Value | Meaning |

|---|---|

| 0.9 | In comparison, one element is extremely important compared to the other. |

| 0.8 | In comparison, one element is much more important than the other. |

| 0.7 | In comparison, one element is significantly more important than the other. |

| 0.6 | In comparison, one element is slightly more important than the other. |

| 0.5 | In comparison, one element is equally important as the other. |

| 0.1~0.4 | Anti-comparison |

| b1 | c1 | c2 | c3 |

|---|---|---|---|

| c1 | c11 | c12 | c13 |

| c2 | c21 | c22 | c23 |

| c3 | c31 | c32 | c33 |

| Level 1 Indicator (B) | Secondary Indicator (C) | Three-Level Indicator (D) | Weight |

|---|---|---|---|

| Management Foundation (B1) 0.09 | Management Manual (C1) | Pocket Book (D1) | 0.015 |

| Management and Operations Manual (D2) | 0.01 | ||

| Engineering delimitation (C2) | Scope delineation (D3) | 0.015 | |

| Boundary Pile Embedding (D4) | 0.005 | ||

| Management Facilities (C3) | Number of identification plates (D5) | 0.005 | |

| Identification and Signage Category (D6) | 0.01 | ||

| Archive Management (C4) | Archive facilities (D7) | 0.02 | |

| Data storage (D8) | 0.01 | ||

| Safety Management(B2) 0.225 | Responsible person (C5) | Responsible person implementation (D9) | 0.02 |

| Safety Production (C6) | Safety inspection (D10) | 0.02 | |

| Safety equipment (D11) | 0.01 | ||

| Work with certificate (D12) | 0.005 | ||

| Emergency Management (C7) | Emergency Plan (D13) | 0.02 | |

| Emergency drill (D14) | 0.02 | ||

| Flood prevention and control (C8) | Flood control materials (D15) | 0.03 | |

| Flood Control Traffic (D16) | 0.03 | ||

| Flood Control Team (D17) | 0.03 | ||

| Flood Control Duty (D18) | 0.04 | ||

| Operation Management (B3) 0.31 | Engineering Inspection (C9) | Inspection frequency (D19) | 0.07 |

| Inspection content (D20) | 0.07 | ||

| Inspection Record (D21) | 0.03 | ||

| Engineering Observation (C10) | Observation facility integrity rate (D22) | 0.03 | |

| Observation content and frequency (D23) | 0.02 | ||

| Observation Record (D24) | 0.01 | ||

| Operation (C11) | Operate according to chapter (D25) | 0.06 | |

| Operation Record (D26) | 0.02 | ||

| Maintenance Management (B4) 0.265 | Repair and maintenance (C12) | Dike maintenance (D27) | 0.045 |

| Piercing structures (D28) | 0.04 | ||

| Prevention and control measures (D29) | 0.045 | ||

| Maintenance Record (D30) | 0.03 | ||

| Equipment maintenance (C13) | Metal structure (D31) | 0.02 | |

| Mechanical and Electrical Equipment (D32) | 0.02 | ||

| Maintenance Record (D33) | 0.015 | ||

| Engineering Image (C14) | Embankment Appearance (D34) | 0.03 | |

| Office area (D35) | 0.02 | ||

| Management Assurance (B5) 0.11 | Position personnel (C15) | Job Setting (D36) | 0.005 |

| Education and Training (D37) | 0.015 | ||

| Informatization level (C16) | Video surveillance (D38) | 0.01 | |

| Platform Construction (D39) | 0.005 | ||

| Platform Operation and Maintenance (D40) | 0.01 | ||

| Evaluation incentive (C17) | Management self-assessment (D41) | 0.01 | |

| Reward and Punishment Hook (D42) | 0.025 | ||

| Management and protection funds (C18) | Budget (D43) | 0.01 | |

| Fund availability rate (D44) | 0.02 |

| Indicator | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 198 | 199 | 200 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pocket Book (D1) | 1 | 0.9 | 1 | 0.98 | 1 | 1 | 0.98 | 1 | 0.53 | 0.81 | 0.61 | |

| Management and Operations Manual (D2) | 1 | 1 | 1 | 1 | 0.82 | 1 | 1 | 0.9 | 0.75 | 0.67 | 0.68 | |

| Scope delineation (D3) | 0.17 | 0.21 | 0.95 | 0.22 | 0.85 | 0.51 | 0.19 | 0.58 | 0.5 | 0.93 | 0.11 | |

| Boundary Pile Embedding (D4) | 0.88 | 0.83 | 1 | 0.81 | 1 | 1 | 1 | 0.93 | 0.56 | 0.45 | 0.41 | |

| Number of identification plates (D5) | 0.89 | 1 | 1 | 0.84 | 0.91 | 1 | 0.92 | 0.88 | 0.61 | 0.6 | 0.8 | |

| Identification and Signage Category (D6) | 1 | 0.84 | 0.95 | 1 | 1 | 1 | 1 | 1 | 0.83 | 0.66 | 0.85 | |

| Archive facilities (D7) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0.84 | 0.77 | 0.45 | 0.74 | |

| Data storage (D8) | 1 | 1 | 0.92 | 0.85 | 0.93 | 0.95 | 1 | 0.82 | 0.68 | 0.74 | 0.52 | |

| Responsible person implementation (D9) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0.62 | 0.62 | 0.56 | |

| Safety inspection (D10) | 0.72 | 1 | 1 | 0.6 | 0.68 | 0.55 | 0.77 | 1 | 0.86 | 0.82 | 0.88 | |

| Safety equipment (D11) | 0.58 | 0.52 | 0.47 | 0.85 | 1 | 0.69 | 0.87 | 0.97 | 0.19 | 0.62 | 0.93 | |

| Work with certificate (D12) | 0.68 | 0.86 | 1 | 0.66 | 0.83 | 1 | 0.55 | 0.92 | 0.58 | 0.45 | 0.22 | |

| Emergency Plan (D13) | 0.59 | 0.59 | 1 | 0.94 | 1 | 0.94 | 0.64 | 0.76 | 0.54 | 0.26 | 0.43 | |

| Emergency drill (D14) | 0.8 | 0.87 | 0.56 | 0.96 | 1 | 1 | 0.57 | 1 | 0.44 | 0.89 | 0.67 | |

| Flood control materials (D15) | 0.54 | 0.57 | 0.56 | 0.83 | 0.98 | 0.43 | 1 | 1 | 0.36 | 0.87 | 0.36 | |

| Flood Control Traffic (D16) | 0.97 | 1 | 0.82 | 1 | 1 | 0.95 | 1 | 0.85 | 0.47 | 0.58 | 0.63 | |

| Flood Control Team (D17) | 1 | 1 | 0.83 | 0.96 | 0.7 | 0.77 | 0.58 | 0.98 | 0.73 | 0.78 | 0.46 | |

| Flood Control Duty (D18) | 0.95 | 0.95 | 1 | 0.79 | 0.78 | 1 | 0.89 | 0.57 | 0.6 | 0.33 | 0.33 | |

| Inspection frequency (D19) | 1 | 1 | 0.92 | 1 | 1 | 1 | 1 | 0.92 | 0.37 | 0.4 | 0.47 | |

| Inspection content (D20) | 0.69 | 1 | 1 | 1 | 0.84 | 1 | 1 | 1 | 0.56 | 0.56 | 0.52 | |

| Inspection Record (D21) | 1 | 0.94 | 0.96 | 1 | 1 | 0.87 | 0.93 | 1 | 0.65 | 0.51 | 0.47 | |

| Observation facility integrity rate (D22) | 1 | 0.67 | 0.88 | 0.52 | 0.63 | 1 | 0.79 | 1 | 0.53 | 0.59 | 0.6 | |

| Observation content and frequency (D23) | 0.93 | 1 | 0.62 | 0.83 | 1 | 0.9 | 1 | 1 | 0.76 | 0.82 | 0.72 | |

| Observation Record (D24) | 1 | 1 | 0.95 | 1 | 0.98 | 0.98 | 1 | 1 | 0.83 | 0.71 | 0.45 | |

| Operate according to chapter (D25) | 1 | 1 | 1 | 1 | 1 | 0.84 | 0.93 | 1 | 0.75 | 0.64 | 0.7 | |

| Operation Record (D26) | 0.95 | 0.82 | 1 | 0.96 | 1 | 1 | 1 | 1 | 0.85 | 0.69 | 0.48 | |

| Dike maintenance (D27) | 0.76 | 0.89 | 0.94 | 1 | 0.68 | 0.73 | 0.91 | 0.77 | 0.74 | 0.59 | 0.62 | |

| Piercing structures (D28) | 1 | 1 | 1 | 1 | 1 | 1 | 0.86 | 1 | 0.81 | 0.64 | 0.49 | |

| Prevention and control measures (D29) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0.58 | 0.48 | 0.54 | |

| Maintenance Record (D30) | 1 | 1 | 1 | 0.95 | 1 | 0.95 | 0.88 | 1 | 0.38 | 0.66 | 0.56 | |

| Metal structure (D31) | 0.88 | 1 | 1 | 1 | 1 | 1 | 0.91 | 1 | 0.71 | 0.73 | 0.85 | |

| Mechanical and Electrical Equipment (D32) | 1 | 1 | 1 | 1 | 1 | 0.92 | 1 | 0.99 | 0.5 | 0.79 | 0.78 | |

| Maintenance Record (D33) | 0.88 | 1 | 0.87 | 1 | 1 | 1 | 1 | 0.89 | 0.65 | 0.71 | 0.52 | |

| Embankment Appearance (D34) | 0.86 | 0.98 | 1 | 1 | 1 | 0.91 | 0.99 | 0.9 | 0.61 | 0.43 | 0.46 | |

| Office area (D35) | 1 | 1 | 0.9 | 0.81 | 0.9 | 1 | 0.91 | 1 | 0.46 | 0.72 | 0.7 | |

| Job Setting (D36) | 1 | 0.92 | 0.89 | 1 | 1 | 0.91 | 1 | 1 | 0.79 | 0.45 | 0.83 | |

| Education and Training (D37) | 1 | 1 | 1 | 1 | 0.96 | 1 | 1 | 1 | 0.38 | 0.44 | 0.81 | |

| Video surveillance (D38) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0.52 | 0.67 | 0.62 | |

| Platform Construction (D39) | 1 | 1 | 1 | 0.96 | 1 | 1 | 1 | 0.81 | 0.66 | 0.64 | 0.68 | |

| Platform Operation and Maintenance (D40) | 0.83 | 0.9 | 1 | 1 | 0.99 | 1 | 1 | 1 | 0.7 | 0.75 | 0.65 | |

| Management self-assessment (D41) | 0.9 | 0.93 | 0.97 | 1 | 1 | 1 | 0.92 | 1 | 0.47 | 0.41 | 0.6 | |

| Reward and Punishment Hook (D42) | 0.48 | 0.1 | 0.22 | 0.97 | 0.01 | 0.56 | 0.67 | 0.88 | 0.53 | 0.92 | 0.77 | |

| Budget (D43) | 1 | 1 | 1 | 0.85 | 1 | 1 | 1 | 1 | 0.8 | 0.4 | 0.62 | |

| Fund availability rate (D44) | 0.99 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0.48 | 0.46 | 0.81 | |

| Desired output | 0.89 | 0.91 | 0.91 | 0.93 | 0.90 | 0.91 | 0.91 | 0.93 | 0.60 | 0.61 | 0.58 |

| Sample Serial Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Desired output | 0.602 | 0.679 | 0.795 | 0.919 | 0.721 | 0.826 | 0.908 | 0.854 | 0.828 | 0.658 |

| Actual output | 0.600 | 0.666 | 0.786 | 0.923 | 0.732 | 0.859 | 0.897 | 0.850 | 0.822 | 0.657 |

| Error | −0.002 | −0.013 | −0.008 | 0.004 | 0.011 | 0.034 | −0.011 | −0.004 | −0.006 | −0.001 |

| Error rate | 0% | −2% | −1% | 0% | 2% | 4% | −1% | 0% | −1% | 0% |

| Sample Serial Number | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 |

| Desired output | 0.853 | 0.576 | 0.899 | 0.928 | 0.691 | 0.704 | 0.922 | 0.695 | 0.553 | 0.588 |

| Actual output | 0.853 | 0.565 | 0.890 | 0.925 | 0.688 | 0.717 | 0.906 | 0.685 | 0.541 | 0.580 |

| Error | 0.001 | −0.011 | −0.009 | −0.004 | −0.003 | 0.013 | −0.016 | −0.010 | −0.012 | −0.008 |

| Error rate | 0% | −2% | −1% | 0% | 0% | 2% | −2% | −1% | −2% | −1% |

| Sample Serial Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Desired output | 0.811 | 0.738 | 0.679 | 0.922 | 0.840 | 0.613 | 0.614 | 0.607 | 0.793 | 0.676 |

| Actual output | 0.801 | 0.721 | 0.676 | 0.916 | 0.830 | 0.603 | 0.597 | 0.612 | 0.787 | 0.664 |

| Error | −0.01 | −0.02 | 0.00 | −0.01 | −0.01 | −0.01 | −0.02 | 0.00 | −0.01 | −0.01 |

| Error rate | −1.3% | −2.4% | −0.5% | −0.7% | −1.3% | −1.6% | −2.8% | 0.8% | −0.7% | −1.7% |

| Sample Serial Number | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 |

| Desired output | 0.562 | 0.900 | 0.871 | 0.595 | 0.730 | 0.897 | 0.897 | 0.687 | 0.693 | 0.556 |

| Actual output | 0.567 | 0.903 | 0.861 | 0.592 | 0.743 | 0.881 | 0.884 | 0.693 | 0.702 | 0.569 |

| Error | 0.00 | 0.00 | −0.01 | 0.00 | 0.01 | −0.02 | −0.01 | 0.01 | 0.01 | 0.01 |

| Error rate | 0.9% | 0.4% | −1.2% | −0.5% | 1.9% | −1.8% | −1.4% | 1.0% | 1.3% | 2.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Fang, S.; Wang, Q.; Tu, W. Research on the Standardized Management System and Operational Indicators of Water Control Dikes Based on GA-BP Artificial Neural Network Model. Water 2023, 15, 3713. https://doi.org/10.3390/w15213713

Zhou Z, Fang S, Wang Q, Tu W. Research on the Standardized Management System and Operational Indicators of Water Control Dikes Based on GA-BP Artificial Neural Network Model. Water. 2023; 15(21):3713. https://doi.org/10.3390/w15213713

Chicago/Turabian StyleZhou, Zhiwei, Shibiao Fang, Qing Wang, and Wenrong Tu. 2023. "Research on the Standardized Management System and Operational Indicators of Water Control Dikes Based on GA-BP Artificial Neural Network Model" Water 15, no. 21: 3713. https://doi.org/10.3390/w15213713

APA StyleZhou, Z., Fang, S., Wang, Q., & Tu, W. (2023). Research on the Standardized Management System and Operational Indicators of Water Control Dikes Based on GA-BP Artificial Neural Network Model. Water, 15(21), 3713. https://doi.org/10.3390/w15213713