1. Introduction

High dams and large reservoirs play an irreplaceable role in ensuring social and economic development and national water resource security, and their security is related to national major public security. With the intensification of the impact of human activities, global climate change, and the frequent occurrence of natural disasters, the problems of reservoir dam-break and landslide dam-break have become increasingly prominent [

1]. Effectively ensuring the safety of hydropower projects and cascade hydropower stations in the basin is of far-reaching and significant significance to ensuring national energy security and the safety of human life and property. The Basin Hydropower Emergency Plan and Requirements, which is being prepared by the National Development and Reform Commission and the Energy Administration of the People’s Republic of China, clearly stipulates the principles of emergency work for basin hydropower emergencies and the requirements for emergency dispatching and security and requires that cascade hydropower projects should have the emergency venting capacity and should regularly repair and maintain the flood discharge and venting facilities. When the cascade hydropower project encounters such emergencies as excessive inflow flood in the upstream river channel, inflow flood in the upstream cascade or reservoir landslide, a flood caused by the dangerous situation of the backwater building itself, and war and terrorist attacks on the project, the reservoir capacity shall be adjusted in time according to the requirements of the government emergency management department. The requirements for emergency drawdown capacity of high dams and large reservoirs are written into the specification, which shows the importance and necessity of emergency venting capacity of reservoir dams.

The operation and maintenance experience of water conservancy and hydropower projects shows that the drawdown facilities play a significant role in reducing the incidence of engineering accidents, reducing the impact of accidents and disasters, and improving the safe operation of the project. For example, in China, after an earthquake, the Zipingpu concrete face dam was damaged. The upstream water level of the dam was reduced in time through the flushing and venting tunnels and the flood discharge tunnel, which created construction conditions for the repair of the dam’s concrete slab and water stop system. And Seepage occurred downstream of the Qizishan dam with the flow rate reached 1170 L/s. From March to July 2002, the emptying tunnel was used to withdraw the reservoir for treatment. The operation has been normal so far, which has played an important role in the rapid inspection and treatment of basic leakage. Others, such as Sayanshushensk in Russia, Kolbrien and Zillergrund in Austria, Zezier and Sacred Maria in Switzerland, and El Ataza in Spain, also occurred on the heel. In the case of cracking, the emptying of the reservoir provides favorable conditions for engineering maintenance.

According to incomplete statistics, there are relatively few venting facilities for rigid dams in China, and high dams generally have bottom outlets for flood discharge, such as Xiaowan, Guangzhao, Ertan, etc. There are many examples of setting up emptying facilities for rock-fill dams. Medium and low dams generally meet the emptying requirements by combining spillway tunnels and diversion tunnels; high dams are generally equipped with special emptying facilities. Investigation of the relevant parameters of the deep-hole arc gates for hydropower projects at home and abroad shows that the domestic leader in various indicators is the second-level concrete double-curved arch dam of Dongjiang Hydropower Station. The maximum dam height is 157 m, the working gate of the emptying tunnel has a water head of 123.40 m, and the size of the orifice is 6.4 m × 7.5 m (width × height). The total horizontal static water pressure is 5743 kN, and the maximum flow is 1625.00 m3/s. The leading foreign index is India’s Tarbela. The earth-rock dam has an inclined core, and the maximum dam height is 143 m. The water head of the working door of the emptying tunnel is 135.60 m, the orifice size is 4.88 m × 7.3 m (width × height), the total horizontal static water pressure is 4697 kN, and the maximum flow rate is 1260.00 m3/s. As the layout depth of the vent hole increases, the size of the orifice of the arc gate decreases and the flow rate decreases. The layout depth of the prior art venting buildings is generally about 120 m, and the small orifice size results in limited leakage, which can only be vented during specific periods of the dry season, and the venting depth is limited and can only be used for routine maintenance and overhaul of the project.

In short, the scientific and reasonable setting of venting facilities will not only provide the dam with maintenance conditions but also improve the emergency response capability of the dam, avoid major disasters, and ensure the safety of people’s lives and property. However, the emergency response capacity of the reservoir dam emptying facility designed according to the existing specifications is insufficient and does not fully meet the requirements of national emergency management. The main manifestations are the inability to withdraw all the time, the limited drawdown volume, the insufficient drawdown depth, the limited drawdown storage capacity, and so on.

2. Method

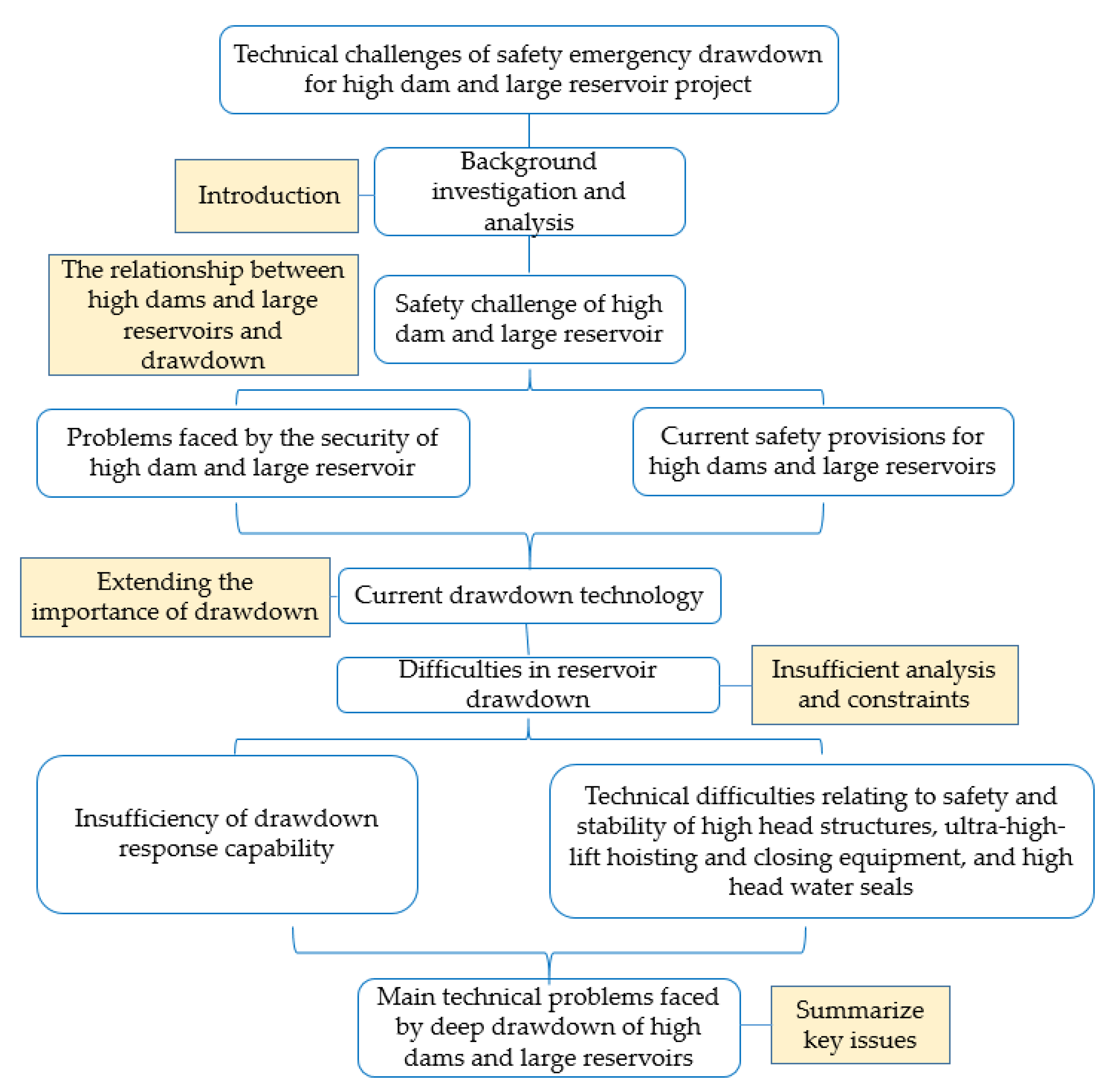

On the basis of researching a large amount of engineering data, the research method in this article is shown in

Figure 1:

3. Safety Challenge of High Dam and Large Reservoir

3.1. Problems Faced by the Security of High Dam and Large Reservoir

Global climate change and the increase in extreme weather, earthquakes, landslides, debris flows, and other natural disasters lead to the damage of flood discharge facilities, dam overtopping, dam collapse, and other accidents in some hydropower projects, which seriously affect the safety of people’s lives and property and public safety, e.g., the failure of the dam in Zhumadian, China, in 1975; the landslide surge generated by the Cascade Mountains in the United States in 1966; the swell generated by the Nosteyuko River in Canada in 1983, which caused severe damage, including the collapse of the downstream barrier dam; the formation of the Hongshiyan barrier lake, caused by the Ludian earthquake in Yunnan, China, in 2014; the Baige barrier lake on the Jinsha River, caused by a landslide in the Tibetan Autonomous Region of China in 2018; and the dam failure in the Sardoba Reservoir in Uzbekistan in 2020. All these examples caused a huge loss of life and property and undermined the safety of local people.

Large reservoirs with high dams are generally the leading reservoirs in a basin, and their structural design is usually based on natural floods and check floods. However, in recent years, with the emergence of non-natural extreme flooding, it has become clear that most high dam reservoirs are lacking in emergency response capacity. When a major incident occurs in a cascade reservoir group, there are severe potential safety hazards which may even trigger a disastrous chain reaction through successive reservoirs. Therefore, safety provision in terms of emergency emptying capacity in cascade reservoirs has become a matter of widespread concern; the improvement of the emergency capacity of high dam and large reservoir projects is now an urgent priority requiring immediate attention.

3.2. Current Safety Provisions for High Dams and Large Reservoirs

At present, the safety guarantee measures of high dam and large reservoir projects are mainly to deal with sudden adverse conditions such as non-standard floods, landslide surges, earthquakes, etc., by setting up relevant water withdrawal structures and comprehensively evaluating whether the overall operation status of the building is safe and supplemented by special underwater detection, regular maintenance, and other work. The traditional underwater detection method cannot meet the underwater detection and maintenance requirements of high dams and large reservoirs due to its low efficiency, high cost, high safety risk, and limited coverage of underwater work within 60 m. There are a few projects in China that attempt to use underwater robots or manned submersibles to detect the high dam reservoir [

2], but the existing deep-water defect detection and intelligent operation underwater robots (ROV) and miniaturized manned diving equipment [

3] can only adapt to the water depth of 100 m, far from meeting the requirements for the repair and maintenance of 300 m high dam. In addition, the existing underwater detection means are mainly to inspect the surface of the building, and the types of NDT equipment that can be carried are also extremely limited. The acquired detection data can not only reach the depth of comprehensive evaluation of the building’s operation status but also cannot play the role of emergency elimination. Therefore, where large reservoir capacity, wide water area, and deep-water levels prevail, existing methods of detection cannot meet operational safety needs, and emptying facilities take on particular importance.

Years of operational and maintenance experience also show that emptying facilities play a significant role in reducing the occurrence and impact of accidents and improving the assurance of a project’s operational safety. For example, the deep outlets in the Zipingpu Dam, Zhushuqiao Panel Dam, Qiezi Mountain, and Meishan Reservoir projects in China play an important role in facilitating rapid inspection and the treatment of problems. When damage occurs, the reservoir can be emptied promptly, and maintenance conditions can be provided to ensure the continuing safety of the project. In 2018, China’s “11.03” Baige barrier lake emergency rescue took “about 1.3 billion m

3 of storage capacity to absorb dam break flood” in emergency treatment measures [

4,

5], which successfully averted the danger. The arch dam of Kölnbrein in Austria, with cracks in the heel, was also reinforced by a number of drainage reservoirs. However, the early Baiyun Hydropower Station, Sanbanxi Hydropower Station, Zhushuqiao Panel Dam, and other projects in China cannot be overhauled or maintained because of a lack of drainage facilities; consequently, problems with these dams cannot be adequately addressed, and their operation continues to be compromised [

6,

7]. The Oroville Dam in the United States is also not equipped with venting facilities [

8]. In February 2017, due to the large inflow, the reservoir water level rose sharply, and there was no time to discharge. The spillway was damaged, resulting in major losses. So, high dams and large reservoirs lack effective means to respond to extreme events and still face great hidden dangers. With the continuous development of dam height, the existing drawdown technology has been difficult to cope with the challenges faced by high dams and large reservoirs.

4. Current Drawdown Technology

Emptying facilities are defined in this paper as structures that can lower the reservoir water level. These principally include spillways, spillway tunnels, and discharge cavities in embankment dams, surface outlets, mid-level outlets, low-level (bottom) outlets, and other drainage structures in concrete dams. These can be categorized by function, type, and layout. In terms of function, specialized emptying facilities include emptying tunnels and low-level (bottom) outlets, that is, those facilities intended for emptying the water in the reservoir as far as possible. In terms of type, current usage includes more pressure holes, no pressure holes with pressure, and full pressure holes; in terms of layout on the facade, there are “dragon head up” type, “dragon tail down” type as well as steep groove type, deep-hole type/straight line type, and swirling vertical shaft type.

Current emptying facilities in a representative worldwide range of dams over 200 m in height are summarized in

Table 1.

Amongst high dams above 200 m, early concrete dams were generally equipped with deep outlets for drawdown. The construction and development of high dams and large reservoirs have led to increased attention being given to drawdown facilities. Concrete dams are increasingly equipped with dedicated bottom outlets, used to withdraw the reservoir water below the deep outlet. More than 90% of China’s earth-rock dam and rock-fill dam projects are equipped with emptying tunnels as dedicated drawdown facilities. By contrast, the majority of projects in other countries do not have dedicated emptying facilities but combine these with flood discharge, water diversion, or sand discharge structures to withdraw water levels when necessary. Traditionally, withdrawal facilities have been designed primarily to meet the maintenance requirements of high dams and large reservoirs, which is a normal emergency emptying method. However, the Jinsha River, Yarlung Zangbo River, and Niulan River barrier lake accidents that have occurred in China in recent years demonstrate that hydropower and water conservancy projects struggle to meet the challenge of emptying a large number of reservoirs in a short time. The emergency capacity of traditional drawdown facilities is insufficient, and the safety emergency drawdown technology of high dam and large reservoir projects needs innovation.

At present, some exploratory studies have been carried out on the layout of new deep drawdown facilities. Deng Gang et al. [

19] proposed an inverted “U” shaped drawdown tunnel and set a vent gate at the downstream side of the top of the emptying tunnel. Since the inlet elevation is higher than the outlet elevation, when the reservoir water level is higher than the top elevation of the emptying tunnel and the reservoir water needs to be emptied, lift the vent gate, and the reservoir water can automatically flow out of the outlet and be emptied under its own weight. Although this structure can reduce the water pressure borne by the vent gate, the vent tunnel is arranged in an inverted “U” shape, and the drawdown of high dams and large reservoirs requires a large tunnel diameter, which increases the construction difficulty. In addition, the hydraulic characteristics under high-water heads are extremely complex, and the safety of this structure needs to be verified.

Yang Jiaxiu et al. [

20] proposed a rapid deep drawdown technology for high dams and large reservoirs based on the combined water retaining of multistage gates. This technology provides the reverse hydraulic thrust by filling water at the downstream side of the single-stage gate so that the hydraulic thrust of the single-stage gate can meet the conventional design requirements. The total waterhead is shared by the “graded water retaining” of the multistage gate so that the drawdown facilities are arranged at a deeper underwater position. Under the condition of large discharge and high-water pressure, the dynamic water operating head of each gate and the flow velocity in each channel can still be at the normal level. At the same time, the technical idea of “channel layering + relay drawdown” is adopted to achieve the sustainability of drawdown depth in theory. This technology can rapidly empty high dams and large reservoir projects in the flood season and dry season. This technology meets the drawdown requirements of high dam and large reservoir project safety, cascade joint operation management, health diagnosis, upgrading and reconstruction, engineering accident rescue, disaster prevention, and emergencies and can effectively improve the safety of the operation and maintenance of the high dam and large reservoir project and the anti-risk ability under various major natural disasters and emergencies. This structure theoretically realizes the deep safety emergency venting of high dams and large reservoirs, and its engineering practice application in 300 m high dams is still in progress.

5. Difficulties in Reservoir Drawdown

5.1. Insufficiency of Drawdown Response Capability

The emptying capacity of the reservoir is evaluated by the drawdown ratio of the waterhead and the drawdown ratio of storage capacity [

21]. Define the drawdown ratio of waterhead

and storage capacity venting rate

, The higher the value of

and

, the higher the drawdown capacity.

and

can be calculated by using Formulas (1) and (2).

where:

—Drawdown ratio of waterhead;

—Normal water level, m;

—Drawdown level, m;

H—Dam water head, m;

—Drawdown ratio of storage capacity;

—Storage capacity corresponding to normal water level, m3;

—Storage capacity corresponding to emptying water level, m3.

Using formulas (1) and (2), the following observations can be made regarding the emptying capacity of representative high dam and large reservoir projects in China: at present, the largest reduction rate of emptying head is Shuibuya Hydropower Station with 62.44%, while the reduction rate of most projects is only 30~50%, and the largest reduction rate of emptying capacity is Goupitan Hydropower Station with 96.75%, while most are in the range of 70~90% (

Figure 2). Even for the high dam after the emptying storage decreasing rate is as high as 90%, an empty head lower rate can reach 50%. Only the remaining reservoir water sinks to the depth of an a-level one-hundred-meter high dam, which still has more than 100 million cubic meters that need to be filled with water (

Figure 3). The same large storage capacity is equal to the (1) type of hydropower project. This emptying capacity is still drastically insufficient, to the extent that conditions do not even allow for adequate maintenance, and emergency safety provisions are seriously compromised.

From the treatment of dammed lakes such as Jinsha River, Yarlung Zangbo River, and Niulan River in recent years, the frequent occurrence of serious and special natural disasters has put forward new requirements for an emergency response of hydropower and water conservancy projects. The most effective way to reduce the impact of accidents is to empty the storage capacity after disasters. Traditional water conservancy and hydropower projects, even if equipped with drawdown facilities, are basically based on the maintenance needs of high dams and large reservoirs. They are a normal drawdown means. When faced with emergencies, they often cannot withdraw the reservoir in a timely and effective manner, which cannot meet the emergency needs of emergencies. Therefore, the safety emergency drawdown technology needs to emerge at the historic moment. On the premise of meeting the requirements of safe operation and maintenance of high dams and large reservoirs, further improve the corresponding emergency capacity of the project, give full play to the disaster prevention and mitigation capacity of hydropower projects, and reduce the secondary disaster risk.

In addition to the above indicators, the emergency drawdown capacity can also be evaluated according to the drawdown time, drawdown capacity, and orifice area. According to the statistics of the drawdown time of the high dam and large reservoir project (

Figure 4), it can be seen that the drawdown time is generally 20 to 40 days, some of which are 4.25 days short, and some of which are 102 days long. The average drawdown time per 100 million m

3 of storage capacity is 1.86 days, the average drawdown time per 1 m of water level drop is 3.78 days, and the drawdown can only be carried out in the dry season when the upstream inflow is small. In the flood season, because the upstream inflow is large, the drawdown flow is small, and the drawdown cannot be carried out. Because the time of the emergency cannot be predicted, the emergency response can only be carried out according to the principle of “the reservoir water shall be as low as possible, the drawdown shall be as fast as possible, and the loss shall be as small as possible”. The existing 20-day or even 40-day emergency response time is relatively long. Therefore, the current drawdown time cannot meet the emergency venting requirements.

According to the statistics of the drawdown capacity and orifice area of the high dam and large reservoir project (

Figure 5), the existing high dam and large reservoir project has a huge storage capacity. Because the discharge of the single hole of the concrete dam is small, with an average of 1300 m

3/s, it has to increase the discharge by arranging multiple bottom holes to achieve the purpose of emptying the reservoir. However, when the local material dam is equipped with a special emptying reservoir, the maximum discharge is 2000 m

3/s, which is the emptying tunnel of Lianghekou Hydropower Station. At present, the area of the vent hole is 41 m

2 on average, and the largest is the vent hole of Lianghekou Hydropower Station, up to 84 m

2. With the construction of a 300 m high dam, the demand for drawdown discharge is increasing, and the area of the vent hole also needs to be increased accordingly, which brings unprecedented challenges to drawdown technology.

To sum up, at present, the area of a single hole of high dam and large reservoir projects is relatively small, the drawdown discharge is relatively small, the drawdown time is relatively long, and it can only be vented during the dry season. It is feasible for drawdown under normal operation, but if extreme conditions (earthquake, excessive flood, military strike, and cascade engineering disasters in the basin) require drawdown in flood season or rapid drawdown, it cannot meet the requirements. The lack of drawdown and emergency capacity is an important problem for the development of drawdown facilities in high dams and large reservoirs.

5.2. Technical Difficulties Relating to Safety and Stability of High Head Structures, Ultra-High-Lift Hoisting and Closing Equipment, and High Head Water Seals

In comparison with high dams, either the inlet of the discharge tunnel floor in conventional dams is higher or the gate well is located behind the dam’s seepage prevention curtain. In addition, the structure bears less external water pressure, and the main load-bearing components of the gate shaft lining are only used as a safety reserve in the initial support and the secondary lining. However, for high dam and large reservoir projects, the intake floor is set deep, the gate well is located before the anti-seepage curtain, and external water pressure and surrounding rock deformation pressure are larger. When conventional structural mechanics or the boundary value method is used for calculation, the lining section size and the amount of reinforcement are larger. When the external water exceeds a certain head, the excavation section size and lining structure calculated are distinctly uneconomical and unreasonable [

22]. In addition, during the operation of the circular hydraulic tunnel, the reinforced concrete lining is under the influence of internal water pressure, and its circum-axial stress is generally expressed as tensile stress. Under the action of a high-water head, the concrete may exceed its tensile strength and crack, leading to the seepage of internal water [

23]. Therefore, the following points represent the most important design challenges for the safety and stability of emptying structures: consideration of the interaction between surrounding rock and lining, accurate analysis of the stability and safety of surrounding rock and lining structure, realistic simulation of damage and cracking behavior of hydraulic tunnel lining under pressure, and the economical and rational design of the reinforced concrete lining.

When the reservoir is drawn down, water is discharged by opening the upper spillway or surface outlet, spillway tunnel, and other gates. After the water level drops further, the emptying hole or the bottom outlet’s arc gate is opened.

It can be seen from

Table 2 that the current maximum water-retaining head for the bottom outlet gate of Xiaowan Hydropower Station is 160 m. This figure represents the highest design level. That is to say, the maximum pressure of the gate is 160 m static pressure; however, the operating water head is less than 160 m. The highest water pressure of 124,000 kN is found in the emptying and repair gate of the Lianghekou Hydropower Station; this represents a worldwide maximum.

The extreme pressure borne by gates in high dams and large reservoirs necessitates larger hoisting equipment and higher water seal pressure. For high-head arc gates, swing hydraulic presses are generally used as hoisting equipment. By increasing the orifice area to improve discharge volume, the hydraulic press capacity exceeds the limit and the ultra-high lift and high-capacity opening and closing equipment volume. The outer side of the cylinder is too large, making it difficult to manufacture and transport, and the wire rope is easily damaged during the opening and closing of the gate. The head of the water seal of the gate changes in accordance with the water level of the reservoir area, and the stress state of the water seal varies greatly in response to the large water level fluctuations in the emptying tunnel. Research has been carried out on a number of domestic super-high head gates (including Dongfeng, Hongjiadu, Guangzhao, Xiaowan, and Laxiwa) to test water seal materials and types, to address the problem of water seal behavior under the action of high-water heads. When the water level is low, the contact stress between the water seal head and the water seal seat plate is low, and the risk of leakage is high. When the water level is high, the contact stress between the water seal head and the water seal seat plate becomes too large, leading to compression, deformation, and possible failure, of the water seal. The water seal is under unidirectional force: there is no water on the downstream side. Under the action of high-water levels, crevice jets are easily created, leading to “crevice cavities”, cavitation or wear of the sluice panel and embedded parts, and vibration of the sluice, adversely affecting the normal operation of the gate and the safety of the structure.

When the water pressure of the gate cannot be increased, there is a conflict between the gate orifice area and emptying depth, namely, as emptying depth increases, the gate orifice area can only be reduced. Concurrently, discharge volume will decrease, which may damage the gate or prevent it from opening by excess pressure. When the discharge volume is less than the incoming flow of the reservoir, the water level of the reservoir cannot continue to decrease, and it cannot be emptied. Therefore, the pressure-bearing capacity of the gate, the capacity of the gate hoist, and the water seal performance in high dam and large reservoir projects, both domestically and internationally, have reached the limits of technology. The safety design of the metal structure is a further industry technical problem facing discharge outlets.

6. Main Technical Problems Faced by Deep Venting of High Dams and Large Reservoirs

China’s Lancang River, Jinsha River, Nu River, and Yarlung Zangbo River basins are planning to build a number of 300 m high dams and large reservoirs, mostly cascade “leading” power stations in the basin. Some of the projects are located in the western frontier and minority areas, with complex political and social environments. The valleys with deep overburden and high unloading and steep slopes in the dam areas are ecologically fragile. The project area is cold, at a high altitude, and has a high seismic intensity, and the construction and operation conditions are complex. The technical difficulties of ultra-high dam construction technology, low-pressure flood discharge and energy dissipation, risk control, and emergency treatment have exceeded the scope of existing experience and specifications.

At present, the effective drawdown means of water conservancy projects are mainly to set up bottom holes, and the control equipment is a hydraulic gate. Due to the limitation of the pressure-bearing capacity of the gate and the capacity of the hoist, the drawdown facilities cannot be arranged deeper and the orifice cannot be larger, resulting in the limited drawdown depth and capacity, and the water cannot be discharged in the flood season, which cannot meet the requirements of emptying the reservoir at any time. This is a technical problem in the industry that needs to be solved urgently. However, the understanding of dam emptying at home and abroad is not uniform, and some are still quite different. On the one hand, it is suggested to set up deep drawdown facilities, which must be completely vented; on the other hand, due to the consideration of the project economy and lack of understanding of drawdown, it is recommended not to set up venting facilities. However, for ultra-high dam projects, it is necessary to set up deep drawdown facilities as an important engineering means to control complex political, social, engineering, and other risks.

To sum up, the main technical problems faced by the construction of high dam deep drawdown facilities are as follows:

(1) Determination of drawdown safety control standard: The long operation time of the high dam project, the large range of water level fluctuation, and the large discharge and flow rate will have an impact on the earth-rock dam body, the reservoir bank slope, and the rigid dam abutment and dam foundation. How to discharge water safely and quickly is the premise of studying the deep release of the high dam and large reservoir.

(2) Study of ultra-deep drawdown technology above 180 m water head: A key problem of the existing drawdown facilities is the contradiction between the drawdown depth and the discharge. The hydraulic thrust borne by the gate of the drawdown facility is proportional to the drawdown depth and the gate orifice area. With the increase in the drawdown depth being limited by the level of metal structure manufacturing technology, the hydraulic thrust borne by the gate extends to the maximum value of the current hydraulic thrust, the gate orifice area S decreases, and the discharge Q decreases. When the discharge is less than the inflow, the water increases instead of decreasing and cannot be emptied. Therefore, the first core problem to be solved for the emptying of high dams and large reservoirs is how to bear the high-water head of the gate. The development of ultra-deep drawdown technology above 180 m water head is the key to realizing the deep drawdown of high dams and large reservoirs.

(3) Study on drawdown intelligent control system: In order to realize the deep safe drawdown of high dams and large reservoirs, it is necessary to ensure the safe and stable operation of the drawdown system under various working conditions, and at the same time, it can be maintained frequently to avoid the situation that it cannot be opened when it is necessary to open. Therefore, the development of an intelligent control platform, the formation of an intelligent control process and emergency plan, and the realization of an intelligent reservoir drawdown control are important conditions to ensure the safe drawdown of high dams and large reservoirs.

(4) Drawdown effect evaluation: The effect of drawdown is directly related to the strength of the emergency response capability of high dams and large reservoirs. The traditional drawdown usually takes the drawdown depth, period, and drawdown rate as the evaluation indicators, but for different projects, the dam height is different, the inflow is different, the discharge channel is different, and the ratio of reservoir capacity to dam height is different, so it is impossible to compare the horizontal drawdown capacity based on the above three parameters. Even for the same project, only the above three parameters cannot qualitatively express the actual engineering significance of the drawdown effect on project safety, maintenance, and other aspects. Therefore, it is an important judgment basis for a safe drawdown of high dams and large reservoirs to explore the evaluation of the drawdown effect in many aspects.

(5) Risk prevention and control technology of cascade basin: On the premise that the drawdown safety of a single project can be guaranteed, the drawdown process should pay special attention to the impact of the cascade basin. Therefore, the multi-step emergency dispatching and stepwise drawdown mode of the catastrophic flood should be studied, and the stepwise drawdown time and flow technical requirements considering the impact of the cascade basin should be put forward. With the protection object of the basin as the target, a multi-objective collaborative emergency drawdown mode for cascade reservoirs is established. From the basin system level, it is an important requirement to study the risk prevention and control technology of engineering safety and coastal public safety in the process of multi-objective collaborative drawdown of cascade reservoirs and to build the risk prevention and control technology of emergency venting of high dams and large reservoirs as well as cascade reservoirs to adapt to the development of cascade basins.

7. Key Technologies to Be Solved Urgently

In the emptying facility, let the head of the pressure center of the gate be

, the cross-sectional area of the emptying facility be

, and the bulk density of water be

. Then, the water pressure on the gate is given by means of

. Ignoring the traveling head of the reservoir and considering the effects of energy loss, the constant coefficient

and structural shape coefficient as

, the discharge flow capacity is

Q [

20].

is proportional to the emptying depth

(the head of the gate pressure center is

) and the gate orifice area

. As the emptying depth increases, the gate’s water pressure F tends to

, the gate orifice area

decreases, and the discharge

decreases accordingly. When the discharge flow is lower than the incoming flow of the reservoir, the water level does not decrease but increases and the reservoir cannot be emptied. Emergency emptying capability is expressed in terms of emptying time, discharge volume, and discharge orifice area. The orifice area is the crucial factor: the larger the orifice area, the larger the discharge capacity, and the shorter the corresponding emptying time. The effectiveness of the emergency emptying response is therefore largely determined by the size of the discharge orifice. However, as we have seen, until now, discharge structures have been limited by the pressure-bearing capacity of the gate and the capacity of the hoist: the floor elevation cannot be deeper and the orifice cannot be too large. This results in limited emptying depth and discharge volume, which cannot meet any period of time. To meet the requirement of full emptying, this key technological problem urgently needs to be solved.

8. Conclusions and Outlook

The high dam and large reservoir projects have large storage capacities, high-water heads, period ring benefits, and high technical requirements for safety assurance purposes. From the perspective of long-term operation requirements, comprehensive inspection, maintenance, and reinforcement require a deeper lowering of the reservoir water level. In response to emergencies, it is necessary to have the capability of the emergency emptying reservoir water at any time. Based on a thorough investigation of the current situation of venting facilities for high dams and large reservoirs with a height of 200 m or more in the world, this paper finds that drawdown facilities currently face difficulties such as insufficient drawdown capacity, poor safety and stability of high head structures, extremely high lift hoisting equipment, and high difficulty in high head water seal technology. It is pointed out that the key technologies that need to be urgently addressed for a deep drawdown of high dams and large reservoirs are the pressure-bearing capacity of gates and the capacity limit of hoists. As a result, the elevation of the bottom plate of the drawdown building cannot be arranged, the orifice is limited, and the drawdown depth and drawdown discharge capacities are limited.

The emptying technology of high dams and large reservoirs needs to be further improved. First, it is necessary to conduct research into the formulation of relevant specifications and specify emptying capacity, emptying depth, emptying storage capacity, and emptying time. Second, limited to the particularity of the current emptying tunnel, it is difficult to design the structure under the conditions of the high-water head and large water level variation. The principle of an inverted siphon can be considered. The height of the inlet is higher than that of the outlet, and the gate position is relatively high. The water’s self-weight and the inverted siphon principle are used for emptying dams. We used the hierarchical emptying concept for arranging emptying facilities and multiple emptying tunnels. Each emptying tunnel is equipped with multi-level gates. The downstream of the gate is filled with water to reduce the total water pressure of the gate, increase the safety and stability of the structure, and reduce the difficulty of structural design. In the future, we can also break through the limits of thinking and find new ways to solve the problem of safety and emergency emptying, e.g., drawing lessons from the working principle of deep-water submarines, designing high-pressure inflatable gates, using hollow inflatable gates to resist the high-water head upstream, reducing the total water pressure of the gates, and using composite nanomaterials to make gates, increase the strength of the gates, and achieve the purpose of deep-hole water blocking and emptying.