Effect of Median Soil–Particle Size Ratio on Water Storage Capacity of Capillary Barrier

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Equipment

2.2. Experiment

3. Results and Discussion

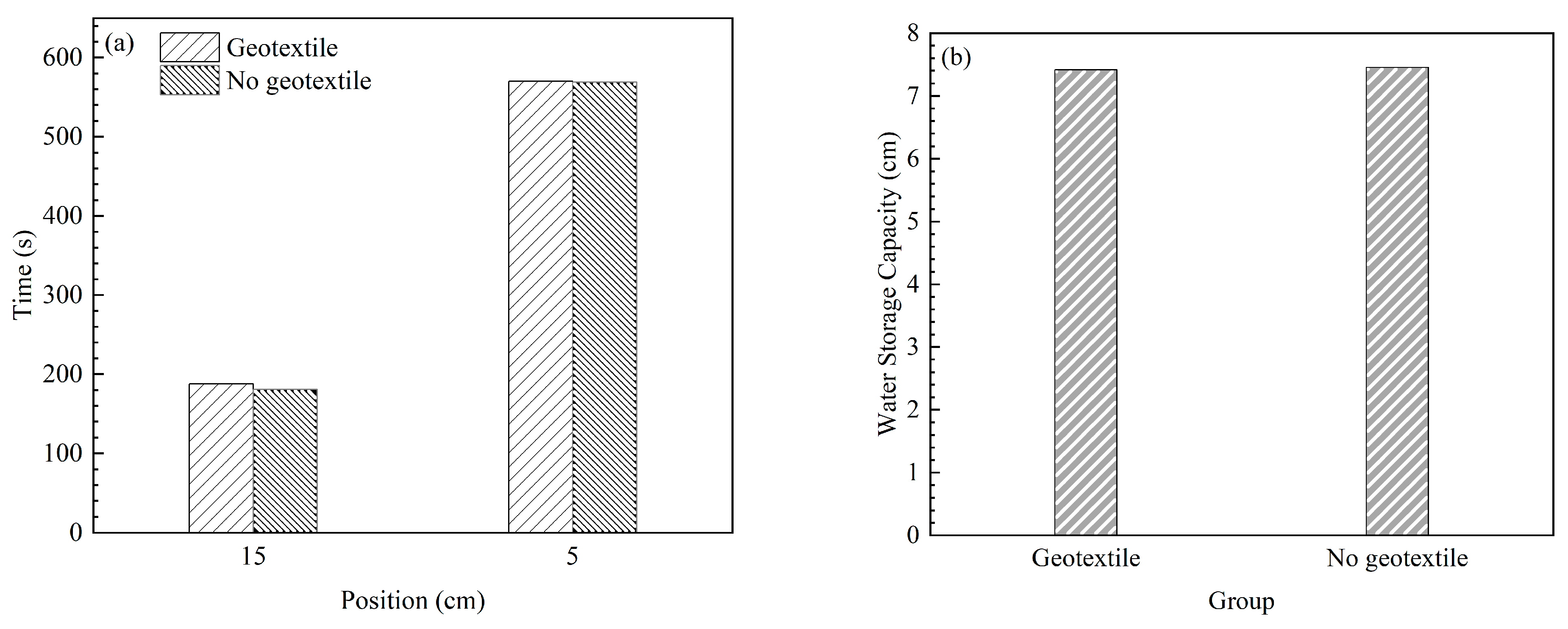

3.1. Influence of Median Soil–Particle Size Ratio on Water Storage Capacity of Capillary Barrier

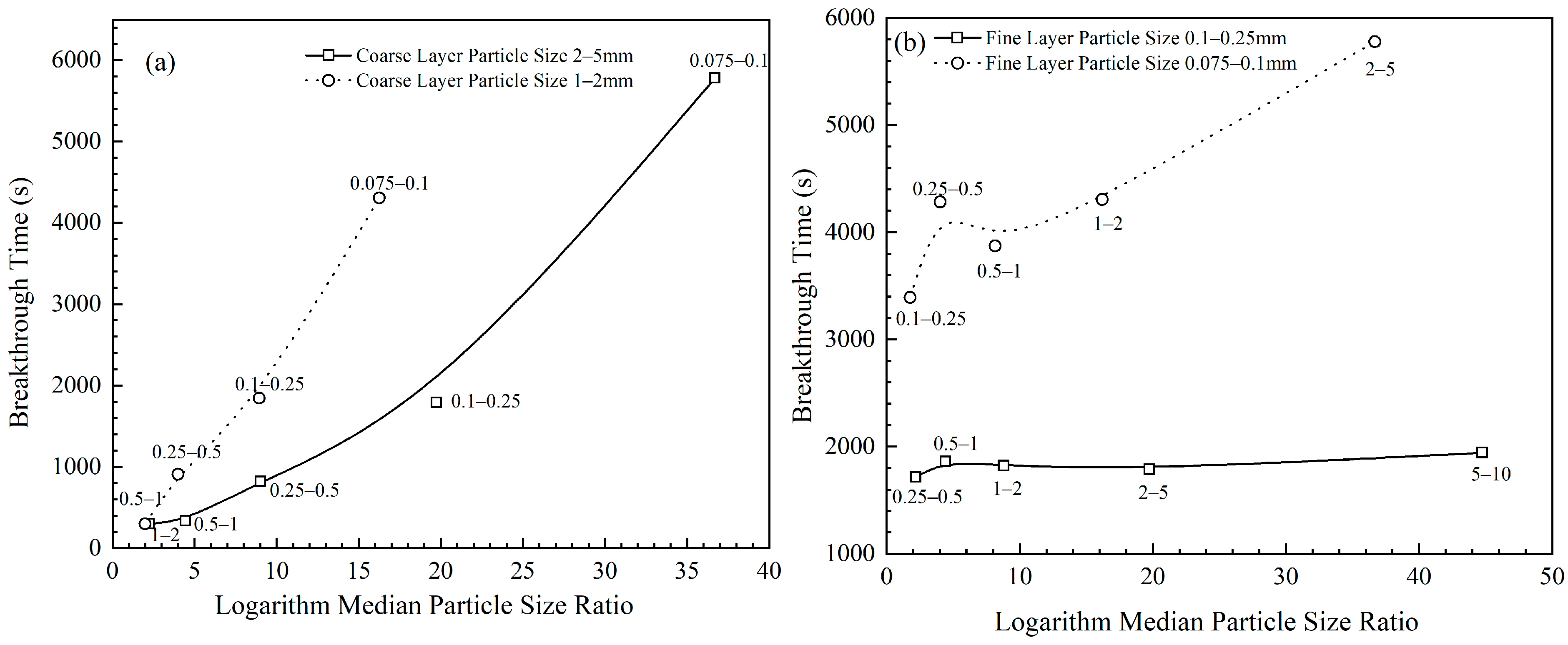

3.2. Effect of Median Soil-Particle Size Ratio on Breakthrough Time of Capillary Barrier

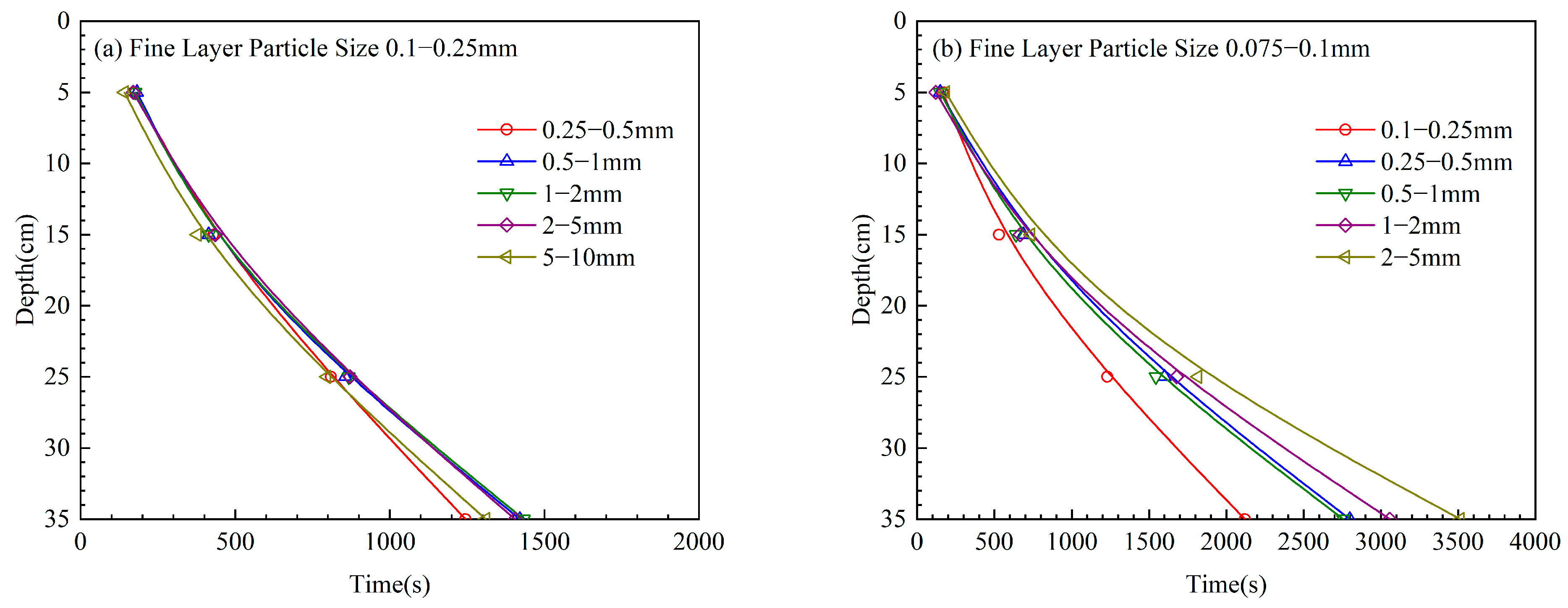

3.3. Effect of Capillary Barrier on Infiltration Rate of Fine-Grained Soil Layer

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Benson, C.H. Final covers for waste containment systems: A North American perspective. In Proceedings of the XVII Conference of Geotechnics of Torino, Control and Management of Subsoil Pollutants, Italian Geotechnical Society, Torino, Italy, 23–25 November 1999. [Google Scholar]

- Dwyer, S.F. Water Balance Measurements and Computer Simulations of Landfill Covers. Ph.D. Dissertation, The University of New Mexico, Albuquerque, NM, USA, 2003. [Google Scholar]

- Simon, F.G.; Müller, W.W. Standard and alternative landfill capping design in Germany. Environ. Sci. Policy 2004, 7, 277–290. [Google Scholar] [CrossRef]

- Forman, A.D.; Anderson, J.E. Design and performance of four evapotranspiration caps. Pract. Period. Hazard. Toxic Radioact. Waste Manag. 2005, 9, 263–272. [Google Scholar] [CrossRef]

- Hey, C.; Simms, P. Preliminary assessment of biosolids in covers with capillary barrier effects. Eng. Geol. 2021, 280, 105973. [Google Scholar] [CrossRef]

- Al-Mayahi, A.; Al-Ismaily, S.; Al-Maktoumi, A.; Al-Busaidi, H.; Imnek, J. A smart capillary barrier-wick irrigation system for home gardens in arid zones. Irrig. Sci. 2020, 38, 235–250. [Google Scholar] [CrossRef]

- Menezes-Blackburn, D.; Al-Ismaily, S.; Al-Mayahi, A.; Al-Siyabi, B.; Al-Kalbani, A.; Al-Busaid, H.; Al-Naabi, I.; Al-Mazroui, M.; Al-Yahyai, R. Impact of a nature-inspired engineered soil structure on microbial diversity and community composition in the bulk soil and rhizosphere of tomato grown under saline irrigation water. J. Soil Sci. Plant Nutr. 2021, 21, 173–186. [Google Scholar] [CrossRef]

- Noguchi, K.; Saito, H.; Saefuddin, R.; Šimůnek, J. Evaluation of Subsurface Drip Irrigation Designs in a Soil Profile with a Capillary Barrier. Water 2021, 13, 1300. [Google Scholar] [CrossRef]

- Rahardjo, H. Application of unsaturated soil mechanics in capillary barrier system. In Proceedings of the 3rd Asian Conference on Unsaturated Soils, Nanjing, China, 21–23 April 2007. [Google Scholar]

- Satyanaga, A.; Zhai, Q.; Rahardjo, H.; Gitirana, G.d.F.N., Jr.; Moon, S.-W.; Kim, J. Performance of capillary barrier as a sustainable slope protection. In Proceedings of the 3rd Pan-American Conference on Unsaturated Soils, Rio de Janeiro, Brazil, 26–28 July 2021. [Google Scholar]

- Guo, G.; Araya, K.; Jia, H.; Zhang, Z.; Ohomiya, K.; Matsuda, J. Improvement of Salt-Affected Soils, Part 1: Interception of Capillarity. Biosyst. Eng. 2006, 94, 139–150. [Google Scholar] [CrossRef]

- Chavez-Garcia, E.; Christina, S. Rehabilitation of a highly saline-sodic soil using a rubble barrier and organic amendments. Soil Tillage Res. 2019, 189, 176–188. [Google Scholar] [CrossRef]

- Selker, J. Design of interface shape for protective capillary barriers. Water Resour. Res. 1997, 33, 259–260. [Google Scholar] [CrossRef]

- Stormont, J.C.; Anderson, C.E. Capillary barrier effect from underlying coarser soil layer. J. Geotech. Geoenvironmental Eng. 1999, 125, 641–648. [Google Scholar] [CrossRef]

- Khire, M.V.; Benson, C.H.; Bosscher, P.J. Capillary barriers: Design variables and water balance. J. Geotech. Geoenvironmental Eng. 2000, 126, 695–708. [Google Scholar] [CrossRef]

- Fala, O.; Molson, J.; Aubertin, M.; Bussiere, B. Numerical modelling of flow and capillary barrier effects in unsaturated waste rock piles. Mine Water Environ. 2005, 24, 172–185. [Google Scholar] [CrossRef]

- Parent, S.E.; Cabral, A. Design of Inclined Covers with Capillary Barrier Effect. Geotech. Geol. Eng. 2006, 24, 689–710. [Google Scholar] [CrossRef]

- Smagin, A.V.; Khakimova, G.M.; Khineeva, D.A.; Sadovnikova, N.B. Gravity factor of the formation of the field and capillary water capacities in soils and artificial layered soil-like bodies. Eurasian Soil Sci. 2008, 41, 1189–1197. [Google Scholar] [CrossRef]

- Qian, T.; Huo, L.; Zhao, D. Laboratory investigation into factors affecting performance of capillary barrier system in unsaturated soil. Water Air Soil Pollut. 2010, 206, 295–306. [Google Scholar] [CrossRef]

- Li, J.H.; Du, L.; Chen, R.; Zhang, L.M. Numerical investigation of the performance of covers with capillary barrier effects in south china. Comput. Geotech. 2013, 48, 304–315. [Google Scholar] [CrossRef]

- Walter, M.T.; Kim, J.S.; Steenhuis, T.S.; Parlange, J.Y.; Heilig, A.; Braddock, R.D. Funneled flow mechanisms in a sloping layered soil: Laboratory investigation. Water Resour. Res. 2000, 36, 841–849. [Google Scholar] [CrossRef]

- Tami, D.; Rahardjo, H.; Leong, E.C.; Fredlund, D.G. Design and laboratory verification of a physical model of sloping capillary barrier. Can. Geotech. J. 2004, 41, 814–830. [Google Scholar] [CrossRef]

- Chen, R.; Liu, J.; Ng, C.; Chen, Z.K. Influence of slope angle on water flow in a three-layer capillary barrier soil cover under heavy rainfall. Soil Sci. Soc. Am. J. 2019, 83, 1637–1647. [Google Scholar] [CrossRef]

- Aubertin, M.; Cifuentes, E.; Martin, V.; Apithy, S.; Maqsoud, A. An investigation of factors that influence the water diversion capacity of inclined covers with capillary barrier effects. In Unsaturated Soils 2006; American Society of Civil Engineers: Reston, VA, USA, 2006. [Google Scholar]

- Tojo, Y.; Tanaka, N.; Matsuto, T.; Matsuo, T. An application of capillary barrier as a leachate drainage system at bottom of landfill. numerical analysis. Proc. Jpn. Soc. Civ. Eng. 2010, 692, 53–62. [Google Scholar]

- Gong, Z.; Huang, Y.; Zhou, C.; Wang, L.; Tan, C. Influence of temperature change on the diversion of CCBE layer. J. Water Resour. Archit. Eng. 2019, 17, 125–130+142. [Google Scholar]

- Lipiec, J.; Wójciga, A.; Horn, R. Hydraulic properties of soil aggregates as influenced by compaction. Soil Tillage Res. 2009, 103, 170–177. [Google Scholar] [CrossRef]

- Scott, N.A.; Cole, C.V.; Elliott, E.T.; Huffman, S.A. Soil Textural Control on Decomposition and Soil Organic Matter Dynamics. Soil Sci. Soc. Am. J. 1996, 60, 1102–1109. [Google Scholar] [CrossRef]

- Baker, R.S.; Hillel, D. Laboratory tests of a theory of fingering during infiltration into layered soils. Soil Sci. Soc. Am. J. 1990, 54, 20–30. [Google Scholar] [CrossRef]

- Morris, C.E.; Stormont, J.C. Parametric study of unsaturated drainage layers in a capillary barrier. J. Geotech. Geoenvironmental Eng. 1999, 125, 1057–1065. [Google Scholar] [CrossRef]

- Zhan, L.T.; He, L.; Jia, G.W.; Chen, Y.M.; Fredlund, D.G. Physical and numerical study of lateral diversion by three-layer inclined capillary barrier covers under humid climatic conditions 1. Can. Geotech. J. 2014, 51, 1438–1448. [Google Scholar] [CrossRef]

- Ng, C.; Coo, J.L.; Chen, Z.K.; Chen, R. Water infiltration into a new three-layer landfill cover system. J. Environ. Eng. 2016, 142, 04016007. [Google Scholar] [CrossRef]

- Smesrud, J.K.; Selker, J.S. Effect of soil-particle size contrast on capillary barrier performance. J. Geotech. Geoenvironmental Eng. 2001, 127, 885–888. [Google Scholar] [CrossRef]

- Apambilla, A.J.; Pax, C.L.; Abdul, A.M. Capillary cut design for soil-groundwater salinity control. J. Fac. Environ. Sci. Technol. Okayama Univ. 2009, 14, 17–22. [Google Scholar]

- ASTM D7263-2009(R2018); Standard Test Methods for Laboratory Determination of Density (Unit Weight) of Soil Specimens. ASTM International: West Conshohocken, PA, USA, 2009.

- ASTM D854-2014; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2014.

- Stormont, J.C.; Morris, C.E. Method to estimate water storage capacity of capillary barriers. J. Geotech. Geoenvironmental Eng. 1998, 124, 297–302. [Google Scholar] [CrossRef]

- Liu, Q.; Xi, P.; Miao, J.; Li, X.; Wang, K. Applicability of wetting front advancing method in the sand to silty clay soils. Soils Found. 2020, 60, 1215–1225. [Google Scholar] [CrossRef]

| Sand Diameter (mm) | Specific Gravity | Maximum Compaction Density (g/cm3) | Saturated Hydraulic Conductivity (cm/s) | Porosity |

|---|---|---|---|---|

| <0.075 | 2.80 | 1.66 | 2.11 × 10−4 | 0.408 |

| 0.075–0.1 | 2.77 | 1.56 | 3.16 × 10−3 | 0.439 |

| 0.1–0.25 | 2.88 | 1.57 | 4.39 × 10−3 | 0.454 |

| 0.25–0.5 | 2.68 | 1.57 | 4.11 × 10−2 | 0.416 |

| 0.5–1 | 2.64 | 1.57 | 1.69 × 10−1 | 0.408 |

| 1–2 | 2.63 | 1.56 | 3.61 × 10−1 | 0.406 |

| 2–5 | 2.64 | 1.65 | 1.43 | 0.378 |

| Number | Coarse Quartz Sand Grade/mm | Fine Quartz Sand Grade/mm | Median Soil-Particle Size Ratio |

|---|---|---|---|

| XLC1 | 2–5 | 1–2 | 2.24 |

| XLC2 | 0.5–1 | 4.45 | |

| XLC3 | 0.25–0.5 | 9.03 | |

| XLC4 | 0.1–0.25 | 19.75 | |

| XLC5 | 0.075–0.1 | 36.7 | |

| XLC6 | 1–2 | 0.5–1 | 2 |

| XLC7 | 0.25–0.5 | 3.99 | |

| XLC8 | 0.1–0.25 | 8.95 | |

| XLC9 | 0.075–0.1 | 16.25 | |

| CLC1 | 0.25–0.5 | 0.1–0.25 | 2.19 |

| CLC2 | 0.5–1 | 4.44 | |

| CLC3 | 1–2 | 8.81 | |

| CLC4 | 2–5 | 19.75 | |

| CLC5 | 5–10 | 44.75 | |

| CLC6 | 0.1–0.25 | 0.075–0.1 | 1.78 |

| CLC7 | 0.25–0.5 | 4.02 | |

| CLC8 | 0.5–1 | 8.16 | |

| CLC9 | 1–2 | 16.20 | |

| CLC10 | 2–5 | 36.70 | |

| JZT1 | 2–5 | 2–5 | 1 |

| JZT2 | 1–2 | 1–2 | |

| JZT3 | 0.5–1 | 0.5–1 | |

| JZT4 | 0.25–0.5 | 0.25–0.5 | |

| JZT5 | 0.1–0.25 | 0.1–0.25 | |

| JZT6 | 0.075–0.1 | 0.075–0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Dong, J.; Liu, Q.; Geng, L.; Wang, Z.; Sun, C. Effect of Median Soil–Particle Size Ratio on Water Storage Capacity of Capillary Barrier. Water 2024, 16, 1774. https://doi.org/10.3390/w16131774

Liu H, Dong J, Liu Q, Geng L, Wang Z, Sun C. Effect of Median Soil–Particle Size Ratio on Water Storage Capacity of Capillary Barrier. Water. 2024; 16(13):1774. https://doi.org/10.3390/w16131774

Chicago/Turabian StyleLiu, Honghua, Jie Dong, Qiang Liu, Lin Geng, Zhongsheng Wang, and Chong Sun. 2024. "Effect of Median Soil–Particle Size Ratio on Water Storage Capacity of Capillary Barrier" Water 16, no. 13: 1774. https://doi.org/10.3390/w16131774