Abstract

As industrialization and urbanization accelerate, the quality of the water environment has been deteriorating, and pollution from novel pollutants (ECs), such as microplastics, pharmaceutical residues, and endocrine disruptors, has become increasingly prominent. Although the concentration of these new pollutants in the environment is very low, they pose a long-term cumulative threat to human health and ecosystem security because of their persistent and difficult-to-degrade properties. This paper reviews the treatment technologies for novel pollutants such as microplastics, pharmaceutical residues, and endocrine disruptors, including physical (e.g., sand filtration, adsorption, membrane separation), chemical (e.g., flocculation, advanced oxidation, photocatalysis), and biological (e.g., microbial degradation) methods. The various technologies’ advantages, disadvantages, and application statuses are analyzed, and future research directions and challenges are presented.

1. Introduction

With the acceleration of industrialization and urbanization, the quality of the water environment is deteriorating, and pollution by emerging contaminants (ECs) such as microplastics, pharmaceutical residues, and endocrine disruptors is increasingly prominent. It is estimated that globally, 3.5 million tons of various active ingredients will be used in agriculture in 2021, with over 100,000 different commercial formulations available on the market, despite the presence of more than 1680 unique active ingredients [1]. These pesticides enter aquatic ecosystems through a variety of pathways, leading to widespread contamination of freshwater ecosystems globally [1,2,3]. Compared to conventional pollutants such as chemical oxygen demand (COD), nitrogen, and phosphorus in sewage, the concentration of these new pollutants is very low (ng/L). However, their persistence and difficulty in degrading results in a long-term cumulative impact on human health and ecosystem security. These new pollutants also have a certain degree of biotoxicity, posing unpredictable hazards due to their long-term accumulation [4,5]. Each year, more than 9 million people die from exposure to contaminated food, water, workplace, or consumer products, among other contaminants, including microplastics, antibiotics, drugs, endocrine disruptors, and chemicals [6].

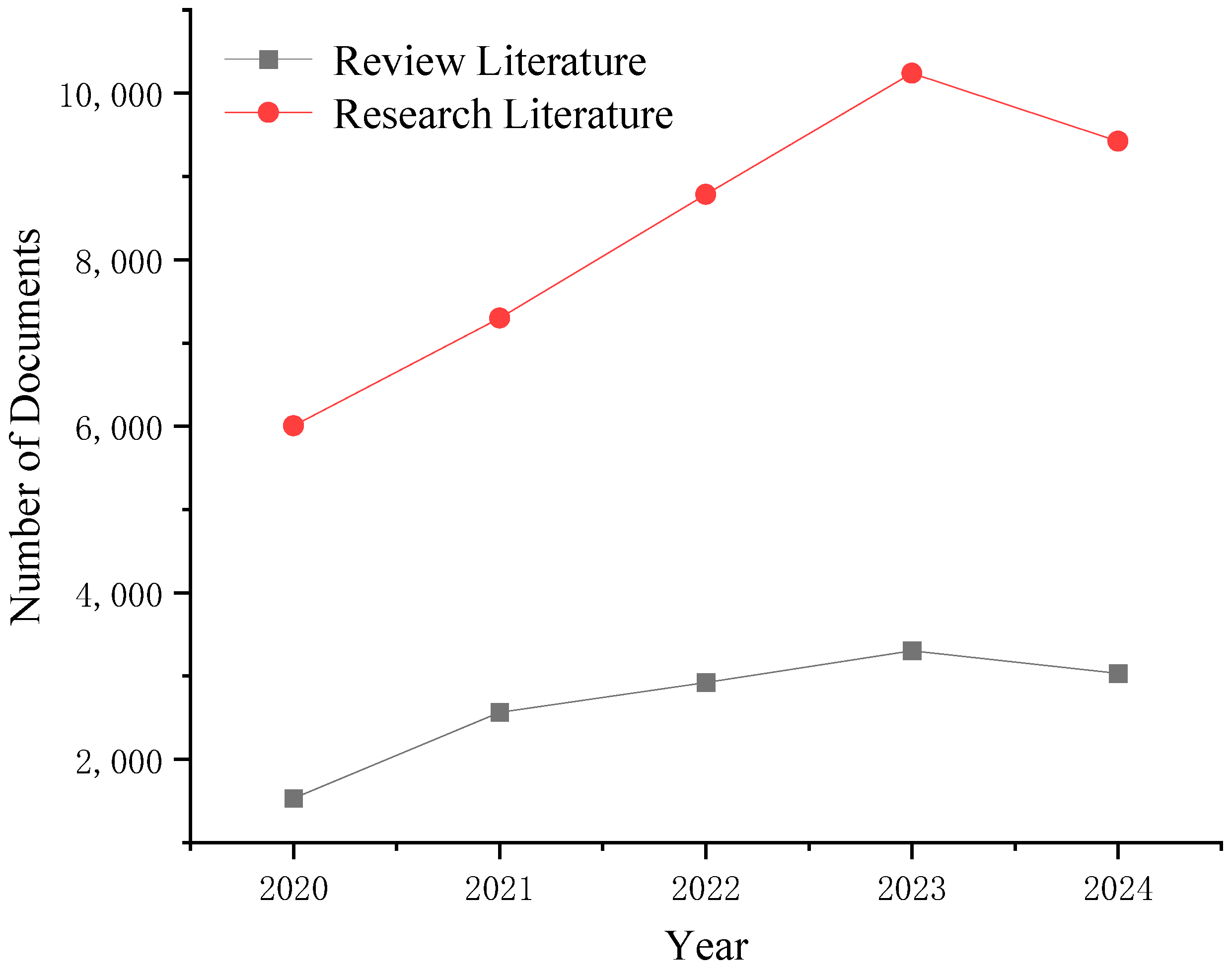

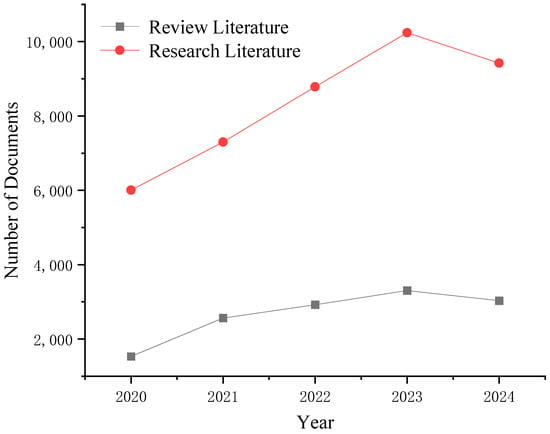

A study by Guimarães et al. on zebrafish larvae found that microplastics can damage neural tissue and cause metabolic imbalances [7]. Lu et al.’s study on human umbilical vein epithelial cells revealed that 500 nm microplastics can effectively interact with cell membranes, causing damage, while 100 nm microplastics not only cause cell membrane damage but also induce autophagosome formation and disrupt autophagic flow [8]. Therefore, studying new pollutants is crucial for environmental protection and public health maintenance. Statistics from the ScienceDirect core collection database show that the number of articles on new pollutants has been increasing over the past five years, as illustrated in Figure 1.

Figure 1.

Trends of the number of reviews and research papers on emerging contaminants published in the last 5 years.

Everyday activities and industrial production continually generate new types of pollutants that are widespread in surface water and sediments and can even be detected in drinking water. These new pollutants negatively impact aquatic organisms. To minimize the introduction of these pollutants into the environment, wastewater treatment plants play a crucial role. Consequently, studying emerging pollutant water treatment technology not only provides technical references for wastewater treatment facilities but also holds great significance for the protection of water environments and human health. This paper will summarize the current research status of emerging pollutant water treatment technologies, offering reference guidance for researchers conducting new pollutant removal studies and proposing future research directions and challenges.

2. Water Treatment Technologies for Microplastics

Microplastics (MPs) with particle sizes smaller than 5 mm are considered new pollutants in the environment [9,10], primarily originating from sources such as the weathering abrasion of plastic items and the release of plastic particles from personal care products. MP contamination is widespread, reaching all corners of the world, including inhospitable polar environments [11,12,13,14]. The aquatic environment is the primary host area for MPs, and various levels of MPs have been found in different river water quality surveys: 3670–10,700 MPs/m3 in the Wei River in northwestern China [15], 19,860 MPs/m3 and 8902 MPs/m3 in the urban part of the Pearl River Basin in the southern part of the country and its estuary, respectively [16], 13.33–113.33 MPs/m3 in the Cisadane River in Indonesia [17], and an average of (400 ± 270) MPs/m3 in the Goulburn River Basin in Australia [18]. Under the influence of COVID-19, the widespread use of epidemic prevention supplies, such as masks, may lead to the introduction of more MPs into environmental waters [19,20], exacerbating the critical situation of MP pollution prevention and control. Due to their small size, large quantity, and difficulty degrading, microplastics can easily be ingested by organisms, retained within them, enriched, and cause harm. Polystyrene (PS) microplastics, once ingested, can enter the bloodstream, leading to the clogging and damage of blood vessels and posing risks to organs such as the heart [21]. The ingestion of high concentrations of polyethylene (PE) microplastics can directly induce inflammation in the intestinal tract [22], and the leaching of toxic additives, such as plasticizers and flame retardants, can further poison the organism [23]. In addition, microplastics’ large specific surface area and hydrophobicity enable them to carry and transport heavy metals, persistent organic pollutants (POPs), and pathogens from the environment, which can make them more potentially hazardous when ingested [24,25]. Due to their transmission and enrichment through the food chain, the risks posed to organisms by microplastics will continue to spread and intensify. Consequently, scholars are increasingly refining the risk assessment of the dangers of environmental microplastics to living organisms. It is acknowledged that research into microplastic treatment technology is of significant theoretical and practical importance. Table 1 presents a comparison of the existing treatment techniques and their respective advantages and disadvantages.

Table 1.

Advantages and disadvantages of microplastic water treatment technologies.

2.1. Physical Methods

2.1.1. Sand Filtration

Sand filtration is a process that involves the separation of suspended particles and colloids from water using a layer of particle-based media such as quartz sand. This method is typically employed following coagulation and sedimentation to further eliminate suspended solids and is considered part of the advanced treatment process. Compared with coagulation and sedimentation, sand filtration showed better removal of MPs, but its removal efficiency is closely correlated with the size of MPs, and sand filtration systems can remove 70~80% or more of MPs larger than 20 μm, and the removal efficiency of MPs smaller than 20 μm is limited, which leads to the escape of some MPs from the sand filtration system [27,38,39]. Research [26] has indicated that the sand filtration process, when used independently, is relatively inefficient at removing 100 nm polystyrene (PS) particles, achieving a removal efficiency of only 54.3%. However, the incorporation of an activated carbon filtration step following sand filtration significantly enhances the removal efficiency of PS to 73.9%. This suggests that for the effective removal of small-sized microplastics (MPs), relying solely on sand filtration is not sufficient, and it must be combined with other techniques to achieve optimal results. The migration of MPs in quartz sand is limited by the surface charge of the sand grains and water conditions (ionic strength, pH, and dissolved organic matter, etc.), e.g., the negatively charged surface of unmodified PS will produce electrostatic repulsion with negatively charged quartz sand, increasing the mobility; whereas, the surface of the quartz sand coated with Fe/Al hydroxide has reduced electronegativity and decreased electrostatic repulsion, and the PS is more likely to be immobilized on the surface of the sand, resulting in a decrease in mobility [40]. In terms of water quality conditions, as the ionic strength increases, the migration ability of PS decreases. This is because a large number of cations and anions in the solution compress the electrostatic double layer on the surface of both PS and quartz sand. Consequently, the zeta potential on their surface decreases, leading to a reduction in electrostatic repulsive forces and a decrease in the height of the energy barrier. As a result, it becomes easier for PS to overcome these barriers and remain on the surface of the sand grains. Additionally, with the increase in pH or the presence of dissolved organic matter, such as fulvic acid, in the solution, the negative charge on the surface of PS and sand increases. This results in an increase in electrostatic repulsive forces and an elevation of the energy barriers, making it more difficult for PS to break through the potential barriers and, consequently, harder to be retained on the surface of sand grains [41]. The study of these adsorption mechanisms is crucial for improving the sand filtration process and enhancing its ability to remove MPs.

2.1.2. Adsorption

Adsorption is widely utilized for the removal of MPs due to its advantages of low cost and ease of operation. The selection of an adsorbent is key to determining adsorption efficiency, and the quest for low-cost, efficient, and recyclable adsorbent materials has been a prominent research topic.

Activated carbon has become a commonly used adsorption material in water treatment due to its advantages of low cost, large specific surface area, and stable chemical properties. Arenas et al. [42] investigated the removal of 80 nm PS particles using granular coconut shell activated carbon (GAC) as the adsorbent. The maximum adsorption capacity of PS by GAC in ultrapure water at pH 7.4 ± 0.1 after 240 min was determined to be (2.20 ± 0.06) mg/g. The amount of PS adsorbed increased with the initial concentration of PS. However, in real lake water, the maximum adsorption capacity was significantly higher, reaching (6.33 ± 0.20) mg/g. This is because the adsorption mechanism of GAC primarily involves electrostatic attraction between the positively charged PS particles, which contain amidinium-based functional groups, and the negatively charged surface of GAC. Additionally, the natural organic matter present in lake water can alter the surface potential of PS, thereby changing the extent of adsorption. This also suggests that the impact of co-existing ions in actual ambient waters should be considered when studying removal efficiency. Zhu et al. [43] prepared mesoporous biochar from corn cobs for PS removal, achieving a maximum adsorption capacity of 56.02 mg/g. After five cycles, the adsorption capacity remained at 45 mg/g, demonstrating both reproducibility and cost-effectiveness. Further research is needed to optimize the utilization of activated carbon’s adsorption properties in conjunction with real-world environmental conditions to enhance the removal of MPs.

Several biocompatible adsorbent materials are being developed, and their primary adsorption mechanisms include electrostatic interactions, hydrogen bonding, and π–π interactions. Sun et al. [44] modified chitin-based sponges with graphene oxide, oxygen-doped carbon nitride, and chitosan to create sponges with good mechanical properties and elasticity. These sponges achieved removal efficiencies as high as 71.6–92.1% for 1 μm PS, carboxyl-modified PS, and amine-modified PS at pH 6–8. Additionally, the sponges maintained their adsorption efficiency after being rinsed with ethanol and lyophilized for recycling, indicating their potential for reuse. Notably, chitin-based sponges are biocompatible and biodegradable, classifying them as green adsorbent materials. Similarly, Zheng et al. [45] prepared dopamine-enhanced magnetic chitosan (PDA-MCS) aerogels, inspired by coral adhesion to MPs. These aerogels achieved removal efficiencies of 97.3%, 94.6%, and 92.3% for polyethylene terephthalate (PET), PE, and PS, respectively, in river water. Even after three cycles, the PDA-MCS aerogel maintained a high removal efficiency of 83.4%. The pursuit of green and efficient adsorbent materials is a significant research direction for the future.

Magnetic separation technology is a specialized adsorption separation technique that involves using magnetic nanoparticles with a larger surface area and more adsorption sites as adsorbents to capture MPs in water, followed by the removal of MPs and recovery of magnetic materials under the influence of an applied magnetic field. This technology has been studied extensively due to its high removal efficiency and the ease with which the magnetic materials can be recovered. Tang et al. [46] prepared magnetic carbon nanotubes (M-CNTs) capable of removing up to 100% of 48 μm PET, PE, and polyamide (PA), with maximum adsorption capacities reaching 1650, 1400, and 1100 mg/g, respectively. When applied to real wastewater, M-CNTs can achieve 100% removal efficiency of MPs, and the efficiency remains above 80% after four uses, which positions them as a very promising adsorption material. Wang et al. [47] synthesized magnetic biochar (MBC), magnesium-modified magnetic biochar (Mg-MBC), and zinc-modified magnetic biochar (Zn-MBC) as adsorbents, utilizing biochar as the base material. These adsorbents exhibited removal efficiencies of 94.81%, 98.75%, and 99.46% for PS particles (1 μm, 100 mg/mL) for MBC, Mg-MBC, and Zn-MBC, respectively, which were considerably superior to the efficiency of the unmodified biochar (25.89%). Even after undergoing five adsorption–pyrolysis cycles, the removal efficiencies of MPs by MBC, Mg-MBC, and Zn-MBC retained their high levels at 95.02%, 94.60%, and 95.79%, respectively. Shi et al. [29] developed magnetic seafoam for the removal of 48 μm PE, achieving a removal efficiency of up to 98.4%. The magnetic seafoam was recyclable under an appropriate magnetic field, and after five cycles, the removal efficiency of PE remained above 90%. Hamzah et al. [48] developed a ferromagnetic fluid by mixing lubricating oil with magnetite. This fluid was thoroughly mixed with 2 mm PET particles and then separated using neodymium magnets, achieving a removal efficiency of up to 99%. However, when applied to actual laundry wastewater, the removal efficiency decreased to 64%. This demonstrates that while magnetic adsorbent materials have excellent potential for removing MPs and are easy to recover and reuse, their efficiency may be influenced by the conditions of the water environment during practical applications. Therefore, it is necessary to investigate more efficient magnetic adsorbent materials tailored to specific local conditions. The mechanisms through which magnetic adsorbent materials act on different types of MPs vary. For example, the adsorption of M-CNTs onto PE primarily relies on the strong hydrophobicity of PE, whereas the adsorption onto PET is mainly due to hydrophobic interactions and π–π electron conjugation. In the case of PA, adsorption is a result of a combination of π–π electron interactions, complexation, electrostatic interactions, and hydrogen bonding interactions [46]. As another example, the adsorption mechanism of PS by ferric ion-modified fly ash involves the material’s complex pore structure, electrostatic attraction, complexation, and π–π interactions [49]. Therefore, selecting appropriate magnetic materials based on the characteristics of different MPs could optimize the removal effect. Additionally, the removal efficiency of MPs can be further improved by combining different removal techniques. By combining the degradation technique with the magnetic separation technique, the PET enzyme immobilized on Fe3O4 nanoparticles effectively degraded PET. This resulted in an increase in the degradation efficiency by nearly 80% compared to ordinary PET enzyme, and the synthesized enzyme retained about 50% of its initial activity after 10 cycles [50]. This coupling technology leverages the environmental friendliness of biodegradation and the recyclability of magnetic separation, effectively addressing the low biodegradation efficiency issue; thus it holds great research promise.

2.1.3. Membrane Separation

Membrane separation technology involves the use of a semi-permeable membrane to separate suspended particles and colloidal substances from water. This process is a part of the advanced treatment stage in water treatment plants and is known for its low energy consumption, straightforward process, and effective removal of microplastics. The effectiveness of membrane separation technology for removing MPs is influenced by several key factors, including the membrane’s characteristics (material, thickness, pore size, and surface properties) and the particle size and shape of the plastic [51]. The larger the particle size, the higher the removal efficiency, as larger particles can deposit on the membrane surface, leading to the blockage of pores and thus enhancing the removal efficiency of microplastics [52]. Conversely, compared to granular and membrane microplastics, fibrous microplastics can more easily penetrate the membrane due to their smaller cross-sectional area [53]. Common membrane separation technologies include microfiltration (MF), ultrafiltration (UF), and membrane bioreactor (MBR). MF and UF are widely employed to remove colloidal substances, macromolecules of organic matter, and algae. The pore size of the membranes typically ranges around 0.1 μm, which enables effective removal of microplastics from water. Pranmanik et al. [52] reported that MF and UF achieved removal efficiencies of 91% and 96%, respectively, for microplastics larger than 75 μm. Tadsuwan et al. [54] studied the removal of microplastics (with particle sizes ranging from 0.05 to 5 mm) through various processes in a wastewater treatment plant in Thailand. They found that the overall removal efficiency of the conventional process was 86.14%. With the addition of an ultrafiltration (UF) unit, the removal efficiency increased to 96.97%. However, despite the small pore size of the UF membrane, microplastics with particle sizes between 0.05 and 0.5 mm were still present in the effluent. MBR is a novel wastewater treatment process that integrates membrane technology with biological treatment. It is primarily used to remove organic matter and ammonia nitrogen from water but has also demonstrated a good removal effect on microplastics. In laboratory settings, MBR can remove over 95% of microplastics larger than 0.1 mm [55,56]. In a real water treatment plant, the removal efficiency of MPs larger than 1 mm was 79.01% [57]. When combined with UF technology, the removal efficiency of MPs larger than 0.1 mm can exceed 99% [56]. Membrane contamination poses a significant challenge in membrane separation technology [30]. The presence of microplastics accelerates the rate of membrane fouling, primarily due to the blockage of membrane pores by microplastics or the formation of a microplastic cake layer [58]. The presence of microplastics smaller than 10 μm can lead to a decrease in the membrane flux of MF and UF membranes, impacting the efficiency of membrane operation [59]. Backwashing is a critical step in restoring the membrane’s filtration capacity, and chemical cleaning is a commonly employed backwashing method. However, prolonged chemical cleaning can degrade the performance of the UF membrane, and the aging of the membrane can result in the release of microplastics, which in turn can affect the quality of the effluent water [60].

2.2. Chemical Methods

2.2.1. Coagulation

Coagulation is a prevalent water purification process employed in water and wastewater treatment plants, encompassing both condensation and flocculation processes. The efficiency of MP removal during the coagulation process is influenced by factors such as the type and dosage of flocculant, the particle size of MPs, pH, and temperature. Existing coagulation and sedimentation processes in wastewater plants and waterworks do not entirely eliminate small-scale MPs and nanoplastics [61]. Under laboratory coagulation conditions, the removal efficiency of PS particles larger than 500 μm is above 90%, while the removal efficiency of PS particles smaller than 500 μm is only 60% [62]. Even after optimizing coagulation conditions, MPs smaller than 5 μm remain challenging to remove [63]. Zhang et al. [61] investigated the removal efficiency of the coagulation process for MPs ranging in size from 0.18 to 125 μm by simulating the coagulation conditions of a typical water plant in Michigan. They found that the removal efficiency was less than 2.0% without the addition of a coagulant. Even with the addition of a coagulant, the highest removal efficiency was only achieved for particles with sizes ranging from 45 to 53 μm (16.5%). Ma et al. [31] investigated the efficacy of coagulation in removing PE microplastics under neutral pH conditions. The conventional coagulation process yielded disappointing results. In a simulated experiment, adding 2 mmol/L of iron salt (FeCl3·6H2O) failed to effectively precipitate some microplastic particles, as they were not adequately captured by the formed flocs. Consequently, the removal efficiency of microplastics with diameters below 0.5 mm was only (13.27 ± 2.19)%. In contrast, the addition of 15 mg/L of anionic polyacrylamide significantly enhanced floc stability and density through electrostatic interactions caused by the opposite charge of the anionic polyacrylamide and iron-based flocs. Under these optimized conditions, the removal efficiency of microplastics increased dramatically to (90.91 ± 1.01)%.

Electroflocculation is a technology that uses the anode metal electrode to produce metal cation flocculants under the influence of an electric field. These flocculants combine with suspended particles in water to form flocs, which help retain the suspended solid particles. This technology is primarily employed in industrial wastewater treatment. The electroflocculation mechanism is composed of three stages: (1) the dissolution of the anode, primarily aluminum and iron, under the electric field to generate metal cations; (2) the hydrolysis of these metal cations to produce hydroxides, which act as flocculants and form microflocs with suspended pollutant particles; and (3) the electrolysis of water to produce H2 gas at the cathode, allowing lighter and heavier flocs to be separated by flotation and precipitation, respectively. The reactions involved are as follows [64]:

| Anode: | M—ne− | → | Mn+ | (1) |

| Mn+ (aq) + nOH− (aq) | → | M(OH)n (s) | (2) | |

| Cathode: | 2H2O (l) + 2e− | → | H2 (g) + 2OH− | (3) |

| 2H+ + 2e− | → | H2 | (5) |

William et al. [65] were the first to apply electroflocculation for the removal of microplastics. They removed microplastics from simulated wastewater using Al electrodes in a bipolar parallel configuration and investigated the effects of pH, conductivity, and current density on the removal effect. The results revealed that the removal efficiency exceeded 90% under all simulated conditions, with the highest removal efficiency achieved at pH = 7.5, NaCl concentration of 2 g/L, and current density of 11 A/m2. This method is effective for removing microplastics. Compared to Fe electrodes, Al electrodes produce flocs with smaller particle sizes and larger specific surface areas that are more suitable for removing microplastics due to their rapid floc formation and strong adsorption capacity. Furthermore, the removal efficiency of fibrous microplastics was significantly higher than that of granular microplastics, as the particle size and density of fibrous microplastics are generally larger, making them easier to capture by the flocs [66].

The advantages of electroflocculation technology over conventional chemical coagulation, which does not require the addition of chemicals like aluminum sulfate or ferric chloride, are its more environmentally friendly and efficient nature, its low sludge volume, its transferability, and its replicability in both laboratory and industrial settings. However, the cost of electrical energy consumption is also a challenge in the commercial application of the electrocoagulation process, which increases the operating cost of electrocoagulation. Additionally, electrode contamination can sometimes occur during electrocoagulation due to prolonged electrolysis time, which needs to be optimized to reduce power and electrode consumption.

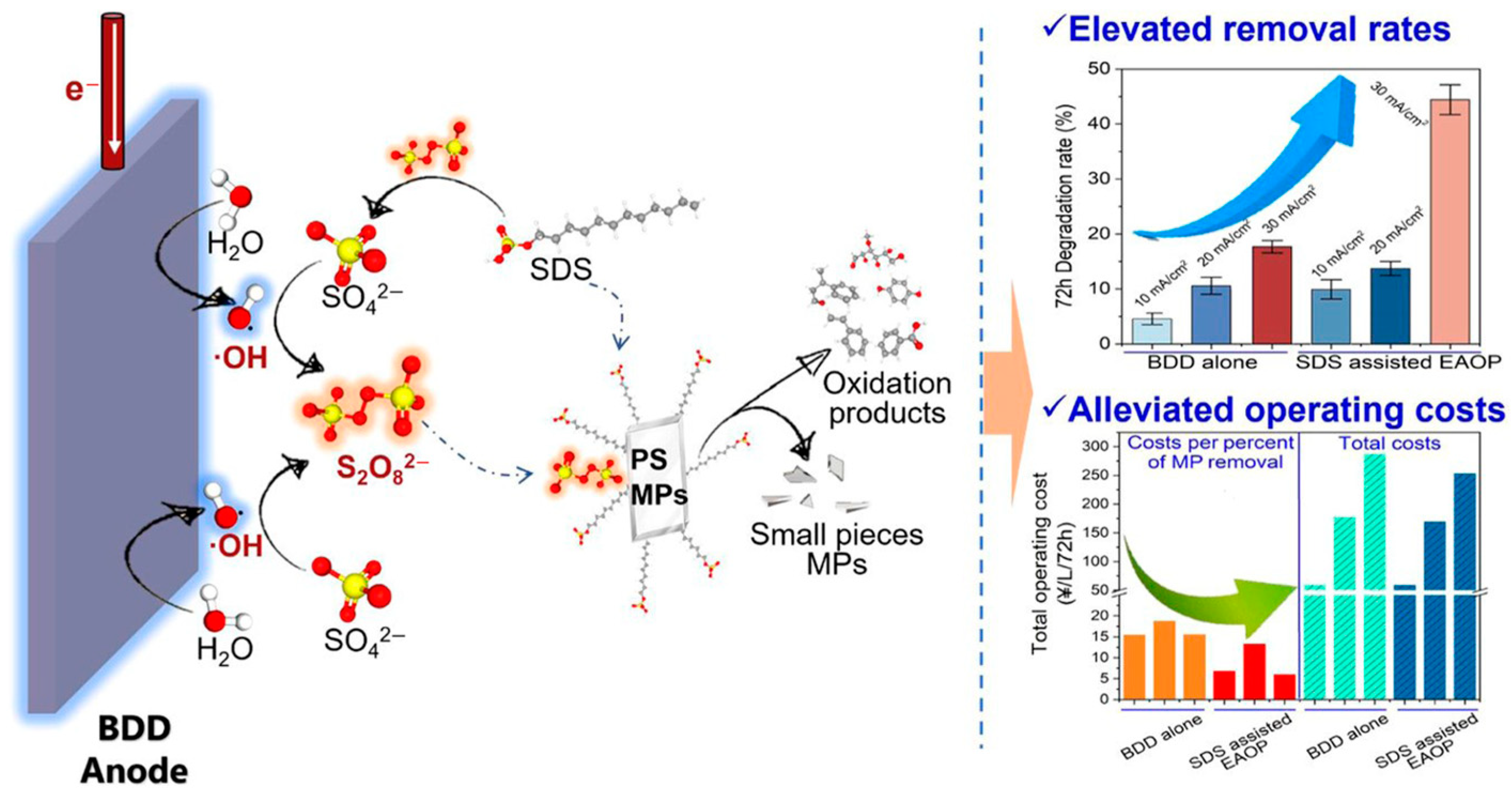

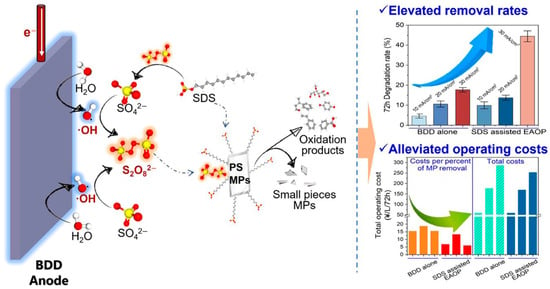

2.2.2. Advanced Oxidation Process

Advanced oxidation processes (AOPs) are methods for removing organic pollutants by activating peroxides to produce, for example, hydroxyl radicals (∙OH, E0 = 2.7 V vs. NHE) and sulfate radicals (SO4∙−, E0 = 3.1 V vs. NHE), which have a high oxidation potential (standard hydrogen electrode potential, V vs. NHE). Although MPs are an emerging organic pollutant, their unique characteristics, such as high molecular weight, high crystallinity, and the absence of surface active groups, make their degradation challenging. Kang et al. [33] successfully degraded polyethylene microplastic particles and fragments from commercial personal care products using a hydrothermal autoclave equipped with a persulfate-based advanced oxidation process (SR-AOPs). Through the combined action of hydroxyl and sulfate radicals, the degradation process resulted in a 54% weight loss of the microplastics at 160 °C over an 8 h period. Toxicity tests revealed that the organic intermediates produced during the degradation were environmentally benign and could potentially serve as a carbon source for algal cultivation. Miao et al. [34] developed an electro-Fenton-inspired system for the degradation of PVC microplastics, utilizing a titanium dioxide/graphite cathode to generate hydroxyl radicals (∙OH). This approach mirrors the strategy employed by Kang et al. [33] but offers several advantages. The system functions within a sealed electrolytic cell under hydrothermal conditions, resulting in a 56% weight reduction of microplastics at a temperature of 100 °C and a pH level of 6. Key to this system is its avoidance of hydrogen peroxide (H2O2), thereby reducing operational costs. Instead, it converts dissolved oxygen in the water into H2O2 and activates ∙OH through a 2-electron redox reaction at the cathode. Additionally, the system benefits from the reduction of inactive Ti4+ to highly Fenton-like Ti3+ at the cathode, further enhancing its sustainability and efficiency. Lu et al. [67] introduced sodium dodecyl sulfate to enhance the electrochemical oxidative degradation performance of polystyrene microplastics on boron–diamond-doped anode (Figure 2). The addition of sodium dodecyl sulfate significantly increased the electrochemical oxidative degradation rate of polystyrene microplastics within 72 h. The rate increased 1.35–2.29 times compared to the degradation rate of polystyrene microplastics on the boron–diamond-doped anode alone.

Figure 2.

Enhanced electrochemical oxidative degradation of polystyrene microplastics by sodium dodecyl sulfate [67]. The unit Ұ/L/72 h in the graph represents the cost in RMB per liter in 72 h.

2.2.3. Photocatalysis

Photocatalytic technology is a more mature approach that harnesses solar energy and boasts the advantages of low cost and environmental friendliness. In recent years, this technology has seen significant application in the purification of organic pollutants in water environments. The core principle of photocatalytic degradation lies in the interaction between reactive oxidative species and organic pollutants. Within the photocatalytic system, the exposed surfaces of semiconductors and organic matrices serve as sites for the generation of hydroxyl radicals (OH) and superoxide radicals (O2−). These radicals possess a high degree of reactivity and are capable of cleaving the chemical bonds within organic pollutants, facilitating their complete transformation into water and carbon dioxide through a process known as mineralization [68]. Furthermore, the photogenerated holes (hVB+) that are produced as a result of photoexcitation—i.e., the transfer of electrons from the valence band to the conduction band—play a dual role. They not only facilitate the generation of hydroxyl radicals but also directly oxidize organic matter into water and carbon dioxide. Nabi et al. [69] demonstrated the effective degradation of PS microspheres using a TiO2 film under the influence of ultraviolet (UV) light at 365 and 254 nm wavelengths, respectively. The TiO2 film, a pivotal component of the photocatalytic system, is meticulously prepared by dispersing TiO2 nanoparticles (P25) within Triton X-100 (TXT) and subsequently applying a drop-coating technique to the fluorine-doped tin oxide (FTO) glass-conductive surface. Following the application, the film is subjected to calcination under ambient air conditions. To facilitate the photodegradation experiments, PS microspheres measuring 400 nm in diameter were also drop-coated onto the TiO2 films and subsequently allowed to dry. Under the 365 nm UV irradiation, the polystyrene microspheres underwent near-total mineralization within a remarkably short span of 12 h, achieving a mineralization rate of an impressive 98.40%. Uheida et al. [36] catalyzed the degradation of PP microplastic particles suspended in water under visible light irradiation using zinc oxide nanorods (ZnO NRs) on glass fiber substrates. The volume of PP particles reduced by about 65% on average compared to fresh PP particles after two weeks of irradiation. The major photodegradation by-products were characterized using GC/MS and were found to be mostly non-toxic, including compounds such as formaldehyde, acetaldehyde, acetone, butyraldehyde, and various organic radicals. Ariza-Tarazona et al. [35] conducted degradation experiments on PE microplastic particles extracted from facial scrubs under visible light irradiation using a porous N-TiO2 semiconductor based on mussel proteins. They found that the photocatalytic degradation efficiency was significantly influenced by various reaction conditions, including solution pH, temperature, humidity, and porosity. Low humidity, which causes sample dehydration, reduces the generation of hydroxyl radicals and thereby stalls the reaction. Acidic conditions stimulate the binding of H+ ions to the surface of the microplastics, promoting degradation. Additionally, high porosity increases the contact area between the microplastics and the N-TiO2, leading to a higher degradation efficiency.

Photocatalytic degradation technology employs light (ultraviolet, sunlight) as a clean energy source. In most cases, the by-products produced are non-toxic, with the potential for converting microplastics into fuels in the future. However, the light exposure time required for degradation is too long, and the conditions are harsh. Consequently, the development of more effective photocatalysts is necessary to further enhance the degradation rate.

2.3. Microbial Degradation

Biodegradation, which involves the isolation and cultivation of plastic-degrading bacteria and fungi from wastewater, and sludge, within certain organisms, and from landfills, is the most economical and environmentally friendly technique for removing MPs. The genus Pseudomonas has gained attention for its ability to degrade various types of plastics. Nanda et al. [37] used Pseudomonas strains collected from three different regions to degrade both natural and synthetic polyethylene. They found that Pseudomonas isolated from sewage sludge heaps was the most effective, achieving 46.2% degradation of natural polyethylene and 29.1% of synthetic polyethylene. Pseudomonas strains from domestic dumps had the lowest biodegradation rates, at 31.4% and 16.3% for natural and synthetic polyethylene, respectively. Pseudomonas from textile wastewater exhibited a degradation rate of 39.7%. Skariyachan et al. [70] demonstrated that the weight loss of low-density polyethylene (LDPE) and high-density polyethylene (HDPE) pellets was approximately (55 ± 2) % and (43 ± 3) %, respectively, after 120 days of treatment under high-temperature conditions using microbial communities formulated with Bacillus, Bacillus-like, Stenotrophomonas maltophilia, and Pseudomonas. Dang et al. [71] treated three different types of plastic bags with Bacillus isolated from agricultural compost residues for 30 days at 55 °C. They found that the molecular weight of the bags was significantly reduced, and their surface morphology was altered. This was attributed to the fact that Bacillus can secrete MP hydrolyzing enzymes, primarily comprising protease, xylanase, carboxymethyl cellulase, lipase, and chitinase. Yan et al. [72] successfully developed a thermophilic holobacterial catalyst capable of degrading poly(ethylene terephthalate) (PET) through the heterologous expression of a thermophilic keratase (LCC) from the metagenome of branch and leaf composting, using Clostridium thermophilum as the chassis cell. This holobacterial catalyst efficiently degraded 60% of commercially available polyethylene terephthalate plastic flakes into environmentally friendly monomers such as ethylene glycol and terephthalic acid at 60 °C over a period of 14 days. The catalyst was also employed for the degradation of PET and terephthalic acid (TTA). However, due to the enzyme’s inactivation by high temperatures, there was a significant decrease in the degradation rate in the later stages, hindering further development of the catalyst. Tournier et al. [73] enhanced the degradation activity and thermal stability of the pristine LCC enzyme through targeted mutagenesis, achieving a degradation rate as high as 90% at 72 °C after 10 h. The use of microorganisms in the degradation process also improved the degradation rate of the LCC enzyme. Although microbial-based technologies for targeted degradation of plastics hold great promise, challenges such as the amplification of enzymatic degradation and the difficulties in genetic modification must be addressed by researchers in a sustained effort to enhance the practical feasibility of microbial degradation. Bioinformatics has proven to be an invaluable tool in advancing the biodegradation of plastic waste, particularly microplastic particles [74]. A range of databases have been created to evaluate biodegradation mechanisms by offering insights into metabolic pathways, microbial enzymes, and genes involved in the degradation process [75]. These databases and computational approaches aid in pinpointing enzymes that participate in particular metabolic pathways and in forecasting biodegradation routes for toxic substances. They provide a foundation for devising innovative techniques to enhance the biodegradation of plastics [76]. The creation of genetically modified microbial scavengers capable of reducing various contaminants has become feasible thanks to diverse genetic engineering methods and ready access to synthetic organisms as well as genetic manipulation tools [77]. However, safety concerns related to genetically modified microorganisms continue to restrict their use in field experiments. This limitation impedes the accurate evaluation of the efficacy of gene editing techniques in the bioremediation of microplastics [78].

3. Water Treatment Technologies for Drug Residues

The use of drugs in large quantities, or even in excess, has led to an increase in the amount of drugs entering the ecosystem, resulting in environmental pollution. Residual drugs have an impact on the ecosystem, but the specific effects on humans, plants, and animals are still being studied. In the case of antibiotics, which have received the most attention, few countries in the world have included antibiotics in their various water quality standards. The study of drug residues in the environment has been extensive over the last two decades [79,80,81,82,83,84], and the results have shown that antibiotics have been detected in surface rivers. With the development of water analysis and testing technologies, the analytical capabilities of various instruments are increasing (with lower and lower detection limits), and more and more emerging contaminants are being detected in drinking water. As these compounds are not included in drinking water standards, there is no guidance on safe concentrations, and concerns have been raised about whether the low concentrations have negative impacts on human health. According to the World Health Organization, the concentration of pharmaceuticals in treated drinking water is typically less than 0.05 μg/L [85]. Such low concentrations do not pose an immediate health risk to humans, but long-term consumption warrants attention. There are three reasons for this: firstly, these drugs are designed to interact biologically with the human body; secondly, studies have shown that they can harm aquatic organisms; and thirdly, there is no scientific evidence to conclude whether long-term exposure to these drugs will impact human health [86]. Antibiotics are not readily biodegradable, and the continuous release of antibiotics into the environment by humans is likely to result in the formation of enrichment, negative ecological impacts, and possible synergistic effects of residual drugs [87]. Therefore, drugs are considered important environmental pollutants, and there is a need to develop effective and advanced treatment technologies to remove them from the environment. The advantages and disadvantages of various treatment technologies are given in Table 2.

Table 2.

Comparison of drug residue treatment technologies.

3.1. Physical Methods

Sand filtration has a removal effect on antibiotics, and it is generally believed that this is primarily carried out by the biofilm formed on the sand filtration media, with different antibiotics exhibiting varying adsorption effects. Rooklidge et al. [88] investigated the removal of antimicrobial agents from water by sand filtration. The results revealed that after 14 days, the removal of trimethoprim was >99%, lincomycin was <25%, and sulfonamide antimicrobials were <4%. Considering the stability of sulfonamide antimicrobials, the researchers concluded that they could serve as an indicator of pharmaceutical contamination in drinking water sources. Membrane filtration is a process for separating antibiotics from wastewater using microporous membranes. This method is commonly employed to remove both tiny particulate matter and dissolved substances. The pore size of the membrane can be selected to ensure that antibiotic molecules are effectively intercepted. While membrane filtration is efficient in removing antibiotics, it requires regular cleaning and membrane replacement to maintain performance. The combined nanofiltration (NF)/reverse osmosis (RO) membrane filtration process can remove up to 98.5% of Levamisole, Sulfaguanidine, Sulfadiazine, Sulfamethazine, Trimethoprim, et al. [89]. Adsorption is the process of capturing antibiotic molecules on the surface of a solid adsorbent. Activated carbon and iron oxide are commonly used adsorbents due to their large number of tiny pores and active sites, which facilitate the capture of antibiotic molecules. To enhance the adsorption of atrazine, Huang et al. [96] synthesized a novel P(DVB-MA) copolymer adsorbent through a simple and economical method of copolymerizing divinylbenzene with methyl acrylate. The results indicated that the polymer adsorbent with a monomer ratio of 4:1 exhibited a high specific surface area of 712.92 m2/g and appropriate hydrophilicity, with an atrazine adsorption capacity of 75.75 mg/g. Guo et al. [97] successfully developed a novel magnetic hypercrosslinked polymer and utilized it as a magnetic solid-phase extraction (MSPE) adsorbent for the magnetic extraction of benzoylurea insecticides (BUs). Adams et al. [98] studied the adsorption of seven antibiotics (Carbadox, Sulfachloropyridazine, Sulfadimethoxine, Sulfamerazine, Sulfamethazine, Sulfathiazole, and Methoxybenzylaminopyrimidine) using powdered activated carbon. The results indicated that the removal efficiency was strongly dependent on the amount of activated carbon used. The removal efficiency of each antibiotic in both distilled/deionized water and river water was higher than 90% when powdered activated carbon was added at 50 mg/L. Biochar is a carbonaceous material produced by pyrolysis of biomass under anoxic conditions, such as agricultural waste, forestry residues, or organic waste. It possesses a high degree of porosity and a large specific surface area, which enables it to effectively adsorb organic pollutants in water, including dyes, pesticides, drug residues, and other harmful chemicals [99,100]. Tian et al. [90] added biochar powder and KMnO4 alone to their formulated sulfamethoxazole (SMX) solution and allowed the reaction to proceed for 30 min. The results indicated that the removal of SMX by both biochar and KMnO4 was less than 10%. However, when KMnO4 and biochar were mixed and added to the SMX solution after the initial 30 min reaction, the removal of SMX reached 97%, almost completely removing the compound. This reaction process can be well described using the first-stage kinetic model. Unlike activated carbon, biochar is a novel adsorbent with low cost and high efficiency [101]. The creation of activated carbon entails a process that demands high temperatures and the application of activation agents, whereas the production of biochar is more cost-effective and energy-efficient. As a sustainable resource, biochar stands out as an ideal candidate for environmental applications in the purification of water pollutants, offering a compelling combination of economic and ecological advantages.

3.2. Advanced Oxidation Technology

Advanced oxidation technology is a novel treatment technique that has been under research for wastewater treatment in recent years. This technology is capable of producing hydroxyl radicals, which have a strong oxidizing property, during the water treatment reaction. It offers advantages such as strong degradation ability and simple operation and is thus widely utilized in wastewater treatment [102,103].

3.2.1. Ozone Oxidation

Ozone-catalyzed oxidation is commonly employed in the pre-oxidation treatment of drinking water disinfection. In the treatment of antibiotic-containing water, ozone oxidation is often combined with other oxidants/catalysts, such as O3/H2O2, O3/peroxysulfate, and O3/peroxocarbonate systems, among others. These combinations promote the formation of OH radicals, thereby enhancing the catalytic efficiency. Huber et al. [91] investigated the removal of pharmaceuticals and personal care products, including antibiotics, from municipal wastewater using ozone. At an ozone concentration of 2 mg/L, removal efficiencies of 90–99% were achieved for macrolide and sulfonamide antibiotics. Ao et al. [104] investigated the direct oxidation process of ozone for four typical β-lactam antibiotics. They found that the degradation of amoxicillin and cefadroxil was insignificant at different pH levels. Additionally, the degradation of penicillin was inhibited under acidic conditions, while that of ceftriaxone sodium was significantly accelerated under alkaline conditions. Studies have shown that the degradation of amoxicillin and cefadroxil is mainly due to the direct oxidation by ozone molecules. During the ozone oxidation reaction, amoxicillin, cefadroxil, penicillin sodium, and ceftriaxone sodium undergo lactam ring breakage, demethylation, hydration, and addition reactions.

3.2.2. Photocatalytic Oxidation

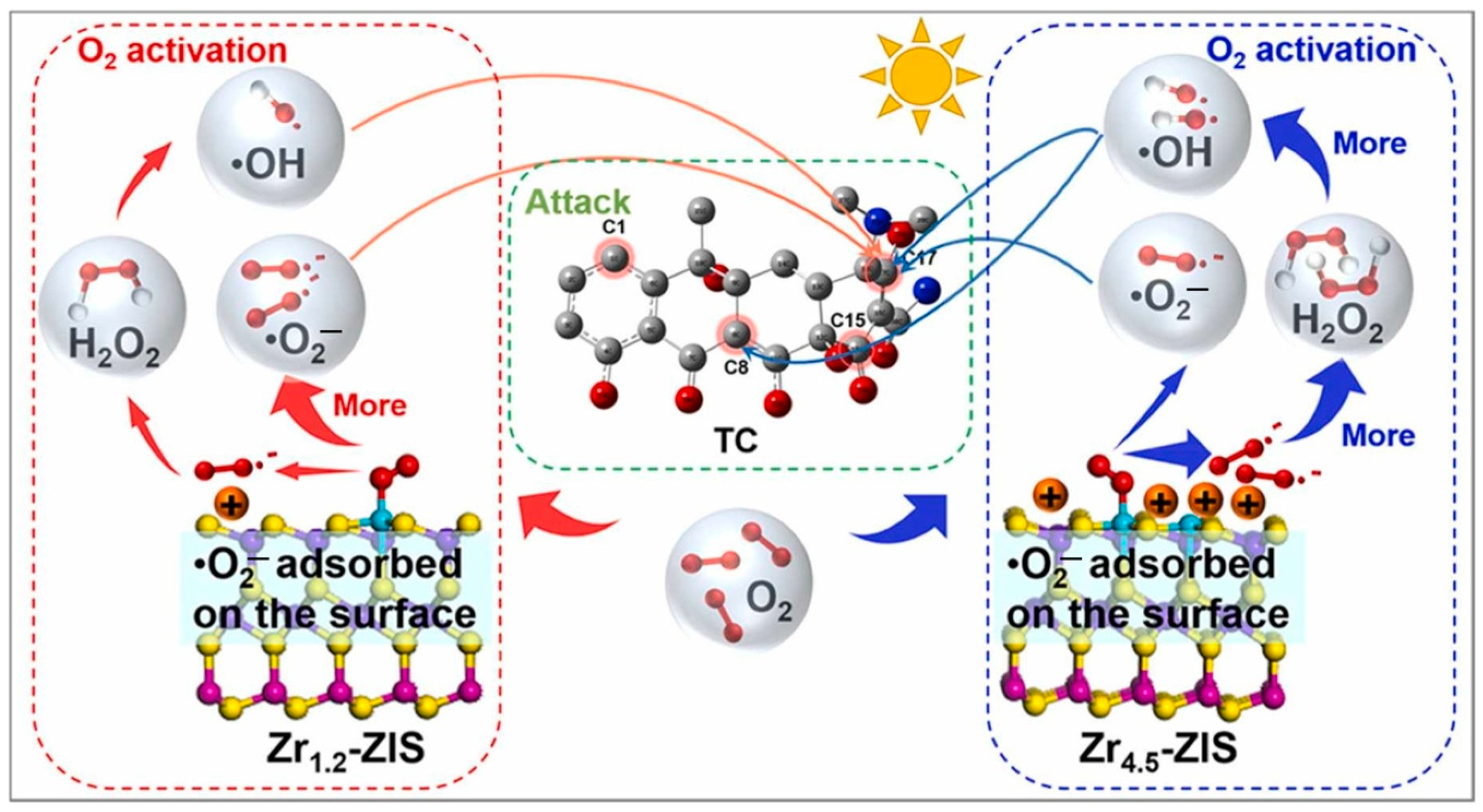

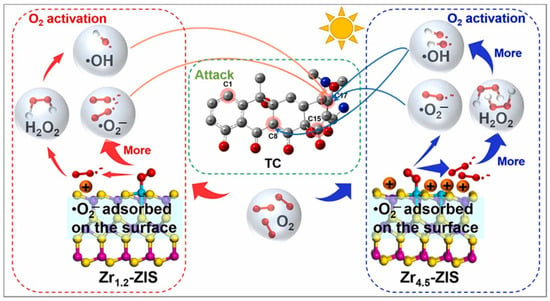

The initial discovery that TiO2 could act as a photocatalyst to generate hydrogen energy from the splitting of water in the presence of light was made in 1972 by Fujishima and Honda [105]. Photocatalytic technology was first applied to the degradation of polychlorinated biphenyls (PCBs) in 1976 by Carey et al. [106], marking the beginning of the use of photocatalysis for the degradation of organic pollutants. Photocatalytic oxidation involves the addition of a specific amount of semiconductor catalysts to the reaction solution. Currently, the most commonly used catalyst is TiO2, which, under natural or ultraviolet light irradiation, generates hydroxyl radicals (∙OH) that lead to the strong oxidation of antibiotics, ultimately degrading them into small inorganic molecules. Photocatalytic technology is known for its high efficiency, rapid processing, low cost, and absence of secondary pollution [107]. The photocatalytic oxidation process has favorable reaction conditions, excellent oxidation performance, and can completely degrade organic matter. It also effectively degrades microorganisms, bacteria, and molds in water. Sanaz et al. [92] prepared Zn, Cu-WO3 composites by the sol-gel precipitation method and investigated their photocatalytic degradation properties. The degradation efficiency of Gentamicin (GM) by Zn and Cu-WO3 could reach 95% after 90 min of reaction under UV light conditions at pH = 9. Hatice et al. [93] synthesized cobalt-doped titanium dioxide (Co-doped TiO2) composites using a refluxing method for the degradation of amoxicillin (AMX) through a photocatalytic reaction. The results indicated that after 240 min of reaction under UV-C illumination, with an initial concentration of AMX at 10 mg/L and a mass-to-volume ratio of Co-doped TiO2 at 0.4%, the removal efficiency reached 100%. Similarly, under visible light irradiation, with the same reaction conditions, the removal efficiency reached 100% after 300 min of reaction, demonstrating that the prepared Co-doped TiO2 composites exhibited excellent photocatalytic performance. Li et al. [108] effectively created Zr-S4 active sites on ZnIn2S4 nanosheets, which effectively regulated the reaction interface and energy band structure, thereby enhancing the photocatalytic activity. The kinetic rate constants for the optimized material, Zr1.2-ZIS, in the photocatalytic degradation of tetracycline were three times higher than those of the original material, ZnIn2S4 (Figure 3). Photocatalysis is an environmentally friendly technology that effectively removes antibiotics and other organic pollutants from water. It has diverse applications in wastewater treatment and water purification, particularly in areas with ample light or where low energy consumption is desired.

Figure 3.

Photocatalytic degradation of tetracycline by Zr1.2-ZIS [108].

3.2.3. Fenton Oxidation

Among the various advanced oxidation techniques, the Fenton method is an important and highly convenient method for wastewater treatment, particularly for the degradation of antibiotics. This method achieves this by generating hydroxyl radicals (OH) through a chain reaction involving iron salts and H2O2 in an acidic medium. In recent years, photo-Fenton and electro-Fenton processes have been extensively studied for their superiority over conventional Fenton oxidation [109]. When applied, the electro-Fenton process exhibits significant advantages over the conventional Fenton process, such as the elimination of the need to store large amounts of H2O2 and the reduction of iron-containing sludge. Additionally, it overcomes the limitation of the conventional Fenton process, which cannot control the synthesis of H2O2 under acidic conditions. Mansour et al. [110] used the electro-Fenton technique to degrade sulfamethazine (SMT) in wastewater, enhancing its biochemistry by increasing the biochemical oxygen demand (BOD5)/COD ratio from 0.17 to 0.50 after 60 min of reaction. This improvement was achieved with an initial SMT concentration of 0.2 mM and a current intensity of 0.5 A. Zhou et al. [111] prepared the Mn/Fe@PC-CP cathode through carbonization synthesis, demonstrating that the material exhibits good catalytic activity and stability, as well as a wide pH applicability range in the degradation of tetracycline. This is due to the highly dispersed active sites and the synergistic interactions between Fe2+, Mn2+, and Mn3+, which lead to effective regeneration at the cathode.

The photo-Fenton process integrates photocatalysis with the Fenton method to generate hydroxyl radicals (OH). During the photo-Fenton process, the photolysis of Fe3+ ions in acidic media leads to the formation of Fe2+ ions. These Fe2+ ions then react with H2O2 under the radiation of a light source, such as UV, to produce reactive substances that facilitate the degradation of organic matter [112]. Unlike the conventional Fenton process, the photo-Fenton process primarily regenerates Fe2+ through the photoreduction of Fe3+, thereby producing more hydroxyl radicals (∙OH). Additionally, the multiphase photo-Fenton reaction has emerged as an effective degradation process owing to its high efficiency and the ease with which the photocatalysts can be separated from the treated water, thereby preventing the contamination of secondary metal ions. Hu et al. [113] synthesized Fe-g-C3N4 composite catalysts using heat shrinkage polymerization. They found that the degradation rate of phenol reached 100% after only 50 min of reaction under the following conditions: temperature of 25 ± 2 °C, hydrogen peroxide concentration of 8 mM, a phenol concentration of 20 mg/L, and a catalyst dosage of 1 g/L. The results indicated that iron (Fe) formed σ–π conjugate bonds with nitrogen (N), and it was incorporated into the g-C3N4 framework in the Fe3+ oxidation state. Cui et al. [94] synthesized magnetic Fe3O4/g-C3N4 composite catalysts using the electrostatic self-assembly method. Under the reaction conditions of pH 3.0, 5 mM H2O2, a catalyst dosage of 1.0 g/L, and a total cholesterol (TC) concentration of 25 mg/L for a duration of 100 min, the degradation efficiency of the 7% Fe3O4/g-C3N4 composite for TC reached 99.8%, which was 56% higher than that of the separate photocatalytic system and 49% higher than the Fenton system. The results indicate that doping Fe3O4 into the g-C3N4 framework can enhance the separation of photogenerated electrons and holes. The electrons facilitate the cycling of Fe3+ to Fe2+, generating more hydroxyl radicals (∙OH), while simultaneously inhibiting the recombination of holes and electrons. The high efficiency of this photo-Fenton technology offers a novel approach to controlling antibiotic pollution.

3.3. Biological Treatment Technology

Biological treatment is an environmentally friendly and effective method for removing antibiotics that utilizes the natural degradation capabilities of microorganisms. This process can be carried out without the introduction of chemicals or the generation of harmful by-products, making it widely used in water and wastewater treatment. Activated sludge is the most traditional wastewater treatment technology, and the removal efficiency of different antibiotics varies considerably. Batt et al. [95] analyzed and studied four wastewater treatment plants that used different processes: two-stage activated sludge, delayed aeration activated sludge, rotating biological contact reactor, and purely aerobic activated sludge. For some antibiotics, such as ciprofloxacin, the removal efficiencies were similar, ranging from 50% to 60%. However, for other antibiotics, like sulfamethoxazole, the removal efficiencies were nearly twice as high for each process.

Wang et al. [114] developed a new type of circulating aerobic biochemical tank for the treatment of antibiotic wastewater and production applications. The results indicated that the COD removal efficiency could reach 90–95%, and the ammonia nitrogen removal efficiency could reach 70–90% under the following conditions: influent COD of 5000–12,000 mg/L, ammonia nitrogen of 200–500 mg/L, and a volumetric loading greater than 2 kg COD/(m3∙d). The aerobic method offers the advantages of a stable removal effect and high-quality effluent water. However, antibiotic residues can have toxic side effects on many aerobic microorganisms, inhibiting their treatment efficacy. In the future, specialized aerobic bacteria can be cultivated and domesticated to address this issue. Anaerobic treatment of antibiotic wastewater can achieve high removal efficiency and significantly reduce the amount of sludge produced compared to the aerobic method. However, the effluent quality from the anaerobic method is poorer, and it is generally necessary to use it in conjunction with an aerobic biological method [115]. Sun [116] employed a Cyclic Activated Sludge Biological (CASB) anaerobic reactor to treat antibiotic wastewater from an enterprise following primary sedimentation. The influent to the pilot plant was drawn from the upper section of the primary sedimentation tank at the enterprise’s wastewater station, with characteristics including a COD of 5000–9000 mg/L, NH3-N of 600–900 mg/L, SO42− of less than 2000 mg/L, a pH of 4–6, and a B/C ratio of at least 0.3. The reactor achieved a COD removal efficiency of 70% when the hydraulic retention time was set at 3 days. Although the anaerobic reactor effectively treated the antibiotic wastewater after primary sedimentation, the quality of the effluent was suboptimal. With a hydraulic retention time of 3 days, the COD removal efficiency could reach 70%. Compared to the existing Multi-Internal-Circulation (MIC) reactor at the enterprise, even when the hydraulic retention time was halved, the COD removal efficiency could be increased by an additional 10–20 percentage points, achieving a significantly improved treatment effect. The combined process harnesses the advantages of both reactors while mitigating their respective drawbacks through the regulation of relevant indexes, making it an effective approach for the treatment of antibiotic wastewater. Han et al. [117] employed a combined anaerobic and aerobic biological process to treat antibiotic-containing wastewater, achieving a removal efficiency of 95% for COD and 92% for antibiotics within a hydraulic retention time of 3.3 days. This combined process has proven to be effective in the treatment of antibiotic wastewater.

4. Water Treatment Technology for Endocrine Disruptors

Endocrine disruptors (EDCs) are exogenous chemical substances found in the environment that can interfere with the endocrine systems of humans or animals, affecting their ability to maintain regulatory balance and potentially leading to abnormal effects. These disruptors are primarily organic pollutants that are released into the ecosystem through human activities, including production and daily living. Common examples of endocrine disruptors include dioxins, PCBs, certain pesticides, pharmaceuticals, and plasticizers such as bisphenol A (BPA) and phthalates [118]. BPA, an industrial chemical and a typical endocrine disruptor, interferes with hormonal and homeostatic functions, adversely affecting the human endocrine system. It is extensively utilized in the manufacture of polycarbonate plastics, styrene resins, epoxy resins, and flame retardants. BPA has been identified in municipal wastewater, industrial effluent, and landfill leachate. Even trace amounts of BPA can increase the risk of obesity, disrupt thyroid hormone regulation, reduce immune function, and may also lead to higher incidences of cancer and heart disease [119]. The most commonly applied methods for removing EDCs include physical, chemical, and biological treatments. Techniques used to treat endocrine disruptors in secondary effluent primarily encompass advanced oxidation, biodegradation, adsorption, and membrane separation [120]. A comparative analysis of endocrine disruptor treatment techniques is given in Table 3.

Table 3.

Comparison of endocrine disruptor treatment technologies.

4.1. Physical Methods

4.1.1. Adsorption

Adsorption technology effectively removes EDCs by leveraging their large specific surface area, high porosity, and ability to interact effectively with EDCs. This approach has garnered extensive attention from scholars due to its advantages of low operating costs, ease of use, and the production of few toxic and harmful byproducts [125]. Currently, the materials used for adsorbing EDCs are transitioning from traditional adsorption materials such as peat and zeolite to newer materials like resin particles and polymer complexes. Guo et al. [126] investigated the adsorption effect of silica on four types of EDCs, and the results indicated that the adsorption of these EDCs on the silica surface increased with the initial concentration of EDCs, although the removal efficiency was largely unaffected by whether the initial concentration of EDCs was high or low. Murray et al. [121] evaluated the effectiveness of submicron-sized resin particles (SMR) for treating EDCs, including estrone (E1), estradiol (E2), ethinyl estradiol (EE2), bisphenol A (BPA), and hexestrol (DES), as well as 12 other drugs. The study’s results indicated that the removal of E2, EE2, BPA, and DES from water using SMR reached rates of up to 98%, 80%, 87%, and 97%, respectively. Song et al. [127] developed magnetic mesoporous melamine-formaldehyde complexes (Fe3O4-mPMF) for the adsorption of BPA, 4-tert-butylphenol (4-tert-BP), nonylphenol (NP), and 4-tert-octylphenol. The results indicated that Fe3O4-mPMF effectively removed EDCs from river water and juice. Its high adsorption capacity was attributed to π-stacking, hydrogen bonding, and hydrophobic interactions. Biochar, with its advantages of low cost, environmentally friendly raw materials, and superior performance in adsorbing BPA, has also emerged as a focal point for future development of adsorption technology [125]. Lu et al. [128] utilized Ulva prolifera to produce biochar and found that 90% of endocrine disruptors were removed within 4 h. This biochar exhibits a fairly good adsorption capacity, suggesting promising potential for future use as an adsorbent.

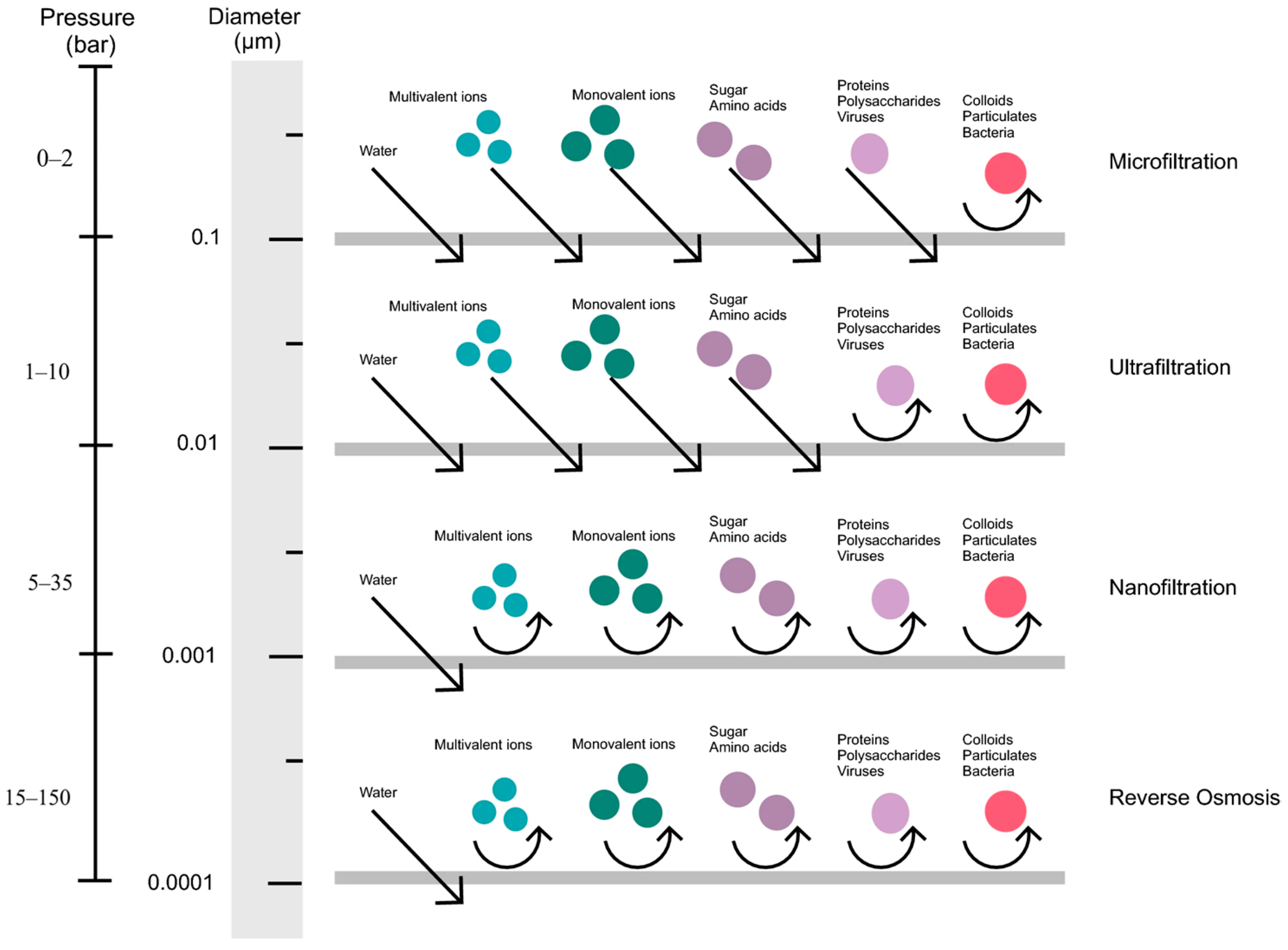

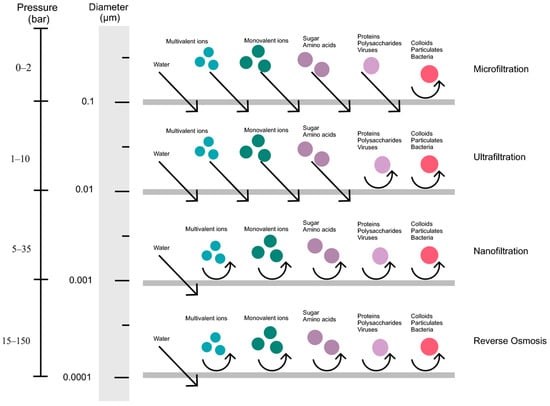

4.1.2. Membrane Separation Technology

Typical EDCs are characterized by their large molecular masses, which determine that they can be effectively removed using membrane separation techniques. The membrane separation methods currently employed in many applications include microfiltration (MF), ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO). Figure 4 illustrates the characteristics of each membrane type.

Figure 4.

Schematic diagram of different membrane properties [125].

Zielińska et al. [129] successfully employed ceramic membranes to microfilter BPA from water that had previously undergone biological treatment. They achieved the removal of approximately 98% of endocrine disruptors from the wastewater, despite the large pore size of the microfiltration membrane. Si et al. [130] studied the removal efficiencies of ultrafiltration and ozonation for five endocrine disruptors. They found that the removal of endocrine disruptors using ultrafiltration ranged from 8% to 46%, was higher than 70% using ozonation alone, and reached up to 99% when an ultrafiltration-O3 system was used. Nanofiltration operates at lower pressures than reverse osmosis, leading to reduced operating costs and lower molecular weight cut-offs compared to microfiltration and ultrafiltration. Guo et al. [131] successfully utilized nanofiltration90 membranes coated with a layer of hydrophilic polydopamine functionalized with silver nanoparticles, which demonstrated superior removal of endocrine disruptors compared to single membranes. Reverse osmosis is a separation process where solvents are passed through a semipermeable membrane while solutes are retained by applying a pressure higher than the osmotic pressure. Rodriguez et al. [132] discovered that RO and forward osmosis (FO) are generally very effective in removing endocrine disruptors, with only a few instances of removal below 50%, such as 1,4-dioxane and acetaminophen. Agata et al. [122] employed BW30-2540 RO membranes for the removal of emerging contaminants, including caffeine, theobromine, theophylline, amoxicillin, and penicillin G, from wastewater treatment plant effluent. This technique has been demonstrated to be an effective tertiary treatment method, achieving 100% removal of contaminants without signs of membrane deterioration over a test duration of 72 h.

4.2. Chemical Method

Currently, advanced oxidation methods for removing EDCs primarily involve the coupling of existing technologies and the development of new catalytic oxidation materials. Photochemical oxidation technology involves the process of oxidizing and degrading organic pollutants under the influence of visible or ultraviolet light. Additionally, some photocatalysts can be utilized to enhance the synergistic effects of light, thereby improving the efficiency of pollutant degradation. Juhola et al. [123] employed an iron catalyst in wet oxidation to degrade BPA, achieving removal efficiencies of 83.0% for BPA and 64.0% for total organic carbon (TOC) at an initial BPA concentration of 60.0 mg/L, a H2O2 concentration of 1500 mg/L, a catalyst concentration of 1000–2000 mg/L, and a temperature of 50 °C. Zheng et al. [133] developed a Bi2WO6-rMoS2 composite photocatalyst using a modified hydrothermal method and examined its removal efficacy for sulfamethoxazole (SMZ) in an aqueous solution. The results indicated that the removal efficiency of SMZ reached 97.6% after 21 min of reaction at a voltage of 9 kV, with a concentration of 80.0 mg/L for the Bi2WO6-rMoS2 photocatalyst and 20 mg/L for SMZ. Moussavi et al. [134] employed vacuum ultraviolet (VUV) radiation in combination with H2O2 to degrade BPA. The results indicated that VUV significantly accelerated the mineralization of BPA, with 97.6% of BPA being mineralized within 60 min at a pH of 3 and an H2O2/BPA mass ratio of 4. de Araujo et al. [135] examined the impact of specific photon emission rates on the degradation of BPA by UV-H2O2. The results revealed that under optimized conditions of BPA degradation under UV light irradiation at a wavelength of 254 nm, the highest removal efficiency of BPA was achieved at 15 min, with the second highest removal efficiency occurring after 180 min. The mineralization rate approached 95.0%, while the removal efficiency of TOC was below 75.0%. Chen et al. [136] introduced cyclodextrin to enhance BPA removal in the Fenton reaction under neutral conditions. The results indicated that the removal efficiency of BPA reached 96.0–100.0% with the addition of carboxymethyl-β-cyclodextrin, and the removal efficiency of β-cyclodextrin reached 87.0–91.0%. Without cyclodextrin under the same conditions, the degradation rate of BPA was only 57.2%.

4.3. Microbiological Method

Biotechnology degrades organic substances in water through the metabolism of microorganisms and plants, offering advantages such as large treatment capacity, low operation costs, excellent purification effects, and minimal energy consumption compared to other treatment methods. Conventional biotechnology targets pollutants such as COD, nitrogen (N), and phosphorus (P), while biotechnology targeting endocrine-disrupting chemicals (EDCs) requires the screening of microorganisms and plants. Currently, the cultivation of specialized fungi is a research focus for using biotechnology to remove EDCs. Kasonga et al. [124] explored the removal of carbamazepine (CBZ), diclofenac (DCF), and ibuprofen (IBP) using a sequencing batch reactor (SBR) process using five South African fungi. The results indicated that the removal efficiencies of CBZ, DCF, and IBP, respectively, were 89.8%, 95.8%, and 91.4% after 1 day of operation. The SBR process with South African fungi demonstrated high removal efficiencies of these pharmaceuticals. Becker et al. [137] examined the effect of two fungal laccases on the removal of estrogenic, androgenic, and anti-androgenic activities. The results revealed that the enzymes, even at low concentrations, could degrade hormones and endocrine-EDCs. In wastewater treatment, the best removal efficiencies achieved were 82% for estrogenic activity and 99% for androgenic activity. Křesinová et al. [138] studied the removal of E1, E2, E3, EE2, BPA, triclosan, and 4-nonylphenol by a fungus. The results indicated that the degradation efficiency exceeded 90% within 12 days under model laboratory conditions. The waste fungal substrate proved to be an effective biodegradant. A pilot-scale drip-bed reactor was installed at the wastewater treatment plant (WWTP) and operated successfully for 10 days. The bioreactor was capable of removing over 76% of the EDCs present in the wastewater. Zhang et al. [139] employed biomanganese oxide and engineered E. coli cells containing CotA, a multicopper oxidase, for the degradation of BPA and nonylphenol (NP). The results indicated that the complex eliminated the estrogenic activity of BPA and NP, and the complex demonstrated good processing stability in repeated use, recovering its activity easily after each use. Bai et al. [140] utilized freshwater green algae to remove EDCs from ultrafiltration and ozonated effluent. The results revealed that E2, EE2, and salicylic acid (SAL) were removed by 60% after 7 days. Triclosan (TCS) was removed by 63–100% within 7 days, with or without the addition of algae.

5. Future Research Directions and Challenges

Development of New Adsorbent Materials: Develop low-cost, high-efficiency, and recyclable adsorbent materials, such as magnetic adsorbent materials and bio-based adsorbent materials, to enhance the removal efficiency of emerging pollutants.

Optimization of Chemical Methods: Research new advanced oxidation technologies, such as electrochemical oxidation and photochemical oxidation, to enhance the degradation efficiency of emerging pollutants and reduce operational costs.

Improvement of Biological Methods: Cultivate and screen microorganisms and plants with the capability to efficiently degrade emerging pollutants and study their degradation mechanisms to enhance the treatment efficiency and stability of biological treatment technologies.

Development of Combined Technologies: Combine various treatment technologies, leveraging their respective advantages to improve the removal effectiveness of emerging pollutants.

Strengthening Interdisciplinary Cooperation: Promote the cross-fertilization of water treatment technology, environmental science, materials science, biotechnology, and other disciplines to drive the innovation and advancement of water treatment technology for emerging pollutants.

6. Conclusions

The research and application of new water treatment technologies for pollutants are of great significance for the protection of the water environment and human health. Physical methods are simple and low-cost, but they have limited removal efficiencies. Chemical methods have high removal efficiencies but may generate secondary pollution. Biological methods are environmentally friendly, but they have a long treatment time and are vulnerable to environmental factors. Future research should focus on the development of new water treatment technologies for pollutants that are efficient, economical, and environmentally friendly, and it should strengthen interdisciplinary cooperation to promote the application and dissemination of these technologies.

Author Contributions

H.W. and Y.Z. conceived and designed the research. X.G. wrote the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

The work was supported by the Natural Science Foundation of Guangxi (NO. 2024GXNSFAA010159).

Data Availability Statement

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bănăduc, D.; Curtean-Bănăduc, A.; Barinova, S.; Lozano, V.L.; Afanasyev, S.; Leite, T.; Branco, P.; Gomez Isaza, D.F.; Geist, J.; Tegos, A.; et al. Multi-Interacting Natural and Anthropogenic Stressors on Freshwater Ecosystems: Their Current Status and Future Prospects for 21st Century. Water 2024, 16, 1483. [Google Scholar] [CrossRef]

- Singh, S.; Rawat, M.; Malyan, S.K.; Singh, R.; Tyagi, V.K.; Singh, K.; Kashyap, S.; Kumar, S.; Sharma, M.; Panday, B.K.; et al. Global distribution of pesticides in freshwater resources and their remediation approaches. Environ. Res. 2023, 225, 115605. [Google Scholar] [CrossRef] [PubMed]

- De Araújo, E.P.; Caldas, E.D.; Oliveira-Filho, E.C. Pesticides in surface freshwater: A critical review. Environ. Monit. Assess. 2022, 194, 452. [Google Scholar] [CrossRef] [PubMed]

- Arman, N.Z.; Salmiati, S.; Aris, A.; Salim, M.R.; Nazifa, T.H.; Muhamad, M.S.; Marpongahtun, M. A Review on Emerging Pollutants in the Water Environment: Existences, Health Effects and Treatment Processes. Water 2021, 13, 3258. [Google Scholar] [CrossRef]

- Kerketta, A.; Sahoo, P.K. A decadal analysis to unravel the global status of emerging contaminants in wastewaters and comparison with the Indian context. Groundw. Sustain. Dev. 2022, 18, 100803. [Google Scholar] [CrossRef]

- Mishra, R.K.; Mentha, S.S.; Misra, Y.; Dwivedi, N. Emerging pollutants of severe environmental concern in water and wastewater: A comprehensive review on current developments and future research. Water-Energy Nexus 2023, 6, 74–95. [Google Scholar] [CrossRef]

- Guimarães, A.T.B.; Charlie-Silva, I.; Malafaia, G. Toxic effects of naturally-aged microplastics on zebrafish juveniles: A more realistic approach to plastic pollution in freshwater ecosystems. J. Hazard. Mater. 2021, 407, 124833. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.-Y.; Li, H.; Ren, H.; Zhang, X.; Huang, F.; Zhang, D.; Huang, Q.; Zhang, X. Size-dependent effects of polystyrene nanoplastics on autophagy response in human umbilical vein endothelial cells. J. Hazard. Mater. 2022, 421, 126770. [Google Scholar] [CrossRef] [PubMed]

- Thompson, R.C.; Olsen, Y.; Mitchell, R.P.; Davis, A.; Rowland, S.J.; John, A.W.; McGonigle, D.; Russell, A.E. Lost at sea: Where is all the plastic? Science 2004, 304, 838. [Google Scholar] [CrossRef]

- Xiang, Y.; Jiang, L.; Zhou, Y.; Luo, Z.; Zhi, D.; Yang, J.; Lam, S.S. Microplastics and environmental pollutants: Key interaction and toxicology in aquatic and soil environments. J. Hazard. Mater. 2022, 422, 126843. [Google Scholar] [CrossRef]

- Alam, F.C.; Sembiring, E.; Muntalif, B.S.; Suendo, V. Microplastic distribution in surface water and sediment river around slum and industrial area (case study: Ciwalengke River, Majalaya district, Indonesia). Chemosphere 2019, 224, 637–645. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.; Yin, L.; Li, Z.; Wen, X.; Luo, X.; Hu, S.; Yang, H.; Long, Y.; Deng, B.; Huang, L. Microplastic pollution in the rivers of the Tibet Plateau. Environ. Pollut. 2019, 249, 91–98. [Google Scholar] [CrossRef]

- Lacerda, A.L.D.F.; Rodrigues, L.d.S.; Van Sebille, E.; Rodrigues, F.L.; Ribeiro, L.; Secchi, E.R.; Kessler, F.; Proietti, M.C. Plastics in sea surface waters around the Antarctic Peninsula. Sci. Rep. 2019, 9, 3977. [Google Scholar] [CrossRef] [PubMed]

- Kanhai, L.D.K.; Gardfeldt, K.; Krumpen, T.; Thompson, R.C.; O’Connor, I. Microplastics in sea ice and seawater beneath ice floes from the Arctic Ocean. Sci. Rep. 2020, 10, 5004. [Google Scholar] [CrossRef] [PubMed]

- Ding, L.; fan Mao, R.; Guo, X.; Yang, X.; Zhang, Q.; Yang, C. Microplastics in surface waters and sediments of the Wei River, in the northwest of China. Sci. Total Environ. 2019, 667, 427–434. [Google Scholar] [CrossRef]

- Yan, M.; Nie, H.; Xu, K.; He, Y.; Hu, Y.; Huang, Y.; Wang, J. Microplastic abundance, distribution and composition in the Pearl River along Guangzhou city and Pearl River estuary, China. Chemosphere 2019, 217, 879–886. [Google Scholar] [CrossRef]

- Sulistyowati, L.; Riani, E.; Cordova, M.R. The occurrence and abundance of microplastics in surface water of the midstream and downstream of the Cisadane River, Indonesia. Chemosphere 2022, 291, 133071. [Google Scholar] [CrossRef]

- Nan, B.; Su, L.; Kellar, C.; Craig, N.J.; Keough, M.J.; Pettigrove, V. Identification of microplastics in surface water and Australian freshwater shrimp Paratya australiensis in Victoria, Australia. Environ. Pollut. 2020, 259, 113865. [Google Scholar] [CrossRef]

- Shen, M.; Zeng, Z.; Song, B.; Yi, H.; Hu, T.; Zhang, Y.; Zeng, G.; Xiao, R. Neglected microplastics pollution in global COVID-19: Disposable surgical masks. Sci. Total Environ. 2021, 790, 148130. [Google Scholar] [CrossRef]

- Hu, T.; Shen, M.; Tang, W. Wet wipes and disposable surgical masks are becoming new sources of fiber microplastic pollution during global COVID-19. Environ. Sci. Pollut. Res. 2022, 29, 284–292. [Google Scholar] [CrossRef]

- Browne, M.A.; Dissanayake, A.; Galloway, T.S.; Lowe, D.M.; Thompson, R.C. Ingested microscopic plastic translocates to the circulatory system of the mussel, Mytilus edulis (L.). Environ. Sci. Technol. 2008, 42, 5026–5031. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Han, Y.; Tang, Y.; Shi, W.; Du, X.; Sun, S.; Liu, G. Microplastics aggravate the bioaccumulation of two waterborne veterinary antibiotics in an edible bivalve species: Potential mechanisms and implications for human health. Environ. Sci. Technol. 2020, 54, 8115–8122. [Google Scholar] [CrossRef] [PubMed]

- Ma, H.; Pu, S.; Liu, S.; Bai, Y.; Mandal, S.; Xing, B. Microplastics in aquatic environments: Toxicity to trigger ecological consequences. Environ. Pollut. 2020, 261, 114089. [Google Scholar] [CrossRef] [PubMed]

- Turner, A. Heavy metals, metalloids and other hazardous elements in marine plastic litter. Mar. Pollut. Bull. 2016, 111, 136–142. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Wang, J. Different partition of polycyclic aromatic hydrocarbon on environmental particulates in freshwater: Microplastics in comparison to natural sediment. Ecotoxicol. Environ. Saf. 2018, 147, 648–655. [Google Scholar] [CrossRef] [PubMed]

- Arenas, L.R.; Gentile, S.R.; Zimmermann, S.; Stoll, S. Fate and removal efficiency of polystyrene nanoplastics in a pilot drinking water treatment plant. Sci. Total Environ. 2022, 813, 152623. [Google Scholar] [CrossRef] [PubMed]

- Na, S.-H.; Kim, M.-J.; Kim, J.-T.; Jeong, S.; Lee, S.; Chung, J.; Kim, E.-J. Microplastic removal in conventional drinking water treatment processes: Performance, mechanism, and potential risk. Water Res. 2021, 202, 117417. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Sun, C.; Li, F.; Chen, L. Fatigue resistance, re-usable and biodegradable sponge materials from plant protein with rapid water adsorption capacity for microplastics removal. Chem. Eng. J. 2021, 415, 129006. [Google Scholar] [CrossRef]

- Shi, C.; Zhang, S.; Zhao, J.; Ma, J.; Wu, H.; Sun, H.; Cheng, S. Experimental study on removal of microplastics from aqueous solution by magnetic force effect on the magnetic sepiolite. Sep. Purif. Technol. 2022, 288, 120564. [Google Scholar] [CrossRef]

- Mohana, A.A.; Farhad, S.; Haque, N.; Pramanik, B.K. Understanding the fate of nano-plastics in wastewater treatment plants and their removal using membrane processes. Chemosphere 2021, 284, 131430. [Google Scholar] [CrossRef]

- Ma, B.; Xue, W.; Ding, Y.; Hu, C.; Liu, H.; Qu, J. Removal characteristics of microplastics by Fe-based coagulants during drinking water treatment. J. Environ. Sci. 2019, 78, 267–275. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Lin, T.; Chen, W. Occurrence and removal of microplastics in an advanced drinking water treatment plant (ADWTP). Sci. Total Environ. 2020, 700, 134520. [Google Scholar] [CrossRef] [PubMed]

- Kang, J.; Zhou, L.; Duan, X.; Sun, H.; Ao, Z.; Wang, S. Degradation of cosmetic microplastics via functionalized carbon nanosprings. Matter 2019, 1, 745–758. [Google Scholar] [CrossRef]

- Miao, F.; Liu, Y.; Gao, M.; Yu, X.; Xiao, P.; Wang, M.; Wang, S.; Wang, X. Degradation of polyvinyl chloride microplastics via an electro-Fenton-like system with a TiO2/graphite cathode. J. Hazard. Mater. 2020, 399, 123023. [Google Scholar] [CrossRef] [PubMed]

- Ariza-Tarazona, M.C.; Villarreal-Chiu, J.F.; Barbieri, V.; Siligardi, C.; Cedillo-González, E.I. New strategy for microplastic degradation: Green photocatalysis using a protein-based porous N-TiO2 semiconductor. Ceram. Int. 2019, 45, 9618–9624. [Google Scholar] [CrossRef]

- Uheida, A.; Mejía, H.G.; Abdel-Rehim, M.; Hamd, W.; Dutta, J. Visible light photocatalytic degradation of polypropylene microplastics in a continuous water flow system. J. Hazard. Mater. 2021, 406, 124299. [Google Scholar] [CrossRef] [PubMed]

- Nanda, S.; Sahu, S.; Abraham, J. Studies on the biodegradation of natural and synthetic polyethylene by Pseudomonas spp. J. Appl. Sci. Environ. Manag. 2010, 14. [Google Scholar] [CrossRef]

- Pivokonsky, M.; Cermakova, L.; Novotna, K.; Peer, P.; Cajthaml, T.; Janda, V. Occurrence of microplastics in raw and treated drinking water. Sci. Total Environ. 2018, 643, 1644–1651. [Google Scholar] [CrossRef]

- Funck, M.; Al-Azzawi, M.S.; Yildirim, A.; Knoop, O.; Schmidt, T.C.; Drewes, J.E.; Tuerk, J. Release of microplastic particles to the aquatic environment via wastewater treatment plants: The impact of sand filters as tertiary treatment. Chem. Eng. J. 2021, 426, 130933. [Google Scholar] [CrossRef]

- Wu, X.; Zeng, X.; Lyu, X.; Gao, B.; Sun, Y.; Wu, J. Combined Effects of Fe/Al Oxyhydroxide Coating and pH on Polystyrene Nanoplastic Transport in Saturated Sand Media. Water Air Soil Pollut. 2022, 233, 2. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, L.; Chen, H.; Zhang, M. Retention and transport behavior of microplastic particles in water-saturated porous media. Sci. Total Environ. 2022, 808, 152154. [Google Scholar] [CrossRef] [PubMed]

- Arenas, L.R.; Gentile, S.R.; Zimmermann, S.; Stoll, S. Nanoplastics adsorption and removal efficiency by granular activated carbon used in drinking water treatment process. Sci. Total Environ. 2021, 791, 148175. [Google Scholar] [CrossRef] [PubMed]

- Zhu, N.; Yan, Q.; He, Y.; Wang, X.; Wei, Z.; Liang, D.; Yue, H.; Yun, Y.; Li, G.; Sang, N. Insights into the removal of polystyrene nanoplastics using the contaminated corncob-derived mesoporous biochar from mining area. J. Hazard. Mater. 2022, 433, 128756. [Google Scholar] [CrossRef]

- Sun, C.; Wang, Z.; Zheng, H.; Chen, L.; Li, F. Biodegradable and re-usable sponge materials made from chitin for efficient removal of microplastics. J. Hazard. Mater. 2021, 420, 126599. [Google Scholar] [CrossRef]