Unraveling the Potential of Microbial Flocculants: Preparation, Performance, and Applications in Wastewater Treatment

Abstract

1. Introduction

2. Sources and Categories of MBFs

2.1. MBF-Producing Microorganisms

2.2. Categories of MBFs

3. MBF Production, Flocculation Performance, and Mechanisms

3.1. MBF Production

3.2. Flocculation Performance

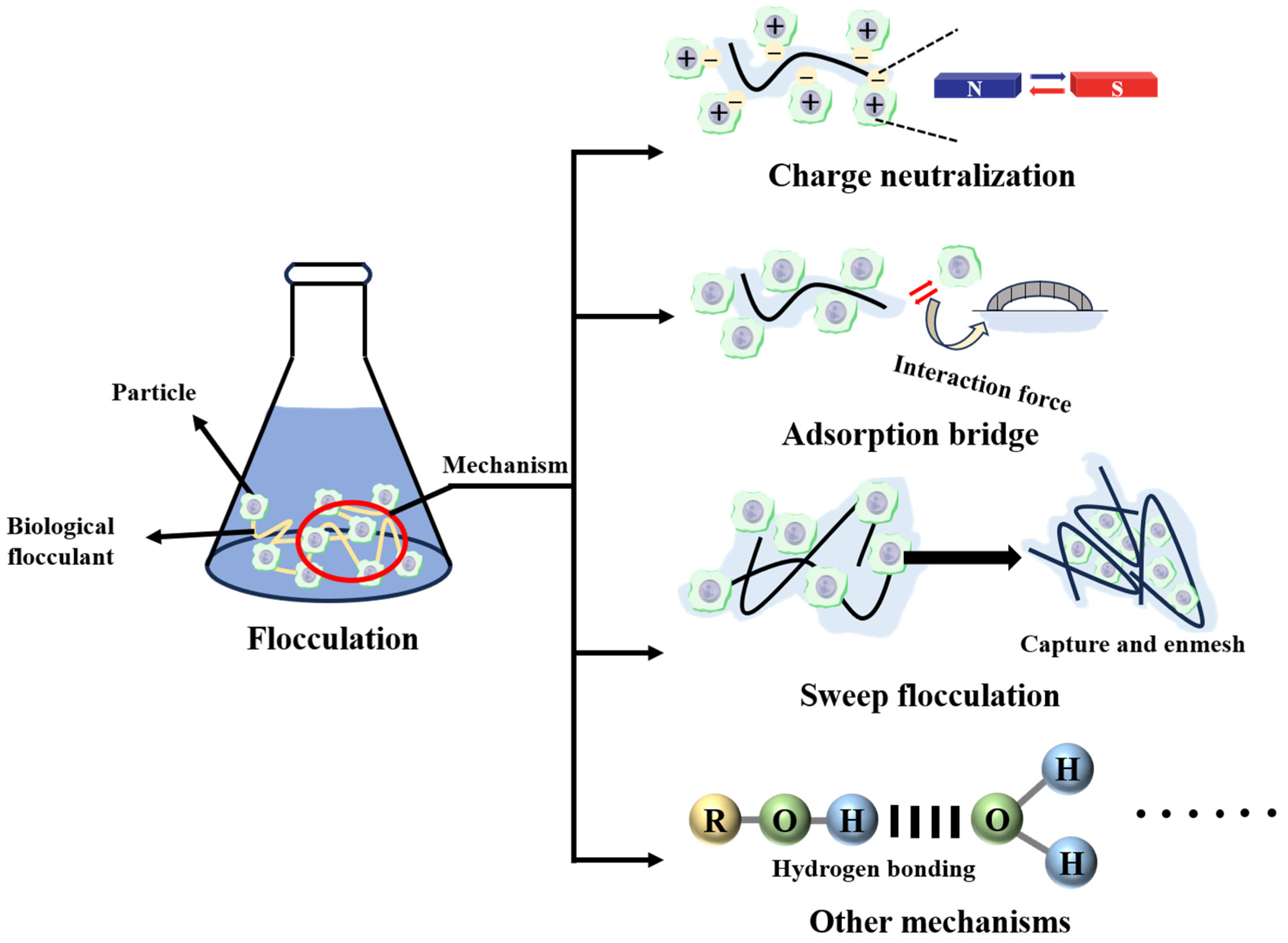

3.3. Flocculation Mechanisms

4. Applications in Wastewater Treatment

4.1. Removal of Suspended Solids

4.2. Removal of Heavy Metals

4.3. Removal of Dyes

4.4. Removal and Recovery of Sulfur Compounds

4.5. Other Applications

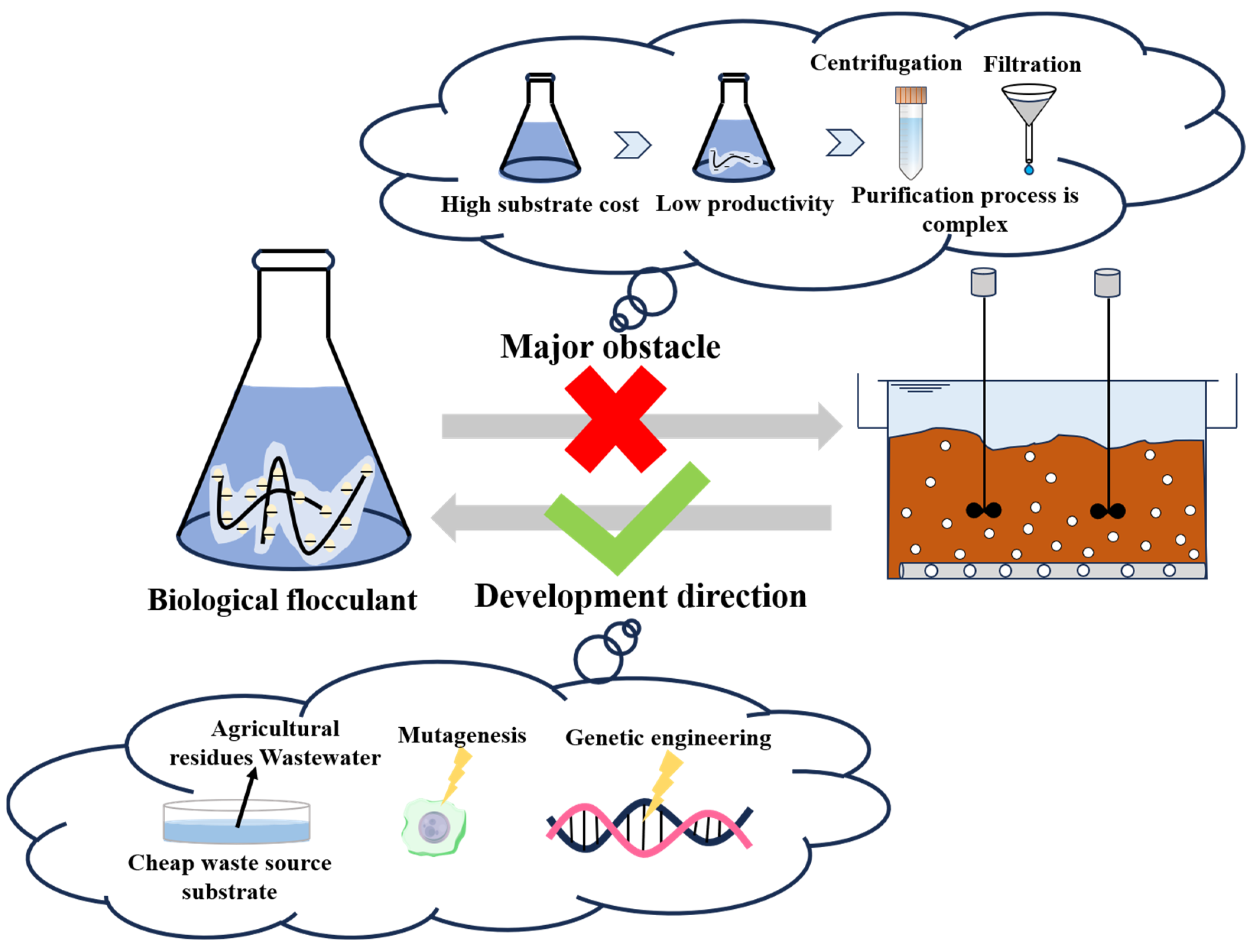

5. Challenges and Future Perspectives

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vimala, R.T.V.; Lija, E.; Chik, C.E.N.C.E.; Owodunni, A.A.; Ahmad, A.; Alnawajha, M.M.; Rahim, N.F.M.; Said, N.S.M.; Abdullah, S.R.S.; Kasan, N.A.; et al. What Compound inside Biocoagulants/Bioflocculants Is Contributing the Most to the Coagulation and Flocculation Processes? Sci. Total Environ. 2022, 806, 150902. [Google Scholar] [CrossRef]

- Abu Bakar, S.N.H.; Abu Hasan, H.; Abdullah, S.R.S.; Kasan, N.A.; Muhamad, M.H.; Kurniawan, S.B. A Review of the Production Process of Bacteria-Based Polymeric Flocculants. J. Water Process Eng. 2021, 40, 101915. [Google Scholar] [CrossRef]

- Wei, H.; Gao, B.; Ren, J.; Li, A.; Yang, H. Coagulation/Flocculation in Dewatering of Sludge: A Review. Water Res. 2018, 143, 608–631. [Google Scholar] [CrossRef]

- Kurniawan, S.B.; Imron, M.F.; Abdullah, S.R.S.; Othman, A.R.; Purwanti, I.F.; Hasan, H.A. Treatment of Real Aquaculture Effluent Using Bacteria-Based Bioflocculant Produced by Serratia marcescens. J. Water Process Eng. 2022, 47, 102708. [Google Scholar] [CrossRef]

- Artifon, W.; Cesca, K.; de Andrade, C.J.; Ulson de Souza, A.A.; de Oliveira, D. Dyestuffs from Textile Industry Wastewaters: Trends and Gaps in the Use of Bioflocculants. Process Biochem. 2021, 111, 181–190. [Google Scholar] [CrossRef]

- Lee, C.S.; Robinson, J.; Chong, M.F. A Review on Application of Flocculants in Wastewater Treatment. Process Saf. Environ. Protection 2014, 92, 489–508. [Google Scholar] [CrossRef]

- Nwodo, U.U.; Green, E.; Mabinya, L.V.; Okaiyeto, K.; Rumbold, K.; Obi, L.C.; Okoh, A.I. Bioflocculant Production by a Consortium of Streptomyces and Cellulomonas Species and Media Optimization via Surface Response Model. Colloids Surf. B Biointerfaces 2014, 116, 257–264. [Google Scholar] [CrossRef]

- Yin, Y.-J.; Tian, Z.-M.; Tang, W.; Li, L.; Song, L.-Y.; McElmurry, S.P. Production and Characterization of High Efficiency Bioflocculant Isolated from Klebsiella sp. ZZ-3. Bioresour. Technol. 2014, 171, 336–342. [Google Scholar] [CrossRef] [PubMed]

- Siddharth, T.; Sridhar, P.; Vinila, V.; Tyagi, R.D. Environmental Applications of Microbial Extracellular Polymeric Substance (EPS): A Review. J. Environ. Manag. 2021, 287, 112307. [Google Scholar] [CrossRef]

- Okaiyeto, K.; Nwodo, U.U.; Okoli, S.A.; Mabinya, L.V.; Okoh, A.I. Implications for Public Health Demands Alternatives to Inorganic and Synthetic Flocculants: Bioflocculants as Important Candidates. Microbiologyopen 2016, 5, 177–211. [Google Scholar] [CrossRef]

- Okaiyeto, K.; Nwodo, U.U.; Mabinya, L.V.; Okoli, A.S.; Okoh, A.I. Evaluation of Flocculating Performance of a Thermostable Bioflocculant Produced by Marine Bacillus sp. Environ. Technol. 2016, 37, 1829–1842. [Google Scholar] [CrossRef] [PubMed]

- Pu, S.; Qin, L.; Che, J.; Zhang, B.; Xu, M. Preparation and Application of a Novel Bioflocculant by Two Strains of Rhizopus sp. Using Potato Starch Wastewater as Nutrilite. Bioresour. Technol. 2014, 162, 184–191. [Google Scholar] [CrossRef]

- Huang, J.; Huang, Z.-L.; Zhou, J.-X.; Li, C.-Z.; Yang, Z.-H.; Ruan, M.; Li, H.; Zhang, X.; Wu, Z.-J.; Qin, X.-L.; et al. Enhancement of Heavy Metals Removal by Microbial Flocculant Produced by Paenibacillus polymyxa Combined with an Insufficient Hydroxide Precipitation. Chem. Eng. J. 2019, 374, 880–894. [Google Scholar] [CrossRef]

- Feng, J.; Xu, Y.; Ding, J.; He, J.; Shen, Y.; Lu, G.; Qin, W.; Guo, H. Optimal Production of Bioflocculant from Pseudomonas sp. GO2 and Its Removal Characteristics of Heavy Metals. J. Biotechnol. 2022, 344, 50–56. [Google Scholar] [CrossRef]

- Fan, H.; Yu, J.; Chen, R.; Yu, L. Preparation of a Bioflocculant by Using Acetonitrile as Sole Nitrogen Source and Its Application in Heavy Metals Removal. J. Hazard. Mater. 2019, 363, 242–247. [Google Scholar] [CrossRef]

- Mohamed Hatta, N.S.; Lau, S.W.; Takeo, M.; Chua, H.B.; Baranwal, P.; Mubarak, N.M.; Khalid, M. Novel Cationic Chitosan-like Bioflocculant from Citrobacter youngae GTC 01314 for the Treatment of Kaolin Suspension and Activated Sludge. J. Environ. Chem. Eng. 2021, 9, 105297. [Google Scholar] [CrossRef]

- Molaei, N.; Chehreh Chelgani, S.; Bobicki, E.R. A Comparison Study between Bioflocculants and PAM for Dewatering of Ultrafine Phyllosilicate Clay Minerals. Appl. Clay Sci. 2022, 218, 106409. [Google Scholar] [CrossRef]

- Guo, J.; Chen, C. Sludge Conditioning Using the Composite of a Bioflocculant and PAC for Enhancement in Dewaterability. Chemosphere 2017, 185, 277–283. [Google Scholar] [CrossRef]

- Cao, G.; Zhang, Y.; Chen, L.; Liu, J.; Mao, K.; Li, K.; Zhou, J. Production of a Bioflocculant from Methanol Wastewater and Its Application in Arsenite Removal. Chemosphere 2015, 141, 274–281. [Google Scholar] [CrossRef]

- Li, H.; Wu, S.; Du, C.; Zhong, Y.; Yang, C. Preparation, Performances, and Mechanisms of Microbial Flocculants for Wastewater Treatment. Int. J. Environ. Res. Public Health 2020, 17, 1360. [Google Scholar] [CrossRef]

- Gan, L.; Huang, X.; He, Z.; He, T. Exopolysaccharide Production by Salt-Tolerant Bacteria: Recent Advances, Current Challenges, and Future Prospects. Int. J. Biol. Macromol. 2024, 264, 130731. [Google Scholar] [CrossRef] [PubMed]

- Alias, J.; Abu Hasan, H.; Sheikh Abdullah, S.R.; Othman, A.R. Properties of Bioflocculant-Producing Bacteria for High Flocculating Activity Efficiency. Environ. Technol. Innov. 2022, 27, 102529. [Google Scholar] [CrossRef]

- de Jesus, C.S.; de Jesus Assis, D.; Rodriguez, M.B.; Menezes Filho, J.A.; Costa, J.A.V.; de Souza Ferreira, E.; Druzian, J.I. Pilot-Scale Isolation and Characterization of Extracellular Polymeric Substances (EPS) from Cell-Free Medium of Spirulina sp. LEB-18 Cultures under Outdoor Conditions. Int. J. Biol. Macromol. 2019, 124, 1106–1114. [Google Scholar] [CrossRef] [PubMed]

- Nie, Y.; Wang, Z.; Zhang, R.; Ma, J.; Zhang, H.; Li, S.; Li, J. Aspergillus oryzae, a Novel Eco-Friendly Fungal Bioflocculant for Turbid Drinking Water Treatment. Sep. Purif. Technol. 2021, 279, 119669. [Google Scholar] [CrossRef]

- Oyewole, O.A.; Jagaba, A.; Abdulhammed, A.A.; Yakubu, J.G.; Maude, A.M.; Abioye, O.P.; Adeniyi, O.D.; Egwim, E.C. Production and Characterization of a Bioflocculant Produced by Microorganisms Isolated from Earthen Pond Sludge. Bioresour. Technol. Rep. 2023, 22, 101492. [Google Scholar] [CrossRef]

- Lian, B.; Chen, Y.; Zhao, J.; Teng, H.H.; Zhu, L.; Yuan, S. Microbial Flocculation by Bacillus mucilaginosus: Applications and Mechanisms. Bioresour. Technol. 2008, 99, 4825–4831. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Liu, H.; Zhou, J. Characterization of a Bioflocculant MBF-5 by Klebsiella pneumoniae and Its Application in Acanthamoeba Cysts Removal. Bioresour. Technol. 2013, 137, 226–232. [Google Scholar] [CrossRef] [PubMed]

- Moghannem, S.A.M.; Farag, M.M.S.; Shehab, A.M.; Azab, M.S. Exopolysaccharide Production from Bacillus velezensis KY471306 Using Statistical Experimental Design. Braz. J. Microbiol. 2018, 49, 452–462. [Google Scholar] [CrossRef]

- Xia, S.; Zhang, Z.; Wang, X.; Yang, A.; Chen, L.; Zhao, J.; Leonard, D.; Jaffrezic-Renault, N. Production and Characterization of a Bioflocculant by Proteus mirabilis TJ-1. Bioresour. Technol. 2008, 99, 6520–6527. [Google Scholar] [CrossRef]

- Deng, S.; Yu, G.; Ting, Y.P. Production of a Bioflocculant by Aspergillus parasiticus and Its Application in Dye Removal. Colloids Surf. B Biointerfaces 2005, 44, 179–186. [Google Scholar] [CrossRef]

- Prasertsan, P.; Dermlim, W.; Doelle, H.; Kennedy, J.F. Screening, Characterization and Flocculating Property of Carbohydrate Polymer from Newly Isolated Enterobacter cloacae WD7. Carbohydr. Polym. 2006, 66, 289–297. [Google Scholar] [CrossRef]

- Xia, X.; Lan, S.; Li, X.; Xie, Y.; Liang, Y.; Yan, P.; Chen, Z.; Xing, Y. Characterization and Coagulation-Flocculation Performance of a Composite Flocculant in High-Turbidity Drinking Water Treatment. Chemosphere 2018, 206, 701–708. [Google Scholar] [CrossRef] [PubMed]

- Gong, W.-X.; Wang, S.-G.; Sun, X.-F.; Liu, X.-W.; Yue, Q.-Y.; Gao, B.-Y. Bioflocculant Production by Culture of Serratia ficaria and Its Application in Wastewater Treatment. Bioresour. Technol. 2008, 99, 4668–4674. [Google Scholar] [CrossRef] [PubMed]

- Aljuboori, A.H.R.; Idris, A.; Abdullah, N.; Mohamad, R. Production and Characterization of a Bioflocculant Produced by Aspergillus flavus. Bioresour. Technol. 2013, 127, 489–493. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.-F.; Cheng, W. Characteristics and Culture Conditions of a Bioflocculant Produced by Penicillium sp. Biomed. Environ. Sci. 2010, 23, 213–218. [Google Scholar] [CrossRef] [PubMed]

- Shih, I.L.; Van, Y.T.; Yeh, L.C.; Lin, H.G.; Chang, Y.N. Production of a Biopolymer Flocculant from Bacillus licheniformis and Its Flocculation Properties. Bioresour. Technol. 2001, 78, 267–272. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Cheng, R.; Xu, X.; Kong, C.; Wang, L.; Fu, R.; Li, J.; Wang, S.; Zhang, J. The Structure and Flocculation Characteristics of a Novel Exopolysaccharide from a Paenibacillus Isolate. Carbohydr. Polym. 2022, 291, 119561. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Wei, X.; Chi, Z.; Liu, G.-L.; Hu, Z.; Chi, Z.-M. Improved Production of an Acidic Exopolysaccharide, the Efficient Flocculant, by Lipomyces starkeyi U9 Overexpressing UDP-Glucose Dehydrogenase Gene. Int. J. Biol. Macromol. 2020, 165, 1656–1663. [Google Scholar] [CrossRef] [PubMed]

- Maliehe, T.S.; Basson, A.K.; Dlamini, N.G. Removal of Pollutants in Mine Wastewater by a Non-Cytotoxic Polymeric Bioflocculant from Alcaligenes faecalis HCB2. Int. J. Environ. Res. Public Health 2019, 16, 4001. [Google Scholar] [CrossRef]

- Sun, R.; Sun, P.; Zhang, J.; Esquivel-Elizondo, S.; Wu, Y. Microorganisms-Based Methods for Harmful Algal Blooms Control: A Review. Bioresour. Technol. 2018, 248, 12–20. [Google Scholar] [CrossRef]

- Pei, X.-Y.; Ren, H.-Y.; Liu, B.-F. Flocculation Performance and Mechanism of Fungal Pellets on Harvesting of Microalgal Biomass. Bioresour. Technol. 2021, 321, 124463. [Google Scholar] [CrossRef] [PubMed]

- Characterization of the Flocculating Agent from the Spontaneously Flocculating Microalga Chlorella vulgaris JSC-7. J. Biosci. Bioeng. 2014, 118, 29–33. [CrossRef] [PubMed]

- Guo, S.-L.; Zhao, X.-Q.; Wan, C.; Huang, Z.-Y.; Yang, Y.-L.; Asraful Alam, M.; Ho, S.-H.; Bai, F.-W.; Chang, J.-S. Characterization of Flocculating Agent from the Self-Flocculating Microalga Scenedesmus obliquus AS-6-1 for Efficient Biomass Harvest. Bioresour. Technol. 2013, 145, 285–289. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, M.H.; Ojima, Y.; Sakka, M.; Sakka, K.; Taya, M. Probing of Exopolysaccharides with Green Fluorescence Protein-Labeled Carbohydrate-Binding Module in Escherichia coli Biofilms and Flocs Induced by bcsB Overexpression. J. Biosci. Bioeng. 2014, 118, 400–405. [Google Scholar] [CrossRef] [PubMed]

- Ummalyma, S.B.; Gnansounou, E.; Sukumaran, R.K.; Sindhu, R.; Pandey, A.; Sahoo, D. Bioflocculation: An Alternative Strategy for Harvesting of Microalgae—An Overview. Bioresour. Technol. 2017, 242, 227–235. [Google Scholar] [CrossRef] [PubMed]

- Pathak, M.; Sarma, H.K.; Bhattacharyya, K.G.; Subudhi, S.; Bisht, V.; Lal, B.; Devi, A. Characterization of a Novel Polymeric Bioflocculant Produced from Bacterial Utilization of N-Hexadecane and Its Application in Removal of Heavy Metals. Front. Microbiol. 2017, 8, 170. [Google Scholar] [CrossRef] [PubMed]

- Salehizadeh, H.; Yan, N.; Farnood, R. Recent Advances in Polysaccharide Bio-Based Flocculants. Biotechnol. Adv. 2018, 36, 92–119. [Google Scholar] [CrossRef] [PubMed]

- Tang, W.; Song, L.; Li, D.; Qiao, J.; Zhao, T.; Zhao, H. Production, Characterization, and Flocculation Mechanism of Cation Independent, pH Tolerant, and Thermally Stable Bioflocculant from Enterobacter sp. ETH-2. PLoS ONE 2014, 9, e114591. [Google Scholar] [CrossRef]

- Li, Z.; Zhong, S.; Lei, H.; Chen, R.; Yu, Q.; Li, H.-L. Production of a Novel Bioflocculant by Bacillus licheniformis X14 and Its Application to Low Temperature Drinking Water Treatment. Bioresour. Technol. 2009, 100, 3650–3656. [Google Scholar] [CrossRef]

- Pu, L.; Zeng, Y.-J.; Xu, P.; Li, F.-Z.; Zong, M.-H.; Yang, J.-G.; Lou, W.-Y. Using a Novel Polysaccharide BM2 Produced by Bacillus megaterium Strain PL8 as an Efficient Bioflocculant for Wastewater Treatment. Int. J. Biol. Macromol. 2020, 162, 374–384. [Google Scholar] [CrossRef]

- Nie, Y.; Wang, Z.; Wang, W.; Zhou, Z.; Kong, Y.; Ma, J. Bio-Flocculation of Microcystis aeruginosa by Using Fungal Pellets of Aspergillus oryzae: Performance and Mechanism. J. Hazard. Mater. 2022, 439, 129606. [Google Scholar] [CrossRef] [PubMed]

- Shahadat, M.; Teng, T.T.; Rafatullah, M.; Shaikh, Z.A.; Sreekrishnan, T.R.; Ali, S.W. Bacterial Bioflocculants: A Review of Recent Advances and Perspectives. Chem. Eng. J. 2017, 328, 1139–1152. [Google Scholar] [CrossRef]

- Guo, J.; Yu, J.; Xin, X.; Zou, C.; Cheng, Q.; Yang, H.; Nengzi, L. Characterization and Flocculation Mechanism of a Bioflocculant from Hydrolyzate of Rice Stover. Bioresour. Technol. 2015, 177, 393–397. [Google Scholar] [CrossRef] [PubMed]

- Nontembiso, P.; Sekelwa, C.; Leonard, M.V.; Anthony, O.I. Assessment of Bioflocculant Production by Bacillus sp. Gilbert, a Marine Bacterium Isolated from the Bottom Sediment of Algoa Bay. Mar. Drugs 2011, 9, 1232–1242. [Google Scholar] [CrossRef] [PubMed]

- Gao, Q.; Zhu, X.-H.; Mu, J.; Zhang, Y.; Dong, X.-W. Using Ruditapes philippinarum Conglutination Mud to Produce Bioflocculant and Its Applications in Wastewater Treatment. Bioresour. Technol. 2009, 100, 4996–5001. [Google Scholar] [CrossRef] [PubMed]

- Salehizadeh, H.; Shojaosadati, S.A. Removal of Metal Ions from Aqueous Solution by Polysaccharide Produced from Bacillus firmus. Water Res. 2003, 37, 4231–4235. [Google Scholar] [CrossRef] [PubMed]

- Toeda, K.; Kurane, R. Microbial Flocculant from Alcaligenes cupidus KT201. Agric. Biol. Chem. 1991, 55, 2793–2799. [Google Scholar] [CrossRef]

- Kumar, C.G.; Joo, H.; Kavali, R.; Choi, J.; Chang, C. Characterization of an Extracellular Biopolymer Flocculant from a Haloalkalophilic Bacillus Isolate. World J. Microbiol. Biotechnol. 2004, 20, 837–843. [Google Scholar] [CrossRef]

- Cosa, S.; Mabinya, L.V.; Olaniran, A.O.; Okoh, O.O.; Bernard, K.; Deyzel, S.; Okoh, A.I. Bioflocculant Production by Virgibacillus sp. Rob Isolated from the Bottom Sediment of Algoa Bay in the Eastern Cape, South Africa. Molecules 2011, 16, 2431–2442. [Google Scholar] [CrossRef]

- Li, Q.; Liu, H.; Qi, Q.; Wang, F.-S.; Zhang, Y. Isolation and Characterization of Temperature and Alkaline Stable Bioflocculant from Agrobacterium sp. M-503. New Biotechnol. 2010, 27, 789–794. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, X.; Zhou, Z.; Feng, J.; Sun, Y.; Ren, J.; Lu, Z. New Insights into Biopolymers: In Situ Collection and Reuse for Coagulation Aiding in Drinking Water Treatment Plants and Microbial Mechanism. Sep. Purif. Technol. 2024, 337, 126448. [Google Scholar] [CrossRef]

- Flaten, T.P. Aluminium as a Risk Factor in Alzheimer’s Disease, with Emphasis on Drinking Water. Brain Res. Bull. 2001, 55, 187–196. [Google Scholar] [CrossRef] [PubMed]

- Brostow, W.; Pal, S.; Singh, R.P. A Model of Flocculation. Mater. Lett. 2007, 61, 4381–4384. [Google Scholar] [CrossRef]

- Mabinya, L.V.; Cosa, S.; Nwodo, U.; Okoh, A.I. Studies on Bioflocculant Production by Arthrobacter sp. Raats, a Freshwater Bacteria Isolated from Tyume River, South Africa. Int. J. Mol. Sci. 2012, 13, 1054–1065. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.-Y.; Ye, H.-F. Characterization and Flocculating Properties of an Extracellular Biopolymer Produced from a Bacillus subtilis DYU1 Isolate. Process Biochem. 2007, 42, 1114–1123. [Google Scholar] [CrossRef]

- Elkady, M. Bioflocculation of Basic Dye onto Isolated Microbial Biopolymers. Chem. Biochem. Eng. Q. 2017, 31, 209–224. [Google Scholar] [CrossRef]

- Gao, J.; Bao, H.; Xin, M.; Liu, Y.; Li, Q.; Zhang, Y. Characterization of a Bioflocculant from a Newly Isolated Vagococcus sp. W31. J. Zhejiang Univ. Sci. B 2006, 7, 186–192. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Luo, K.; Liao, D.; Li, X.; Wang, D.; Liu, X.; Zeng, G.; Li, X. A Novel Bioflocculant Produced by Klebsiella sp. and Its Application to Sludge Dewatering. Water Environ. J. 2012, 26, 560–566. [Google Scholar] [CrossRef]

- Lu, W.-Y.; Zhang, T.; Zhang, D.-Y.; Li, C.-H.; Wen, J.-P.; Du, L.-X. A Novel Bioflocculant Produced by Enterobacter aerogenes and Its Use in Defecating the Trona Suspension. Biochem. Eng. J. 2005, 27, 1–7. [Google Scholar] [CrossRef]

- Yokoi, H.; Natsuda, O.; Hirose, J.; Hayashi, S.; Takasaki, Y. Characteristics of a Biopolymer Flocculant Produced by Bacillus sp. PY-90. J. Ferment. Bioeng. 1995, 79, 378–380. [Google Scholar] [CrossRef]

- Zhang, T.; Lin, Z.; Zhu, H. Microbial Flocculant and Its Application in Environmental Protection. J. Environ. Sci. 1999, 11, 1–12. [Google Scholar]

- Zhong, C.; Xu, A.; Wang, B.; Yang, X.; Hong, W.; Yang, B.; Chen, C.; Liu, H.; Zhou, J. Production of a Value Added Compound from the H-Acid Waste Water—Bioflocculants by Klebsiella pneumoniae. Colloids Surf. B Biointerfaces 2014, 122, 583–590. [Google Scholar] [CrossRef] [PubMed]

- Elkady, M.F.; Farag, S.; Zaki, S.; Abu-Elreesh, G.; Abd-El-Haleem, D. Bacillus mojavensis Strain 32A, a Bioflocculant-Producing Bacterium Isolated from an Egyptian Salt Production Pond. Bioresour. Technol. 2011, 102, 8143–8151. [Google Scholar] [CrossRef]

- Levy, N.; Magdassi, S.; Bar-Or, Y. Physico-Chemical Aspects in Flocculation of Bentonite Suspensions by a Cyanobacterial Bioflocculant. Water Res. 1992, 26, 249–254. [Google Scholar] [CrossRef]

- Deng, S.; Bai, R.; Hu, X.; Luo, Q. Characteristics of a Bioflocculant Produced by Bacillus mucilaginosus and Its Use in Starch Wastewater Treatment. Appl. Microbiol. Biotechnol. 2003, 60, 588–593. [Google Scholar] [CrossRef] [PubMed]

- Hassimi, A.H.; Ezril Hafiz, R.; Muhamad, M.H.; Sheikh Abdullah, S.R. Bioflocculant Production Using Palm Oil Mill and Sago Mill Effluent as a Fermentation Feedstock: Characterization and Mechanism of Flocculation. J. Environ. Manag. 2020, 260, 110046. [Google Scholar] [CrossRef] [PubMed]

- Yim, J.H.; Kim, S.J.; Ahn, S.H.; Lee, H.K. Characterization of a Novel Bioflocculant, p-KG03, from a Marine Dinoflagellate, Gyrodinium impudicum KG03. Bioresour. Technol. 2007, 98, 361–367. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Ye, Z.-L.; Fang, X.-L.; Li, Y.-H.; Cai, W.-M. Production and Characteristics of a Bioflocculant Produced by Bacillus sp. F19. Bioresour. Technol. 2008, 99, 7686–7691. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Hu, Z.; Wang, T.; Chen, Y.; Zhang, J.; Yu, J.; Zhang, T.; Zhang, Y.; Li, Y. Production of Novel Microbial Flocculants by Klebsiella sp. TG-1 Using Waste Residue from the Food Industry and Its Use in Defecating the Trona Suspension. Bioresour. Technol. 2013, 139, 265–271. [Google Scholar] [CrossRef] [PubMed]

- Kurniawan, S.B.; Ahmad, A.; Imron, M.F.; Abdullah, S.R.S.; Othman, A.R.; Hasan, H.A. Potential of Microalgae Cultivation Using Nutrient-Rich Wastewater and Harvesting Performance by Biocoagulants/Bioflocculants: Mechanism, Multi-Conversion of Biomass into Valuable Products, and Future Challenges. J. Clean. Prod. 2022, 365, 132806. [Google Scholar] [CrossRef]

- Li, R.; Gao, B.; Huang, X.; Dong, H.; Li, X.; Yue, Q.; Wang, Y.; Li, Q. Compound Bioflocculant and Polyaluminum Chloride in Kaolin-Humic Acid Coagulation: Factors Influencing Coagulation Performance and Floc Characteristics. Bioresour. Technol. 2014, 172, 8–15. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Sun, J.; Liu, X.; Zhou, J. Production and Flocculating Performance of Sludge Bioflocculant from Biological Sludge. Bioresour. Technol. 2013, 146, 51–56. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Li, Q.; Hao, D.; Hu, Z.; Song, D.; Yang, M. Characterization and Flocculation Mechanism of an Alkali-Activated Polysaccharide Flocculant from Arthrobacter sp. B4. Bioresour. Technol. 2014, 170, 574–577. [Google Scholar] [CrossRef] [PubMed]

- Salim, S.; Bosma, R.; Vermuë, M.H.; Wijffels, R.H. Harvesting of Microalgae by Bio-Flocculation. J. Appl. Phycol. 2011, 23, 849–855. Available online: https://link.springer.com/article/10.1007/s10811-010-9591-x (accessed on 6 June 2024). [CrossRef] [PubMed]

- Zou, X.; Sun, J.; Li, J.; Jia, Y.; Xiao, T.; Meng, F.; Wang, M.; Ning, Z. High Flocculation of Coal Washing Wastewater Using a Novel Bioflocculant from Isaria cicadae GZU6722. Pol. J. Microbiol. 2020, 69, 55–64. [Google Scholar] [CrossRef] [PubMed]

- Buthelezi, S.P.; Olaniran, A.O.; Pillay, B. Production and Characterization of Bioflocculants from Bacteria Isolated from Wastewater Treatment Plant in South Africa. Biotechnol. Bioprocess Eng. 2010, 15, 874–881. [Google Scholar] [CrossRef]

- Fu, F.; Wang, Q. Removal of Heavy Metal Ions from Wastewaters: A Review. J. Environ. Manag. 2011, 92, 407–418. [Google Scholar] [CrossRef] [PubMed]

- Sathiyanarayanan, G.; Dineshkumar, K.; Yang, Y.-H. Microbial Exopolysaccharide-Mediated Synthesis and Stabilization of Metal Nanoparticles. Crit. Rev. Microbiol. 2017, 43, 731–752. [Google Scholar] [CrossRef]

- Sathiyanarayanan, G.; Seghal Kiran, G.; Selvin, J. Synthesis of Silver Nanoparticles by Polysaccharide Bioflocculant Produced from Marine Bacillus subtilis MSBN17. Colloids Surf. B Biointerfaces 2013, 102, 13–20. [Google Scholar] [CrossRef]

- Eman Zakaria, G. Production and Characteristics of a Heavy Metals Removing Bioflocculant Produced by Pseudomonas aeruginosa. Pol. J. Microbiol. 2012, 61, 281–289. [Google Scholar] [CrossRef]

- Liu, J.; Ma, J.; Liu, Y.; Yang, Y.; Yue, D.; Wang, H. Optimized Production of a Novel Bioflocculant M-C11 by Klebsiella sp. and Its Application in Sludge Dewatering. J. Environ. Sci. 2014, 26, 2076–2083. [Google Scholar] [CrossRef]

- Vimala, R.T.V. Role of Bacterial Bioflocculant on Antibiofilm Activity and Metal Removal Efficiency. J. Pure Appl. Microbiol. 2019, 13, 1823–1830. [Google Scholar] [CrossRef]

- Ma, X.; Duan, D.; Chen, X.; Feng, X.; Ma, Y. A Polysaccharide-Based Bioflocculant BP50-2 from Banana Peel Waste: Purification, Structure and Flocculation Performance. Int. J. Biol. Macromol. 2022, 205, 604–614. [Google Scholar] [CrossRef]

- Ayed, L.; Khelifi, E.; Jannet, H.B.; Miladi, H.; Cheref, A.; Achour, S.; Bakhrouf, A. Response Surface Methodology for Decolorization of Azo Dye Methyl Orange by Bacterial Consortium: Produced Enzymes and Metabolites Characterization. Chem. Eng. J. 2010, 165, 200–208. [Google Scholar] [CrossRef]

- Neetha, N.J.; Sandesh, K.; Girish Kumar, K.; Chidananda, B.; Ujwal, P. Optimization of Direct Blue-14 Dye Degradation by Bacillus fermus (Kx898362) an Alkaliphilic Plant Endophyte and Assessment of Degraded Metabolite Toxicity. J. Hazard. Mater. 2019, 364, 742–751. [Google Scholar] [CrossRef]

- Prabhakar, Y.; Gupta, A.; Kaushik, A. Microbial Degradation of Reactive Red-35 Dye: Upgraded Progression through Box–Behnken Design Modeling and Cyclic Acclimatization. J. Water Process Eng. 2021, 40, 101782. [Google Scholar] [CrossRef]

- Artifon, W.; Mazur, L.P.; de Souza, A.A.U.; de Oliveira, D. Production of Bioflocculants from Spent Brewer’s Yeast and Its Application in the Treatment of Effluents with Textile Dyes. J. Water Process Eng. 2022, 49, 102997. [Google Scholar] [CrossRef]

- Chen, F.; Yuan, Y.; Chen, C.; Zhao, Y.; Tan, W.; Huang, C.; Xu, X.; Wang, A. Investigation of Colloidal Biogenic Sulfur Flocculation: Optimization Using Response Surface Analysis. J. Environ. Sci. 2016, 42, 227–235. [Google Scholar] [CrossRef]

- Lee, C.-M.; Sublette, K.L. Microbial Treatment of Sulfide-Laden Water. Water Res. 1993, 27, 839–846. [Google Scholar] [CrossRef]

- Shende, A.P.; Chidambaram, R. Cocoyam Powder Extracted from Colocasia antiquorum as a Novel Plant-Based Bioflocculant for Industrial Wastewater Treatment: Flocculation Performance and Mechanism. Heliyon 2023, 9, e15228. [Google Scholar] [CrossRef]

- Lee, D.-J.; Liu, X.; Weng, H.-L. Sulfate and Organic Carbon Removal by Microbial Fuel Cell with Sulfate-Reducing Bacteria and Sulfide-Oxidising Bacteria Anodic Biofilm. Bioresour. Technol. 2014, 156, 14–19. [Google Scholar] [CrossRef]

- Wu, B.; Liu, F.; Fang, W.; Yang, T.; Chen, G.-H.; He, Z.; Wang, S. Microbial Sulfur Metabolism and Environmental Implications. Sci. Total Environ. 2021, 778, 146085. [Google Scholar] [CrossRef]

- Han, F.; Zhang, M.; Shang, H.; Liu, Z.; Zhou, W. Microbial Community Succession, Species Interactions and Metabolic Pathways of Sulfur-Based Autotrophic Denitrification System in Organic-Limited Nitrate Wastewater. Bioresour. Technol. 2020, 315, 123826. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.-Z.; Zhao, X.-Y.; Miao, X.-P.; Chen, J.; Ye, J.-X.; Cheng, Z.-W.; Zhang, S.-H.; Chen, J.-M. A Solid Composite Microbial Inoculant for the Simultaneous Removal of Volatile Organic Sulfide Compounds: Preparation, Characterization, and Its Bioaugmentation of a Biotrickling Filter. J. Hazard. Mater. 2018, 342, 589–596. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Chen, C. Removal of Arsenite by a Microbial Bioflocculant Produced from Swine Wastewater. Chemosphere 2017, 181, 759–766. [Google Scholar] [CrossRef] [PubMed]

- Sajayan, A.; Seghal Kiran, G.; Priyadharshini, S.; Poulose, N.; Selvin, J. Revealing the Ability of a Novel Polysaccharide Bioflocculant in Bioremediation of Heavy Metals Sensed in a Vibrio Bioluminescence Reporter Assay. Environ. Pollut. 2017, 228, 118–127. [Google Scholar] [CrossRef]

- Yu, L.; Hua, J.; Fan, H.; George, O.; Lu, Y. Simultaneous Nitriles Degradation and Bioflocculant Production by Immobilized K. oxytoca Strain in a Continuous Flow Reactor. J. Hazard. Mater. 2020, 387, 121697. [Google Scholar] [CrossRef]

- Sharma, V.K.; Ma, X.; Lichtfouse, E.; Robert, D. Nanoplastics Are Potentially More Dangerous than Microplastics. Environ. Chem. Lett. 2023, 21, 1933–1936. [Google Scholar] [CrossRef]

- Ahmad Shukri, Z.N.; Che Engku Chik, C.E.N.; Hossain, S.; Othman, R.; Endut, A.; Lananan, F.; Terkula, I.B.; Kamaruzzan, A.S.; Abdul Rahim, A.I.; Draman, A.S.; et al. A Novel Study on the Effectiveness of Bioflocculant-Producing Bacteria Bacillus enclensis, Isolated from Biofloc-Based System as a Biodegrader in Microplastic Pollution. Chemosphere 2022, 308, 136410. [Google Scholar] [CrossRef]

- Padervand, M.; Lichtfouse, E.; Robert, D.; Wang, C. Removal of Microplastics from the Environment. A Review. Environ. Chem. Lett. 2020, 18, 807–828. [Google Scholar] [CrossRef]

- Shurair, M.; Almomani, F.; Bhosale, R.; Khraisheh, M.; Qiblawey, H. Harvesting of Intact Microalgae in Single and Sequential Conditioning Steps by Chemical and Biological Based–Flocculants: Effect on Harvesting Efficiency, Water Recovery and Algal Cell Morphology. Bioresour. Technol. 2019, 281, 250–259. [Google Scholar] [CrossRef] [PubMed]

- Kurade, M.B.; Murugesan, K.; Selvam, A.; Yu, S.-M.; Wong, J.W.C. Ferric Biogenic Flocculant Produced by Acidithiobacillus ferrooxidans Enable Rapid Dewaterability of Municipal Sewage Sludge: A Comparison with Commercial Cationic Polymer. Int. Biodeterior. Biodegrad. 2014, 96, 105–111. [Google Scholar] [CrossRef]

- Muthulakshmi, L.; Seghal Kiran, G.; Ramakrishna, S.; Cheng, K.Y.; Ampadi Ramachandran, R.; Mathew, M.T.; Pruncu, C.I. Towards Improving the Corrosion Resistance Using a Novel Eco-Friendly Bioflocculant Polymer Produced from Bacillus sp. Mater. Today Commun. 2023, 35, 105438. [Google Scholar] [CrossRef]

- Pritchard, M.; Craven, T.; Mkandawire, T.; Edmondson, A.S.; O’Neill, J.G. A Comparison between Moringa oleifera and Chemical Coagulants in the Purification of Drinking Water—An Alternative Sustainable Solution for Developing Countries. Phys. Chem. Earth Parts A/B/C 2010, 35, 798–805. [Google Scholar] [CrossRef]

- Vimala, R.T.V.; Lija Escaline, J.; Sivaramakrishnan, S. Characterization of Self-Assembled Bioflocculant from the Microbial Consortium and Its Applications. J. Environ. Manag. 2020, 258, 110000. [Google Scholar] [CrossRef]

- Tsilo, P.H.; Basson, A.K.; Ntombela, Z.G.; Maliehe, T.S.; Pullabhotla, V.S.R.R. Production and Characterization of a Bioflocculant from Pichia kudriavzevii MH545928.1 and Its Application in Wastewater Treatment. Int. J. Environ. Res. Public Health 2022, 19, 3148. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Hao, N.; Hou, Y.; Wang, Q.; Liu, Q.; Yan, S.; Chen, F.; Zhao, L. Technologies for Harvesting the Microalgae for Industrial Applications: Current Trends and Perspectives. Bioresour. Technol. 2023, 387, 129631. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Sun, D.; Liu, J.; Zhu, J.; Liu, W. Recent Advances and Perspectives in Efforts to Reduce the Production and Application Cost of Microbial Flocculants. Bioresour. Bioprocess. 2021, 8, 51. [Google Scholar] [CrossRef]

- Zha, X.; Li, C.; Li, X.; Huang, Y. Hydrothermal Liquid Fraction of Concentrated Organic Matter in Sewage for Coarse Flocculant Preparation: The Role and Regulation Mechanism. Sep. Purif. Technol. 2024, 339, 126654. [Google Scholar] [CrossRef]

- Kurniawan, S.B.; Abdullah, S.R.S.; Othman, A.R.; Purwanti, I.F.; Imron, M.F.; Ismail, N.; Izzati; Ahmad, A.; Hasan, H.A. Isolation and Characterisation of Bioflocculant-Producing Bacteria from Aquaculture Effluent and Its Performance in Treating High Turbid Water. J. Water Process Eng. 2021, 42, 102194. [Google Scholar] [CrossRef]

- Li, N.-J.; Lan, Q.; Wu, J.-H.; Liu, J.; Zhang, X.-H.; Zhang, F.; Yu, H.-Q. Soluble Microbial Products from the White-Rot Fungus Phanerochaete chrysosporium as the Bioflocculant for Municipal Wastewater Treatment. Sci. Total Environ. 2021, 780, 146662. [Google Scholar] [CrossRef]

- Kurniawan, S.B.; Imron, M.F.; Sługocki, Ł.; Nowakowski, K.; Ahmad, A.; Najiya, D.; Abdullah, S.R.S.; Othman, A.R.; Purwanti, I.F.; Hasan, H.A. Assessing the Effect of Multiple Variables on the Production of Bioflocculant by Serratia marcescens: Flocculating Activity, Kinetics, Toxicity, and Flocculation Mechanism. Sci. Total Environ. 2022, 836, 155564. [Google Scholar] [CrossRef] [PubMed]

- Rajivgandhi, G.; Vimala, R.T.V.; Maruthupandy, M.; Alharbi, N.S.; Kadaikunnan, S.; Khaled, J.M.; Manoharan, N.; Li, W.-J. Enlightening the Characteristics of Bioflocculant of Endophytic Actinomycetes from Marine Algae and Its Biosorption of Heavy Metal Removal. Environ. Res. 2021, 200, 111708. [Google Scholar] [CrossRef] [PubMed]

- Giri, S.S.; Ryu, E.; Park, S.C. Characterization of the Antioxidant and Anti-Inflammatory Properties of a Polysaccharide-Based Bioflocculant from Bacillus subtilis F9. Microb. Pathog. 2019, 136, 103642. [Google Scholar] [CrossRef] [PubMed]

- Nouha, K.; Kumar, R.S.; Balasubramanian, S.; Tyagi, R.D. Critical Review of EPS Production, Synthesis and Composition for Sludge Flocculation. J. Environ. Sci. 2018, 66, 225–245. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Zhao, B.; An, Q.; Qiu Guo, Z.; Huang, C. The Characteristics and Flocculation Mechanisms of SMP and B-EPS from a Bioflocculant-Producing Bacterium Pseudomonas sp. XD-3 and the Application for Sludge Dewatering. Chem. Eng. J. 2024, 479, 147584. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, W.; Ngo, H.H.; Zhang, X.; Liang, S.; Deng, L.; Cheng, D.; Zhang, H. Bioflocculants in Anaerobic Membrane Bioreactors: A Review on Membrane Fouling Mitigation Strategies. Chem. Eng. J. 2024, 486, 150260. [Google Scholar] [CrossRef]

- Li, L.; He, Z.; Song, Z.; Sheng, T.; Dong, Z.; Zhang, F.; Ma, F. A Novel Strategy for Rapid Formation of Biofilm: Polylactic Acid Mixed with Bioflocculant Modified Carriers. J. Clean. Prod. 2022, 374, 134023. [Google Scholar] [CrossRef]

- Hou, J.; Xia, L.; Ma, T.; Zhang, Y.; Zhou, Y.; He, X. Achieving Short-Cut Nitrification and Denitrification in Modified Intermittently Aerated Constructed Wetland. Bioresour. Technol. 2017, 232, 10–17. [Google Scholar] [CrossRef]

- Yao, S.; Chen, L.; Guan, D.; Zhang, Z.; Tian, X.; Wang, A.; Wang, G.; Yao, Q.; Peng, D.; Li, J. On-Site Nutrient Recovery and Removal from Source-Separated Urine by Phosphorus Precipitation and Short-Cut Nitrification-Denitrification. Chemosphere 2017, 175, 210–218. [Google Scholar] [CrossRef]

- Zheng, X.; Zhou, W.; Wan, R.; Luo, J.; Su, Y.; Huang, H.; Chen, Y. Increasing Municipal Wastewater BNR by Using the Preferred Carbon Source Derived from Kitchen Wastewater to Enhance Phosphorus Uptake and Short-Cut Nitrification-Denitrification. Chem. Eng. J. 2018, 344, 556–564. [Google Scholar] [CrossRef]

- Liu, Y.; Zeng, Y.; Yang, J.; Chen, P.; Sun, Y.; Wang, M.; Ma, Y. A Bioflocculant from Corynebacterium glutamicum and Its Application in Acid Mine Wastewater Treatment. Front. Bioeng. Biotechnol. 2023, 11, 1136473. [Google Scholar] [CrossRef] [PubMed]

- Zeng, F.; Xu, L.; Sun, C.; Liu, H.; Chen, L. A Novel Bioflocculant from Raoultella Planticola Enhances Removal of Copper Ions from Water. J. Sens. 2020, 2020, 1–10. [Google Scholar] [CrossRef]

- Ni, F.; Peng, X.; He, J.; Yu, L.; Zhao, J.; Luan, Z. Preparation and Characterization of Composite Bioflocculants in Comparison with Dual-Coagulants for the Treatment of Kaolin Suspension. Chem. Eng. J. 2012, 213, 195–202. [Google Scholar] [CrossRef]

- Polizzi, C.; Gabriel, D.; Munz, G. Successful Sulphide-Driven Partial Denitrification: Efficiency, Stability and Resilience in SRT-Controlled Conditions. Chemosphere 2022, 295, 133936. [Google Scholar] [CrossRef]

- Liu, H.; Liu, D.; Huang, Z.; Chen, Y. Bioaugmentation Reconstructed Nitrogen Metabolism in Full-Scale Simultaneous Partial Nitrification-Denitrification, Anammox and Sulfur-Dependent Nitrite/Nitrate Reduction (SPAS). Bioresour. Technol. 2023, 367, 128233. [Google Scholar] [CrossRef]

| Microorganism | Source | MBF Yield | Reference |

|---|---|---|---|

| Bacillus mucilaginosus | Farmland soil | 1.58–2.19 g/L | [26] |

| Bacillus licheniformis | Soil | 2.84 g/L | [27] |

| Bacillus velezensis | Activated sludge | 7.6 g/L | [28] |

| Bacillus mojavensis | Agricultural soil | 1.33 g/L | [29] |

| Aspergillus parasiticus | Activated sludge | 0.54 g/L | [30] |

| Enterobacter cloacae | Recycled sludge | 2.27 g/L | [31] |

| Klebsiella variicola | Soil | 6.96 g/L | [32] |

| Serratia ficaria | Soil | 2.41 g/L | [33] |

| Aspergillus flavus | — | 0.4 g/L | [34] |

| Penicillium purpurogenum | Laboratory | 6.4 g/L | [35] |

| Phanerochaete chrysosporium | Wastewater sludge | 2.2 g/L | [36] |

| Paenibacillus mucilaginosus | Soil | 7.8 g/L | [37] |

| Lipomyces starkeyi | Mangrove ecosystem | 62.1 ± 1.2 g/L | [38] |

| Alcaligenes faecalis | Sediment sample | 4 g/L | [39] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Jiang, C.; Wang, X.; Fan, L.; Xie, Y.; Wang, D.; Yang, T.; Peng, J.; Zhang, X.; Zhuang, X. Unraveling the Potential of Microbial Flocculants: Preparation, Performance, and Applications in Wastewater Treatment. Water 2024, 16, 1995. https://doi.org/10.3390/w16141995

Yang Y, Jiang C, Wang X, Fan L, Xie Y, Wang D, Yang T, Peng J, Zhang X, Zhuang X. Unraveling the Potential of Microbial Flocculants: Preparation, Performance, and Applications in Wastewater Treatment. Water. 2024; 16(14):1995. https://doi.org/10.3390/w16141995

Chicago/Turabian StyleYang, Yang, Cancan Jiang, Xu Wang, Lijing Fan, Yawen Xie, Danhua Wang, Tiancheng Yang, Jiang Peng, Xinyuan Zhang, and Xuliang Zhuang. 2024. "Unraveling the Potential of Microbial Flocculants: Preparation, Performance, and Applications in Wastewater Treatment" Water 16, no. 14: 1995. https://doi.org/10.3390/w16141995

APA StyleYang, Y., Jiang, C., Wang, X., Fan, L., Xie, Y., Wang, D., Yang, T., Peng, J., Zhang, X., & Zhuang, X. (2024). Unraveling the Potential of Microbial Flocculants: Preparation, Performance, and Applications in Wastewater Treatment. Water, 16(14), 1995. https://doi.org/10.3390/w16141995