Digital Twin Smart Water Conservancy: Status, Challenges, and Prospects

Abstract

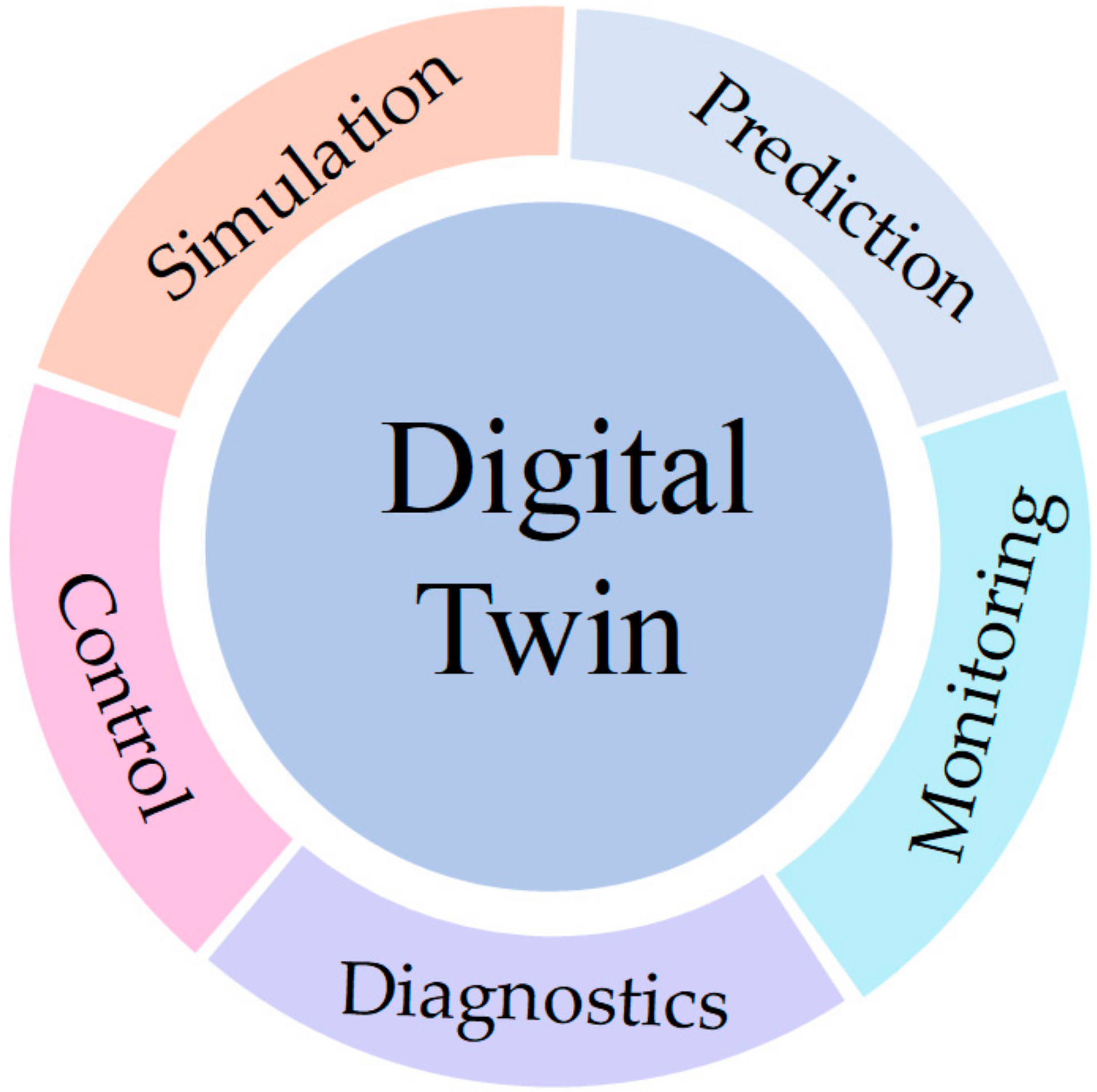

:1. Introduction

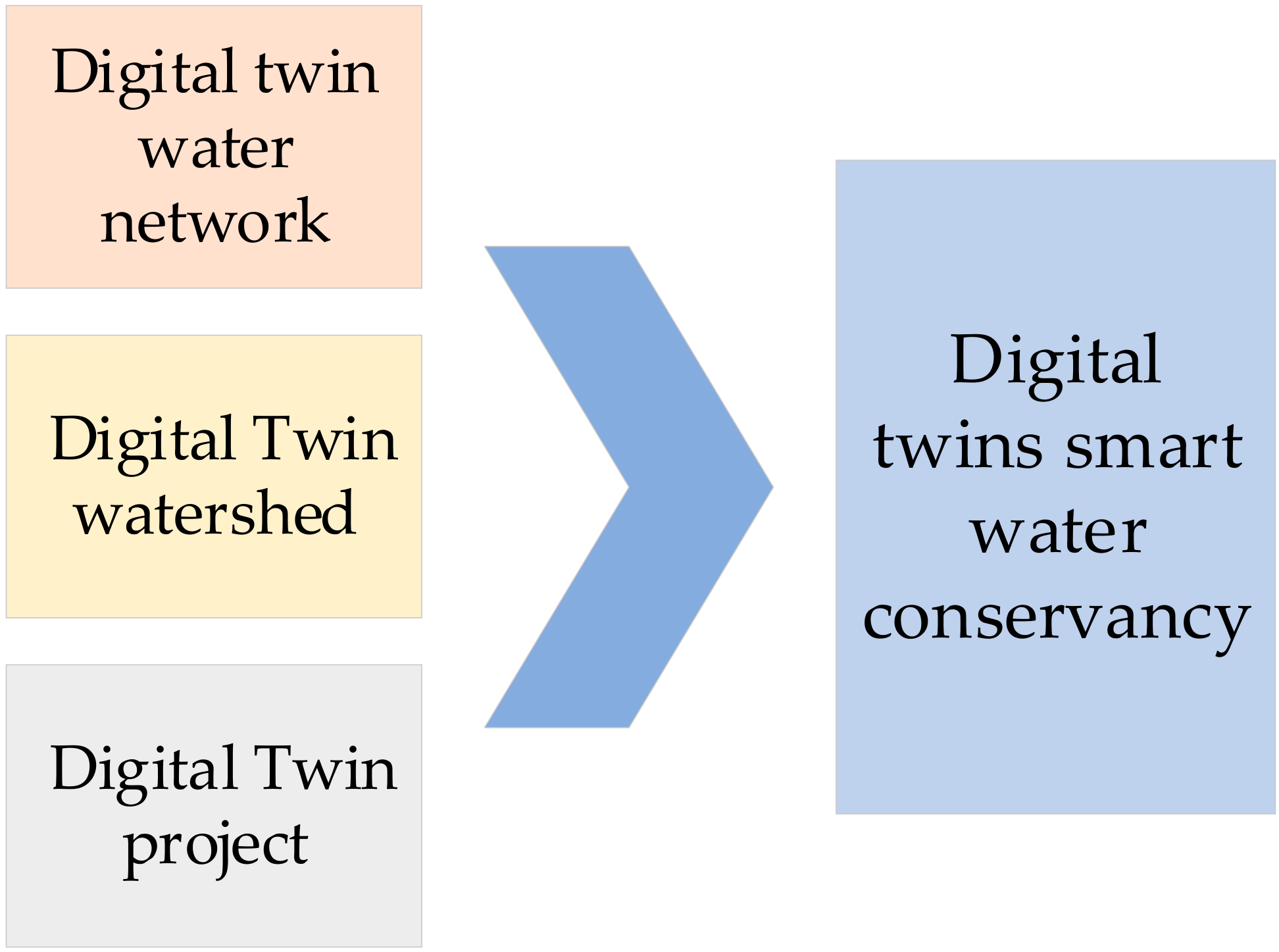

2. Digital Twin Smart Water Conservancy Modeling

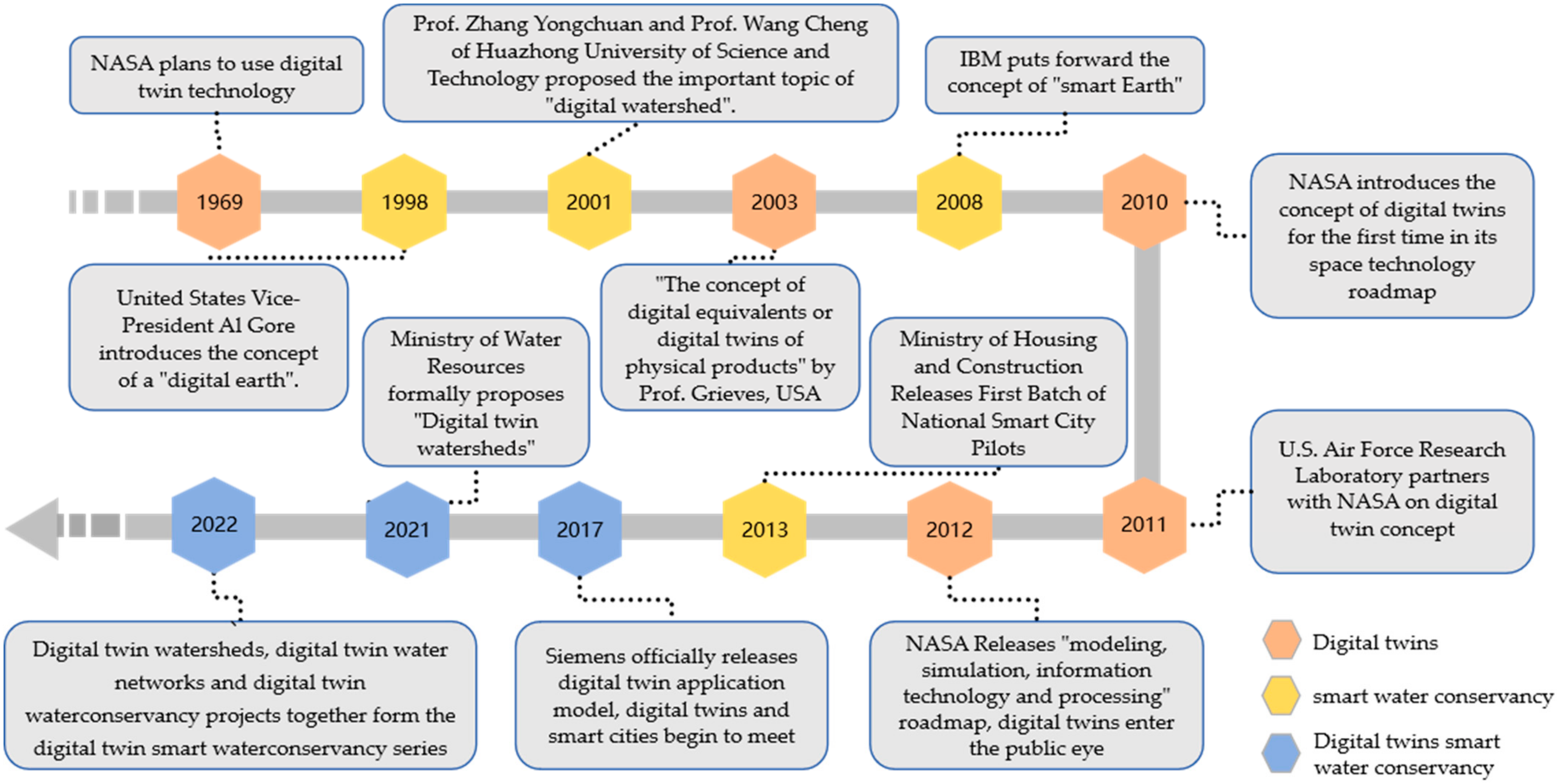

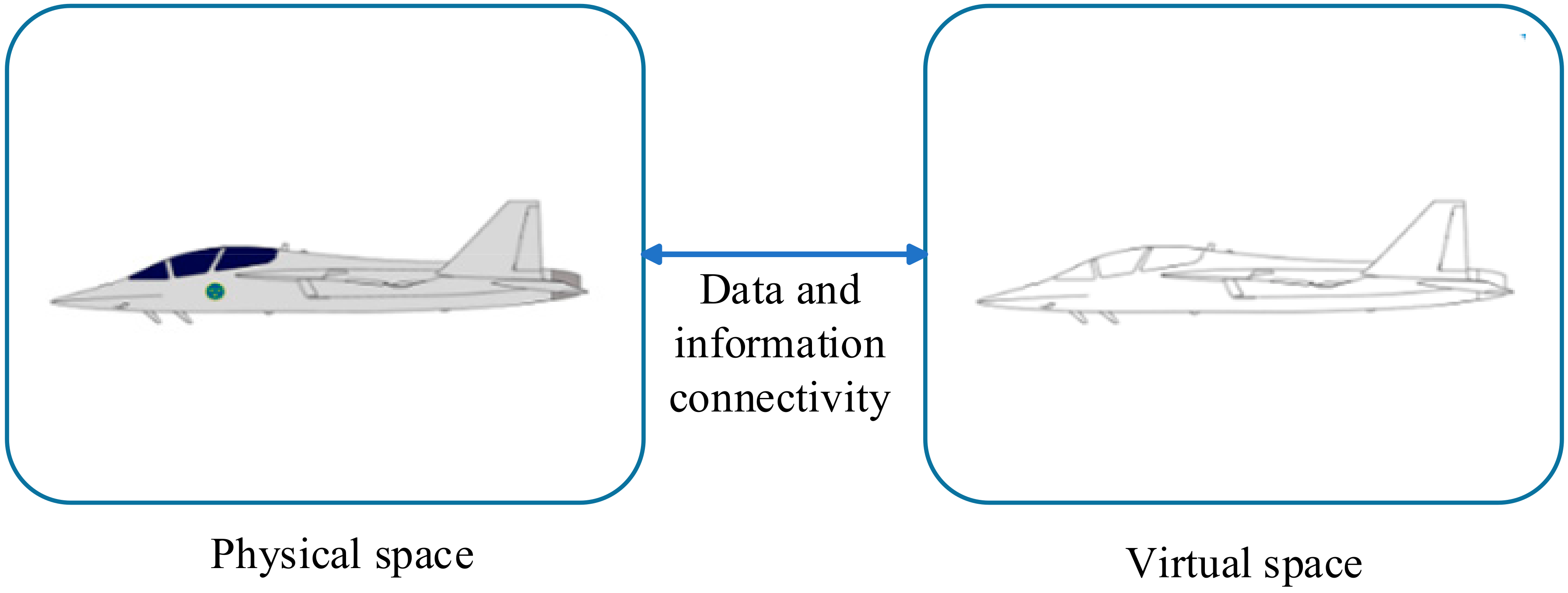

2.1. Development History and Concept of Digital Twin Smart Water Conservancy

| Proposer | Concept of Digital Twin |

|---|---|

| E Tuegel [23] B T Gockel [24] | DT is used only for aircraft and is called “Airframe Digital Twin” or ADT, which is a computational model that manages aircraft throughout their lifecycles. |

| Tao Fei [7] | A digital twin digitally replicates a physical entity by using data to simulate its behavior in a real-world environment. It enhances the physical entity by incorporating new capabilities through virtual–real interactive feedback, data fusion analysis, and iterative decision-making optimization. |

| NASA [25] | An integrated, multi-physics, multi-scale, probabilistic simulation model of a vehicle or system that incorporates current physical models, updated sensor data, historical data, and more to accurately represent the state of the flight entity based on that model. |

| GE [26] | By integrating physical machinery with analytical techniques, machines are tested, debugged, and optimized in a virtual environment. |

| Gartner [15] | A digital twin is a virtual copy of a physical object, meaning that it can be a product, structure, facility or system. |

| PTC [6,26] | Extending the product lifecycle management (PLM) process to the subsequent design cycle establishes a closed-loop product design process that facilitates the predictive maintenance of products. |

| Siemens [6,26] | By utilizing a consistent data model throughout all stages of the product life cycle, accurate and realistic simulations of certain real-life operations can be achieved. |

| Oracle [15] | The actual complexity of physical entities is simulated through virtual models of equipment and products that are projected into the application process. |

| ANSYS [26] | Combining superior simulation capabilities with powerful data analytics can help organizations to gain strategic insights. |

| Dassault [6,26] | The 3D Experience Platform enables designers and customers to engage with products throughout the design or manufacturing process, gaining insights into their functionality. |

| SAP [26] | It drives product development and innovation through real-time data collection and analysis, facilitated by the construction of digital models. |

| Altair [26] | Utilizing advanced virtual simulation technology, we develop virtual models that incorporate multiple physical characteristics to enhance product features. |

| Proposer | The Concept of Smart Water Conservancy |

|---|---|

| Jiang Yunzhong [1] | Utilizing cutting-edge information and communication technologies like big data, artificial intelligence, the Internet of Things, cloud computing and mobile internet, intelligent water management aims to deliver the optimal quantity and quality of water to the right location at the right time. This system is built upon natural water systems, water conservancy engineering systems, and water management systems to ensure sustainable water supply, high-quality water resources, a habitable water environment and a healthy water ecosystem. |

| Liu Guofeng [28] | By integrating technologies such as cloud computing, the Internet of Things, big data, mobile internet, and artificial intelligence, and comprehensively perceiving, interconnecting, intelligently applying, and providing ubiquitous services to water objects and activities, the comprehensive system is conducive to improving the modernization, informatization, and intelligence level of water governance. |

| Guo Hua [29] | Facilities and equipment and their status data are digitized and then loaded with models and algorithms for processing and analysis, providing support for watershed management, reservoir scheduling, urban water services, farmland irrigation, etc. |

| Wang Zhongjing [30] | The concept of water networking is based on the concept of the Internet of Things (IoT) and intelligent water conservancy is another expression of water networking. |

| Zhao Ranhang [31] | A scale information ecosystem for water conservancy applications that integrates information processes such as data collection, analysis, decision-making, control, and feedback to realize autonomous survival, autonomous self-examination, autonomous response and autonomous learning. |

| Cai Yang [32] | Applying new-generation information technology to realize thorough perception, comprehensive interconnection, intelligent application and ubiquitous service for water conservancy objects and activities. |

| Cai Xudong [33] | Intelligent mega-systems that comprehensively address water resources, water management, water safety, water ecology, water environment and other water-related matters. |

| Zhang Jianyun [22] | Harnessing a new wave of information and communication technologies to enhance intelligent water conservancy planning, engineering construction, operation, management and social services. |

2.2. Comparison of Digital Twin Water Conservancy Modeling with Traditional Water Conservancy Modeling

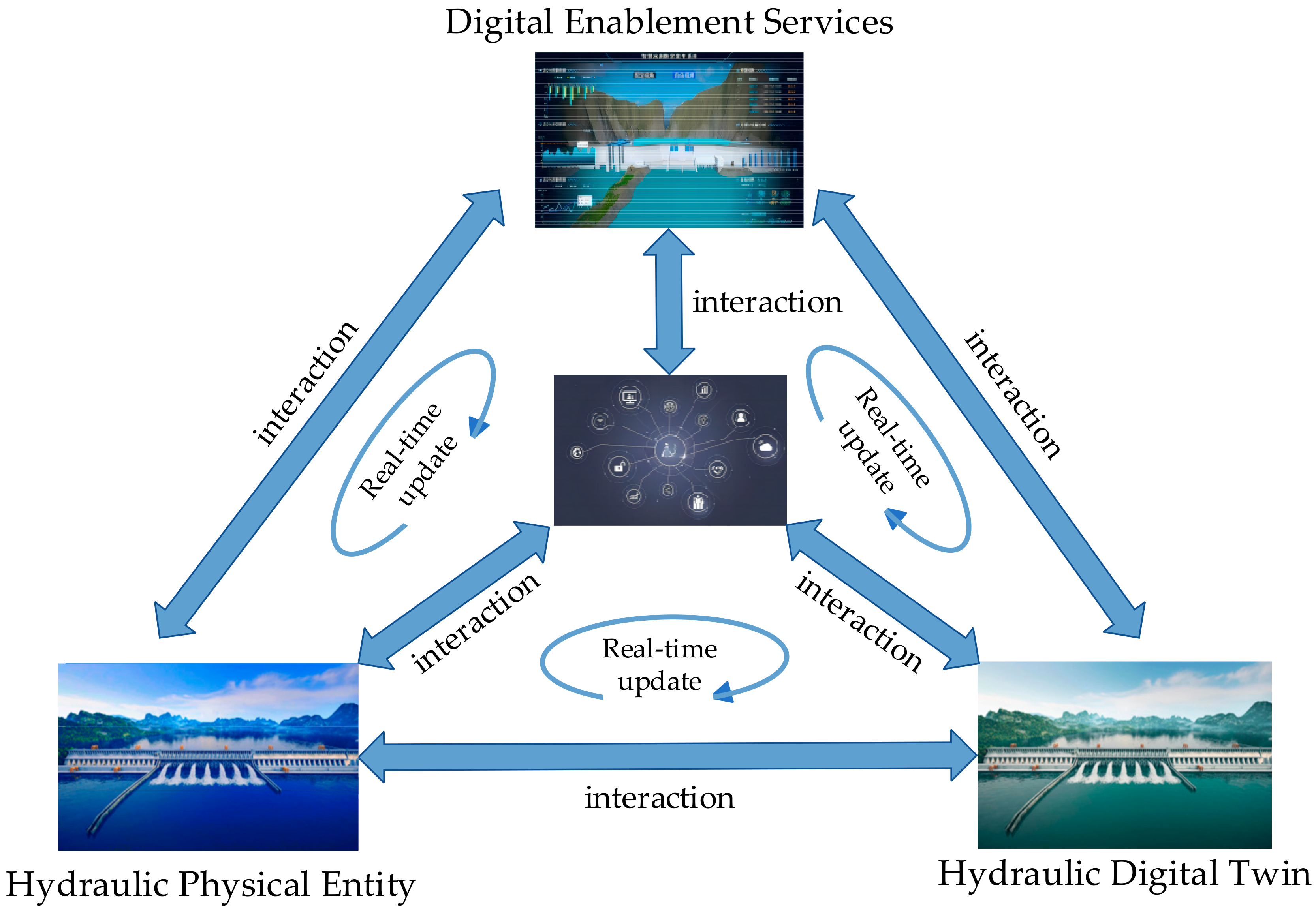

2.3. Digital Twin Water Conservancy Model Construction

2.4. Key Technologies of Digital Twin Water Conservancy Model

2.4.1. Digital Twin Water Conservancy Data Perception

2.4.2. Digital Twin Water Conservancy Data Transmission

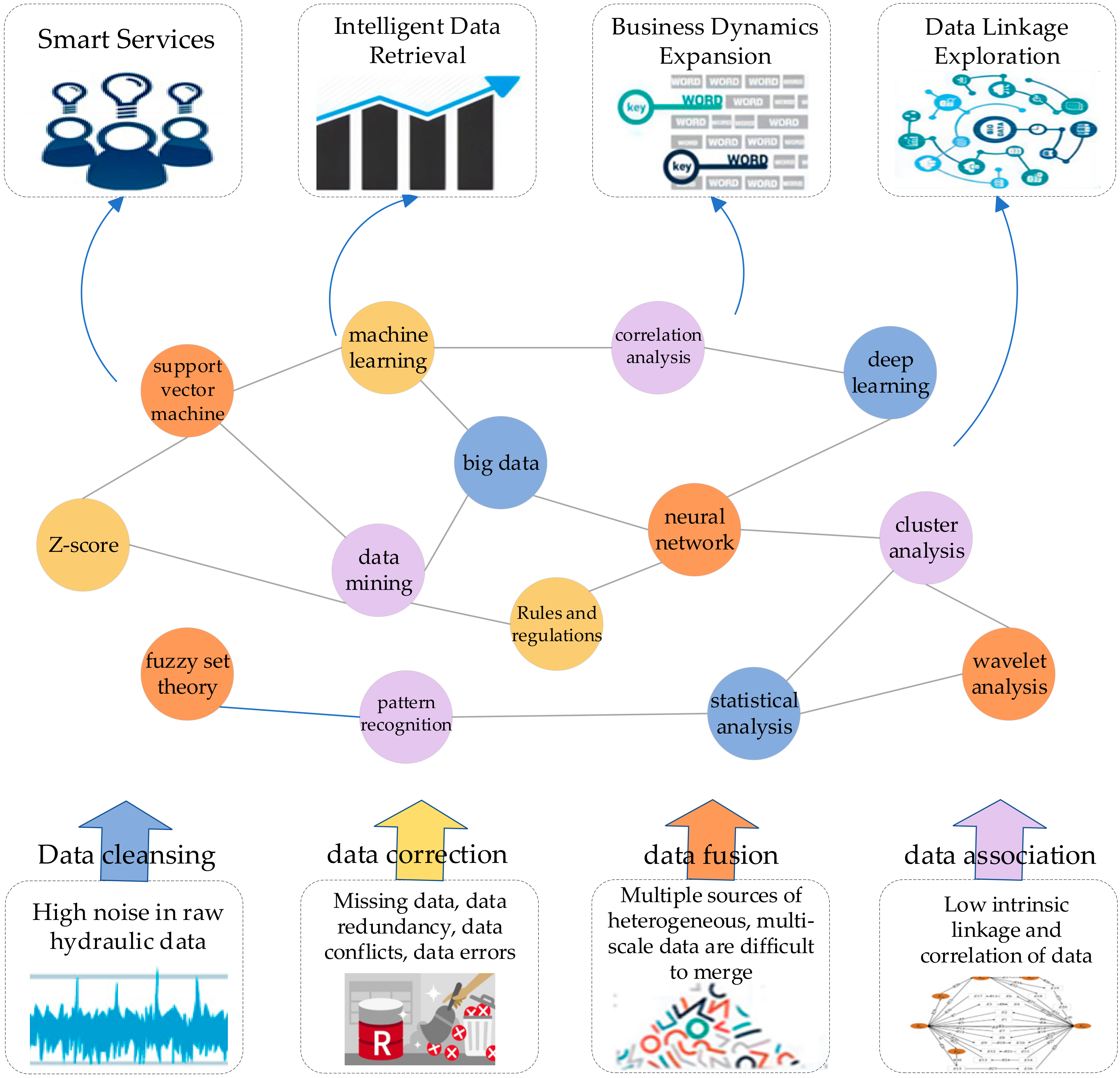

2.4.3. Digital Twin Water Conservancy Data Analysis and Processing

2.4.4. Digital Twin Water Conservancy Model Construction

2.4.5. Virtual–Real Interaction Techniques

2.4.6. Digital Twin Water Conservancy Service Applications

3. Challenges and Problems of Digital Twins in Smart Water Conservancy Applications

3.1. It Is Difficult to Achieve Comprehensive Perception of Digital Twin Water Conservancy Data

3.2. Difficulty in Processing Digital Twin Water Conservancy Perception Data

3.3. The Lack of Standards and Evaluation Systems for Digital Twin Water Conservancy

3.4. Serious Network Security Issues in Digital Twin Water Conservancy

3.5. The Intelligence Level of Digital Twin Water Conservancy Needs to Be Improved

4. Future Development Trends in Digital Twins Smart Water Conservancy

4.1. High-Throughput Sensing and Processing of Multi-Source Data from IoT Sensors

4.2. Highly Integrated Collaborative Control of Data-Driven and Model-Driven Approaches

4.3. Network Security Protection System with Artificial Intelligence Technology as the Core

4.4. Development Trends of Digital Twin Water Conservancy with Multi-Technology and Multi-Industry Integration

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, Y.Z.; Ye, Y.T.; Zhao, H.L.; Zhang, S.H.; Cao, Y.; Gu, J.J. Analysis of smart water conservancy. J. Hydraul. Eng. 2021, 52, 1355–1368. [Google Scholar]

- Yan, Y. Integration and application of digital twin technology and intelligent water conservancy system. Mech. Electr. Tech. Hydropower Stn. 2023, 46, 120–123. [Google Scholar]

- Wang, S.; Chen, F.; Zhu, Z. Application of digital twin technology in the construction of intelligent water conservancy. Shandong Water Resour. 2023, 09, 13–14. [Google Scholar]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, Y.; Cheng, J.; Zhang, M.; Xu, W.; Qi, Q. Theories and technologies for cyber-physical fusion in digital twin shop-floor. Comput. Integr. Manuf. Syst. 2017, 23, 1603–1611. [Google Scholar]

- Tao, F.; Zhang, M. Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Tao, F.; Liu, W.R.; Liu, J.H. Digital twin and its potential application exploration. Comput. Integr. Manuf. Syst. 2018, 24, 1–18. [Google Scholar]

- Cai, Y. Establishing a smart water system with “forecast, early-warning, rehearsal and plan” functions by focusing on the construction of digital twin basin. China Water Resour. 2022, 20, 2–6+60. [Google Scholar]

- Sheng, D.; Lou, Y.; Sun, F.; Xie, J.; Yu, Y. Reengineering and Its Reliability: An Analysis of Water Projects and Watershed Management under a Digital Twin Scheme in China. Water 2023, 15, 3203. [Google Scholar] [CrossRef]

- Ramos, H.M.; Kuriqi, A.; Besharat, M.; Creaco, E.; Tasca, E.; Coronado-Hernández, O.E.; Pienika, R.; Iglesias-Rey, P. Smart Water Grids and Digital Twin for the Management of System Efficiency in Water Distribution Networks. Water 2023, 15, 1129. [Google Scholar] [CrossRef]

- Liu, Y.; Liu CHao, M.; Song, W.; Qu, W.; Chen, S.; Lyu, J. Data baseboard construction on digital twin river basins for flood management with four functions of FEDE. China Flood Drought Manag. 2022, 32, 6–14. [Google Scholar]

- Zhou, C.; Tang, H.; Li, Q.; Luo, B.; Feng, K. Technology and application of digital twin modeling platform of water conservancy business. Yangtze River 2022, 53, 203–208. [Google Scholar]

- Liu, Z. BIM technology to promote digital empowerment to promote the construction of smart water conservancy projects. China Water Resour. 2021, 20, 6–7. [Google Scholar]

- Wang, N.; Xu, B.; Qiu, M. Overview of Digital Twin and Its Application Prospect. Telecommun. Inf. 2021, 08, 6–9+12. [Google Scholar]

- Li, X.; Liu, X.; Wan, X. Overview of Digital Twins Application and safe Development. J. Syst. Simul. 2019, 31, 385–392. [Google Scholar]

- Grieves, M.W. Product lifecycle management: The new paradigm for enterprises. Int. J. Prod. Dev. 2005, 2, 71–84. [Google Scholar] [CrossRef]

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future NASA and US Air Force vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012; p. 1818. [Google Scholar]

- Tuegel, E.J.; Ingraffea, A.R.; Eason, T.G.; Spottswood, S.M. Reengineering aircraft structural life prediction using a digital twin. Int. J. Aerosp. Eng. 2011, 2011, 154798. [Google Scholar] [CrossRef]

- Korth, B.; Schwede, C.; Zajac, M. Simulation-ready digital twin for realtime management of logistics systems. In Proceedings of the 2018 IEEE International Conference on Big Data (Big Data), Seattle, WA, USA, 10–13 December 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 4194–4201. [Google Scholar]

- Zhang, Y.; Wang, C. Digital Valley—An Important Regional Level of Digital Earth. Int. Water Resour. Power 2001, 03, 1–3. [Google Scholar]

- Zhang, Y. Discussion On Digital Twinning Technology and Intelligent Water Conservancy Construction. Hydraul. Sci. Technol. 2022, 50, 180–183. [Google Scholar]

- Zhang, J.; Liu, J.; Jin, J. Understanding and thinking of smart water conservancy. Hydro-Sci. Eng. 2019, 06, 1–7. [Google Scholar]

- Tuegel, E. The airframe digital twin: Some challenges to realization. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012; p. 1812. [Google Scholar]

- Gockel, B.; Tudor, A.; Brandyberry, M.; Penmetsa, R.; Tuegel, E. Challenges with structural life forecasting using realistic mission profiles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012; p. 1813. [Google Scholar]

- Rosen, R.; von Wichert, G.; Lo, G.; Bettenhausen, K.D. About the importance of autonomy and digital twins for the future of manufacturing. IFAC-PapersOnLine 2015, 48, 567–572. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Zuo, Y.; Zhao, D. Digital Twin Service towards Smart Manufacturing. Procedia CIRP 2018, 72, 237–242. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F. Digital Twin and Big Data Towards Smart Manufacturing and Industry 4.0: 360 Degree Comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Liu, G. Research and Practice on Smart Water Conservancy in the Context of “Internet Plus”. In Proceedings of the 2022 (10th) China Water Conservancy Informatization Technology Forum, Putian, China, 19 August 2022; p. 12. [Google Scholar] [CrossRef]

- Guo, H.; Chu, M.; He, L. First exploration on prception system construction concept of smart water conservancy. Water Resour. Dev. Manag. 2022, 42, 3–7. [Google Scholar]

- Wang, Z.; Wang, G.; Wang, J.; Wang, H. Developing the internet of water to prompt water utilization efficiency. Water Resour. Hydropower Eng. 2013, 44, 1–6. [Google Scholar]

- Zhao, R.; Zheng, C.; Li, H.; Du, W.; Fan, B. Further discussions on Intelligent—Water. China Flood Drought Manag. 2017, 27, 55–58. [Google Scholar]

- Cai, Y. Status analysis and development thinking of Smart Water Conservancy construction. Water Resour. Informatiz. 2018, 04, 1–6. [Google Scholar]

- Cai, X. Thought of construction of Intelligent Water Conservancy in new era. Water Resour. Informatiz. 2019, 02, 7–10. [Google Scholar]

- Xia, K.; Sacco, C.; Kirkpatrick, M.; Saidy, C.; Nguyen, L.; Kircaliali, A.; Harik, R. A digital twin to train deep reinforcement learning agent for smart manufacturing plants: Environment, interfaces and intelligence. J. Manuf. Syst. 2021, 58, 210–230. [Google Scholar] [CrossRef]

- Bauer, P.; Stevens, B.; Hazeleger, W. A digital twin of Earth for the green transition. Nat. Clim. Chang. 2021, 11, 80–83. [Google Scholar] [CrossRef]

- Bauer, P.; Dueben, P.D.; Hoefler, T.; Quintino, T.; Schulthess, T.C.; Wedi, N.P. The digital revolution of Earth-system science. Nat. Comput. Sci. 2021, 1, 104–113. [Google Scholar] [CrossRef] [PubMed]

- Ye, Y.; Jiang, Y.; Liang, L.; Zhao, H.; Gu, J.; Dong, J.; Cao, Y.; Duan, H. Digital twin watershed: New infrastructure and new paradigm of future watershed governance and management. Adv. Water Sci. 2022, 33, 683–704. [Google Scholar]

- Wu, J.; Yang, Y.; Cheng, X.U.; Zuo, H.; Cheng, Z. The development of digital twin technology review. In Proceedings of the Chinese Automation Congress (CAC), Shanghai, China, 6–8 November 2020; pp. 4901–4906. [Google Scholar]

- Austin, M.; Delgoshaei, P.; Coelho, M.; Heidarinejad, M. Architecting Smart City Digital Twins: Combined Semantic Model and Machine Learning Approach. J. Manag. Eng. 2020, 36, 04020026. [Google Scholar] [CrossRef]

- Jyeniskhan, N.; Keutayeva, A.; Kazbek, G.; Ali, H.; Shehab, E. Integrating Machine Learning Model and Digital Twin System for Additive Manufacturing. IEEE Access 2023, 11, 71113–71126. [Google Scholar] [CrossRef]

- Ren, Z.; Wan, J.; Deng, P. Machine-Learning-Driven Digital Twin for Lifecycle Management of Complex Equipment. IEEE Trans. Emerg. Top. Comput. 2022, 10, 9–22. [Google Scholar] [CrossRef]

- Meierhofer, J.; West, S. Data-driven decision support by digital twins in manufacturing. In Proceedings of the IEEE 7th Swiss Conference on Data Science (SDS) (Electr Network, 2020), Luzern, Switzerland, 26–26 June 2020; pp. 53–54. [Google Scholar]

- Shen, Y.; Li, K.; Xu, Z.; Wang, Z.; Ge, J. Research on energy digital twin quality model based on data driven. In Proceedings of the IEEE Intl Conf on Dependable, Autonomic and Secure Computing, Intl Conf on Pervasive Intelligence and Computing, Intl Conf on Cloud and Big Data Computing, Intl Conf on Cyber Science and Technology Congress (DASC/PiCom/CBDCom/CyberSciTech), Falerna, Italy, 12–15 September 2022; pp. 1000–1006. [Google Scholar]

- Wunderlich, A.; Booth, K.; Santi, E. Hybrid analytical and data-driven modeling techniques for digital twin applications. In Proceedings of the 2021 IEEE Electric Ship Technologies Symposium (ESTS), Arlington, VA, USA, 3–6 August 2021; pp. 1–7. [Google Scholar]

- Grieves, M. Digital twin: Manufacturing excellence through virtual factory replication. White Pap. 2014, 1, 1–7. [Google Scholar]

- Uhlemann, T.H.J.; Lehmann, C.; Steinhilper, R. The digital twin: Realizing the cyber-physical production system for industry 4.0. In Proceedings of the 24th CIRP Conference on Life Cycle Engineering (CIRP LCE), Kamakura, Japan, 8–10 March 2017; Volume 61, pp. 335–340. [Google Scholar]

- Zheng, Y.; Yang, S.; Cheng, H. An application framework of digital twin and its case study. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 1141–1153. [Google Scholar] [CrossRef]

- Tao, F.; Liu, W.; Zhang, M.; Hu, T.L.; Qi, Q.; Zhang, H.; Sui, F.; Wang, T.; Xu, H.; Huang, Z.; et al. Five-dimension digital twin model and its ten applications. Comput. Integr. Manuf. Syst. 2019, 25, 1–18. [Google Scholar]

- Wen, J.; Wu, M.; Su, J. Cyber-physical System. Acta Autom. Sin. 2012, 38, 507–517. [Google Scholar] [CrossRef]

- Cintuglu, M.H.; Mohammed, O.A.; Akkaya, K.; Uluagac, A.S. A Survey on Smart Grid Cyber-Physical System Testbeds. IEEE Commun. Surv. Tutor. 2017, 19, 446–464. [Google Scholar] [CrossRef]

- Graja, I.; Kallel, S.; Guermouche, N.; Cheikhrouhou, S.; Kacem, A.H. A comprehensive survey on modeling of cyber-physical systems. Concurr. Comput. Pract. Exp. 2020, 32, e4850. [Google Scholar] [CrossRef]

- Chattopadhyay, D.; Dasgupta, R. A survey of available sensor data modeling techniques. In Proceedings of the 2012 National Conference on Computing and Communication Systems, Durgapur, India, 21–22 November 2012; pp. 1–7. [Google Scholar]

- Yang, C.; Luo, J.; Hu, C.; Tian, L.; Li, J.; Wang, K. An Observation Task Chain Representation Model for Disaster Process-Oriented Remote Sensing Satellite Sensor Planning: A Flood Water Monitoring Application. Remote Sens. 2018, 10, 375. [Google Scholar] [CrossRef]

- Chen, D.; Zhang, X.; Chen, N. Smart City Perception Base Station: Comprehensive Perception Infrastructure for Future Smart Cities. Geomat. Inf. Sci. Wuhan Univ. 2022, 47, 159–180. [Google Scholar]

- Guo, A.; Yu, D.; Hu, Y.; Wang, S.; An, T.; Zhang, T. Design and implementation of data collection system based on CPS model. In Proceedings of the 2015 International Conference on Computer Science and Mechanical Automation (CSMA), Hangzhou, China, 23–25 October 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 139–143. [Google Scholar]

- Chen, F.; Fang, G. Harnessing digital twin and IoT for real-time monitoring, diagnostics, and error correction in domestic solar energy storage. Energy Rep. 2024, 11, 3614–3623. [Google Scholar] [CrossRef]

- Kuo, S.-Y.; Chou, Y.-H.; Chen, C.-Y. Quantum-inspired algorithm for cyber-physical visual surveillance deployment systems. Comput. Networks 2017, 117, 5–18. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Kim, C.-M.; Han, Y.-H.; Jeong, Y.-S.; Park, D.-S. An efficient strategy of nonuniform sensor deployment in cyber physical systems. J. Supercomput. 2013, 66, 70–80. [Google Scholar] [CrossRef]

- Lynch, C.; Adeyeye, A.; Abbara, E.M.; Umar, A.; Alhendi, M.; Minnella, C.; Iannotti, J.; Stoffel, N.; Poliks, M.; Tentzeris, M.M. 5G-enabled, battery-less smart skins for self-monitoring megastructures and digital twin applications. Sci. Rep. 2024, 14, 10002. [Google Scholar] [CrossRef]

- Karnik, N.; Abdo, M.G.; Estrada-Perez, C.E.; Yoo, J.S.; Cogliati, J.J.; Skifton, R.S.; Calderoni, P.; Brunton, S.L.; Manohar, K. Constrained Optimization of Sensor Placement for Nuclear Digital Twins. IEEE Sens. J. 2024, 24, 15501–15516. [Google Scholar] [CrossRef]

- Siddiqa, A.; Hashem, I.A.T.; Yaqoob, I.; Marjani, M.; Shamshirband, S.; Gani, A.; Nasaruddin, F. A survey of big data management: Taxonomy and state-of-the-art. J. Netw. Comput. Appl. 2016, 71, 151–166. [Google Scholar] [CrossRef]

- Agrawal, N.; Kumar, R. Security Perspective Analysis of Industrial Cyber Physical Systems (I-CPS): A Decade-wide Survey. ISA Trans. 2022, 130, 10–24. [Google Scholar] [CrossRef] [PubMed]

- Elattar, M.; Cao, T.; Wendt, V.; Jaspemeite, J.; Trächtler, A. Reliable multipath communication approach for internet-based cyber-physical systems. In Proceedings of the 2017 IEEE 26th International Symposium on Industrial Electronics (ISIE), Edinburgh, UK, 19–21 June 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1226–1233. [Google Scholar]

- Xia, F.; Wang, L.; Zhang, D.; He, D.; Kong, X. An adaptive MAC protocol for real-time and reliable communications in medical cyber-physical systems. Telecommun. Syst. 2015, 58, 125–138. [Google Scholar] [CrossRef]

- Wang, C.; Liu, X.; Zhu, M.; Zhu, C.; Lv, F.; Ni, Z. Digital twin connection model based on virtual sensor. Int. J. Adv. Manuf. Technol. 2023, 129, 3283–3302. [Google Scholar] [CrossRef]

- Gupta, D.; Wadhwa, S.; Rani, S.; Khan, Z.; Boulila, W. EEDC: An Energy Efficient Data Communication Scheme Based on New Routing Approach in Wireless Sensor Networks for Future IoT Applications. Sensors 2023, 23, 8839. [Google Scholar] [CrossRef] [PubMed]

- Zambal, S.; Eitzinger, C.; Clarke, M.; Klintworth, J.; Mechin, P.Y. A digital twin for composite parts manufacturing: Effects of defects analysis based on manufacturing data. In Proceedings of the 16th IEEE International Conference on Industrial Informatics (INDIN), Porto, Portugal, 18–20 July 2018; pp. 803–808. [Google Scholar]

- Jin, F.; Ma, L.; Zhao, C.; Liu, Q. State estimation in networked control systems with a real-time transport protocol. Syst. Sci. Control. Eng. 2024, 12, 2347885. [Google Scholar] [CrossRef]

- El Saddik, A. Digital Twins: The Convergence of Multimedia Technologies. IEEE Multimed. 2018, 25, 87–92. [Google Scholar] [CrossRef]

- Shahriar, M.R.; Al Sunny, S.N.; Liu, X.; Leu, M.C.; Hu, L.; Nguyen, N.T. MTComm based virtualization and integration of physical machine operations with digital-twins in cyber-physical manufacturing cloud. In Proceedings of the 5th IEEE International Conference on Cyber Security and Cloud Computing (CSCloud)/4th IEEE International Conference on Edge Computing and Scalable Cloud (EdgeCom), Shanghai, China, 22–24 June 2018; pp. 46–51. [Google Scholar]

- Yumnam, A.S.; Sreeram, Y.C.; Naeem, S.A. Overview: Weblog mining, privacy issues and application of Web Log mining. In Proceedings of the 2014 International Conference on Computing for Sustainable Global Development (INDIACom), New Delhi, India, 5–7 March 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 638–641. [Google Scholar]

- Uchimiya, M. Big data-driven water research towards metaverse. Water Sci. Eng. 2024, 17, 101–107. [Google Scholar] [CrossRef]

- Smith, D.; Singh, S. Approaches to multisensor data fusion in target tracking: A survey. IEEE Trans. Knowl. Data Eng. 2006, 18, 1696–1710. [Google Scholar] [CrossRef]

- He, Y.; Guo, J.C.; Zheng, X.L. From Surveillance to Digital Twin Challenges and recent advances of signal processing for the industrial Internet of Things. IEEE Signal Process. Mag. 2018, 35, 120–129. [Google Scholar] [CrossRef]

- Yi, B.; Li, X.; Yang, Y. Heterogeneous model integration of complex mechanical parts based on semantic feature fusion. Eng. Comput. 2017, 33, 797–805. [Google Scholar] [CrossRef]

- Atat, R.; Liu, L.; Wu, J.; Li, G.; Ye, C.; Yang, Y. Big Data Meet Cyber-Physical Systems: A Panoramic Survey. IEEE Access 2018, 6, 73603–73636. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. A BIM-data mining integrated digital twin framework for advanced project management. Autom. Constr. 2021, 124, 103564. [Google Scholar] [CrossRef]

- Zhang, Z.; Zeng, Y.; Liu, H.; Zhao, C.; Wang, F.; Chen, Y. Smart DC: An AI and Digital Twin-based Energy-Saving Solution for Data Centers. In Proceedings of the IEEE/IFIP Network Operations and Management Symposium, Budapest, Hungary, 25–29 April 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Farhadi, H.; Najafzadeh, M. Flood Risk Mapping by Remote Sensing Data and Random Forest Technique. Water 2021, 13, 3115. [Google Scholar] [CrossRef]

- DebRoy, T.; Zhang, W.; Turner, J.; Babu, S.S. Building digital twins of 3D printing machines. Scr. Mater. 2017, 135, 119–124. [Google Scholar] [CrossRef]

- Schroeder, G.N.; Steinmetz, C.; Pereira, C.E.; Espindola, D.B. Digital twin data modeling with automationml and a communication methodology for data exchange. In Proceedings of the 4th IFAC Symposium on Telematics Applications (TA), Porto Alegre, Brazil, 6–9 November 2016; Volume 49, pp. 12–17. [Google Scholar]

- Liu, H.; Su, H.; Li, H. Study on Digital Twin Technologies for Watershed Information Modeling (WIM): A Systematic Literature Review and Bibliometric Analysis. Arch. Comput. Methods Eng. 2024, 31, 263–289. [Google Scholar] [CrossRef]

- Tao, F.; Xiao, B.; Qi, Q.; Cheng, J.; Ji, P. Digital twin modeling. J. Manuf. Syst. 2022, 64, 372–389. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2021, 58, 3–21. [Google Scholar] [CrossRef]

- Talkhestani, B.A.; Jazdi, N.; Schloegl, W.; Weyrich, M. Consistency check to synchronize the Digital Twin of manufacturing automation based on anchor points. In Proceedings of the 51st CIRP Conference on Manufacturing Systems (CIRP CMS), Stockholm, Sweden, 16–18 May 2018; Volume 72, pp. 159–164. [Google Scholar]

- Martinez, G.S.; Sierla, S.; Karhela, T.; Vyatkin, V. Automatic generation of a simulation-based digital twin of an industrial process plant. In Proceedings of the IEEE 44th Annual Conference of the IEEE Industrial-Electronics-Society (IECON), Washington, DC, USA, 21–23 October 2018; pp. 3084–3089. [Google Scholar]

- Park, D.; You, H. A Digital Twin Dam and Watershed Management Platform. Water 2023, 15, 2106. [Google Scholar] [CrossRef]

- Morlot, M.; Rigon, R.; Formetta, G. Hydrological digital twin model of a large anthropized italian alpine catchment: The Adige river basin. J. Hydrol. 2024, 629, 130587. [Google Scholar] [CrossRef]

- Zhao, X.; Mao, X.; Xu, H.; Chen, Z.; Ma, J. Construction and Application of Multi-scale Spatial Geographic Information Model in Digital Watershed—A Case Study of the Qiantang River Basin. Yangtze River 2021, 52, 293–297. [Google Scholar]

- Zhang, L.; Zhang, H.; Liu, C.; Zhu, C. Research and application of key technologies for 3D simulation of water conservancy digital twin platform. Yangtze River 2023, 54, 9–18. [Google Scholar]

- Kuenzel, M.; Kraus, T.; Straub, S. Collaborative Engineering—Main features and challenges of cross-company collaboration in engineering of products and services. In Proceedings of the 25th IEEE International Conference on Engineering, Technology and Innovation/25th ICE/IEEE International Technology Management Conference (ITMC), Valbonne Sophia-Antipolis, France, 17–19 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–7. [Google Scholar] [CrossRef]

- Schluse, M.; Priggemeyer, M.; Atorf, L.; Rossmann, J. Experimentable digital twins—Streamlining simulation-based systems engineering for industry 4.0. IEEE Trans. Ind. Inform. 2018, 14, 1722–1731. [Google Scholar] [CrossRef]

- Song, E.Y.; Burns, M.; Pandey, A.; Roth, T. IEEE 1451 Smart Sensor Digital Twin Federation for IoT/CPS Research. In Proceedings of the 14th IEEE Sensors Applications Symposium (SAS), Sophia Antipolis, France, 11–13 March 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Cai, Y.; Starly, B.; Cohen, P.; Lee, Y.S. Sensor data and information fusion to construct digital-twins virtual machine tools for cyber-physical manufacturing. In Proceedings of the 45th SME North American Manufacturing Research Conference (NAMRC), Los Angeles, CA, USA, 4–8 June 2017; Volume 10, pp. 1031–1042. [Google Scholar]

- Bazilevs, Y.; Deng, X.; Korobenko, A.; di Scalea, F.L.; Todd, M.D.; Taylor, S.G. Isogeometric Fatigue Damage Prediction in Large-Scale Composite Structures Driven by Dynamic Sensor Data. J. Appl. Mech. 2015, 82, 091008. [Google Scholar] [CrossRef]

- Ramos, H.M.; Morani, M.C.; Carravetta, A.; Fecarrotta, O.; Adeyeye, K.; López-Jiménez, P.A.; Pérez-Sánchez, M. New Challenges towards Smart Systems’ Efficiency by Digital Twin in Water Distribution Networks. Water 2022, 14, 1304. [Google Scholar] [CrossRef]

- Sharifi, A.; Beris, A.T.; Javidi, A.S.; Nouri, M.S.; Lonbar, A.G.; Ahmadi, M. Application of artificial intelligence in digital twin models for stormwater infrastructure systems in smart cities. Adv. Eng. Inform. 2024, 61, 102485. [Google Scholar] [CrossRef]

- Huang, Y. Study on key technology and pilot of digital twin Yangtze River construction. China Flood Drought Manag. 2022, 32, 16–26. [Google Scholar]

- Mücke, N.T.; Pandey, P.; Jain, S.; Bohté, S.M.; Oosterlee, C.W. A Probabilistic Digital Twin for Leak Localization in Water Distribution Networks Using Generative Deep Learning. Sensors 2023, 23, 6179. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.-G.; Bartos, M. A digital twin model for contaminant fate and transport in urban and natural drainage networks with online state estimation. Environ. Model. Softw. 2024, 171, 105868. [Google Scholar] [CrossRef]

- Ham, Y.; Kim, J. Participatory Sensing and Digital Twin City: Updating Virtual City Models for Enhanced Risk-Informed Decision-Making. J. Manag. Eng. 2020, 36, 04020005. [Google Scholar] [CrossRef]

- Shi, Y.; Xu, J.; Du, W. Discussion on the New Operation Management Mode of Hydraulic Engineering Based on the Digital Twin Technique. In Proceedings of the International Conference on Computer Information Science and Application Technology (CISAT), Daqing, China, 7–9 December 2018; IOP: Bristol, UK, 2018; Volume 1168. [Google Scholar]

- Du, Z.; Gao, Y.; Wan, J.; Han, K. Intelligent management method of river engineering based on Digital Twin technology. China Water Resour. 2020, 12, 60–62. [Google Scholar]

- Singh, M.; Fuenmayor, E.; Hinchy, E.P.; Qiao, Y.; Murray, N.; Devine, D. Digital twin: Origin to future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, H.; Leng, J.; Chen, X. Digital twin-driven rapid individualised designing of automated flow-shop manufacturing system. Int. J. Prod. Res. 2019, 57, 3903–3919. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Vickers, approaches, Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Springer: Cham, Switzerland, 2017; pp. 85–113. [Google Scholar] [CrossRef]

- LaGrange, E. Developing a digital twin: The roadmap for oil and gas optimization. In Proceedings of the SPE Offshore Europe Conference and Exhibition, Aberdeen, UK, 3–6 September 2019; SPE: Richardson, TX, USA, 2019; p. D011S003R001. [Google Scholar]

- Redelinghuys, A.; Basson, A.; Kruger, K. A six-layer digital twin architecture for a manufacturing cell. In Service Orientation in Holonic and Multi-Agent Manufacturing: Proceedings of SOHOMA 2018; Springer: Berlin/Heidelberg, Germany, 2019; pp. 412–423. [Google Scholar]

- Riemer, D. Feeding the Digital Twin: Basics, Models and Lessons Learned from Building an IoT Analytics Toolbox (Invited Talk). In Proceedings of the IEEE International Conference on Big Data (Big Data), Seattle, WA, USA, 10–13 December 2018; p. 4212. [Google Scholar]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Equipment design optimization based on digital twin under the framework of zero-defect manufacturing. Procedia Comput. Sci. 2021, 180, 525–533. [Google Scholar] [CrossRef]

- Zhang, Z.; Sun, B.; Cao, Z. Data Extraction method for Heterogeneous Database Based on EJB. Adv. Mater. Res. 2013, 756, 1408–1412. [Google Scholar] [CrossRef]

- Liu, Q.; Li, T.; Fan, H.; Zeng, S.; Ren, J.; Wang, X. State Inference and Evaluation Technology of Relay Protection Based on Digital Twinning. J. Phys. Conf. Ser. 2023, 2584, 012118. [Google Scholar] [CrossRef]

- Zhang, H.; Qi, Q.; Tao, F. A consistency evaluation method for digital twin models. J. Manuf. Syst. 2022, 65, 158–168. [Google Scholar] [CrossRef]

- Zhang, C.; Tao, F. Evaluation index system for digital twin model. Comput. Integr. Manuf. Syst. 2021, 27, 2171–2186. [Google Scholar]

- He, C.; Luan, T.H.; Lu, R.; Su, Z.; Dong, M. Security and Privacy in Vehicular Digital Twin Networks: Challenges and Solutions. IEEE Wirel. Commun. 2023, 30, 154–160. [Google Scholar] [CrossRef]

- Li, Q.; Huo, D.; Jiang, L. A Digital Twin System for Monitoring the Security of Theatrical Stages. In Proceedings of the 2022 IEEE Smartworld, Ubiquitous Intelligence & Computing, Scalable Computing & Communications, Digital Twin, Privacy Computing, Metaverse, Autonomous & Trusted Vehicles (SmartWorld/UIC/ScalCom/DigitalTwin/PriComp/Meta), Haikou, China, 15–18 December 2022; pp. 2224–2230. [Google Scholar]

- Wang, K.; Du, H.; Su, L. Digital Twin Network based Network Slice Security Provision. In Proceedings of the 2022 IEEE 2nd International Conference on Digital Twins and Parallel Intelligence (2022), Boston, MA, USA, 24–28 October 2022; pp. 1–6. [Google Scholar]

- Zhao, C. State-of-the-art and recommended developmental strategic objectives of smart agriculture. Smart Agric. 2019, 1, 1–7. [Google Scholar]

- Alsoufi, M.A.; Razak, S.; Siraj, M.M.; Nafea, I.; Ghaleb, F.A.; Saeed, F.; Nasser, M. Anomaly-Based Intrusion Detection Systems in IoT Using Deep Learning: A Systematic Literature Review. Appl. Sci. 2021, 11, 8383. [Google Scholar] [CrossRef]

- Thamilarasu, G.; Chawla, S. Towards Deep-Learning-Driven Intrusion Detection for the Internet of Things. Sensors 2019, 19, 1977. [Google Scholar] [CrossRef] [PubMed]

- Diro, A.A.; Chilamkurti, N. Distributed attack detection scheme using deep learning approach for Internet of Things. Futur. Gener. Comput. Syst. 2018, 82, 761–768. [Google Scholar] [CrossRef]

- de Araujo Zanella, A.R.; da Silva, E.; Albini, L.C. Security challenges to smart agriculture: Current state, key issues, and future directions—ScienceDirect. Array 2020, 8, 100048. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, J.; Su, H. Toward the third generation of artificial intelligence. Sci. China Inf. Sci. 2020, 50, 1281–1302. (In Chinese) [Google Scholar] [CrossRef]

- He, J. Secure and trusted AI. Inf. Secur. Commun. Priv. 2019, 310, 7–10. [Google Scholar]

- Chen, L.; Deng, H.; Zhang, Y.; Li, Y. Security Risk and Governance of Artificial Intelligence in Cyberspace Security. J. CAEIT 2021, 16, 1086–1093. [Google Scholar]

- Abbas, N.N.; Ahmed, T.; Shah, S.H.U.; Omar, M.; Park, H.W. Investigating the applications of artificial intelligence in cyber security. Scientometrics 2019, 121, 1189–1211. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, B.; Lin Yang, H. Risks and countermeasures of artificial intelligence data security and privacy protection. Cyberspace Secur. 2023, 14, 30–34. [Google Scholar]

- Ma, X.; Tao, F.; Zhang, M.; Wang, T.; Zuo, Y. Digital twin enhanced human-machine interaction in product lifecycle. In Proceedings of the 11th CIRP Conference on Industrial Product-Service Systems, Zhuhai and Hong Kong, China, 29–31 May 2019; Volume 83, pp. 789–793. [Google Scholar]

- Kolesnikov, M.V.; Atmojo, U.D.; Vyatkin, V. Data-Driven Human Factors Enabled Digital Twin. In Proceedings of the IECON 2023-49th Annual Conference of the IEEE Industrial Electronics Society (2023), Singapore, 16–19 October 2023; pp. 1–6. [Google Scholar]

- Li, F.; He, Z.; Tian, Y.; Song, J.; Su, Y. Research on spatial technology of distribution network digital twin model based on multimodule data fusion. In Proceedings of the Second International Conference on Physics, Photonics, and Optical Engineering (ICPPOE 2023), Kunming, China, 10–12 November 2023; pp. 125–131. [Google Scholar]

- Liu, Z.; Meyendorf, N.; Mrad, N. The Role of Data Fusion in Predictive Maintenance Using Digital Twin. InAIP Conf. Proc. 2018, 1949, 1–6. [Google Scholar]

- Wang, Z.; Zhang, P.; Shen, W. Dynamic management system of large-scale water conservancy project construction based on ArcGIS. In Proceedings of the International Conference on Smart Transportation and City Engineering, Chongqing, China, 10 November 2021; Volume 12050, pp. 261–266. [Google Scholar]

| Comparison of Content | Traditional Water Conservancy Modeling | Digital Twin Water Conservancy Modeling |

|---|---|---|

| Application method | Analytical and support computational tools for businesses based on physical equations and data-driven static descriptions | Based on real-time data and machine learning [39,40,41] for dynamic description, deeply integrated with digital business systems, achieving automatic closed-loop intelligent water resource management and decision-making activities |

| Application phase | Mostly used in the planning phase | Full life cycle of planning, design, construction and operation |

| Modeling methodology | Manual offline approach, mechanism-driven modeling, mathematical and statistical modeling as the focus | Automated approach, supplemented by a manual approach; multi-dimensional and multi-scale high-fidelity models such as geometric, mechanistic–analytical, mathematical–statistical and hybrid models |

| Model update | Updating model structure and model parameters manually | Adopting a data-driven approach, the model structure, state variables and parameters are automatically updated by continuously acquiring real-time operational data [42,43,44]. |

| Model validation | Possible validation of models through comparison with historical data or known results | Validate model accuracy by comparing real-time data with physical entities |

| Model Extensibility | The structure and scope of the application of the model may be fixed at the design time, with limited extensibility | Designed to be scalable to accommodate changing system requirements and data sources |

| Model integration | Lack of standardization support, poor standardization of model interfaces and poor connectivity of models with different dimensions and scales | Use standardized interfaces to connect physical water conservancy entities, water digital twins, data and services, with the ability to integrate, add and replace digital models |

| accessibility | Requires specific hardware facilities and software support that can only be accessed and operated by users of specific devices | Receive real-time monitoring data from water conservancy systems via the internet and remotely control and monitor physical equipment |

| model performance | Predominantly 2D presentation | Predominantly 3D presentation |

| Perception Object | Perception Data | Perceptual Method | Transmission Method |

|---|---|---|---|

| Natural water system, topography, reservoirs, dams, gates, pumps, embankments, power stations, irrigation districts, meteorology, soil, facilities and equipment, ecological environment, users, etc. | Hydrological data including real-time monitoring data such as water level, flow, flow rate, water temperature, etc.; water quality data including pH, dissolved oxygen, ammonia nitrogen, total phosphorus and other water quality indicators; meteorological data such as rainfall, wind speed, wind direction, temperature, etc.; soil data including soil moisture, soil type, soil erosion, etc.; water conservancy facilities data involving reservoirs, sluice gates, pumping stations, embankments, and other water conservancies, such as the operational status of the water conservancy facilities, maintenance records, etc.; water resource utilization data including data on water consumption and water use efficiency in agricultural irrigation, industrial water use, urban water supply, etc. Ecological environment data such as the number of aquatic organisms populations, biodiversity, vegetation cover, etc. | The Internet of Things, sensors, satellite remote sensing, drones, unmanned boats, high-definition video, ground robots, underwater robots, manual recording, etc. | ZigBee wireless protocol, Bluetooth (BT) wireless protocol, Multi-hop Communication protocol, Cooperative Communication protocol, UAV-Assisted Communication protocol, Wi-Fi wireless protocol, long-range radio (LoRa) protocol, Intelligent Reflecting Surface-Assisted Cooperative Relaying, SigFox protocol, flat routing protocol, hierarchical routing protocol, Energy-Efficient Data Communication protocol, Ada-MAC protocol, Real-Time Transport Protocol, etc. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Ma, Z.; Li, J.; Li, Q.; Li, Y.; Yang, J. Digital Twin Smart Water Conservancy: Status, Challenges, and Prospects. Water 2024, 16, 2038. https://doi.org/10.3390/w16142038

Li W, Ma Z, Li J, Li Q, Li Y, Yang J. Digital Twin Smart Water Conservancy: Status, Challenges, and Prospects. Water. 2024; 16(14):2038. https://doi.org/10.3390/w16142038

Chicago/Turabian StyleLi, Wengang, Zifei Ma, Jing Li, Qinghua Li, Yang Li, and Juan Yang. 2024. "Digital Twin Smart Water Conservancy: Status, Challenges, and Prospects" Water 16, no. 14: 2038. https://doi.org/10.3390/w16142038