Evaluation of Straw Mulch as an Erosion Control Practice for Varying Soil Types on a 4:1 Slope

Abstract

1. Introduction

1.1. Standardized Testing of Erosion Controls

1.2. Research Importance

2. Materials and Methods

2.1. ASTM D6459-19

2.2. Test Facility at AU-SRF

2.3. Calibration of ASTM D6459-19 Rainfall Simulator

2.3.1. Rainfall Intensity Calibration

2.3.2. Drop Size Calibration

2.4. ASTM D6459-19 Test Procedure at AU-SRF

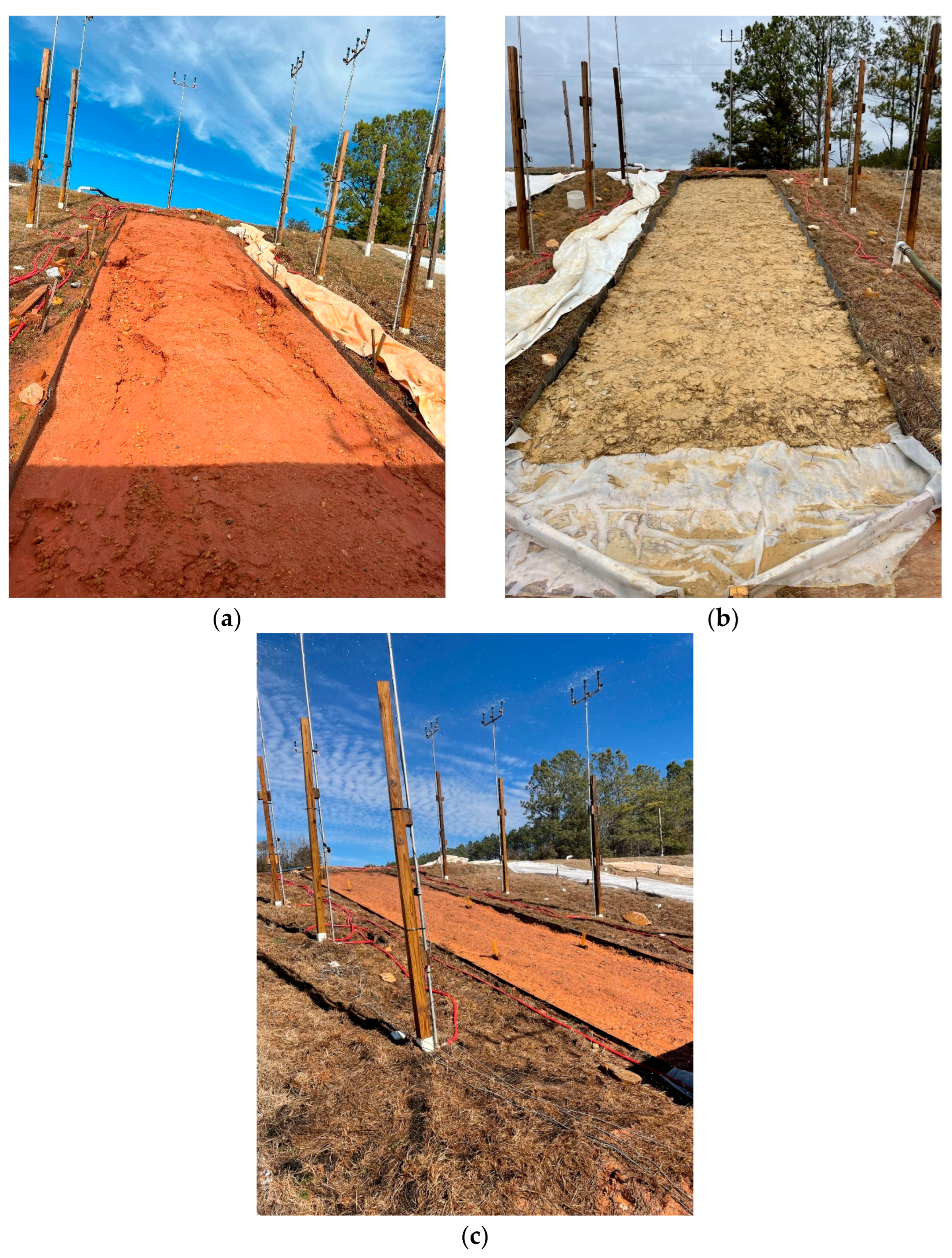

2.4.1. Plot Preparation and Practice Installation

2.4.2. Test Procedure

2.4.3. Sediment Collection and Quantification

3. Results and Discussion

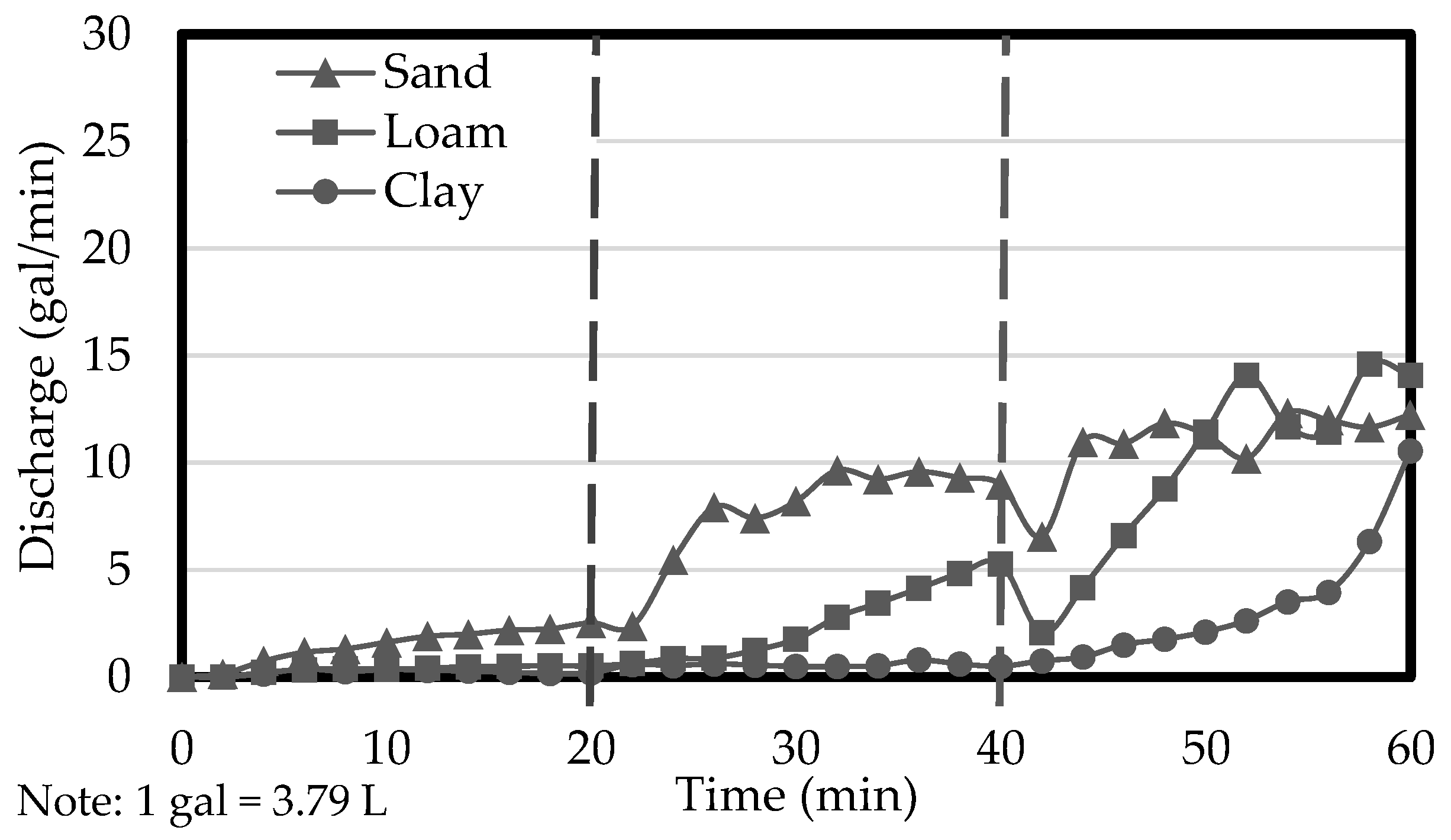

3.1. Bare Soil Test Results

3.2. Straw Test Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Allen, S. Evaluation and Standardization of Rolled Erosion Control Products. Geotext. Geomembr. 1996, 1, 207–221. [Google Scholar] [CrossRef]

- Ziegler, A.; Sutherland, R. Influence of Rolled Erosion Control Systems on Temporal Rainsplash Response—A Laboratory Rainfall Simulation Experiment. Land Degrad. Dev. 1996, 8, 139–157. [Google Scholar] [CrossRef]

- Telles, T.; Guimarães, M.; Dechen, S. The costs of soil erosion. Rev. Bras. Cienc. Solo 2011, 35, 287–298. [Google Scholar] [CrossRef]

- Panagos, P.; Matthews, F.; Patault, E.; De Michele, C.; Quaranta, E.; Bezak, N.; Borrelli, P. Understanding the cost of soil erosion: An assessment of the sediment removal costs from the reservoirs of the European Union. J. Clean. Prod. 2024, 434, 140–183. [Google Scholar] [CrossRef]

- Sutherland, R. Rolled Erosion Control Systems for Hillslope Surface Protection: A Critical Review, Synthesis, and Analysis of Available Data. Land Degrad. Dev. 1998, 1, 465–486. [Google Scholar] [CrossRef]

- Li, M. Evaluating erosion control performance of crimped straw mulch in comparison with RECPs on simulated highway roadsides. Int. J. Geotech. Eng. 2014, 8, 307–314. [Google Scholar] [CrossRef]

- Lee, G.; McLaughlin, R.; Whitely, K.; Brown, V. Evaluation of seven mulch treatments for erosion control and vegetation establishment on steep slopes. J. Soil Water Conserv. 2018, 73, 434–442. [Google Scholar] [CrossRef]

- ASTM D6459; Standard Test Method for Determination of Rolled Erosion Control Product (RECP) Performance in Protecting Earthen Channels from Stormwater-Induced Erosion. ASTM: West Conshohocken, PA, USA, 2019; pp. 1–6.

- Tyner, J.; Yoder, D.; Chomicki, B.; Tyagi, A. A review of construction site best management practices for erosion control. Trans. ASABE 2011, 54, 441–450. [Google Scholar] [CrossRef]

- Manning, C.; Faulkner, B.; Donald, W.; Perez, M. Comparison of Erosion Control Products Using an ASTM D6459 Rainfall Simulator: Insights and Suggestions. J. Irrig. Drain. Eng. 2023, 149, 04023017. [Google Scholar] [CrossRef]

- Clopper, P.; Vielleux, M.; Johnson, A. Quantifying the performance of hillslope erosion control best management practices. In Bridging the Gap: Meeting the World’s Water and Environmental Resources Challenges, Proceedings of the World Water and Environmental Resources Congress 2001, Orlando, FL, USA, 20–24 May 2001; American Society of Civil Engineers: Reston, VA, USA, 2001; pp. 1–10. [Google Scholar]

- Li, M.H.; McFalls, J.; Yi, Y.J. Comparing Erosion Control Products’ Performance Results from Field and Large-Scale Laboratory Testing. Indian Geotech. J. 2013, 43, 382–387. [Google Scholar] [CrossRef]

- Schussler, J.; Perez, M.; Donald, W.; Whitman, J.; Zech, W.; Fang, X.; Fagan, B. Decade of Research in Review at the Auburn University Stormwater Research Facility. Transp. Res. Rec. 2022, 2676, 590–604. [Google Scholar] [CrossRef]

- Renard, K.; Foster, G.; Weesies, G.; Porter, J. RUSLE Revised Universal Soil Loss Equation. J. Soil Water Conserv. 1991, 46, 30–33. [Google Scholar]

- Renard, K. Predicting Soil Erosion by Water: A Guide to Conservation Planning with the Revised Universal Soil Loss Equation (RUSLE); US Department of Agriculture, Agricultural Research Service: Washington, DC, USA, 1997. [Google Scholar]

- Manning, C. Rainfall Simulator Construction and Evaluation of Erosion Control Practices. Master’s Thesis, Auburn University, Auburn, AL, USA, 2021. [Google Scholar]

- Etheridge, J. Construction and Calibration of Large-Scale Rainfall Simulators. Master’s Thesis, Auburn University, Auburn, AL, USA, 2023. [Google Scholar]

- ASTM D698; Standard Index Test Method for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kN-m/m3)). ASTM: West Conshohocken, PA, USA, 2012; pp. 1–13.

| Particle Size (mm) | Sand | Loam | Clay |

|---|---|---|---|

| D100 | 25 > D100 > 3.0 | 10 > D100 > 0.3 | 3.0 > D100 > 0.02 |

| D85 | 4.0 > D85 > 0.8 | 0.8 > D85 > 0.08 | 0.08 > D85 > 0.003 |

| D50 | 0.9 > D50 > 0.2 | 0.15 > D50 > 0.015 | 0.015 > D50 > 0.0008 |

| D15 | 0.3 > D15 > 0.01 | 0.03 > D15 > 0.001 | D15 < 0.002 |

| Plasticity Index | N/A (non-plastic) | 2 < PI <8 | 10 < PI |

| Target Intensity, in./h (cm/h) | 2.0 (5.08) | 4.0 (10.16) | 6.0 (15.24) |

|---|---|---|---|

| ASTM D6459-19 20-Rainfall Gauge Test in./h (cm/h) | 2.1 (5.33) | 4.2 (10.67) | 6.3 (16.00) |

| Christiansen Uniformity (%) | 82.24% | 83.35% | 81.1% |

| ASTM D6459-19 Method Percent Error from Target Intensity (%) | 7.0% | 4.5% | 4.7% |

| Bin Size (mm) | 2.0 in./h (5.08 cm/h) | 4.0 in./h (10.16 cm/h) | 6.0 in./h (15.24 cm/h) |

|---|---|---|---|

| 2.38 to 4.76 | 0.00% | 1.92% | 4.52% |

| 2 to 2.38 | 38.39% | 35.70% | 27.95% |

| 1.68 to 2 | 12.22% | 13.32% | 31.77% |

| 1.19 to 1.68 | 21.50% | 21.45% | 16.09% |

| 0.841 to 1.19 | 19.27% | 18.19% | 11.98% |

| 0.595 to 0.841 | 8.63% | 9.42% | 7.69% |

| Soil Type | Parameter | Values | ||

|---|---|---|---|---|

| Target Intensity, in./h | 2 | 4 | 6 | |

| (cm./h) | (5.08) | (10.16) | (15.24) | |

| Sand | Experimental Avg. Intensity, in./h | 2.45 | 4.18 | 5.67 |

| (cm./h) | (6.22) | (10.62) | (14.4) | |

| Avg. Dry Weight of Soil Loss., lb | 325.95 | 284.58 | 1367.33 | |

| (kg) | (147.85) | (129.08) | (620.21) | |

| K-Factor Avg. (Sand) | 0.37 | |||

| Loam | Experimental Avg. Intensity, in./h | 2.32 | 3.97 | 6 |

| (cm./h) | (5.98) | (10.08) | (15.24) | |

| Avg. Dry Weight of Soil Loss., lb | 16.18 | 74.69 | 145.3 | |

| (kg) | (7.34) | (33.88) | (65.91) | |

| K-Factor Avg. (Loam) | 0.043 | |||

| Clay | Experimental Avg. Intensity, in./h | 2.48 | 4.42 | 6.95 |

| (cm./h) | (6.3) | (11.23) | (17.65) | |

| Avg. Dry Weight of Soil Loss., lb | 5.06 | 21.97 | 87.17 | |

| (kg) | (7.34) | (33.88) | (65.91) | |

| K-Factor Avg. (Clay) | 0.013 | |||

| Soil Type | Parameter | Values | ||

|---|---|---|---|---|

| Target Intensity, in./h | 2 | 4 | 6 | |

| (cm./h) | (5.08) | (10.16) | (15.24) | |

| Sand | Experimental Avg. Intensity, in./h | 2.34 | 4.18 | 6.33 |

| (cm./h) | (5.94) | (10.62) | (16.08) | |

| Avg. Dry Weight of Soil Loss., lb | 3.45 | 12.19 | 28.67 | |

| (kg) | (7.61) | (26.87) | (63.21) | |

| C-Factor Avg. | 0.021 | |||

| Loam | Experimental Avg. Intensity, in./h | 2.28 | 3.90 | 5.38 |

| (cm./h) | (5.79) | (9.91) | (13.67) | |

| Avg. Dry Weight of Soil Loss., lb | 0.91 | 1.86 | 3.97 | |

| (kg) | (0.41) | (0.84) | (1.80) | |

| C-Factor Avg. | 0.047 | |||

| Clay | Experimental Avg. Intensity, in./h | 2.45 | 4.68 | 6.75 |

| (cm./h) | (6.22) | (11.89) | (17.15) | |

| Avg. Dry Weight of Soil Loss., lb | 1.64 | 2.79 | 12.7 | |

| (kg) | (0.74) | (1.27) | (5.76) | |

| C-Factor Avg. | 0.193 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cater, J.R.; Donald, W.N.; Perez, M.; Fang, X. Evaluation of Straw Mulch as an Erosion Control Practice for Varying Soil Types on a 4:1 Slope. Water 2024, 16, 2819. https://doi.org/10.3390/w16192819

Cater JR, Donald WN, Perez M, Fang X. Evaluation of Straw Mulch as an Erosion Control Practice for Varying Soil Types on a 4:1 Slope. Water. 2024; 16(19):2819. https://doi.org/10.3390/w16192819

Chicago/Turabian StyleCater, John R., Wesley N. Donald, Michael Perez, and Xing Fang. 2024. "Evaluation of Straw Mulch as an Erosion Control Practice for Varying Soil Types on a 4:1 Slope" Water 16, no. 19: 2819. https://doi.org/10.3390/w16192819

APA StyleCater, J. R., Donald, W. N., Perez, M., & Fang, X. (2024). Evaluation of Straw Mulch as an Erosion Control Practice for Varying Soil Types on a 4:1 Slope. Water, 16(19), 2819. https://doi.org/10.3390/w16192819