Study on Damage Rupture and Crack Evolution Law of Coal Samples Under the Influence of Water Immersion Pressure

Abstract

:1. Introduction

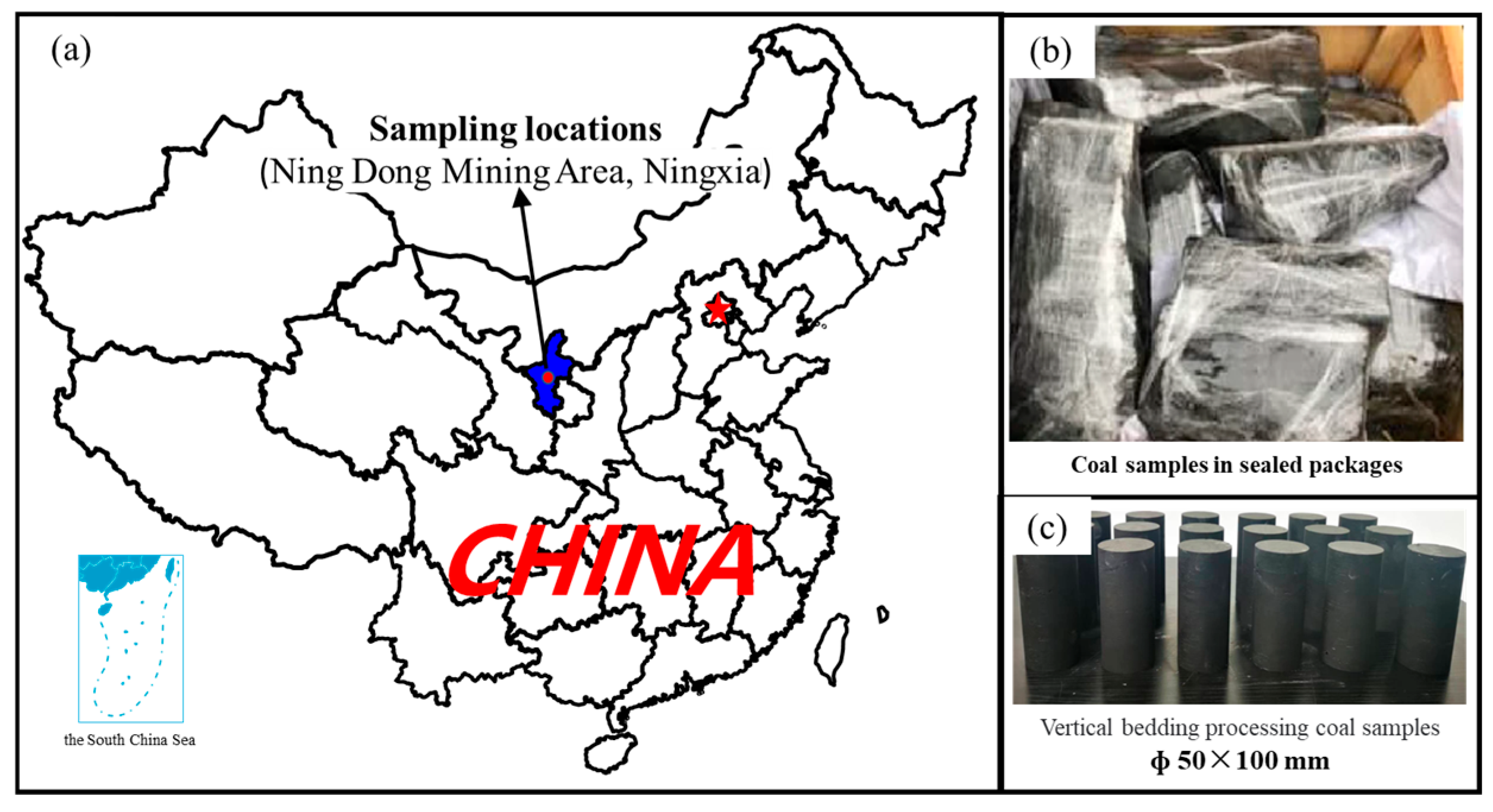

2. Materials and Methods

2.1. Materials

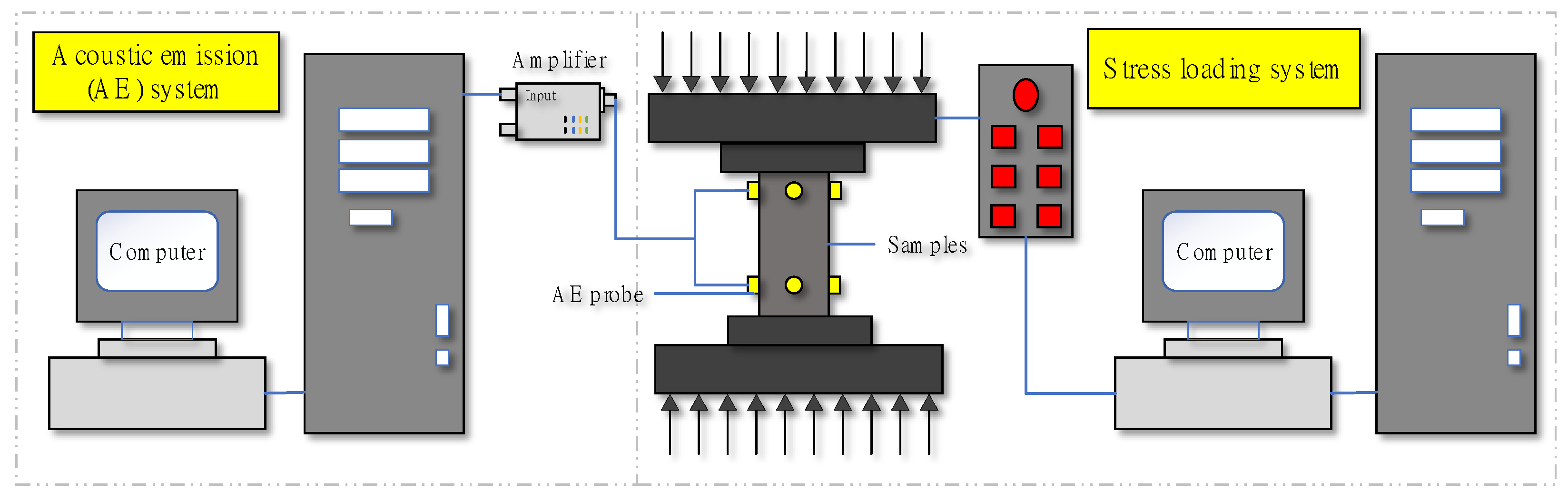

2.2. Methods

- (1)

- Drying: The coal samples were dried in an electric air-drying oven, heating under a constant temperature of 110 °C for 8 h. To ensure the complete evaporation of free water without the decomposition of crystal water, a drying time of 8 h was selected, which greatly exceeded the maximum duration specified in GB/T 212-2008 [34] for moisture content determination in coal (2 h for lignite). This extended drying period ensured the complete volatilization of free water.

- (2)

- Cooling and sealing: The coal samples were cooled to room temperature and sealed with plastic wrap to prevent reabsorption of moisture from the air.

- (3)

- Immersion: Samples #1–12 were placed under dry conditions and water pressures of 0 MPa, 0.3 MPa, and 0.5 MPa, respectively, until the immersed samples were fully saturated. The corresponding groundwater head levels were 0, 30, and 50 m based on the following water pressure formula: P = ρgh, where P refers to the water pressure, Pa; ρ is the density of the flowing water (approximately 1 g/cm3); g is typically set to 10 N/kg; and h represents the groundwater head level in the underground reservoir, m.

- (4)

- Uniaxial compression tests: Uniaxial compression tests were conducted on the samples, and the stress thresholds of the samples under different water pressures were calculated using the stress–strain curve.

- (5)

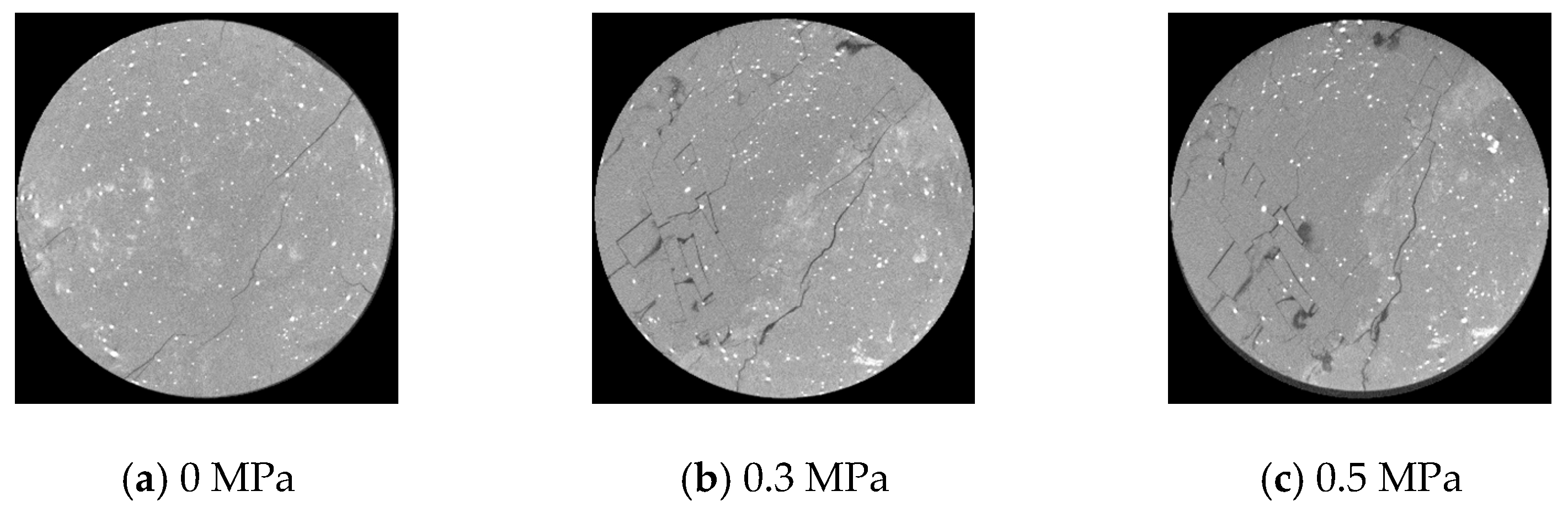

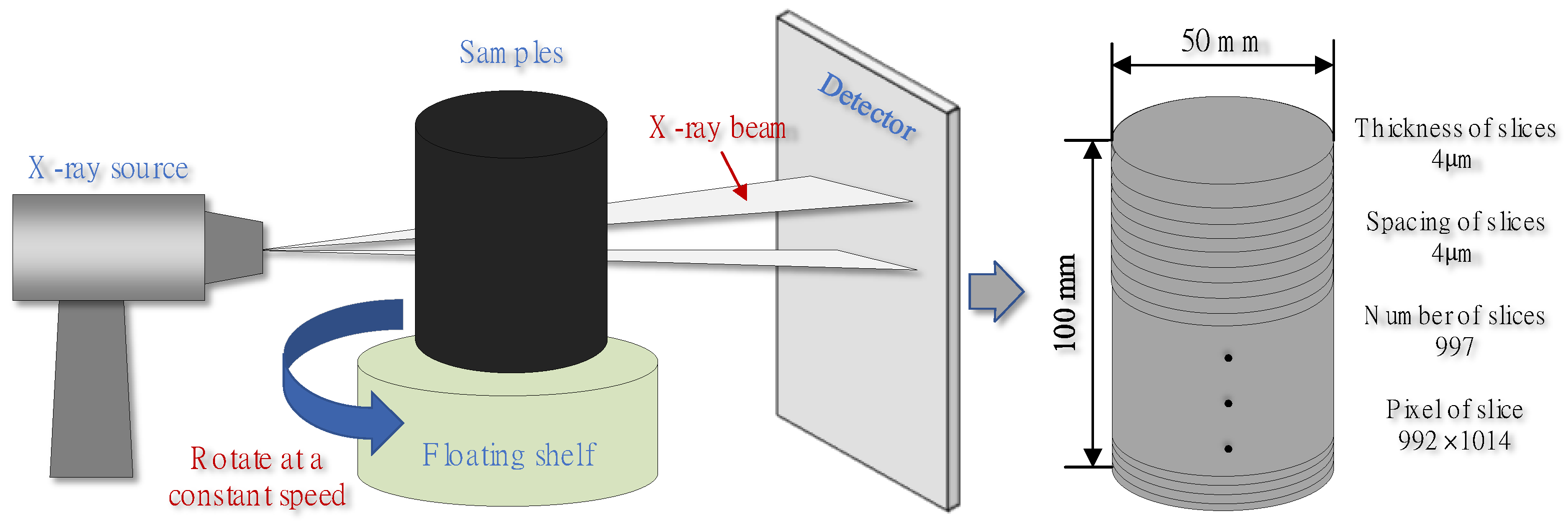

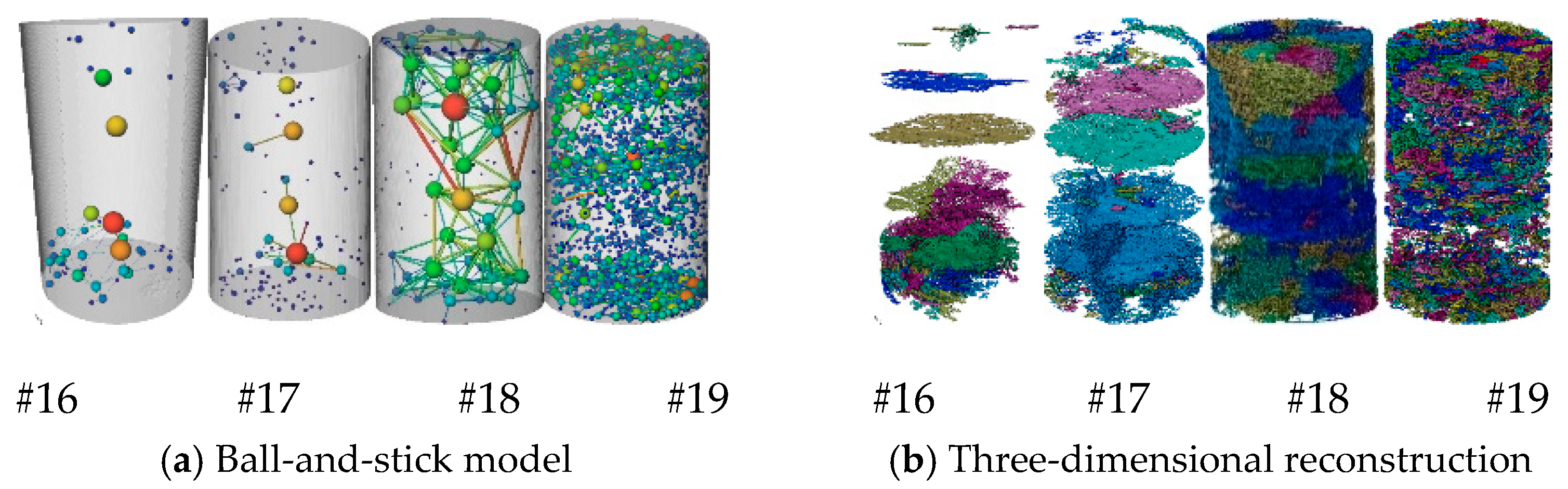

- Computed tomography (CT) scan (Part 1): Step 3 was repeated for samples #13, #14, and #15, and then CT scans were performed on the coal samples.

- (6)

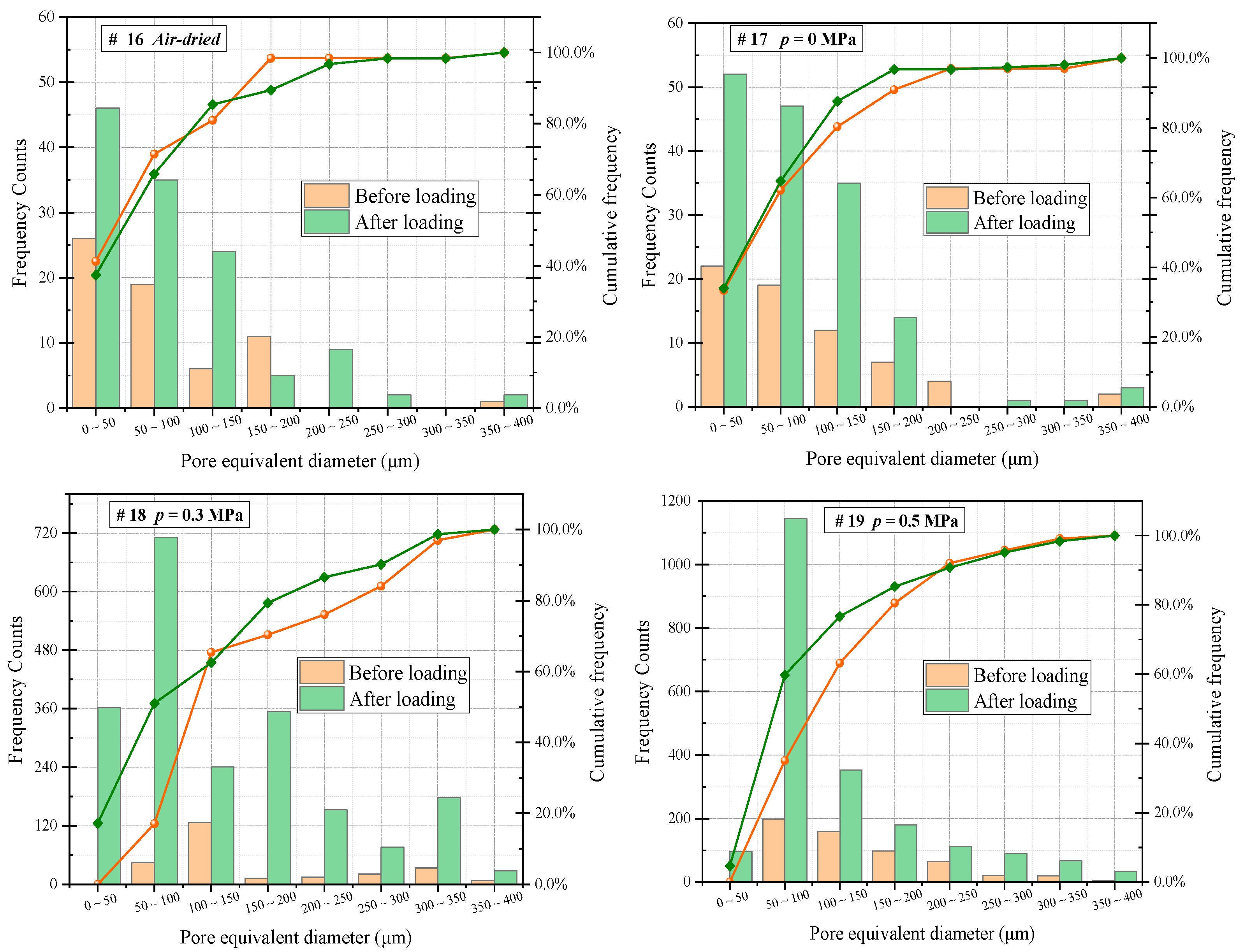

- CT scan (Part 2): Step 3 was repeated for samples #16, #17, #18, and #19. Subsequently, uniaxial compression loading was performed on the fracture damage stress threshold determined in Step 4, and CT scans were performed on the coal samples before and after loading, and an AE experiment was conducted on the coal samples during loading.

- (1)

- Data Collection: High-resolution images are obtained for model training.

- (2)

- Preprocessing: Images are cropped to 128 × 128 pixels to reduce computational resource consumption.

- (3)

- Downsampling: Low-resolution images are generated using the Bicubic method to simulate image degradation.

- (4)

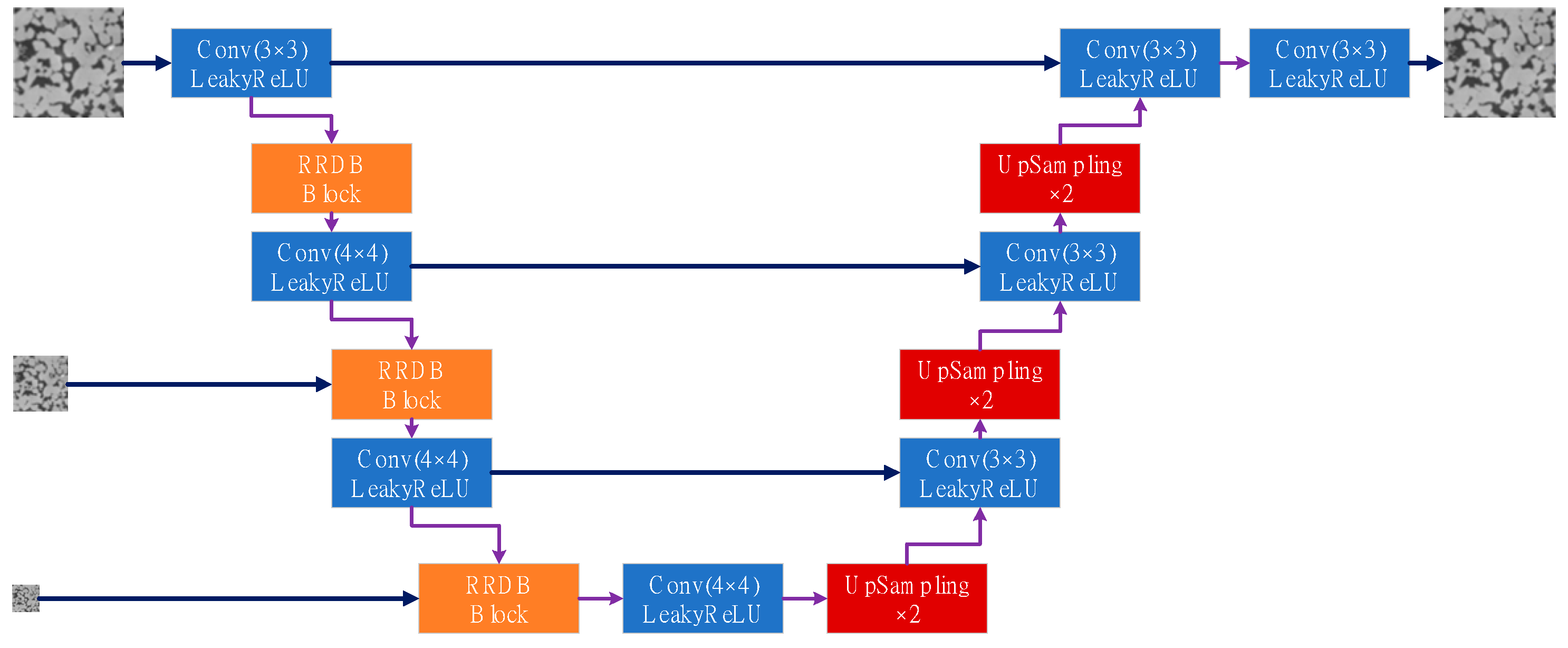

- Generator Construction: A U-Net architecture is employed, incorporating residual connections and multi-scale convolutional kernels, as shown in Figure 3.

- (5)

- Discriminator Construction: Similarly, U-Net is used with added residual connections and frequency normalization, as shown in Figure 4.

- (6)

- Initial Training of Generator: The generator is optimized for Peak Signal-to-Noise Ratio (PSNR) using the L1 loss function.

- (7)

- Adversarial Training: The model is trained with a combination of L1 loss, perceptual loss, and GAN loss to improve image quality and realism.

- (8)

- Parameter Tuning: The model is optimized based on training results.

- (9)

- Performance Testing: The model is evaluated on the test set using PSNR and Structural Similarity Index (SSIM) metrics.

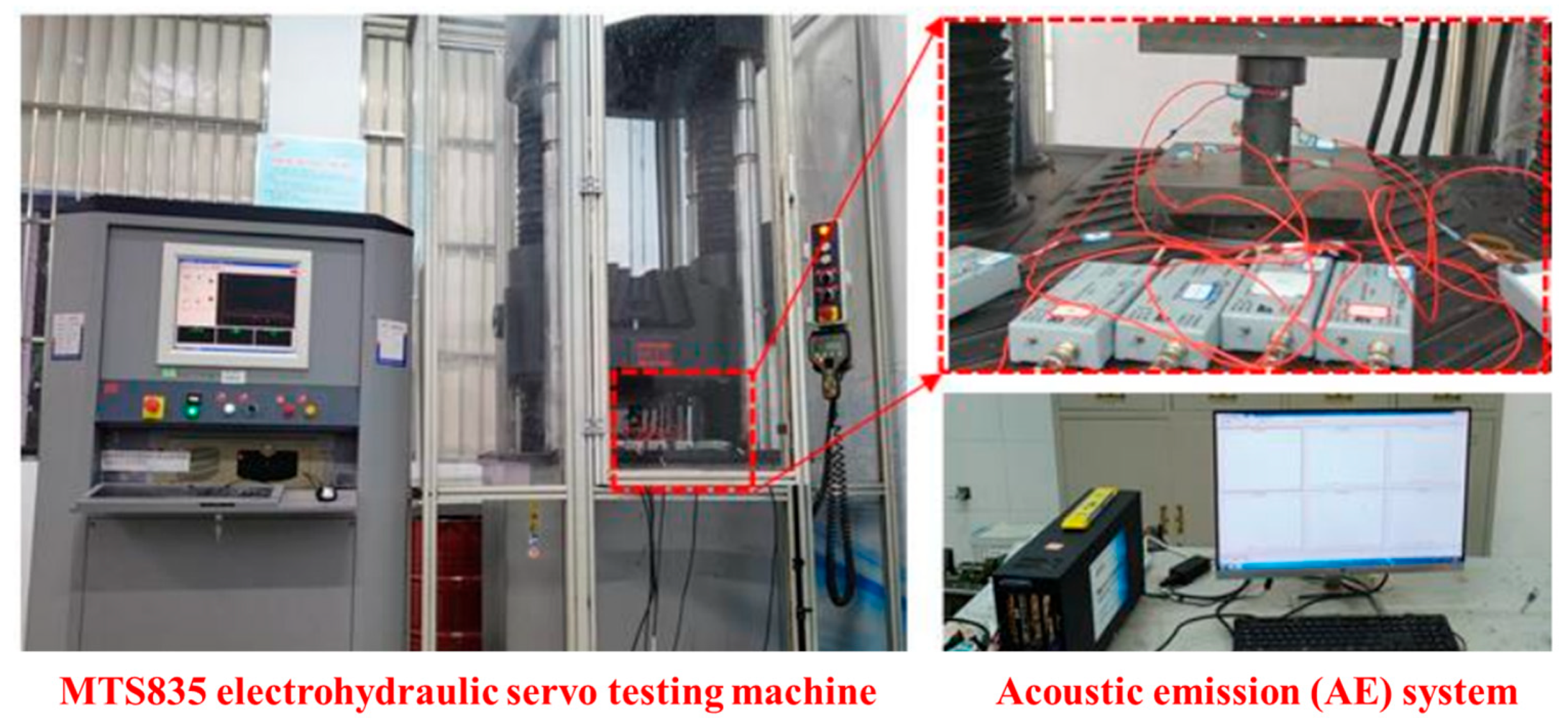

2.3. Experimental Apparatus

3. Experimental Results and Analysis

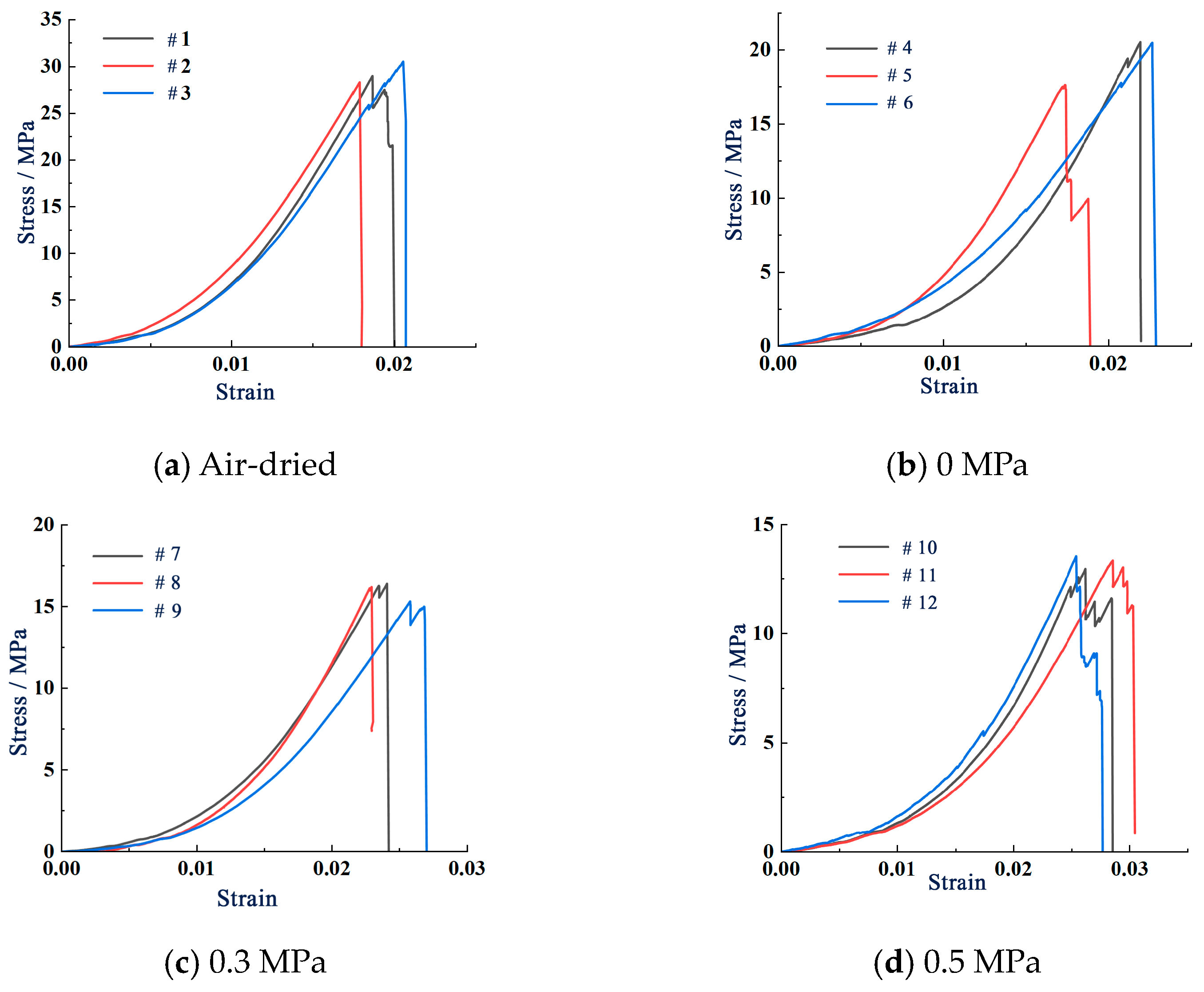

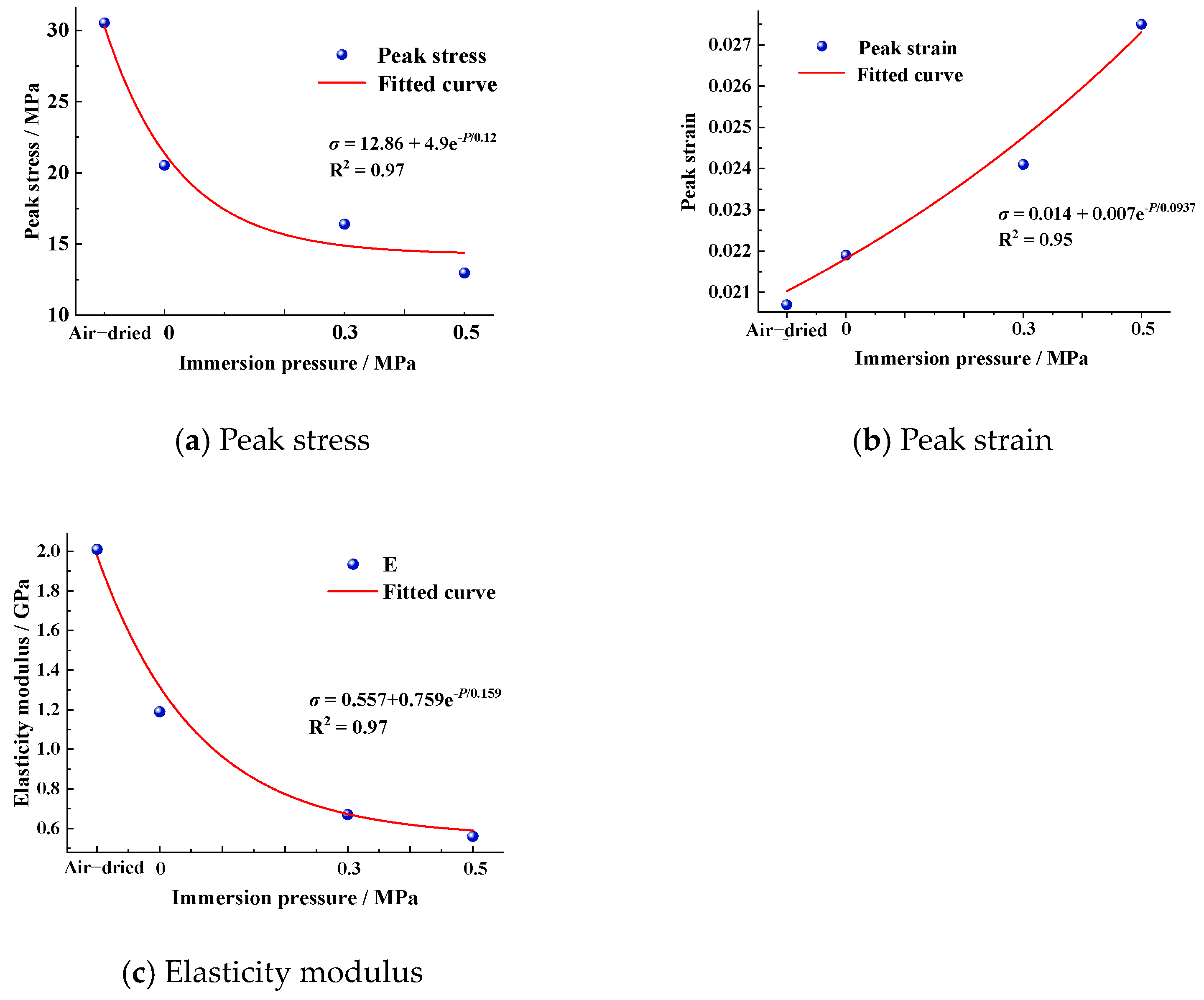

3.1. Mechanical Properties of Coal Samples

3.2. Distribution and Evolution of Cracks in Coal Samples

4. Conclusions

- (1)

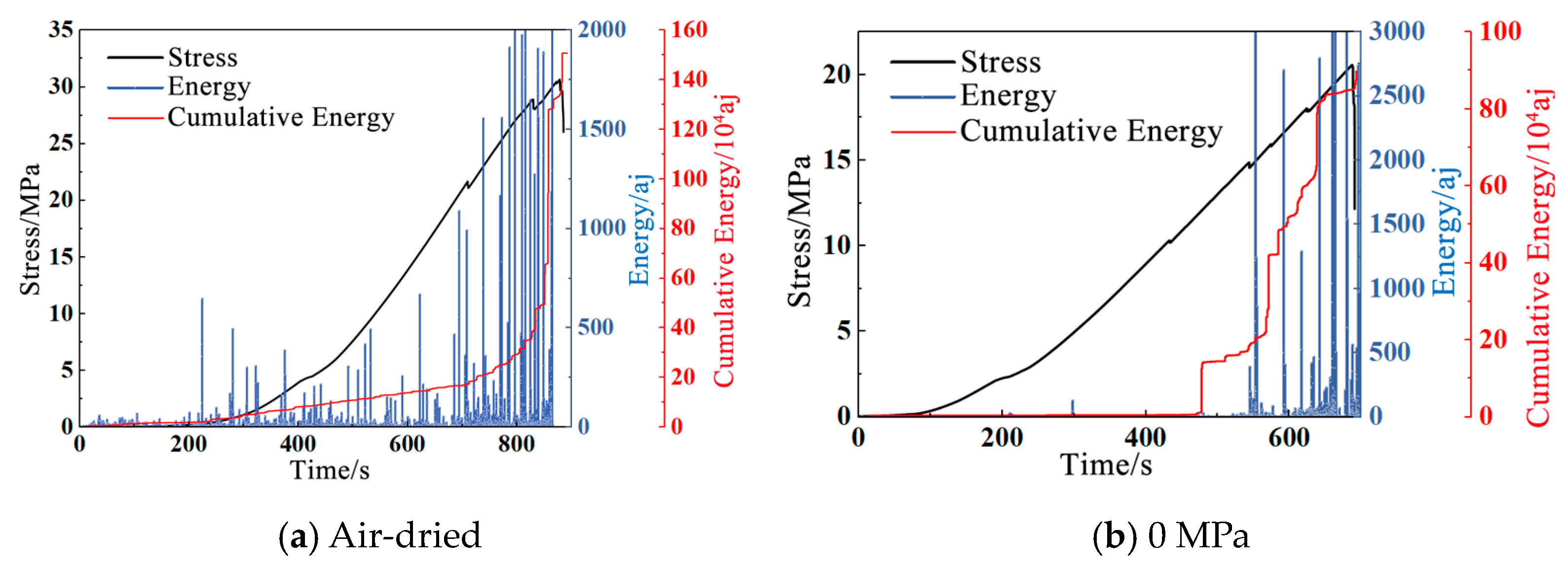

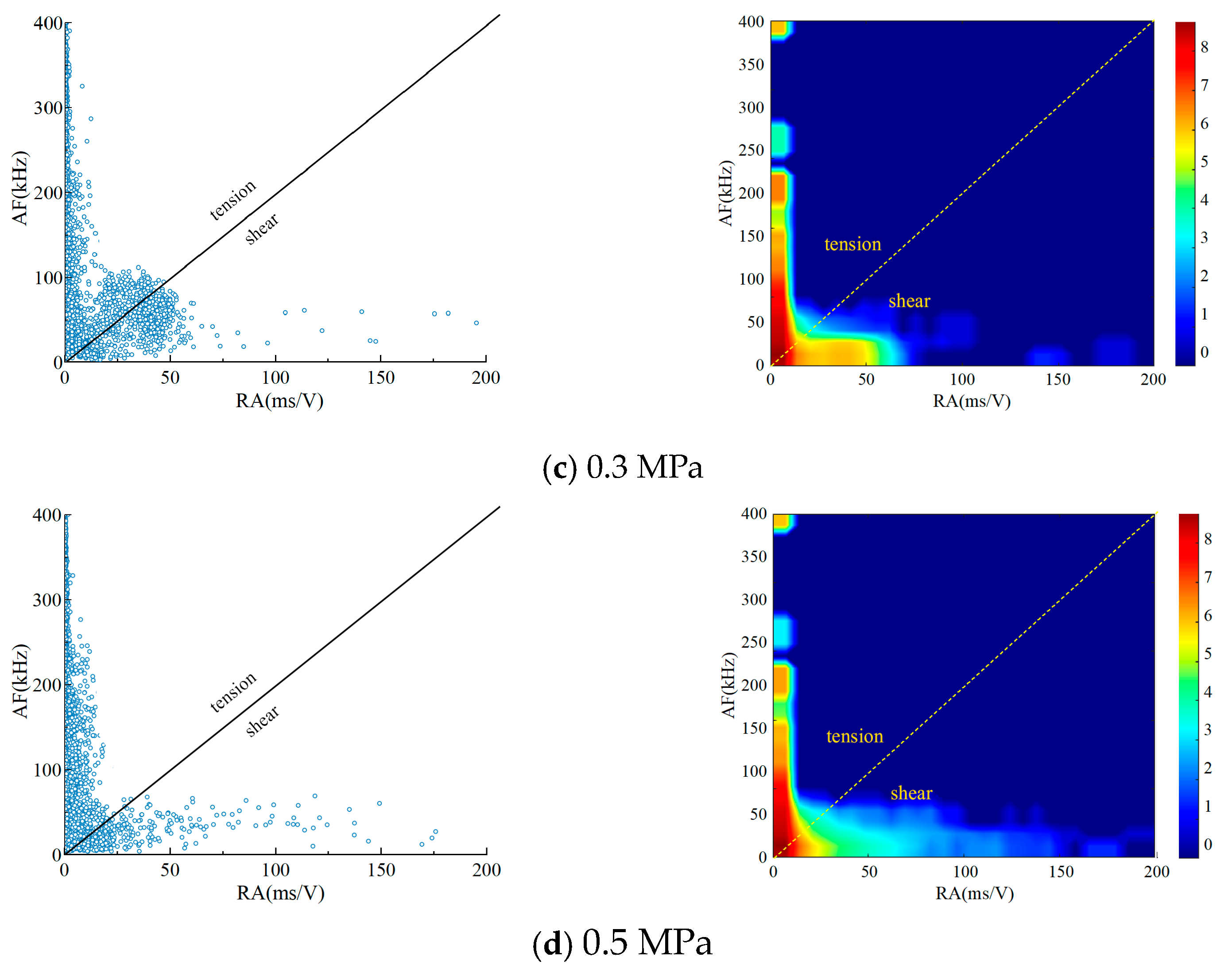

- Compared with the dry coal samples, the water-immersed samples exhibited fewer AE counts and slower cumulative AE curve growth throughout the loading process until failure. The cumulative energy of the water-immersed samples decreased, and the rate of energy reduction gradually decreased with increasing immersion pressure. While dry coal samples were primarily characterized by tensile fractures, the formation of tensile–shear composite cracks under immersion conditions shifted the failure mode to a tensile–shear composite mechanism.

- (2)

- From the air-dried state to saturation under various immersion pressures, the average peak strength decreased from 29.98 to 11.96 MPa, representing a reduction of 57.4%. With increasing water immersion pressure, the average peak strength of the coal samples decreased from 29.98 to 11.96 MPa, a reduction of 57.4%. The peak strain increased to varying degrees.

- (3)

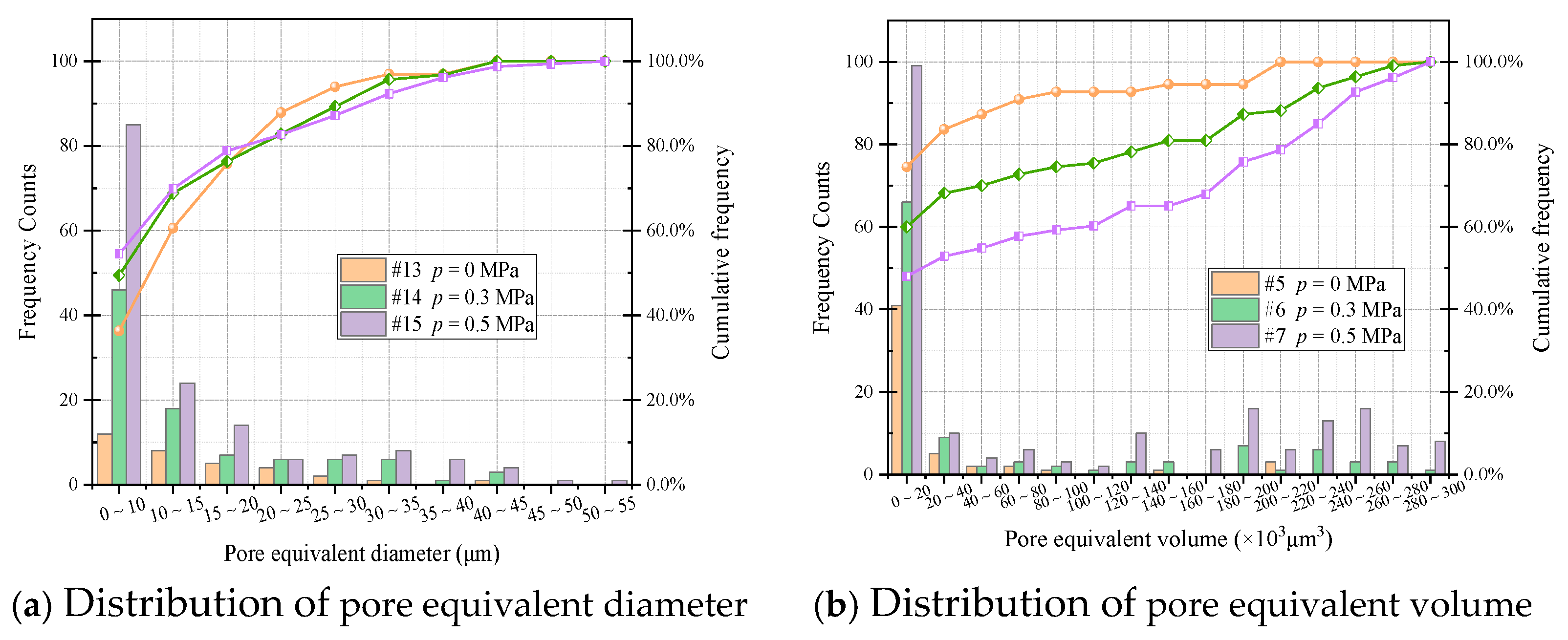

- The size and number of various types of pores increased to some extent under different water saturation pressures. As the water pressure increased, its role in promoting pore development in the coal samples gradually decreased. Most of the pores in the water-saturated samples had diameters smaller than 10 µm. The number of pores was inversely proportional to the pore diameter, with the pore volume primarily concentrated in the range of 0–20 × 103 µm3. The average porosity of the samples increased with the increase in immersion pressure, and as the coal sample approached the fracture damage threshold, the porosity increased from 7.1% to 22.5%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, Z.; Li, W.; Pei, Y.; Qiao, W.; Wu, Y. Classification of the type of eco-geological environment of a coal mine district: A case study of an ecologically fragile region in Western China. J. Clean. Prod. 2018, 174, 1513–1526. [Google Scholar] [CrossRef]

- Xu, G.; Schwarz, P.; Yang, H. Adjusting energy consumption structure to achieve China’s CO2 emissions peak. Renew. Sustain. Energy Rev. 2020, 122, 109737. [Google Scholar] [CrossRef]

- Chi, M.; Zhang, D.; Zhao, Q.; Yu, W.; Liang, S. Determining the scale of coal mining in an ecologically fragile mining area under the constraint of water resources carrying capacity. J. Environ. Manag. 2020, 279, 111621. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Bai, Q.; Han, P. A review of water rock interaction in underground coal mining: Problems and analysis. Bull. Eng. Geol. Environ. 2023, 82, 157. [Google Scholar] [CrossRef]

- Liu, X.; Zeng, Y.; Wu, Q.; Meng, S.; Liang, J.; Hou, Z. Ecological-based mining: A coal–water–thermal collaborative paradigm in ecologically fragile areas in western china. Engineering 2024, 38, 209–222. [Google Scholar] [CrossRef]

- Hou, J.; Guo, Z.; Li, J.; Zhao, L. Study on triaxial creep test and theoretical model of cemented gangue-fly ash backfill under seep-age-stress coupling. Constr. Build. Mater. 2021, 273, 121722. [Google Scholar] [CrossRef]

- Ma, H.; Wang, Y.; Li, X.; Wang, J. Evolution law and mechanism analysis of strength for backfill under different stress and drainage conditions. Constr. Build. Mater. 2024, 428, 136406. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, K.; He, X.; Zhao, X.; Wei, Z.; He, S. Research status of comprehensive utilization of coal-based solid waste (CSW) and key tech-nologies of filling mining in China: A review. Sci. Total Environ. 2024, 926, 171855. [Google Scholar] [CrossRef]

- Ma, L.; Yu, Y.; Spearing, A. Water conservation mining method and its applicability: A case study in Yushen mining area. J. Min. Saf. Eng. 2019, 36, 1079–1085. [Google Scholar]

- Zhang, C.; Wang, F.; Bai, Q. Underground space utilization of coalmines in China: A review of underground water reservoir construction. Tunn. Undergr. Space Technol. 2020, 107, 103657. [Google Scholar] [CrossRef]

- Xu, Y.; Ma, L.; Khan, N.M. Prediction and maintenance of water resources carrying capacity in mining area—A case study in the Yu-Shen mining area. Sustainability 2020, 12, 7782. [Google Scholar] [CrossRef]

- Chi, M.; Li, Q.; Cao, Z.-G.; Fang, J.; Wu, B.-Y.; Zhang, Y.; Wei, S.-R.; Liu, X.-Q.; Yang, Y.-M. Evaluation of water resources carrying capacity in ecologically fragile mining areas under the influence of underground reservoirs in coal mines. J. Clean. Prod. 2022, 379, 134449. [Google Scholar] [CrossRef]

- Winde, F.; Kaiser, F.; Erasmus, E. Exploring the use of deep level gold mines in South Africa for underground pumped hydro-electric energy storage schemes. Renew. Sustain. Energy Rev. 2017, 78, 668–682. [Google Scholar] [CrossRef]

- Menéndez, J.; Loredo, J.; Galdo, M.; Fernández-Oro, J.M. Energy storage in underground coal mines in NW Spain: Assessment of an underground lower water reservoir and preliminary energy balance. Renew. Energy 2019, 134, 1381–1391. [Google Scholar] [CrossRef]

- González-Quirós, A.; Fernández-Álvarez, J. Conceptualization and finite element groundwater flow modeling of a flooded underground mine reservoir in the Asturian Coal Basin, Spain. J. Hydrol. 2019, 578, 124036. [Google Scholar] [CrossRef]

- Menéndez, J.; Ordóñez, A.; Álvarez, R.; Loredo, J. Energy from closed mines: Underground energy storage and geothermal applications. Renew. Sustain. Energy Rev. 2019, 108, 498–512. [Google Scholar] [CrossRef]

- Liu, C.; Wang, F.; Zhang, Z.; Zhu, D.; Hao, W.; Tang, T.; Zhang, X.; Zhu, C. Surrounding rock deformation mechanism and control technology for the roadway in the fault-disturbed zone under special-shaped coal pillars. Processes 2023, 11, 3264. [Google Scholar] [CrossRef]

- Zhang, C.; Luo, B.; Xu, Z.; Sun, Y.; Feng, L. Research on the capacity of underground reservoirs in coal mines to protect the groundwater resources: A case of zhangshuanglou coal mine in Xuzhou, China. Water 2023, 15, 1468. [Google Scholar] [CrossRef]

- Fan, J.; Li, Z.; Feng, G.; Zhang, H.; Qi, C.; Zhang, J. Failure analysis of coal pillars and overburden from underground water reservoir under the mining-water invasion coupling effect. Eng. Fail. Anal. 2023, 151, 107406. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, F.; Kou, M.; Li, M. A review of stability of dam structures in coal mine underground reservoirs. Water 2024, 16, 1856. [Google Scholar] [CrossRef]

- Yao, Q.; Tang, C.; Xia, Z.; Liu, X.; Zhu, L.; Chong, Z.; Hui, X. Mechanisms of failure in coal samples from underground water reservoir. Eng. Geol. 2020, 267, 105494. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Xia, F.; Xing, Z.; Wang, L. Impacts of underground reservoir site selection and water storage on the groundwater flow system in a mining Area—A case study of daliuta mine. Water 2022, 14, 3282. [Google Scholar] [CrossRef]

- Yao, Q.; Yu, L.; Shan, C.; Xia, Z.; Chen, N.; Xie, H.; Zhu, L. Experimental study on the mechanical damage and deformation failure of water-bearing coal samples. Mine Water Environ. 2023, 42, 251–265. [Google Scholar] [CrossRef]

- Rabat, Á.; Cano, M.; Tomás, R.; Tamayo, E.; Alejano, L.R. Evaluation of strength and deformability of soft sedimentary rocks in dry and saturated conditions through needle penetration and point load tests: A comparative study. Rock Mech. Rock Eng. 2020, 53, 2707–2726. [Google Scholar] [CrossRef]

- Liu, C.; Cheng, Y.; Jiao, Y.-Y.; Zhang, G.-H.; Zhang, W.-S.; Ou, G.-Z.; Tan, F. Experimental study on the effect of water on mechanical properties of swelling mudstone. Eng. Geol. 2021, 295, 106448. [Google Scholar] [CrossRef]

- Han, P.; Zhang, C.; Wang, X.; Wang, L. Study of mechanical characteristics and damage mechanism of sandstone under long-term immersion. Eng. Geol. 2023, 315, 107020. [Google Scholar] [CrossRef]

- Hawkins, A.B.; McConnell, B.J. Sensitivity of sandstone strength and deformability to changes in moisture content. Q. J. Eng. Geol. 1992, 25, 115–130. [Google Scholar] [CrossRef]

- Hashiba, K.; Fukui, K. Effect of water on the deformation and failure of rock in uniaxial tension. Rock Mech. Rock Eng. 2014, 48, 1751–1761. [Google Scholar] [CrossRef]

- Burshtein, L.S. Effect of moisture on the strength and deformability of sandstone. J. Min. Sci. 1969, 5, 573–576. [Google Scholar] [CrossRef]

- Özdemir, E.; Sarici, D.E. Combined effect of loading rate and water content on mechanical behavior of natural stones. J. Min. Sci. 2018, 54, 931–937. [Google Scholar] [CrossRef]

- Xie, H. Pore Structure Evolution and Fatigue Damage Mechanism of Dry-Wet Cycles Coal Samples. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2023. [Google Scholar]

- Ding, Y.; Yin, D.; Hu, H.; Tan, Y.; Liu, H.; Li, X.; Jiang, N. Influence characteristics and macro-meso mechanism of pressure immersion time on tensile properties for coal materials. J. Mater. Res. Technol. 2023, 26, 2358–2370. [Google Scholar] [CrossRef]

- Wang, G.; Li, J.; Liu, Z.; Qin, X.; Yan, S. Relationship between wave speed variation and microstructure of coal under wet conditions. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2020, 126, 104203. [Google Scholar] [CrossRef]

- GB/T 212-2008; Proximate Analysis of Coal. National Standardization Administration of China: Beijing, China, 2008.

- Ai, T.; Wu, S.; Zhang, R.; Gao, M.; Zhou, J.; Xie, J.; Ren, L.; Zhang, Z. Changes in the structure and mechanical properties of a typical coal induced by water immersion. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2021, 138, 104597. [Google Scholar] [CrossRef]

- Lu, S.; Li, M.; Ma, Y.; Wang, S.; Zhao, W. Permeability changes in mining-damaged coal: A review of mathematical models. J. Nat. Gas Sci. Eng. 2022, 106, 104739. [Google Scholar] [CrossRef]

- Gu, H.; Lai, X.; Tao, M.; Cao, W.; Yang, Z. The role of porosity in the dynamic disturbance resistance of water-saturated coal. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2023, 166, 105388. [Google Scholar] [CrossRef]

- Lin, Y.; Qin, Y.; Ma, D.; Zhao, J. Experimental research on dynamic variation of permeability and porosity of low-rank inert-rich coal under stresses. ACS Omega 2020, 5, 28124–28135. [Google Scholar] [CrossRef]

- Yu, Y.; Rong, K.; Cui, W.; Cheng, W.; Chen, Y.; Wei, W. Pore structure dynamic evolution of coal during hydraulic intrusion based on NMR. Measurement 2024, 227, 114247. [Google Scholar] [CrossRef]

- Shan, C.; Yao, Q.; Cao, S.; Xu, Q.; Zheng, C.; Xia, Z.; Li, Y.; Yan, L. Fracture development patterns and micro–macrostructural fractal characteristics of acid–base coal samples. Nat. Resour. Res. 2024, 33, 831–865. [Google Scholar] [CrossRef]

| Rock Type | Sample Mass | Seismic Velocity | ||

|---|---|---|---|---|

| Average (g) | Discrete Degree | Average (m/s) | Discrete Degree | |

| Coal | 267.91 | 0.02168 | 1450.53 | 0.02185 |

| Samples | Air-Dried | P = 0 MPa | P = 0.3 MPa | P = 0.5 MPa | |

|---|---|---|---|---|---|

| Experiment | |||||

| Study on failure mode of coal sample | #1–3 | #4–6 | #7–9 | #10–12 | |

| Immersion pressure test | #13 | #14 | #15 | ||

| Study on fracture distribution and evolution | #16 | #17 | #18 | #19 | |

| Resonant Frequency (MHz) | Threshold Value (dB) | Sampling Frequency (MHz) | Peak Detection Time (s) | Hardware Trigger Delay (s) |

|---|---|---|---|---|

| 140 | 40 | 1.0 | 50 | 200 |

| Samples | Compressive Strength (MPa) | Peak Strain | Elasticity Modulus (GPa) |

|---|---|---|---|

| #1 | 30.54 | 0.0198 | 2.01 |

| #2 | 30.52 | 0.0179 | 1.98 |

| #3 | 28.87 | 0.0207 | 2.12 |

| #4 | 20.53 | 0.0219 | 1.19 |

| #5 | 17.64 | 0.0189 | 1.32 |

| #6 | 20.49 | 0.0229 | 1.43 |

| #7 | 16.28 | 0.0242 | 0.67 |

| #8 | 16.19 | 0.0237 | 0.72 |

| #9 | 14.98 | 0.0268 | 0.63 |

| #10 | 11.62 | 0.0285 | 0.56 |

| #11 | 11.28 | 0.0304 | 0.43 |

| #12 | 12.98 | 0.0276 | 0.76 |

| Samples | E/GPa | μ | Stress Characteristic Values (MPa) | Stress Ratio | |||||

|---|---|---|---|---|---|---|---|---|---|

| σcc | σci | σcd | σf | σcc/σf | σci/σf | σcd/σf | |||

| #1 | 2.01 | 0.24 | 4.89 | 15.41 | 21.57 | 30.54 | 0.16 | 0.51 | 0.71 |

| #4 | 1.19 | 0.21 | 3.95 | 10.23 | 14.83 | 20.54 | 0.19 | 0.49 | 0.72 |

| #7 | 0.67 | 0.15 | 2.32 | 5.19 | 12.26 | 16.41 | 0.14 | 0.31 | 0.74 |

| #10 | 0.56 | 0.13 | 1.87 | 4.13 | 7.96 | 12.98 | 0.14 | 0.32 | 0.61 |

| Samples | #16 | #17 | #18 | #19 |

|---|---|---|---|---|

| Accumulated energy (104aj) | 153.74 | 90.52 | 35.91 | 27.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shangguan, J.; Guo, H.; Cao, S.; Sun, J. Study on Damage Rupture and Crack Evolution Law of Coal Samples Under the Influence of Water Immersion Pressure. Water 2025, 17, 263. https://doi.org/10.3390/w17020263

Shangguan J, Guo H, Cao S, Sun J. Study on Damage Rupture and Crack Evolution Law of Coal Samples Under the Influence of Water Immersion Pressure. Water. 2025; 17(2):263. https://doi.org/10.3390/w17020263

Chicago/Turabian StyleShangguan, Jianhua, Haotian Guo, Shenggen Cao, and Jialong Sun. 2025. "Study on Damage Rupture and Crack Evolution Law of Coal Samples Under the Influence of Water Immersion Pressure" Water 17, no. 2: 263. https://doi.org/10.3390/w17020263

APA StyleShangguan, J., Guo, H., Cao, S., & Sun, J. (2025). Study on Damage Rupture and Crack Evolution Law of Coal Samples Under the Influence of Water Immersion Pressure. Water, 17(2), 263. https://doi.org/10.3390/w17020263