Experimental Study on the Behavior of Gas–Water Two-Phase Fluid Flow Through Rock Fractures Under Different Confining Pressures and Shear Displacements

Abstract

:1. Introduction

2. Test Samples and Test Methods

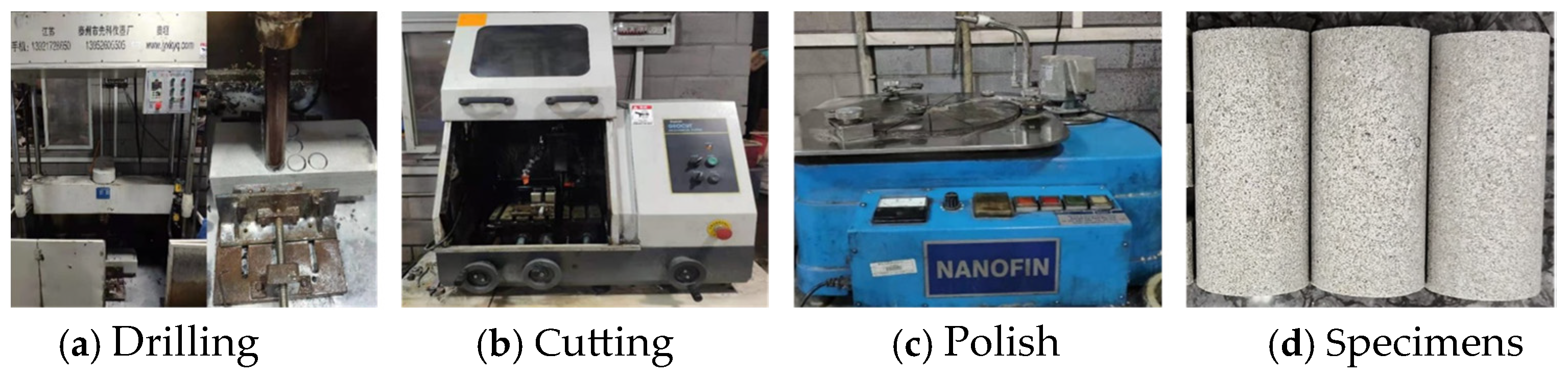

2.1. Rock Fractured Specimen Preparation

2.2. Characterization of the Rough Morphology of Rock Fracture

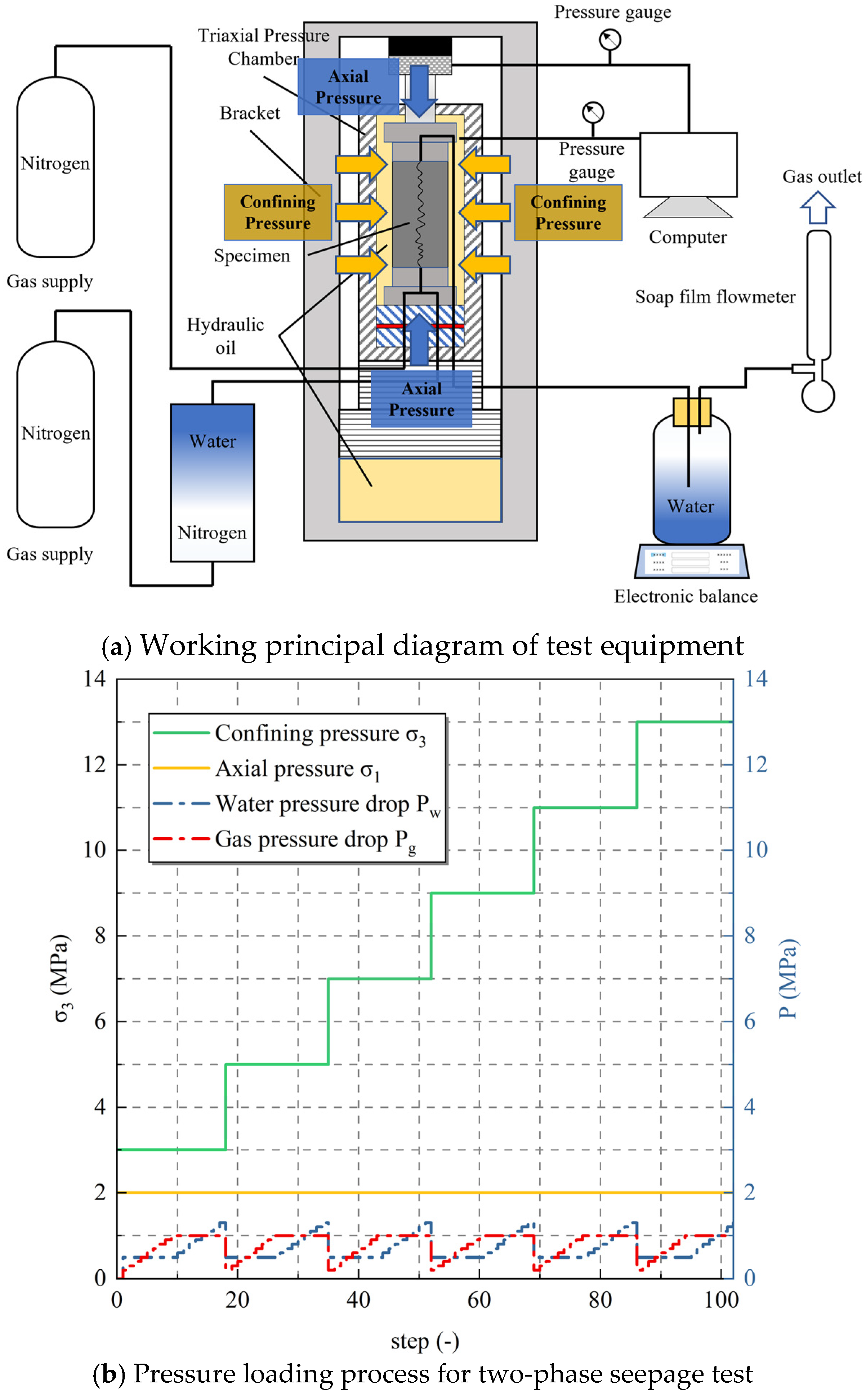

2.3. Gas–Water Two-Phase Fluid Flow Test Method

- (1)

- Securely connect the water-saturated rock fracture specimen with the indenter using heat-shrink tubing and place it into the sealed triaxial pressure chamber.

- (2)

- Connect and seal the base with the triaxial pressure chamber using a fixture. Inject hydraulic oil into the sealed chamber until oil pressure stabilizes inside and steady flow is observed from the outlet.

- (3)

- Apply an axial load of 3 MPa at a rate of 0.05 MPa/s and maintain it constant. After confining pressure stabilizes, open the valves for water and nitrogen separately. Increase fluid pressure to set value while measuring and recording flow rate after stabilization for complete seepage measurement.

- (4)

- Gradually increase fluid pressure until all desired points are tested under this level of pressurization before unloading fluid pressure to complete fixed-pressure two-phase seepage testing.

- (5)

- Incrementally increase confining pressures step by step (5 MPa, 7 MPa, 9 MPa, 11 MPa, and 13 MPa), repeating the operations described in (3) and (4), to conduct two-phase seepage tests under different confining pressures along with varying fluid pressures on each specimen (refer to Figure 3b for the detailed process).

- (6)

- Repeat the operations in (3), (4), and (5) to complete the two-phase seepage test for all rock fracture specimens.

3. Gas–Water Relative Permeability in Rock Fracture Under Pressure and Shear Effect

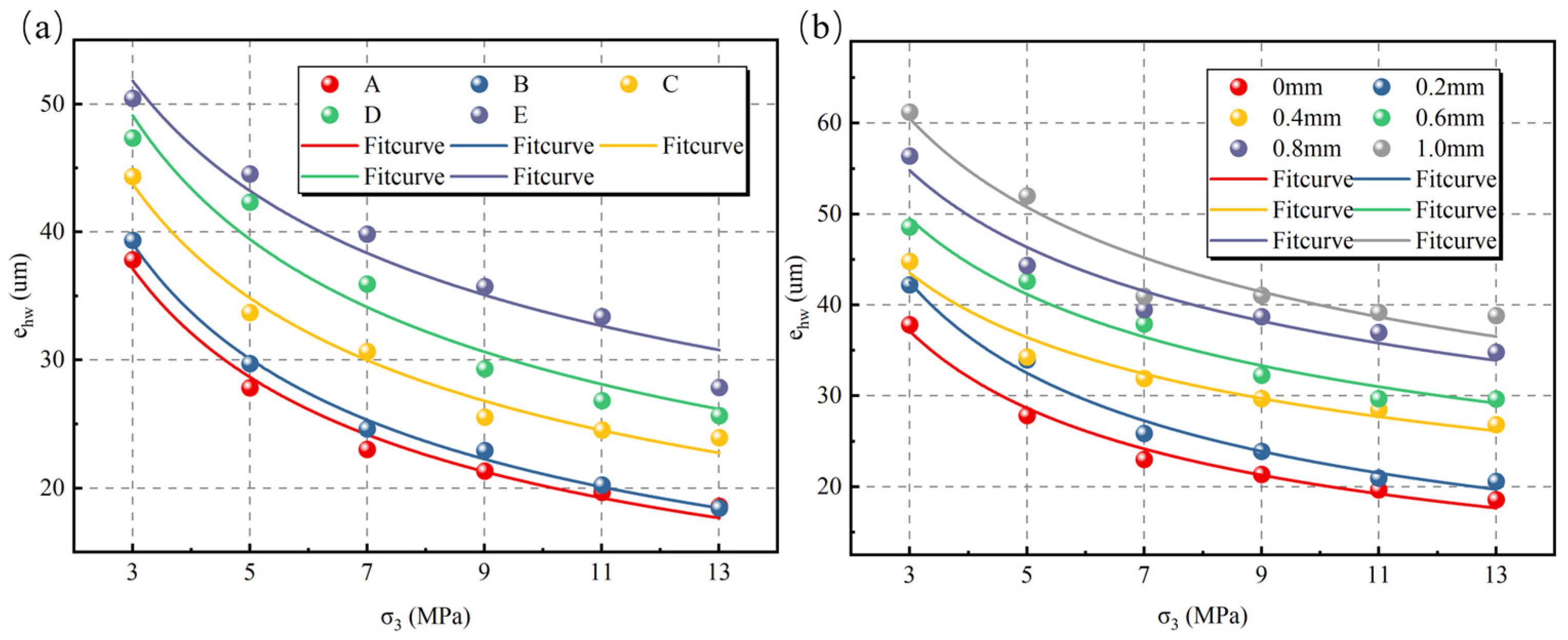

3.1. Evolution of Equivalent Hydraulic Aperture of Rock Fracture

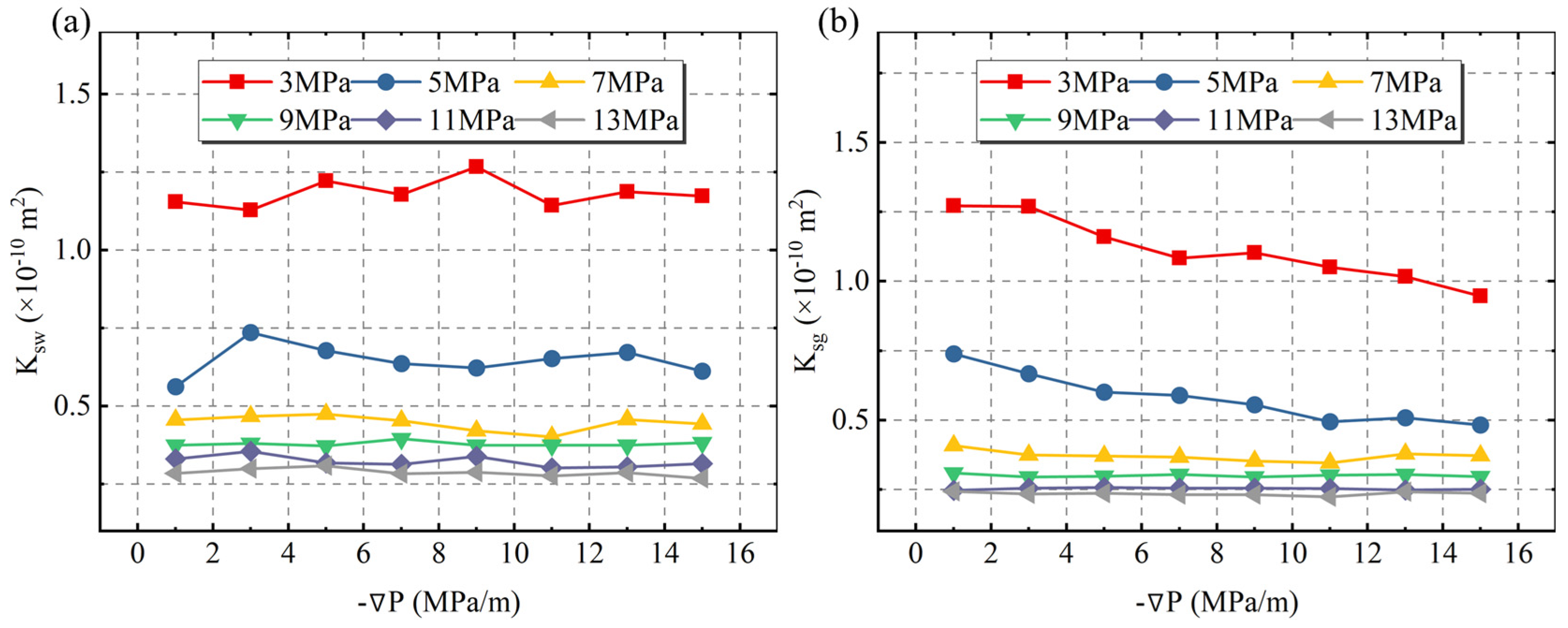

3.2. Evolution of Relative Permeability of Gas–Water Two-Phase Fluid in In Situ Closed Fractures Under Different Confining Pressures

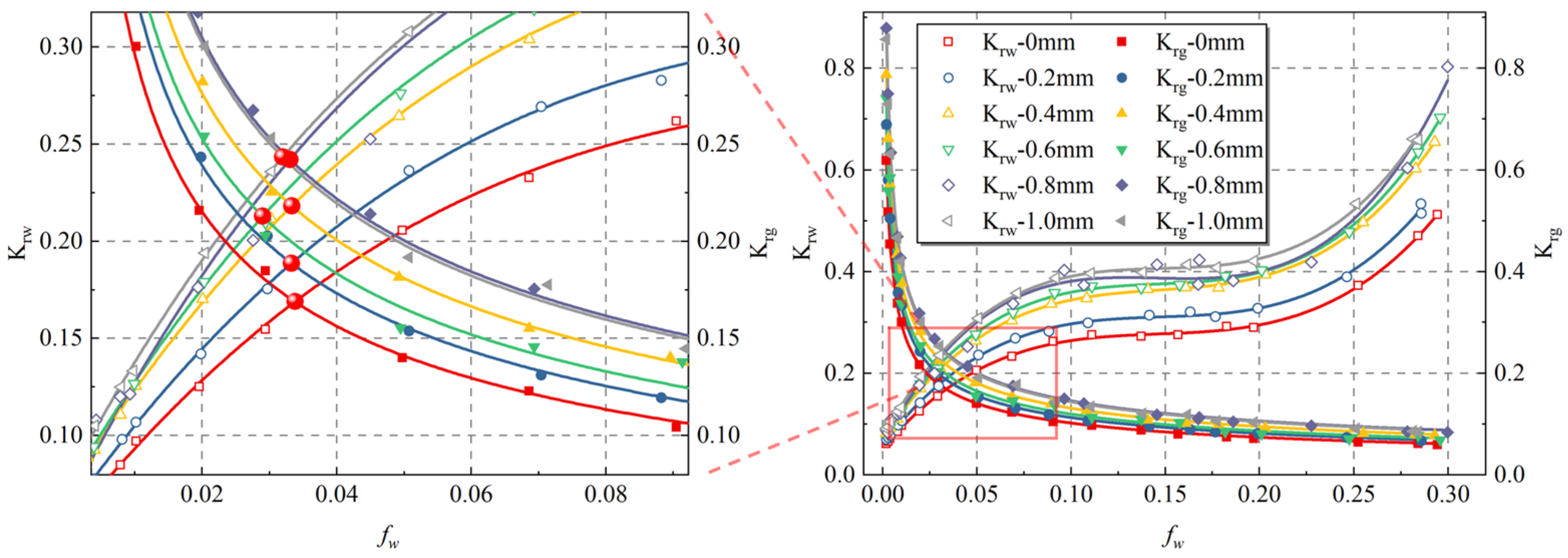

3.3. Evolution of Relative Permeability of Gas–Water Two-Phase in Rock Fracture Under Shearing Effect

4. Analysis and Discussion

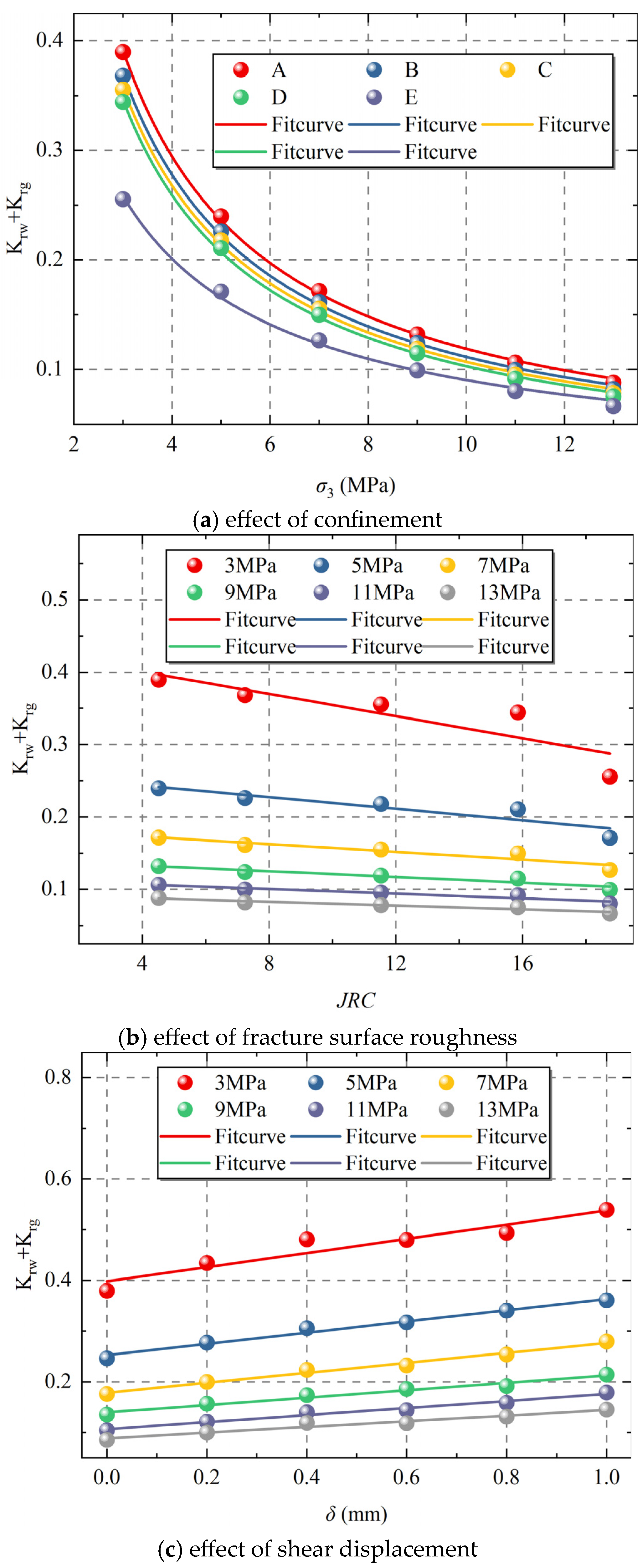

4.1. Analysis of Inter Phase Resistance of Gas–Water Two-Phase Fluids in Rock Fractures

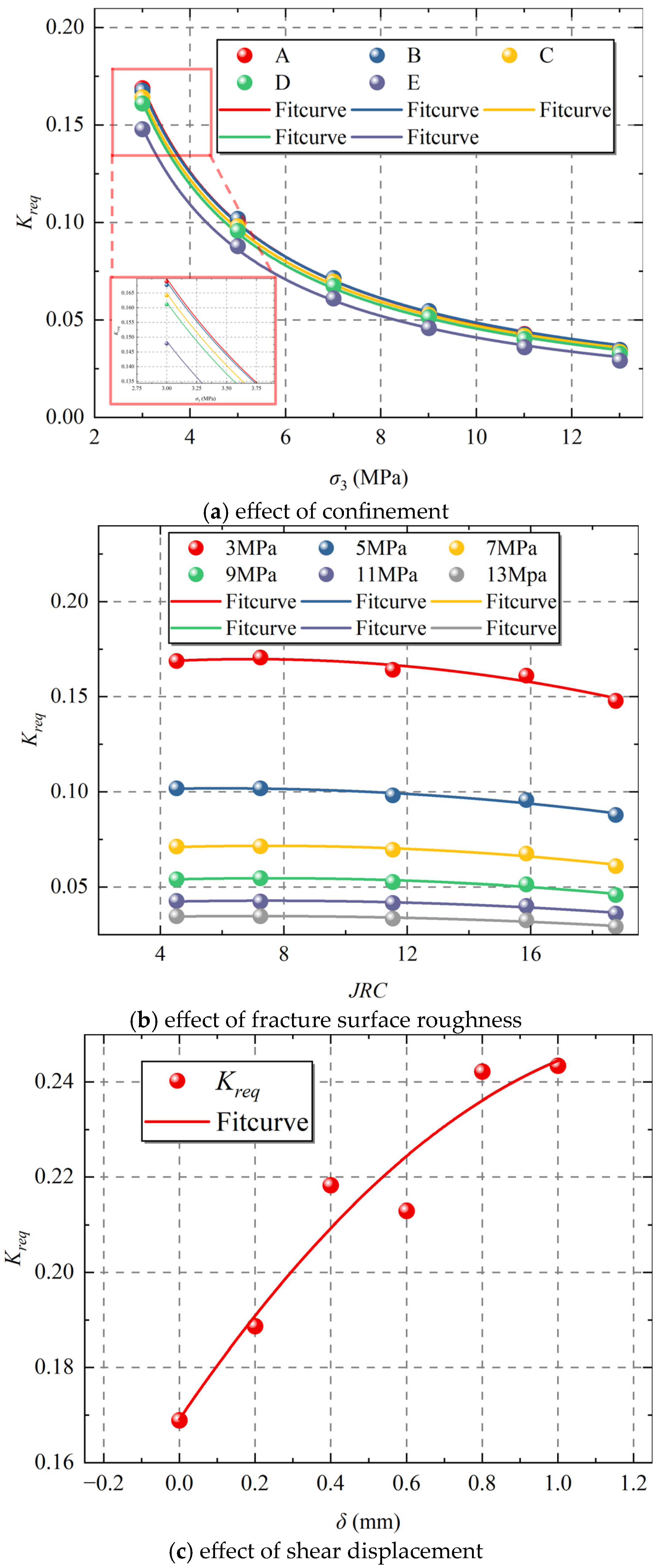

4.2. Characterization of the Equal-Permeability Point in Rock Fracture

5. Conclusions

- (1)

- With the increase in roughness, the equivalent hydraulic aperture of the fractures increased when compared with the in situ closed fractures, and the equivalent hydraulic aperture of the fractures after shear appeared to be significantly increased.

- (2)

- When the fractional flow of water is high, the water phase is affected by the confining pressure, and the surface topography of the fracture is significantly higher than that of the gas phase; and when the fractional flow of water is low, the water phase is affected by the confining pressure, and the surface topography of the fracture is significantly lower than that of the gas phase. The influence of confining pressure and fracture surface morphology on the water phase is lower than that on the gas phase.

- (3)

- The influence of dislocation on relative permeability results in a decrease in the inter-phase resistance of the fracture, which causes the relative permeability of the water phase to rise obviously after the dislocation. The relative permeability of the water phase increased significantly after the dislocation, contrasting with a smaller increase in the relative permeability of the gas phase.

- (4)

- Under the effect of roughness, confining pressure, and shear, the fractional flow of water at the equal-permeability point did not change significantly; the relative permeability at the equal-permeability point increased with the decrease in confining pressure and roughness; and the relative permeability at the equal-permeability point increased after shear, which indicates that shear has an important role in promoting gas–water flow in rock fractures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Xi | X-coordinates of the converted points |

| Yi | Y-coordinates of the converted points |

| Zi | Z-coordinates of the converted points |

| xi | X-coordinates of the original points |

| yi | Y-coordinates of the original points |

| zi | Z-coordinates of the original points |

| R | Scale parameter of rotation matrix |

| [α, β, γ] | Rotation matrix |

| [x0, y0, z0]T | Conversion vector between coordinate systems |

| JRC | Joint roughness coefficient |

| Z2 | Root mean square of the first-order derivative of the absolute height of the fracture surface |

| σ1 | Axial pressure |

| σ3 | Confining pressure |

| Pw | Water pressure drop |

| Pg | Gas pressure drop |

| ehw | Equivalent hydraulic aperture |

| μ | Fluid viscosity |

| μw | Fluid viscosity of water |

| μg | Fluid viscosity of gas |

| Q | Mean flow rate |

| Qsw | Water flow rate |

| Qsg | Gas flow rate |

| Qmw | Water flow rate in two phase flow |

| Qmg | Gas flow rate in two phase flow |

| w | Width of the fracture |

| Pressure gradient along the flow direction | |

| Ksw | Absolute permeability of water |

| Ksg | Absolute permeability of gas |

| Ks | Absolute permeability |

| Krw | Relative permeability of water |

| Krg | Relative permeability of gas |

| Kreq | Relative permeability of equal-permeability point |

| L | Fracture length |

| A | Cross-section area perpendicular to the flow direction |

| Pin | Inlet pressure |

| Pout | Outlet pressure |

| fw | Fractional flow of water |

References

- Li, P.; Zhang, J.C.; Tang, X.; Huo, Z.P.; Li, Z.; Luo, K.Y.; Li, Z.M. Assessment of shale gas potential of the Lower Permian transitional Shanxi–Taiyuan shales in the southern North China Basin. Aust. J. Earth Sci. 2020, 68, 262–284. [Google Scholar] [CrossRef]

- Li, S.; Zhou, Z.; Nie, H.; Liu, M.; Meng, F.; Shen, B.; Zhang, X.; Wei, S.; Xi, Z.; Zhang, S. Organic matter accumulation mechanisms in the Wufeng–Longmaxi shales in western Hubei Province, China and paleogeographic implications for the uplift of the Hunan-Hubei Submarine high. Int. J. Coal Geol. 2023, 270, 104223. [Google Scholar] [CrossRef]

- Rahman, M.K.; Suarez, Y.A.; Chen, Z.; Rahman, S.S. Unsuccessful hydraulic fracturing cases in Australia: Investigation into causes of failures and their remedies. J. Pet. Sci. Eng. 2007, 57, 70–81. [Google Scholar] [CrossRef]

- Kang, Y.; Xu, C.; You, L.; Yu, H.; Zhang, B. Comprehensive evaluation of formation damage induced by working fluid loss in fractured tight gas reservoir. J. Nat. Gas Sci. Eng. 2014, 18, 353–359. [Google Scholar] [CrossRef]

- Zolfaghari, A.; Dehghanpour, H.; Noel, M.; Bearinger, D. Laboratory and field analysis of flowback water from gas shales. J. Unconv. Oil Gas Resour. 2016, 14, 113–127. [Google Scholar] [CrossRef]

- Bin, Y.; Hao, Z.; Yili, K. In situ sequestration of a hydraulic fracturing fluid in Longmaxi shale gas formation in the Sichuan Basin. Energy Fuels 2019, 33, 6983–6994. [Google Scholar]

- Bai, J.; Kang, Y.; Chen, Z.; You, L.; Chen, M.; Li, X. Changes in retained fracturing fluid properties and their effect on shale mechanical properties. J. Nat. Gas Sci. Eng. 2020, 75, 103163. [Google Scholar] [CrossRef]

- Zhang, J.; Ouyang, L.; Zhu, D.; Hill, A.D. Experimental and numerical studies of reduced fracture conductivity due to proppant embedment in the shale reservoirs. J. Pet. Sci. Eng. 2015, 130, 37–45. [Google Scholar] [CrossRef]

- Baungartner, R.; Goncalves, G.F.N.; Loureiro, J.B.R.; Freire, A.P.S. Slug flows of gas and shear-thinning fluids in horizontal pipes. Int. J. Multiph. Flow 2023, 165, 104473. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, Z.; Zhang, L.; Xue, K.; Long, K. Influence of fracture roughness and void space morphology on nonlinear fluid flow through rock fractures. Eur. Phys. J. Plus 2022, 137, 1288. [Google Scholar] [CrossRef]

- Shekhar, S.; Kelkar, M.; Hearn, W.J.; Hain, L.L. Improved prediction of liquid loading in gas wells. SPE Prod. Oper. 2017, 32, 539–550. [Google Scholar] [CrossRef]

- Kareem, H.J.; Hasini, H.; Abdulwahid, M.A. Investigation of flow regimes, pressure drop, void fraction, film thickness, friction factor and production of two phase flow in a perforated horizontal wellbore. Geoenergy Sci. Eng. 2023, 229, 212099. [Google Scholar] [CrossRef]

- Barton, N.; Bandis, S.; Bakhtar, K. Strength deformation and conductivity coupling of rock joints. Int. J. Rock Mech. Geomech. Abstr. 1979, 16, 303–307. [Google Scholar] [CrossRef]

- Jaeger, J.; Santos, C.M.; Rosa, L.M.; Meier, H.F.; Noriler, D. Experimental and numerical evaluation of slugs in a vertical air-water flow. Int. J. Multiph. Flow 2018, 101, 152–166. [Google Scholar] [CrossRef]

- Muralha, J.; Grasselli, G.; Tatone, B.; Blümel, M.; Chryssanthakis, P.; Yujing, J. ISRM suggested method for laboratory determination of the shear strength of rock joints: Revised version. Rock Mech. Rock Eng. 2014, 47, 291–302. [Google Scholar] [CrossRef]

- Tenthorey, E.; Fitz Gerald, J.D. Feedbacks between deformation, hydrothermal reaction and permeability evolution in the crust: Experimental insights. Earth Planet. Sci. Lett. 2006, 247, 117–129. [Google Scholar] [CrossRef]

- Bing, H.O.U.; Mian, C.H.E.N.; Zhimeng, L.I.; Yonghui, W.A.N.G.; Ce, D.I.A.O. Propagation area evaluation of hydraulic fracture networks in shale gas reservoirs. Pet. Explor. Dev. 2014, 41, 833–838. [Google Scholar]

- Gu, H.; Weng, X.; Lund, J.; Mack, M.; Ganguly, U.; Suarez-Rivera, R. Hydraulic fracture crossing natural fracture at nonorthogonal angles: A criterion and its validation. SPE Prod. Oper. 2012, 27, 20–26. [Google Scholar] [CrossRef]

- Gan, Q.; Elsworth, D.; Alpern, J.S.; Marone, C.; Connolly, P. Breakdown pressures due to infiltration and exclusion in finite length boreholes. J. Pet. Sci. Eng. 2015, 127, 329–337. [Google Scholar] [CrossRef]

- Zou, L.; Jing, L.; Cvetkovic, V. Shear-enhanced nonlinear flow in rough-walled rock fractures. Int. J. Rock Mech. Min. Sci. 2017, 97, 33–45. [Google Scholar] [CrossRef]

- Xie, L.Z.; Gao, C.; Ren, L.; Li, C.B. Numerical investigation of geometrical and hydraulic properties in a single rock fracture during shear displacement with the Navier–Stokes equations. Environ. Earth Sci. 2015, 73, 7061–7074. [Google Scholar] [CrossRef]

- Xiong, X.; Li, B.; Jiang, Y.; Koyama, T.; Zhang, C. Experimental and numerical study of the geometrical and hydraulic characteristics of a single rock fracture during shear. Int. J. Rock Mech. Min. Sci. 2011, 48, 92–1302. [Google Scholar] [CrossRef]

- Wang, M.; Chen, Y.-F.; Ma, G.-W.; Zhou, J.-Q.; Zhou, C.-B. Influence of surface roughness on nonlinear flow behaviors in 3D self-affine rough fractures: Lattice Boltzmann simulations. Adv. Water Resour. 2016, 96, 373–388. [Google Scholar] [CrossRef]

- Xu, B.; Haghighi, M.; Li, X.; Cooke, D. Development of new type curves for production analysis in naturally fractured shale gas/tight gas reservoirs. J. Pet. Sci. Eng. 2013, 105, 107–115. [Google Scholar] [CrossRef]

- Duncan, P.M.; Eisner, L. Reservoir characterization using surface microseismic monitoring. Geophysics 2010, 75, 139–146. [Google Scholar] [CrossRef]

- Huang, S.; Zhang, J.; Fang, S.; Wang, X. An analytical method for parameter interpretation of fracture networks in shale gas reservoirs considering uneven support of fractures. Geofluids 2021, 3800525, 1–15. [Google Scholar] [CrossRef]

- Li, T.; Song, H.; Wang, J.; Wang, Y.; Killough, J. Ananalytical method for modeling and analysis gas-water relative permeability in nano scale pores with interfacial effects. Int. J. Coal Geol. 2016, 159, 71–81. [Google Scholar] [CrossRef]

- Shad, S.; Maini, B.B.; Gates, I.D. Effect of gap and flow orientation on two-phase flow in an oil-wet gap: Relative permeability curves and flow structures. Int. J. Multiph. Flow 2013, 57, 78–87. [Google Scholar] [CrossRef]

- Fourar, M.; Lenormand, R. A new model for two-phase flows at high velocities through porous media and fractures. J. Pet. Sci. Eng. 2001, 30, 121–127. [Google Scholar] [CrossRef]

- Luo, Y.; Wang, Y.; Guo, H.; Liu, X.; Luo, Y.; Liu, Y. Relationship between joint roughness coefficient and statistical roughness parameters and its sensitivity to sampling interval. Sustainability 2022, 14, 13597. [Google Scholar] [CrossRef]

- Tse, R.; Cruden, D.M. Estimating joint roughness coefficients. Int. J. Rock Mech. Min. Sci. 1979, 16, 303–307. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Ranjith, P.G.; Luo, Y. Water-gas flow in rough rock fractures: Insights from coupled triaxial compression experiments. Hydrogeol. J. 2022, 30, 1569–1581. [Google Scholar] [CrossRef]

- Xue, K.; Zhang, Z.; Jiang, Y.; Luo, Y. Estimating the permeability of fractured rocks using topological characteristics of fracture network. Comput. Geotech. 2023, 157, 105337. [Google Scholar] [CrossRef]

- Liu, X.-J.; Xiong, J.; Liang, L.-X.; Luo, C.; Zhang, A.-D. Analysis of the Wettability of Longmaxi Formation Shale in the South Region of Sichuan Basin and Its Influence. Nat. Gas Geosci. 2014, 25, 1644–1652. [Google Scholar]

- Ye, Z.; Liu, H.-H.; Jiang, Q.; Zhou, C. Two-phase flow properties of a horizontal fracture: The effect of aperture distribution. Adv. Water Resour. 2015, 76, 43–54. [Google Scholar] [CrossRef]

- Zeidan, D.; Bähr, P.; Farber, P. Numerical investigation of a mixture two-phase flow model in two-dimensional space. Comput. Fluids 2019, 181, 90–106. [Google Scholar] [CrossRef]

- Gong, Y.B.; Sedghi, M.; Piri, M. Two-Phase Relative Permeability of Rough-Walled Fractures: A Dynamic Pore-Scale Modeling of the Effects of Aperture Geometry. Water Resour. Res. 2021, 57, e2021WR030104. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Liu, X.; Xue, K. Relative permeability of two-phase fluid flow through rough fractures: The roles of fracture roughness and confining pressure. Adv. Water Resour. 2023, 175, 104426. [Google Scholar] [CrossRef]

- Zhang, Z.; Nemcik, J. Friction Factor of Water Flow Through Rough Rock Fractures. Rock Mech. Rock Eng. 2013, 46, 1125–1134. [Google Scholar] [CrossRef]

| Sample | Width (mm) | Height (mm) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Mean |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 50.30 | 98.70 | 5.52 | 3.87 | 5.93 | 5.24 | 2.99 | 5.92 | 5.89 | 3.22 | 2.11 | 4.52 |

| S2 | 50.30 | 98.60 | 5.22 | 9.50 | 6.41 | 8.24 | 4.52 | 9.80 | 4.92 | 7.41 | 9.14 | 7.24 |

| S3 | 50.32 | 98.90 | 15.45 | 8.75 | 7.85 | 8.16 | 14.21 | 5.93 | 17.09 | 12.86 | 13.48 | 11.53 |

| S4 | 50.30 | 98.62 | 13.27 | 18.98 | 19.16 | 8.79 | 11.39 | 18.87 | 18.64 | 17.63 | 15.92 | 15.85 |

| S5 | 50.16 | 99.24 | 16.45 | 20.53 | 23.26 | 13.28 | 18.71 | 22.14 | 18.07 | 21.46 | 14.84 | 18.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Xue, K.; Li, C.; Liu, X.; Li, B. Experimental Study on the Behavior of Gas–Water Two-Phase Fluid Flow Through Rock Fractures Under Different Confining Pressures and Shear Displacements. Water 2025, 17, 296. https://doi.org/10.3390/w17030296

Wang Y, Xue K, Li C, Liu X, Li B. Experimental Study on the Behavior of Gas–Water Two-Phase Fluid Flow Through Rock Fractures Under Different Confining Pressures and Shear Displacements. Water. 2025; 17(3):296. https://doi.org/10.3390/w17030296

Chicago/Turabian StyleWang, Yang, Kangsheng Xue, Cheng Li, Xiaobo Liu, and Boyang Li. 2025. "Experimental Study on the Behavior of Gas–Water Two-Phase Fluid Flow Through Rock Fractures Under Different Confining Pressures and Shear Displacements" Water 17, no. 3: 296. https://doi.org/10.3390/w17030296

APA StyleWang, Y., Xue, K., Li, C., Liu, X., & Li, B. (2025). Experimental Study on the Behavior of Gas–Water Two-Phase Fluid Flow Through Rock Fractures Under Different Confining Pressures and Shear Displacements. Water, 17(3), 296. https://doi.org/10.3390/w17030296