The Water–Energy Nexus in Thermoelectric Power Plants: A Focus on Italian Installations Regulated Under the Integrated Emission Directive

Abstract

:1. Introduction

1.1. Water–Energy Nexus in Industrial Sector

- Energy for water: the use of energy required in phases such as withdrawal and transport, treatment, heating and cooling, especially in industrial applications, and desalination of water.

- Water for energy: the use of water for energy production in hydroelectric, thermoelectric, biomass, biofuel plants, fuel extraction, and treatment and refining.

1.2. Literature Background

1.3. European and Italian Framework

1.4. The Link with the Industrial Emissions Directive in Europe

1.5. Objectives of the Study

- (a)

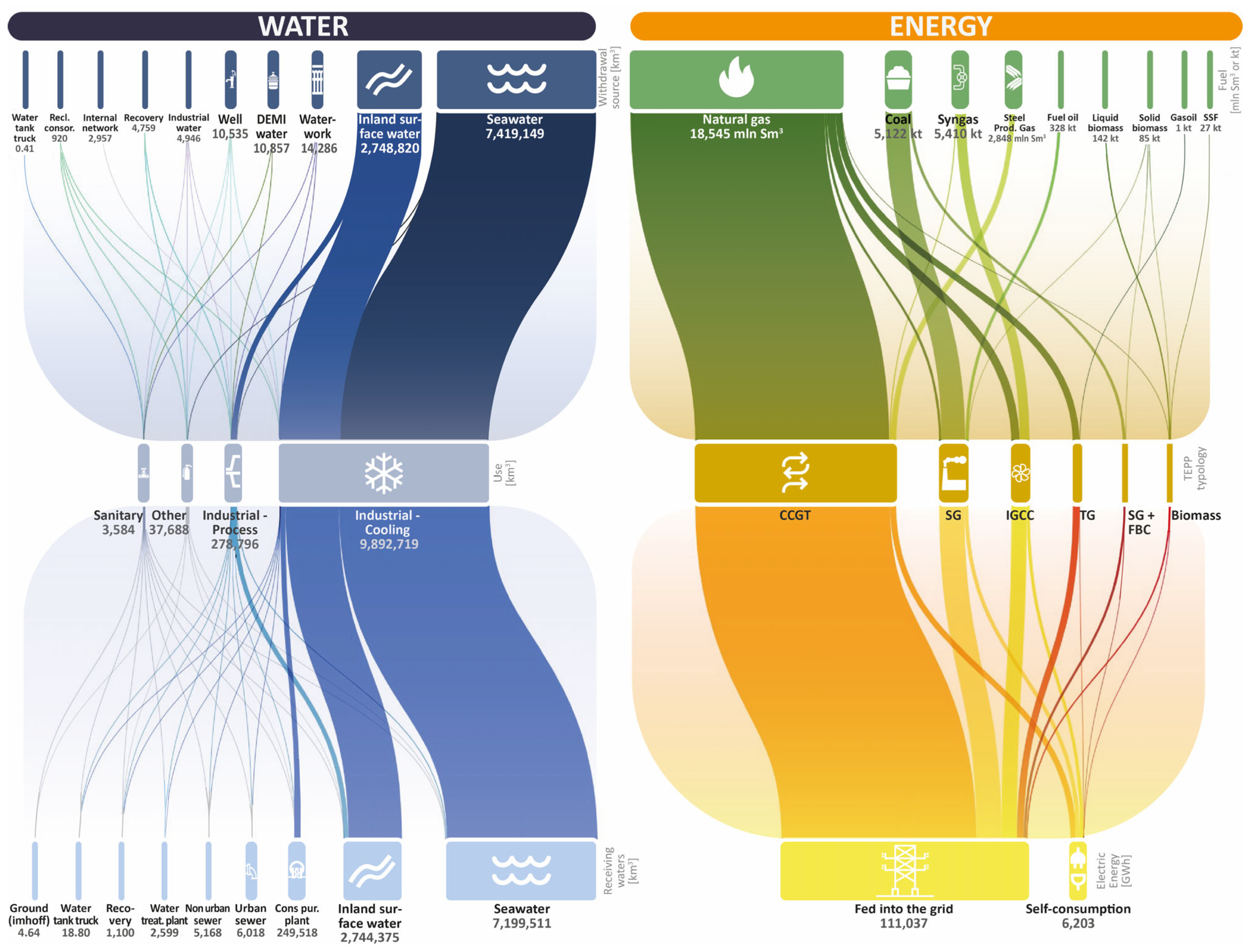

- Estimate the use of water resources in electricity production and the impact on different sources of supply.

- (b)

- Analyze the flow of water and energy resources in the production of electricity in large combustion plants.

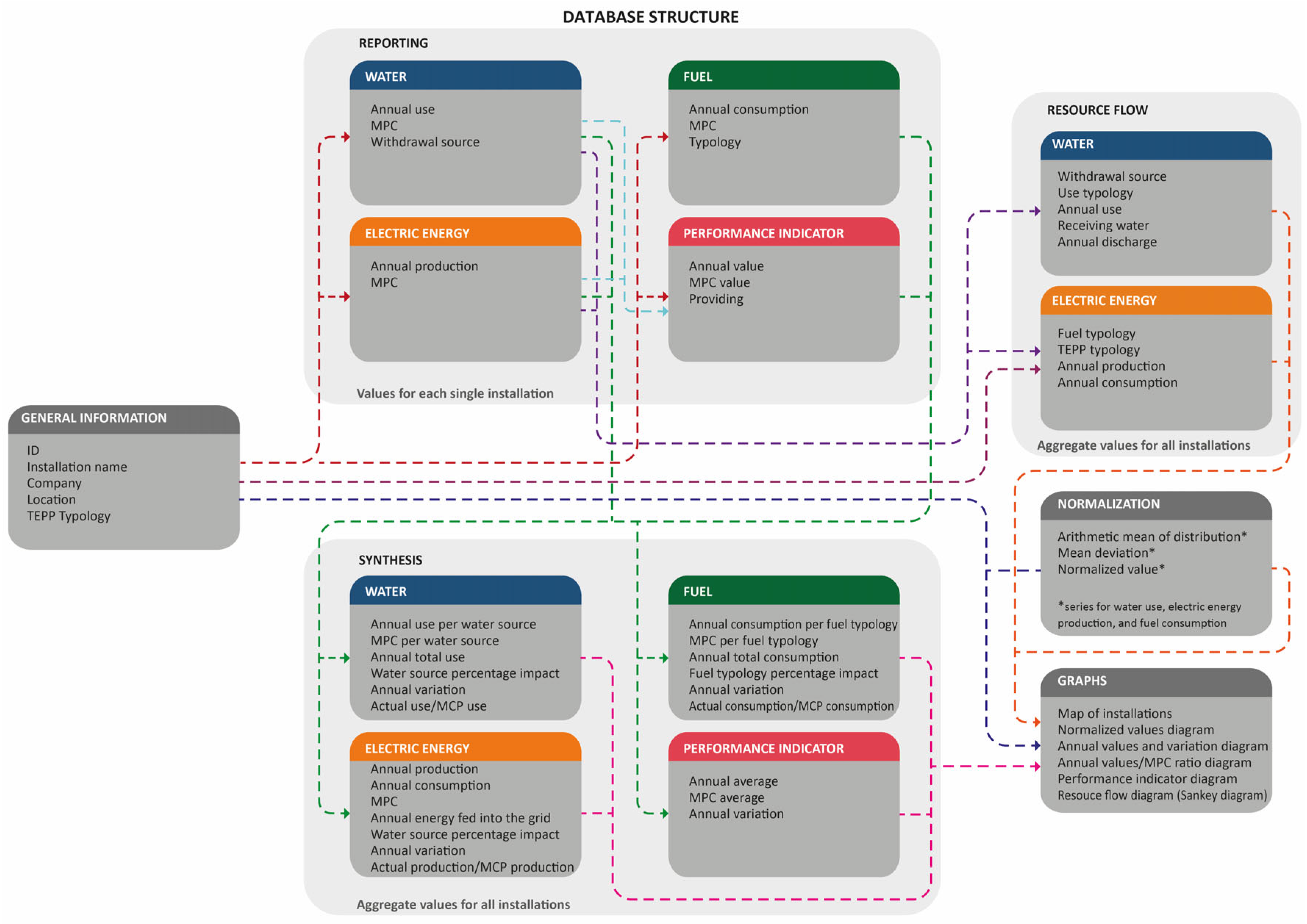

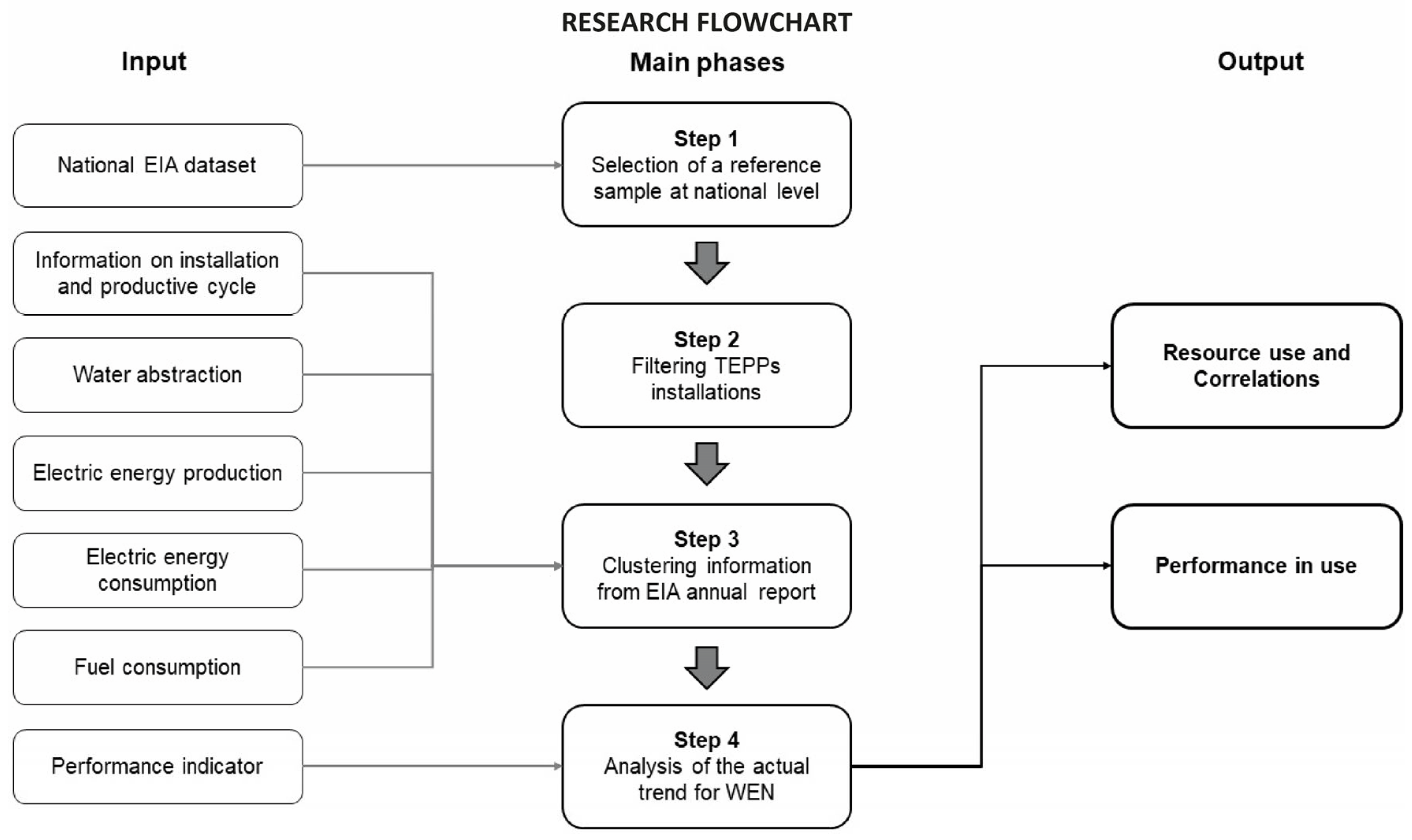

2. Materials and Methods

- Selecting a reference dataset to conduct the study (i.e., the national EIA data);

- Filtering the above-mentioned dataset with the TEPPs installations;

- Clustering data with reference to water, energy, and fuel;

- Assessing the actual trend for WEN.

- Information on the type of installation, in terms of technology used in the productive cycle;

- Water abstraction, restricted to the field of use of industrial cooling (where not specified, including process water) and the relative supply source;

- Electric energy gross production and self-consumption for production;

- Fuel used in terms of quantity (mass for solid and liquid fuels, volume for gaseous fuels);

- Performance indicator, defined as the ratio between water use and energy produced.

3. Results

4. Discussion

Limitations of the Study

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Plant ID | Installation | Company | Province | Region | TEPP Typology | Notes |

|---|---|---|---|---|---|---|

| nr | TEPP name | Society Name | es. Rome | es. Lazio | es. CCGT | Description |

| … | … | … | … | … | … | … |

| ID | Water Use [m3/Year] | Electric Energy Production [MWh/Year] | Fuel Consumption [t/Year] or [Sm3/Year] | Performance Indicator [m3/MWh] | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2021 | 2022 | 2023 | MPC | Withdrawal Source | 2021 | 2022 | 2023 | MPC | 2021 | 2022 | 2023 | MPC | Fuel typology | 2021 | 2022 | 2023 | MPC | Provided | |

| nr | Value | Value | Value | Value | es. Well | Value | Value | Value | Value | Value | Value | Value | Value | es. Coal | Value | Value | Value | Value | YES/ NO |

| … | … | … | … | … | … | … | … | … | … | … | … | … | … | … | … | … | … | … | … |

| ID | Withdrawal Source | Use Typology | Use | Receiving Water | Discharge | ||||

|---|---|---|---|---|---|---|---|---|---|

| 2021 | 2022 | 2023 | 2021 | 2022 | 2023 | ||||

| nr | es. Seawater | Cooling | Value | Value | Value | es. Seawater | Value | Value | Value |

| Process | Value | Value | Value | Value | Value | Value | |||

| Sanitary | Value | Value | Value | Value | Value | Value | |||

| Other | Value | Value | Value | Value | Value | Value | |||

| … | … | … | … | … | … | … | … | … | … |

| ID | Fuel | TEPP Typology | Use | 2021 | 2022 | 2023 |

|---|---|---|---|---|---|---|

| nr | es. Natural gas | es. CCGT | Production | Value | Value | Value |

| Consumption | Value | Value | Value | |||

| … | … | … | … | … | … | … |

| Resource | Category | Use | Impact | Annual Variation | Actual Use/MPC Use | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2021 | 2022 | 2023 | MPC | 2021 | 2022 | 2023 | ||||

| Water [m3] | Seawater | Value | Value | Value | Value | % | Value and % | % | % | % |

| Inland surface water | Value | Value | Value | Value | % | Value and % | % | % | % | |

| … | … | … | … | … | … | … | … | … | … | |

| TOTAL | Value | Value | Value | Value | % | Value and % | % | % | % | |

| Electric energy [MWh] | Fed into the grid | Value | Value | Value | Value | % | Value and % | % | % | % |

| Self-consumption | Value | Value | Value | Value | % | Value and % | % | % | % | |

| PRODUCED | Value | Value | Value | Value | % | Value and % | % | % | % | |

| Fuel [t] or [Sm3] | Solid | Value | Value | Value | Value | % | Value and % | % | % | % |

| Solid biomass | Value | Value | Value | Value | % | Value and % | % | % | % | |

| … | … | … | … | … | … | … | … | … | … | |

| TOTAL | ||||||||||

| Performance indicator [m3/MWh] | Average | Value | Value | Value | Value | n.a. | Value and % | n.a. | n.a. | n.a. |

| … | … | … | … | … | … | … | … | … | … | |

| ID | Water | Electric Energy | Fuel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Use | Arithmetic Mean of Distribution | Mean Deviation | Normalized Value | Pro-duction | Arithmetic Mean of Distribution | Mean Deviation | Normalized Value | Con-sumption | Typology | Calorific Value | Arithmetic Mean of Distribution | Mean Deviation | Normalized Value | |

| nr | Value | Value | Value | Value | Value | Value | Value | Value | Value | Value | Value | Value | Value | Value |

| … | … | … | … | … | … | … | … | … | … | … | … | … | … | … |

References

- Helerea, E.; Calin, M.D.; Musuroi, C. Water Energy Nexus and Energy Transition—A Review. Energies 2023, 16, 1879. [Google Scholar] [CrossRef]

- Hussey, K.; Pittock, J. The energy–water nexus: Managing the links between energy and water for a sustainable future. Ecol. Soc. 2012, 17. [Google Scholar] [CrossRef]

- Vázquez, V.L.; Rodríguez, G.; Daddi, T.; De Giacomo, M.R.; Polders, C.; Dils, E. Policy challenges in transferring the integrated pollution prevention and control approach to Southern Mediterranean countries: A case study. J. Clean. Prod. 2015, 107, 486–497. [Google Scholar] [CrossRef]

- Fayiah, M.; Dong, S.; Singh, S.; Kwaku, E.A. A review of water–energy nexus trend, methods, challenges and future prospects. Int. J. Energy Water Resour. 2020, 4, 91–107. [Google Scholar] [CrossRef]

- European Parliament; Council of the European Union. Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency. This Directive Establishes a Common Framework of Measures for the Promotion of Energy Efficiency Within the European Union. 2012. Available online: https://eur-lex.europa.eu/eli/dir/2012/27/oj/eng (accessed on 23 April 2025).

- Kalvani, S.R.; Pinardi, R.; Celico, F. The Water–Energy Nexus in 26 European Countries: A Review from a Hydrogeological Perspective. Water 2024, 16, 2981. [Google Scholar] [CrossRef]

- Larsen, M.A.D.; Drews, M. Water use in electricity generation for water-energy nexus analyses: The European case. Sci. Total Environ. 2019, 651, 2044–2058. [Google Scholar] [CrossRef]

- Chini, C.M.; Excell, L.E.; Stillwell, A.S. A review of energy-for-water data in energy-water nexus publications. Environ. Res. Lett. 2021, 15, 123011. [Google Scholar] [CrossRef]

- Melo Zurita, M.D.L.; Thomsen, D.C.; Holbrook, N.J.; Smith, T.F.; Lyth, A.; Munro, P.G.; De Bruin, A.; Seddaiu, G.; Roggero, P.P.; Baird, J.; et al. Global Water Governance and Climate Change: Identifying Innovative Arrangements for Adaptive Transformation. Water 2018, 10, 29. [Google Scholar] [CrossRef]

- Siddiqi, A.; Anadon, L.D. The water–energy nexus in Middle East and North Africa. Energy Policy 2011, 39, 4529–4540. [Google Scholar] [CrossRef]

- Dai, J.; Wu, S.; Han, G.; Weinberg, J.; Xie, X.; Wu, X.; Song, X.; Jia, B.; Xue, W.; Yang, Q. Water-energy nexus: A review of methods and tools for macro-assessment. Appl. Energy 2018, 210, 393–408. [Google Scholar] [CrossRef]

- Hardy, L.; Garrido, A.; Juana, L. Evaluation of Spain’s water-energy nexus. Int. J. Water Resour. Dev. 2012, 28, 151–170. [Google Scholar] [CrossRef]

- Fang, D.; Chen, B. Linkage analysis for the water–energy nexus of city. Appl. Energy 2017, 189, 770–779. [Google Scholar] [CrossRef]

- Stracqualursi, A.; Andreucci, M.B. Water Resources Management in a Regenerative Design Approach. In Design for Rethinking Resources; Thomsen, M.R., Ratti, C., Tamke, M., Eds.; Springer International Publishing: Cham, Switzerland, 2024; pp. 615–631. [Google Scholar] [CrossRef]

- Hamiche, A.M.; Stambouli, A.B.; Flazi, S. A review of the water-energy nexus. Renew. Sustain. Energy Rev. 2016, 65, 319–331. [Google Scholar] [CrossRef]

- Kiteto, M.K.; Mecha, C.A. Navigating the Water–Energy Nexus: A Mathematical Approach. Foundations 2024, 4, 713–737. [Google Scholar] [CrossRef]

- Silva-Rubio, S.A.; Salgueiro, Y.; Mora-Meliá, D.; Gutiérrez-Bahamondes, J.H. Improving Water and Energy Resource Management: A Comparative Study of Solution Representations for the Pump Scheduling Optimization Problem. Mathematics 2024, 12, 1994. [Google Scholar] [CrossRef]

- Sanders, K.T. Critical Review: Uncharted Waters? The Future of the Electricity-Water Nexus. Environ. Sci. Technol. 2015, 49, 51–66. [Google Scholar] [CrossRef]

- Li, H.; Zhao, Y.; Lin, J. A review of the energy–carbon–water nexus: Concepts, research focuses, mechanisms, and methodologies. WIREs Energy Environ. 2020, 9, e358. [Google Scholar] [CrossRef]

- Russo, T.; Alfredo, K.; Fisher, J. Sustainable Water Management in Urban, Agricultural, and Natural Systems. Water 2014, 6, 3934–3956. [Google Scholar] [CrossRef]

- Bazilian, M.; Rogner, H.; Howells, M.; Hermann, S.; Arent, D.; Gielen, D.; Steduto, P.; Mueller, A.; Komor, P.; Tol, R.S.; et al. Considering the energy, water and food nexus: Towards an integrated modelling approach. Energy Policy 2011, 39, 7896–7906. [Google Scholar] [CrossRef]

- Al-Thani, N.A.; Al-Ansari, T. Comparing the convergence and divergence within industrial ecology, circular economy, and the energy-water-food nexus based on resource management objectives. Sustain. Prod. Consum. 2021, 27, 1743–1761. [Google Scholar] [CrossRef]

- David, L.O.; Nwulu, N.I.; Aigbavboa, C.O.; Adepoju, O.O. Integrating fourth industrial revolution (4IR) technologies into the water, energy & food nexus for sustainable security: A bibliometric analysis. J. Clean. Prod. 2022, 363, 132522. [Google Scholar] [CrossRef]

- Skoczko, I. Energy Efficiency Analysis of Water Treatment Plants: Current Status and Future Trends. Energies 2025, 18, 1086. [Google Scholar] [CrossRef]

- European Parliament; Council of the European Union. Directive 2000/60/EC of the European Parliament and of the Council Establishing a Framework for the Community Action in the Field of Water Policy (Water Framework Directive). 2000. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02000L0060-20140101 (accessed on 23 April 2025).

- European Commission—Directorate-General for Communication (DG COMM). Circular Economy Action Plan: For a Cleaner and More Competitive Europe; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar] [CrossRef]

- European Environment Agency (EEA). Water Abstraction by Economic Sector in the 27 EU Member States, 2000–2019. 2022. Available online: https://www.eea.europa.eu/en/analysis/maps-and-charts/water-abstraction-by-economic-sector (accessed on 23 April 2025).

- Istituto Nazionale di Statistica (ISTAT). Utilizzo e Qualità Della Risorsa Idrica in Italia; Rome, Italy, 2019; Available online: https://www.istat.it/it/files/2019/10/Utilizzo-e-qualit%C3%A0-della-risorsa-idrica-in-Italia.pdf (accessed on 23 April 2025).

- European Parliament; Council of the European Union. Council Directive 96/61/EC of 24 September 1996 Concerning Integrated Pollution Prevention and Control. 1996. Available online: https://eur-lex.europa.eu/eli/dir/1996/61/oj/eng?eliuri=eli%3Adir%3A1996%3A61%3Aoj&locale=en (accessed on 23 April 2025).

- European Parliament; Council of the European Union. Directive 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on Industrial Emissions (Integrated Pollution Prevention and Control) (Recast). 2010. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02010L0075-20240804 (accessed on 23 April 2025).

- European Parliament; Council of the European Union. Directive (EU) 2024/1785 of the European Parliament and of the Council of 24 April 2024 Amending Directive 2010/75/EU of the European Parliament and of the Council on Industrial Emissions (Integrated Pollution Prevention and Control) and Council Directive 1999/31/EC on the Landfill of Waste. 2024. Available online: https://eur-lex.europa.eu/eli/dir/2024/1785/oj/eng (accessed on 23 April 2025).

- European Commission. Commission Implementing Decision (EU) 2021/2326 of 30 November 2021 Establishing Best Available Techniques (BAT) Conclusions, Under Directive 2010/75/EU of the European Parliament and of the Council, for Large Combustion Plants. 2024. Available online: https://eur-lex.europa.eu/eli/dec_impl/2021/2326/oj/eng (accessed on 23 April 2025).

- Consiglio dei Ministri. Decreto Legislativo 3 Aprile 2006, n. 152, “Norme in Materia Ambientale”. GU Serie Generale n.88 del 14-04-2006—Suppl. Ordinario n. 96, Rome, IT. 2006. Available online: https://www.gazzettaufficiale.it/dettaglio/codici/materiaAmbientale (accessed on 23 April 2025).

- Ministero della Transizione ecologica (MITE). Decreto Ministeriale 16 dicembre 2015, n. 274, “Direttiva per Disciplinare la Conduzione dei Procedimenti AIA”. Rome, IT. 2015. Available online: https://va.mite.gov.it/it-IT/DatiEStrumenti/MetadatoRisorsaCondivisione/9a772424-2cd6-406d-9e90-d263b79f1270 (accessed on 23 April 2025).

- Borghesi, R.; Carlucci, C.; Mauro, F. Preventing Environmental Impacts in National IED Plants: A Self-Monitoring Model. In Frontiers of Energy and Environmental Engineering; Wen, F., Zhu, J., Eds.; Springer Nature: Singapore, 2024; pp. 79–88. [Google Scholar] [CrossRef]

- Mauro, F.; Borghesi, R. Using Citizen Science to Manage Odour Emissions in National IED Plants: A Systematic Review of the Scientific Literature. Atmosphere 2024, 15, 302. [Google Scholar] [CrossRef]

- Autorità di Regolazione per Energia Reti e Ambiente (ARERA). Produttori, Impianti e Generazione per Fonte. 2023. Available online: https://www.arera.it/dati-e-statistiche?ambito=22&sottoambito=23&sezione=&keyword=&settore=4&orderby= (accessed on 23 April 2025).

- Ministero dell’Ambiente e della Sicurezza Energetica (MASE). Environmental Assessments and Authorizations: SEA-EIA-IPPC Permit. Available online: https://va.mite.gov.it/en-GB (accessed on 23 April 2025).

- Ministero dello Sviluppo Economico (MISE); Ministero dell’Ambiente e della Tutela del Territorio e del Mare (MAATM); Ministero delle Infrastrutture e dei Trasporti (MIT). Piano Nazionale Integrato per l’Energia e il Clima. Rome, IT. 2019. Available online: https://www.mase.gov.it/sites/default/files/archivio/pniec_finale_17012020.pdf (accessed on 23 April 2025).

- Schmidt, M. The Sankey diagram in energy and material flow management: Part II: Methodology and current applications. J. Ind. Ecol. 2008, 12, 173–185. [Google Scholar] [CrossRef]

| TEPP Typology | Acronym | Description | Quantity | Share of Total |

|---|---|---|---|---|

| Combined cycle gas turbine | CCGT | Gas turbine cycle combined with a steam turbine cycle. The gas turbine generates electricity and produces high-temperature exhaust gases, which are then used to generate steam in a heat recovery steam generator. | 53 | 75% |

| Steam generator | SG | Conventional steam boiler plant that burns solid, liquid, or gaseous fuels to heat water in a boiler, producing steam that drives a steam turbine for electricity generation. | 8 | 11% |

| Turbogas | TG | Plant with a single-cycle gas turbine, where fuel combustion directly drives the turbine. | 6 | 8% |

| Integrated gasification combined cycle | IGCC | Technology to convert solid or liquid fuels (such as coal or petroleum coke) into a synthetic gas (syngas) through gasification. The syngas is cleaned and combusted in a gas turbine, with the hot exhaust gases used to produce steam for a steam turbine, similar to a CCGT configuration. | 3 | 4% |

| SG combined with fluidized bed combustion | SG + FBC | In FBC systems, fuels are combusted in a fluidized bed of inert particles (such as sand) that enhances heat transfer and allows for more uniform temperature control. | 1 | 1% |

| Biomass | Biomass | Plant that uses organic materials as fuel to produce energy through direct combustion or gasification. The steam or syngas generated is used in a turbine for electricity production. | 1 | 1% |

| TOTAL | 72 | 100% |

| TEPP Typology | Installation Quantity | Water Use | Performance Indicator [m3/MWh/Year] | |

|---|---|---|---|---|

| Volume [m3/Year] | Share of Total [%] | |||

| CCGT | 53 | 5,848,387,636 | 59% | 73 |

| SG | 8 | 3,398,637,248 | 34% | 225 |

| SG + FBC | 1 | 535,090,837 | 5% | 406 |

| IGCC | 3 | 97,656,756 | 1% | 15 |

| TG | 1 | 12,880,924 | <1% | 4 |

| Biomass | 1 | 66,563 | <1% | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stracqualursi, A.; Mauro, F.; Borghesi, R. The Water–Energy Nexus in Thermoelectric Power Plants: A Focus on Italian Installations Regulated Under the Integrated Emission Directive. Water 2025, 17, 1285. https://doi.org/10.3390/w17091285

Stracqualursi A, Mauro F, Borghesi R. The Water–Energy Nexus in Thermoelectric Power Plants: A Focus on Italian Installations Regulated Under the Integrated Emission Directive. Water. 2025; 17(9):1285. https://doi.org/10.3390/w17091285

Chicago/Turabian StyleStracqualursi, Alessandro, Francesca Mauro, and Roberto Borghesi. 2025. "The Water–Energy Nexus in Thermoelectric Power Plants: A Focus on Italian Installations Regulated Under the Integrated Emission Directive" Water 17, no. 9: 1285. https://doi.org/10.3390/w17091285

APA StyleStracqualursi, A., Mauro, F., & Borghesi, R. (2025). The Water–Energy Nexus in Thermoelectric Power Plants: A Focus on Italian Installations Regulated Under the Integrated Emission Directive. Water, 17(9), 1285. https://doi.org/10.3390/w17091285