Abstract

The ceramic industry has been vital to the city’s development and prosperity in Jingdezhen, but the development of the ceramics industry in Jingdezhen has been unclear since China’s economic reforms, which will become a bottleneck limiting the sustainable development of the city. This study explored the spatial agglomeration and spatiotemporal evolution of the ceramics industry in Jingdezhen from 1980 to 2020 using enterprise directory data. The study opted for a microscopic perspective and employed kernel density estimation and exploratory spatial data analysis to obtain the necessary results. It also analyzed the influencing factors using a Geodetector. The results show that the temporal evolution of the ceramics industry in Jingdezhen went through two stages from 1980 to 2020. The number of enterprises experienced exponential growth, with fluctuations. The spatial evolution of the ceramics industry transitioned from a “single-center” to a “double-center” model and further evolved into a “multi-center” model. Moreover, the spatial agglomeration of the ceramics industry underwent the process of “agglomeration-diffusion-polarization”, ultimately developing into four ceramic industrial agglomeration patterns in six hotspots. Agglomeration, historical, technological, policy, and transportation factors had positive effects on the evolution of the ceramics industry in Jingdezhen, with agglomeration being the top contributor. Likewise, there were obvious interactions between the factors. This study can provide a basis for formulating policies to support urban spatial planning for urban revitalization, and provide foundation for the development of the national ceramic culture inheritance and innovation pilot zone in Jingdezhen.

1. Introduction

With over 2000 years of pottery production experience and over 600 years of imperial kiln history [1], Jingdezhen is known as the “Porcelain Capital” [2], with a rich ceramics culture and exquisite porcelain craftsmanship [3]. In Pilgrim Art: Cultures of Porcelain in World History, American historian Robert Finlay said that “Jingdezhen dominated the global porcelain market not only because of the quality of its products, but also because of the scale and organization of its production. It represented the height of the craft industry before the age of steam-powered machines, and the most spectacular achievement of mass, concentrated manufacturing.” [4]. However, from the mid-1990s to the early 21st century, Jingdezhen’s ceramics industry encountered a seatback and eventually a downturn due to the rapid rise of other ceramic regions in China and the booming international ceramics industry [2,3]. Designated as the national ceramic culture inheritance and innovation pilot zone, Jingdezhen was able to flourish and establish itself as a national center of excellence in the field. Nevertheless, how to cultivate new technologies and business models for the ceramics industry remains the key issue that requires urgent attention. To solve the issue, researchers are required to have a clear understanding of the historical development of the ceramics industry, explore the characteristics of the temporal and spatial evolution of the industry, and identify the most critical influencing factors. Therefore, this study offers support for the spatial reconstruction of the ceramics industry under social and economic transformation.

The spatial pattern of industries and the factors influencing the choice of location are the most popular topics in the fields of economic geography and urban planning. In the context of the ceramics industry, current research is oriented towards the spatial and temporal evolution of ceramic industrial clusters. For example, Hervas et al. traced the evolution and organizational pattern of the ceramic tile industrial cluster in Castellón, Spain, from 1727 to 2000 through qualitative interviews and archival data [5]. Scur and Garcia explored the life-cycle evolution of the ceramic industrial cluster in Brazil based on the impact of actors, networks, and institutions [6]. Furthermore, Bellandi et al. explored the ceramic district in Stoke-on-Trent, UK, and the long-term evolution of its industrial zones from 2005 to 2013 [7]. Tolliday and Yonemitsu focused on the roles of social, technological, and individual dilemmas and the effect of the industry’s evolution on microenterprises and industrial districts in Arita, Japan, in the twentieth century [8]. Cusmano et al. investigated the formation and evolution of ceramics districts in Sassuolo, Italy, and confirmed that organizational reproduction and heredity represent the primary clustering mechanisms [9]. Moreover, Molina et al. studied the dynamic evolution of ceramic clusters in Valencia, indicating that regional innovation had the greatest impact on cluster productivity [10]. In the context of the Chinese ceramics industry, Zhou et al. examined the evolutionary process of ceramic carving technology inheritance and innovation in Shiwan, Guangdong [11] from the perspective of cultural ecology. Using cluster theory, Li studied the spatial relocation of the ceramics industrial cluster during its formation, development, and upgrading in Chancheng, Foshan [12]. Liu studied the historical changes of ceramic clusters in Jingdezhen and focused on the role of infrastructure, policy, labor quality, and scientific and technological innovation on clusters evolution [13]. In contrast, Xu and Zuo incorporated a finite-time distributed lag model to analyze the influencing factors of the dynamic evolution of ceramic industrial clusters in Jingdezhen during the Chinese economic reform [14]. In summary, research on the ceramics industry primarily utilizes qualitative methods to explore its evolution from a macroscopic perspective. As a result, these studies lack quantitative methods and the microscopic perspective of enterprises. Research on the spatial optimization of the ceramics industry has yet to be thoroughly conducted. Geographic information technology, as important method and tool for spatial modeling of urban processes, can be used to investigate the spatial and temporal evolution of the ceramic industry in Jingdezhen from an urban scale and to better understand the phenomenon of industrial evolution in the process of urban expansion from the perspectives of industrial agglomeration and industrial diffusion. In this regard, it is possible to fill the research gap related to the industrial evolution within the city.

The agglomeration and diffusion of the industry within cities represent the spatial manifestation of the enterprises’ location selection [15] and are influenced by a combination of factors. For instance, focusing on the factors that shape the ceramic industrial cluster, Bellandi et al. introduced a novel approach to explain the influence of the diverse pool of knowledge inside ceramic industrial districts on the evolution of ceramic industrial clusters in Stoke-on-Trent (UK) [7]. According to Tomlinson and Branston [16], the ceramics industrial district in North Staffordshire started to reverse its long phase decline when it began adopting new strategies, technologies, and attitudes that addressed external challenges. Using ceramic clusters in Italy as examples, Cusmano et al. confirmed that organizational reproduction and heredity represent the primary mechanisms of clustering in ceramic districts in Sassuolo [9]. Lo and Han found that the ceramic industrial district of Sassuolo has three benefits, including first-mover advantage, a tied-up proximity network of core industries within a formal association, and informal collaboration based on trust and a positive competitive environment, compared to the ceramic cluster in Foshan [17]. Moreover, using ceramic clusters in Spain as examples, Gabaldon-Estevan et al. discussed how environmental issues affect the development of manufacturing in Europe [18]. Albors-Garrigos and Hervas-Oliver analyzed the role of high-tech entrepreneurs in determining the innovative development of traditional clusters at the Kerajet Ceramic Tile Cluster [19]. Segarra-Ona and Peiro-Signes found out that process innovation is an important factor influencing the eco-innovative orientation of the industries in the Spanish Ceramic Cluster [20]. Furthermore, Gabaldón-Estevan and Fernández-de-Lucio applied Nelson’s primary typology of enterprises in order to investigate the innovation capacity of the two most important industrial districts of ceramic tiles in Castellon (east Spain) and Emilia Romagna in Italy, and found that innovation depends on the relative level of technology and the presence of advanced service providers in the districts, which would benefit from stronger links with universities [21]. In addition, Scur and Garcia analyzed the impact of the capabilities and strategies of the actors, networks, and institutions on the evolution of the ceramic clusters in Brazil [6]. De Souza et al. found that the deployment of eco-innovation in Brazilian ceramic clusters is mainly driven by specific legislation and market requirements [22]. Finally, Wu and Coe investigated the impact of cluster branding and external cluster markets on creative ceramic clusters in Jingdezhen [23,24]. Yang et al. explored the impact of the materiality of craft production and the mobility of creative craftsmen on the creative renewal of ceramic craft clusters in Jingdezhen [25]. In summary, knowledge and technology (e.g., production processes, institutions, and universities), policy and market environment (e.g., specific legislation and market requirements), and management and labor quality (e.g., high-tech entrepreneurs and creative craftsmen) have a significant impact on the agglomeration of ceramic industry clusters.

In the context of economic globalization, the development model of the local economic cluster has been gradually integrated into the global industrial network. Furthermore, ceramic industry clusters are usually embedded in the global value chain industry, Sassuolo ceramic clusters in Italy and Castellon ceramic clusters in Spain were the value chain of research and development and design links as well as sales, while China’s ceramics industry clusters are in the manufacturing sector [26,27]. Despite their similar contexts, there are substantial differences between the Spanish and Italian ceramic tile districts. The strengths of Castellon’s are in the glaze sub-sector (Type B2) and in chemistry (training and research and development), while Sassuolo’s is in research and development conducted by machinery providers (Type B1) and training in business administration and industrial engineering [21]. Thus, the Sassuolo cluster is a world leader in the ceramic machinery design and manufacturing, while the Castellon cluster has a clear advantage in the design of colored glaze materials and glazing technology [21,27]. They drive the upgrade and innovation in the global tile industry together, through formal and informal links within the Tile Global Network as well as through the interaction with local ceramic tile clusters in other regions. In the global industrial network, the fine ceramic machinery of the Sassuolo cluster is significant for the development of local ceramic tiles in Asia, especially in China. The evolution of the ceramic clusters in Italy and Spain was driven by the design and manufacture of ceramic tile machinery and raw materials for colored glazes, respectively. However, the evolution of China’s ceramic clusters is mainly driven by industrial agglomeration, innovation ability, and productive capacity [28].

Due to its importance in the ceramics industry, China is the world’s largest producer and consumer of ceramic tiles [29]. However, the influencing factors and the spatiotemporal pattern of China’s ceramics industry are not clear. For example, the spatial structure of ceramics industry in Chaozhou is influenced by regional resources, transportation factors, agglomeration and diffusion of production space, and different policies [30]. The spatial evolution of the Jun porcelain industry in the Shenhou Ancient Town in Yuzhou was driven by policies and technological progress [31]. In Foshan, the spatial relocation of the ceramics industry is primarily driven by market factors, while policies play only a supporting role [32]. Lastly, the spatial evolution of Jingdezhen’s ceramics industry is mainly influenced by policies, transportation, and historical factors [33]. Jingdezhen has established itself as a ceramic city around the world. However, it has experienced rapid socioeconomic changes in the last 40 years. Current studies overlook research on the spatiotemporal evolution of the ceramics industry in Jingdezhen at a micro-level. Similarly, the influencing factors in the ceramics industry are still unclear. These factors especially need to be explored through quantitative methods. Therefore, this study explored the spatiotemporal evolution of the ceramics industry in Jingdezhen from a microscopic perspective using spatial analysis. It introduced the Geodetector to quantify the factors influencing the evolution of the ceramics industry. This study hopes to provide valuable insight into the development and layout of the ceramics industry in urban areas.

2. Study Area, Materials and Methods

2.1. Study Area

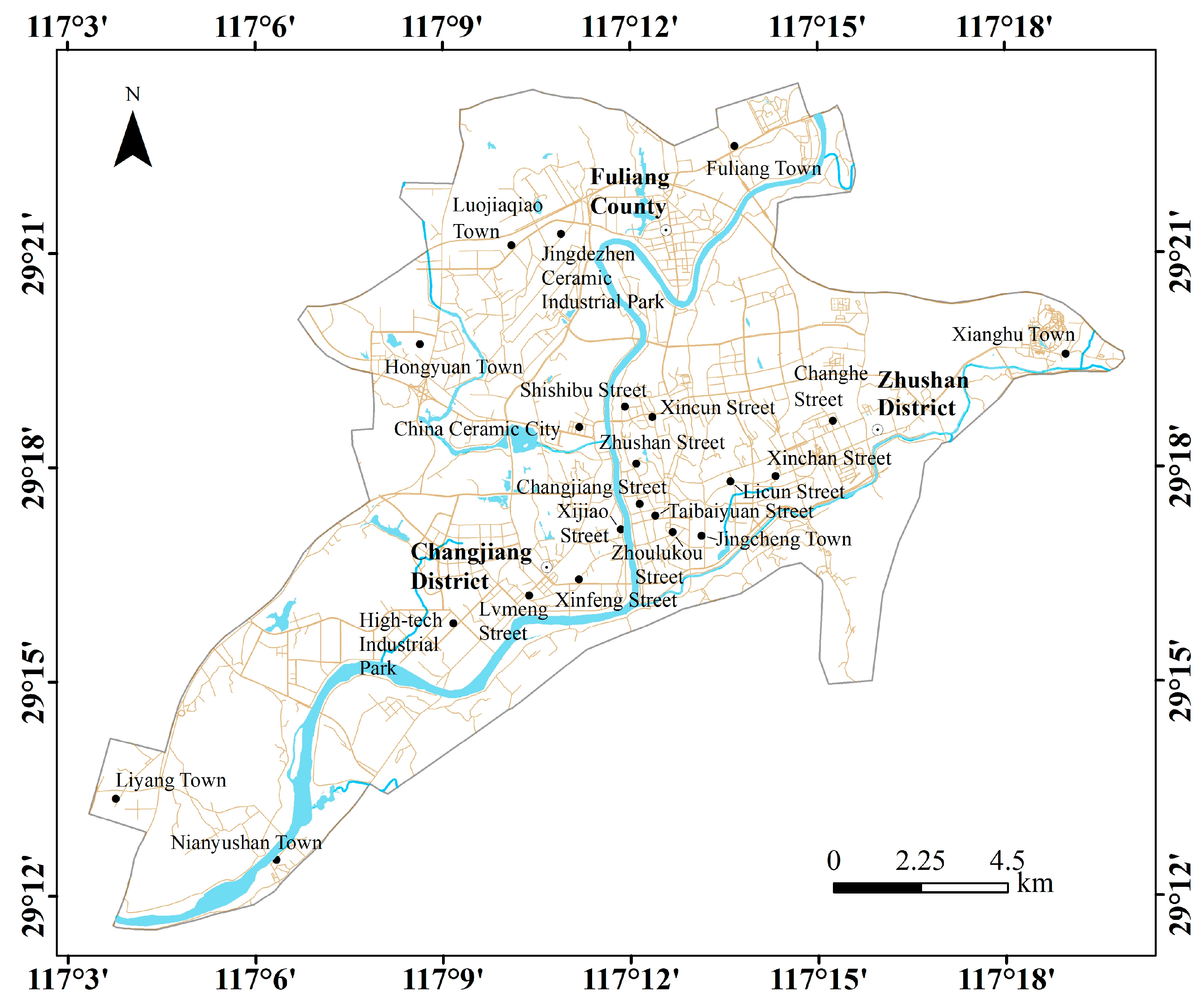

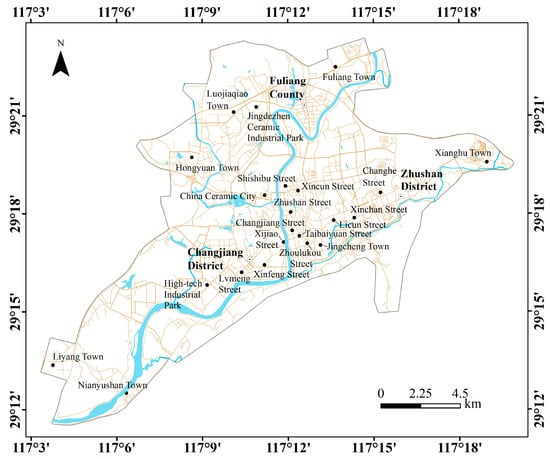

Jingdezhen is situated in the northeastern region of Jiangxi Province, China, along the Changjiang River. During the Eastern Jin Dynasty, the name of the study area was Xinpingzhen (i.e., Xinping Town); it was renamed Changnanzhen (i.e., Changnan Town) during the Tang Dynasty. Ultimately, the area of Jingdezhen was renamed according to the reign title of the emperor Zhenzong in 1004, and this area was managed as part of the ancient Fuliang County. The name Jingdezhen has been used since then [2]. This study selected the main urban area of Jingdezhen (29°11′ N–29°23′ N, 117°3′ E–117°20′ E) as the study area, the boundary of which was planned by “The Master Planning of Jingdezhen City (2012–2030)”, and the data obtained from the “City Atlas of Jingdezhen” [34]. This area is known for the clustering of the ceramics industry. The study also encompassed the neighboring towns of Sanlong and Fuliang to the north, Jingcheng to the south, Xianghu to the east, and Hongyuan and Liyang to the west. The area includes 20 townships, spanning 241.36 km2 (Figure 1).

Figure 1.

The study area.

2.2. Materials

Referring to the “Industrial classification for national economic activities” (GB/T 4754-2017) as a guide for categorizing the ceramics industry, this study obtained enterprise information data from two sources, namely “The Second National Industrial Census of Jingdezhen City (1985)” and the TianYanCha platform (https://www.tianyancha.com/, accessed on 24 October 2022). TianYanCha is a business search platform operating under the National SME Development Sub-Fund. It provides access to publicly available information on 280 million social entities, including data on business information, trademarks and patents, business changes, and annual reports. Enterprise information data include enterprise name, enterprise establishment date, registered capital amount, enterprise address, business scope, etc. This study processed the data in three steps. Firstly, the researchers manually confirmed and cross-referenced the enterprise address information using the “Jingdezhen city gazetteer” and city historical maps to ensure the accuracy of the enterprise address. Secondly, they used the confirmed addresses to retrieve geographic coordinates using the Baidu’s map API. Finally, they spatialized the geographic coordinates using ArcGIS 10.2, obtaining spatial location vector data of 7714 ceramic enterprises in Jingdezhen. According to the shape and number of enterprise data points in the study area, the study used the equal-area spatial grid method to divide the study area into 1 km × 1 km grids. The total number of grids is 1084. They were used as base cells for data calculation, and the data were then linked to the grid using spatial connections in ArcGIS.

2.3. Methodology

2.3.1. Kernel Density Estimation

Kernel density estimation, introduced by Rosenblatt and Emanuel Parzen, estimates the density of a point or line pattern within a moving cell [35]. It is a nonparametric estimation method used to estimate an overall probability distribution density without assuming the overall distribution function and calculates the density of discrete points within each cell, allowing the density of the surrounding neighborhood to be estimated. With this method, it is possible to visually represent the spatial distribution of the ceramics industry. The formula for kernel density estimation is [36]:

where is the kernel density estimate; n is the number of points; k is the kernel density function; t is the smoothing parameter or the bandwidth; p is a vector of coordinates defining the location where the function is estimated; and pi are the vectors of coordinates that define each observation i.

2.3.2. Exploratory Spatial Data Analysis

Exploratory spatial data analysis (ESDA) has spatial correlation measures at its core. It establishes spatial relationships between a region and its surrounding neighborhoods through spatial weight matrices. In addition, it determines the spatial neighborhood status of each region through spatial lag vectors, thereby revealing the features of the data, including global and local autocorrelation. Commonly, Moran’s I or Geary’s C are used to measure global autocorrelation, while local indicators of spatial association (LISA) or Getis-Ord Gi*, are used to measure local autocorrelation [37].

- (1)

- Global spatial autocorrelation analysis

Global spatial autocorrelation analysis is often used to measure the overall spatial correlation and the spatial agglomeration of a spatial unit. In this study, the global Moran’s I index was used to measure the spatial correlation characteristics and spatial agglomeration of the ceramics industry in Jingdezhen. The formula of the global Moran’s I is [38]:

where n is the total number of grids; wij denotes the inverse distance weight matrix; xi and xj are the values of the number of enterprises in location i and location j, respectively; is the mean value of xi; s2 is the sample variance, that is,. The Moran’s I usually range from −1 to 1. If Moran’s I∈[−1, 1] has a value greater than 0, it indicates a positive spatial correlation. This means that the ceramics industry in Jingdezhen exhibits high-high or low-low agglomeration. If Moran’s I∈[−1, 1] has a value less than 0, it indicates negative spatial correlation, meaning that the ceramics industry is spatially discrete. If Moran’s I∈[−1, 1] has a value equal to 0, there is no correlation, i.e., the ceramics industry does not show a spatial distribution pattern.

- (2)

- Local spatial autocorrelation analysis

Local spatial autocorrelation analysis uses local Moran’s I to determine the type of spatial agglomeration of a spatial unit [39]. In this study, the local spatial autocorrelation index (LISA) was used to measure the local spatial correlation of the ceramics industry in Jingdezhen. The LISA agglomeration maps were generated based on the local Moran’s I index. The formula is [40]:

where is the local Moran’s I index and is the variance. Other parameters are set to be the same as those in Formula (2). The LISA agglomeration maps were generated by combining scatter maps derived from Moran’s index with the significance of the LISA agglomeration. This study conducted local spatial autocorrelation analysis using ArcGIS 10.3 and GeoDa 1.2. The spatial weight matrix was generated based on adjacent boundaries, and all software parameters retained their default values.

2.3.3. Geodetector

Geodetector is a spatial statistical method that functions on the principle of spatially stratified heterogeneity. It can quantitatively analyze the influence of explanatory factors on detection targets and measure the interaction between variables without making linear assumptions. This method applied equally applied in the natural and social sciences [41,42]. The formula is:

where h = 1, 2, …; L is the strata of variable Y or factor X; Nh and N are sample sizes of the h (h = 1, 2, …, and L) strata and total strata, respectively; σ2h and σ2 are variances of the h strata and total strata, respectively; SSW and SST are the within sum of squares and total sum of squares, respectively.

Although the Geodetector consists of four modules, this study only included factor and interaction detection. Factor detection uses the q-value to quantify the extent to which a certain factor explains the spatial differentiation of an attribute within the ceramics industry in Jingdezhen. The value of q is in the range [0, 1]. Higher values indicate a stronger influence on the dependent variable.

The interaction detector was used to measure the interaction between covariates. It was classified into five types (Table 1): Weaken, uni-; Weaken, nonlinear-; Enhanced, bi-; Enhanced, nonlinear-; and Independent [42,43].

Table 1.

Types of interaction between two covariates.

2.3.4. Selection and Calculation of Influencing Factors

Previous research has revealed that the ceramics industry is influenced by multiple factors, including regional resources, transportation conditions, market factors, technological innovation, agglomeration conditions, policy factors, and history and culture. Considering the current state of the ceramics industry in Jingdezhen and the availability and effectiveness of data, the factors influencing the evolution of the ceramics industry were explored from five aspects, namely history, technology, transportation, agglomeration, and policy (Table 2). Jingdezhen has a thousand-year history of porcelain production. After the founding of the People’s Republic of China, the historical porcelain workshops were reorganized into more than ten large porcelain factories, commonly referred to as the “Ten Porcelain Factories” [44]. The shortest distance to the “Ten Porcelain Factories” represents the historical variable (HIS). The development of the ceramics industry is closely tied to innovative developments of production technology and equipment. Ceramic research institutes and higher education institutions provide the necessary support for the development of ceramic production. Thus, the shortest distance to ceramic research institutes and higher education institutions represents the knowledge and technology variable (TECH). Similar enterprises can share public infrastructure services to achieve positive external benefits through spatial agglomeration. This study used the distribution of ceramics industry enterprises in the first 10 years to depict the impact of the industrial agglomeration variable (AGGL). Furthermore, policies for industrial park construction are important for promoting industrial development. Jingdezhen implemented the “retreating from the city into the industrial park” policy to address environmental pollution problems caused by the ceramics industry. Thus, the park policy variable (PARK) was introduced to assess the impact of policy implementation on the ceramics industry. Finally, the transportation factor is a key element in traditional location theory that explains the spatial distribution of industries. Road density (RDEN) was used to describe internal city transportation, while distance to the nearest railway station (RAIL) and distance to the nearest expressway entrance (EXPR) were used to describe the external transportation.

Table 2.

Selection and definition of influencing factors in the ceramics industry in Jingdezhen.

Geodetector used a 1 km × 1 km grid as the basic unit of analysis. The number of enterprises in the ceramics industry within the grid represents the dependent variable, while the seven indicators (Table 2) represent the independent variables. This study measured influence of dependent and independent variables on the spatial evolution of the ceramics industry. Firstly, all independent variables were divided into five levels using the natural break point method in ArcGIS 10.3 software. The values of each variable were transformed into categorical values. Subsequently, Geodetector was used to calculate factor detection and interaction detection, which expressed the influence on the spatial distribution of ceramics industry in Jingdezhen.

3. Results

3.1. The Temporal Evolution of the Ceramics Industry

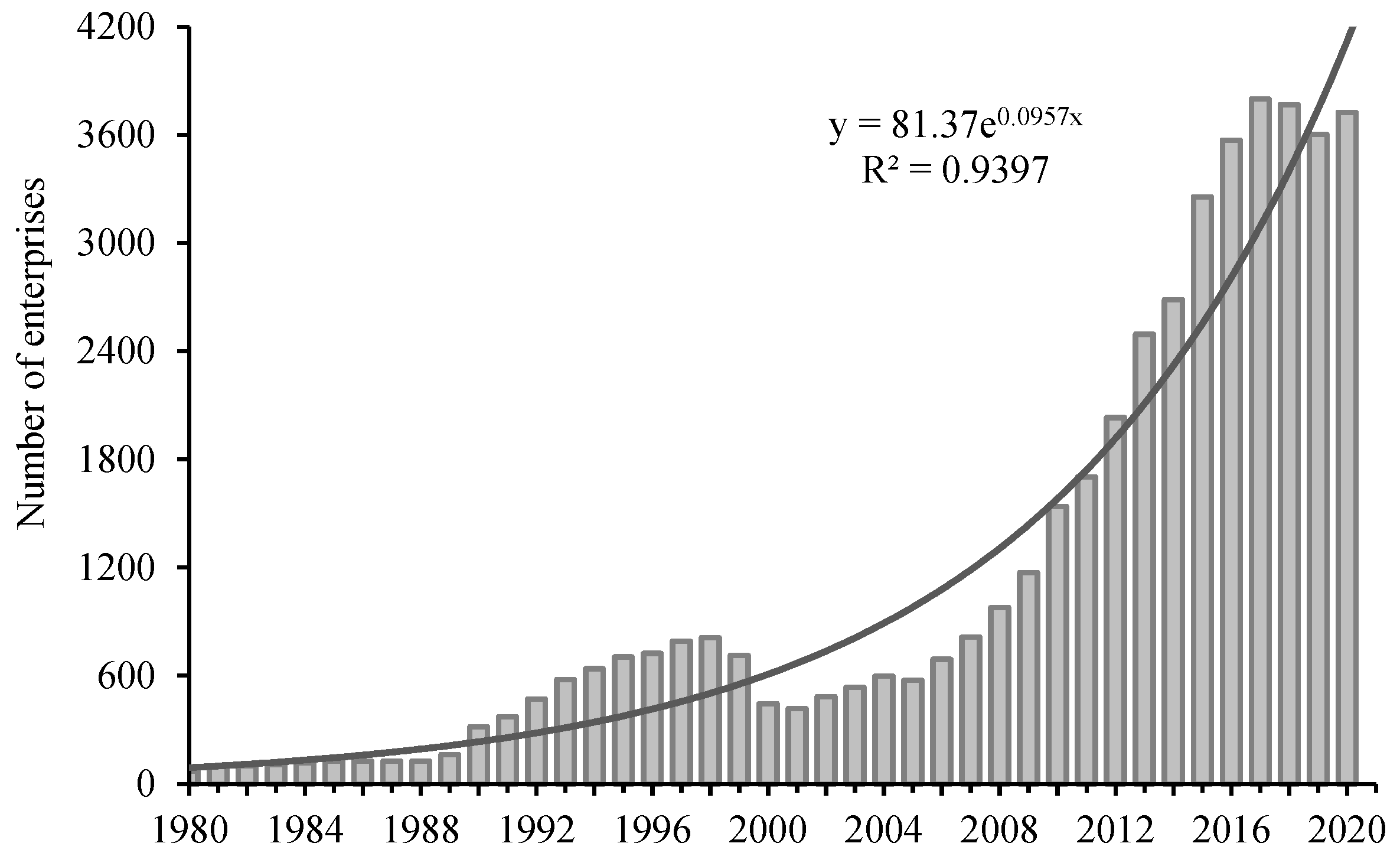

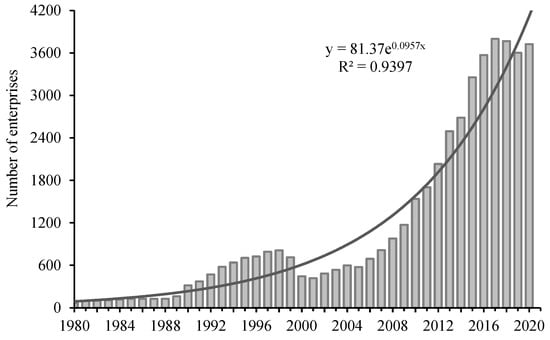

The temporal evolution of the ceramics industry in Jingdezhen has shown exponential growth with fluctuations during the last 40 years (Figure 2). The evolution can be divided into two phases, with 2001 as the cornerstone. In the first phase, the ceramics industry in Jingdezhen experienced growth, followed by a decline. The number of enterprises grew slowly from 1980 to 1989 and grew rapidly in the 1990s. Afterwards, the number of enterprises declined, reaching its peak and lowest point in 1998 and 2001, respectively. With the Chinese economic reform in the 1980s, community branch offices, villages surrounding Jingdezhen, and other collective organizations were allowed to open ceramic enterprises, which was the main driving force for the growth of ceramic enterprises in this period. Due to the intensification of the reform in the 1990s, state-owned ceramic enterprises in Jingdezhen were closed or restructured. This led an the influx of skilled workers and equipment into the ceramics industry, with laid-off workers taking up contracts in ceramic enterprises [45]. Consequently, the number of ceramic enterprises grew rapidly, reaching its peak. The ceramics industry in Jingdezhen has formed a decentralized business model, with small enterprises and family workshops present in the industry. At the same time, the organized operation and large-scale production in the Jingdezhen ceramics industry were disrupted. This, combined with severe market competition, has severely hampered the development of Jingdezhen’s ceramics industry. As a result, it lagged behind other ceramics industries, such as Foshan and Dehua [33]. With the rapid decline in the production of everyday ceramics, only the traditional porcelain art industry was able to maintain its development.

Figure 2.

The temporal evolution of the ceramics industry in the last 40 years.

In the second phase, the number of ceramic enterprises in Jingdezhen grew over time. They experienced a slow growth phase from 2002 to 2009 and a rapid one from 2010, i.e., after 2015, when the number of enterprises in the ceramics industry exceeded 3000. With the rapid urbanization and industrialization in Jingdezhen [33], the city government established the Jingdezhen Porcelain Bureau to unify the planning, organizing, guiding, coordinating, and managing the development of the ceramics industry. The Bureau also serves to optimize the environment for the development of the ceramics industry by introducing quality capital through investments. They also aim to promote the reconstruction of the ceramics industry, build industrial parks, create business incubators for small and medium enterprises, and provide facilities, capital, and technology to ceramicists. Thus, a new pattern of development took shape within the ceramics industry in Jingdezhen, with high-tech ceramics as a pillar, high-quality everyday ceramics and traditional porcelain art as the mainstay, and architectural and sanitary ceramics as auxiliary [46]. As a result, the ceramics industry in Jingdezhen entered a new period of rapid development.

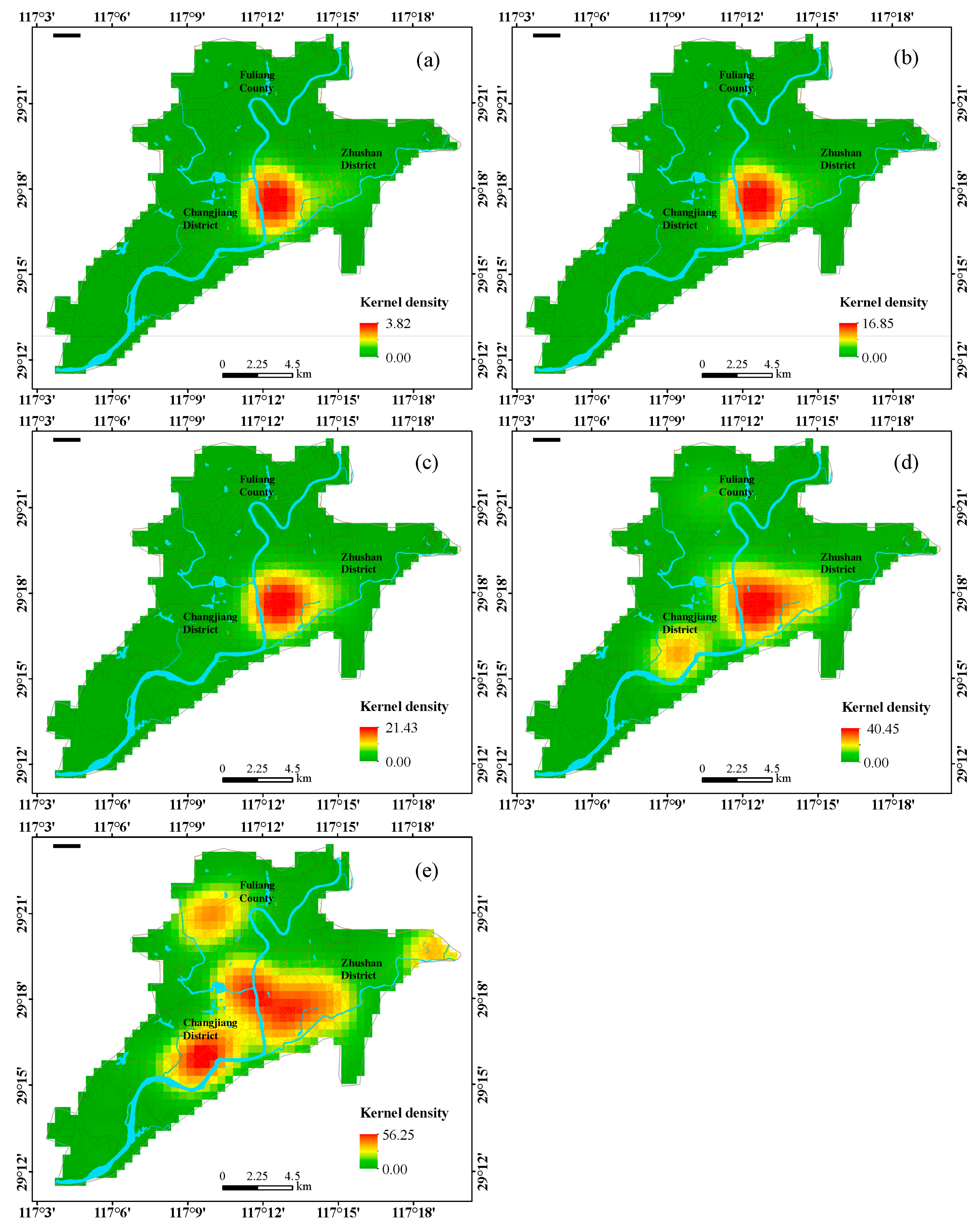

3.2. The Spatial Distribution of the Ceramics Industry

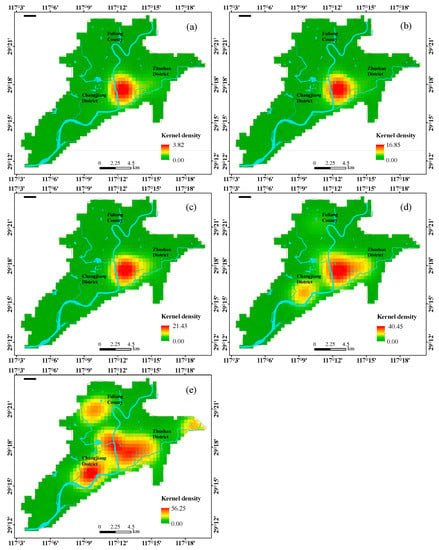

The spatial distribution of the ceramics industry in Jingdezhen evolved from a “single-center” to a “double-center” model, and further to a “multi-center” model (Figure 3). The kernel density estimation analysis shows that the “single-center” model was concentrated in the old urban area of Zhushan District from 1980 to 2000. This model gradually extended eastward along the Chaoyang Road, encompassing areas such as Fanjiajing, Shouqiwu, Fenghuang Mountain, and Xiguazhou [45]. With the implementation of the “retreating from the city into the industrial park” policy and investment policies after 2002, many air-polluting ceramic enterprises were forced to move to the High-Tech Industrial Park in Changjiang District or the Jingdezhen Ceramic Industrial Park in Fuliang County. Nevertheless, ceramic workshops and enterprises focused on the porcelain art that spread in and around the old urban area. As a result, the spatial distribution of the ceramics industry shifted to a “double-center” model in 2010. The old urban area of Zhushan District and the eastward extension of Chaoyang Road formed the primary core, while the High-Tech Industrial Park formed the secondary core. In addition, ceramic enterprises began to concentrate in the Jingdezhen Ceramic Industrial Park in Fuliang County. In contrast to 2010, the spatial distribution of the ceramics industry further evolved into a “multi-center” model in 2020. In addition to the primary and secondary cores, new sub-centers emerged in the Jingdezhen Ceramic Industrial Park in Fuliang County and Xianghu Town. To sum up, the spatial distribution of the ceramics industry in Jingdezhen shifted from a “single-center” to a “multi-center” model. The industry continuously expanded to new urban areas, while it also developed in old urban areas.

Figure 3.

The kernel density of the ceramics industry in (a) 1980, (b) 1990, (c) 2000, (d) 2010, and (e) 2020.

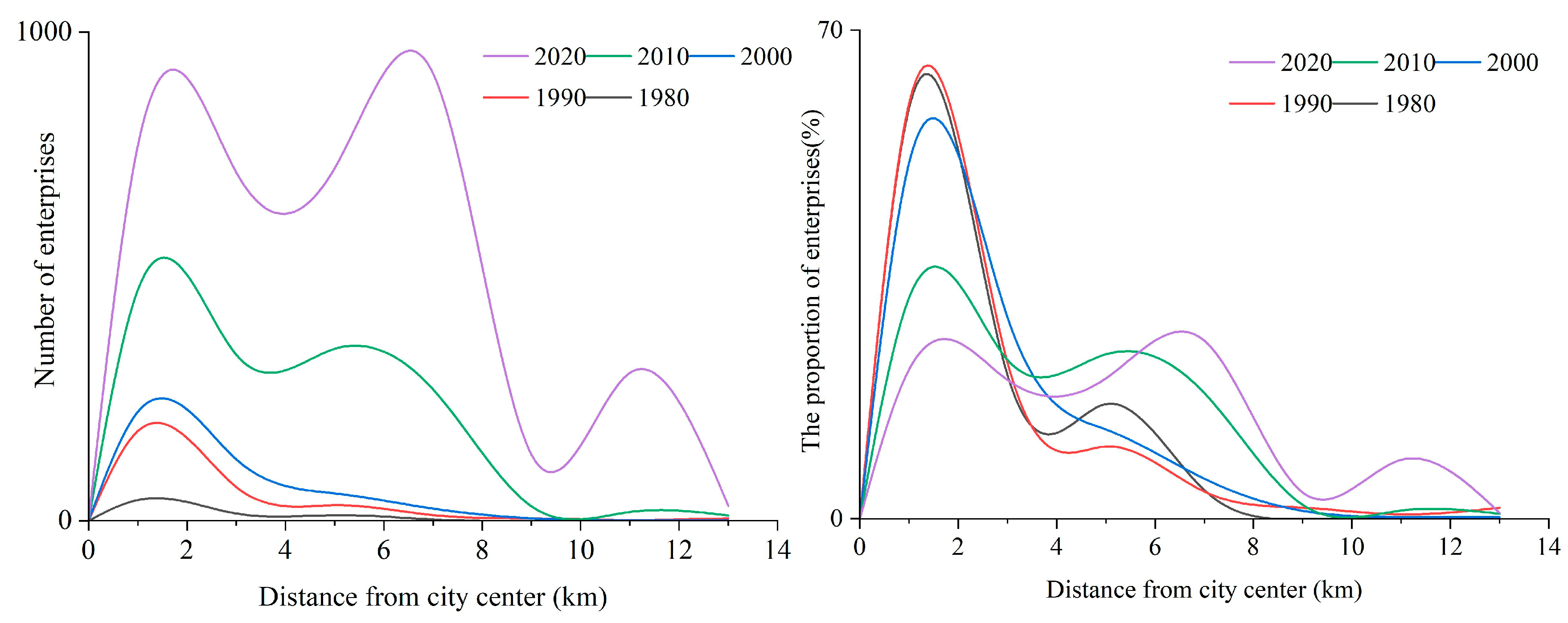

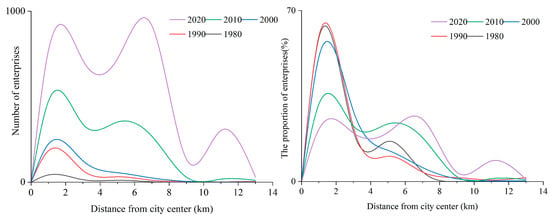

To further illustrate the spatial evolution of the ceramics industry, a buffer zone was set up every 2 km, with Zhushan (the center of the old urban area) at the center. There were a total of seven circles and the spatial distribution of the ceramics industry was observed within each circle (Figure 4). In 1980, 1990, and 2000, the ceramics industry had a unimodal distribution with an increase in distance from the urban center. Enterprises were primarily concentrated within a 0–2 km circle, having a proportion greater than 50%, and gradually diffused with the increase in distance from the center. In 2010, the ceramics industry exhibited a bimodal distribution with an increase in distance from the urban center. The primary center of agglomeration was still the 0–2 km circle. However, a sub-center was formed within the 4–6 km circle. In 2020, the ceramics industry will exhibit multiple peaks with increasing distance from the urban center. Now, the center of the agglomeration was in the 6–8 km circle, with sub-centers forming within the 0–2 km and 10–12 km circles. This suggests that the centers of the ceramics industry in Jingdezhen expanded over time, shifting from the urban center to the suburbs. Nevertheless, the old urban district remained one of the centers of the agglomeration.

Figure 4.

The number and proportion of enterprises within the ceramics industry at different distances from the city center.

3.3. The Spatial Agglomeration of the Ceramics Industry

All parameters of the global Moran′s I were significantly positive and greater than 0, indicating a positive spatial correlation of the spatial distribution of the ceramics industry and showing significant agglomeration. The global Moran′s I increased from 0.371 in 1980 to 0.629 in 2000, indicating an increase in the spatial agglomeration of the ceramics industry. In contrast, the global Moran′s I decreased from 0.629 in 2000 to 0.233 in 2020, indicating that the ceramics industry still exhibited spatial agglomeration, but the degree of the agglomeration was decreasing (Table 3).

Table 3.

Global Moran’s I of the ceramics industry.

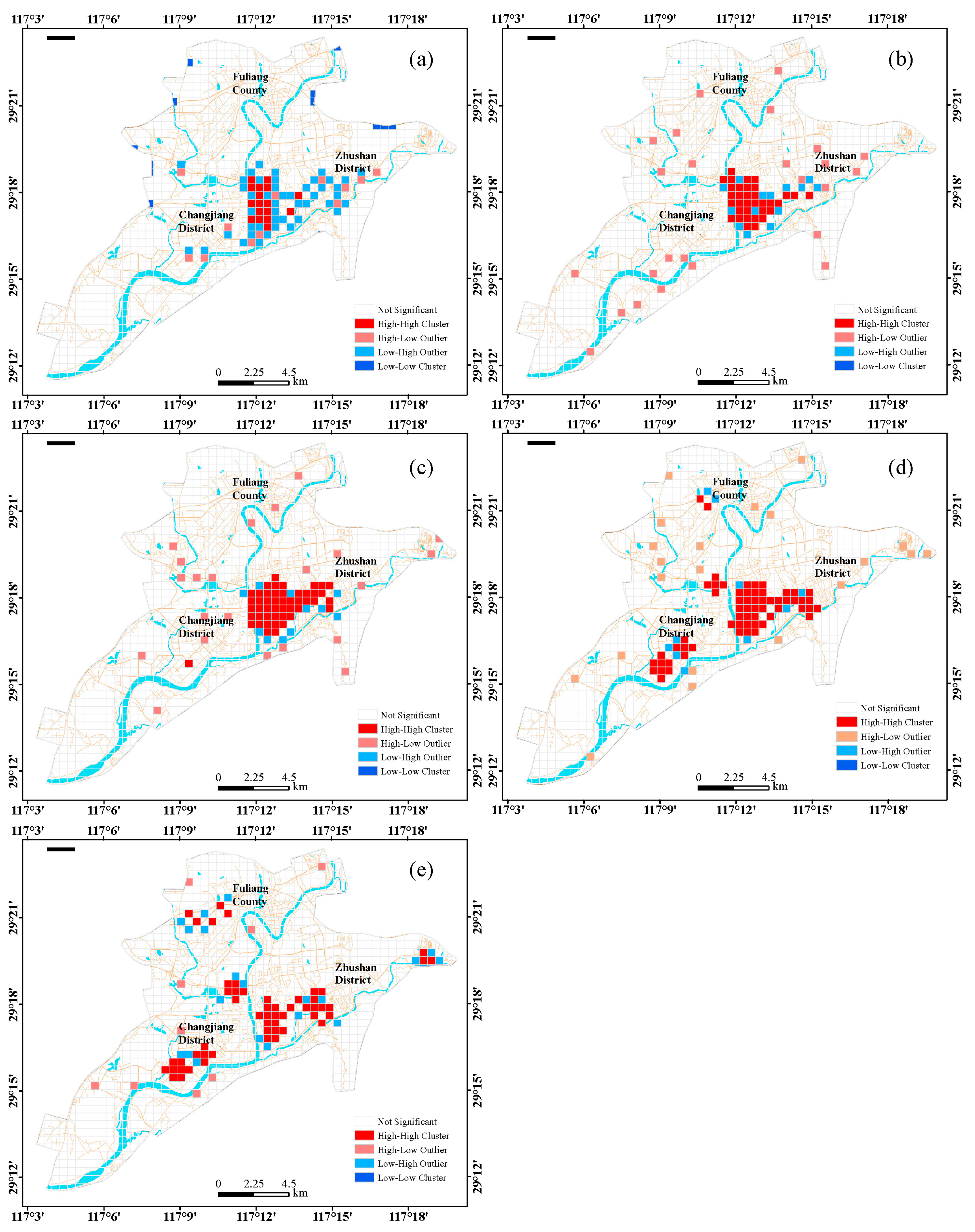

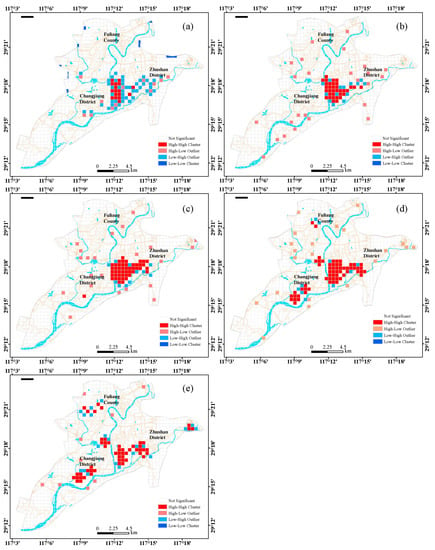

Local spatial autocorrelation was used to analyze local changes and trends in the spatial agglomeration of the ceramics industry. In this study, ArcGIS software was used to combine the local Moran index and the significance level of LISA to draw the LISA agglomeration map (Figure 5). The LISA agglomeration map classified local spatial correlation into four types: high-high (H-H) agglomeration, high-low (H-L) agglomeration, low-high (L-H) agglomeration, and low-low (L-L) agglomeration. In particular, the H-H agglomeration indicates a positive spatial correlation between enterprises in the ceramics industry. Likewise, it represents a statistically high-value agglomeration area (a hotspot). From 1980 to 2000, the high-value area was mainly located in the old urban area of Zhushan District and extended to the eastward of Xinchan Street. In 2010, the high-value area experienced decentralization, extending from Zhushan District to Changjiang District and Fuliang County. This expansion included new agglomeration areas, such as the High-Tech Industrial Park, China Ceramic City, and Jingdezhen Ceramic Industrial Park. Additionally, there were sporadic distributions in other areas. By 2020, the local agglomeration in the ceramics industry has strengthened compared to 2010. Even a new hotspot emerged in Xianghu Town, resulting in a total of 6 new agglomeration areas. These areas are divided into 4 industrial agglomeration patterns.

Figure 5.

The LISA agglomeration maps of the ceramics industry in (a) 1980, (b) 1990, (c) 2000, (d) 2010, and (e) 2020.

The first agglomeration pattern includes two hotspots, namely the old urban area of Zhushan District and Xinchan Street, which were the traditional agglomeration centers for the production of everyday ceramics and porcelain art in Jingdezhen. After 2011, the government used the state-owned porcelain factory to develop the ceramic cultural and the creative industries. It became a new agglomeration center for ceramic culture and creative industries. The second agglomeration pattern formed a comprehensive industrial system, that includes high-tech ceramics, everyday ceramics, porcelain art, architectural and sanitary ceramics, and industrial ceramics. This system was led by the High-Tech Industrial Park and Jingdezhen Ceramic Industrial Park. The third agglomeration pattern was formed in the hotspot of Xianghu Town, with the Xianghu Campus of Jingdezhen Ceramic University at the center. This area represented the pinnacle of ceramic science and education in Jingdezhen, serving as an agglomeration center for innovation in ceramic art, scientific research in ceramic, and ceramic talent training. The fourth and final agglomeration pattern was located in the hotspot of China Ceramic City in Changjiang District. It represented the agglomeration center of the ceramic exhibition and trading. Overall, the spatial agglomeration of the ceramics industry in Jingdezhen underwent a process of “agglomeration-diffusion-polarization”.

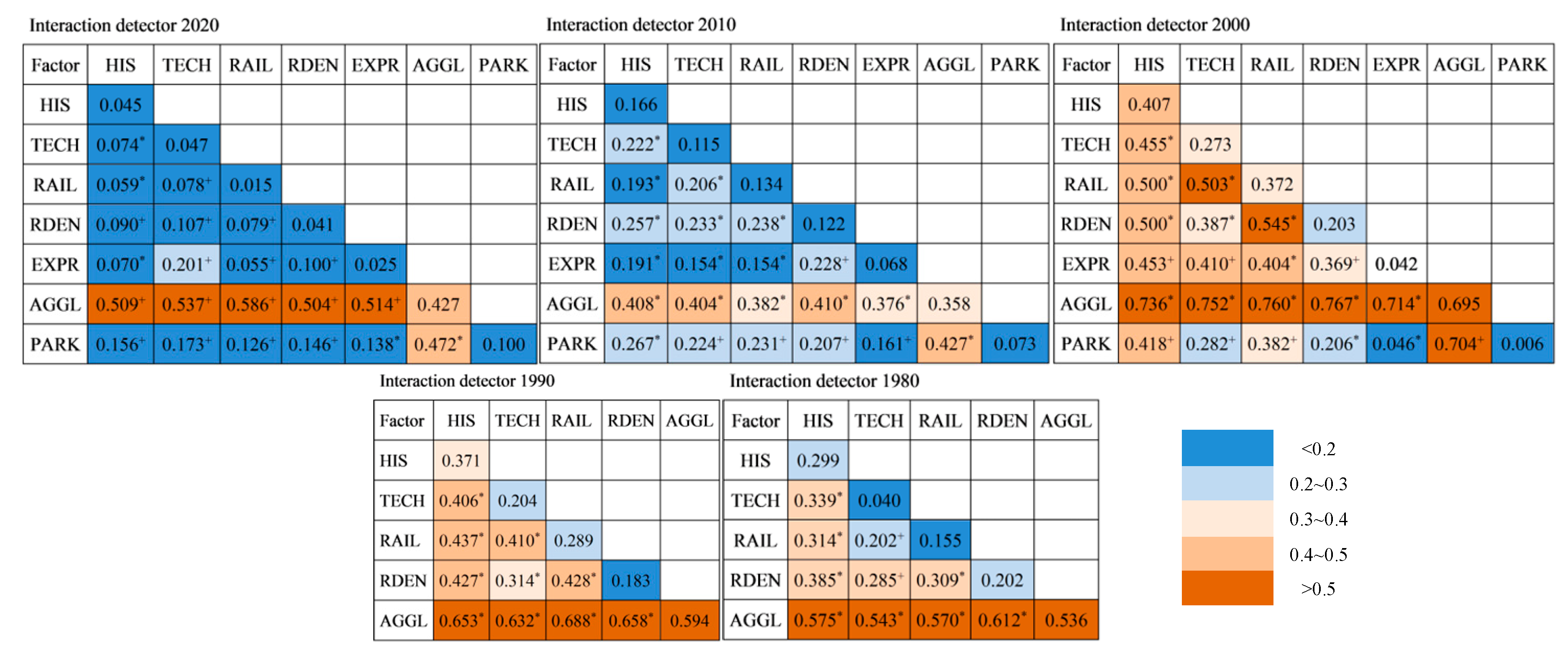

3.4. The influence of Factors on the Evolution of the Ceramics Industry

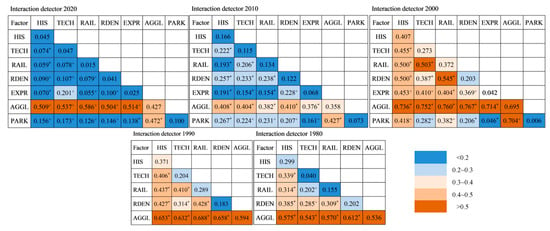

The results of factor detection show that history, technology, transportation, agglomeration, and policy were important factors influencing the evolution of the ceramics industry in Jingdezhen (Table 4). However, each factor influenced the evolution differently depending on the year. The q-value of the agglomeration variable (AGGL) was 0.358–0.695. This factor had the strongest impact among all factors during the study period, indicating that it had the most critical impact on ceramic enterprises. In addition, new enterprises were self-organized and evolved by building upon the foundation of historical enterprises. Although the policy variable (PARK) was not significant in 2000, it became the second most influential factor in 2020, with a q-value of 0.006–0.100. The q-value of the historical variable (HIS) was 0.0453–0.407, indicating that historical factors had a positive impact on the location selection of the ceramics industry. This factor was most influential around 2000. While the variables of technology (TECH), road density (RDEN), railway station (RAIL), and expressway (EXPR) had similar influences on the ceramics industry during the study period, and their q-values were 0.040–0.273, 0.041–0.203, 0.02–0.372, and 0.025–0.068, respectively. Furthermore, AGGL and HIS played significant roles in the spatial distribution of the ceramics industry from 1980 to 2000, while RAIL, RDEN, TECH, and EXPR were the other most influential factors. AGGL was still the most important factor in the spatial distribution of the ceramics industry from 2010 to 2020, while the influence of PARK increased over time. However, the influence of HIS, TECH, and traffic factors (RDEN, RAIL, and EXPR) has significantly decreased.

Table 4.

The q-values for detecting influencing factors in 1980, 1990, 2000, 2010 and 2020.

The results of interaction detection show that the multi-factor interactions had a stronger influence than the single-factor interactions. The interaction is shown as Enhanced, bi-, Enhanced, nonlinear-, which indicates that the spatial evolution of the ceramics industry was not controlled by a single-factor but by multiple factors (Figure 6). The interaction was dominated by Enhanced, bi- from 1980 and 2000. In these years, AGGL had the strongest influence on the interaction between the factors. The q-values of this interaction were all significantly greater than those of the single-factor interactions. In addition, TECH∩RAIL (q = 0.503) and RAIL∩RDEN (q = 0.545) had a greater influence on the spatial evolution of the ceramic industry. This interaction was dominated by Enhanced, nonlinear- from 2010 to 2020. In these years, the interaction of AGGL with other factors was still significant but was less intense compared to 1980 to 2000. Overall, the evolution of the ceramics industry in Jingdezhen was subject to the influence of several factors.

Figure 6.

The results of interaction detection in 1980, 1990, 2000, 2010, and 2020. Note: Band * is Enhanced, bi-, while Band + is Enhanced, nonlinear-.

4. Discussion

The agglomeration factor (AGGL) was the strongest factor among individual variables and the strongest factor in the multi-factor interaction, indicating that the spatial distribution of the ceramics industry was significantly affected by agglomeration. From 1980 to 2000, the ceramics industry in Jingdezhen was primarily concentrated in the old urban area and the surrounding suburbs. During this period, the industry was closely linked to historical factors, ceramic research institutes, and major transportation sites such as railway stations. Since the beginning of the 21st century, the Jingdezhen government has taken steps to restructure and optimize the ceramics industry. They have established areas such as the ceramic industrial park in the High-Tech Industrial Park, the Jingdezhen Ceramic Industrial Park, and ceramic cultural and creative bases [33]. These areas provide favorable conditions for staff mobility, information exchange, technology diffusion, product preparation, and material supply within the agglomeration. By leveraging the advantages of industrial agglomeration, including scale, innovation, and competition effects, the government can promote the development of the ceramics industry in Jingdezhen. However, the agglomeration of the ceramics industry in Jingdezhen also brought challenges. These include the convergence of industrial structure and the lack of innovation in processes, causing fierce competition within agglomerations [47]. Therefore, the six major ceramic industry agglomerations should take advantage of their unique resources and adopt differentiated development strategies to obtain complementary resource advantages and create a favorable environment for orderly development within the agglomerations.

The policy factor (PARK) was the second most influential factor in 2020. The influence of this factor on the spatial evolution of the ceramics industry increased over time. To address the developmental challenges of the ceramics industry and mitigate environmental pollution, the Jingdezhen government introduced the policy concept of “retreating from the city into the industrial park” policy concept and implemented the policy of concentrating the ceramics industry in industrial parks. As part of the policy, the government successively planned and built the High-Tech Industrial Park and the Jingdezhen Ceramic Industrial Park, giving rise to a new industrial pattern that included the production of everyday ceramics, porcelain art, architectural and sanitary porcelain, and high-tech ceramics [3,46]. Although the High-Tech Industrial Park was established in 1994, it was not until 2003, when the Jingdezhen Porcelain Bureau established the Jingdezhen Ceramic Industrial Park, that ceramic enterprises were relocated to the park. As a result, the development of the ceramic industrial park was completed in 2005 [33]. The Jingdezhen Ceramic Industrial Park was established in 2004 based on the Fuliang County Industrial Park. It was approved as a provincial characteristic industrial park in 2006, a ceramic industry base in Jiangxi Province in 2011, and a national ceramic industry demonstration base in 2012. Since then, it has emerged as a strategic hub driving the development of the ceramics industry and is rapidly evolving towards “industry-city integration.” Located on bustling Xinchan Street, the Taoxichuan ceramic art avenue is dedicated to the development of cultural and creative industries. It has been recognized as a national and cultural industrial demonstration park in 2020 and has become a new business model for the development of the ceramics industry in Jingdezhen.

The historical factors (HIS) positively influenced the spatial distribution of the ceramics industry. Jingdezhen has a long history of ceramic production, and for a significant part of this history, it produced traditional everyday ceramics and high-quality porcelain art [33]. As a result, state-owned and municipal ceramic enterprises continued with this tradition after the establishment of the People’s Republic of China. These enterprises were concentrated in the historical porcelain production centers in old urban areas. Located in Fanjiajing, Shouqiwu, and Fenghuang Mountain near the old urban area, individual ceramic handicraft workshops emerged after the Chinese economic reform, producing traditional everyday ceramics and porcelain art, with similar production and operation methods and products in tradition [45]. However, they changed according to the requirements of different periods and historical conditions [48]. To revitalize the historical city district, the government began to develop the ceramic culture and creative industry in 2011. Using the old and vacant facilities of old porcelain factories, including the Cosmos Porcelain Factory, the Sculpture Porcelain Factory, and the Jianguo Porcelain Factory, the government has established an agglomeration area for ceramic artists, a central area for innovation in ceramic culture, and a dynamic new industry in Jingdezhen. As a result, the traditional historical porcelain-making area became a new center for the ceramic production.

The technological factor (TECH) had a significant impact on the ceramics industry in terms of bringing prosperity and encouraging development in Jingdezhen. The ceramic industry is clearly influenced by technology, as evidenced by Jingdezhen’s mastery of handmade porcelain production techniques, which were at the forefront of global advancements during the Ming and Qing dynasties [4], when the industry was the most prosperous. Building upon the foundation of traditional craftsmanship, the contemporary ceramics industry has continued to innovate and develop the whole ceramics industry. Even specialized research and education institutions were established, such as the China Institute of Ceramics for Light Industry, the Jiangxi Institute of Ceramics, the Jingdezhen Institute of Ceramic Archaeology, the Jingdezhen Ceramics University, and the Jingdezhen University [44]. These institutions have a pivotal role in nurturing talent and advancing technology in the ceramics industry [33]. Being the first higher education institution in China to specialize in ceramics, Jingdezhen Ceramics University leverages its advantages and combines industry, academia, and research. It continuously improves its capabilities in ceramic science and technology research, ceramic industry innovation, and ceramic culture and art creativity. Consequently, the University established two ceramic industrial agglomerations; one in the pottery street area near the old campus and the other in Xianghu town near the new campus. The Jingdezhen government cooperates with Jingdezhen University of Ceramics to create an agglomeration for ceramic art innovation, ceramic culture research, ceramic creator entrepreneurship, and industry-academia-research integration. This initiative includes Taoci Town, Zhushan Dongshi, the Entrepreneurship Park for college students, and the Jingdezhen Technical School. This area will serve as a center of ceramics culture and its preservation and promotion in science and education.

Traffic factors, including road density (RDEN), railway stations (RAIL), and expressways (EXPR), were important factors in selecting a location for ceramics industry. RDEN and RAIL were important factors influencing the spatial distribution of the ceramics industry in Jingdezhen, while the influence of EXPR was not prominent. From the 1950s to the 1990s, Jingdezhen expanded eastward along Xinchang East Road (formerly known as Dong Yi Road) and Zhushan Avenue (formerly known as Chaoyang Road). The ceramics industry formed agglomerations on each side of the roads, giving rise to several agglomerations in Bagua Mountains, Fenghuang Mountains, and Lijiaao. With the development of ceramic cultural and creative industries in 2010, the Xinchang East Road once again became the center of the ceramic industrial agglomeration. In addition, ceramic industrial agglomerations were formed near other main roads, including North Shelian Road, North Square Road, and Shuguang Road. Moreover, Jingdezhen’s traditional ceramics industry stretched along the Changjiang River, and leading to the docks through vertical streets, indicating that raw materials and products were transported through the Changjiang River during Jingdezhen’s history. Jingdezhen’s ceramic products were transported by car in the 1960s and by car and rail in the 1990s [33]. As a result, Fanjiajing developed into an influential center of porcelain art production in China due to its proximity to Jingdezhen Railway Station.

5. Conclusions

Jingdezhen occupies an important position in the history of ceramic development in China and represents the pinnacle of ceramic industrial development in the world. This study explored the spatiotemporal evolution and influencing factors of Jingdezhen’s ceramics industry and revealed its spatial agglomerations and diffusion patterns. Based on enterprise data from 1980 to 2020, the spatiotemporal evolution of the ceramics industry was analyzed using kernel density estimation and ESDA. Among the influencing factors, the most important are historical, technological, agglomeration, policy, and transportation factors, analyzed using Geodetector. This study has reached several conclusions, which provide a basis for the formulation of policies and the promotion of sustainable development in the ceramics industry.

(1) The temporal evolution of the ceramics industry in Jingdezhen has experienced exponential growth in the last 40 years. This evolution is divided into two stages, with 2001 as the cornerstone. The number of enterprises in the first stage grewbut then began to decline as time progressed. The largest number of enterprises was recorded in 1998. In the second stage, enterprises experienced rapid but gradual growth, with the number of enterprises growing significantly after 2015.

(2) The spatial evolution of the ceramics industry transitioned from a "single-center” to a "double-center” model, to further develop into a "multi-center” model. This phenomenon was spatially manifested as a continuous spread of the industry to the suburbs while also developing within the old urban area.

(3) The spatial agglomeration of Jingdezhen’s ceramics industry has experienced the process of “agglomeration-diffusion-polarization” in the last 40 years. The ceramics industry expanded from Zhushan District to Changjiang District and Fuliang County, gradually forming four major industrial agglomeration patterns in six hotspots. These hotpots were the old urban area of Zhushan District and Xinchan Street, which represent the agglomeration centers for the production of traditional everyday ceramics; the High-Tech Industrial Park and Ceramic Industrial Park that represent the agglomerations for the production of industrial ceramics, Xianghu Town in Fuliang County, which is the agglomeration center for ceramic science and education; and the China Ceramic City area, which is an agglomeration area for ceramic exhibition and trading.

(4) Factor detection showed that agglomeration, historical, technological, policy, and transportation factors influenced the spatial evolution of Jingdezhen’s ceramic industry. It was also proved that the multi-factor interaction was the most influential. Agglomeration and historical factors had the greatest influence on the spatial distribution of the ceramics industry from 1980 to 2000. Agglomeration was still the most important influencing factor from 2010 to 2020, while policy factors showed their significance over time. However, the influence of historical, technological, and transportation factors gradually decreased.

This study uses enterprise microdata, geographic information technology, and geodetectors to inject new vitality into the study of ceramic industrial spatial evolution at the urban scale. Spatial analysis based on enterprise location data could finely compensate for the limitation of research such as the spatial analysis of industries within cities. The introduction of kernel density estimation and ESDA enables researchers to better reveal the locational choices of industrial agglomeration and diffusion. Furthermore, the introduction of geodetectors can quantify the influencing factors on the choice of industrial locations, especially the interactions of multiple factors, which enriches the analytical methods of economic geography at the urban scale. This is an interdisciplinary and a cross-disciplinary study that connects industrial development, urban planning and geographic information science in the context of urban expansion. Urban managers and urban planners can benefit from the results obtained in this study to better deal with the relationship between ceramic industry development and cultural preservation in Jingdezhen.

Although this study has some theoretical and practical significance, there are limitations. Data on the location of ceramic enterprises is reliable, but the type of production is non-effective, which would make the evolution of sub-sector within the ceramic industry is not sufficiently clear. Future research can clarify the evolution of the sub-sectors within the ceramic industry by classifying the information provided through business licenses of the enterprises.

Author Contributions

Q.H. wrote this article; X.X. embellished the language of the article; X.Z., L.L. and S.H. completed part of the data collection and processing work; H.L. reviewed the whole paper and put forward suggestions for improvement. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Open Fund project of the Hunan Provincial Key Laboratory for Technology and Application of Cultural Heritage Digitalization, grant number JL18K04.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to acknowledge all the reviewers and editors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Li, W. Jingdezhen Taoci Shi: Modern and Contemporary; Jiangxi People’s Publishing House: Nanchang, China, 2016; pp. 2–3. [Google Scholar]

- Zhang, X.M.; Xie, H.L.; Zhou, C.H.; Zeng, B.D. Jingdezhen: The millennium porcelain capital. Cities 2020, 98, 102569. [Google Scholar] [CrossRef]

- Guo, J.; Li, H. Research on the Renaissance of International Ceramic Capital from the Perspective of Ceramic Cultural Industry. Jiangxi Soc. Sci. 2022, 4, 30–40. [Google Scholar]

- Robert, F. The Pilgrim Art: Cultures of Porcelain in World History; Hainan Publishing House: Haikou, China, 2022; p. 32. [Google Scholar]

- Hervas-Oliver, J.L.; Lleo, M.; Cervello, R. The dynamics of cluster entrepreneurship: Knowledge legacy from parents or agglomeration effects? The case of the Castellon ceramic tile district. Res. Policy 2017, 46, 73–92. [Google Scholar] [CrossRef]

- Scur, G.; Garcia, R. The impact of actors, networks and institutions in the cluster’s evolution: The case of the Brazilian ceramic tile industry. Compet. Rev. 2019, 29, 267–286. [Google Scholar] [CrossRef]

- Bellandi, M.; De Propris, L.; Santini, E. An Evolutionary Analysis of Industrial Districts: The Changing Multiplicity of Production Know-How Nuclei. Camb. J. Econ. 2019, 43, 187–204. [Google Scholar] [CrossRef]

- Tolliday, S.; Yonemitsu, Y. Microfirms and industrial districts in Japan: The dynamics of the Arita ceramic-ware industry in the twentieth century. J. Jpn. Stud. 2007, 33, 29–66. [Google Scholar] [CrossRef]

- Cusmano, L.; Morrison, A.; Pandolfo, E. Spin-off and clustering: A return to the Marshallian district. Camb. J. Econ. 2015, 39, 49–66. [Google Scholar] [CrossRef]

- Molina, B.D.; Molina, M.D.; Garrigos, J.A. The Innovative Regional Environment and the Dynamics of its Clusters. Eur. Plan. Stud. 2011, 19, 1713–1733. [Google Scholar] [CrossRef]

- Zhou, L.; Zou, X.; Huang, Y.; Li, Y.; Guo, L.; Fu, J. Inheritance and Innovation of Pottery Sculpture Technique in Shiwan, China: A Grounded Study from Cultural Ecology. Int. J. Environ. Res. Public Health 2023, 20, 3344. [Google Scholar] [CrossRef]

- Li, S. Study onspace-time succession mechanism of ceramic industry transfer baesd on the cluster theory: A Case Study of Chancheng District, Foshan City. Hum. Geogr. 2009, 01, 58–62. [Google Scholar]

- Liu, S. Research on Jingdezhen Ceramics Characteristic Industrial Cluster in the Changing Environment; Social Sciences Academic Press: Beijing, China, 2016; pp. 241–242. [Google Scholar]

- Xu, M.; Zuo, H. Behavioral mechanism, organizational environment and industrial cluster evolution: Take Jingdezhen ceramic industry as an example. Jiangxi Soc. Sci. 2013, 04, 59–63. [Google Scholar]

- Duan, L.; Du, D.; Huang, X. Spatial and temporal changes and influencing factors of the location of internet start-ups in Shanghai, China. Prog. Geogr. 2019, 3, 383–394. [Google Scholar] [CrossRef]

- Tomlinson, P.R.; Branston, J.R. Turning the tide: Prospects for an industrial renaissance in the North Staffordshire ceramics industrial district. Camb. J. Reg. Econ. Soc. 2014, 7, 489–507. [Google Scholar] [CrossRef]

- Lo, M.-h.; Han, D. China Ceramic Tile Industrial Cluster Competitive Strategies under the Global Economy. In Proceedings of the 2014 International Conference on Global Economy, Finance and Humanities Research (GEFHR 2014), Tianjing, China, 27–28 March 2014; pp. 120–123. [Google Scholar]

- Gabaldon-Estevan, D.; Criado, E.; Monfort, E. The green factor in European manufacturing: A case study of the Spanish ceramic tile industry. J. Clean. Prod. 2014, 70, 242–250. [Google Scholar] [CrossRef]

- Albors-Garrigos, J.; Hervas-Oliver, J.L. Disruptive Innovation in Traditional Clusters: The Case of the Kerajet Ceramic Tile Cluster in Spain. Appl. Sci. 2019, 9, 5513. [Google Scholar] [CrossRef]

- Segarra-Ona, M.D.; Peiro-Signes, A. Environmental Eco-orientation Determinants at the Spanish tile Industry. Dyna 2014, 89, 220–228. [Google Scholar] [CrossRef]

- Gabaldón-Estevan, D.; Fernández-de-Lucio., I. How does diversity affect district innovation systems? Findings from a comparative study of European ceramics. Trilogía Cienc. Tecnol. Soc. 2018, 10, 31–50. [Google Scholar] [CrossRef]

- De Souza, W.J.V.; Scur, G.; De Castro Hilsdorf, W. Eco-innovation practices in the brazilian ceramic tile industry: The case of the Santa Gertrudes and Criciuma clusters. J. Clean. Prod. 2018, 199, 1007–1019. [Google Scholar] [CrossRef]

- Wu, D.; Coe, N.M. Boundary spanners and the external market reach of clusters: The case of the Jingdezhen ceramics cluster in China. Reg. Stud. 2022, 57, 880–892. [Google Scholar] [CrossRef]

- Wu, D.; Coe, N.M. Bottom-up cluster branding through boundary spanners: The case of the Jingdezhen ceramics cluster in China. Urban Stud. 2023, 1–27. [Google Scholar] [CrossRef]

- Yang, X.; Xu, H.; Ni, S. The creative renewal of a craft cluster: The role of materiality and mobility in cluster evolution. Regional Studies 2021, 55, 546–555. [Google Scholar] [CrossRef]

- Wen, H.; Zeng, G. Development of the Cluster Embedding in the Global Value Chain: The study of the global ceramic tile cluster. China Ind. Econ. 2004, 6, 36–42. [Google Scholar]

- Zeng, G.; Wen, H. Study on global ceramic tile cluster embedded in the global value chain. China Econ. Geogr. 2005, 25, 467–470. [Google Scholar]

- Zuo, H.; Yang, J. Empirical Study on the Performance of Chinese Ceramic Industry Clusters Based on the Panel Data. China Ind. Econ. 2011, 9, 78–87. [Google Scholar]

- Wang, Y.; Liu, Y.; Cui, S.; Sun, B.; Gong, X.; Gao, F.; Wang, Z. Comparative life cycle assessment of different fuel scenarios and milling technologies for ceramic tile production: A case study in China. J. Clean. Prod. 2020, 273, 122846. [Google Scholar] [CrossRef]

- Zheng, L. A study on Chaozhou Ceramics industry’s space structure and forming mechanism. China Ceram. 2010, 46, 17–20. [Google Scholar]

- Yu, Z.; Li, X. Evolution Mechanism of Scale and Space of Traditional Technology Industry: Taking Jun Porcelain in Shenhou Town of Yuzhou City in Henan Province for Example. Areal Res. Dev. 2016, 35, 41–46. [Google Scholar]

- Li, S. The industrial regional transferring of China enterprise transference in Chancheng of Foshan. China Econ. Geogr. 2007, 27, 208–212. [Google Scholar]

- Guo, A.; Zhang, C. Jing De Zhen; Contemporary China Publishing House: Beijing, China, 2011. [Google Scholar]

- Commission, C.A.o.J.C. City Atlas of Jingdezhen; China Cartographic Publishing House: Beijing, China, 2020; p. 41. [Google Scholar]

- Wang, F. Quantitative Methods Applications in GIS; The Commercial Press: Beijing, China, 2009. [Google Scholar]

- Koutsias, N.; Balatsos, P.; Kalabokidis, K. Fire occurrence zones: Kernel density estimation of historical wildfire ignitions at the national level, Greece. J. Maps 2014, 10, 630–639. [Google Scholar] [CrossRef]

- Cui, N.; Feng, C.; Song, Y. Spatial pattern of residential land parcels and determinants of residential land price in Beijing. Acta Geogr. Sin. 2017, 72, 1049–1062. [Google Scholar] [CrossRef]

- Li, Q.; Yang, L.; Jiang, F.; Liu, Y.; Guo, C.; Han, S. Distribution Characteristics, Regional Differences and Spatial Convergence of the Water-Energy-Land-Food Nexus: A Case Study of China. Land 2022, 11, 1534. [Google Scholar] [CrossRef]

- Rey, S.J. Spatial Empirics for Economic Growth and Convergence. Geogr. Anal. 2010, 33, 195–214. [Google Scholar] [CrossRef]

- Luo, H.; Qu, X. Spatiotemporal Evolution Trends of Urban Total Factor Carbon Efficiency under the Dual-Carbon Background. Land 2023, 12, 69. [Google Scholar] [CrossRef]

- Wang, J.; Li, X.; Christakos, G.; Liao, Y.; Zhang, T.; Gu, X.; Zheng, X. Geographical Detectors-Based Health Risk Assessment and its Application in the Neural Tube Defects Study of the Heshun Region, China. Int. J. Geogr. Inf. Sci. 2010, 24, 107–127. [Google Scholar] [CrossRef]

- Wang, J.; Xu, C. Geodetector: Principle and prospective. Acta Geogr. Sin. 2017, 72, 116–134. [Google Scholar] [CrossRef]

- He, Q.; Yan, M.; Zheng, L.; Wang, B.; Zhou, J. The Effect of Urban Form on Urban Shrinkage-A Study of 293 Chinese Cities Using Geodetector. Land 2023, 12, 779. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, D. Jingdezhen Taoci Shi: Introduction to the History and Culture of Ceramics; Jiangxi People’s Publishing House: Nanchan, China, 2016; pp. 282–289. [Google Scholar]

- Fang, L. Tradition and Changes: Investigation into the History of Jingdezhen’s Folk Porcelains; Jiangxi People’s Publishing House: Nanchan, China, 2000. [Google Scholar]

- Zhu, H. Thoughts on accelerating the development of Jingdezhen ceramic industry. China Ceram. 2015, 51, 1–4. [Google Scholar]

- Zheng, S.; Xiong, X. Problems and countermeasures of resource accumulation area development of Jingdezhen ceramic industry. China Ceramics 2016, 52, 50–53. [Google Scholar]

- Lee, Y. Research on the Transformations of the Ceramics Manufacturing System in Jingdezhen-Focus on Recovery of the Handicrafts after 1950. J. Korean Soc. Ceram. Art 2015, 12, 189–204. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).