Static Behavior of a Retractable Suspen-Dome Structure

Abstract

:1. Introduction

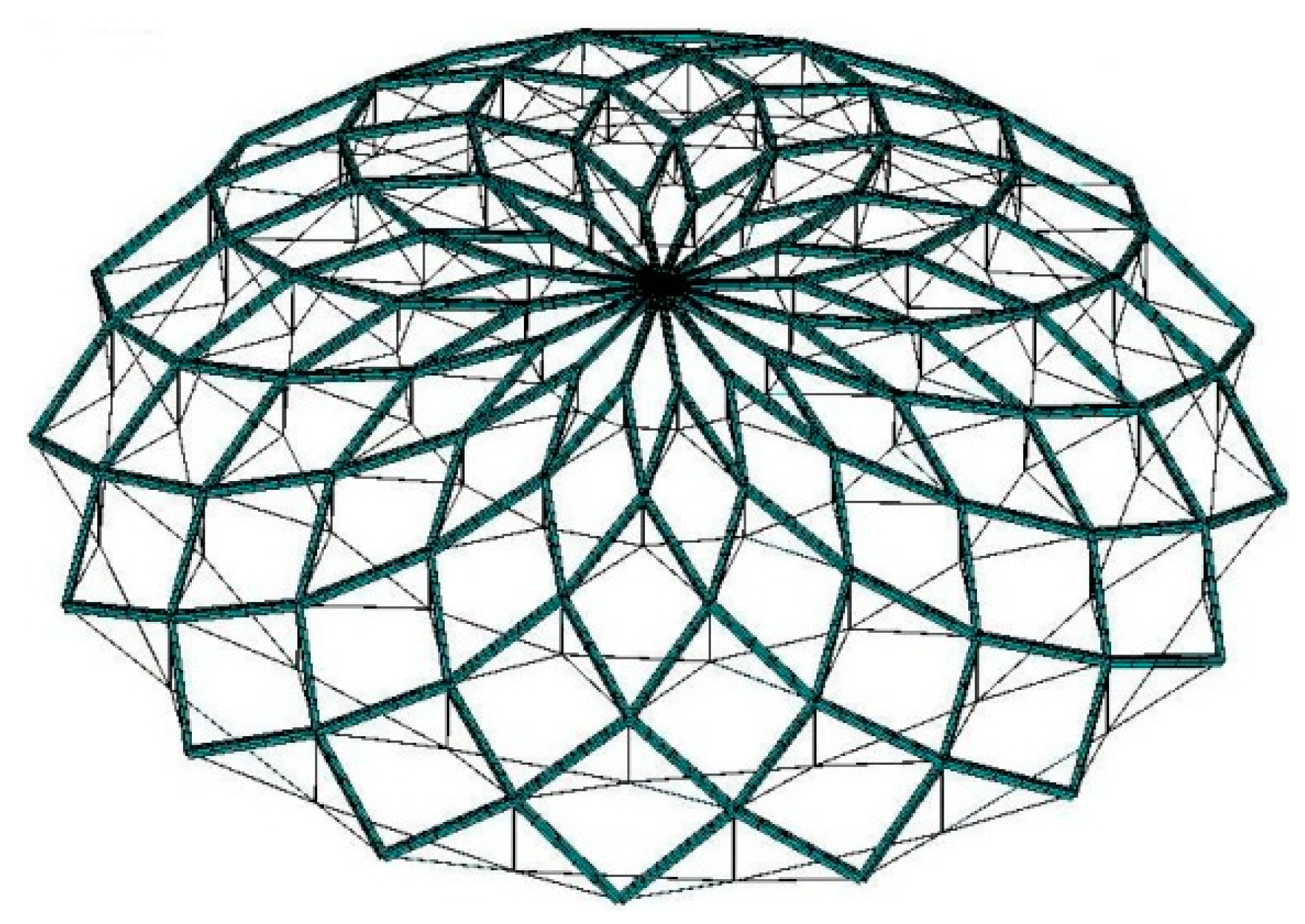

2. Structural System

3. Structural Behavior

3.1. Finite Element Model

3.2. Discussion on the Initial Prestress Level in the Cable-Strut System

- The relation between the hoop cable forces Nh and the radial cable forces Nr can be expressed as

- We can also obtain the relationship of internal forces of vertical struts Nv and radial cables Nr.

3.3. Influence of Cable-Strut System on the Static Behavior of Retractable Suspen-Domes

- Calculate the nodal displacement and element forces under the zero state;

- Calculate the nodal displacement and element forces under the initial state;

- Calculate the nodal displacement and element forces under the load state;

- Subtract results of the first two steps to obtain the structure response only under external loads (without considering self-weight and prestresses).

4. Parametric Analysis for the Retractable Suspen-Dome

4.1. Influence of the Rise-to-Span Ratio

4.2. Influence of the Cross-Section Area of Steel Beams

4.3. Influence of Cable Area

4.4. Influence of Cross-Section Area of Struts

4.5. Influence of Cable Prestress Levels

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ramalingam, R.; Jayachandran, S.A. Postbuckling behavior of flexibly connected single layer steel domes. J. Constr. Steel. Res. 2015, 114, 136–145. [Google Scholar] [CrossRef]

- Liu, H.B.; Chen, Z.H.; Xu, S.; Bu, Y.D. Structural behavior of aluminum reticulated shell structures considering semi-rigid and skin effect. Struct. Eng. Mech. 2015, 54, 121–133. [Google Scholar] [CrossRef]

- Choi, D.I.; Kim, D.J.; Park, K.G. Dynamic response of 100 m, 200 m, 300 m lattice domes with lrb seismic isolator. J. Civ. Eng. Arc. 2019, 13, 523–537. [Google Scholar]

- Zabojszcza, P.; Radoń, U. The impact of node location imperfections on the reliability of single-layer steel domes. Appl. Sci. 2019, 9, 2742. [Google Scholar] [CrossRef] [Green Version]

- Abedi, K.; Parke, G.A.R. Progressive collapse of single-layer braced domes. Int. J. Space Struct. 1996, 11, 291–306. [Google Scholar] [CrossRef]

- Hamid, Y.S. Progressive Collapse of Double Layer Space Trusses. Ph.D. Dissertation, University of Surrey, Guildford, UK, 2015. [Google Scholar]

- Li, H.; Taniguchi, Y. Load-carrying capacity of semi-rigid double-layer grid structures with initial crookedness of member. Eng. Struct. 2019, 184, 421–433. [Google Scholar] [CrossRef]

- Tatemichi, I.; Hatato, T.; Anma, Y.; Fujiwara, S. Vibration tests on a full-size suspen-dome structure. Int. J. Space Struct. 1997, 12, 217–224. [Google Scholar] [CrossRef]

- Kawaguchi, M.; Abe, M.; Tatemichi, I. Design, tests and realization of suspen-dome system. J. Int. Assoc. Shell Spat. Struct. 1999, 40, 179–192. [Google Scholar]

- Kitipornchai, S.; Kang, W.; Lam, H.F.; Albermani, F. Factors affecting the design and construction of Lamella suspen-dome systems. J. Constr. Steel. Res. 2005, 61, 764–785. [Google Scholar] [CrossRef]

- Kaveh, A.; Rezaei, M.; Shiravand, M.R. Optimal design of nonlinear large-scale suspen-dome using cascade optimization. Int. J. Space Struct. 2018, 33, 3–18. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.H.; Yan, R.Z.; Wang, X.D.; Liu, H.B.; Xiao, X. Experimental researches of a suspen-dome structure with rolling cable-strut joints. Adv. Steel Constr. 2015, 11, 15–38. [Google Scholar]

- Guo, J.M.; Yuan, X.F.; Li, Y.Y.; Dong, S.L. A simple approach for force finding analysis of suspended-domes based on the superposition principle. Adv. Struct. Eng. 2014, 17, 1681–1691. [Google Scholar] [CrossRef]

- Liu, H.B.; Han, Q.H.; Chen, Z.H.; Wang, X.; Yan, R.Z.; Zhao, B. Precision control method for prestressing construction of suspen-dome structures. Adv. Steel Constr. 2014, 10, 404–425. [Google Scholar]

- Meloni, M.; Cai, J.G.; Zhang, Q.; Lee, D.S.H.; Li, M.; Ma, R.J.; Parashkevov, T.E.; Feng, J. Engineering Origami: A comprehensive review of recent applications, design methods, and tools. Adv. Sci. 2021, 2000636. [Google Scholar] [CrossRef]

- Zhang, M.; Parke, G.; Tian, S.; Huang, Y.; Zhou, G. Criterion for judging seismic failure of suspen-domes based on strain energy density. Earthq. Struct. 2018, 15, 123–132. [Google Scholar]

- Xiang, P.; Wu, M.E.; Zhou, R.Q. Dynamic analysis of deployable structures using independent displacement modes based on Moore-Penrose generalized inverse matrix. Struct. Eng. Mech. 2015, 54, 1153–1174. [Google Scholar] [CrossRef]

- Kim, H.S.; Kang, J.W. Vibration control of smart TMD for retractable-roof spatial structure considering closed and open roof condition. Int. J. Steel Struct. 2017, 17, 1537–1548. [Google Scholar] [CrossRef]

- Mao, D.; Luo, Y. Analysis and design of a type of retractable roof structure. Adv. Struct. Eng. 2008, 11, 343–354. [Google Scholar] [CrossRef]

- Van Mele, T.; de Temmerman, N.; de Laet, L.; Mollaert, M. Scissor-hinged retractable membrane structures. Int. J. Struct. Eng. 2010, 1, 374–396. [Google Scholar] [CrossRef]

- De Temmerman, N.; Alegria Mira, L.; Vergauwen, A. Feasibility of the Universal Scissor Component (USC): Building a Full-scale Deployable Dome. J. Int. Assoc. Shell Spat. Struct. 2012, 53, 227–236. [Google Scholar]

- Arnouts, L.I.; Massart, T.J.; de Temmerman, N.; Berke, P.Z. Computational Design of Bistable Deployable Scissor Structures: Trends and Challenges. J. Int. Assoc. Shell Spat. Struct. 2019, 60, 19–34. [Google Scholar] [CrossRef]

- Hoberman, C. Radial Expansion Retraction Truss Structure. US Patent 5,024,031, 18 June 1991. [Google Scholar]

- Cai, J.G.; Xu, Y.X.; Feng, J. Kinematic analysis of Hoberman’s Linkages with the screw theory. Mech. Mach. Theory 2013, 63, 28–34. [Google Scholar] [CrossRef]

- Fenci, G.E.; Currie, N.G. Deployable structures classification: A review. Int. J. Space Struct. 2017, 32, 112–130. [Google Scholar] [CrossRef]

- You, Z.; Pellegrino, S. Foldable Bar Structures. Int. J. Solids Struct. 1997, 34, 1825–1847. [Google Scholar] [CrossRef]

- Teall, M.J. Deployable Roof Structures. Masters Dissertation, University of Cambridge, Cambridge, UK, 1996. [Google Scholar]

- Cai, J.G.; Jiang, C.; Deng, X.W.; Feng, J.; Xu, Y.X. Static analysis of a radially retractable hybrid grid shell in the closed position. Steel Compos. Struct. 2015, 18, 1391–1404. [Google Scholar] [CrossRef]

- Cai, J.G.; Liu, Y.Q.; Feng, J.; Tu, Y.M. Nonlinear stability analysis of a radially retractable suspen-dome. Adv. Steel Constr. 2017, 13, 117–131. [Google Scholar]

- Cai, J.G.; Zhang, Q.; Zhang, Y.Q.; Lee, D.S.H.; Feng, J. Structural evaluation of a foldable cable-strut structure for kinematic roofs. Steel Compos. Struct. 2018, 29, 669–680. [Google Scholar]

- Zhang, Q.; Pan, N.; Meloni, M.; Lu, D.; Cai, J.G.; Feng, J. Reliability analysis of radially retractable roofs with revolute joint clearances. Reliab. Eng. Syst. Saf. 2021, 208, 107401. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, X.; Zhang, Q.; Lee, D.S.-H.; Cai, J.; Feng, J. Static Behavior of a Retractable Suspen-Dome Structure. Symmetry 2021, 13, 1105. https://doi.org/10.3390/sym13071105

Shen X, Zhang Q, Lee DS-H, Cai J, Feng J. Static Behavior of a Retractable Suspen-Dome Structure. Symmetry. 2021; 13(7):1105. https://doi.org/10.3390/sym13071105

Chicago/Turabian StyleShen, Xuhong, Qian Zhang, Daniel Sang-Hoon Lee, Jianguo Cai, and Jian Feng. 2021. "Static Behavior of a Retractable Suspen-Dome Structure" Symmetry 13, no. 7: 1105. https://doi.org/10.3390/sym13071105