Heat Transfer on Micro and Nanostructured Rough Surfaces Synthesized by Plasma

Abstract

:1. Introduction

2. Rough Surfaces Synthesized by Plasma

2.1. The Plasma-Surface Interaction

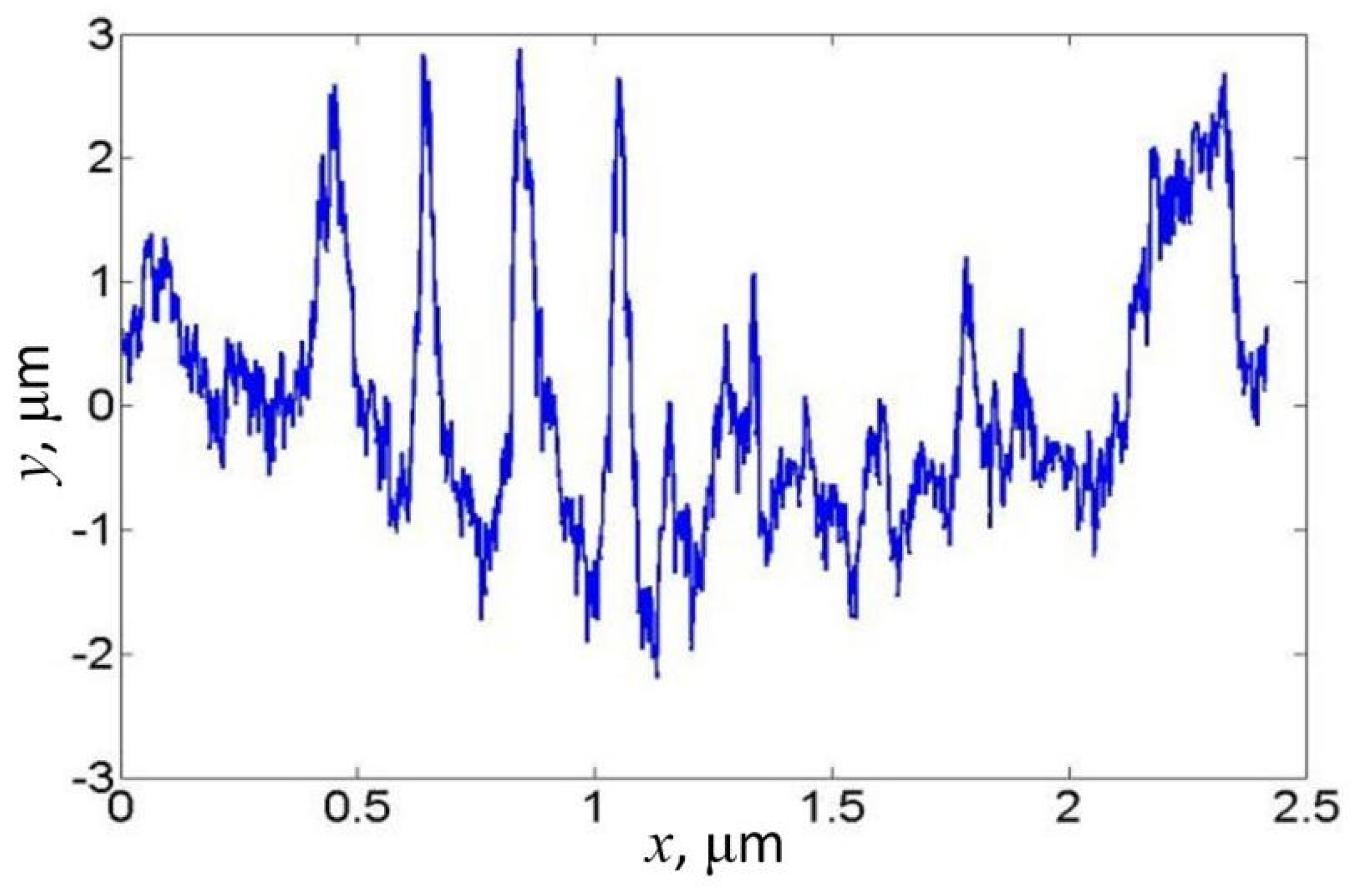

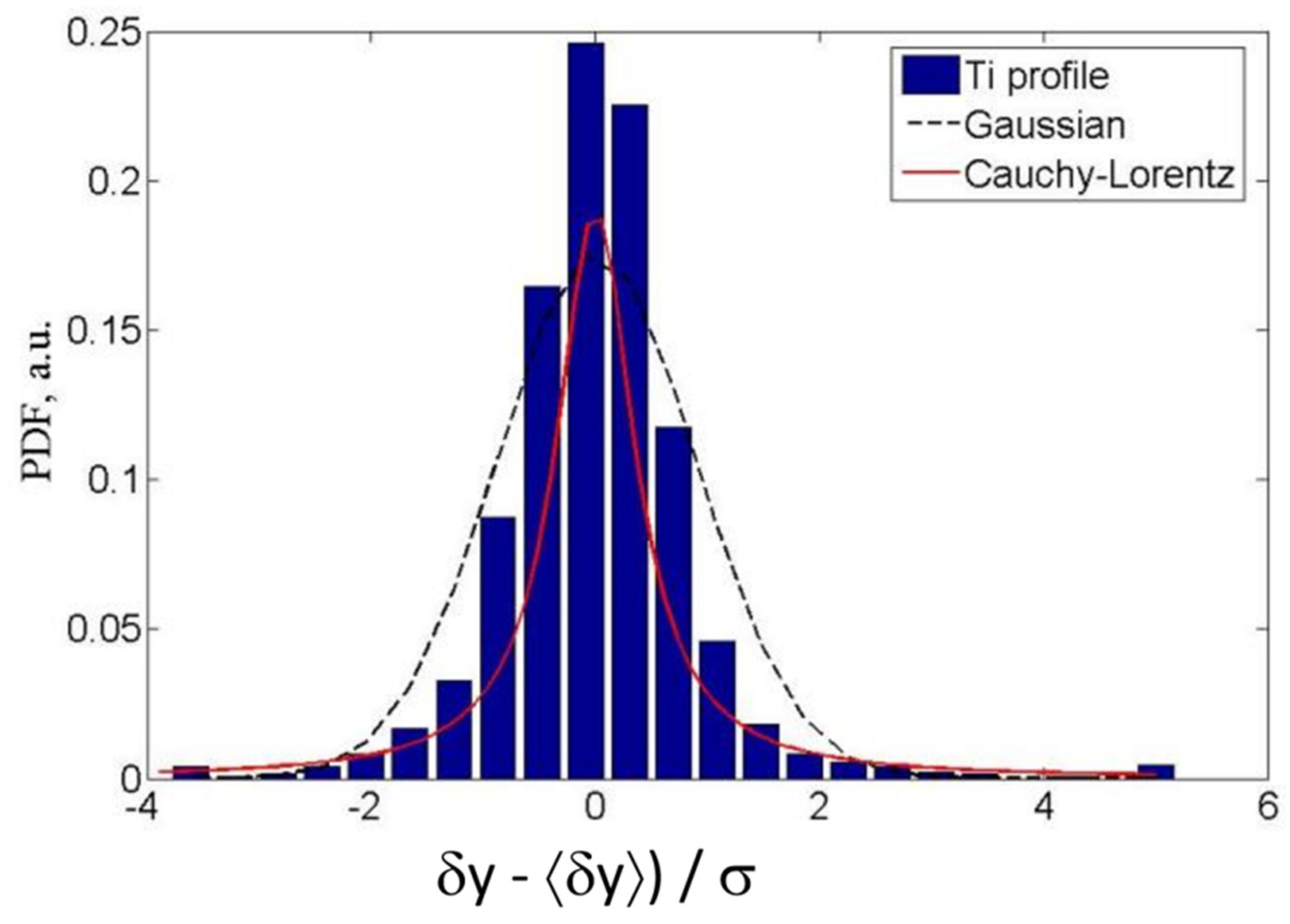

2.2. Stochastic Clustering of the Surface Roughness

2.3. The Micro–and Nanostructured Surfaces

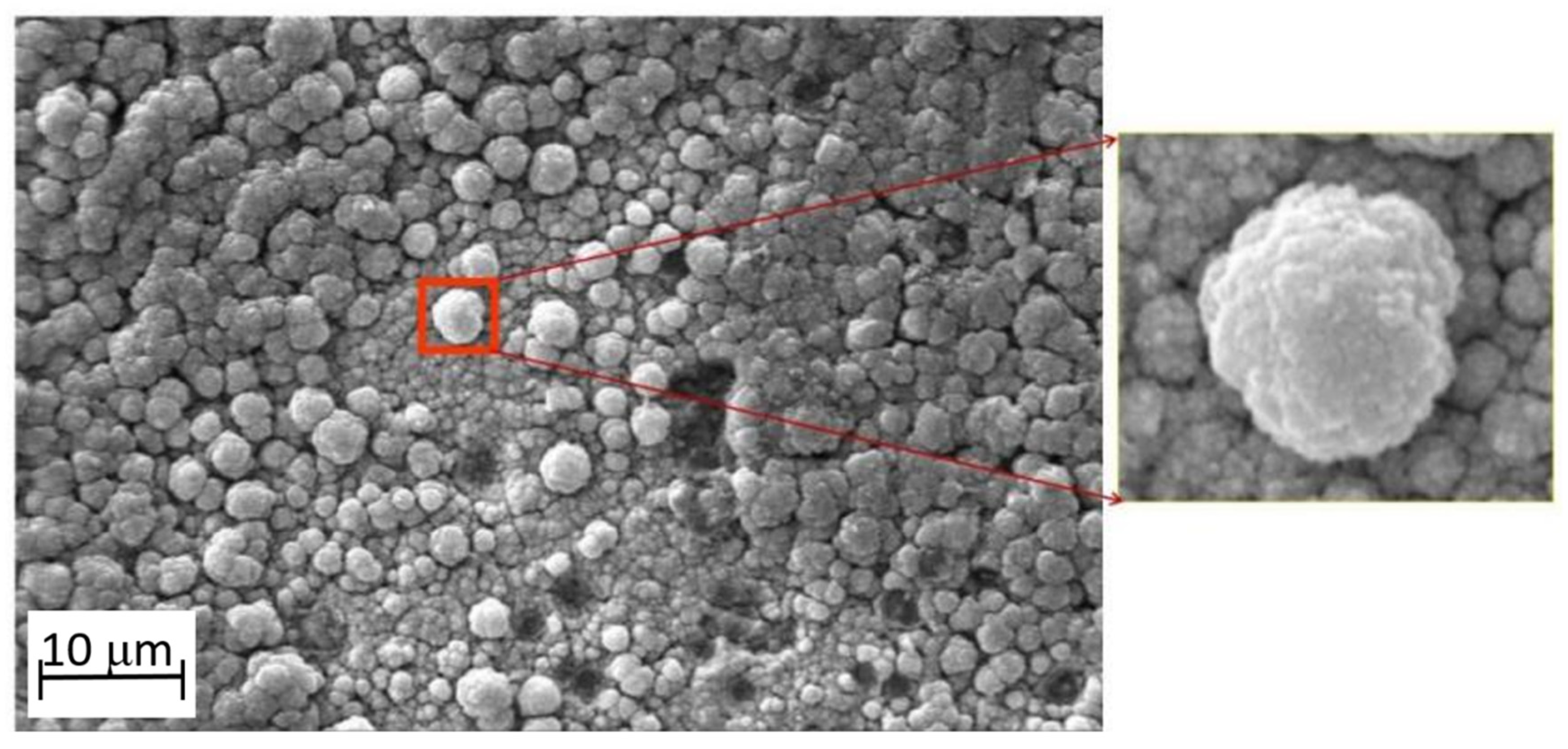

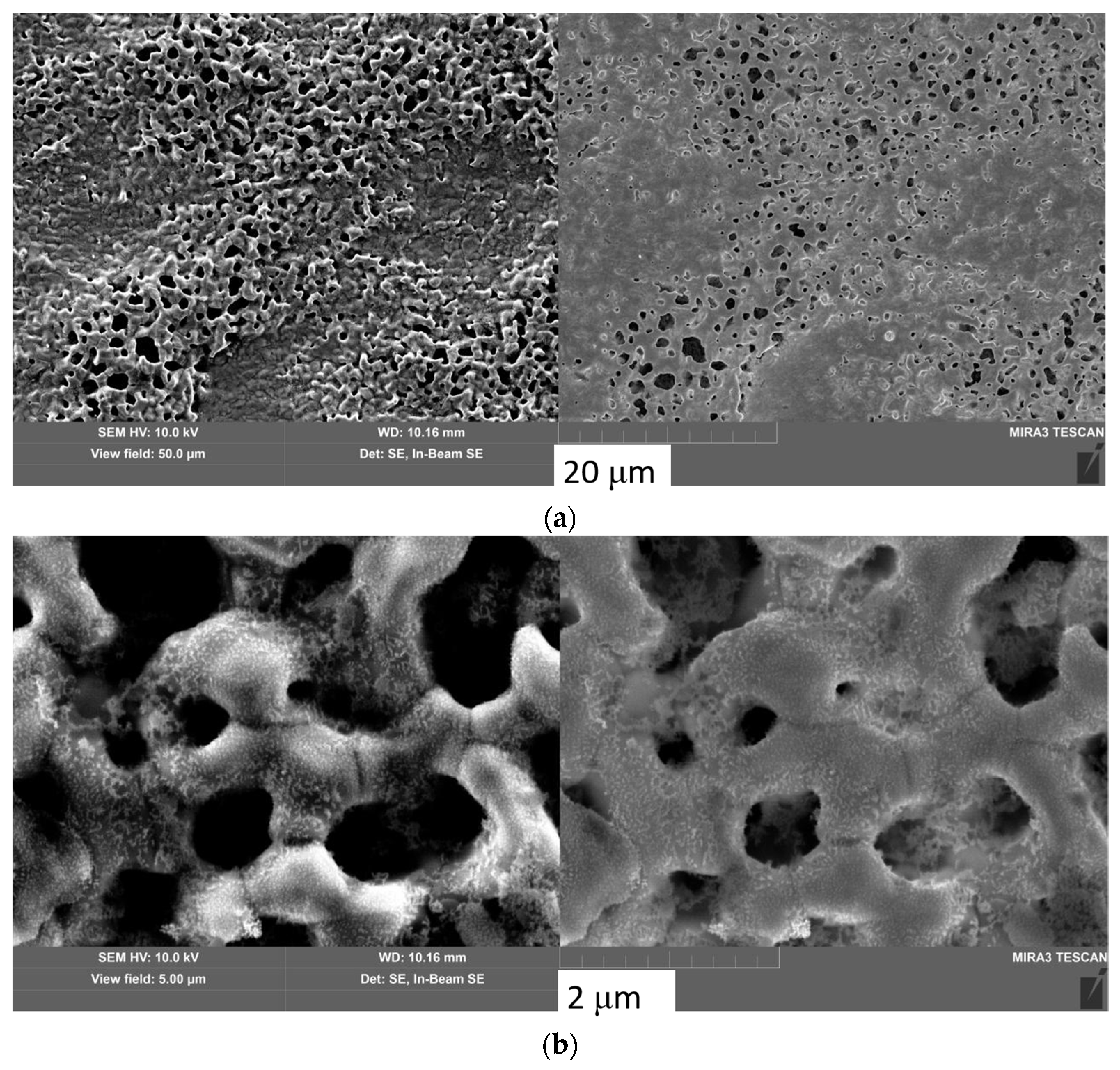

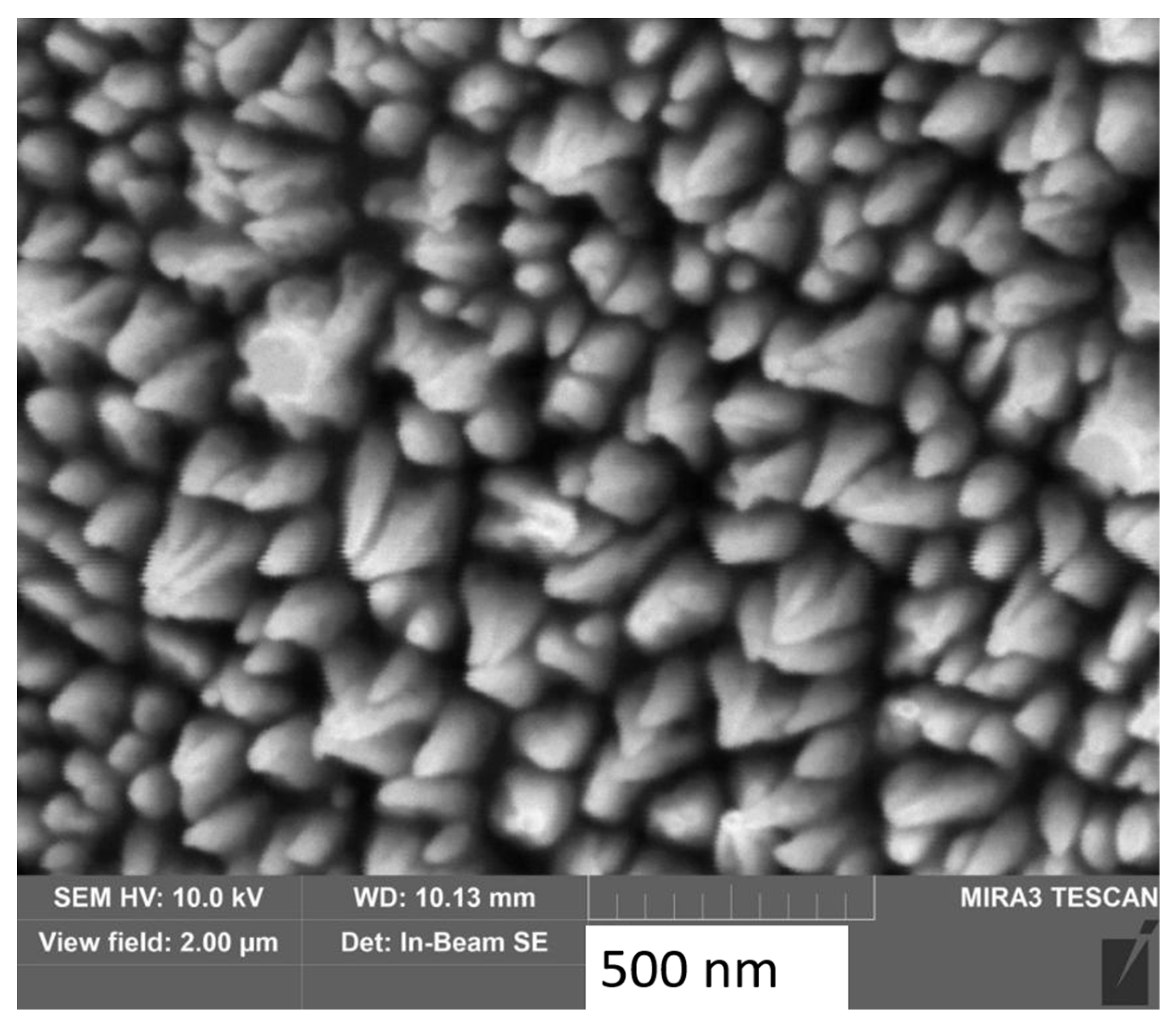

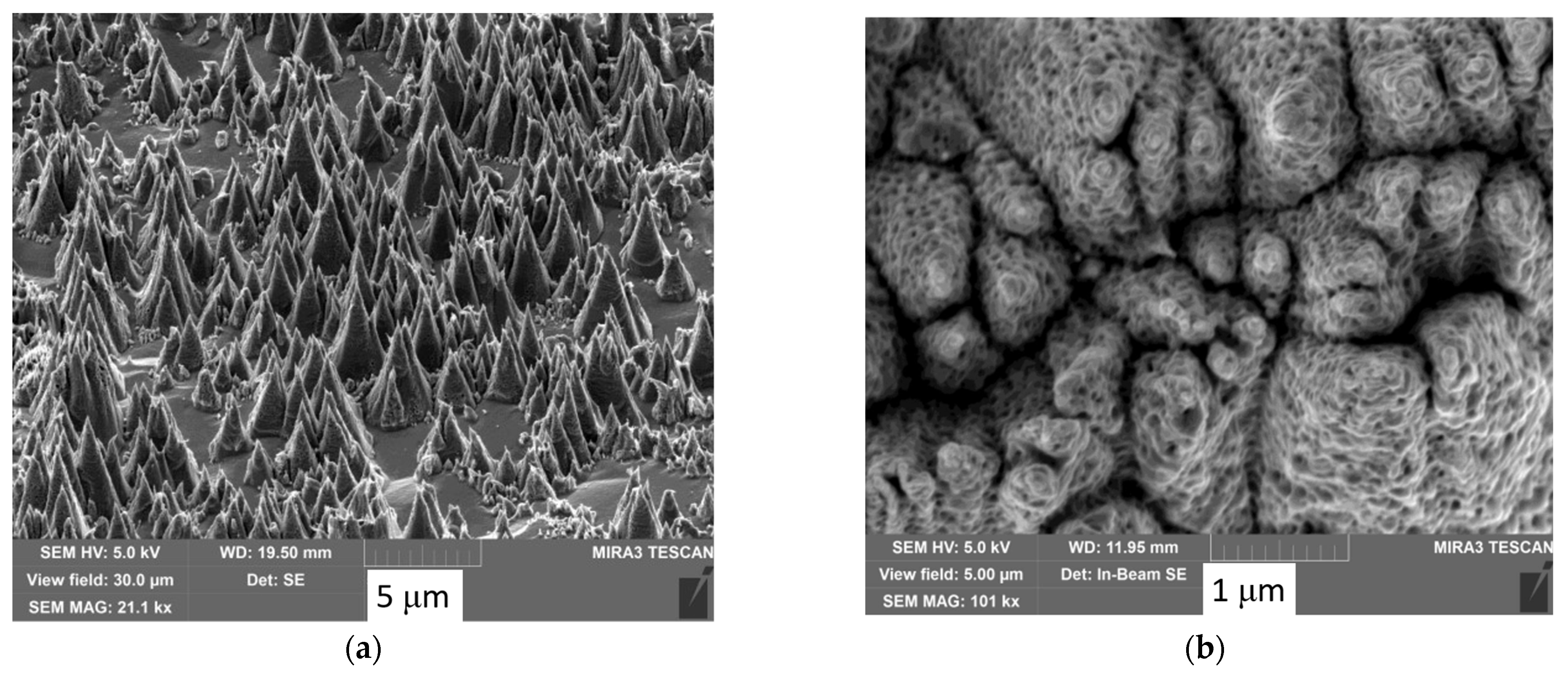

2.3.1. Cauliflower-like Surfaces

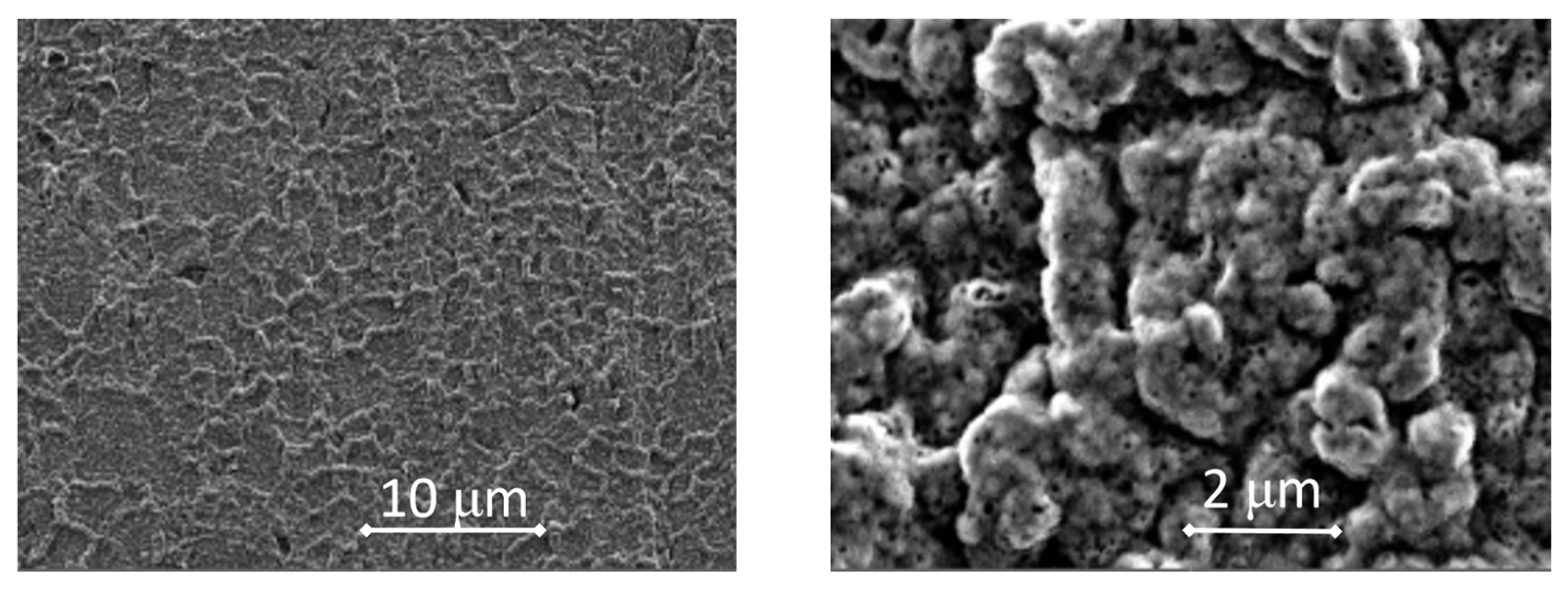

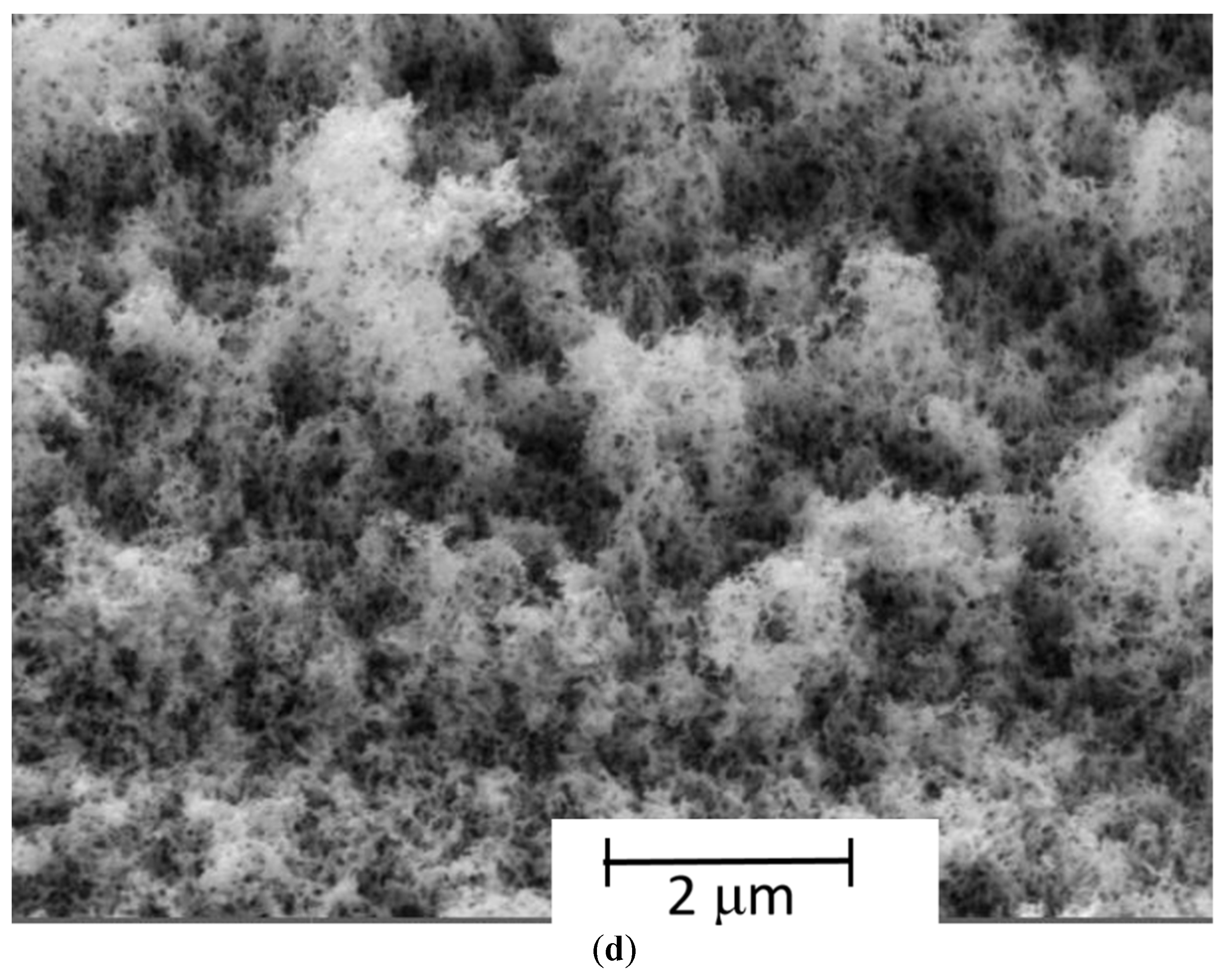

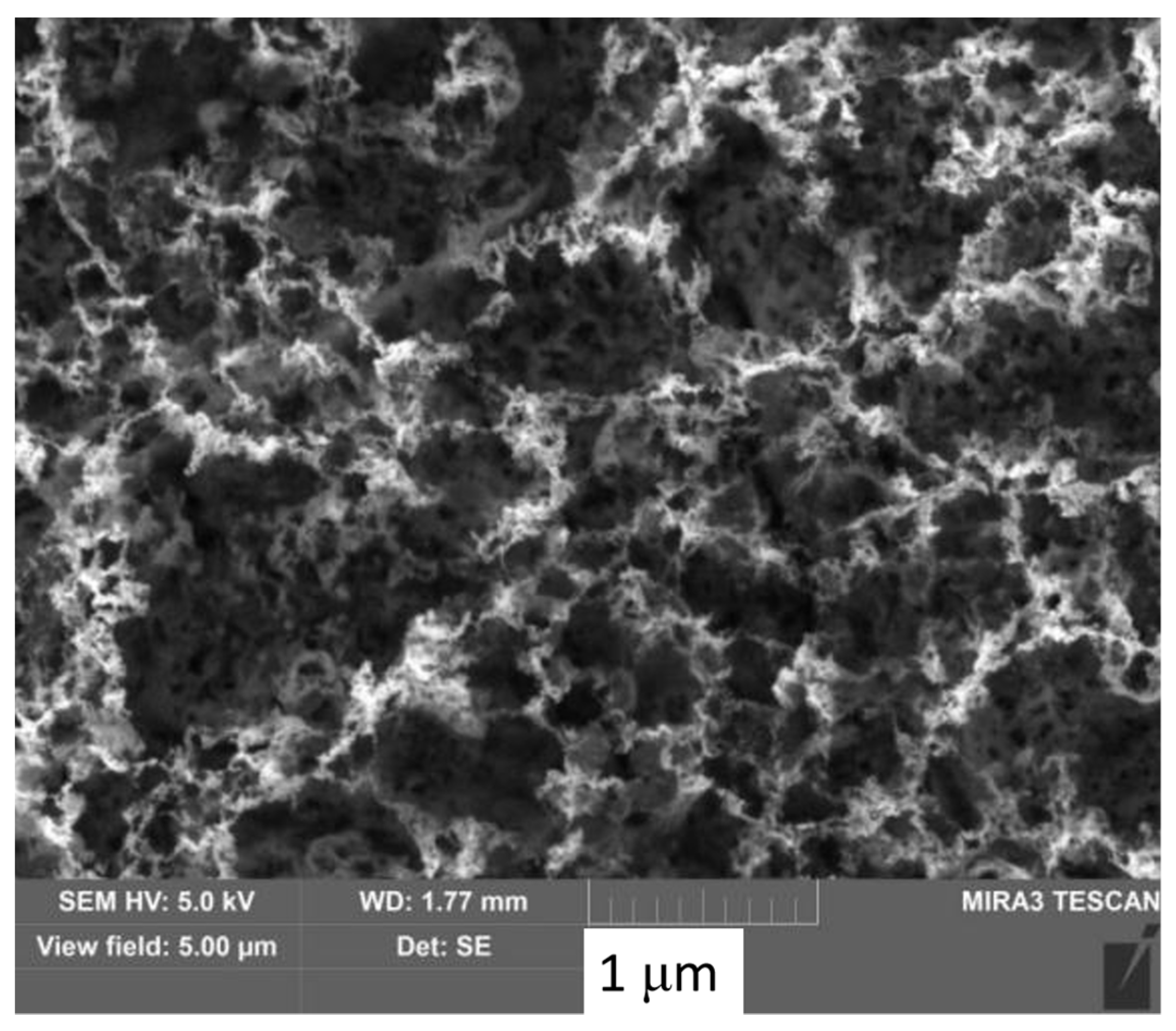

2.3.2. Fuzz-like Surfaces

2.3.3. High-Porous Micro-Structured Surface

2.3.4. Advantages of Practical Applications

3. Heat Transfer on Surfaces Synthesized by Plasma

3.1. Methods for Enchantment Boiling Heat Transfer

- (1)

- influence of internal mechanisms (increase in evaporation centers, increase in the inflow of liquid into the evaporation zone of the microlayer, regulation of wettability, etc.)

- (2)

- increase/development of the heat exchange surface area;

- (3)

- creation of suppression of the least efficient processes during boiling, which ensures the removal of steam from the wall (including boiling in a highly subcooled liquid, alternation of zones with different wettability, etc.).

- Method of nanoscale surface modification, such as coating a substrate with metal nanoparticles, metal oxide, ceramics, carbon-based nanoparticles (carbon nanotubes, graphene), and nanowires;

- Surface modification at the microscale, such as the creation of microgrooves, micropin ribs, deposition of sintered particles, microgrid structure, microchannels of various shapes, and microcavities;

- Metals (Cu, Al, Zn, bronze, Mo, Si, gold), Metal-oxide (Al2O3, TiO2, ZrO2, CuO, BiO2, Fe2O3, Fe3O4, SiO2, ZnO), composite (Cu-Al2O3, GO–Cu, Cu-TiO2), carbon nanomaterial (graphene, diamond, single-walled CNT, multi-walled CNT SiC), nanowires (copper, silicon, TiO2);

- Various test heaters such as stainless steel, copper, copper alloy, aluminum, aluminum alloy, silicon, glass, titanium, bronze, zirconium, zirconium alloy, nickel wire, Ni-Cr wire, Pt wire, and Ti wire have been used;

- Deposition methods such as CVD, ECD, electron beam PVD, electron beam evaporator, dry or chemical etching, atomic layer deposition, lithography, UV radiation, sputtering, pulse laser deposition, nanofluid boiling, free particles, particle sintering, spray coating, spin coating, epoxy binding, dipping and dripping, thermal annealing, sonification, hummer technique were used to deposit on test surface metal, metal oxide, composite and carbon nanomaterials;

- Electric discharge machining (EDM), mechanic machining, wire EDM laser machining, end milling, rolling, polishing, selective laser melting, sintering, orthogonal Ploughing/Extrusion, wire cutting, anodization, photolithography, dry etching, chemical etching was used as methods to fabricate the microgrooves, pin-fin array, and tunnel structured surface.

- -

- the existence of a multiscale structure of the modified surface, combining nano, micro, and meso “roughness”;

- -

- the porosity of the structure, providing the action of capillary forces;

- -

- application of modification technologies that provide zones with contrasting physical and chemical properties (wettability, thermal conductivity).

3.2. Modification of the Heat Transfer Surface by Plasma

3.3. Discussion and Advantages of Practical Applications

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Budaev, V.P. Scale Symmetry of Stochastic Surface Clustering under Plasma Influence in Fusion Devices. Symmetry 2021, 13, 796. [Google Scholar] [CrossRef]

- Budaev, V.P. Stochastic clustering of material surface under high-heat plasma load. Phys. Lett. A 2017, 381, 3706–3713. [Google Scholar] [CrossRef]

- Budaev, V.P.; Grashin, S.A.; Karpov, A.V.; Kraevskii, S.V.; Khimchenko, L.N. Long-range correlations in the structure of fractal films. JETP Lett. 2012, 95, 78–84. [Google Scholar] [CrossRef]

- Kadomtsev, B.B. Tokamak Plasma: A Complex Physical System; IOP Publishing: Bristol, UK; Philadelphia, PA, USA, 1992. [Google Scholar]

- Budaev, V.P.; Savin, S.P.; Zelenyi, L.M. Investigation of intermittency and generalized self-similarity of turbulent boundary layers in laboratory and magnetospheric plasmas: Towards a quantitative definition of plasma transport features. Phys.-Uspekhi 2011, 54, 875. [Google Scholar] [CrossRef] [Green Version]

- Budaev, V.P.; Zelenyi, L.M.; Savin, S.P. Generalized Self-Similarity of Intermittent Plasma Turbulence in Space and Laboratory Plasmas. J. Plasma Phys. 2015, 81, 395810602. [Google Scholar] [CrossRef] [Green Version]

- Pitts, R.; Carpentier, S.; Escourbiac, F.; Hirai, T.; Komarov, V.; Kukushkin, A.; Lisgo, S.; Loarte, A.; Merola, M.; Mitteau, R.; et al. Physics basis and design of the ITER plasma-facing components. J. Nucl. Mater. 2011, 415, S957–S964. [Google Scholar] [CrossRef]

- Federici, G.; Skinner, C.; Brooks, J.; Coad, J.; Grisolia, C.; Haasz, A.; Hassanein, A.; Philipps, V.; Pitcher, C.; Roth, J.; et al. Plasma-material interactions in current tokamaks and their implications for next step fusion reactors. Nucl. Fusion 2001, 41, 1967–2137. [Google Scholar] [CrossRef]

- Budaev, V.P. Results of high heat flux tests of tungsten divertor targets under plasma heat loads expected in ITER and tokamaks (review). Phys. At. Nucl. 2016, 79, 1137–1162. [Google Scholar] [CrossRef]

- Budaev, V.P.; Takamura, S.; Ohno, N.; Masuzaki, S. Superdiffusion and multifractal statistics of edge plasma turbulence in fusion devices. Nucl. Fusion 2006, 46, S181–S191. [Google Scholar] [CrossRef]

- Budaev, V.P.; Kikuchi, Y.; Uesugi, Y.; Takamura, S. Effect of rotating helical magnetic field on the turbulence fractal structure and transport in the tokamak edge plasma. Nucl. Fusion 2004, 44, S108–S117. [Google Scholar] [CrossRef]

- Moyer, R.A.; Lehmer, R.D.; Evans, T.E.; Conn, R.W.; Schmitz, L. Nonlinear analysis of turbulence across the L to H transition. Plasma Phys. Control. Fusion 1996, 38, 1273–1278. [Google Scholar] [CrossRef]

- Budaev, V.P.; Savin, S.; Zelenyi, L.; Ohno, N.; Takamura, S.; Amata, E. Intermittency and extended self-similarity in space and fusion plasma: Boundary effects. Plasma Phys. Control. Fusion 2008, 50, 074014. [Google Scholar] [CrossRef]

- Budaev, V.P. Generalized Self-Similarity of Edge Plasma Turbulence in Fusion Devices. Contrib. Plasma Phys. 2010, 50, 218–227. [Google Scholar] [CrossRef]

- Muzy, J.F.; Delour, J.; Bacry, E. Modelling fluctuations of financial time series: From cascade process to stochastic volatility model. Eur. Phys. J. B 2000, 17, 537–548. [Google Scholar] [CrossRef] [Green Version]

- Barabasi, A.L.; Stanley, H.E. Fractal Concepts in Surface Growth; Cambridge University Press: Cambridge, UK, 1995. [Google Scholar]

- Kardar, M.; Parisi, G.; Zhang, Y.-C. Dynamic Scaling of Growing Interfaces. Phys. Rev. Lett. 1986, 56, 889–892. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Y.-C. Non-universal roughening of kinetic self-affine interfaces. J. Phys. 1990, 51, 2129–2134. [Google Scholar] [CrossRef]

- Smoluchowski, M.V. Versuch einer mathematischen Theorie der Koagulationskinetik kolloider Lösungen. Z. Phys. Chem. 1918, 92, 129–168. [Google Scholar] [CrossRef] [Green Version]

- Voloshchuk, V.M. Kinetic Theory of Coagulation; Gidrometeoizdat: Leningrad, Russia, 1984. [Google Scholar]

- Kolmogorov, A.N. The local structure of turbulence in incompressible viscous fluid for very large Reynolds number. Dokl. Akad. Nauk. SSSR 1941, 30, 299–303. [Google Scholar]

- Zakharov, V.E.; Filonenko, N.N. Weak turbulence of capillary waves. J. Appl. Mech. Tech. Phys. 1971, 8, 37–40. [Google Scholar] [CrossRef]

- Zakharov, V.E.; Filonenko, N.N. Energy spectrum for stochastic oscillations of the surface of a liquid. Sov. Phys. Dokl. 1967, 11, 881–884. [Google Scholar]

- Ma, D.; Stoica, A.D.; Wang, X.-L. Power-law scaling and fractal nature of medium-range order in metallic glasses. Nat. Mater. 2009, 8, 30–34. [Google Scholar] [CrossRef] [PubMed]

- Fratini, M.; Poccia, N.; Ricci, A.; Campi, G.; Burghammer, M.; Aeppli, G.; Bianconi, A. Scale-free structural organization of oxygen interstitials in La2CuO4+y. Nature 2010, 466, 841–844. [Google Scholar] [CrossRef] [PubMed]

- Brezinsek, S.; Kirschner, A.; Mayer, M.; Baron-Wiechec, A.; Borodkina, I.; Borodin, D.; Coffey, I.; Coenen, J.; Harder, N.D.; Eksaeva, A.; et al. Erosion, screening, and migration of tungsten in the JET divertor. Nucl. Fusion 2019, 59, 096035. [Google Scholar] [CrossRef] [Green Version]

- Masuzaki, S.; Tokitani, M.; Otsuka, T.; Oya, Y.; Hatano, Y.; Miyamoto, M.; Sakamoto, R.; Ashikawa, N.; Sakurada, S.; Uemura, Y.; et al. Analyses of microstructure, composition and retention of hydrogen isotopes in divertor tiles of JET with the ITER-like wall. Phys. Scr. 2017, T170, 014031. [Google Scholar] [CrossRef]

- De Temmerman, G.; Hirai, T.; Pitts, R.A. The influence of plasma-surface interaction on the performance of tungsten at the ITER divertor vertical targets. Plasma Phys. Control. Fusion 2018, 60, 044018. [Google Scholar] [CrossRef]

- Grashin, S.; Arkhipov, I.; Budaev, V.P.; Karpov, A.; Klyuchnikov, L.; Khimchenko, L.; Melnikov, A.; Sarychev, D.; Sergeev, N.; Zemtsov, I. ITER-grade tungsten limiters damage under high turbulent heat flux in the T-10 tokamak. Fusion Eng. Des. 2019, 146, 2100–2104. [Google Scholar] [CrossRef]

- Ueda, Y.; Coenen, J.; De Temmerman, G.; Doerner, R.; Linke, J.; Philipps, V.; Tsitrone, E. Research status and issues of tungsten plasma facing materials for ITER and beyond. Fusion Eng. Des. 2014, 89, 901–906. [Google Scholar] [CrossRef]

- Budaev, V.P.; Khimchenko, L.N. Fractal growth of deposited films in tokamaks. Phys. A Stat. Mech. Its Appl. 2007, 382, 359–377. [Google Scholar] [CrossRef]

- Budaev, V.P.; Khimchenko, L.N. Fractal structure of films deposited in a tokamak. J. Exp. Theor. Phys. 2007, 104, 629–643. [Google Scholar] [CrossRef]

- Hirai, T.; Escourbiac, F.; Barabash, V.; Durocher, A.; Fedosov, A.; Ferrand, L.; Jokinen, T.; Komarov, V.; Merola, M.; Carpentier-Chouchana, S.; et al. Status of technology R&D for the ITER tungsten divertor monoblock. J. Nucl. Mater. 2015, 463, 1248–1251. [Google Scholar] [CrossRef]

- Zhitlukhin, A.; Klimov, N.; Landman, I.; Linke, J.; Loarte, A.; Merola, M.; Podkovyrov, V.; Federici, G.; Bazylev, B.; Pestchanyi, S.; et al. Effects of ELMs on ITER divertor armour materials. J. Nucl. Mater. 2007, 363–365, 301–307. [Google Scholar] [CrossRef]

- De Temmerman, G.; van den Berg, M.; Scholten, J.; Lof, A.; van der Meiden, H.; van Eck, H.; Morgan, T.; de Kruijf, T.; van Emmichoven, P.Z.; Zielinski, J. High heat flux capabilities of the Magnum-PSI linear plasma device. Fusion Eng. Des. 2013, 88, 483–487. [Google Scholar] [CrossRef]

- Kajita, S.; Kawaguchi, S.; Ohno, N.; Yoshida, N. Enhanced growth of large-scale nanostructures with metallic ion precipitation in helium plasmas. Sci. Rep. 2018, 8, 56. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kajita, S.; Tanaka, H.; Ohno, N. Tailoring of fuzzy nanostructures on porous tungsten skeleton by helium plasma irradiation. Jpn. J. Appl. Phys. 2017, 56, 030303. [Google Scholar] [CrossRef]

- Budaev, V.P.; Fedorovich, S.D.; Martynenko, Y.V.; Lukashevsky, M.V.; Gubkin, M.K.; Lazukin, A.V.; Karpov, A.V.; Shestakov, E.A. The plasma device for the high-heat plasma testing of refractory metals and inventing of new highly porous materials. J. Phys. Conf. Ser. 2017, 891, 012304. [Google Scholar] [CrossRef]

- Budaev, V.P.; Fedorovich, S.; Lubenchenko, A.; Karpov, A.; Belova, N.; Gubkin, M. Spectroscopic characterization of composite lithium materials irradiated with high-temperature plasma. Heliyon 2020, 6, e05510. [Google Scholar] [CrossRef]

- Budaev, V.P.; Fedorovich, S.D.; Martynenko, Y.V.; Egorikhina, M.N.; Karpov, A.V.; Lukashevsky, M.V.; Gubkin, M.K.; Budaeva, M.V.; Lazukin, A.V.; Aleynik, D.Y.; et al. Plasma technology for creating highly porous titanium materials for biomedical applications. In Proceedings of the XXIV Conference “Plasma-Surface Interaction”, Moscow, Russia, 4–5 January 2021; NRU MEPhI: Moscow, Russia, 2021; p. 63, ISBN 978-5-7262-2741-2. (In Russian). [Google Scholar]

- Muzy, J.F.; Bacry, E.; Arneodo, A. Wavelets and multifractal formalism for singular signals: Application to turbulence data. Phys. Rev. Lett. 1991, 67, 3515–3518. [Google Scholar] [CrossRef]

- Bacry, E.; Muzy, J.F.; Arnéodo, A. Singularity spectrum of fractal signals from wavelet analysis: Exact results. J. Stat. Phys. 1993, 70, 635–674. [Google Scholar] [CrossRef] [Green Version]

- Takamura, S. Initial Stage of Fiber-Form Nanostructure Growth on Refractory Metal Surfaces with Helium Plasma Irradiation. Plasma Fusion Res. 2014, 9, 1302007. [Google Scholar] [CrossRef] [Green Version]

- Nishijima, D.; Ye, M.; Ohno, N.; Takamura, S. Incident ion energy dependence of bubble formation on tungsten surface with low energy and high flux helium plasma irradiation. J. Nucl. Mater. 2003, 313–316, 97–101. [Google Scholar] [CrossRef]

- Nishijima, D.; Ye, M.; Ohno, N.; Takamura, S. Formation mechanism of bubbles and holes on tungsten surface with low-energy and high-flux helium plasma irradiation in NAGDIS-II. J. Nucl. Mater. 2004, 329–333, 1029–1033. [Google Scholar] [CrossRef]

- Takamura, S.; Ohno, N.; Nishijima, D.; Kajita, S. Formation of Nanostructured Tungsten with Arborescent Shape due to Helium Plasma Irradiation. Plasma Fusion Res. 2006, 1, 051. [Google Scholar] [CrossRef]

- Budaev, V.P.; Fedorovich, S.; Dedov, A.; Martynenko, Y.; Frick, P.; Karpov, A.; Van Oost, G.; Lyublinsky, I.; Vertkov, A.; Lukashevsky, M.; et al. High-heat flux tests of fusion materials with stationary plasma in the PLM device. Fusion Eng. Des. 2020, 155, 111694. [Google Scholar] [CrossRef]

- Budaev, V.P.; Fedorovich, S.; Dedov, A.; Karpov, A.; Komov, A.; Martynenko, Y.; Giniyatulin, R.; Makhankov, A.; Litunovsky, N.; Sliva, A.; et al. High-heat flux tests of tungsten divertor mock-ups with steady-state plasma and e-beam. Nucl. Mater. Energy 2020, 25, 100816. [Google Scholar] [CrossRef]

- De Temmerman, G.; Bystrov, K.; Doerner, R.; Marot, L.; Wright, G.; Woller, K.; Whyte, D.; Zielinski, J. Helium effects on tungsten under fusion-relevant plasma loading conditions. J. Nucl. Mater. 2013, 438, S78–S83. [Google Scholar] [CrossRef] [Green Version]

- Baldwin, M.; Doerner, R. Helium induced nanoscopic morphology on tungsten under fusion relevant plasma conditions. Nucl. Fusion 2008, 48, 035001. [Google Scholar] [CrossRef]

- Baldwin, M.J.; Doerner, R.P. Formation of helium induced nanostructure ‘fuzz’ on various tungsten grades. J. Nucl. Mater. 2010, 404, 165–173. [Google Scholar] [CrossRef]

- Wright, G.; Brunner, D.; Baldwin, M.; Doerner, R.; LaBombard, B.; Lipschultz, B.; Terry, J.; Whyte, D. Tungsten nano-tendril growth in the Alcator C-Mod divertor. Nucl. Fusion 2012, 52, 042003. [Google Scholar] [CrossRef]

- Miyamoto, M.; Mikami, S.; Nagashima, H.; Iijima, N.; Nishijima, D.; Doerner, R.; Yoshida, N.; Watanabe, H.; Ueda, Y.; Sagara, A. Systematic investigation of the formation behavior of helium bubbles in tungsten. J. Nucl. Mater. 2015, 463, 333–336. [Google Scholar] [CrossRef]

- Ueda, Y.; Peng, H.; Lee, H.; Ohno, N.; Kajita, S.; Yoshida, N.; Doerner, R.; De Temmerman, G.; Alimov, V.; Wright, G. Helium effects on tungsten surface morphology and deuterium retention. J. Nucl. Mater. 2013, 442, S267–S272. [Google Scholar] [CrossRef]

- Kajita, S.; Nojima, T.; Okuyama, T.; Yamamoto, Y.; Yoshida, N.; Ohno, N. Helium plasma–induced straight nanofiber growth on HCP metals. Acta Mater. 2019, 181, 342–351. [Google Scholar] [CrossRef]

- Martynenko, Y.V.; Nagel’, M.Y. Model of fuzz formation on a tungsten surface. Plasma Phys. Rep. 2012, 38, 996–999. [Google Scholar] [CrossRef]

- Kajita, S.; Ishida, T.; Ohno, N.; Hwangbo, D.; Yoshida, T. Fuzzy nanostructure growth on Ta/Fe by He plasma irradiation. Sci. Rep. 2016, 6, 30380. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kajita, S.; Kitaoka, D.; Ohno, N.; Yoshihara, R.; Yoshida, N.; Yoshida, T. Surface modification of titanium using He plasma. Appl. Surf. Sci. 2014, 303, 438–445. [Google Scholar] [CrossRef]

- Kajita, S.; Yoshida, N.; Ohno, N. Tungsten fuzz: Deposition effects and influence to fusion devices. Nucl. Mater. Energy 2020, 25, 100828. [Google Scholar] [CrossRef]

- Takamura, S.; Miyamoto, T.; Ohno, N. Power Transmission Factor for Tungsten Target w/wo Fiber-Form Nanostructure in He Plasmas with Hot Electron Component Using Compact Plasma Device AIT-PID. Fusion Sci. Technol. 2013, 63, 225–228. [Google Scholar] [CrossRef]

- Takamura, S.; Miyamoto, T.; Ohno, N. Deepening of Floating Potential for Tungsten Target Plate on the way to Nanostructure Formation. Plasma Fusion Res. 2010, 5, 039. [Google Scholar] [CrossRef] [Green Version]

- Patino, M.; Raitses, Y.; Wirz, R. Secondary electron emission from plasma-generated nanostructured tungsten fuzz. Appl. Phys. Lett. 2016, 109, 201602. [Google Scholar] [CrossRef] [Green Version]

- Hwangbo, D.; Kajita, S.; Ohno, N.; Sinelnikov, D. Field Emission from Metal Surfaces Irradiated with Helium Plasmas. IEEE Trans. Plasma Sci. 2017, 45, 2080–2086. [Google Scholar] [CrossRef]

- Kajita, S.; Yagi, T.; Kobayashi, K.; Tokitani, M.; Ohno, N. Measurement of heat diffusion across fuzzy tungsten layer. Results Phys. 2016, 6, 877–878. [Google Scholar] [CrossRef] [Green Version]

- Kajita, S.; Saeki, T.; Yoshida, N.; Ohno, N.; Iwamae, A. Nanostructured Black Metal: Novel Fabrication Method by Use of Self-Growing Helium Bubbles. Appl. Phys. Express 2010, 3, 085204. [Google Scholar] [CrossRef]

- Takamura, S.; Miyamoto, T.; Ohno, N. Effects of fibre-form nanostructures on particle emissions from a tungsten surface in plasmas. Nucl. Fusion 2012, 52, 123001. [Google Scholar] [CrossRef]

- Kajita, S.; Ohno, N.; Yokochi, T.; Yoshida, N.; Yoshihara, R.; Takamura, S.; Hatae, T. Optical properties of nanostructured tungsten in near infrared range. Plasma Phys. Control. Fusion 2012, 54, 105015. [Google Scholar] [CrossRef]

- Kajita, S.; Takamura, S.; Ohno, N. Prompt ignition of a unipolar arc on helium irradiated tungsten. Nucl. Fusion 2009, 49, 032002. [Google Scholar] [CrossRef]

- Tokitani, M.; Kajita, S.; Masuzaki, S.; Hirahata, Y.; Ohno, N.; Tanabe, T.; LHD Experiment Group. Exfoliation of the tungsten fibreform nanostructure by unipolar arcing in the LHD divertor plasma. Nucl. Fusion 2011, 51, 102001. [Google Scholar] [CrossRef]

- Matějíček, J.; Weinzettl, V.; Vilémová, M.; Morgan, T.W.; De Temmerman, G.; Dimitrova, M.; Cavalier, J.; Adámek, J.; Seidl, J.; Jäger, A. ELM-induced arcing on tungsten fuzz in the COMPASS divertor region. J. Nucl. Mater. 2017, 492, 204–212. [Google Scholar] [CrossRef]

- Budaev, V.P. Stochastic Clustering Surfaces of Refractory Materials When Exposed to Plasma-Beam Streams; LAP Lambert Academic Publishing: Saarbrucken, Germany, 2020; p. 152. (In Russian) [Google Scholar]

- Huang, L.-Y.; Huang, J.-F.; Lei, Y.; Qin, S.; Liu, J.-M. Porous Hybrid Materials Based on Mesotetrakis(Hydroxyphenyl) Porphyrins and TiO2 for Efficient Visible-Light-Driven Hydrogen Production. Catalysts 2020, 10, 656. [Google Scholar] [CrossRef]

- Chernyshev, A.A.; Nikitina, E.V. A Porous Tungsten Substrate for Catalytic Reduction of Hydrogen by Dealloying of a Tungsten–Rhenium Alloy in an Aqueous Solution of Hydrochloric Acid. Appl. Sci. 2022, 12, 1029. [Google Scholar] [CrossRef]

- Wang, X.-D.; Xu, Y.-F.; Rao, H.-S.; Xu, W.-J.; Chen, H.-Y.; Zhang, W.-X.; Kuang, D.-B.; Su, C.-Y. Novel porous molybdenum tungsten phosphide hybrid nanosheets on carbon cloth for efficient hydrogen evolution. Energy Environ. Sci. 2016, 9, 1468–1475. [Google Scholar] [CrossRef]

- Yadav, A.A.; Hunge, Y.M.; Kang, S.-W. Porous nanoplate-like tungsten trioxide/reduced graphene oxide catalyst for sonocatalytic degradation and photocatalytic hydrogen production. Surf. Interfaces 2021, 24, 101075. [Google Scholar] [CrossRef]

- Bentley, J.; Desai, S.; Bastakoti, B.P. Porous Tungsten Oxide: Recent Advances in Design, Synthesis, and Applications. Chem.–A Eur. J. 2021, 27, 9241–9252. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Wei, Y.; Yu, R. Multidimensional Tungsten Oxides for Efficient Solar Energy Conversion. Small Struct. 2021, 3, 2100130. [Google Scholar] [CrossRef]

- Tang, L.; Feng, Y.; Chen, W.; Zhang, Y.; Xi, X.; Gao, B.; Wang, J.; Wu, M. Morphology Controllable Fabrication of Tungsten Oxide for Enhanced Photocatalytic Performance. Catal. Surv. Asia 2021, 25, 334–345. [Google Scholar] [CrossRef]

- Bram, M.; Ebel, T.; Wolff, M.; Barbosa, A.P.C.; Tuncer, N. Applications of powder metallurgy in biomaterials. In Advances in Powder Metallurgy. Properties, Processing and Applications; Woodhead Publishing Series in Metals and Surface Engineering; Woodhead Publishing Limited: Cambridge, UK, 2013; pp. 520–554. [Google Scholar]

- Wang, R.; Ni, S.; Ma, L.; Li, M. Porous construction and surface modification of titanium-based materials for osteogenesis: A review. Front. Bioeng. Biotechnol. 2022, 10, 973297. [Google Scholar] [CrossRef]

- Dedov, A.V.; Khaziev, I.A.; Laharev, D.A.; Fedorovich, S.D. Study of Nucleate Pool Boiling Heat Transfer Enhancement on Surfaces Modified by Beam Technologies. Heat Transf. Eng. 2022, 43, 598–607. [Google Scholar] [CrossRef]

- Chu, K.-H.; Enright, R.; Wang, E.N. Structured surfaces for enhanced pool boiling heat transfer. Appl. Phys. Lett. 2012, 100, 241603. [Google Scholar] [CrossRef]

- Cooke, D.; Kandlikar, S.G. Pool Boiling Heat Transfer and Bubble Dynamics Over Plain and Enhanced Microchannels. J. Heat Transf. 2011, 133, 052902. [Google Scholar] [CrossRef]

- Rahman, M.M.; Ölçeroğlu, E.; McCarthy, M. Role of Wickability on the Critical Heat Flux of Structured Superhydrophilic Surfaces. Langmuir 2014, 30, 11225–11234. [Google Scholar] [CrossRef]

- Zou, A.; Maroo, S.C. Critical height of micro/nano structures for pool boiling heat transfer enhancement. Appl. Phys. Lett. 2013, 103, 221602. [Google Scholar] [CrossRef]

- Dhillon, N.S.; Buongiorno, J.; Varanasi, K.K. Critical heat flux maxima during boiling crisis on textured surfaces. Nat. Commun. 2015, 6, 8247. [Google Scholar] [CrossRef] [Green Version]

- Dedov, A.V. Peculiarities of boiling in subcooled flow. Therm. Eng. 2009, 56, 691–699. [Google Scholar] [CrossRef]

- Dedov, A.V. A Review of Modern Methods for Enhancing Nucleate Boiling Heat Transfer. Therm. Eng. 2019, 66, 881–915. [Google Scholar] [CrossRef]

- Singh, S.K.; Sharma, D. Review of pool and flow boiling heat transfer enhancement through surface modification. Int. J. Heat Mass Transf. 2021, 181, 122020. [Google Scholar] [CrossRef]

- Yuan, X.; Du, Y.; Su, J. Approaches and potentials for pool boiling enhancement with superhigh heat flux on responsive smart surfaces: A critical review. Renew. Sustain. Energy Rev. 2022, 156, 111974. [Google Scholar] [CrossRef]

- Nguyen, D.H.; Ahn, H.S. A comprehensive review on micro/nanoscale surface modification techniques for heat transfer enhancement in heat exchanger. Int. J. Heat Mass Transf. 2021, 178, 121601. [Google Scholar] [CrossRef]

- Devahdhanush, V.; Mudawar, I. Review of Critical Heat Flux (CHF) in Jet Impingement Boiling. Int. J. Heat Mass Transf. 2021, 169, 120893. [Google Scholar] [CrossRef]

- Liang, G.; Mudawar, I. Review of nanoscale boiling enhancement techniques and proposed systematic testing strategy to ensure cooling reliability and repeatability. Appl. Therm. Eng. 2021, 184, 115982. [Google Scholar] [CrossRef]

- Chen, J.; Ahmad, S.; Cai, J.; Liu, H.; Lau, K.T.; Zhao, J. Latest progress on nanotechnology aided boiling heat transfer enhancement: A review. Energy 2021, 215, 119114. [Google Scholar] [CrossRef]

- Basak, S.; Annapure, U.S. Recent trends in the application of cold plasma for the modification of plant proteins—A review. Future Foods 2022, 5, 100119. [Google Scholar] [CrossRef]

- Men, Y.-L.; Liu, P.; Meng, X.-Y.; Pan, Y.-X. Recent progresses in material fabrication and modification by cold plasma technique. FirePhysChem 2022, 2, 214–220. [Google Scholar] [CrossRef]

- He, J.; Wen, X.; Wu, L.; Chen, H.; Hu, J.; Hou, X. Dielectric barrier discharge plasma for nanomaterials: Fabrication, modification and analytical applications. TrAC Trends Anal. Chem. 2022, 156, 116715. [Google Scholar] [CrossRef]

- Subeshan, B.; Asmatulu, R. Corrosion mitigation of metals and alloys via superhydrophobic coatings with plasma surface and heat treatment processes. Eng. Fail. Anal. 2022, 139, 106437. [Google Scholar] [CrossRef]

- Gryta, M. Surface modification of polypropylene membrane by helium plasma treatment for membrane distillation. J. Membr. Sci. 2021, 628, 119265. [Google Scholar] [CrossRef]

- Kuzenov, V.; Ryzhkov, S. The Qualitative and Quantitative Study of Radiation Sources with a Model Configuration of the Electrode System. Symmetry 2021, 13, 927. [Google Scholar] [CrossRef]

- Wang, R.; Guo, J.; Muckleroy, E.A.; Antao, D.S. Robust silane self-assembled monolayer coatings on plasma-engineered copper surfaces promoting dropwise condensation. Int. J. Heat Mass Transf. 2022, 194, 123028. [Google Scholar] [CrossRef]

- Mohammadi, H.R.; Taghvaei, H.; Rabiee, A. Experimental study of pool boiling on hydrophilic and hydrophobic thin films deposited on copper surfaces using atmospheric cold plasma. Int. J. Therm. Sci. 2022, 175, 107474. [Google Scholar] [CrossRef]

- Surtaev, A.; Kuznetsov, D.; Serdyukov, V.; Pavlenko, A.; Kalita, V.; Komlev, D.; Ivannikov, A.; Radyuk, A. Structured capillary-porous coatings for enhancement of heat transfer at pool boiling. Appl. Therm. Eng. 2018, 133, 532–542. [Google Scholar] [CrossRef]

- Starodubtseva, I.; Kuznetsov, D.; Pavlenko, A. Experiments and modeling on cryogenic quenching enhancement by the structured capillary-porous coatings of surface. Int. J. Heat Mass Transf. 2021, 176, 121388. [Google Scholar] [CrossRef]

- Kim, S.J.; Zou, L.; Jones, B.G. An experimental study on sub-cooled flow boiling CHF of R134a at low pressure condition with atmospheric pressure (AP) plasma assisted surface modification. Int. J. Heat Mass Transf. 2015, 81, 362–372. [Google Scholar] [CrossRef]

- Fedorovich, S.D.; Dedov, A.V.; Khaziev, I.A. Creating heat exchange surfaces using laser, electronic, and plasma energy fluxes. High Temp. Mater. Process. 2021, 25, 81–93. [Google Scholar] [CrossRef]

- Surtaev, A.S.; Pavlenko, A.N.; Kuznetsov, D.V.; Kalita, V.I.; Komlev, D.I.; Ivannikov, A.Y.; Radyuk, A.A. Heat transfer and crisis phenomena at pool boiling of liquid nitrogen on the surfaces with capillary-porous coatings. Int. J. Heat Mass Transf. 2017, 108, 146–155. [Google Scholar] [CrossRef]

- Sun, Y.; Tang, Y.; Zhang, S.; Yuan, W.; Tang, H. A review on fabrication and pool boiling enhancement of three-dimensional complex structures. Renew. Sustain. Energy Rev. 2022, 162, 112437. [Google Scholar] [CrossRef]

- Chu, H.; Yu, X.; Jiang, H.; Wang, D.; Xu, N. Progress in enhanced pool boiling heat transfer on macro- and micro-structured surfaces. Int. J. Heat Mass Transf. 2022, 200, 123530. [Google Scholar] [CrossRef]

- Chu, H.; Xu, N.; Yu, X.; Jiang, H.; Ma, W.; Qiao, F. Review of surface modification in pool boiling application: Coating manufacturing process and heat transfer enhancement mechanism. Appl. Therm. Eng. 2022, 215, 119041. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dedov, A.V.; Budaev, V.P. Heat Transfer on Micro and Nanostructured Rough Surfaces Synthesized by Plasma. Symmetry 2022, 14, 2346. https://doi.org/10.3390/sym14112346

Dedov AV, Budaev VP. Heat Transfer on Micro and Nanostructured Rough Surfaces Synthesized by Plasma. Symmetry. 2022; 14(11):2346. https://doi.org/10.3390/sym14112346

Chicago/Turabian StyleDedov, Alexey Victorovich, and Viacheslav Petrovich Budaev. 2022. "Heat Transfer on Micro and Nanostructured Rough Surfaces Synthesized by Plasma" Symmetry 14, no. 11: 2346. https://doi.org/10.3390/sym14112346

APA StyleDedov, A. V., & Budaev, V. P. (2022). Heat Transfer on Micro and Nanostructured Rough Surfaces Synthesized by Plasma. Symmetry, 14(11), 2346. https://doi.org/10.3390/sym14112346