Magneto-Nanofluid Flow via Mixed Convection Inside E-Shaped Square Chamber

Abstract

:1. Introduction

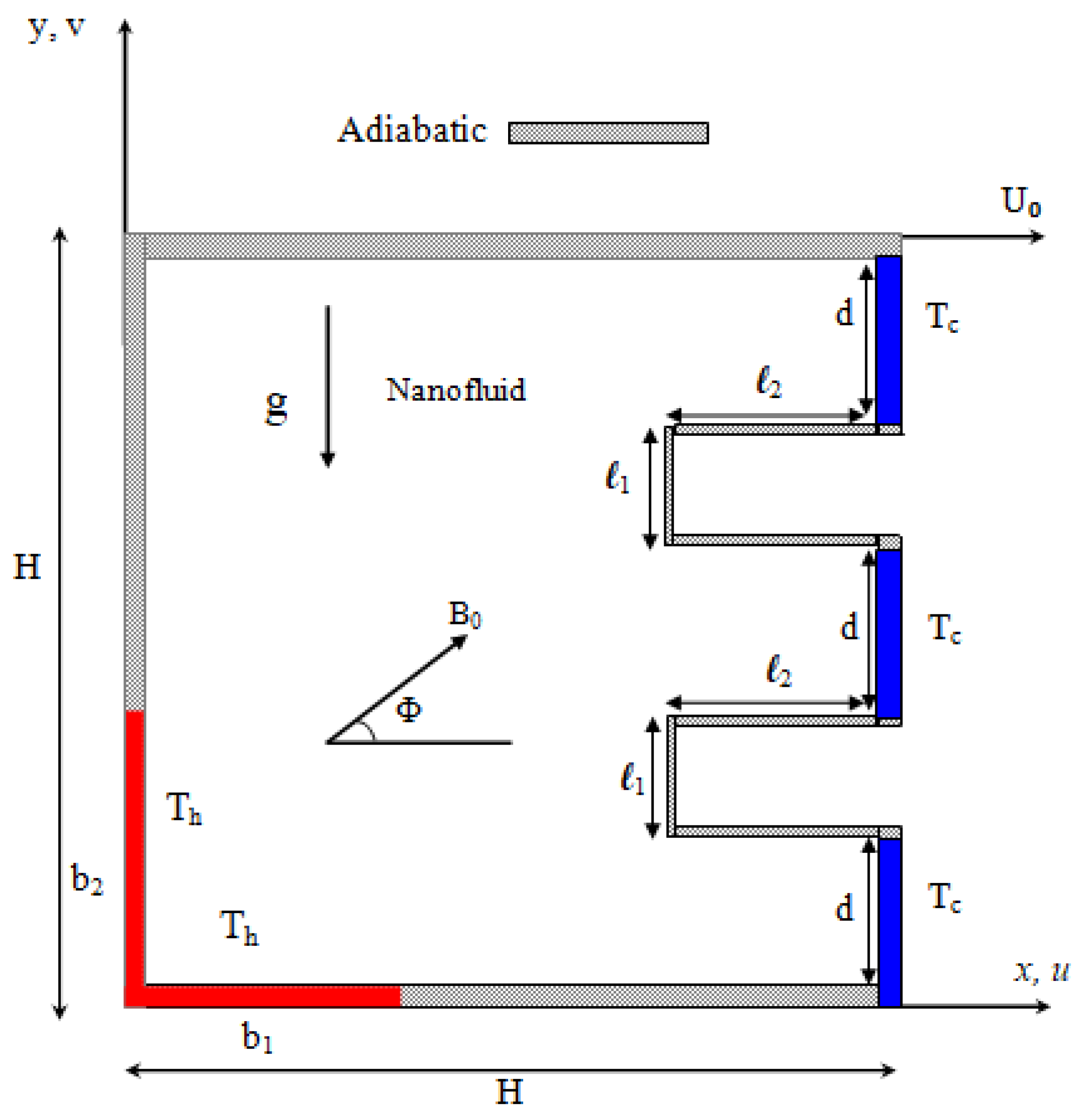

2. Modeling

- ⮚

- Steady viscous mixed convection flow.

- ⮚

- The chamber filled with copper-water nanofluid is considered to be steady Newtonian, Laminar, and incompressible.

- ⮚

- The upper surface of the chamber is adiabatic and moves with a fixed velocity U0.

- ⮚

- The heated corner is submitted to a fixed hot temperature Th in both left and lower directions with length sb1 and b2.

- ⮚

- The right side is maintained at a fixed cold temperature, TC, while the remaining portions of the left and lower parts are considered adiabatic.

- ⮚

- The height and width of the portions on the right side are measured as l1 and l2, respectively.

- ⮚

- The gravity force is directed downward and internal heat generation at a constant rate of Q0 is included.

- ⮚

- An application of magnetic strength B0 is utilized on the left side of the cavity, with angle Φ along the positive horizontal direction.

- ⮚

- It is assumed that the fluid flow within the enclosure is in thermal equilibrium and the working fluid is incompressible nanofluid.

- ⮚

- There will be no jump of temperature between base fluid and nanosized particles, and both the viscous dissipation term and Joule heating term due to magnetic field has been waived.

- ⮚

- The magnetic field created by induction is small enough to be negligible compared to the magnetic field which is applied.

- ⮚

- The thermophysical characteristics of the nanoparticles and the base liquid are addressed in Table 1.

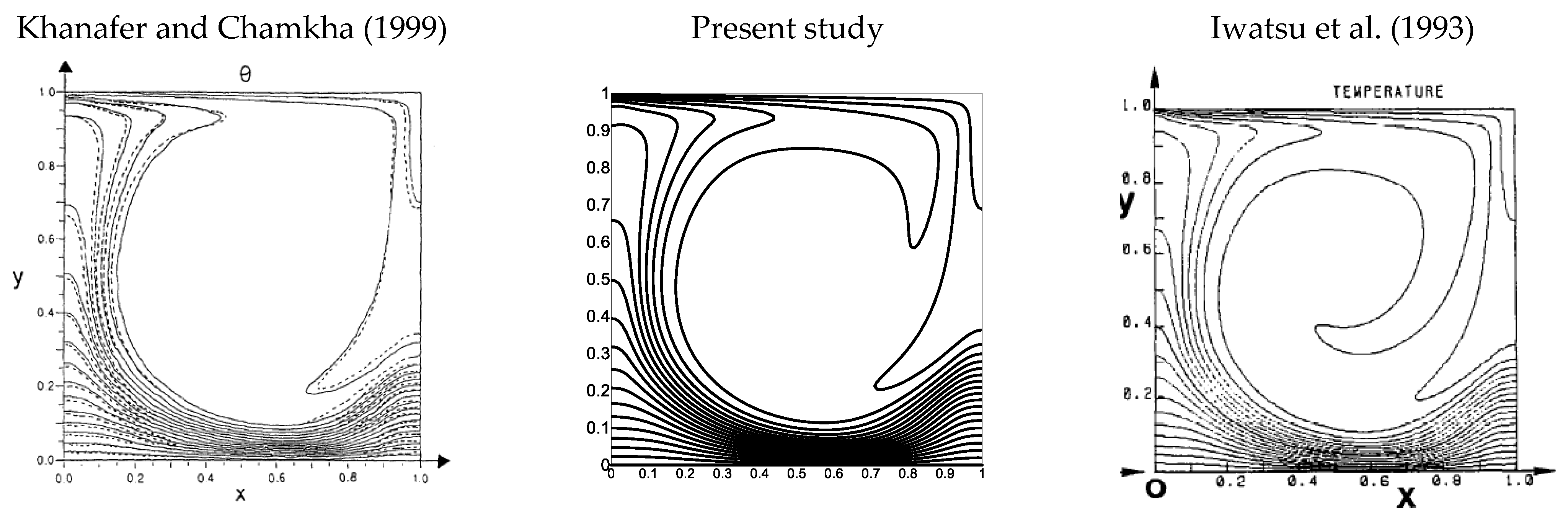

3. Numerical Solution and Validation

4. Discussions

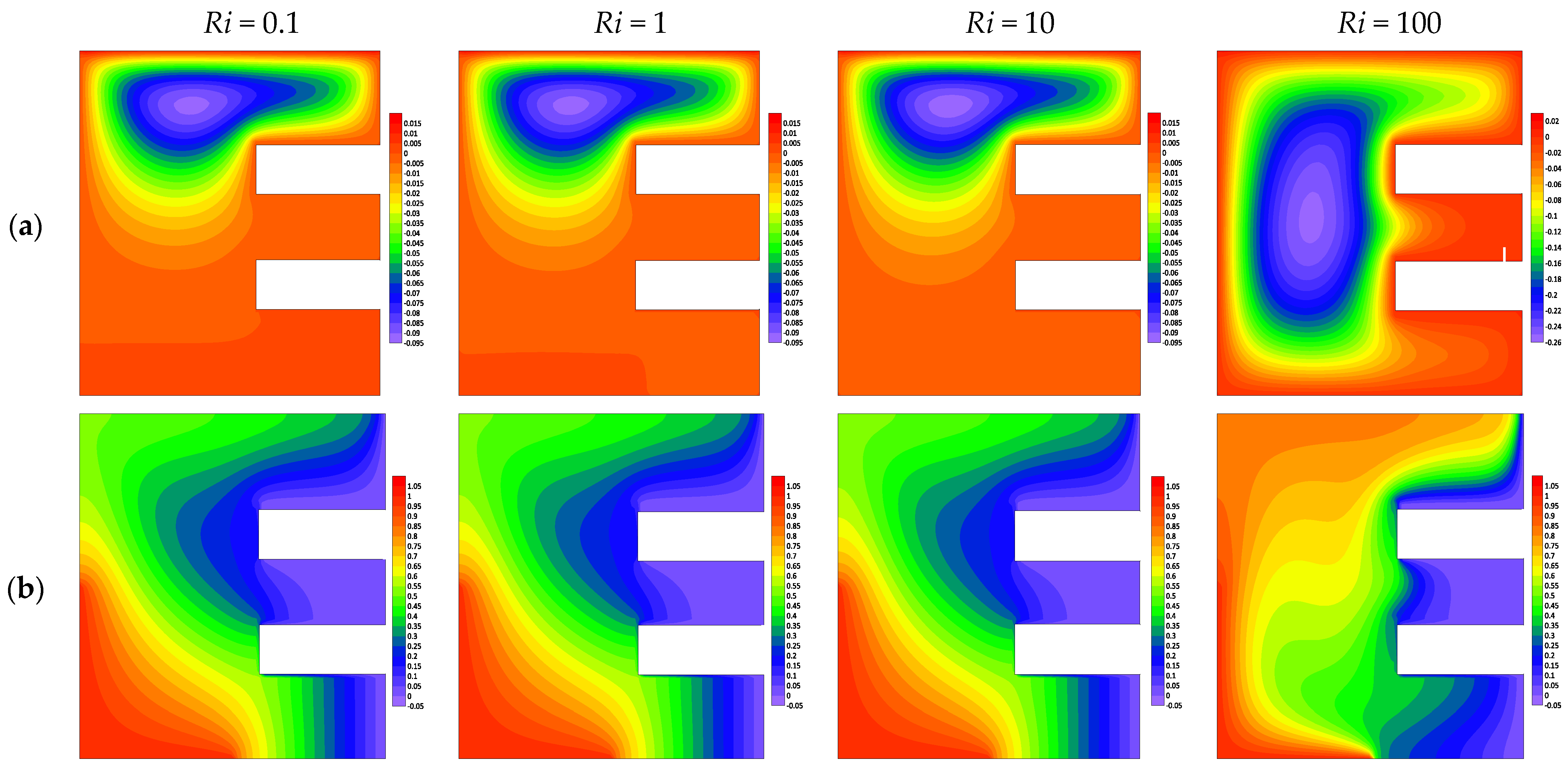

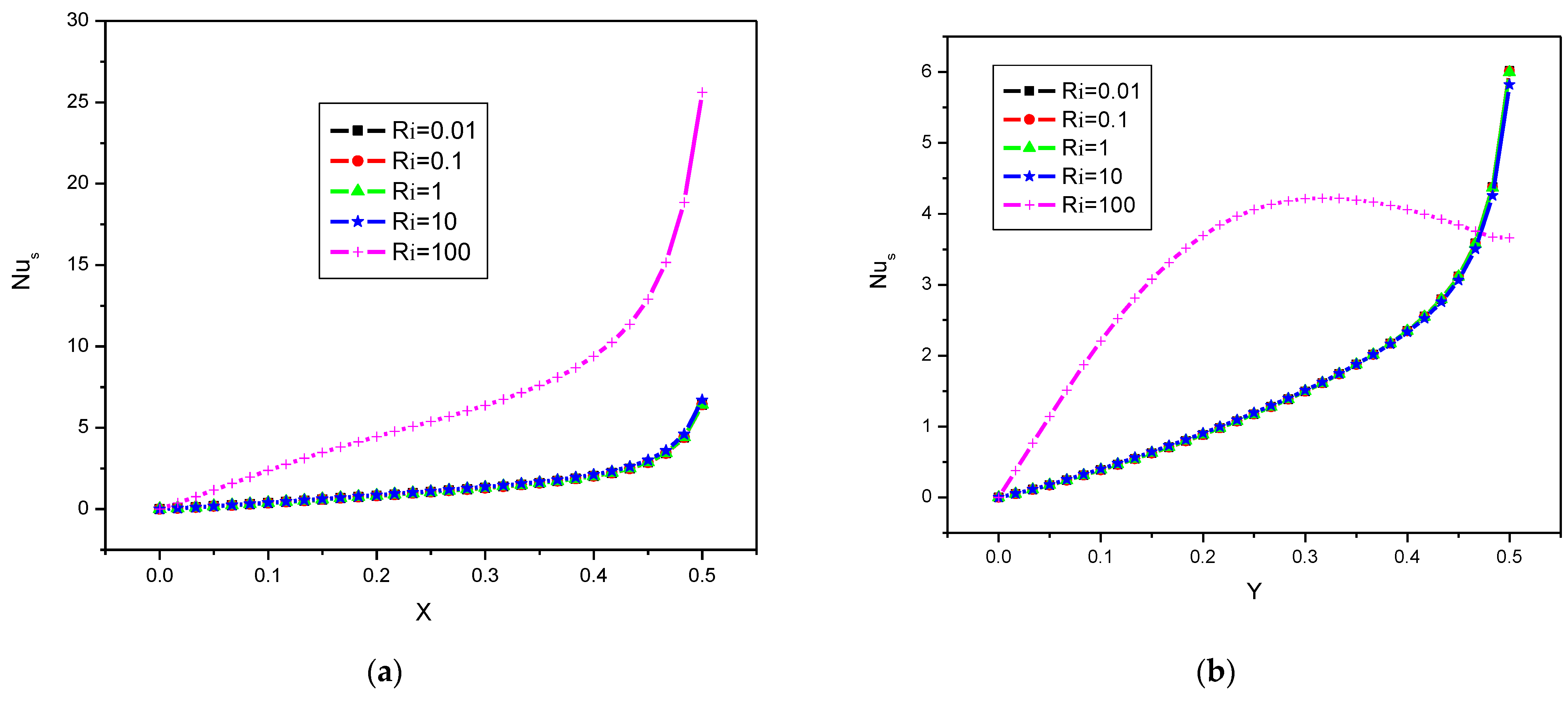

4.1. Effect of Richardson Number Ri

4.2. Effect of the HARTMANN Number Ha

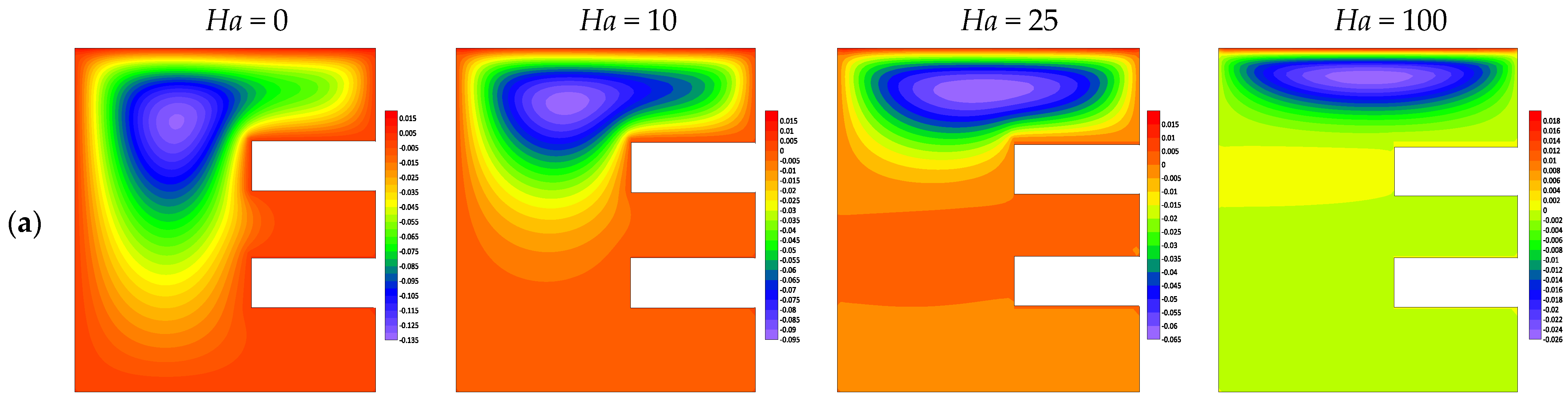

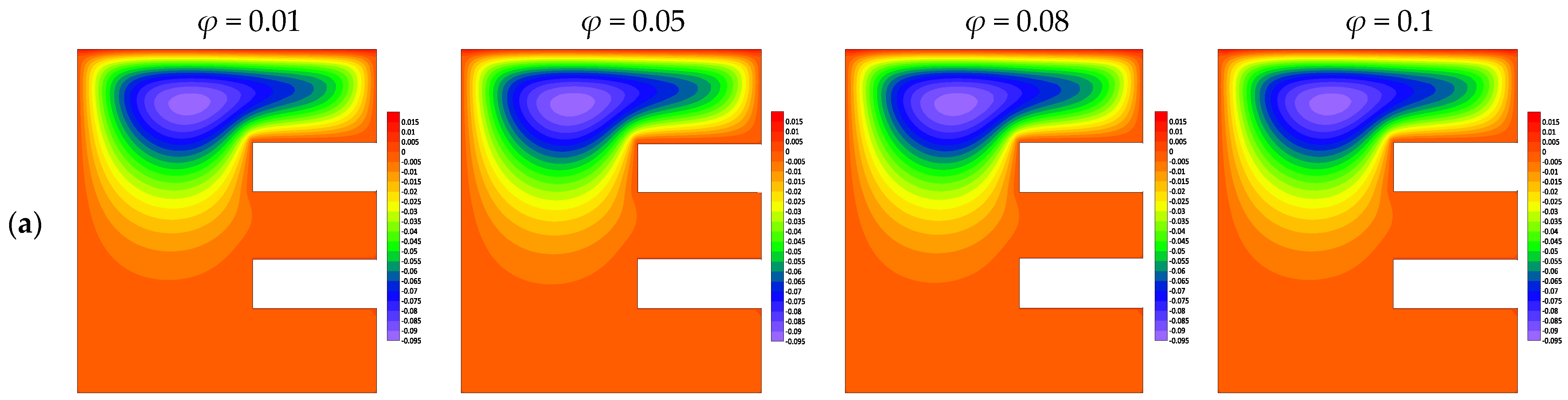

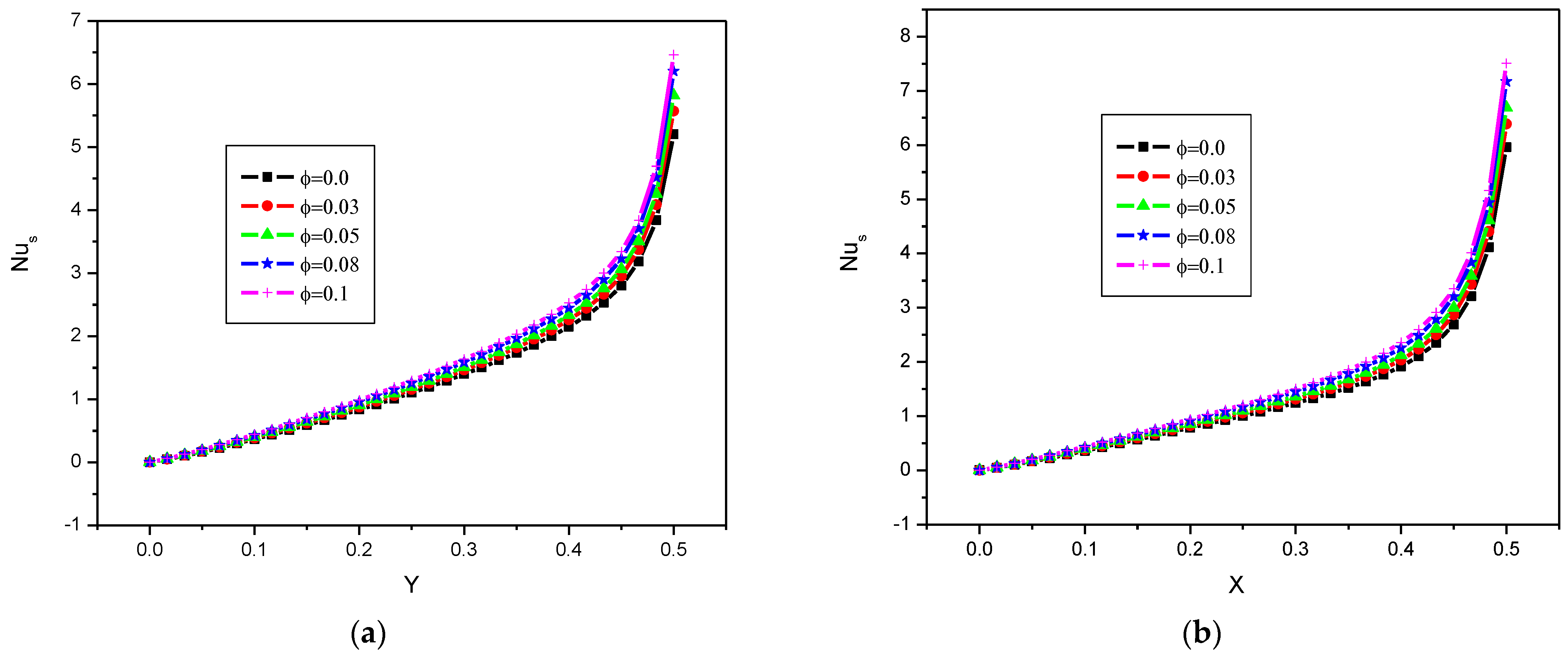

4.3. Effect of Nanoparticle Volume Fraction φ

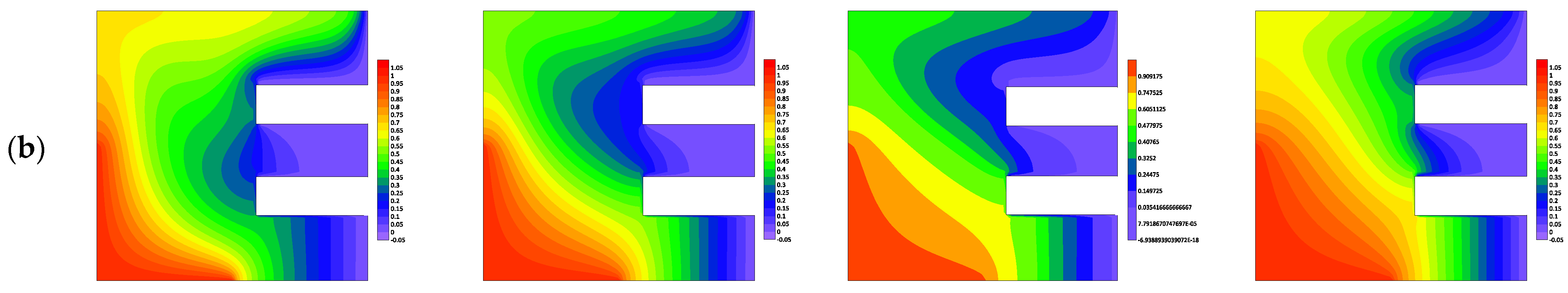

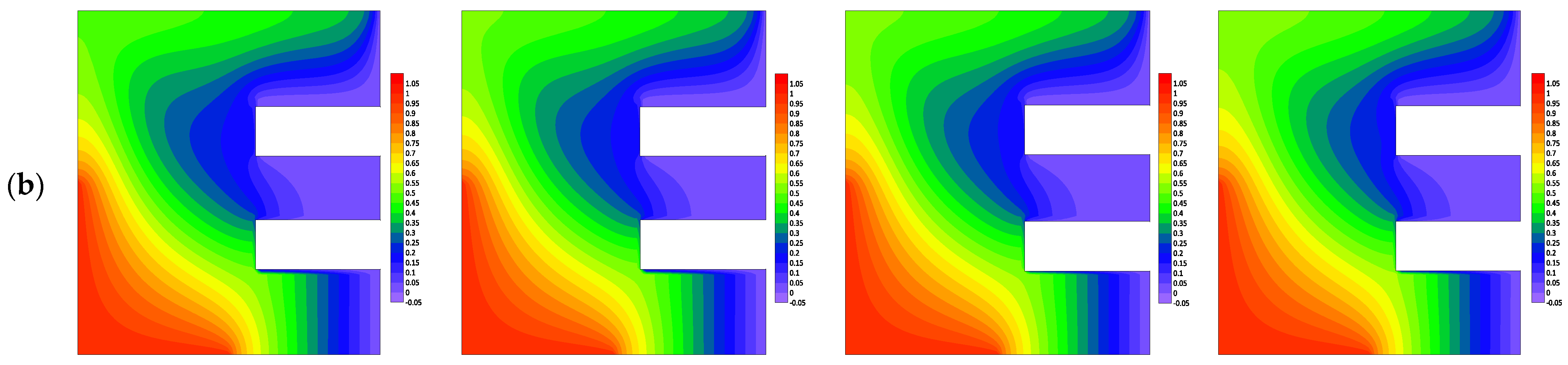

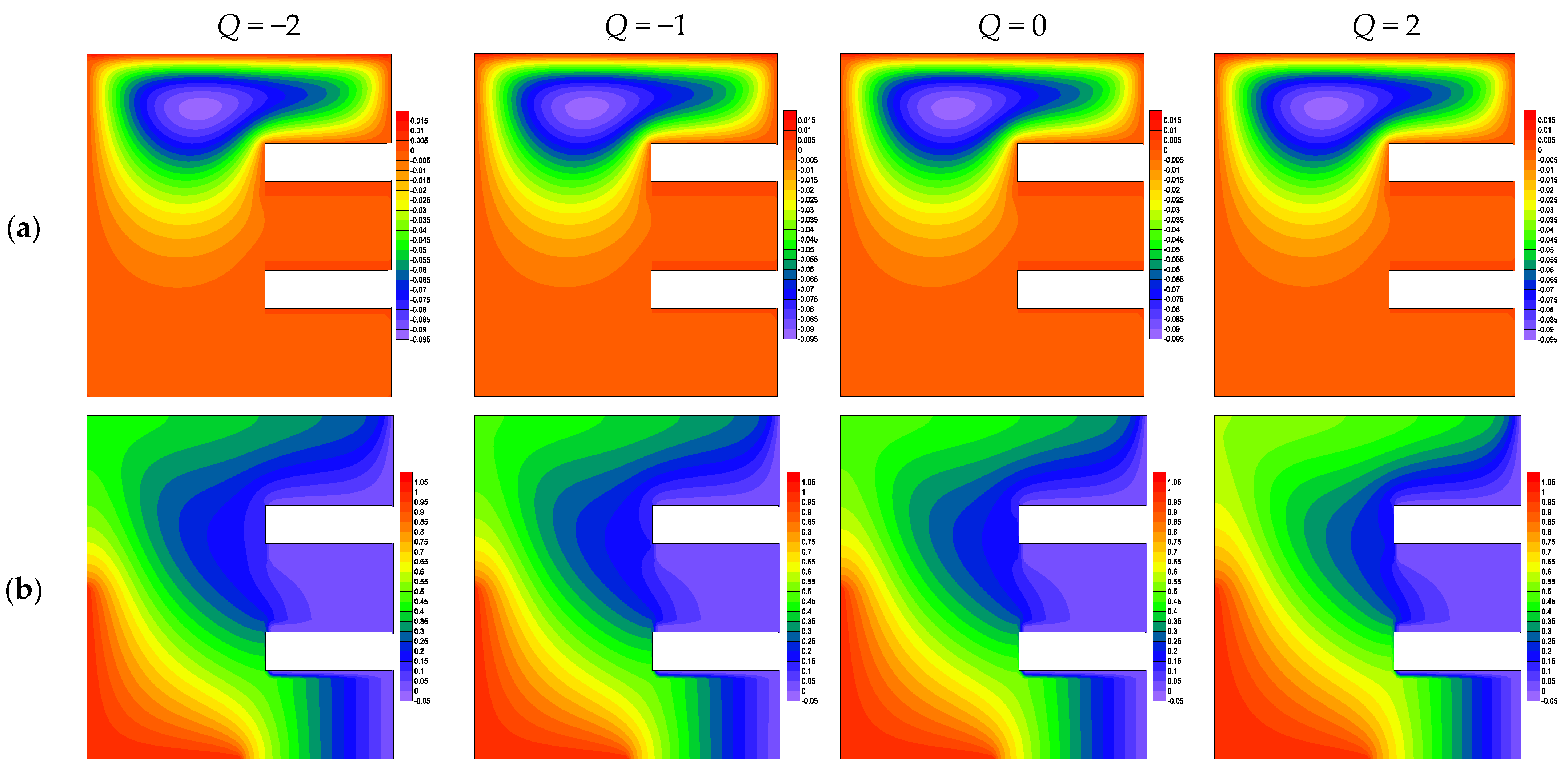

4.4. Effect of Heat Generation Coefficient Q

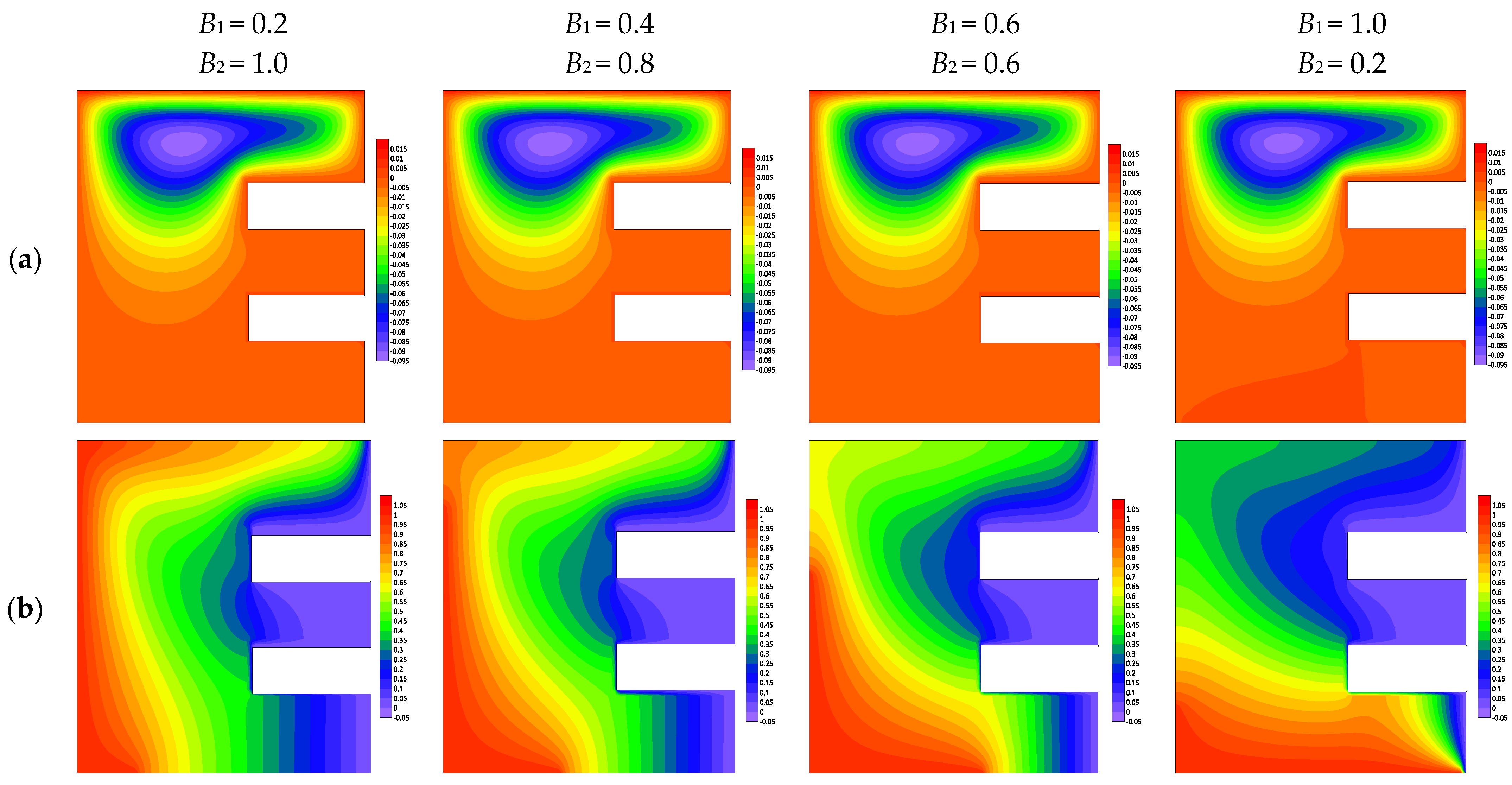

4.5. Effect of Length of the Heat Source B1 and B2

5. Conclusions

- -

- The heat transfer rate increases by raising the volume fraction of nanoparticles. It is important to point out that the presence of nanoparticles leads to height convective heat transfer coefficient.

- -

- The Nusselt number increases as the thermal conductivity and the size of nanoparticles increase.

- -

- The increment in heat transfers outweighs the increment in dynamic viscosity, which causes a decrease in pressure and force.

- -

- The magnetic field reduces the fluid circulation inside the E-shaped square chamber.

- -

- The augmentation of the Richardson number leads to an increase in the heat transfer.

- -

- The circulations inside the chamber are practically unaffected by the length of heat source.

- -

- The circulations and temperature contours are practically unaffected by the addition of nanoparticles to regular fluid.

- -

- The decrease in heat generation coefficient declines along with the nanofluid temperature and the flow fields.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| b1, b2 | Heat source lengths (m) |

| B1, B2 | Dimensionless Heat source lengths |

| Magnetic field strength, T | |

| Specific heat at constant pr, Messure, | |

| D | cold length |

| G | Acceleration due to gravity, m s−2 |

| Gr | Grashofnumber, |

| H | Length of cavity |

| Ha | Hartmann number, |

| Thermal conductivity, Wm−1K−1 | |

| l1 | Length of cold temperutre (m) |

| l2 | width of cold temperutre (m) |

| L1 | Dimensionless Length of cold temperutre |

| L2 | Dimensionlesswidth of cold temperutre |

| Nus | Local Nusselt number |

| Average Nusselt number of heat source | |

| Fluid pressure, Pa | |

| Re | |

| Ri | Richardson number |

| T | Temperature, K |

| Tc | Cold wall temperature, K |

| Th | Heated wall temperature, K |

| u, v | Velocity components in x, y directions, ms−1 |

| Dimensionless velocity components, u/U0, v/U0 | |

| Cartesian coordinates | |

| X, Y | Dimensionlesscoordinates, x/H, y/H |

| Greek symbols | |

| Thermal expansion coefficient, K−1 | |

| Solid volume fraction | |

| Dimensionless temperature, | |

| Dynamic viscosity, N.S.m−2 | |

| Density, | |

| Φ | Inclination angle |

| Subscripts | |

| Cold | |

| Pure fluid | |

| Hot | |

| Average | |

| Nanofluid | |

| P | Nanoparticle |

References

- Boulemtafes-Boukadoum, A.; Abid, C.; Benzaoui, A. 3D Numerical study of the effect of aspect ratio on mixed convection air flow in upward solar air heater. Int. J. Heat Fluid Flow 2020, 84, 108570. [Google Scholar] [CrossRef]

- Hadavand, M.; Yousefzadeh, S.; Akbari, O.A.; Pourfattah, F.; Nguyen, H.M.; Asadi, A. A numerical investigation on the effects of mixed convection of Ag-water nanofluid inside a simcircular lid-driven cavity on the temperature of an electronic silicon chip. Appl. Therm. Eng. 2019, 162, 114298. [Google Scholar] [CrossRef]

- Shin, D.-H.; Kim, C.S.; Park, G.-C.; Cho, H.K. Experimental analysis on mixed convection in reactor cavity cooling system of HTGR for hydrogen production. Int. J. Hydrogen Energy 2017, 42, 22046–22053. [Google Scholar] [CrossRef]

- Tassone, A.; Caruso, G.; Giannetti, F.; del Nevo, A. MHD mixed convection flow in the WCLL: Heat transfer analysis and cooling system optimization. Fusion Eng. Des. 2019, 146, 809–813. [Google Scholar] [CrossRef] [Green Version]

- Xiao, C.; Liao, Q.; Fu, Q.; Huang, Y.; Xia, A.; Chen, H.; Zhu, X. Numerical investigation of laminar mixed convection of microalgae slurry flowing in a solar collector. Appl. Therm. Eng. 2020, 175, 115366. [Google Scholar] [CrossRef]

- Gangawane, K.M. Computational analysis of mixed convection heat transfer characteristics in lid-driven cavity containing triangular block with constant heat flux: Effect of Prandtl and Grashof numbers. Int. J. Heat Mass Transf. 2017, 105, 34–57. [Google Scholar] [CrossRef]

- Nayak, A.K.; Haque, A.; Banerjee, A. Thermosolutal mixed convection of a shear thinning fluid due to partially active mixed zones within a lid-driven cavity. Int. J. Heat Mass Transf. 2017, 106, 686–707. [Google Scholar] [CrossRef]

- Razera, A.L.; da Fonseca, R.J.C.; Isoldi, L.A.; Santos, E.D.d.; Rocha, L.A.O.; Biserni, C. Constructal design of a semi-elliptical fin inserted in a lid-driven square cavity with mixed convection. Int. J. Heat Mass Transf. 2018, 126, 81–94. [Google Scholar] [CrossRef]

- Gangawane, K.M.; Oztop, H.F.; Abu-Hamdeh, N. Mixed convection characteristic in a lid driven cavity containing heated triangular block: Effect of location and size of block. Int. J. Heat Mass Transf. 2018, 124, 860–875. [Google Scholar] [CrossRef]

- Manchanda, M.; Gangawane, K.M. Mixed convection in a two-sided lid-driven cavity containing heated triangular block for non-Newtonian power-law fluids. Int. J. Mech. Sci. 2018, 144, 235–248. [Google Scholar] [CrossRef]

- Zhou, W.; Yan, Y.; Liu, X.; Chen, H.; Liu, B. Lattice Boltzmann simulation of mixedconvection of nanofluid with different heat sources in a double lid-driven cavity. Int. Commun. Heat Mass Transf. 2018, 97, 39–46. [Google Scholar] [CrossRef]

- Gangawane, K.M.; Oztop, H.F. Mixed convection in the semi-circular lid-driven cavity with heated curved wall subjugated to constant heat flux for non-Newtonian power-law fluids. Int. Commun. Heat Mass Transf. 2020, 114, 104563. [Google Scholar] [CrossRef]

- Choi, S.U.S.; Eastman, J.A. Enhancing thermal conductivity of fluids withnanoparticles. In Proceedings of the 1995 International Mechanical Engineering Congress and Exhibition, San Francisco, CA, USA, 12–17 November 1995. [Google Scholar]

- Shahi, M.; Mahmoudi, A.H.; Talebi, F. Numerical study of mixed convective cooling in a square cavity ventilated and partially heated from the below utilizing nanofluid. Int. Heat Mass Transf. 2010, 37, 201–213. [Google Scholar] [CrossRef]

- Hussain, S.; Ahmad, S.; Mehmood, K.; Sagheer, M. Effects of inclination angle on mixed convective nanofluid flow in a double lid-driven cavity with discrete heat sources. Int. Heat Mass Transf. 2017, 106, 847–860. [Google Scholar] [CrossRef]

- Esfe, M.H.; Akbari, M.; Karimipour, A.; Afrand, M.; Mahian, O.; Wongwises, S. Mixed-convection flow and heat transfer in an inclined cavity equipped to a hot obstacle using nanofluids considering temperature-dependent properties. Int. J. Heat Mass Transf. 2015, 85, 656–666. [Google Scholar] [CrossRef]

- Ismael, M.A.; Abu-Nada, E.; Chamkha, A.J. Mixed convection in a square cavity filled with CuO-water nanofluid heated by corner heater. Int. J. Mech. Sci. 2017, 133, 42–50. [Google Scholar] [CrossRef]

- Alsabery, A.I.; Ismael, M.A.; Chamkha, A.J.; Hashim, I. Mixed convection of Al2O3-water nanofluid in a double lid-driven square cavity with a solid inner insert using Buongiorno’s twophasemodel. Int. J. Heat Mass Transf. 2018, 119, 939–961. [Google Scholar] [CrossRef]

- Cho, C.-C. Heat transfer and entropy generation of mixed convection flow in Cu-waternanofluid-filled lid-driven cavity with wavy surface. Int. J. Heat Mass Transf. 2018, 119, 163–174. [Google Scholar] [CrossRef]

- Pal, S.K.; Bhattacharyya, S.; Pop, I. Effect of solid-to-fluid conductivity ratio on mixedconvection and entropy generation of a nanofluid in a lid-driven enclosure with a thick wavywall. Int. J. Heat Mass Transf. 2018, 127, 885–900. [Google Scholar] [CrossRef]

- Karbasifar, B.; Akbari, M.; Toghraie, D. Mixed convection of Water-Aluminum oxidenanofluid in an inclined lid-driven cavity containing a hot elliptical centric cylinder. Int. J. Heat Mass Transf. 2018, 116, 1237–1249. [Google Scholar] [CrossRef]

- Ali, I.; Alsabery, A.I.; Bakar, N.; Roslan, R. Mixed Convection in a Double Lid-Driven Cavity Filled with Hybrid Nanofluid by Using Finite Volume Method. Symmetry 2020, 12, 1977. [Google Scholar] [CrossRef]

- Elshehabey, H.M.; Ahmed, S.E. MHD mixed convection in a lid-driven cavity filled by ananofluid with sinusoidal temperature distribution on the both vertical walls using Buongiorno’s nanofluid model. Int. J. Heat Mass Transf. 2015, 88, 181–202. [Google Scholar] [CrossRef]

- Mehmood, K.; Hussain, S.; Sagheer, M. Mixed convection in alumina-water nanofluidfilled lid-driven square cavity with an isothermally heated square blockage inside withmagnetic field effect: Introduction. Int. J. Heat Mass Transf. 2017, 109, 397–409. [Google Scholar] [CrossRef]

- Hussain, S.; Öztop, H.F.; Mehmood, K.; Abu-Hamdeh, N. Effects of inclined magnetic fieldon mixed convection in a nanofluid filled double lid-driven cavity with volumetric heatgeneration or absorption using finite element method. Chin. J. Phys. 2018, 56, 484–501. [Google Scholar] [CrossRef]

- Mondal, P.; Mahapatra, T.R.; Parveen, R. Entropy generation in nanofluid flow due todouble diffusive MHD mixed convection. Heliyon 2021, 7, e06143. [Google Scholar] [CrossRef] [PubMed]

- Rasool, G.; Wakif, A. Numerical spectral examination of EMHD mixed convective flow of second-grade nanofluid towards a vertical Riga plate using an advanced version of the revised Buongiorno’s nanofluid model. J. Therm. Anal. Calorim. 2021, 143, 2379–2393. [Google Scholar] [CrossRef]

- Punith Gowda, R.J.; Naveen Kumar, R.; Jyothi, A.M.; Prasannakumara BCSarris, I.E. Impact of binary chemical reaction and activation energy on heat and mass transfer of marangoni driven boundary layer flow of a non-Newtonian nanofluid. Processes 2021, 9, 702. [Google Scholar] [CrossRef]

- Shah, N.A.; Wakif, A.; El-Zahar, E.R.; Ahmad, S.; Yook, S.-J. Numerical simulation of a thermally enhanced EMHD flow of a heterogeneous micropolar mixture comprising (60%)-ethylene glycol (EG),(40%)-water (W), and copper oxide nanomaterials (CuO). Case Stud. Therm. Eng. 2022, 35, 102046. [Google Scholar] [CrossRef]

- Benos, T.L.; Karvelas, E.G.; Sarris, I.E. Crucial effect of aggregations in CNT-water nanofluid magnetohydrodynamic natural convection. Therm. Sci. Eng. Prog. 2019, 11, 263–271. [Google Scholar] [CrossRef]

- Song, Y.Q.; Khan, M.I.; Qayyum, S.; Gowda, R.P.; Kumar, R.N.; Prasannakumara, B.C.; Elmasry, Y.; Chu, Y.-M. Physical impact of thermo-diffusion and diffusion-thermo on marangoni convective flow of hybrid nanofluid (MnZiFe2O4–NiZnFe2O4–H2O) with nonlinear heat source/sink and radiative heat flux. Mod. Phys. Lett. B 2021, 35, 2141006. [Google Scholar] [CrossRef]

- Gowda, R.P.; Al-Mubaddel, F.S.; Kumar, R.N.; Prasannakumara, B.; Issakhov, A.; Rahimi-Gorji, M.; Al-Turki, Y.A. Computational modelling of nanofluid flow over a curved stretching sheet using Koo–Kleinstreuer and Li (KKL) correlation and modified Fourier heat flux model. Chaos Solitons Fractals 2021, 145, 110774. [Google Scholar] [CrossRef]

- Xiong, P.-Y.; Hamid, A.; Chu, Y.-M.; Khan, M.I.; Gowda, R.J.P.; Kumar, R.N.; Prasannakumara, B.C.; Qayyum, S. Prasannakumara, and Sumaira Qayyum. Dynamics of multiple solutions of Darcy–Forchheimer saturated flow of Cross nanofluid by a vertical thin needle point. Eur. Phys. J. Plus 2021, 136, 315. [Google Scholar] [CrossRef]

- Li, Y.-X.; Khan, M.I.; Gowda, R.J.P.; Ali, A.; Farooq, S.; Chu, Y.-M.; Khan, S.U. Dynamics of aluminum oxide and copper hybrid nanofluid in nonlinear mixed Marangoni convective flow with entropy generation: Applications to renewable energy. Chin. J. Phys. 2021, 73, 275–287. [Google Scholar] [CrossRef]

- El-Zahar, E.; Rashad, A.M.; Seddek, L.F. Impacts of Viscous Dissipation and Brownian Motion on Jeffrey Nanofluid Flow over an Unsteady Stretching Surface with Thermophoresis. Symmetry 2020, 12, 1450. [Google Scholar] [CrossRef]

- Ali, B.; Shafiq, A.; Manan, A.; Wakif, A.; Hussain, S. Bioconvection: Significance of mixed convection and MHD on dynamics of Cassonnanofluid in the stagnation point of rotating sphere via finite element simulation. Math. Comput. Simul. 2022, 194, 254–268. [Google Scholar] [CrossRef]

- Habib, D.; Salamat, N.; Hussain, S.; Ali, B.; Abdal, S. Significance of Stephen blowing and Lorentz force on dynamics of Prandtlnanofluid via Keller box approach. Int. Commun. Heat Mass Transf. 2021, 128, 105599. [Google Scholar] [CrossRef]

- Asjad, M.I.; Sarwar, N.; Ali, B.; Hussain, S.; Sitthiwirattham, T.; Reunsumrit, J. Impact of Bioconvection and Chemical Reaction on MHD Nanofluid Flow Due to Exponential Stretching Sheet. Symmetry 2021, 13, 2334. [Google Scholar] [CrossRef]

- Wang, F.; Asjad, M.I.; Ur Rehman, S.; Ali, B.; Hussain, S.; Gia, T.N.; Muhammad, T. MHD Williamson Nanofluid Flow over a Slender Elastic Sheet of Irregular Thickness in the Presence of Bioconvection. Nanomaterials 2021, 11, 2297. [Google Scholar] [CrossRef]

- Haider, S.M.A.; Ali, B.; Wang, Q.; Zhao, C. Stefan Blowing Impacts on Unsteady MHD Flow of Nanofluid over a Stretching Sheet with Electric Field, Thermal Radiation and Activation Energy. Coatings 2021, 11, 1048. [Google Scholar] [CrossRef]

- Benos, L.; Sarris, I.E. Analytical study of the magnetohydrodynamic natural convection of a nanofluid filled horizontal shallow cavity with internal heat generation. Int. J. Heat Mass Transf. 2019, 130, 862–873. [Google Scholar] [CrossRef]

- Sarris, I.E.; Zikos, G.K.; Grecos, A.P.; Vlachos, N.S. On the limits of validity of the low magnetic Reynolds number approximation in MHD natural-convection heat transfer. Numer. Heat Transf. Part B Fundam. 2006, 50, 157–180. [Google Scholar] [CrossRef]

- Raja, M.A.Z.; Shoaib, M.; Tabassum, R.; Khan, M.I.; Gowda, R.J.P.; Prasannakumara, B.C.; Malik, M.Y.; Xia, W.-F. Intelligent computing for the dynamics of entropy optimized nanofluidic system under impacts of MHD along thick surface. Int. J. Mod. Phys. B 2021, 35, 2150269. [Google Scholar] [CrossRef]

- Aminossadati, S.M.; Ghasemi, B. Natural convection cooling of a localized heat source at thebottom of a nanofluid-filled enclosure. Eur. J. Mech. B/Fluids 2009, 28, 630–640. [Google Scholar] [CrossRef]

- Brinkman, H.C. The viscosity of concentrated suspensions and solution. J. Chem. Phys. 1952, 20, 571–581. [Google Scholar] [CrossRef]

- Patankar, S.V. Numerical Heat Transfer and Fluid Flow; Hemisphere: New York, NY, USA, 1980. [Google Scholar]

- Khanafer, K.M.; Chamkha, A.J. Mixed convection flow in a lid-driven enclosure filled with a fluid-saturated porous medium. Int. J. Heat Mass Transf. 1999, 31, 1354–1370. [Google Scholar] [CrossRef]

- Iwatsu, R.; Hyun, J.M.; Kuwahara, K. Mixed convection in a driven cavity with a stable vertical temperature gradient. Int. J. Heat Mass Transf. 1993, 36, 1601–1608. [Google Scholar] [CrossRef]

| (kg m−3) | (Jkg−1K−1) | (Wm−1K−1) | (K−1) | (μS/cm) | |

|---|---|---|---|---|---|

| Pure water | 997.1 | 4179 | 0.613 | 21 × 10−5 | 0.05 |

| Copper (Cu) | 8933 | 385 | 401 | 1.67 × 10−5 | 5.96 × 107 |

| Grid-Size | 41 × 41 | 61 × 61 | 81 × 81 | 91 × 91 | 101 × 101 | 121 × 121 |

|---|---|---|---|---|---|---|

| 1.464692 | 1.732480 | 1.904552 | 1.984808 | 1.994244 | 1.9948425 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nabwey, H.A.; Rashad, A.M.; Mansour, M.A.; Salah, T. Magneto-Nanofluid Flow via Mixed Convection Inside E-Shaped Square Chamber. Symmetry 2022, 14, 1159. https://doi.org/10.3390/sym14061159

Nabwey HA, Rashad AM, Mansour MA, Salah T. Magneto-Nanofluid Flow via Mixed Convection Inside E-Shaped Square Chamber. Symmetry. 2022; 14(6):1159. https://doi.org/10.3390/sym14061159

Chicago/Turabian StyleNabwey, Hossam A., Ahmed M. Rashad, Mohamed A. Mansour, and Taha Salah. 2022. "Magneto-Nanofluid Flow via Mixed Convection Inside E-Shaped Square Chamber" Symmetry 14, no. 6: 1159. https://doi.org/10.3390/sym14061159

APA StyleNabwey, H. A., Rashad, A. M., Mansour, M. A., & Salah, T. (2022). Magneto-Nanofluid Flow via Mixed Convection Inside E-Shaped Square Chamber. Symmetry, 14(6), 1159. https://doi.org/10.3390/sym14061159