Effects of Tip Clearance and Impeller Eccentricity on the Aerodynamic Performance of Mixed Flow Fan

Abstract

:1. Introduction

2. Experimental Scheme and Result Analysis

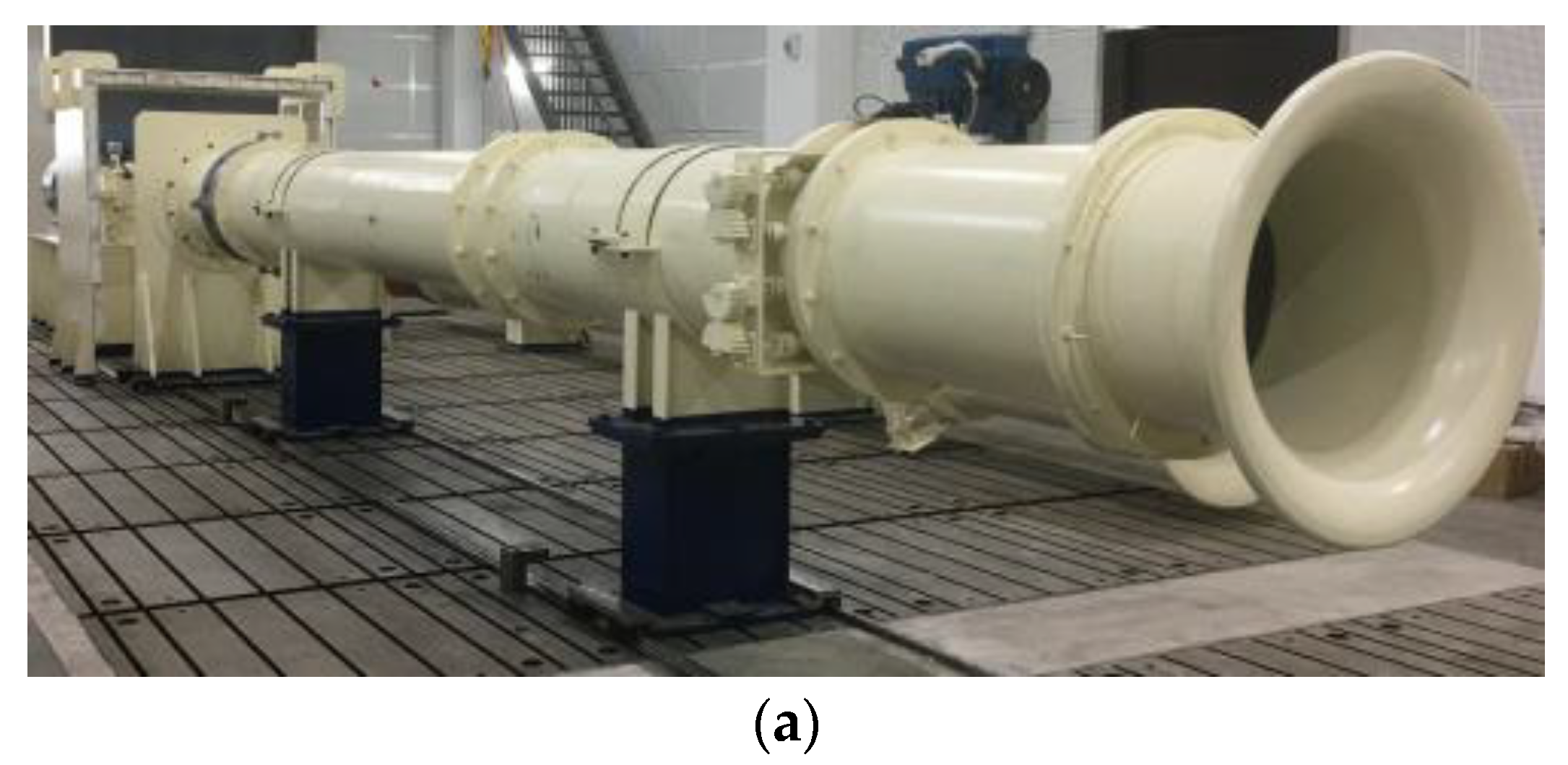

2.1. Test Device

2.2. Experimental Setup

2.3. Experimental Results

2.3.1. Effect of Clearance on Fans-Performance Testing

2.3.2. Effect of Eccentricity on Fans-Performance Testing

3. Modeling and Simulation

3.1. Numerical Simulation Method

3.1.1. Modeling

3.1.2. Mesh Division

3.1.3. Solution Method and Boundary

- The inlet is set as mass flow inlet, and the velocity direction is perpendicular to the inlet boundary.

- A pressure outlet is used for the outlet and the static pressure is set at zero.

- The fixed walls all adopt the no-slip boundary condition.

- The inlet section and outlet section are stationary zones, the impeller zone is rotating zone, and the stationary and rotating zones are connected using the intersection interface.

- The rotational speed of the impeller region is set to 5000 rpm, and the impeller wall surface is used as the rotational coordinate system and moves with the rotational region.

3.1.4. Grid Independence Verification

3.2. Numerical Simulation Results

3.2.1. Efficiency Calculation of Fan

3.2.2. Analysis of the Effect of Tip Clearance on Fans-Performance Testing

3.2.3. Analysis of the Effect of Eccentric on Fans-Performance Testing

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Satish, T.N.; Rao, A.N.V.; Nambiar, A.S.; Uma, G.; Umapathy, M.; Chandrashekhar, U.; Petley, V.U. Investigation into the Development and Testing of a Simplex Capacitance Sensor for Rotor Tip Clearance Measurement in Turbo Machinery. Exp. Tech. 2018, 42, 575–592. [Google Scholar] [CrossRef]

- John, A.; Qin, N.; Shahpar, S. The Impact of Realistic Casing Geometries and Clearances on Fan Blade Tip Aerodynamics. J. Turbomach. 2018, 140, 061002. [Google Scholar] [CrossRef]

- Mokhtari, N.; Pelham, J.G.; Nowoisky, S.; Bote-Garcia, J.L.; Gühmann, C. Friction and wear monitoring methods for journal bearings of geared turbofans based on acoustic emission signals and machine learning. Lubricants 2020, 8, 29. [Google Scholar] [CrossRef] [Green Version]

- Satish, T.N.; Murthy, R.; Singh, A.K. Analysis of uncertainties in measurement of rotor blade tip clearance in gas turbine engine under dynamic condition. Proc. Inst. Mech. Eng. Part G-J. Aerosp. Eng. 2014, 228, 652–670. [Google Scholar] [CrossRef]

- Fan, T.; Behdinan, K. The Evaluation of Linear Complementarity Problem Method in Modeling the Fluid Cavitation for Squeeze Film Damper with Off-Centered Whirling Motion. Lubricants 2017, 5, 46. [Google Scholar] [CrossRef] [Green Version]

- Jung, U.-H.; Kim, J.-H.; Kim, S.; Kim, J.-H.; Choi, Y.-S. Analyzing the shape parameter effects on the performance of the mixed-flow fan using CFD & Factorial design. J. Mech. Sci. Technol. 2016, 30, 1149–1161. [Google Scholar] [CrossRef]

- Luo, D.; Huang, D.; Sun, X.; Chen, X.; Zheng, Z. A Computational Study on the Performance Improvement of Low-Speed Axial Flow Fans with Microplates. J. Appl. Fluid. Mech. 2017, 10, 1537–1546. [Google Scholar] [CrossRef]

- Pelz, P.F.; Saul, S.; Broetz, J. Efficiency Scaling: Influence of Reynolds and Mach Numbers on Fan Performance. J. Turbomach. 2022, 144, 061001. [Google Scholar] [CrossRef]

- Suriyanarayanan, V.; Rendu, Q.; Vahdati, M.; Salles, L. Effect of Manufacturing Tolerance in Flow Past a Compressor Blade. J. Turbomach. 2022, 144, 041005. [Google Scholar] [CrossRef]

- Li, W.; Ji, L.; Li, E.; Zhou, L.; Agarwal, R.K. Effect of Tip Clearance on Rotating Stall in a Mixed-Flow Pump. J. Turbomach. 2021, 143, 091013. [Google Scholar] [CrossRef]

- Pretorius, J.P.; Erasmus, J.A. Effect of Tip Vortex Reduction on Air-Cooled Condenser Axial Flow Fan Performance: An Experimental Investigation. J. Turbomach. 2022, 144, 031001. [Google Scholar] [CrossRef]

- Moghadam, S.M.A.; Meinke, M.; Schroeder, W. Analysis of tip-leakage flow in an axial fan at varying tip-gap sizes and operating conditions. Comput. Fluids 2019, 183, 107–129. [Google Scholar] [CrossRef]

- Yu, B.; Ke, H.; Shen, E.; Zhang, T. A review of blade tip clearance-measuring technologies for gas turbine engines. Meas. Control. 2020, 53, 339–357. [Google Scholar] [CrossRef] [Green Version]

- Fan, C.; Adjei, R.A.; Wu, Y.; Wang, A. Parametric study on the aerodynamic performance of a ducted-fan rotor using free-form method. Aerosp. Sci. Technol. 2020, 101, 105842. [Google Scholar] [CrossRef]

- Lee, S.I.; Kang, Y.J.; Kim, W.J.; Kwak, J.S.; Kim, T.S.; Kim, D.H.; Jung, I.Y. Effects of tip clearance, number of teeth, and tooth front angle on the sealing performance of straight and stepped labyrinth seals. J. Mech. Sci. Technol. 2021, 35, 1539–1547. [Google Scholar] [CrossRef]

- Miguel Gil-Garcia, J.; Zubia, J.; Aranguren, G. Architecture for Measuring Blade Tip Clearance and Time of Arrival with Multiple Sensors in Airplane Engines. Int. J. Aerosp. Eng. 2018, 2018, 3756278. [Google Scholar] [CrossRef] [Green Version]

- Cao, W.D.; Yao, L.J.; Liu, B.; Zhang, Y.N. The influence of impeller eccentricity on centrifugal pump. Adv. Mech. Eng. 2017, 9, 1687814017722496. [Google Scholar] [CrossRef] [Green Version]

- Huang, H.-C.; Yang, S.-H. Thrust-Bearing Layout Design of a Large-Sized Hydrostatic Rotary Table to Withstand Eccentric Loads for Horizontal Boring Machine Applications. Lubricants 2022, 10, 49. [Google Scholar] [CrossRef]

- Ren, K.-X.; Shuai, Z.-J.; Wang, X.; Jian, J.; Yu, T.; Dong, L.-Y.; Li, W.-Y.; Jiang, C.-X. Aerodynamic noise prediction of a high-speed centrifugal fan considering impeller-eccentric effect. Eng. Appl. Comp. Fluid. 2022, 16, 780–803. [Google Scholar] [CrossRef]

- Tao, R.; Xiao, R.F.; Liu, W.C. Investigation of the flow characteristics in a main nuclear power plant pump with eccentric impeller. Nucl. Eng. Des. 2018, 327, 70–81. [Google Scholar] [CrossRef]

- Lun, Y.X.; Lin, L.M.; He, H.J.; Ye, X.X.; Zhu, Z.C.; Wei, Y.K. Effects of vortex structure on performance characteristics of a multiblade fan with inclined tongue. Proc. Inst. Mech. Eng. Part A-J. Power Energy 2019, 233, 1007–1021. [Google Scholar] [CrossRef]

- Zhu, T.; Carolus, T.H. Axial fan tip clearance noise: Experiments, Lattice-Boltzmann simulation, and mitigation measures. Int. J. Aeroacoust. 2018, 17, 159–183. [Google Scholar] [CrossRef]

- Akin, A.; Kahveci, H.S. Effect of turbulence modeling for the prediction of flow and heat transfer in rotorcraft avionics bay. Aerosp. Sci. Technol. 2019, 95, 105453. [Google Scholar] [CrossRef]

- Zhu, L.F.; Jin, Y.Z.; Li, Y.; Jin, Y.Z.; Wang, Y.P.; Zhang, L. Numerical and Experimental Study on Aerodynamic Performance of Small Axial Flow Fan with Splitter Blades. J. Therm. Sci. 2013, 22, 333–339. [Google Scholar] [CrossRef]

| Serial Number | Measurement Parameters (Units) |

|---|---|

| 1 | Atmospheric pressure (Pa) |

| 2 | Temperature (°C) |

| 3 | Humidity (RH) |

| 4 | Static pressure at fan inlet (Pa) |

| 5 | Pipeline downstream pressure (Pa) |

| 6 | Rotational speed (r/min) |

| 7 | Torque (N∙m) |

| Measurement Parameters | Value | Measurement Parameters | Value |

|---|---|---|---|

| Atmospheric temperature (°C) | 26.3 | Standard speed (rpm) | 5000 |

| Saturated vapor pressure (Pa) | 3422.59 | Airways diameter (mm) | 600 |

| Relative humidity (%) | 20.74 | Impeller diameter (mm) | 620 |

| Atmospheric pressure (Pa) | 101,655 |

| Scenario | Number of Grids | Total Pressure Efficiency |

|---|---|---|

| 1 | 3,343,365 | 57.01% |

| 2 | 6,396,627 | 64.78% |

| 3 | 6,814,085 | 65.17% |

| 4 | 7,601,490 | 65.24% |

| 5 | 8,565,474 | 65.29% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Guo, Y.; Zhang, Y.; Gu, C.; Yang, L. Effects of Tip Clearance and Impeller Eccentricity on the Aerodynamic Performance of Mixed Flow Fan. Symmetry 2023, 15, 201. https://doi.org/10.3390/sym15010201

Liu S, Guo Y, Zhang Y, Gu C, Yang L. Effects of Tip Clearance and Impeller Eccentricity on the Aerodynamic Performance of Mixed Flow Fan. Symmetry. 2023; 15(1):201. https://doi.org/10.3390/sym15010201

Chicago/Turabian StyleLiu, Shulian, Yizhe Guo, Yuchi Zhang, Cunkai Gu, and Likang Yang. 2023. "Effects of Tip Clearance and Impeller Eccentricity on the Aerodynamic Performance of Mixed Flow Fan" Symmetry 15, no. 1: 201. https://doi.org/10.3390/sym15010201