Electron Microscopy Study of Structural Defects Formed in Additively Manufactured AlSi10Mg Alloy Processed by Equal Channel Angular Pressing

Abstract

:1. Introduction

2. Methodology

- Laser power: 175 W;

- Scan speed: 1.4 m/s;

- Layer thickness: 20 µm.

- Low-temperature annealing at 280 °C for 9 min (sample designation–HT280);

- Low-temperature annealing at 320 °C for 9 min (sample designation HT320).

3. Results

3.1. Effect of Heat Treatment and Plastic Deformation on the Cellular Microstructure

3.2. Submicrometric Microstructure Analysis

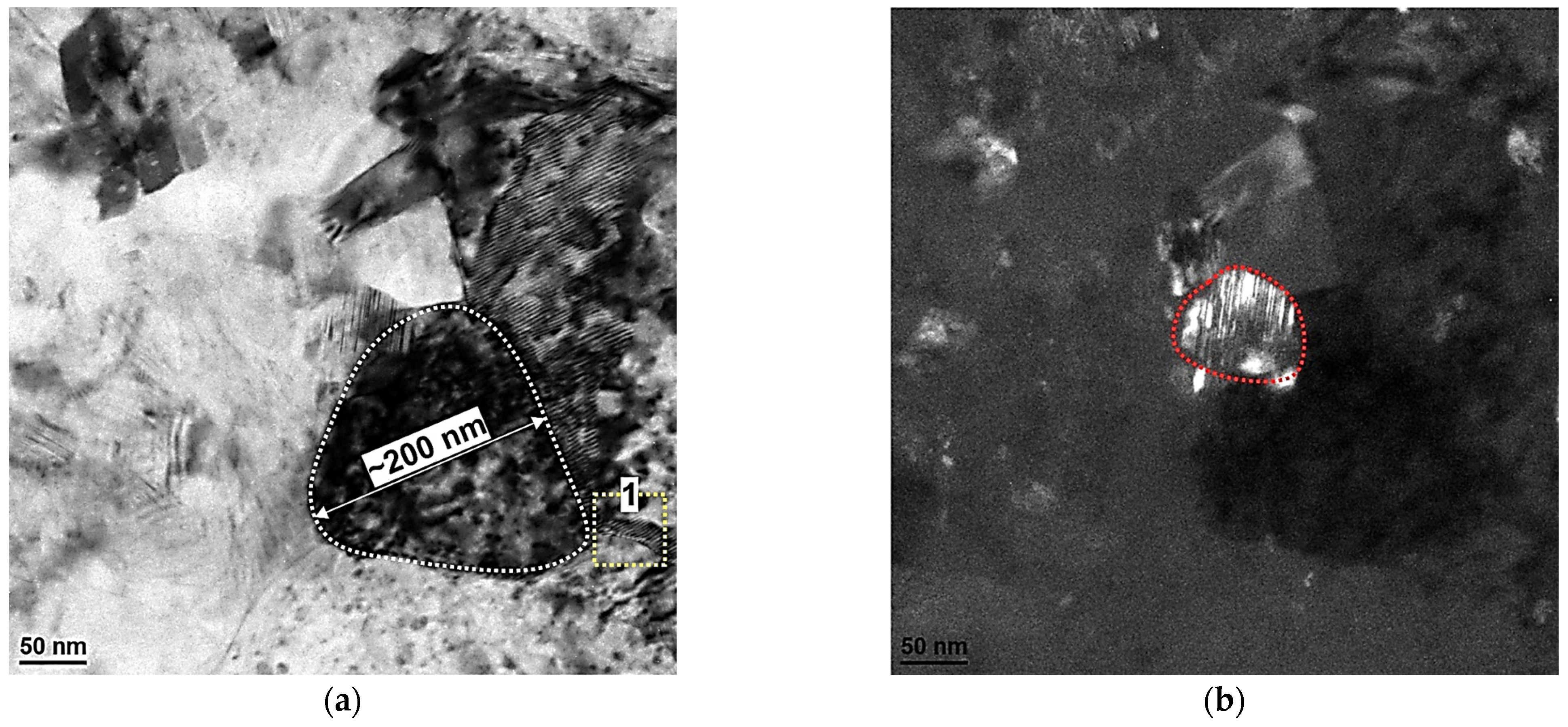

3.2.1. Sample HT280E150

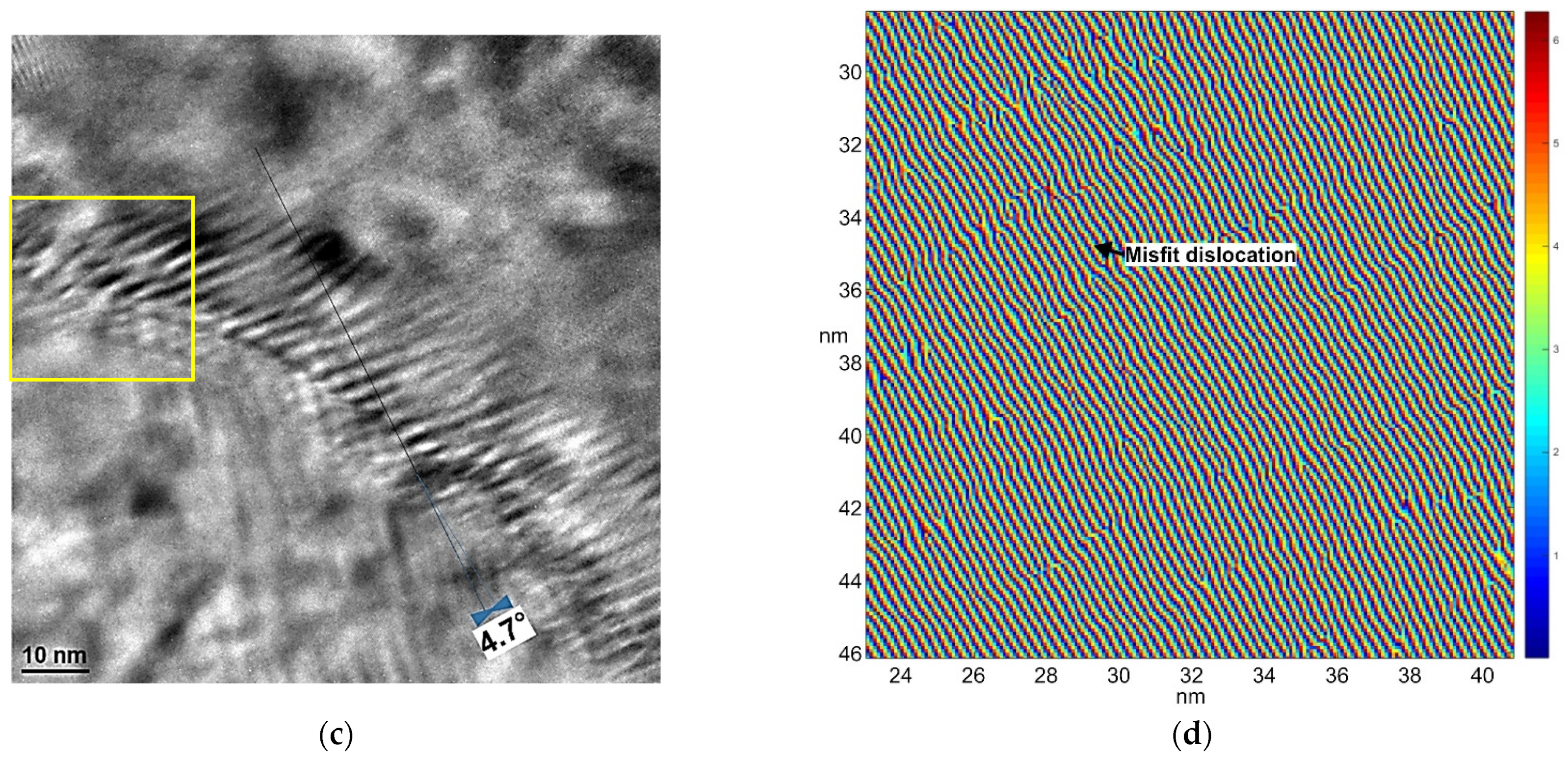

3.2.2. Sample HT320E100

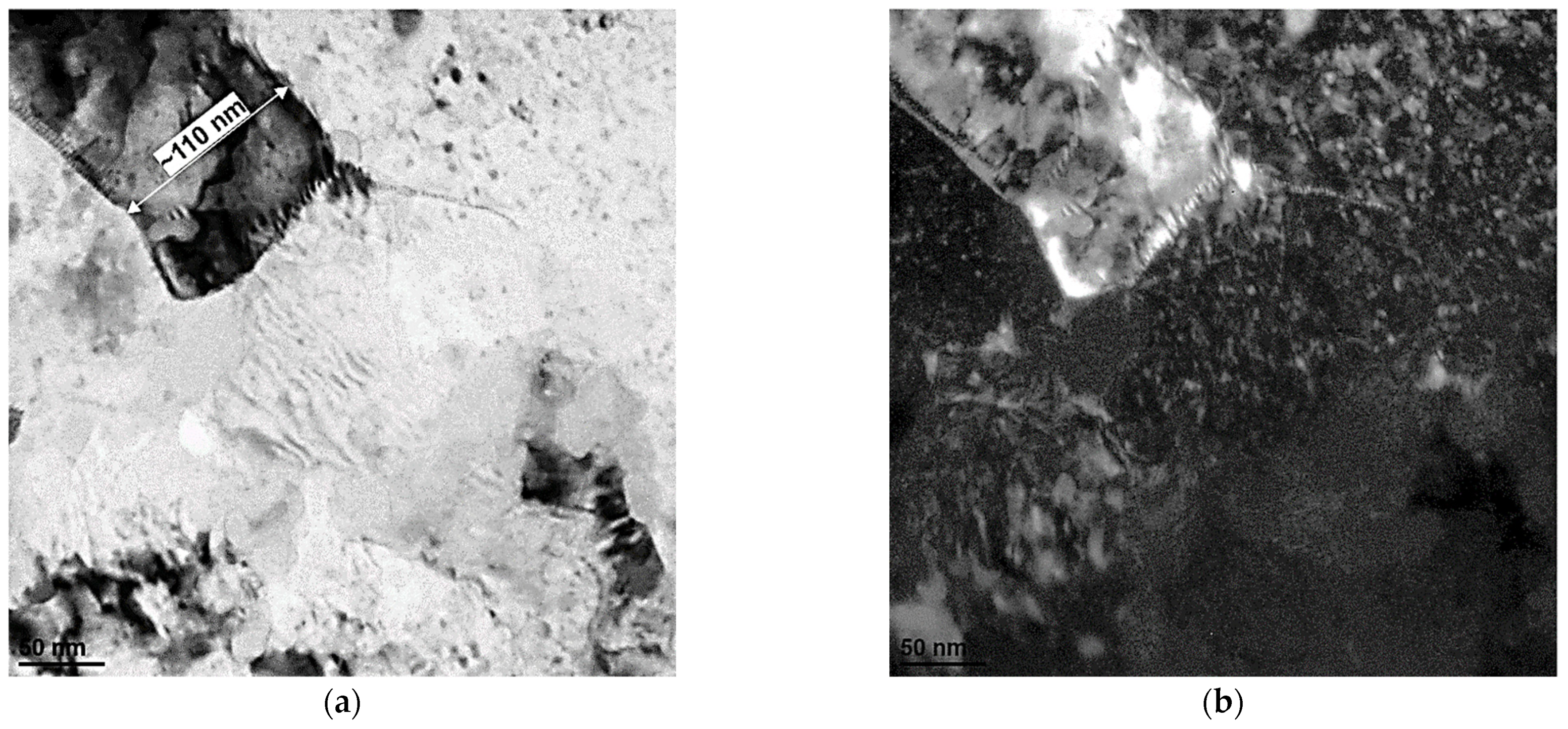

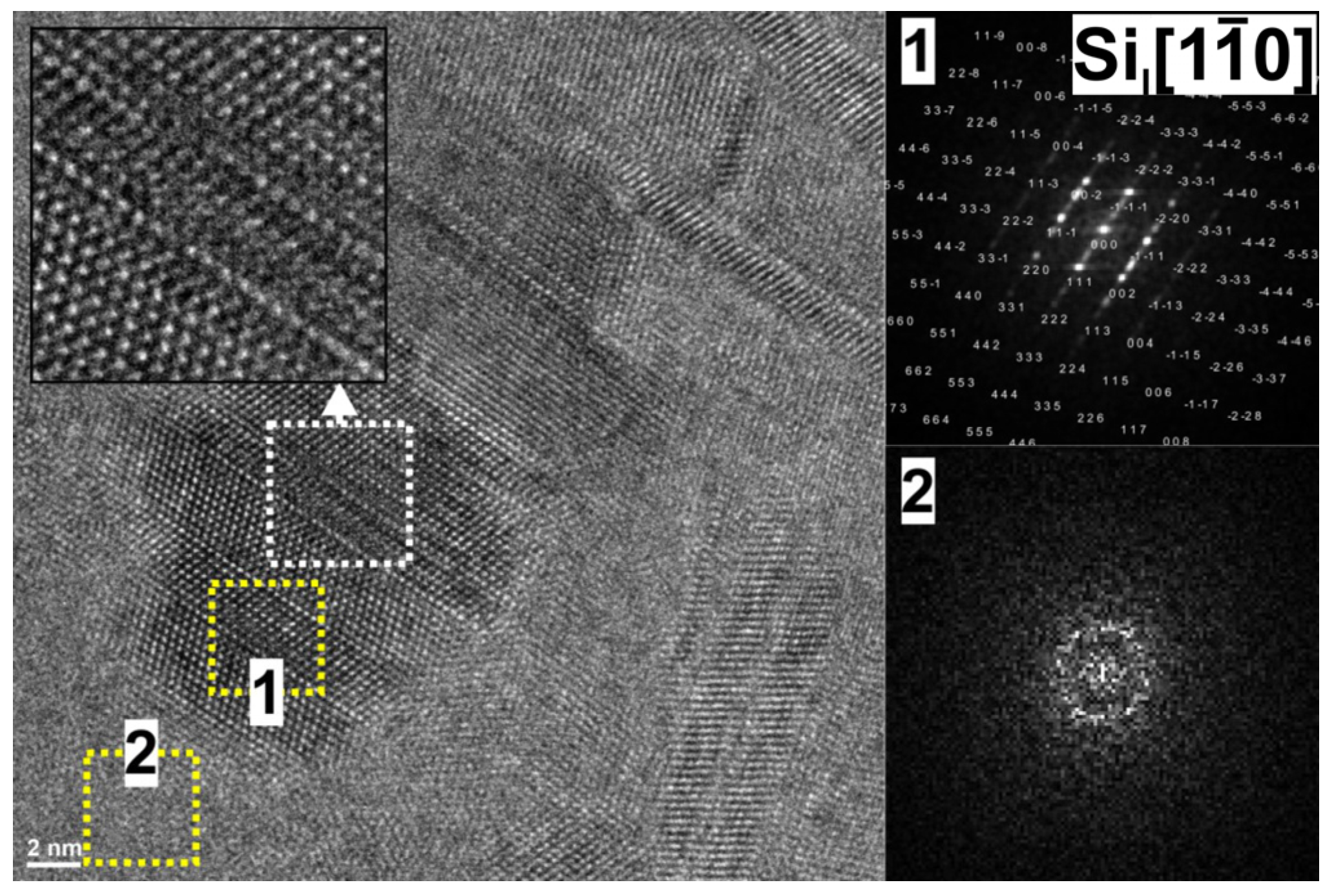

3.3. Plastic Deformation Modes of the Si Phase at 150 °C

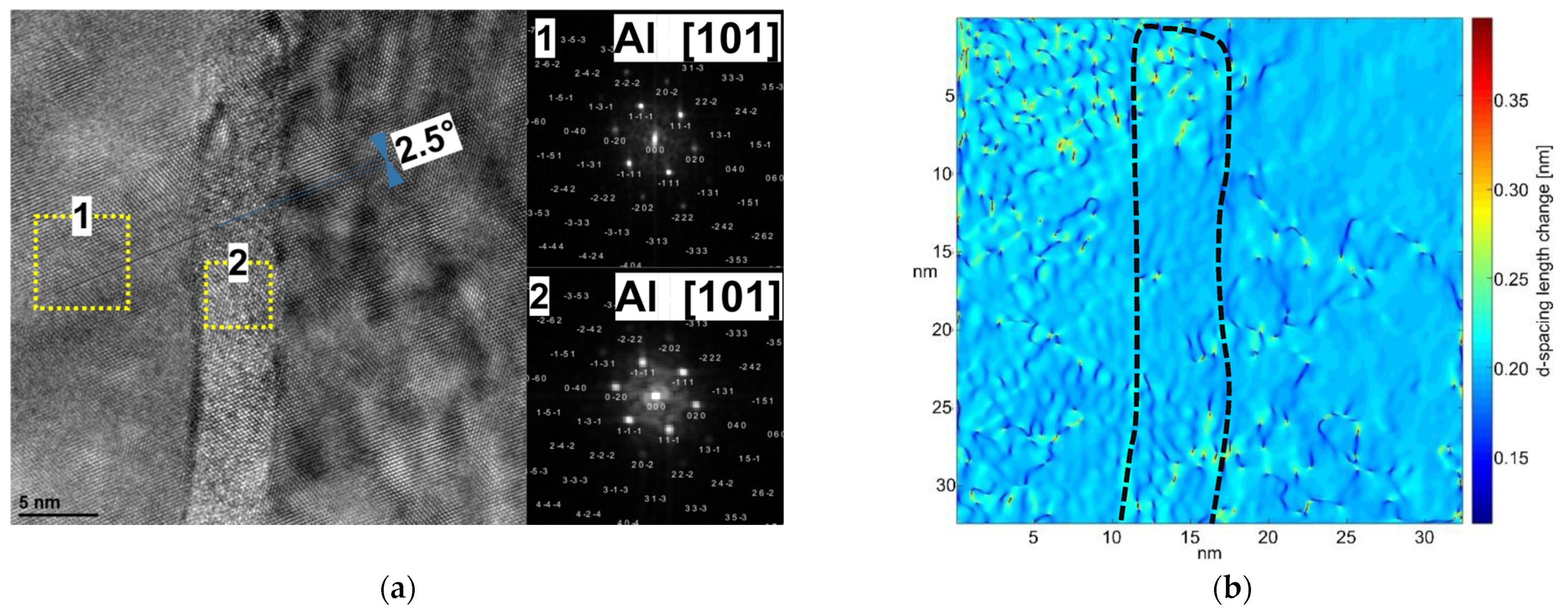

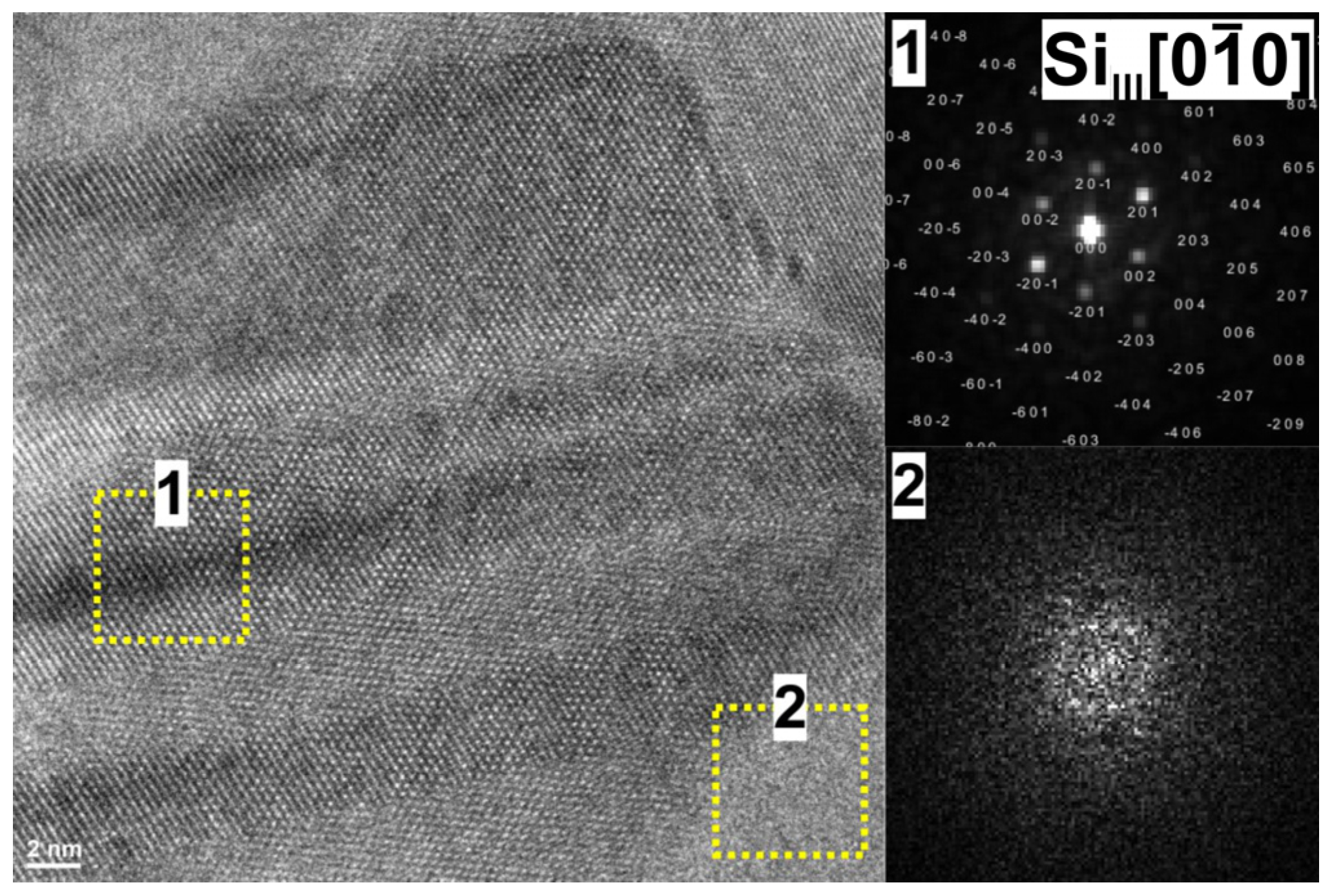

3.4. Plastic Deformation Modes of the Si Phase at 100 °C

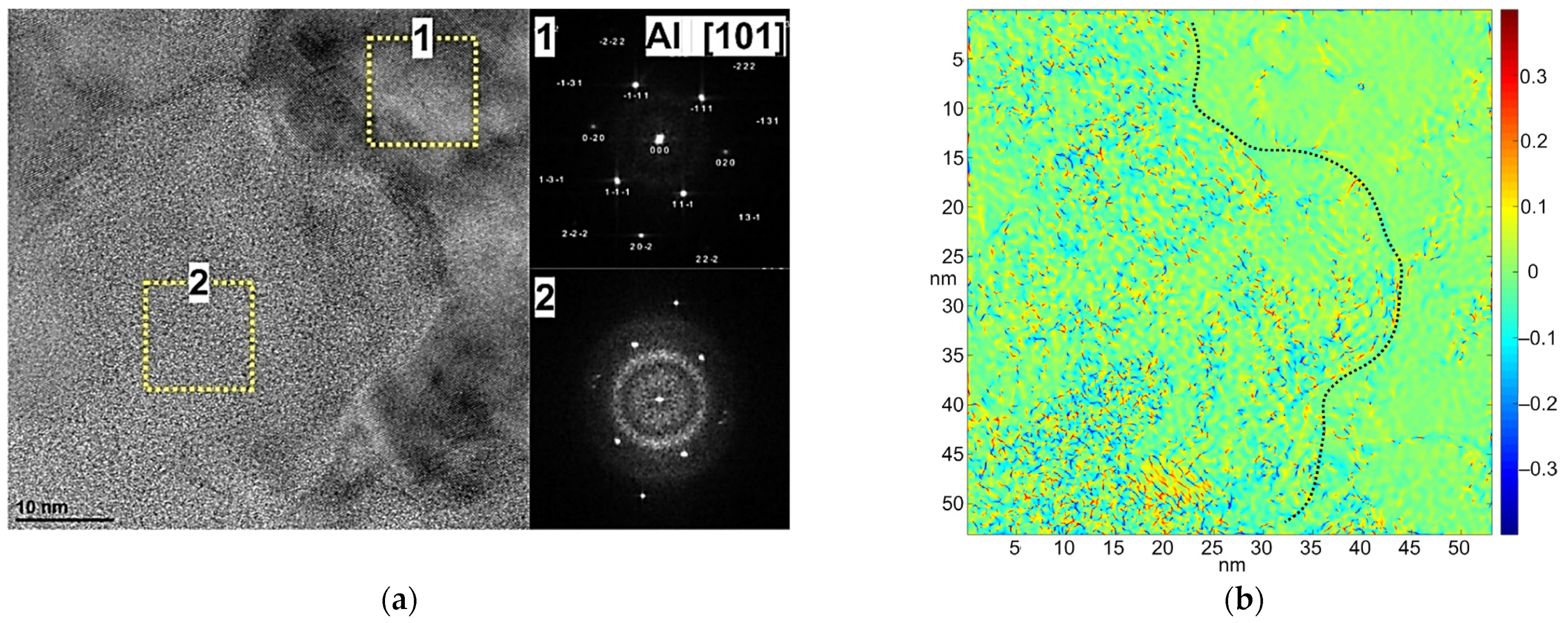

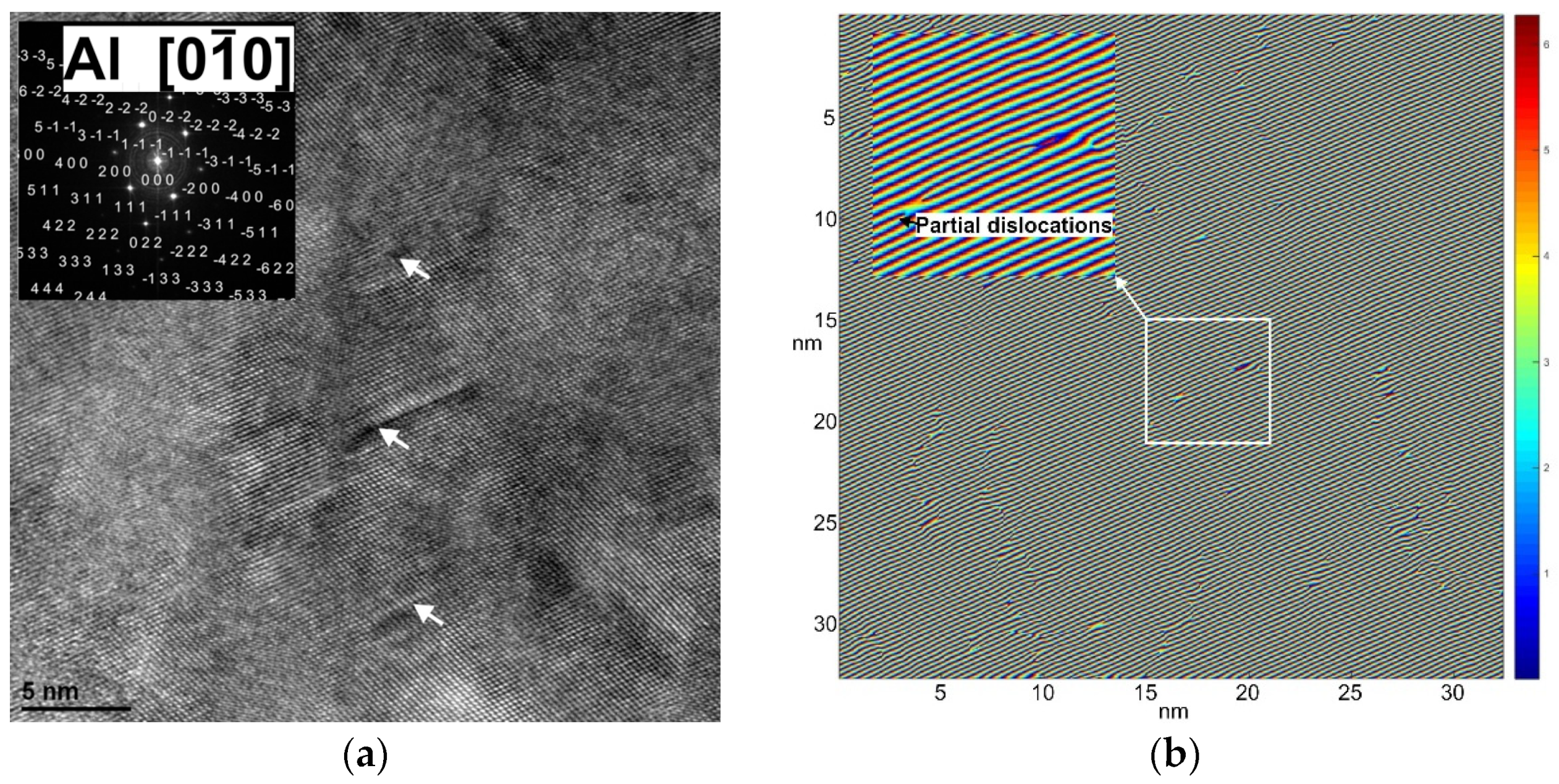

3.5. Aluminium Phase Deformation Mode

- Defect (ii) is a single Y-like edge dislocation caused by the slippage of the atomic plane by half a layer;

- The defects (i) and (iv) consist of a pair of (ii) defects with opposite Burgers vector interacting at a certain distance. Such a configuration is advantageous to reduce the total stress energy;

- Defect (iii) is a single strain region extending over a relatively large area (more than 3–4 layers), where the lattice displacement is less than half of the interlayer.

4. Conclusions

- The ECAP processing of additively manufactured AlSi10Mg alloy resulted in a very fine-grained microstructure sizes in the range of 0.1–0.2 µm. The refined microstructure consisted of dislocation arrays.

- During ECAP processing, the dislocation slip was the dominant mechanism of the aluminium matrix in both investigated samples.

- Partial dislocation-associated stacking faults formation was an additional deformation mechanism of the sample deformed at 100 °C.

- The phase transformation of diamond cubic Si phase was a dominant deformation mode at higher deformation temperature (ECAP at 150 °C); whereas, at lower deformation temperature (ECAP at 100 °C), only amorphous Si phase was formed.

- All of the deformation mechanisms shown could inhibit the initiation and propagation of cracks and significantly affect the ductility of an alloy. Materials scientists should incorporate these mechanisms when designing novel post-processing methods to accurately design the properties of SLMed Al–Si alloys.

Funding

Data Availability Statement

Conflicts of Interest

References

- Kurian, S.; Mirzaeifar, R. Deformation mechanisms of the subgranular cellular structures in selective laser melted 316L stainless steel. Mech. Mater. 2020, 148, 103478. [Google Scholar] [CrossRef]

- Pilgar, C.M.; Fernandez, A.M.; Lucarini, S.; Segurado, J. Effect of printing direction and thickness on the mechanical behavior of SLM fabricated Hastelloy-X. Int. J. Plast. 2022, 153, 103250. [Google Scholar] [CrossRef]

- Limbasiya, N.; Jain, A.; Soni, H.; Wankhede, V.; Krolczyk, G.; Sahlot, P. A comprehensive review on the effect of process parameters and post-process treatments on microstructure and mechanical properties of selective laser melting of AlSi10Mg. J. Mater. Res. Technol. 2022, 21, 1141–1176. [Google Scholar] [CrossRef]

- Cai, X.; Liu, T.; Yan, X.; Cheng, Z.; Pan, L.; Tian, Z.; Luo, L.; Su, Y. Effect of process parameters on microstructures and properties of Al–42Si alloy fabricated by selective laser melting. Heliyon 2022, 8, e09680. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Wei, S.; Ni, X.; Zhang, L.; Li, R.; Wang, L.; Man, C.; Li, X. About metastable cellular structure in additively manufactured austenitic stainless steels. Addit. Manuf. 2021, 38, 101804. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, J.; Fu, Y.; Xu, B.; Li, B.; Xu, S.; Huang, P.; Cheng, J.; Han, Y.; Han, J.; et al. Tuning strength-ductility combination on selective laser melted 316L stainless steel through gradient heterogeneous structure. Addit. Manuf. 2021, 48, 102373. [Google Scholar] [CrossRef]

- Mohd Yusuf, S.; Chen, Y.; Yang, S.; Gao, N. Microstructural evolution and strengthening of selective laser melted 316L stainless steel processed by high-pressure torsion. Mater. Charact. 2020, 159, 110012. [Google Scholar] [CrossRef]

- Hirata, T.; Kimura, T.; Nakamoto, T. Effects of hot isostatic pressing and internal porosity on the performance of selective laser melted AlSi10Mg alloys. Mater. Sci. Eng. A 2020, 772, 138713. [Google Scholar] [CrossRef]

- Zhang, H.; Li, C.; Yao, G.; Zhang, Y. Hot isostatic pressing of laser powder-bed-fused 304L stainless steel under different temperatures. Int. J. Mech. Sci. 2022, 226, 107413. [Google Scholar] [CrossRef]

- Zhong, Y.; Liu, L.; Wikman, S.; Cui, D.; Shen, Z. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J. Nucl. Mater. 2016, 470, 170–178. [Google Scholar] [CrossRef]

- Maamoun, A.; Elbestawi, M.; Veldhuis, S. Influence of Shot Peening on AlSi10Mg Parts Fabricated by Additive Manufacturing. J. Manuf. Mater. Process. 2018, 2, 40. [Google Scholar] [CrossRef] [Green Version]

- Ma, R.; Peng, C.; Cai, Z.; Wang, R.; Zhou, Z.; Li, X.; Cao, X. Enhanced strength of the selective laser melted Al-Mg-Sc-Zr alloy by cold rolling. Mater. Sci. Eng. A 2020, 775, 138975. [Google Scholar] [CrossRef]

- Hosseinzadeh, A.; Radi, A.; Richter, J.; Wegener, T.; Sajadifar, S.V.; Niendorf, T.; Yapici, G.G. Severe plastic deformation as a processing tool for strengthening of additive manufactured alloys. J. Manuf. Process. 2021, 68, 788–795. [Google Scholar] [CrossRef]

- Mohd Yusuf, S.; Nie, M.; Chen, Y.; Yang, S.; Gao, N. Microstructure and corrosion performance of 316L stainless steel fabricated by Selective Laser Melting and processed through high-pressure torsion. J. Alloys Compd. 2018, 763, 360–375. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Hoegden, M.; Gao, N. Effect of sample orientation on the microstructure and microhardness of additively manufactured AlSi10Mg processed by high-pressure torsion. Int. J. Adv. Manuf. Technol. 2020, 106, 4321–4337. [Google Scholar] [CrossRef] [Green Version]

- Langdon, T.G. The principles of grain refinement in equal-channel angular pressing. Mater. Sci. Eng. A 2007, 462, 3–11. [Google Scholar] [CrossRef]

- Snopiński, P.; Tański, T.; Gołombek, K.; Rusz, S.; Hilser, O.; Donič, T.; Nuckowski, P.M.; Benedyk, M. Strengthening of AA5754 Aluminum Alloy by DRECE Process Followed by Annealing Response Investigation. Materials 2020, 13, 301. [Google Scholar] [CrossRef] [Green Version]

- Snopiński, P.; Woźniak, A.; Pagáč, M. Microstructural Evolution, Hardness, and Strengthening Mechanisms in SLM AlSi10Mg Alloy Subjected to Equal-Channel Angular Pressing (ECAP). Materials 2021, 14, 7598. [Google Scholar] [CrossRef]

- Liu, M.; Roven, H.J.; Liu, X.; Murashkin, M.; Valiev, R.Z.; Ungár, T.; Balogh, L. Grain refinement in nanostructured Al-Mg alloys subjected to high pressure torsion. J. Mater. Sci. 2010, 45, 4659–4664. [Google Scholar] [CrossRef]

- Reza Toroghinejad, M.; Ashrafizadeh, F.; Jamaati, R. On the use of accumulative roll bonding process to develop nanostructured aluminum alloy 5083. Mater. Sci. Eng. A 2013, 561, 145–151. [Google Scholar] [CrossRef]

- Orlov, D.; Beygelzimer, Y.; Synkov, S.; Varyukhin, V.; Tsuji, N.; Horita, Z. Plastic flow, structure and mechanical properties in pure Al deformed by twist extrusion. Mater. Sci. Eng. A 2009, 519, 105–111. [Google Scholar] [CrossRef]

- Saxl, I.; Kalousová, A.; Ilucová, L.; Sklenička, V. Grain and subgrain boundaries in ultrafine-grained materials. Mater. Charact. 2009, 60, 1163–1167. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Wang, Q.; Attarilar, S. A comprehensive review of magnesium-based alloys and composites processed by cyclic extrusion compression and the related techniques. Prog. Mater. Sci. 2023, 131, 101016. [Google Scholar] [CrossRef]

- Song, X.; Wang, L.; Wang, R.; Liu, Y. Effects of annealing on microstructure evolution and mechanical properties of constrained groove pressed pure titanium. Mater. Sci. Eng. A 2022, 831, 142245. [Google Scholar] [CrossRef]

- Zhang, L.; Ren, R.; Ren, J.; Liu, Y.; Liao, W.; Li, T.; Liu, C.; Wang, Q. Effects of cyclic closed-die forging on the microstructural evolution and mechanical properties of SiC/AZ91D nanocomposites. Int. J. Mod. Phys. B 2022, 36, 2240066. [Google Scholar] [CrossRef]

- Tang, L.; Peng, X.; Huang, J.; Ma, A.; Deng, Y.; Xu, G. Microstructure and mechanical properties of severely deformed Al-Mg-Sc-Zr alloy and their evolution during annealing. Mater. Sci. Eng. A 2019, 754, 295–308. [Google Scholar] [CrossRef]

- Frint, P.; Wagner, M.F.-X. Strain partitioning by recurrent shear localization during equal-channel angular pressing of an AA6060 aluminum alloy. Acta Mater. 2019, 176, 306–317. [Google Scholar] [CrossRef]

- Park, J.M.; Asghari-Rad, P.; Zargaran, A.; Bae, J.W.; Moon, J.; Kwon, H.; Choe, J.; Yang, S.; Yu, J.-H.; Kim, H.S. Nano-scale heterogeneity-driven metastability engineering in ferrous medium-entropy alloy induced by additive manufacturing. Acta Mater. 2021, 221, 117426. [Google Scholar] [CrossRef]

- Snopiński, P.; Matus, K.; Tatiček, F.; Rusz, S. Overcoming the strength-ductility trade-off in additively manufactured AlSi10Mg alloy by ECAP processing. J. Alloys Compd. 2022, 918, 165817. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.; Tan, Z.; Xiong, D.B.; Guo, Q. Stress relaxation and the cellular structure-dependence of plastic deformation in additively manufactured AlSi10Mg alloys. Int. J. Plast. 2020, 127, 102640. [Google Scholar] [CrossRef]

- Zhang, Z.; Ódor, É.; Farkas, D.; Jóni, B.; Ribárik, G.; Tichy, G.; Nandam, S.-H.; Ivanisenko, J.; Preuss, M.; Ungár, T. Dislocations in Grain Boundary Regions: The Origin of Heterogeneous Microstrains in Nanocrystalline Materials. Metall. Mater. Trans. A 2020, 51, 513–530. [Google Scholar] [CrossRef] [Green Version]

- Gerberich, W.W.; Mook, W.M.; Cordill, M.J.; Carter, C.B.; Perrey, C.R.; Heberlein, J.V.; Girshick, S.L. Reverse plasticity in single crystal silicon nanospheres. Int. J. Plast. 2005, 21, 2391–2405. [Google Scholar] [CrossRef]

- Fang, Q.; Zhang, L. Emission of partial dislocations in silicon under nanoindentation. J. Mater. Res. 2013, 28, 1995–2003. [Google Scholar] [CrossRef]

- Jiapeng, S.; Cheng, L.; Han, J.; Ma, A.; Fang, L. Nanoindentation Induced Deformation and Pop-in Events in a Silicon Crystal: Molecular Dynamics Simulation and Experiment. Sci. Rep. 2017, 7, 10282. [Google Scholar] [CrossRef]

- Huang, J.Y.; Yasuda, H.; Mori, H. Deformation-induced amorphization in ball-milled silicon. Philos. Mag. Lett. 1999, 79, 305–314. [Google Scholar] [CrossRef]

- Kiran, M.S.R.N.; Tran, T.T.; Smillie, L.A.; Haberl, B.; Subianto, D.; Williams, J.S.; Bradby, J.E. Temperature-dependent mechanical deformation of silicon at the nanoscale: Phase transformation versus defect propagation. J. Appl. Phys. 2015, 117, 205901. [Google Scholar] [CrossRef] [Green Version]

- Crain, J.; Ackland, G.J.; Maclean, J.R.; Piltz, R.O.; Hatton, P.D.; Pawley, G.S. Reversible pressure-induced structural transitions between metastable phases of silicon. Phys. Rev. B 1994, 50, 13043–13046. [Google Scholar] [CrossRef]

- Zhao, S.; Hahn, E.N.; Kad, B.; Remington, B.A.; Wehrenberg, C.E.; Bringa, E.M.; Meyers, M.A. Amorphization and nanocrystallization of silicon under shock compression. Acta Mater. 2016, 103, 519–533. [Google Scholar] [CrossRef] [Green Version]

- Follstaedt, D.M.; Knapp, J.A.; Myers, S.M. Mechanical properties of ion-implanted amorphous silicon. J. Mater. Res. 2004, 19, 33. [Google Scholar] [CrossRef]

- Kulikovsky, V.; Vorlíček, V.; Boháč, P.; Stranyánek, M.; Čtvrtlík, R.; Kurdyumov, A. Mechanical properties of amorphous and microcrystalline silicon films. Thin Solid Film. 2008, 516, 5368–5375. [Google Scholar] [CrossRef]

- Chen, H.; Levitas, V.I.; Xiong, L. Amorphization induced by 60° shuffle dislocation pileup against different grain boundaries in silicon bicrystal under shear. Acta Mater. 2019, 179, 287–295. [Google Scholar] [CrossRef]

- McBride, E.E.; Krygier, A.; Ehnes, A.; Galtier, E.; Harmand, M.; Konôpková, Z.; Lee, H.J.; Liermann, H.-P.; Nagler, B.; Pelka, A.; et al. Phase transition lowering in dynamically compressed silicon. Nat. Phys. 2019, 15, 89–94. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Ma, Y.; An, Q.; Levitas, V.; Zhang, Y.; Feng, B.; Chaudhuri, J.; Goddard, W.A. Shear driven formation of nano-diamonds at sub-gigapascals and 300 K. Carbon 2019, 146, 364–368. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.Q.; Huang, H.; Zou, J.; Zhang, L.C.; Dell, J.M. Nanoscratch-induced phase transformation of monocrystalline Si. Scr. Mater. 2010, 63, 847–850. [Google Scholar] [CrossRef]

- Zhang, W.; Hu, Y.; Ma, X.; Qian, G.; Zhang, J.; Yang, Z.; Berto, F. Very-high-cycle fatigue behavior of AlSi10Mg manufactured by selected laser melting: Crystal plasticity modeling. Int. J. Fatigue 2021, 145, 106109. [Google Scholar] [CrossRef]

- Shu, X.; Kong, D.; Lu, Y.; Long, H.; Sun, S.; Sha, X.; Zhou, H.; Chen, Y.; Mao, S.; Liu, Y. Size effect on the deformation mechanisms of nanocrystalline platinum thin films. Sci. Rep. 2017, 7, 13264. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Knezevic, M.; Gao, H.; Wang, J.; Kang, M.; Sun, B. Phase interface induced stacking faults in Al-7.5Y alloy revealed by in-situ synchrotron X-ray diffraction and ex-situ electron microscopy. Mater. Charact. 2021, 179, 111322. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Snopiński, P. Electron Microscopy Study of Structural Defects Formed in Additively Manufactured AlSi10Mg Alloy Processed by Equal Channel Angular Pressing. Symmetry 2023, 15, 860. https://doi.org/10.3390/sym15040860

Snopiński P. Electron Microscopy Study of Structural Defects Formed in Additively Manufactured AlSi10Mg Alloy Processed by Equal Channel Angular Pressing. Symmetry. 2023; 15(4):860. https://doi.org/10.3390/sym15040860

Chicago/Turabian StyleSnopiński, Przemysław. 2023. "Electron Microscopy Study of Structural Defects Formed in Additively Manufactured AlSi10Mg Alloy Processed by Equal Channel Angular Pressing" Symmetry 15, no. 4: 860. https://doi.org/10.3390/sym15040860

APA StyleSnopiński, P. (2023). Electron Microscopy Study of Structural Defects Formed in Additively Manufactured AlSi10Mg Alloy Processed by Equal Channel Angular Pressing. Symmetry, 15(4), 860. https://doi.org/10.3390/sym15040860