The Thermoelastic Dynamic Response of a Rod Due to a Moving Heat Source under the Fractional-Order Thermoelasticity Theory

Abstract

1. Introduction

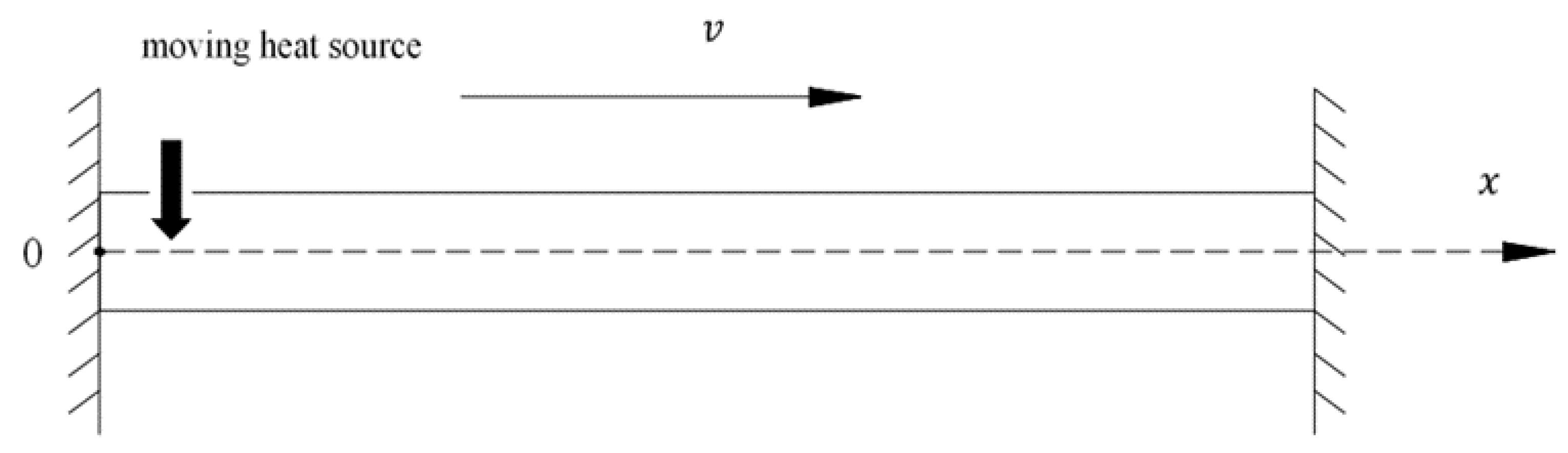

2. Basic Control Equations

3. Formulation of the Problem

4. Laplace’s Solution

5. Numerical Inverse Laplace Transforms

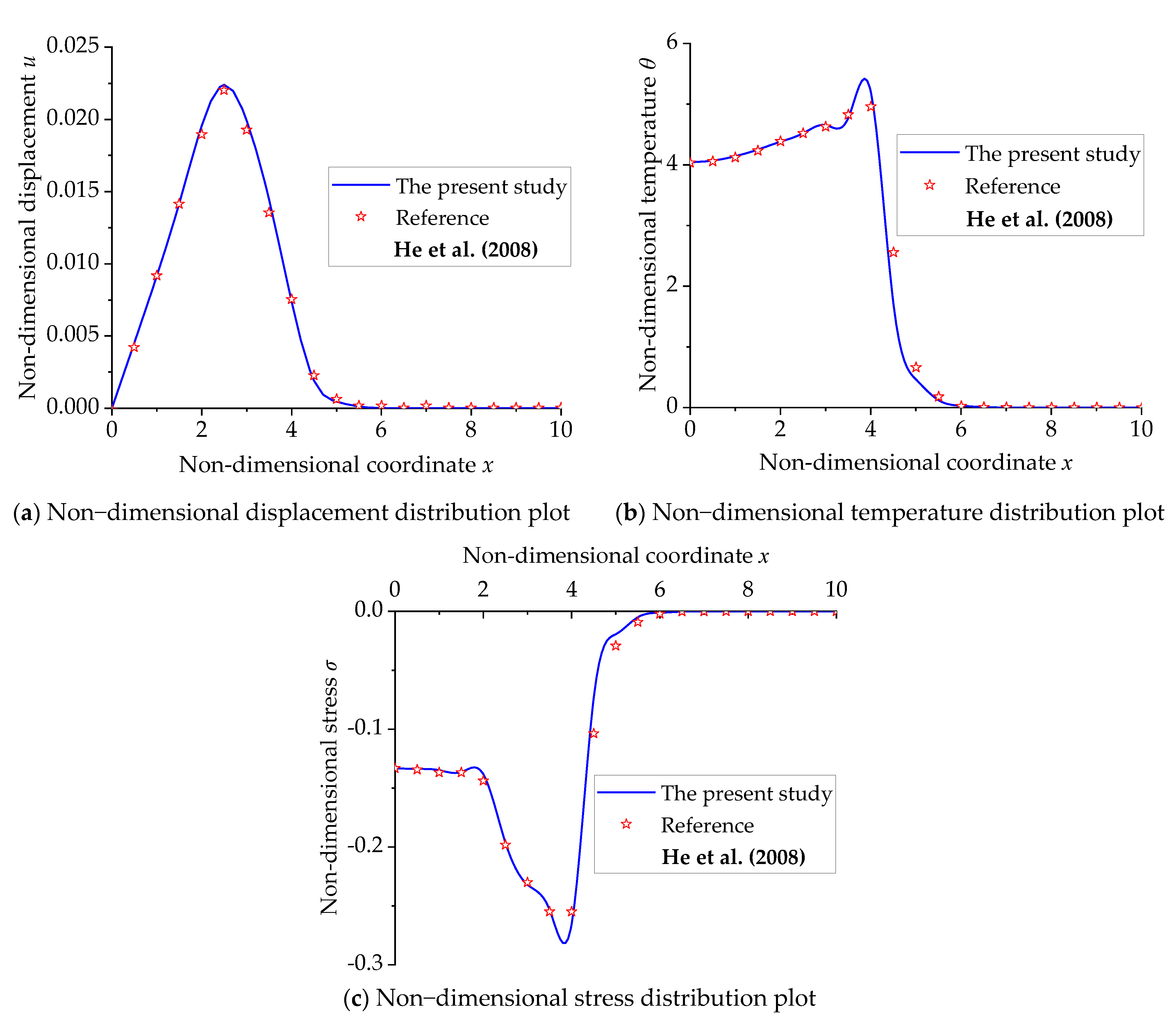

6. Analysis of Numerical Results

7. Conclusions

- (1)

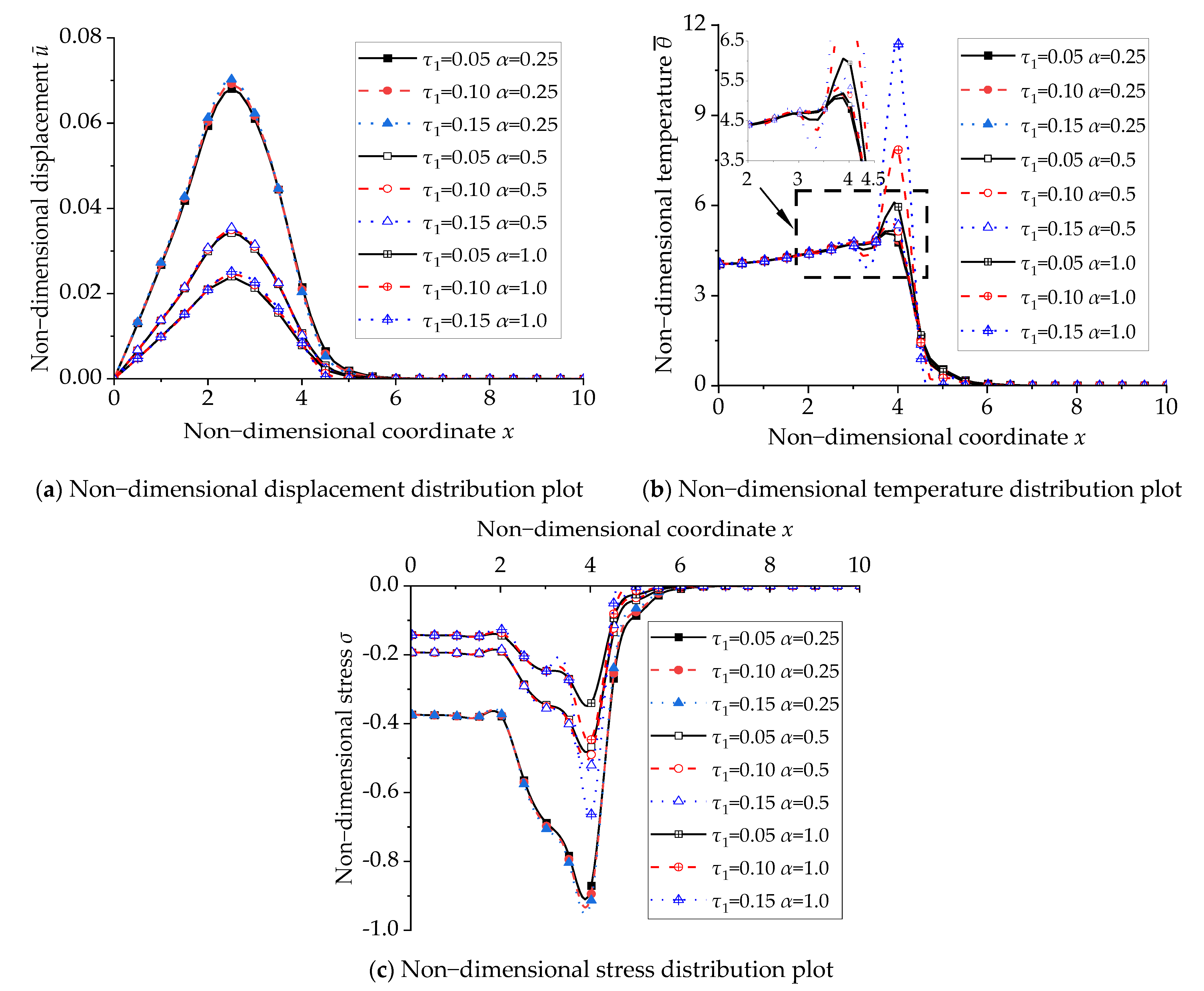

- The fractional coefficient has an important impact on the thermoelastic behavior of a fixed rod within the framework of the fractional-order thermoelasticity theory. The thermoelastic reaction of the fixed rod becomes increasingly noticeable as the fractional-order coefficient declines, particularly for the displacements and stresses within the rod.

- (2)

- The thermal relaxation time has significant effects on the displacements and stresses, which gradually increase as the thermal relaxation time increases for the rod. The thermal relaxation time has no significant effect on the temperature of the rod.

- (3)

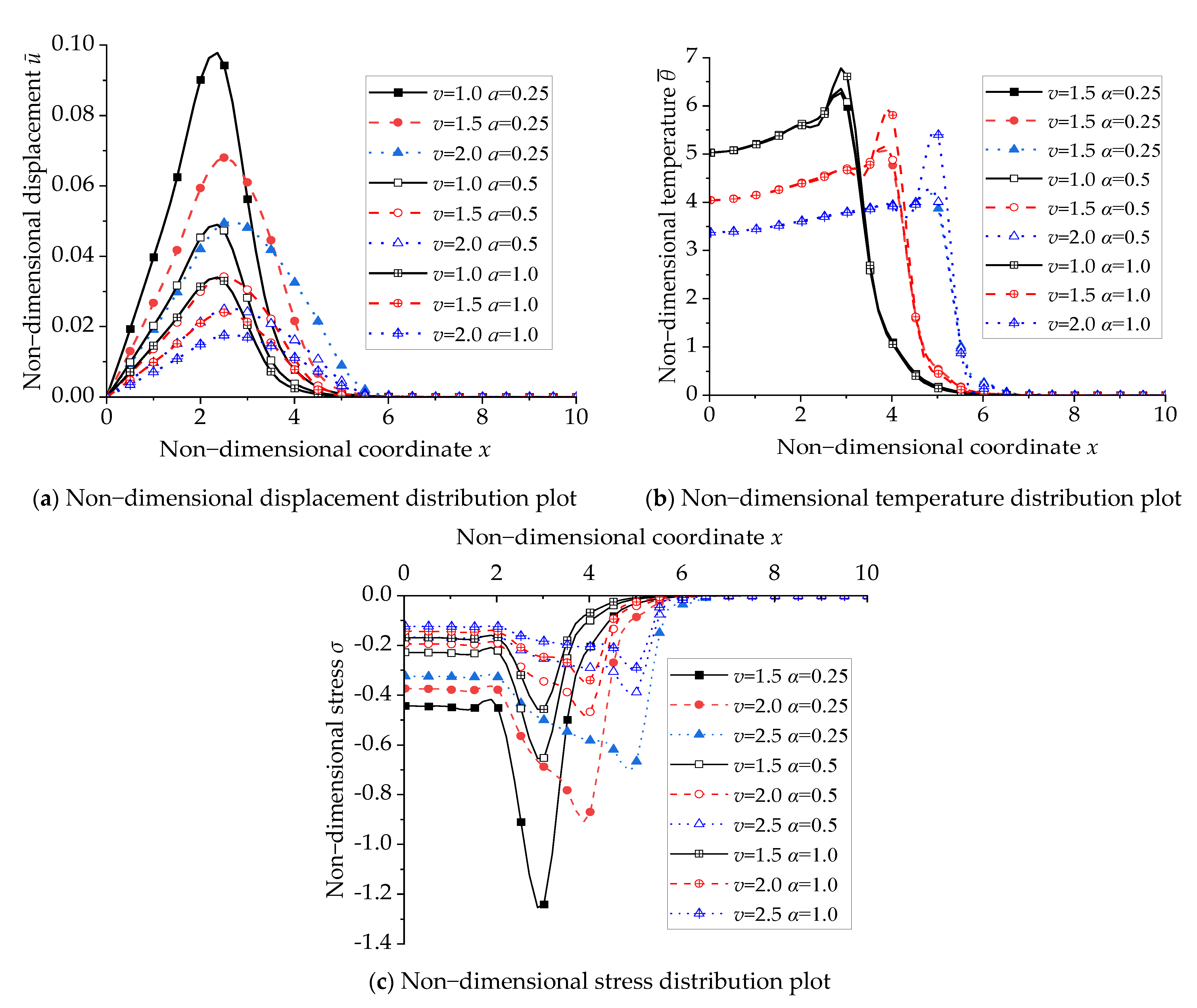

- The thermal relaxation time exerts a considerable influence on the temperature peak region within the rod, whereas its impacts on the stress and displacement within the rod are relatively modest.

- (4)

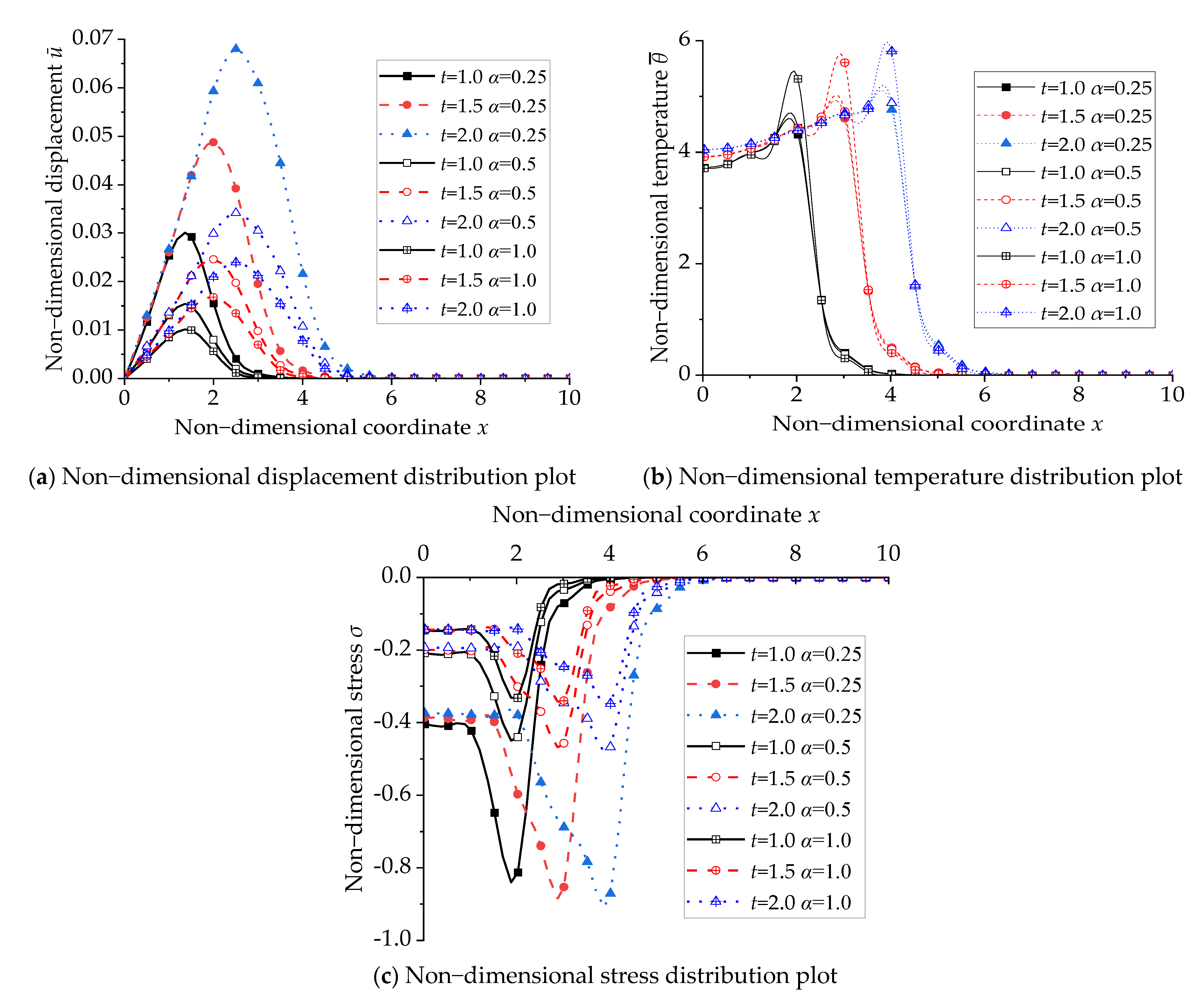

- The time and the heat source’s traveling speed have significant effects on the displacement, temperature, and stress in the rod. Each physical variable decreases with the increasing heat source traveling speed and increases with time.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Biot, M.A. Thermoelasticity and irreversible thermodynamics. J. Appl. Phys. 1956, 27, 240–253. [Google Scholar] [CrossRef]

- Lord, H.W.; Shulman, Y. A generalized dynamical theory of thermoelasticity. J. Mech. Phys. Solids 1967, 15, 299–309. [Google Scholar] [CrossRef]

- Green, A.E.; Lindsay, K.A. Thermoelasticity. J. Elast. 1972, 2, 1–7. [Google Scholar] [CrossRef]

- Green, A.E.; Naghdi, P.M. A reexamination of the basic results of thermomechanics. P. Roy. Soc. 1991, 432, 171–194. [Google Scholar]

- Green, A.E.; Naghdi, P.M. On undamped heat waves in an elastic solid. J. Therm. Stress. 1992, 15, 253–264. [Google Scholar] [CrossRef]

- Green, A.E.; Naghdi, P.M. Thermoelasticity without energy dissipation. J. Elast. 1993, 31, 189–208. [Google Scholar] [CrossRef]

- Oskouie, M.F.; Ansari, R.; Rouhi, H. Studying nonlinear thermomechanical wave propagation in a viscoelastic layer based upon the Lord-Shulman theory. Mech. Adv. Mater. Struc. 2020, 27, 800–806. [Google Scholar] [CrossRef]

- Yu, Y.J.; Xue, Z.N.; Tian, X.G. A modified Green–Lindsay thermoelasticity with strain rate to eliminate the discontinuity. Meccanica 2018, 53, 2543–2554. [Google Scholar] [CrossRef]

- Deswal, S.; Punia, B.S.; Kalkal, K.K. Reflection of plane waves at the initially stressed surface of a fiber-reinforced thermoelastic half space with temperature dependent properties. Int. J. Mech. Mater. Des. 2019, 15, 159–173. [Google Scholar] [CrossRef]

- Youssef, H.M.; Al-Lehaibi, E.A.N. General generalized thermoelasticity theory (GGTT). J. Therm. Anal. Calorim. 2023, 148, 5917–5926. [Google Scholar] [CrossRef]

- Povstenko, Y.Z. Fractional radial heat conduction in an infinite medium with a cylindrical cavity and associated thermal stresses. Mech. Res. Commun. 2010, 37, 436–440. [Google Scholar] [CrossRef]

- Sherief, H.H.; El-Sayed, A.M.A.; El-Latief, A.M.A. Fractional order theory of thermoelasticity. Int. J. Solids Struct. 2010, 47, 269–275. [Google Scholar] [CrossRef]

- Sherief, H.; El-Latief, A.M.A. Effect of variable thermal conductivity on a half-space under the fractional order theory of thermoelasticity. Int. J. Mech. Sci. 2013, 74, 185–189. [Google Scholar] [CrossRef]

- Youssef, H.M. Theory of fractional order generalized thermoelasticity. J. Heat. Trans. 2010, 132, 061301. [Google Scholar] [CrossRef]

- Ezzat, M.A.; El-Karamany, A.S.; Ezzat, S.M. Two-temperature theory in magneto-thermoelasticity with fractional order dual-phase-lag heat transfer. Nucl. Eng. Des. 2012, 252, 267–277. [Google Scholar] [CrossRef]

- Ezzat, M.A.; El-Karamany, A.S.; Fayik, M.A. Fractional order theory in thermoelastic solid with three-phase lag heat transfer. Arch. Appl. Mech. 2012, 82, 557–572. [Google Scholar] [CrossRef]

- Hobiny, A.; Abbas, I. The Effect of a Nonlocal Thermoelastic Model on a Thermoelastic Material under Fractional Time Derivatives. Fractal. Fract. 2022, 6, 639. [Google Scholar] [CrossRef]

- Abouelregal, A.E.; Ahmad, H. A modified thermoelastic fractional heat conduction model with a single-lag and two different fractional-orders. J. Appl. Comput. Mech. 2021, 7, 1676–1686. [Google Scholar]

- Sherief, H.H.; Hussein, E.M. The effect of fractional thermoelasticity on two-dimensional problems in spherical regions under axisymmetric distributions. J. Therm. Stress. 2020, 43, 440–455. [Google Scholar] [CrossRef]

- Sherief, H.H.; El-Latief, A.M.A. A one-dimensional fractional order thermoelastic problem for a spherical cavity. Math. Mech. Solids 2015, 20, 512–521. [Google Scholar] [CrossRef]

- Youssef, H.M.; Alghamdi, A.A. Influence of the fractional-order strain on an infinite material with a spherical cavity under Green-Naghdi hyperbolic two-temperature thermoelasticity theory. J. Eng. Therm. Sci. 2023, 3, 11–24. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, D.; Wang, Q. Effect of fractional order parameter on thermoelastic behaviors in infinite elastic medium with a cylindrical cavity. Acta. Mech. Solida. Sin. 2015, 28, 285–293. [Google Scholar] [CrossRef]

- Hamza, F.; Abdou, M.; El-Latief, A.M.A. Generalized fractional thermoelasticity associated with two relaxation times. J. Therm. Stress. 2014, 37, 1080–1098. [Google Scholar] [CrossRef]

- Kothari, S.; Mukhopadhyay, S. A problem on elastic half space under fractional order theory of thermoelasticity. J. Therm. Stress. 2011, 34, 724–739. [Google Scholar] [CrossRef]

- Varghese, V.; Bhoyar, S.; Khalsa, L. Thermoelastic response of a nonhomogeneous elliptic plate in the framework of fractional order theory. Arch. Appl. Mech. 2021, 91, 3223–3246. [Google Scholar] [CrossRef]

- Tian, X.; Yapeng, S. Research progress in generalized thermoelastic problems. Adv. Mech. 2012, 42, 18–28. [Google Scholar]

- Shakeriaski, F.; Ghodrat, M.; Escobedo-Diaz, J.; Behnia, M. Recent advances in generalized thermoelasticity theory and the modified models: A review. J. Comput. Des. Eng. 2021, 8, 15–35. [Google Scholar] [CrossRef]

- Youssef, H.M.; Al-Lehaibi, E.A.N. The boundary value problem of a three-dimensional generalized thermoelastic half-space subjected to moving rectangular heat source. Bound. Value. Probl. 2019, 2019, 8. [Google Scholar] [CrossRef]

- Youssef, H.M. Two-temperature generalized thermoelastic infinite medium with cylindrical cavity subjected to moving heat source. Arch. Appl. Mech. 2010, 80, 1213–1224. [Google Scholar] [CrossRef]

- Youssef, H.M. Generalized thermoelastic infinite medium with spherical cavity subjected to moving heat source. Comput. Math. Model. 2010, 21, 212–225. [Google Scholar] [CrossRef]

- Mondal, S.; Sur, A.; Bhattacharya, D.; Kanoria, M. Thermoelastic interaction in a magneto-thermoelastic rod with memory-dependent derivative due to the presence of moving heat source. Indian J. Phys. 2020, 94, 1591–1602. [Google Scholar] [CrossRef]

- Zenkour, A.M.; Mashat, D.S.; Allehaibi, A.M. Thermoelastic coupling response of an unbounded solid with a cylindrical cavity due to a moving heat source. Mathematics 2021, 10, 9. [Google Scholar] [CrossRef]

- Sarkar, N.; Mondal, S. Transient responses in a two-temperature thermoelastic infinite medium having cylindrical cavity due to moving heat source with memory-dependent derivative. ZAMM-J. Appl. Math. Mech. Z. Für Angew. Math. Und Mech. 2019, 99, e201800343. [Google Scholar] [CrossRef]

- Abbas, I.A. Eigenvalue approach to fractional order generalized magneto-thermoelastic medium subjected to moving heat source. J. Magn. Magn. Mater. 2015, 377, 452–459. [Google Scholar] [CrossRef]

- Abbas, I.; Marin, M.; Hobiny, A.; Vlase, S. Thermal Conductivity Study of an Orthotropic Medium Containing a Cylindrical Cavity. Symmetry 2022, 14, 2387. [Google Scholar] [CrossRef]

- Ma, Y.B.; Peng, W. Dynamic response of an infinite medium with a spherical cavity on temperature-dependent properties subjected to a thermal shock under fractional-order theory of thermoelasticity. J. Therm. Stress. 2018, 41, 302–312. [Google Scholar] [CrossRef]

- Ma, Y.B.; He, T.H. The transient response of a functionally graded piezoelectric rod subjected to a moving heat source under fractional order theory of thermoelasticity. Mech. Adv. Mater. Struc. 2017, 24, 789–796. [Google Scholar] [CrossRef]

- Ma, Y.B.; He, T.H. Dynamic response of a generalized piezoelectric-thermoelastic problem under fractional order theory of thermoelasticity. Mech. Adv. Mater. Struc. 2016, 23, 1173–1180. [Google Scholar] [CrossRef]

- Youssef, H.M. State-space approach to fractional order two-temperature generalized thermoelastic medium subjected to moving heat source. Mech. Adv. Mater. Struc. 2013, 20, 47–60. [Google Scholar] [CrossRef]

- Al-Huniti, N.S.; Al-Nimr, M.A.; Naji, M. Dynamic response of a rod due to a moving heat source under the hyperbolic heat conduction model. J. Sound. Vib. 2001, 242, 629–640. [Google Scholar] [CrossRef]

- He, T.H.; Guo, Y. A One-Dimensional Thermoelastic Problem due to a Moving Heat Source under Fractional Order Theory of Thermoelasticity. Adv. Mater. Sci. Eng. 2014, 2014, 510205. [Google Scholar] [CrossRef]

- Xiong, C.B.; Guo, Y. Effect of Variable Properties and Moving Heat Source on Magnetothermoelastic Problem under Fractional Order Thermoelasticity. Adv. Mater. Sci. Eng. 2016, 2016, 5341569. [Google Scholar] [CrossRef]

- Ezzat, M.A. Thermoelectric MHD non-Newtonian fluid with fractional derivative heat transfer. Phys. B 2010, 405, 4188–4194. [Google Scholar] [CrossRef]

- Jumarie, G. Derivation and solutions of some fractional Black–Scholes equations in coarse-grained space and time. Application to Merton’s optimal portfolio. Comput. Math. Appl. 2010, 59, 1142–1164. [Google Scholar] [CrossRef]

- Honig, G.; Hirdes, U. A method for the numerical inversion of Laplace transforms. J. Comput. Appl. Math. 1984, 10, 113–132. [Google Scholar] [CrossRef]

- He, T.H.; Cao, L.; Zhen, Y.H. Generalized thermoelastic coupled problem of a rod fixed at both ends and subjected to a moving heat source. Eng. Mech. 2008, 25, 22–026. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Shi, P.; Guo, Y. The Thermoelastic Dynamic Response of a Rod Due to a Moving Heat Source under the Fractional-Order Thermoelasticity Theory. Symmetry 2024, 16, 666. https://doi.org/10.3390/sym16060666

Liu F, Shi P, Guo Y. The Thermoelastic Dynamic Response of a Rod Due to a Moving Heat Source under the Fractional-Order Thermoelasticity Theory. Symmetry. 2024; 16(6):666. https://doi.org/10.3390/sym16060666

Chicago/Turabian StyleLiu, Fengjun, Pengjie Shi, and Ying Guo. 2024. "The Thermoelastic Dynamic Response of a Rod Due to a Moving Heat Source under the Fractional-Order Thermoelasticity Theory" Symmetry 16, no. 6: 666. https://doi.org/10.3390/sym16060666

APA StyleLiu, F., Shi, P., & Guo, Y. (2024). The Thermoelastic Dynamic Response of a Rod Due to a Moving Heat Source under the Fractional-Order Thermoelasticity Theory. Symmetry, 16(6), 666. https://doi.org/10.3390/sym16060666