Anti-Fatigue-Damage-Oriented Through-Life Optimization and Control of High-Power IGCT Converters in Wind Energy Systems

Abstract

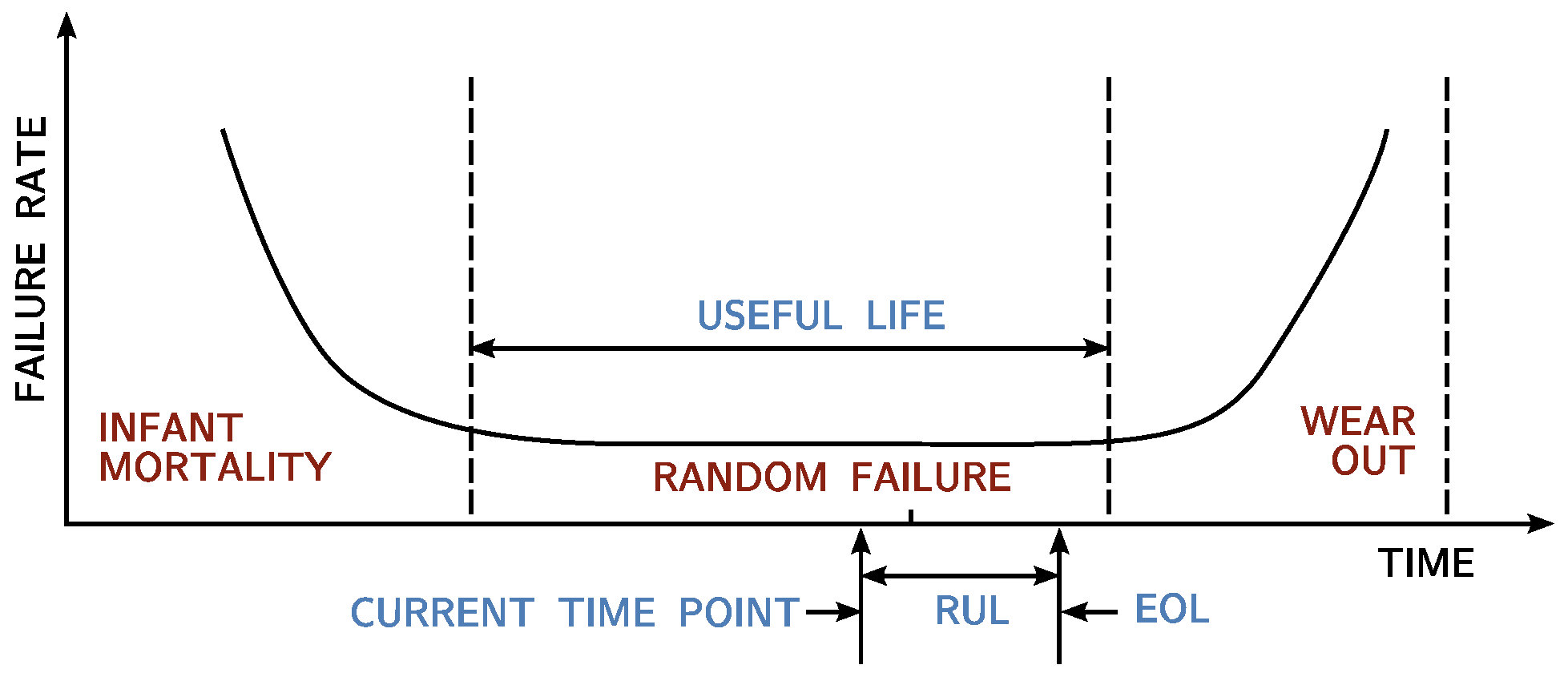

1. Introduction

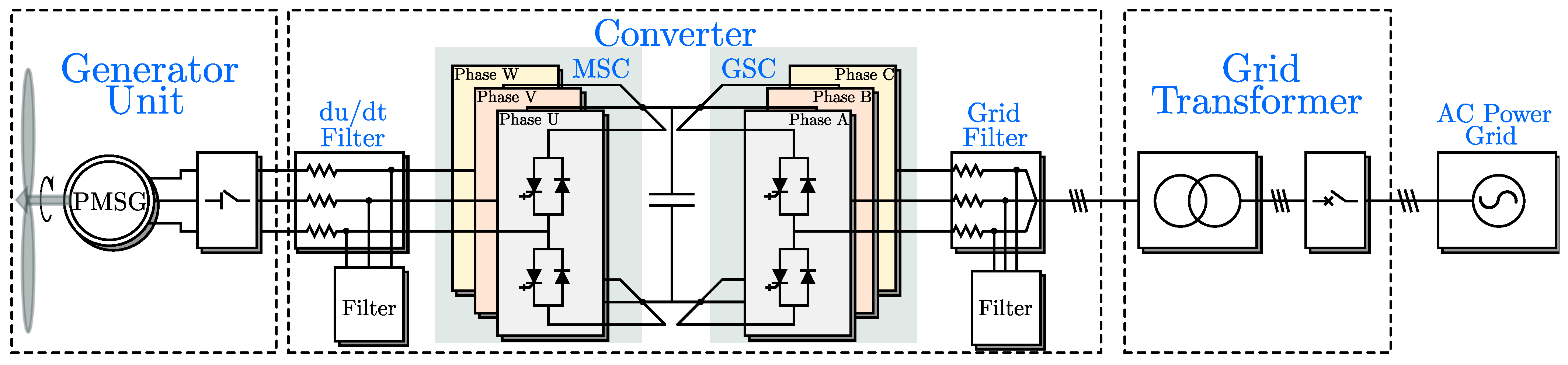

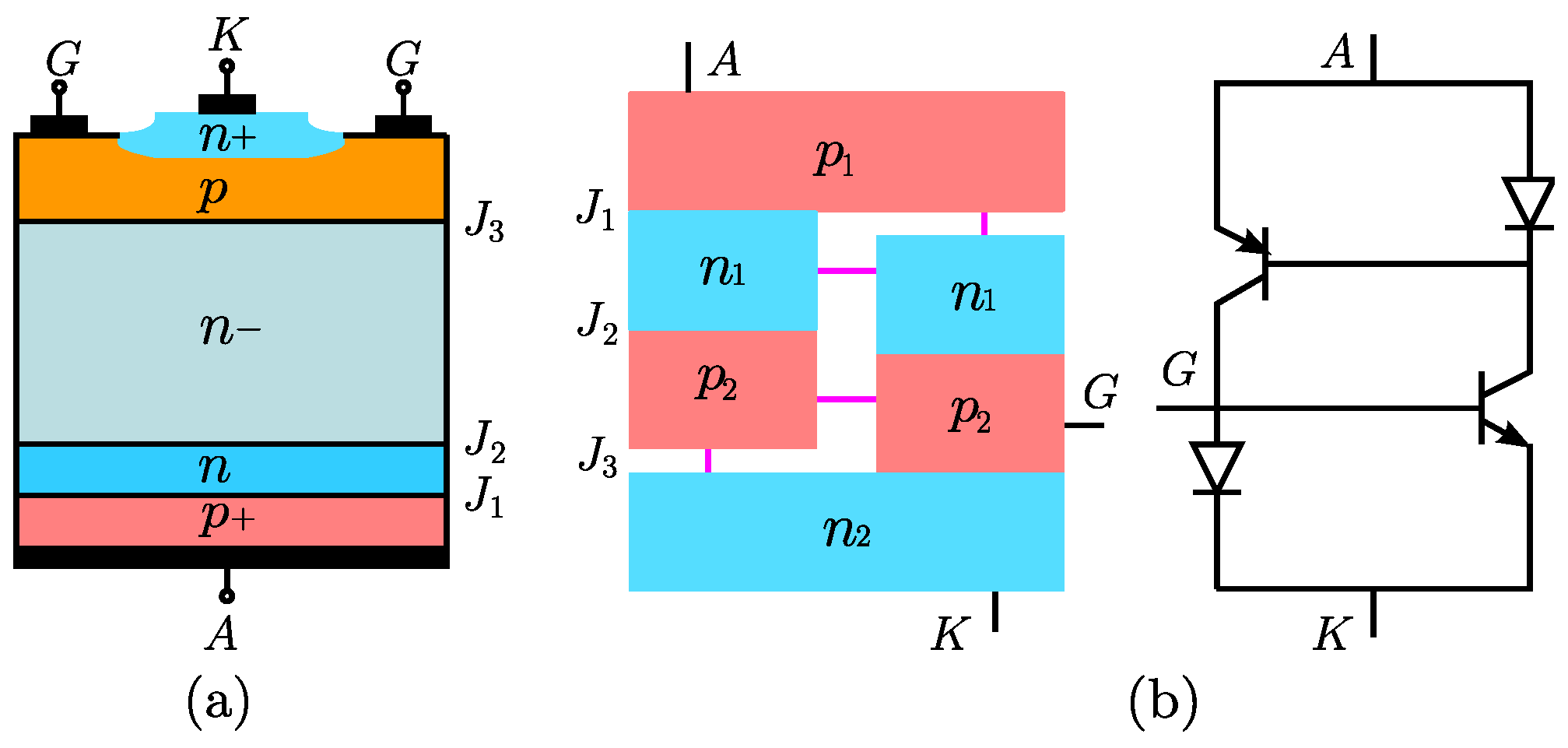

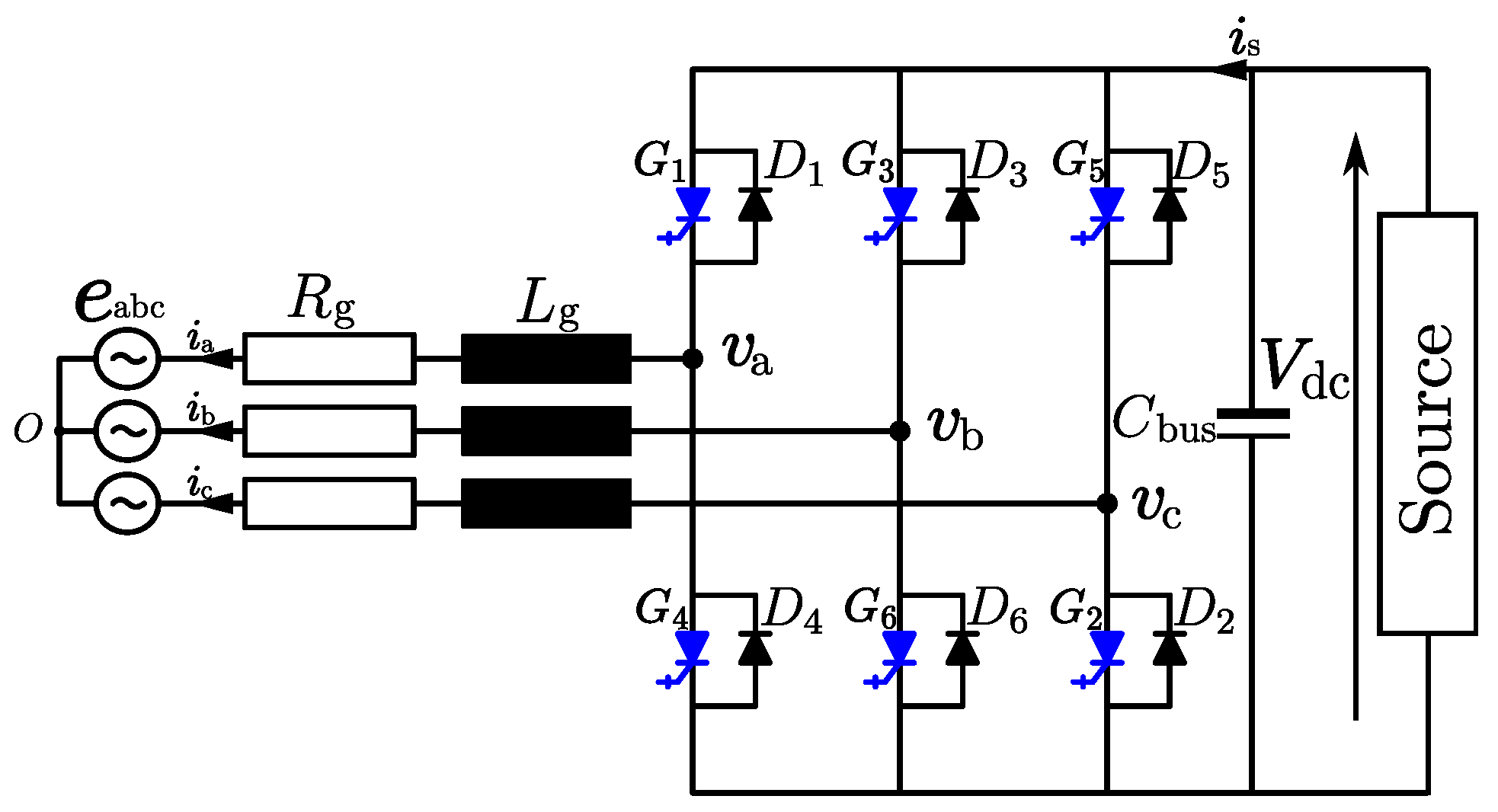

2. The Characteristics of IGCT

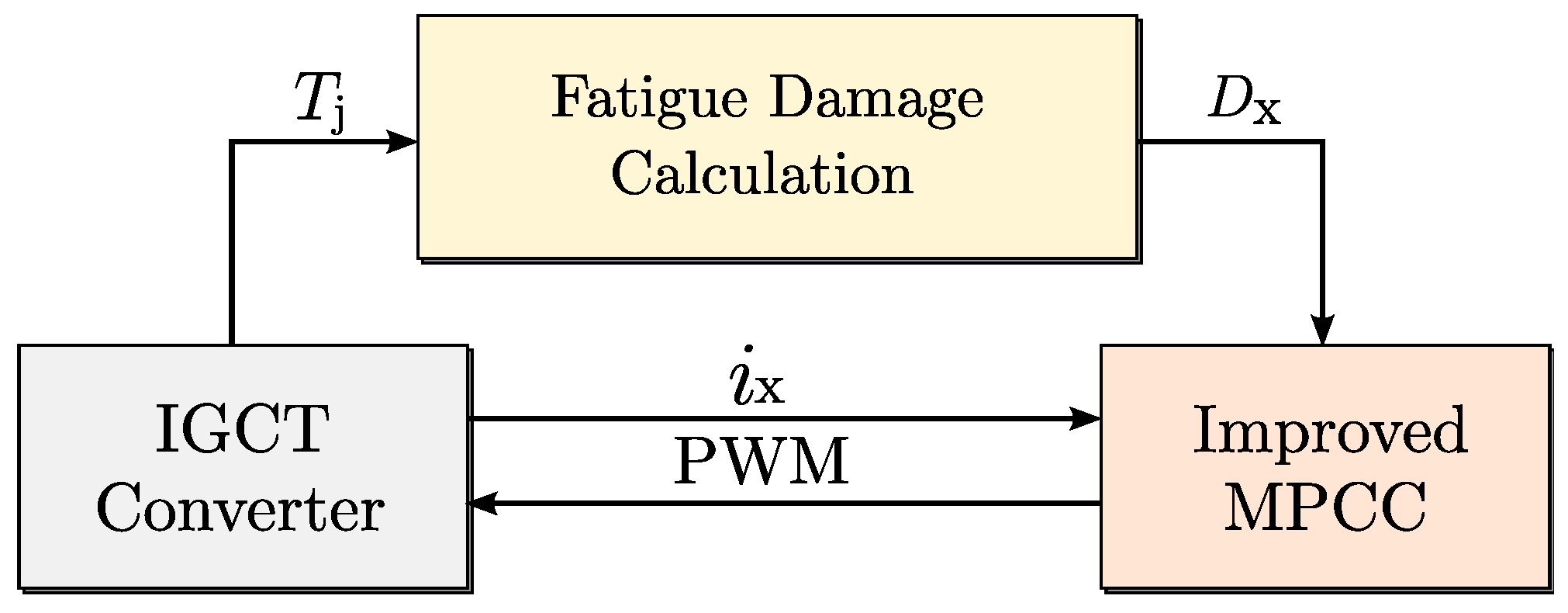

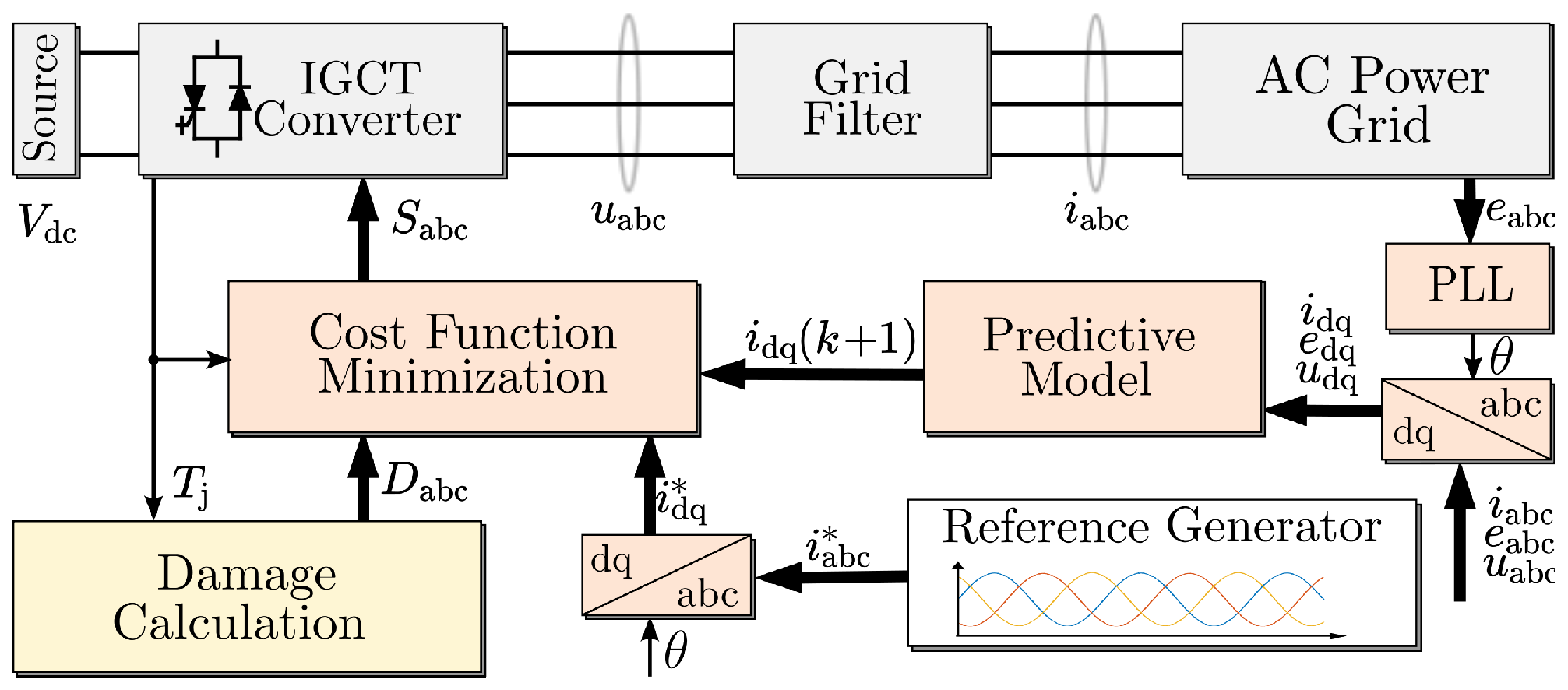

3. System Description

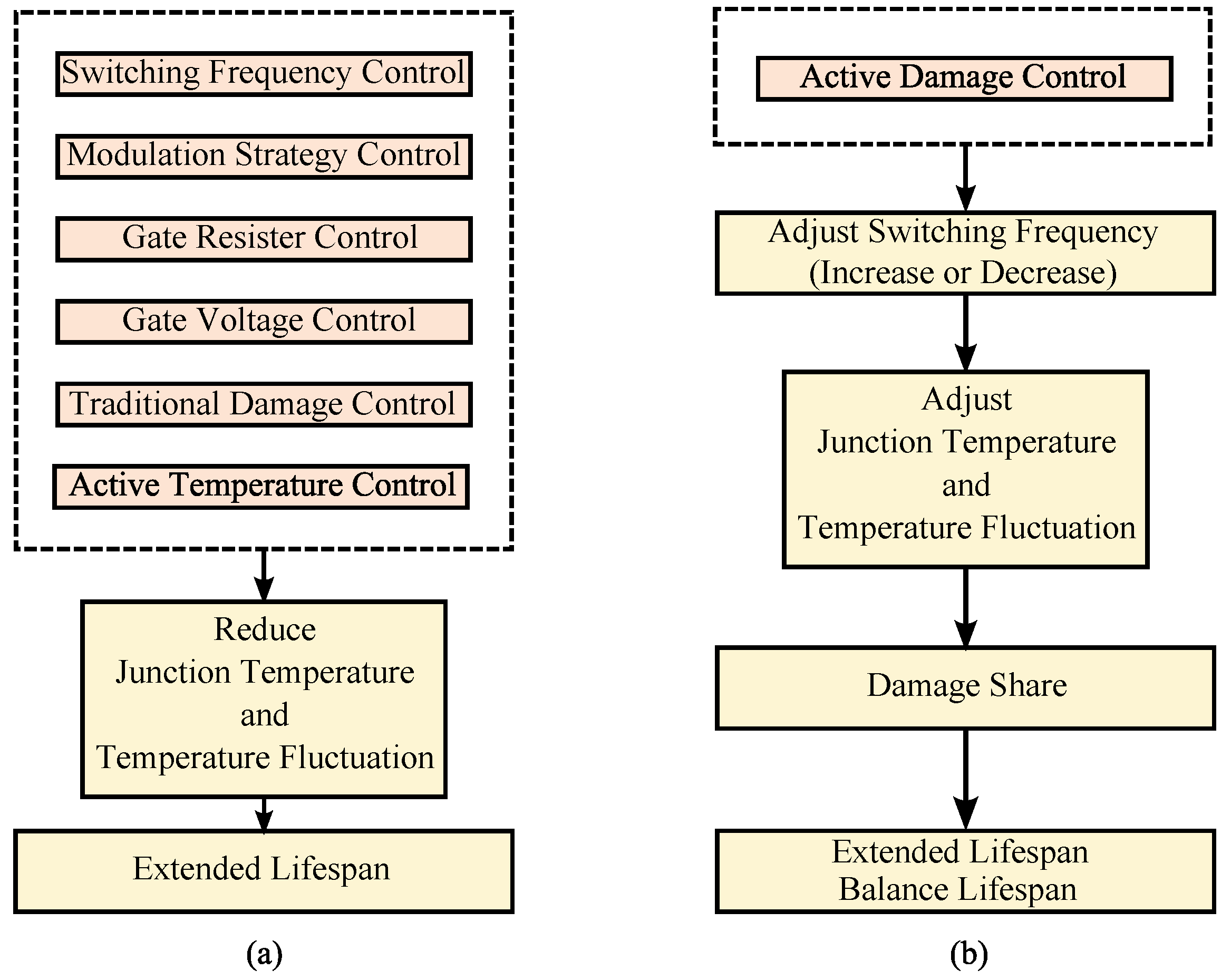

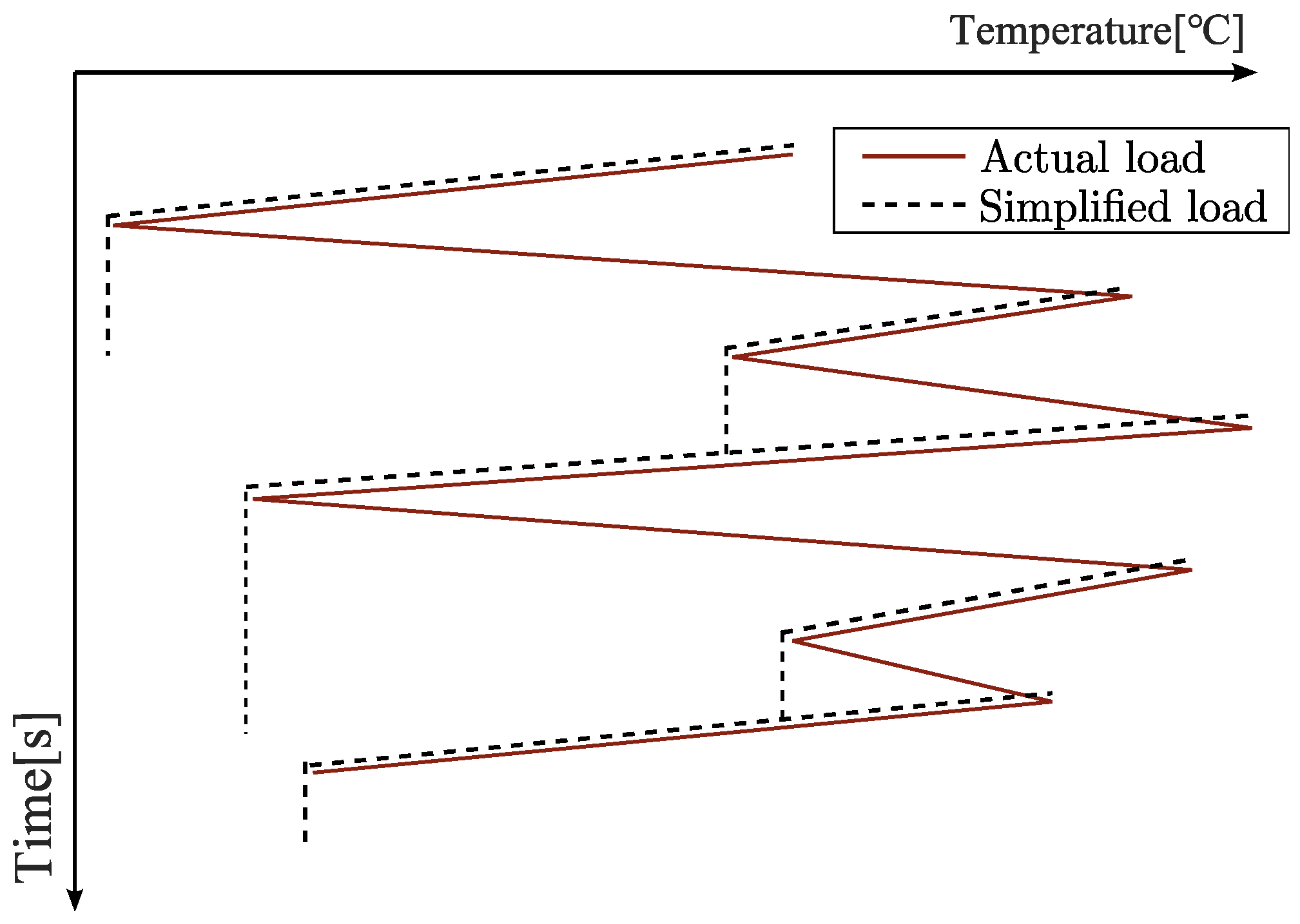

4. Active Temperature and Damage Control

5. Simulation Result Analysis

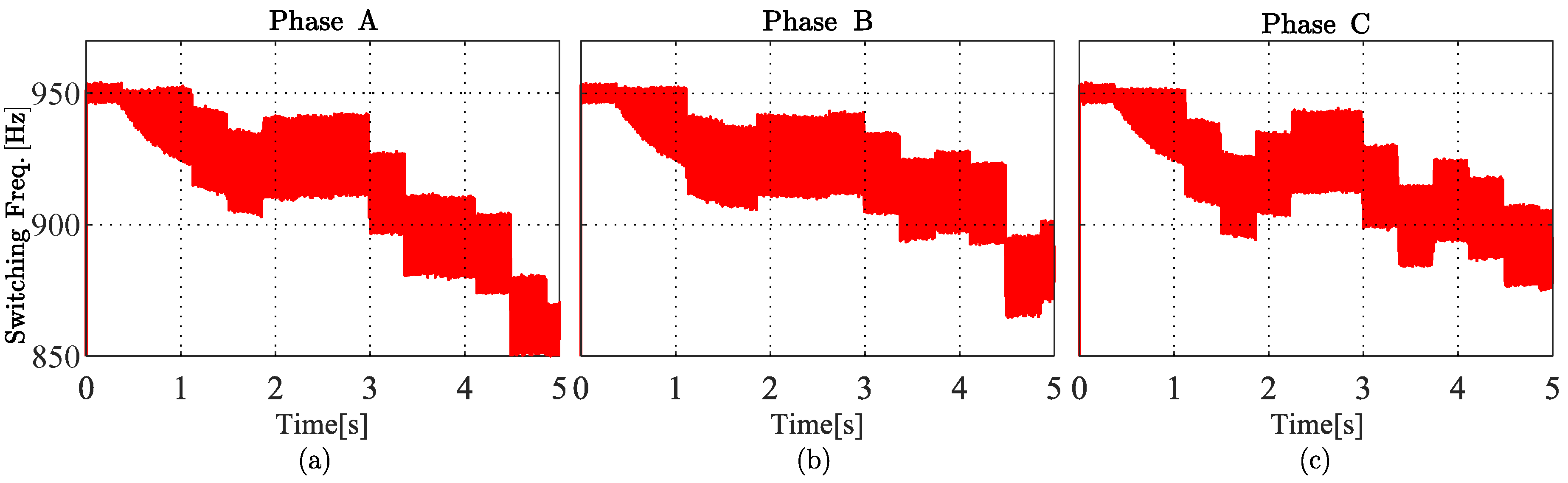

5.1. Active Temperature Control

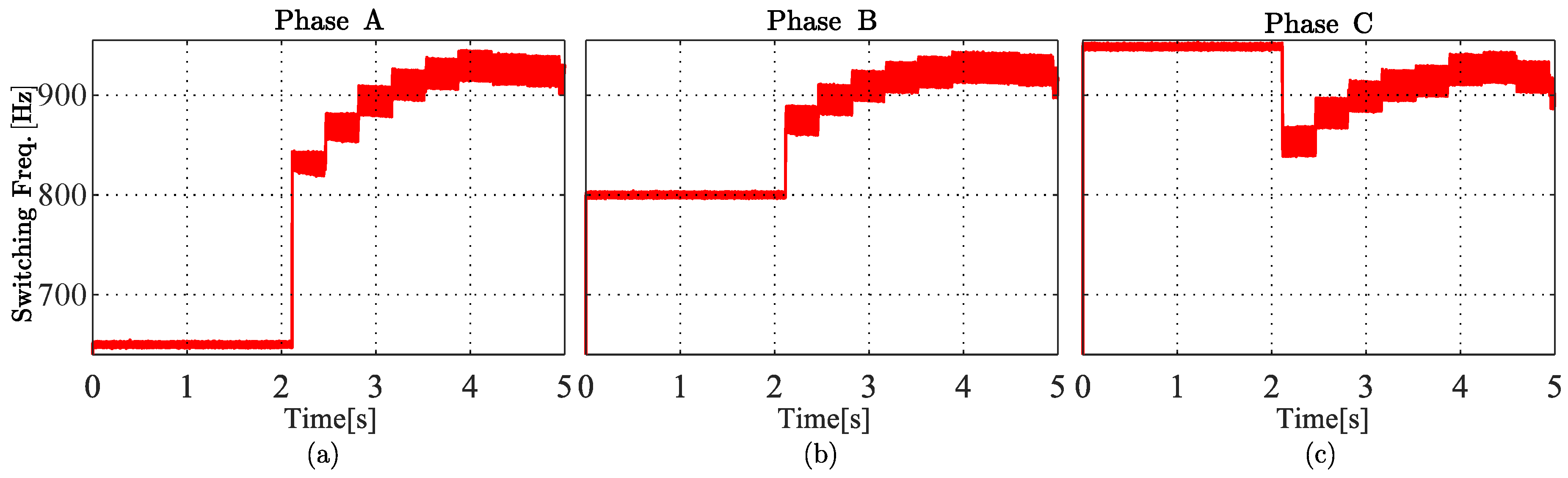

5.2. Active Damage Control

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vemulapati, U.; Rahimo, M.; Arnold, M.; Wikström, T.; Vobecky, J.; Backlund, B.; Stiasny, T. Recent advancements in IGCT technologies for high power electronics applications. In Proceedings of the 2015 17th European Conference on Power Electronics and Applications (EPE’15 ECCE-Europe), Geneva, Switzerland, 8–10 September 2015; pp. 1–10. [Google Scholar]

- Chengsheng, W.; Chongjian, L.; Chuyi, Z.; Zhiming, L.; Qiongtao, Y.; Wei, D.; Fan, L. Study on the over-current protection method of the large power inverter with IGCTs. In Proceedings of the 2013 15th European Conference on Power Electronics and Applications (EPE), Lille, France, 2–6 September 2013; pp. 1–7. [Google Scholar]

- Vemulapati, U.; Bellini, M.; Arnold, M.; Rahimo, M.; Stiasny, T. The concept of Bi-mode Gate Commutated Thyristor-A new type of reverse conducting IGCT. In Proceedings of the 2012 24th International Symposium on Power Semiconductor Devices and ICs, Bruges, Belgium, 3–7 June 2012; pp. 29–32. [Google Scholar]

- Zou, P.; Chen, F.; Zeng, H.; Pan, X.; Chen, Y.; Sun, Y. Research on the Characteristics of Reverse Blocking IGCT and Module for DC Power Grid Application. In Proceedings of the 2020 4th International Conference on HVDC (HVDC), Xi’an, China, 6–9 November 2020; pp. 888–893. [Google Scholar]

- Cai, X.; Chen, G.; Zhou, D.; Zhang, J.; Wang, Y.; Shao, H.; Wang, W. Review and Prospect on Key Technologies for Offshore Wind Power Converters. J. Glob. Energy Interconnect. 2019, 2, 102–115. [Google Scholar]

- Spinato, F.; Tavner, P.J.; Van Bussel, G.J.; Koutoulakos, E. Reliability of wind turbine subassemblies. IET Renew. Power Gener. 2009, 3, 387–401. [Google Scholar] [CrossRef]

- Ma, L.; Huang, J.; Chai, X.; He, S. Life Prediction for IGBT Based on Improved Long Short-Term Memory Network. In Proceedings of the 2023 IEEE 18th Conference on Industrial Electronics and Applications (ICIEA), Ningbo, China, 18–22 August 2023; pp. 868–873. [Google Scholar]

- Wang, Y.; Li, N.; Zhao, W.; Guo, S.; Shen, M.; Li, X. Research on Life Prediction of Inverter IGBT Based on WOA Optimized LSTM Model. In Proceedings of the 2023 IEEE 5th International Conference on Civil Aviation Safety and Information Technology (ICCASIT), Dali, China, 11–13 October 2023; pp. 1475–1479. [Google Scholar]

- Mao, H.; Jiang, H.; Ran, L.; Chen, H.; Xie, Y.; Yang, M. Electrical and Thermal Performances of IGCT in High Voltage DC Circuit Breaker. In Proceedings of the 2022 2nd International Conference on Electrical Engineering and Control Science (IC2ECS), Nanjing, China, 16–18 December 2022; pp. 75–79. [Google Scholar]

- Jianping, S. Study on Thermal Characteristics of IGBT Module with Variable Switching Frequency of Converter. Master’s Thesis, University of Electronic Science and Technology of China, Chengdu, China, 2023. [Google Scholar]

- Quan, C.; Shule, H.; Guoli, L.; Bin, X. Research on three-level loss and junction temperature based on dynamic DPWM. Power Electron. 2023, 57, 131–134. [Google Scholar]

- Luo, H.; Iannuzzo, F.; Ma, K.; Blaabjerg, F.; Li, W.; He, X. Active gate driving method for reliability improvement of IGBTs via junction temperature swing reduction. In Proceedings of the 2016 IEEE 7th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Vancouver, BC, Canada, 27–30 June 2016; pp. 1–7. [Google Scholar]

- Kumar Prasobhu, P.; Raveendran, V.; Buticchi, G.; Liserre, M. Active Thermal Control of GaN-Based DC/DC Converter. IEEE Trans. Ind. Appl. 2018, 54, 3529–3540. [Google Scholar] [CrossRef]

- Xiang, C.; Du, J.; Sun, S.; Li, J.; Fan, Z.; Yu, T. Lifetime optimization control of three-level auxiliary converter. J. Railw. Sci. Eng. 2024, 21, 328–341. [Google Scholar]

- Rezaeizadeh, A.; Mastellone, S. Reliability and Lifetime Optimal Control for Electric Vehicle Power Converters. IEEE Control. Syst. Lett. 2024, 1. [Google Scholar] [CrossRef]

- Chen, T.; Fu, P.; Huang, L.; Chen, X.; He, S.; Wang, Z. An IGCT Electrical-thermal Unified Model Suitable for Simulation Software. In Proceedings of the 2021 IEEE Pulsed Power Conference (PPC), Denver, CO, USA, 12–16 December 2021; pp. 1–4. [Google Scholar]

- Chen, T.; Fu, P.; Huang, L.; Chen, X.; He, S.; Wang, Z.; Yang, T. An IGCT Unified Simulation Model Based on the Electrical Model and Thermistor. IEEE Trans. Plasma Sci. 2022, 50, 3412–3421. [Google Scholar] [CrossRef]

- Zhou, W.; Zeng, R.; Zhao, B.; Chen, Z.; Liu, J.; Bai, R.; Wu, J.; Yu, Z. Comparative Analysis of Large-capacity Fully-controlled Press-pack IGBT and IGCT: Principle, Structure, Characteristics and Application. Proc. CSEE 2022, 42, 2940–2957. [Google Scholar]

- Falck, J.; Buticchi, G.; Liserre, M. Thermal Stress Based Model Predictive Control of Electric Drives. IEEE Trans. Ind. Appl. 2018, 54, 1513–1522. [Google Scholar] [CrossRef]

- Yang, C.; Peng, T.; Huang, X.; Fan, X.; Tao, H.; Yang, C.; Gui, W. Electrothermal Performance-Based FCS-MPC for Dynamic Thermal Balance Control of Traction Converters. IEEE Trans. Transp. Electrif. 2022, 8, 277–287. [Google Scholar] [CrossRef]

- Novak, M.; Ferreira, V.; Andresen, M.; Dragicevic, T.; Blaabjerg, F.; Liserre, M. FS-MPC Based Thermal Stress Balancing and Reliability Analysis for NPC Converters. IEEE Open J. Power Electron. 2021, 2, 124–137. [Google Scholar] [CrossRef]

- Liu, J.; Pan, J.; Wu, J.; Meng, L.; Liu, F.; Zhu, Y.; Xu, X.; Chen, Z.; Li, Z.; Zeng, R. Experimental Investigation on the Turn-Off Failure Mechanism of IGCT. IEEE Trans. Power Electron. 2024, 1–9. [Google Scholar] [CrossRef]

- Hofmeister, J.; Pena, W.; Goodman, D.; Curti, C. Condition-Based-Events Life Curve: Conceptual View to Support Fault Management of Complex Systems of Overlapped, Distributed Events. In Proceedings of the 2022 IEEE International Conference on Prognostics and Health Management (ICPHM), Detroit (Romulus), MI, USA, 6–8 June 2022; pp. 48–51. [Google Scholar]

- Sado, K.; Hannum, J.; Booth, K. Digital Twin Modeling of Power Electronic Converters. In Proceedings of the 2023 IEEE Electric Ship Technologies Symposium (ESTS), Alexandria, VA, USA, 1–4 August 2023; pp. 86–90. [Google Scholar]

- Zhang, Y.; Li, Z.; Zhang, M.; Chen, H.; Zhang, X.; Zhang, Z. A Fast and Simple Open-Circuit-Fault Diagnosis for T-Type Three-Level Power Converters. In Proceedings of the 2023 IEEE 2nd International Power Electronics and Application Symposium (PEAS), Guangzhou, China, 10–13 November 2023; pp. 691–696. [Google Scholar]

- Pan, W.; Chongjian, L.; Gang, G.; Chunyi, Z.; Chengsheng, W. Research on rectifier system in high power IGCT three-level PWM converters. In Proceedings of the 2015 18th International Conference on Electrical Machines and Systems (ICEMS), Pattaya, Thailand, 25–28 October 2015; pp. 1541–1546. [Google Scholar]

- Vemulapati, U.R.; Bianda, E.; Torresin, D.; Arnold, M.; Agostini, F. A Method to Extract the Accurate Junction Temperature of an IGCT During Conduction Using Gate–Cathode Voltage. IEEE Trans. Power Electron. 2016, 31, 5900–5905. [Google Scholar] [CrossRef]

- Held, M.; Jacob, P.; Nicoletti, G.; Scacco, P.; Poech, M.H. Fast power cycling test of IGBT modules in traction application. In Proceedings of the Proceedings of Second International Conference on Power Electronics and Drive Systems, Singapore, 26–29 May 1997; Volume 1, pp. 425–430. [Google Scholar]

- Haque, M.R.; Eka, S.Z.; Ferdous, S.; Razzak, M.A. Analysis of Loss Profile and Thermal Distribution of Heat Sink of IGBT-Based Asynchronous and Synchronous Buck Converters for EV Charging System. In Proceedings of the 2021 5th International Conference on Electronics, Materials Engineering and Nano-Technology (IEMENTech), Kolkata, India, 24–26 September 2021; pp. 1–6. [Google Scholar]

- Amro, R.; Lutz, J.; Lindemann, A. Power cycling with high temperature swing of discrete components based on different technologies. In Proceedings of the 2004 IEEE 35th Annual Power Electronics Specialists Conference (IEEE Cat. No.04CH37551), Aachen, Germany, 20–25 June 2004; Volume 4, pp. 2593–2598. [Google Scholar]

- Liao, L.L.; Liu, C.K.; Chiang, K.N. Power cycling test and failure mode analysis of high-power module. In Proceedings of the 2016 International Conference on Electronics Packaging (ICEP), Hokkaido, Japan, 20–22 April 2016; pp. 372–377. [Google Scholar]

- Curtis, L.R.; Ayyub, B.M. A Meta-Analysis of Miner’s Rule. In Proceedings of the 2024 Annual Reliability and Maintainability Symposium (RAMS), Albuquerque, NM, USA, 22–25 January 2024; pp. 1–6. [Google Scholar]

- Zhang, Y.; Zhang, Z.; Babayomi, O.; Li, Z. Weighting Factor Design Techniques for Predictive Control of Power Electronics and Motor Drives. Symmetry 2023, 15, 1219. [Google Scholar] [CrossRef]

- Li, J.; Babayomi, O.; Zhang, Z.; Li, Z. Robust Predictive Current Control of PMSG Wind Turbines with Sensor Noise Suppression. Energies 2023, 16, 6255. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Z.; Chen, H.; Babayomi, O.; Zhang, M.; Zhang, X.; Zhang, Z. A Robust Predictive Current Control of T-Type Three-Level Power Converters Based on Adaptive Linear Neural Network. In Proceedings of the 2023 IEEE 2nd International Power Electronics and Application Symposium (PEAS), Guangzhou, China, 10–13 November 2023; pp. 1122–1127. [Google Scholar]

- Xu, P.; Yang, K.; Tang, T.; Sun, N.; Ye, C.; Song, W. Life Prediction Method for Power Device of Traction Inverter in Metros. In Proceedings of the 2022 4th International Conference on Smart Power and Internet Energy Systems (SPIES), Beijing, China, 9–12 December 2022; pp. 624–629. [Google Scholar]

- Li, J.; Zhang, Z.; Li, Z.; Babayomi, O. Predictive Control of Modular Multilevel Converters: Adaptive Hybrid Framework for Circulating Current and Capacitor Voltage Fluctuation Suppression. Energies 2023, 16, 5772. [Google Scholar] [CrossRef]

- Wang, L.; He, J.; Han, T.; Zhao, T. Finite Control Set Model Predictive Control With Secondary Problem Formulation for Power Loss and Thermal Stress Reductions. IEEE Trans. Ind. Appl. 2020, 56, 4028–4039. [Google Scholar] [CrossRef]

- Li, J.; Sha, Y.; Zhou, M.; Wang, L. Analysis of the Influence of Bond Wire Aging on Junction Temperature Estimation in IGBT Modules. In Proceedings of the 2024 IEEE 7th International Electrical and Energy Conference (CIEEC), Harbin, China, 10–12 May 2024; pp. 4675–4679. [Google Scholar]

- Yang, K.; Chen, J.; Tang, T.; Xu, P.; Song, W. An Optimized Online Monitoring Method of IGBT Junction Temperature based on Switch Overshoot Voltage. In Proceedings of the 2022 IEEE International Power Electronics and Application Conference and Exposition (PEAC), Guangzhou, China, 4–7 November 2022; pp. 1626–1630. [Google Scholar]

- Chen, J.; Deng, E.; Zhao, Z.; Huang, Y. Influence of low junction temperature swing on the power cycling lifetime of bond wire. In Proceedings of the 2021 33rd International Symposium on Power Semiconductor Devices and ICs (ISPSD), Nagoya, Japan, 30 May–3 June 2021; pp. 375–378. [Google Scholar]

| Control Method | Difficulty in Realization | Cooling Effects | Reference |

|---|---|---|---|

| Switching Frequency Control | Easy | Junction temperature fluctuations reduced by 50% | [10] |

| Modulation Strategy Control | Complex | Junction temperature reduced by 8 °C–10 °C | [11] |

| Gate Resistance Control | Complex | Junction temperature fluctuations reduced by 20% Mean junction temperature reduced by 8% | [12] |

| Gate Voltage Control | Complex | Junction temperature fluctuations reduced by 30%–40% Mean junction temperature reduced by 8%–10% | [13] |

| Layer | Description |

|---|---|

| n+ | Cathode layer |

| p | P-type base region |

| n− | N-type base region |

| n | Field stop layer |

| p+ | Transparent anode layer |

| Parameters | Descriptions | Values |

|---|---|---|

| A | Constant | |

| Constant | −5.039 | |

| Activation energy | ||

| Boltzmann constant |

| Parameters | Values |

|---|---|

| Reference voltage /V | 2800 |

| DC Voltage /V | 2800 |

| Current amplitude /A | 2400 |

| Current frequency f/Hz | 50 |

| IGCT shell temperature /°C | 50 |

| Simulation time t/s | 5 |

| State | Maximum Temperature (°C) | Temperature Fluctuation (°C) |

|---|---|---|

| Without active temperature control | 121.0 | 17.0 |

| With active temperature control | 114.9 | 15.5 |

| State | Maximum Number of Switching Times |

|---|---|

| Without active temperature control | |

| With active temperature control |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Zhang, Y.; Chen, H.; Li, Z.; Zhang, Z. Anti-Fatigue-Damage-Oriented Through-Life Optimization and Control of High-Power IGCT Converters in Wind Energy Systems. Symmetry 2024, 16, 1047. https://doi.org/10.3390/sym16081047

Chen Y, Zhang Y, Chen H, Li Z, Zhang Z. Anti-Fatigue-Damage-Oriented Through-Life Optimization and Control of High-Power IGCT Converters in Wind Energy Systems. Symmetry. 2024; 16(8):1047. https://doi.org/10.3390/sym16081047

Chicago/Turabian StyleChen, Yiyang, Yimin Zhang, Haoyu Chen, Zhen Li, and Zhenbin Zhang. 2024. "Anti-Fatigue-Damage-Oriented Through-Life Optimization and Control of High-Power IGCT Converters in Wind Energy Systems" Symmetry 16, no. 8: 1047. https://doi.org/10.3390/sym16081047

APA StyleChen, Y., Zhang, Y., Chen, H., Li, Z., & Zhang, Z. (2024). Anti-Fatigue-Damage-Oriented Through-Life Optimization and Control of High-Power IGCT Converters in Wind Energy Systems. Symmetry, 16(8), 1047. https://doi.org/10.3390/sym16081047