Research on Small Sample Rolling Bearing Fault Diagnosis Method Based on Mixed Signal Processing Technology

Abstract

1. Introduction

- Migration learning: The method employs models that have been pre-trained on large-scale datasets and subsequently fine-tuned to accommodate small sample datasets. This approach fully exploits the existing knowledge and mitigates the reliance on limited sample datasets [32].

- Generative Adversarial Networks (GANs): It is possible to enhance the diversity of the sample set by developing models that can generalize more effectively when dealing with smaller sample sizes. Generative Adversarial Networks (GANs) can create virtual samples that resemble real ones, allowing the training dataset to be expanded [33].

- Feature selection and dimensionality reduction: In a limited number of samples, feature selection and transformed dimensionality techniques remove redundant information and retain the most useful features for fault diagnosis, improving model performance [34].

2. Relevant Methodologies

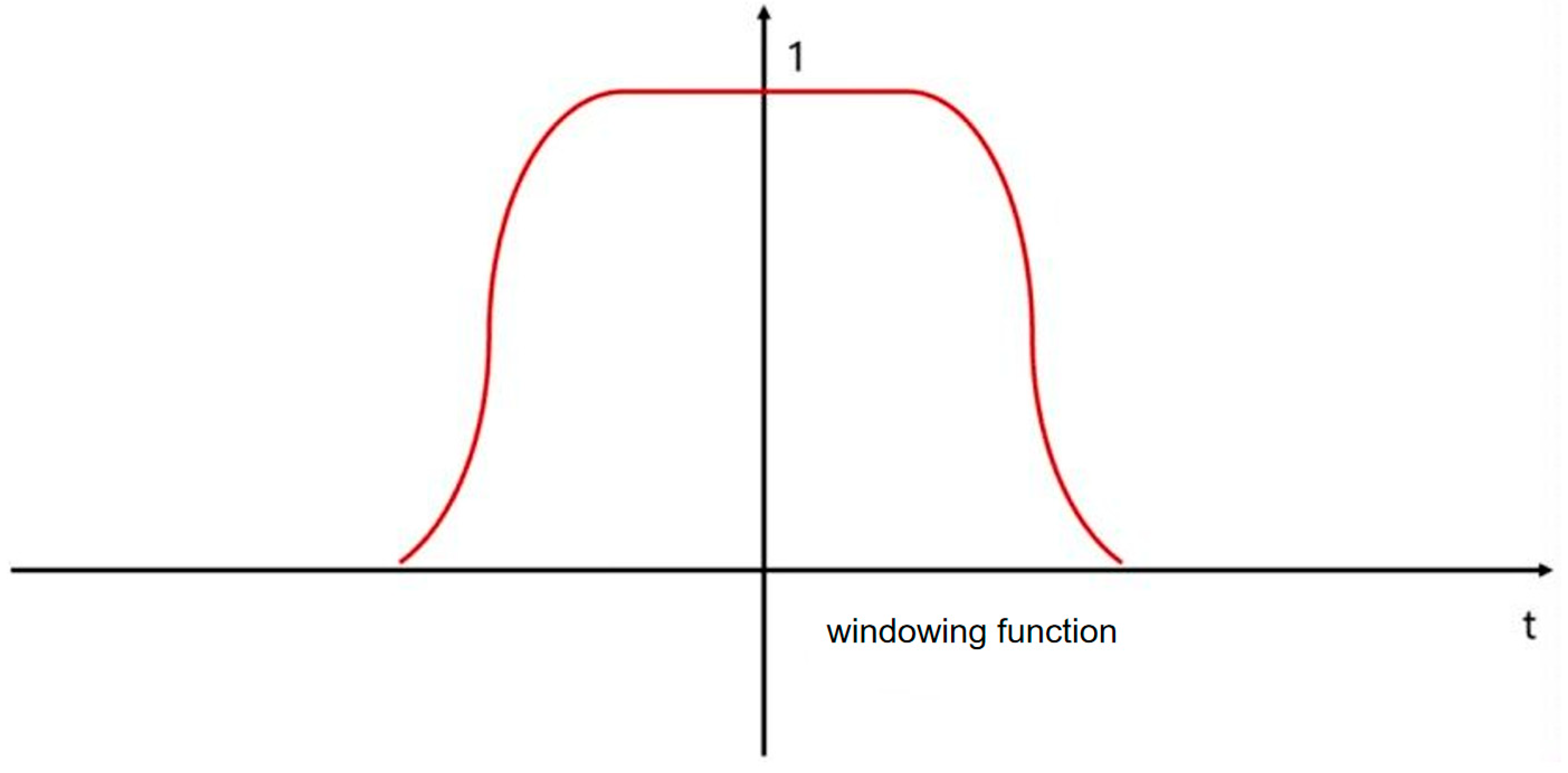

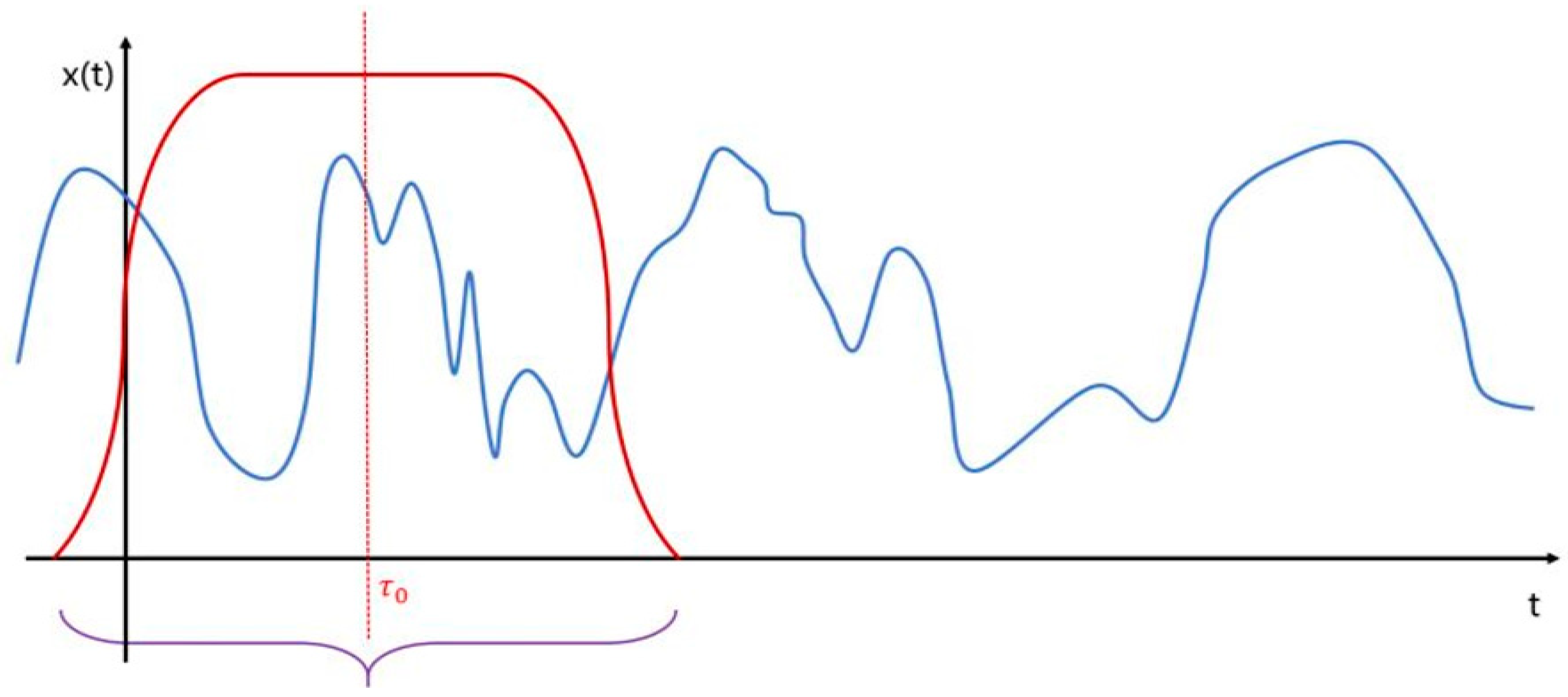

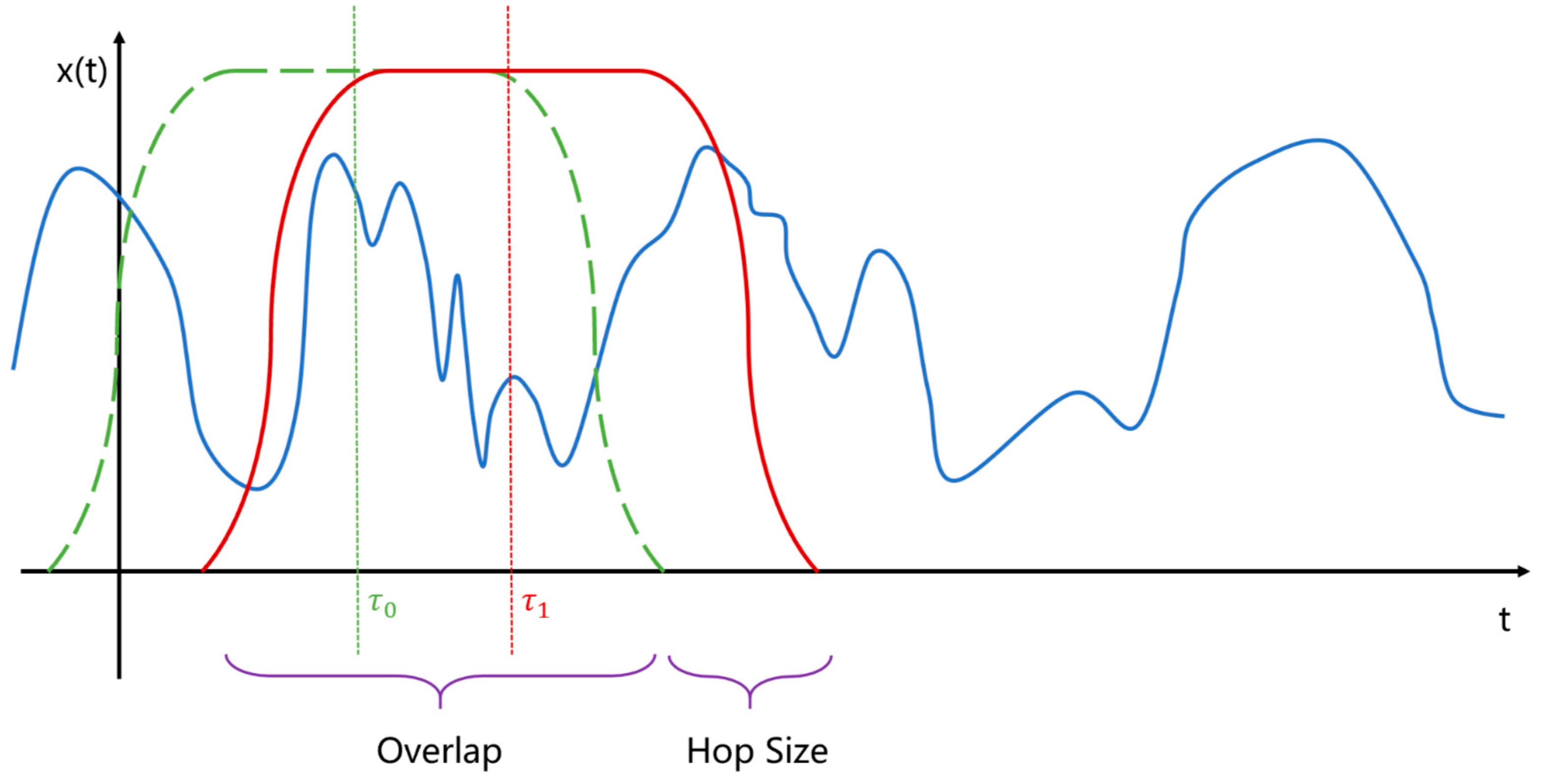

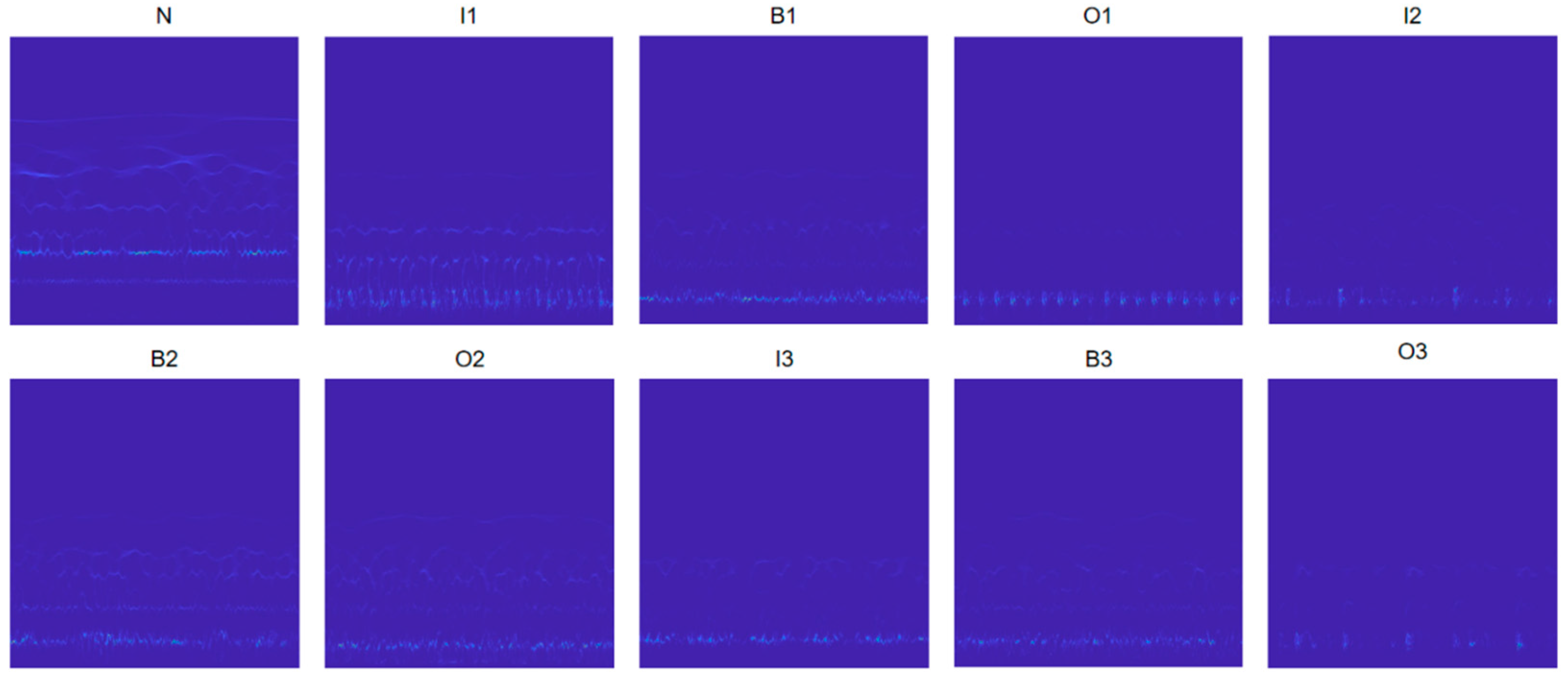

2.1. Short-Time Fourier Transforms

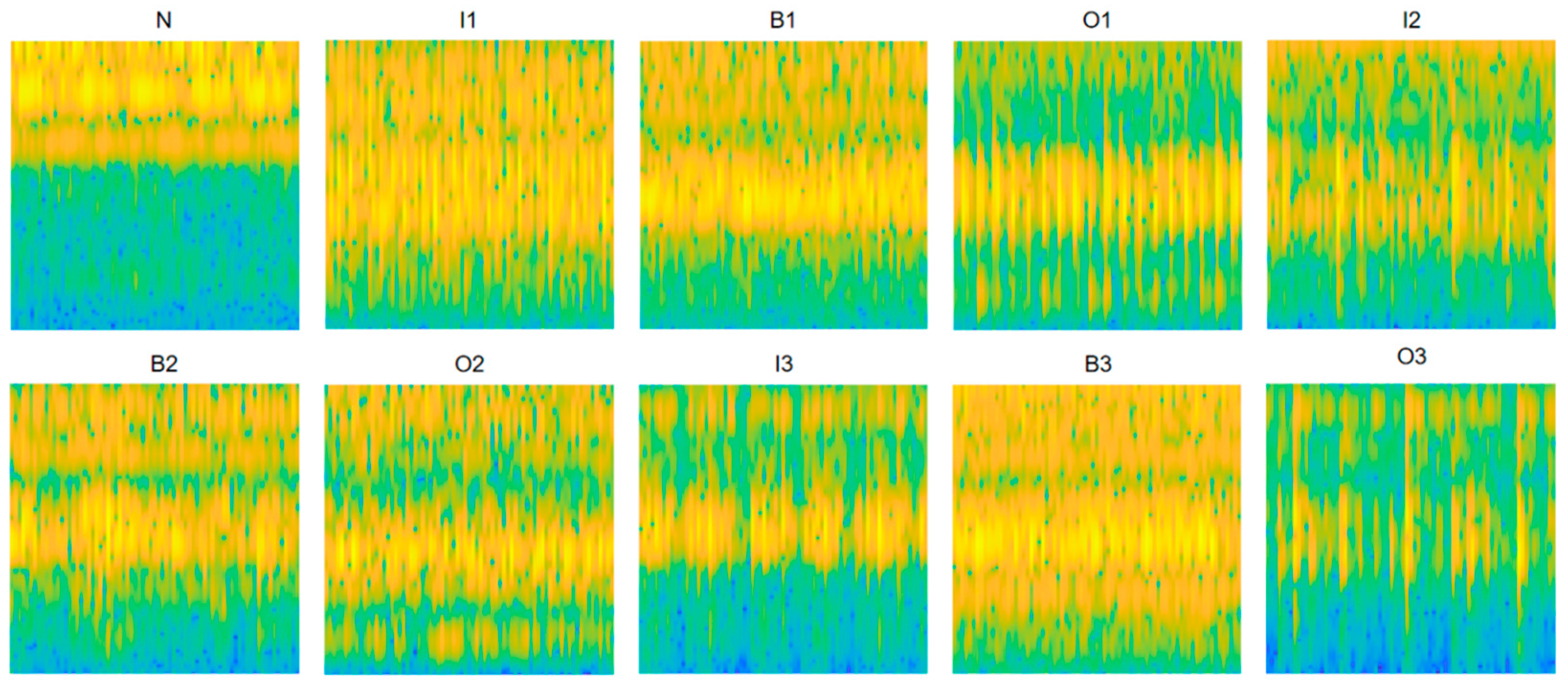

2.2. Synchronized Compressed Wavelet Transform

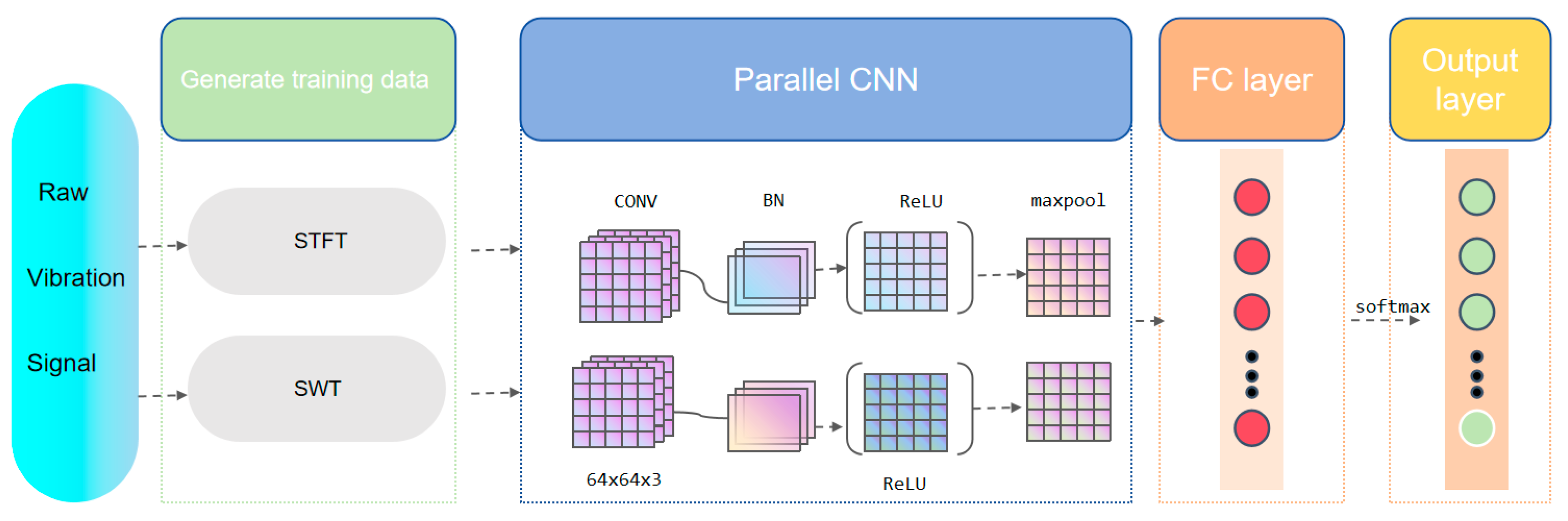

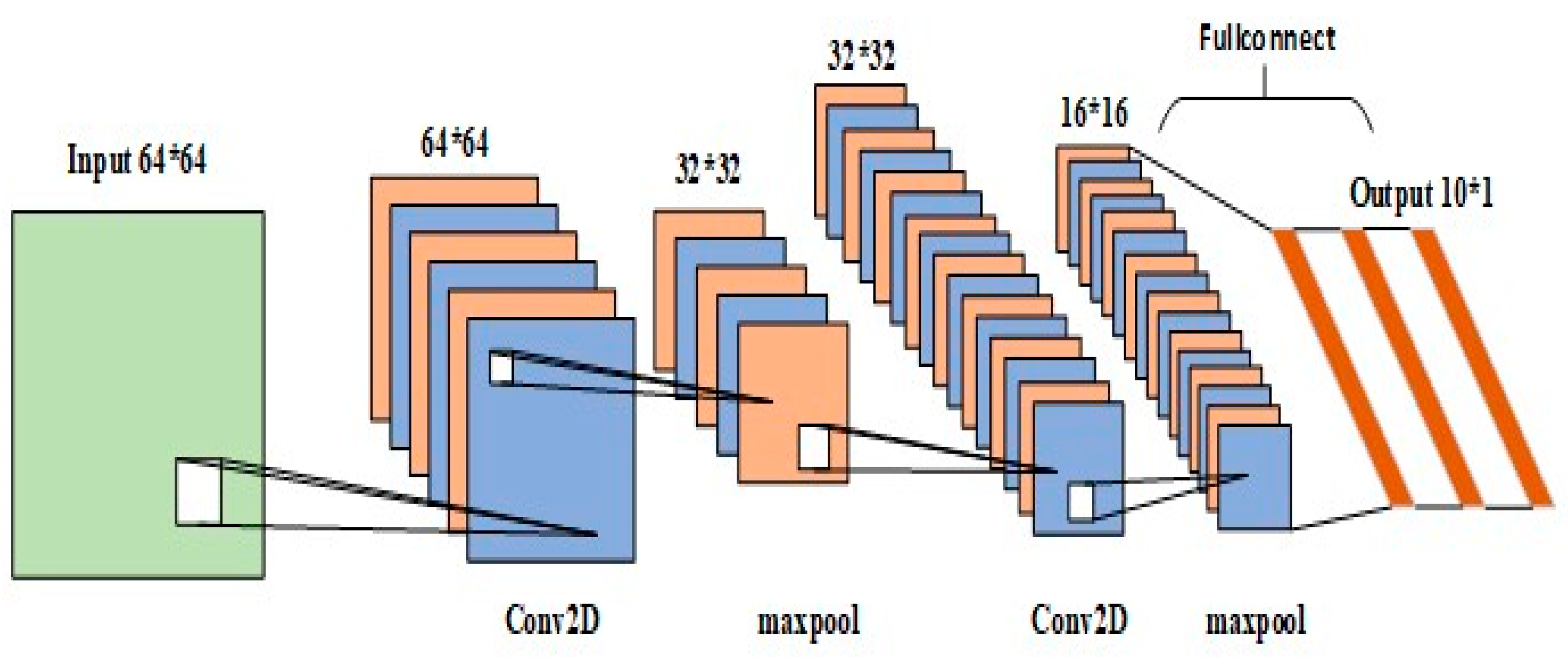

2.3. Dual-Channel Parallel CNN Model with Symmetry

3. Diagnostic Methods and Processes

- (1)

- Data processing: The overlapping intercepts of signals, adding labels, and obtaining sample sets.

- (2)

- The sample set’s vibration signals undergo a short-time Fourier transform and a synchronized compressed wavelet transform, creating an image for each sample to form the feature sample set. This feature sample set is then randomly split into a training set and a test set based on a specified ratio.

- (3)

- A parallel CNN model is constructed and the model parameters are initialized.

- (4)

- The dual-channel parallel CNN training model processes both the training and test sets at the same time. During each iteration of training, the model is validated using the test set to monitor its convergence. After completing the necessary iterations and reaching convergence, the model is saved for future evaluation.

- (5)

- Once the training is complete, the model’s performance is assessed using the test set.

4. Experimental Section

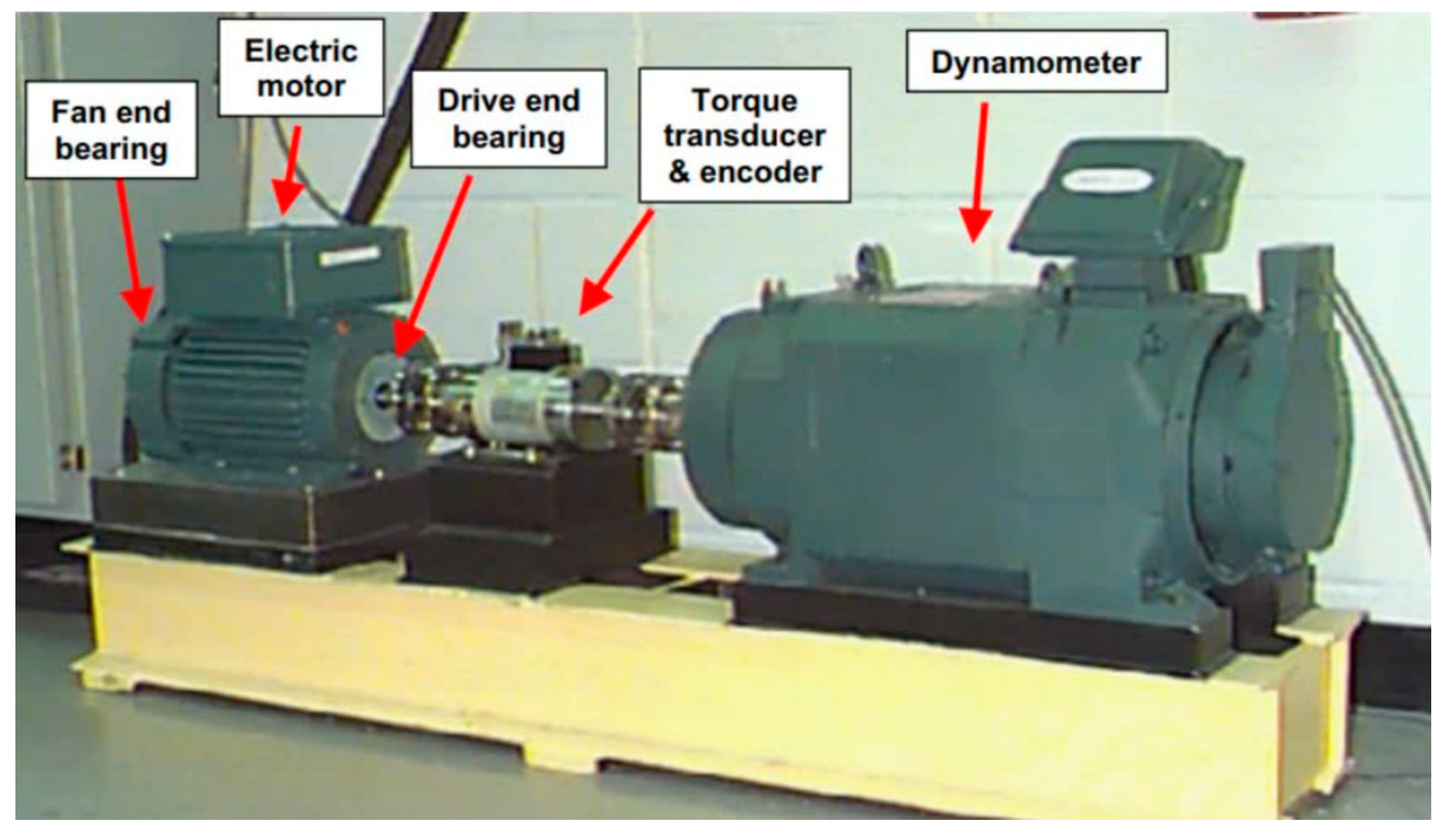

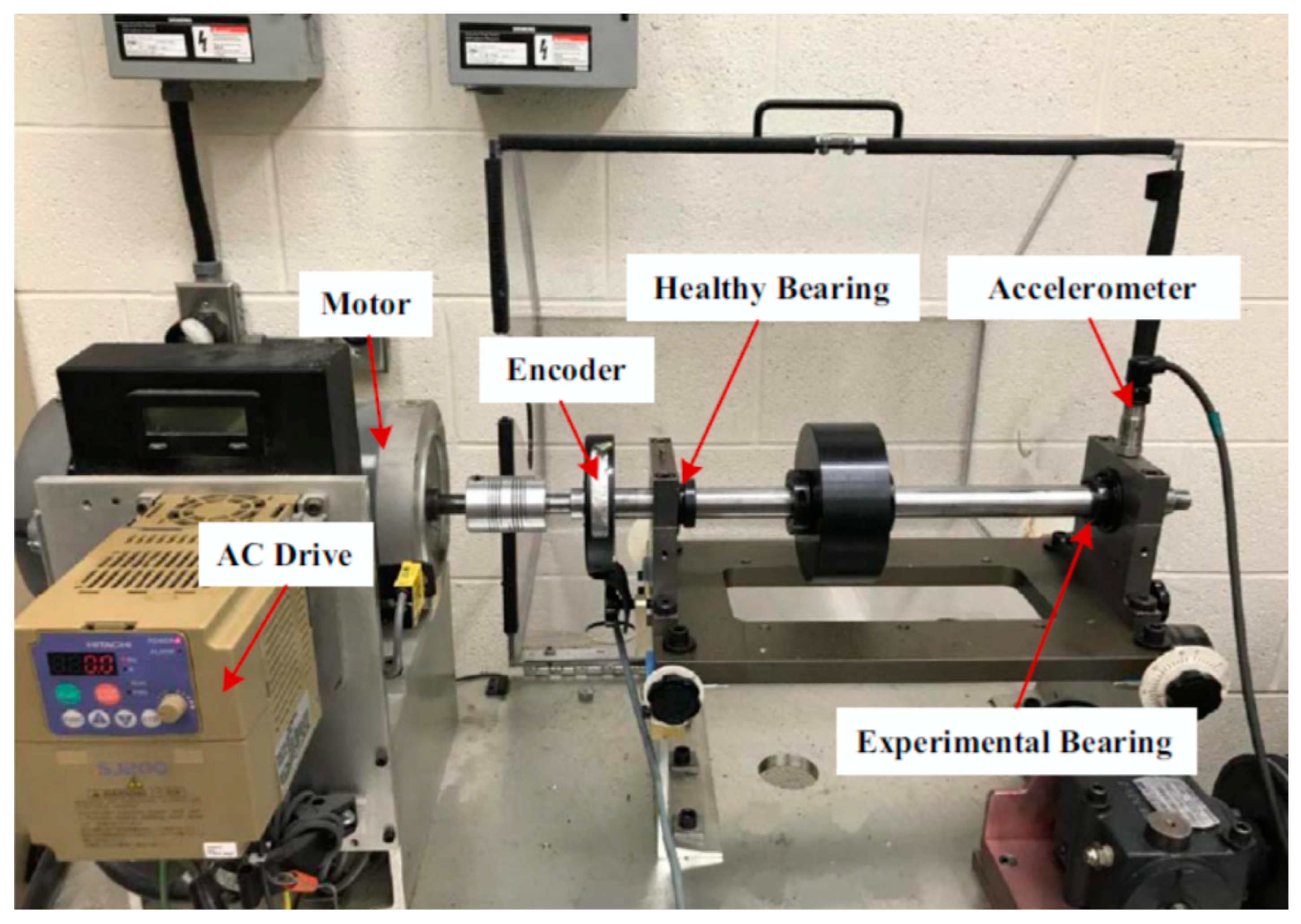

4.1. CWRU Dataset

4.2. Data Generation and Model Training

4.2.1. Data Generation

4.2.2. Model Training

4.2.3. Fault Diagnosis with Different Sample Sizes

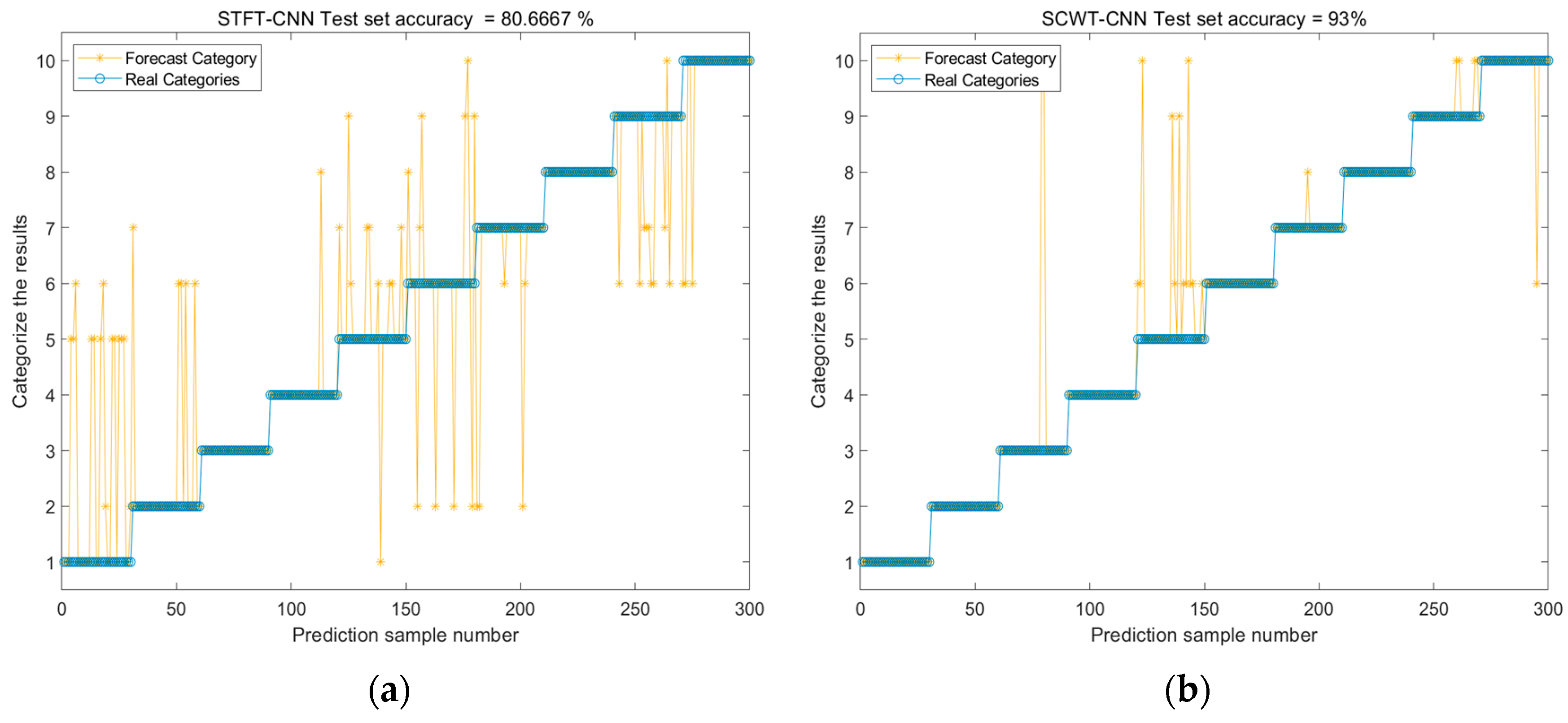

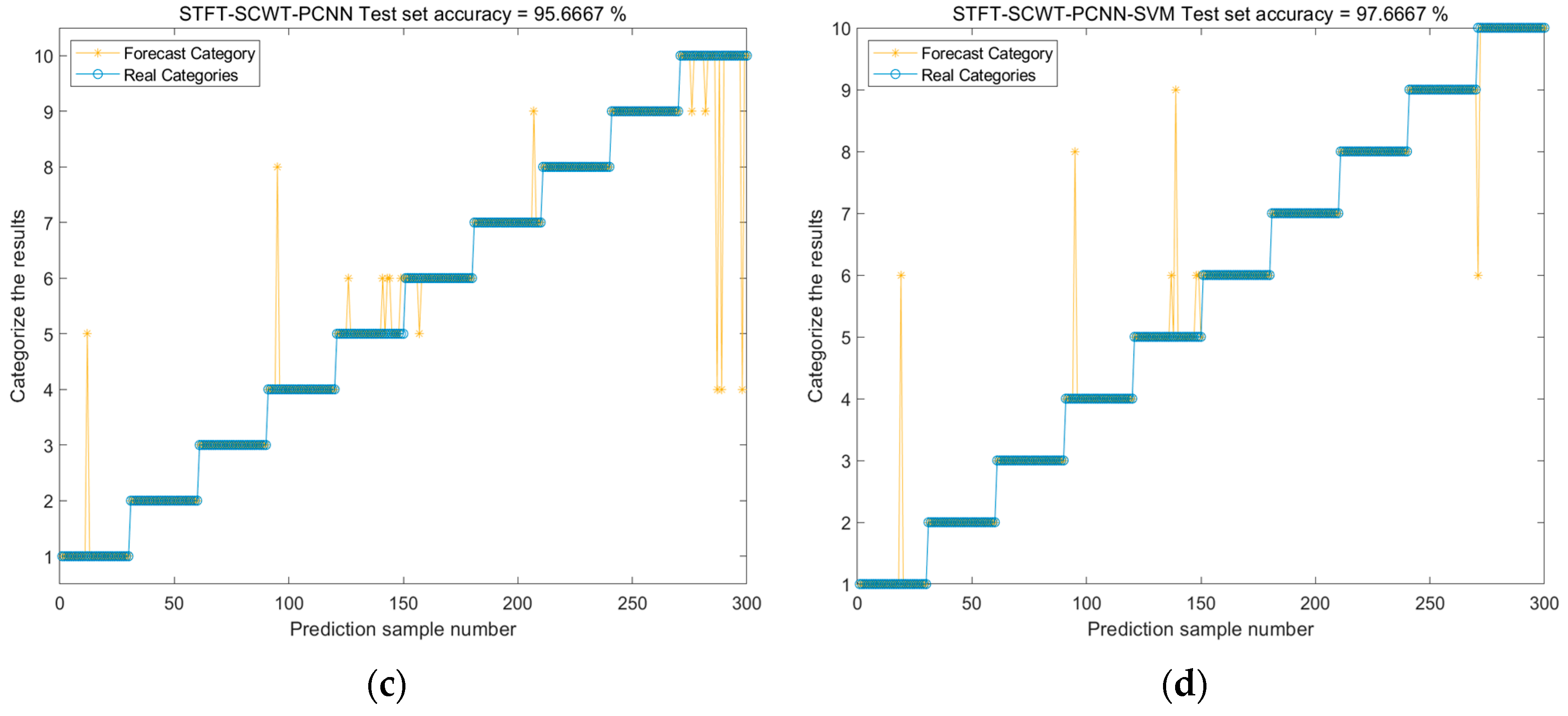

4.3. Advantages of Integrated Processing Methods and Parallel Networks

4.4. Sample Size and Fault Diagnosis Accuracy Experiment

4.5. Exploring Generalizability

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, G. Exploration of the safety management and maintenance of machinery manufacturing and processing equipment. J. Phys. Conf. Ser. 2021, 1885, 042047. [Google Scholar] [CrossRef]

- Yani, I.; Resti, Y.; Burlian, F. Identification of bearing failure using signal vibrations. J. Phys. Conf. Ser. 2018, 1007, 012067. [Google Scholar] [CrossRef]

- Firouzi, N.; Kazemi, S.R. Investigation on dynamic stability of Timoshenko beam using axial parametric excitation. Appl. Phys. A 2023, 129, 869. [Google Scholar] [CrossRef]

- Simkulet, V.; Kočiško, M.; Hutyrová, Z.; Fečová, V. Analysis of the damage causes of high speed bearing failure. Appl. Mech. Mater. 2014, 616, 200–206. [Google Scholar] [CrossRef]

- Khan, M.A.; Asad, B.; Kudelina, K.; Vaimann, T.; Kallaste, A. The bearing faults detection methods for electrical machines—The state of the art. Energies 2022, 16, 296. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, B.; Lin, Y. Machine learning based bearing fault diagnosis using the case western reserve university data: A review. EEE Access 2021, 9, 155598–155608. [Google Scholar] [CrossRef]

- Hu, L.; Wang, L.; Chen, Y.; Hu, N.; Jiang, Y. Bearing fault diagnosis using piecewise aggregate approximation and complete ensemble empirical mode decomposition with adaptive noise. Sensors 2022, 22, 6599. [Google Scholar] [CrossRef] [PubMed]

- Barcelos, A.S.; Cardoso, A.J.M. Current-based bearing fault diagnosis using deep learning algorithms. Energies 2021, 14, 2509. [Google Scholar] [CrossRef]

- Chan, H.P.; Hadjiiski, L.M.; Samala, R.K. Computer-aided diagnosis in the era of deep learning. Med. Phys. 2020, 47, e218–e227. [Google Scholar] [CrossRef]

- Feng, J.; Yao, Y.; Lu, S.; Liu, Y. Domain knowledge-based deep-broad learning framework for fault diagnosis. IEEE Trans. Ind. Electron. 2020, 68, 3454–3464. [Google Scholar] [CrossRef]

- Niu, G.; Wang, X.; Golda, M.; Mastro, S.; Zhang, B. An optimized adaptive PReLU-DBN for rolling element bearing fault diagnosis. Neurocomputing 2021, 445, 26–34. [Google Scholar] [CrossRef]

- Lu, C.; Wang, Z.; Zhou, B. Intelligent fault diagnosis of rolling bearing using hierarchical convolutional network based health state classification. Adv. Eng. Inform. 2017, 32, 139–151. [Google Scholar] [CrossRef]

- Qin, Y.; Shi, X. Fault diagnosis method for rolling bearings based on two-channel CNN under unbalanced datasets. Appl. Sci. 2022, 12, 8474. [Google Scholar] [CrossRef]

- Li, J.; Liu, Y.; Li, Q. Intelligent fault diagnosis of rolling bearings under imbalanced data conditions using attention-based deep learning method. Measurement 2022, 189, 110500. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, J.; Li, F.; Zhang, K.; Lv, H.; He, S.; Xu, E. Intelligent fault diagnosis of machines with small & imbalanced data: A state-of-the-art review and possible extensions. ISA Trans. 2022, 119, 152–171. [Google Scholar]

- Huang, Z.; Lei, Z.; Wen, G.; Huang, X.; Zhou, H.; Yan, R.; Chen, X. A multisource dense adaptation adversarial network for fault diagnosis of machinery. IEEE Trans. Ind. Electron. 2021, 69, 6298–6307. [Google Scholar] [CrossRef]

- Hu, Y.; Liu, R.; Li, X.; Chen, D.; Hu, Q. Task-sequencing meta learning for intelligent few-shot fault diagnosis with limited data. IEEE Trans. Ind. Inform. 2021, 18, 3894–3904. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, L.; Liu, Y.; Gao, L. Wavelet-prototypical network based on fusion of time and frequency domain for fault diagnosis. Sensors 2021, 21, 1483. [Google Scholar] [CrossRef]

- Altaf, M.; Akram, T.; Khan, M.A.; Iqbal, M.; Ch, M.M.I.; Hsu, C.-H. A new statistical features based approach for bearing fault diagnosis using vibration signals. Sensors 2022, 22, 2012. [Google Scholar] [CrossRef] [PubMed]

- Pei, Z.; Jiang, H.; Li, X.; Zhang, J.; Liu, S. Data augmentation for rolling bearing fault diagnosis using an enhanced few-shot Wasserstein auto-encoder with meta-learning. Meas. Sci. Technol. 2021, 32, 084007. [Google Scholar] [CrossRef]

- Gao, X.; Deng, F.; Yue, X. Data augmentation in fault diagnosis based on the Wasserstein generative adversarial network with gradient penalty. Neurocomputing 2019, 396, 487–494. [Google Scholar] [CrossRef]

- Meng, Z.; Guo, X.; Pan, Z.; Sun, D.; Liu, S. Data segmentation and augmentation methods based on raw data using deep neural networks approach for rotating machinery fault diagnosis. IEEE Access 2019, 7, 79510–79522. [Google Scholar] [CrossRef]

- Luo, J.; Huang, J.; Li, H. A case study of conditional deep convolutional generative adversarial networks in machine fault diagnosis. J. Intell. Manuf. 2020, 32, 407–425. [Google Scholar] [CrossRef]

- Han, S.; Niu, P.; Luo, S.; Li, Y.; Zhen, D.; Feng, G.; Sun, S. A novel deep convolutional neural network combining global feature extraction and detailed feature extraction for bearing compound fault diagnosis. Sensors 2023, 23, 8060. [Google Scholar] [CrossRef] [PubMed]

- Guo, Q.; Li, Y.; Liu, Y.; Gao, S.; Song, Y. Data augmentation for intelligent mechanical fault diagnosis based on local shared multiple-generator GAN. IEEE Sensors J. 2022, 22, 9598–9609. [Google Scholar] [CrossRef]

- Tang, T.; Wu, J.; Chen, M. Lightweight model-based two-step fine-tuning for fault diagnosis with limited data. Meas. Sci. Technol. 2022, 33, 125112. [Google Scholar] [CrossRef]

- Yin, H.; Li, Z.; Zuo, J.; Liu, H.; Yang, K.; Li, F. Wasserstein Generative Adversarial Network and Convolutional Neural Network (WG-CNN) for Bearing Fault Diagnosis. Math. Probl. Eng. 2020, 2020, 2604191. [Google Scholar] [CrossRef]

- Manda, B.; Bhaskare, P.; Muthuganapathy, R. A convolutional neural network approach to the classification of engineering models. IEEE Access 2021, 9, 22711–22723. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, S.; Zhang, S. Review on Fault Diagnosis on the Rolling Bearing. J. Phys. Conf. Ser. 2021, 1820, 012107. [Google Scholar] [CrossRef]

- Bapir, A.; Aydin, I. A comparative analysis of 1D convolutional neural networks for bearing fault diagnosis. In Proceedings of the 2022 International Conference on Decision Aid Sciences and Applications (DASA), Chiangrai, Thailand, 23–25 March 2022. [Google Scholar]

- Schneider, A.P.; Paoletti, B.; Ottavy, X.; Brandstetter, C. Experimental monitoring of vibrations and the problem of amplitude quantification. J. Phys. Conf. Ser. 2023, 2511, 012017. [Google Scholar] [CrossRef]

- Jain, S.; Salman, H.; Khaddaj, A.; Wong, E.; Park, S.M.; Mądry, A. A data-based perspective on transfer learning. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, Vancouver, BC, Canada, 17–24 June 2023. [Google Scholar]

- Ferdowsi, A.; Saad, W. Brainstorming Generative Adversarial Networks (BGANs): Towards Multi-Agent Generative Models with Distributed Datasets. IEEE Internet Things J. 2023, 11, 7828–7840. [Google Scholar] [CrossRef]

- Zheng, W.; Jin, M. Improving the performance of feature selection methods with low-sample-size data. Comput. J. 2022, 66, 1664–1686. [Google Scholar] [CrossRef]

- Alvarez, R.; Borbor, E.; Grijalva, F. Comparison of methods for signal analysis in the time-frequency domain. In Proceedings of the 2019 IEEE Fourth Ecuador Technical Chapters Meeting (ETCM), Guayaquil, Ecuador, 13–15 November 2019. [Google Scholar]

- Zielinski, T.P. Joint time-frequency resolution of signal analysis using Gabor transform. IEEE Trans. Instrum. Meas. 2001, 50, 1436–1444. [Google Scholar] [CrossRef]

- Guo, J.; Wang, X.; Zhai, C.; Niu, J.; Lu, S. Fault diagnosis of wind turbine bearing using synchrosqueezing wavelet transform and order analysis. In Proceedings of the 2019 14th IEEE Conference on Industrial Electronics and Applications (ICIEA), Xi’an, China, 19–21 June 2019. [Google Scholar]

- Zhang, J.H.; Sun, S.Y.; Zhu, X.L.; Zhou, Q.D.; Dai, H.W.; Lin, J.W. Diesel engine fault diagnosis based on an improved convolutional neural network. J. Vib. Shock 2022, 41, 139–146. [Google Scholar]

- Liang, K.; Qin, N.; Huang, D.; Fu, Y. Convolutional Recurrent Neural Network for Fault Diagnosis of High-Speed Train Bogie. Complexity 2018, 2018, 4501952. [Google Scholar] [CrossRef]

- Hu, P.; Zhao, C.; Huang, J.; Song, T. Intelligent and Small Samples Gear Fault Detection Based on Wavelet Analysis and Improved CNN. Processes 2023, 11, 2969. [Google Scholar] [CrossRef]

- Smith, W.A.; Randall, R.B. Rolling element bearing diagnostics using the Case Western Reserve University data: A benchmark study. Mech. Syst. Signal Process. 2015, 64–65, 100–113. [Google Scholar] [CrossRef]

- Sehri, M.; Dumond, P.; Bouchard, M. University of Ottawa constant load and speed rolling-element bearing vibration and acoustic fault signature datasets. Data Brief 2023, 49, 109327. [Google Scholar] [CrossRef]

| Fault Diameter/mm | Type of Fault | Fault Category | Sample Size |

|---|---|---|---|

| 0 | N | 1 | 100 |

| 0.007 | I1 | 2 | 100 |

| 0.014 | I2 | 3 | 100 |

| 0.021 | I3 | 4 | 100 |

| 0.007 | B1 | 5 | 100 |

| 0.014 | B2 | 6 | 100 |

| 0.021 | B3 | 7 | 100 |

| 0.007 | O1 | 8 | 100 |

| 0.014 | O2 | 9 | 100 |

| 0.021 | O3 | 10 | 100 |

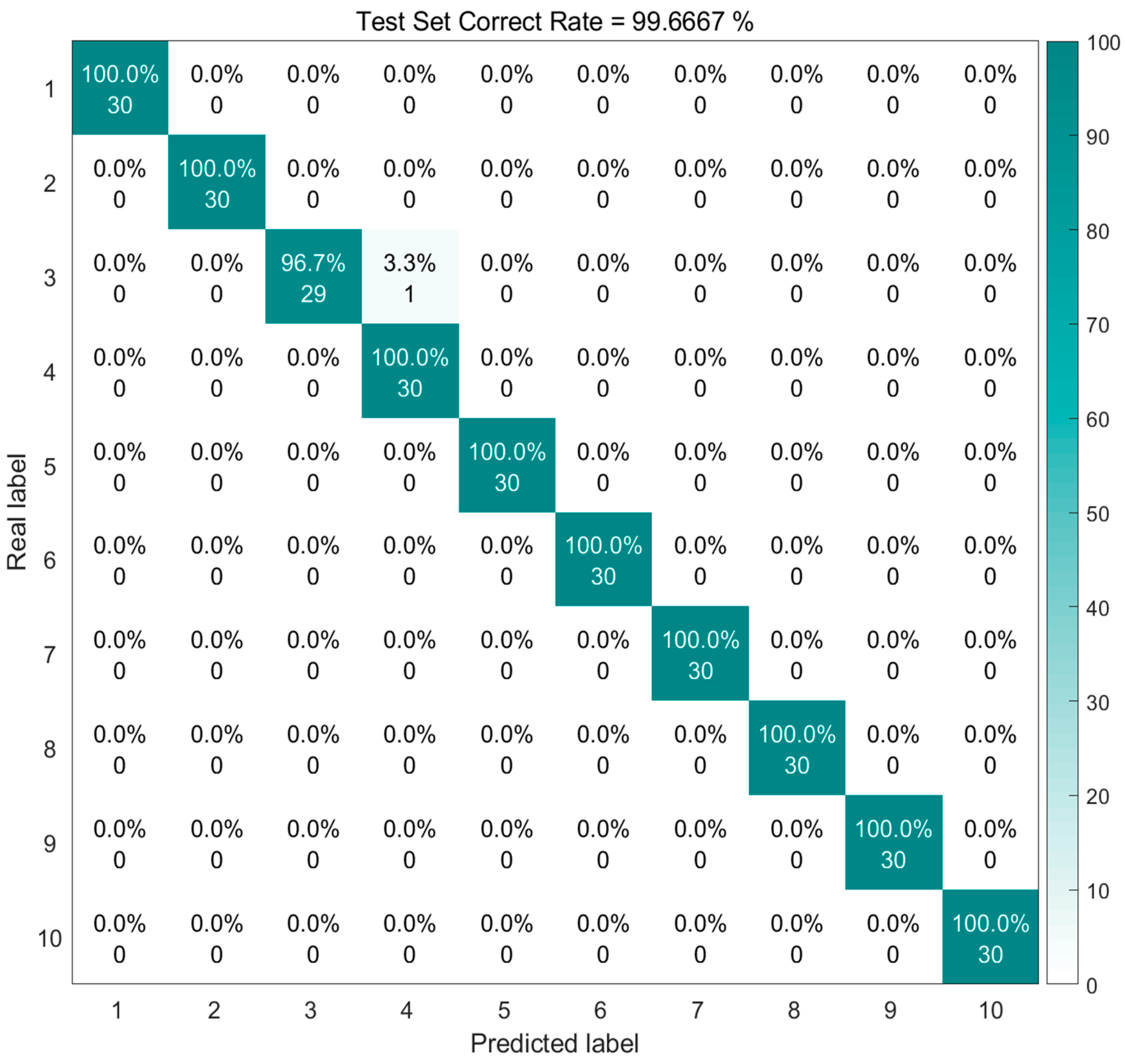

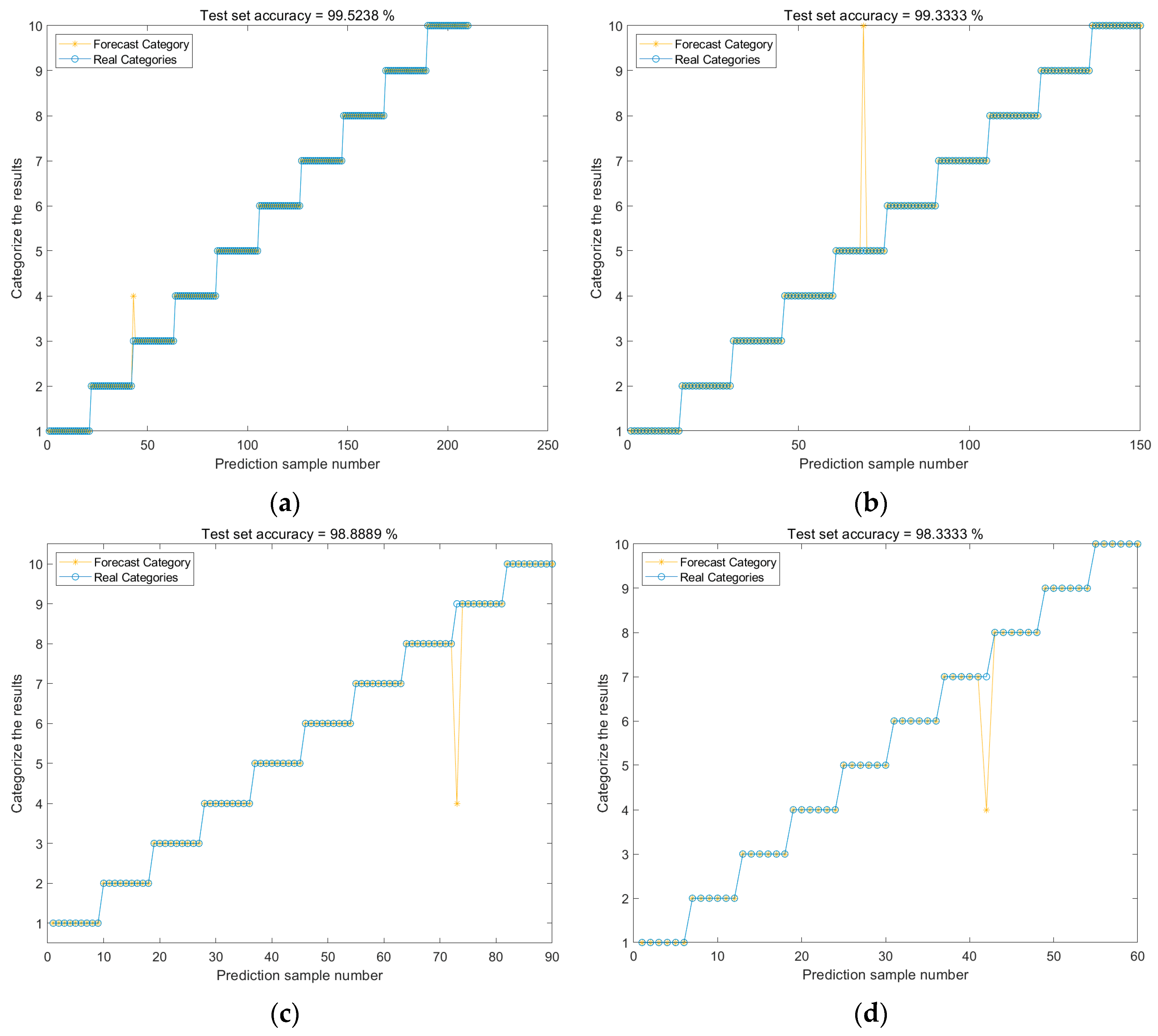

| Experiment Number | Sample Size | Accuracy | F1 Score |

|---|---|---|---|

| 1 | 700 | 99.52% | 99.57% |

| 2 | 500 | 99.33% | 99.37% |

| 3 | 300 | 98.89% | 98.91% |

| 4 | 200 | 98.33% | 98.37% |

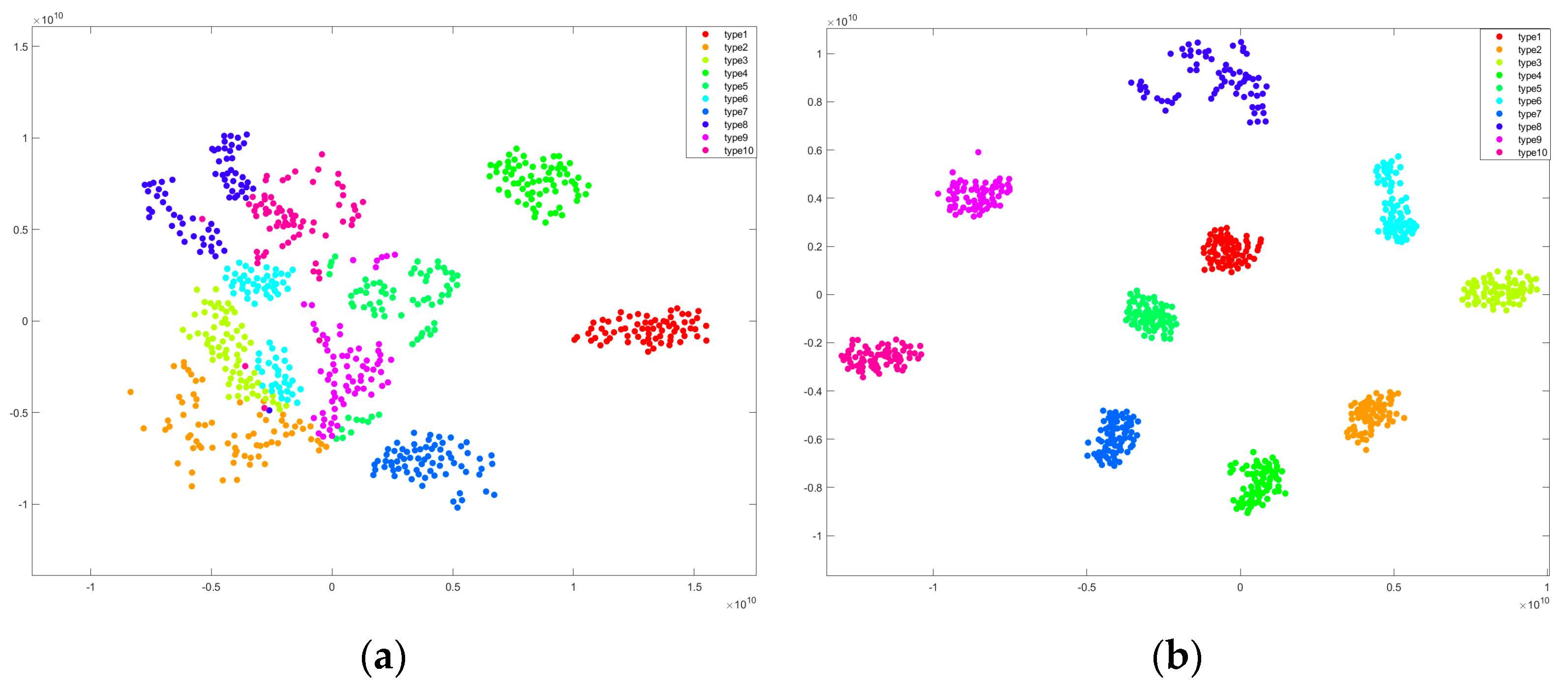

| Mold | Treatment | Accuracy |

|---|---|---|

| CNN | SCWT | 97.34% |

| CNN-SVM | 98.00% | |

| CNN | SFTF | 94.28% |

| CNN-SVM | 98.67% | |

| SVM | SCWT-SFTF | 85.63% |

| PCNN | 98.67% | |

| PCNN-SVM | 99.34% |

| Sample Size | SFTF-CNN | SCWT-CNN | SCWT-CNN-SVM | STFT-CNN-SVM | SCWT-SFTF-PCNN | SCWT-SFTF-PCNN-SVM |

|---|---|---|---|---|---|---|

| 200 | 81.38% | 82.5% | 77.38% | 81.86% | 93.75% | 98.43% |

| 300 | 92.84% | 94.57% | 95.37% | 93.71% | 96.29% | 98.57% |

| 500 | 93.61% | 96.60% | 96.80% | 98.67% | 98.38% | 98.67% |

| 700 | 94.28% | 97.34% | 98.00% | 98.67% | 98.67% | 99.34% |

| Bearing Condition | Operational State | Fault Category | Sample Size |

|---|---|---|---|

| Well-being | expedite | 1 | 100 |

| decelerations | 2 | 100 | |

| Inner-ring failure | expedite | 3 | 100 |

| decelerations | 4 | 100 | |

| Outer-ring failure | expedite | 5 | 100 |

| decelerations | 6 | 100 | |

| Ball fault | expedite | 7 | 100 |

| decelerations | 8 | 100 | |

| Composite fault | expedite | 9 | 100 |

| decelerations | 10 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, P.; Zhang, J.; Zhang, B.; Cao, J.; Peng, Y. Research on Small Sample Rolling Bearing Fault Diagnosis Method Based on Mixed Signal Processing Technology. Symmetry 2024, 16, 1178. https://doi.org/10.3390/sym16091178

Yu P, Zhang J, Zhang B, Cao J, Peng Y. Research on Small Sample Rolling Bearing Fault Diagnosis Method Based on Mixed Signal Processing Technology. Symmetry. 2024; 16(9):1178. https://doi.org/10.3390/sym16091178

Chicago/Turabian StyleYu, Peibo, Jianjie Zhang, Baobao Zhang, Jianhui Cao, and Yihang Peng. 2024. "Research on Small Sample Rolling Bearing Fault Diagnosis Method Based on Mixed Signal Processing Technology" Symmetry 16, no. 9: 1178. https://doi.org/10.3390/sym16091178

APA StyleYu, P., Zhang, J., Zhang, B., Cao, J., & Peng, Y. (2024). Research on Small Sample Rolling Bearing Fault Diagnosis Method Based on Mixed Signal Processing Technology. Symmetry, 16(9), 1178. https://doi.org/10.3390/sym16091178