Sustainable Soil Bearing Capacity Improvement Using Natural Limited Life Geotextile Reinforcement—A Review

Abstract

:1. Introduction

2. Natural Fibre

3. Fibre Treatment

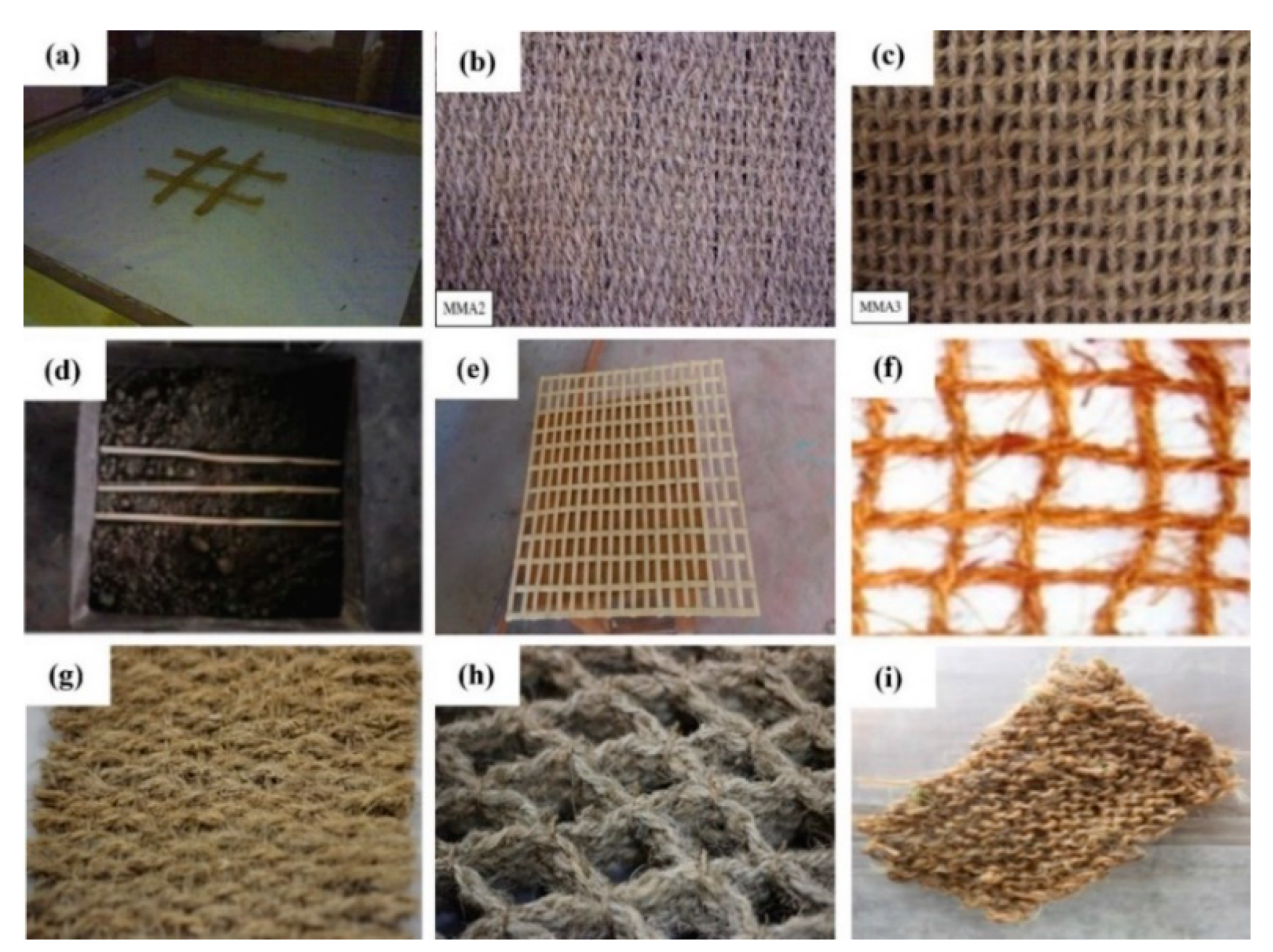

4. Geotextile-Reinforced Soil Systems

5. Previous Studies on Natural Reinforcement Layer

6. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alonso, E.; Gens, A.; Lloret, A. Discussion: Precompression design for secondary settlement reduction. Géotechnique 2000, 50, 822–826. [Google Scholar] [CrossRef]

- Baumann, V.; Bauer, G.E.A. The Performance of Foundations on Various Soils Stabilized by the Vibro-compaction Method. Can. Geotech. J. 1974, 11, 509–530. [Google Scholar] [CrossRef]

- Bergado, D.; Teerawattanasuk, C. 2D and 3D numerical simulations of reinforced embankments on soft ground. Geotext. Geomembr. 2008, 26, 39–55. [Google Scholar] [CrossRef]

- Caron, J.; Kay, B.D.; Stone, J.A. Improvement of Structural Stability of a Clay Loam with Drying. Soil Sci. Soc. Am. J. 1992, 56, 1583–1590. [Google Scholar] [CrossRef]

- Chai, J.-C.; Shen, S.-L.; Miura, N.; Bergado, D. Simple Method of Modeling PVD-Improved Subsoil. J. Geotech. Geoenviron. Eng. 2001, 127, 965–972. [Google Scholar] [CrossRef]

- Chu, J.; Bo, M.; Choa, V. Improvement of ultra-soft soil using prefabricated vertical drains. Geotext. Geomembr. 2006, 24, 339–348. [Google Scholar] [CrossRef]

- Dehghanbanadaki, A.; Ahmad, K.; Ali, N. Influence of natural fillers on shear strength of cement treated peat. J. Croat. Assoc. Civ. Eng. 2013, 65, 633–640. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Suddeepong, A.; Chamket, P.; Chinkulkijniwat, A. Compaction behavior of fine-grained soils, lateritic soils and crushed rocks. Soils Found. 2013, 53, 166–172. [Google Scholar] [CrossRef] [Green Version]

- Shen, S.-L.; Wang, Z.-F.; Horpibulsuk, S.; Kim, Y.-H. Jet grouting with a newly developed technology: The Twin-Jet method. Eng. Geol. 2013, 152, 87–95. [Google Scholar] [CrossRef]

- Bo, M.W.; Arulrajah, A.; Horpibulsuk, S.; Leong, M.; Disfani, M.M. Densification of Land Reclamation Sands by Deep Vibratory Compaction Techniques. J. Mater. Civ. Eng. 2014, 26, 06014016. [Google Scholar] [CrossRef]

- Finno, R.J.; Gallant, A.P.; Sabatini, P.J. Evaluating Ground Improvement after Blast Densification: Performance at the Oakridge Landfill. J. Geotech. Geoenviron. Eng. 2016, 142, 04015054. [Google Scholar] [CrossRef]

- Ou, C.-Y.; Chien, S.-C.; Chang, H.-H. Soil improvement using electroosmosis with the injection of chemical solutions: Field tests. Can. Geotech. J. 2009, 46, 727–733. [Google Scholar] [CrossRef]

- Raju, V. The behavior of very soft cohesive soils improved by vibroreplacement. In Ground Improvement Geosystems—Densification and Reinforcement; Thomas Telford Publishing: London, UK, 1997; pp. 253–259. [Google Scholar]

- Chen, J.; Shen, S.-L.; Yin, Z.-Y.; Xu, Y.-S.; Horpibulsuk, S. Evaluation of Effective Depth of PVD Improvement in Soft Clay Deposit: A Field Case Study. Mar. Georesources Geotechnol. 2015, 34, 420–430. [Google Scholar] [CrossRef]

- Rashid, A.S.A.; Shirazi, M.G.; Mohamad, H.; Sahdi, F. Bearing capacity of sandy soil treated by Kenaf fibre geotextile. Environ. Earth Sci. 2017, 76, 431. [Google Scholar] [CrossRef]

- Udomchai, A.; Horpibulsuk, S.; Suksiripattanapong, C.; Mavong, N.; Rachan, R.; Arulrajah, A. Performance of the bearing reinforcement earth wall as a retaining structure in the Mae Moh mine, Thailand. Geotext. Geomembr. 2017, 45, 350–360. [Google Scholar] [CrossRef]

- Rashid, A.S.A.; Rashid, A.S.A.; Mohamad, H. Behaviour of soft soil improved by floating soil-cement columns. Int. J. Phys. Model. Geotech. 2018, 18, 95–116. [Google Scholar] [CrossRef]

- Voottipruex, P.; Jamsawang, P.; Sukontasukkul, P.; Jongpradist, P.; Horpibulsuk, S.; Chindaprasirt, P. Performances of SDCM and DCM walls under deep excavation in soft clay: Field tests and 3D simulations. Soils Found. 2019, 59, 1728–1739. [Google Scholar] [CrossRef]

- Ngo, D.H.; Horpibulsuk, S.; Suddeepong, A.; Hoy, M.; Udomchai, A.; Doncommul, P.; Rachan, R.; Arulrajah, A. Consolidation behavior of dredged ultra-soft soil improved with prefabricated vertical drain at the Mae Moh mine, Thailand. Geotext. Geomembr. 2020, 48, 561–571. [Google Scholar] [CrossRef]

- Maghool, F.; Arulrajah, A.; Mirzababaei, M.; Suksiripattanapong, C.; Horpibulsuk, S. Interface shear strength properties of geogrid-reinforced steel slags using a large-scale direct shear testing apparatus. Geotext. Geomembr. 2020. [Google Scholar] [CrossRef]

- Mehrpazhouh, A.; Tafreshi, S.N.M.; Mirzababaei, M. Impact of repeated loading on mechanical response of a reinforced sand. J. Rock Mech. Geotech. Eng. 2019, 11, 804–814. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; Soltani, A.; Khayat, N. Stabilization of soft clay using short fibers and poly vinyl alcohol. Geotext. Geomembr. 2018, 46, 646–655. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Arulrajah, A.; Haque, A.; Nimbalkar, S.; Mohajerani, A. Effect of fiber reinforcement on shear strength and void ratio of soft clay. Geosynth. Int. 2018, 25, 471–480. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; Aldava, M. Shear strength of a fibre-reinforced clay at large shear displacement when subjected to different stress histories. Geotext. Geomembr. 2017, 45, 422–429. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Mohamed, M.; Miraftab, M. Analysis of Strip Footings on Fiber-Reinforced Slopes with the Aid of Particle Image Velocimetry. J. Mater. Civ. Eng. 2017, 29, 04016243. [Google Scholar] [CrossRef] [Green Version]

- Soltani, A.; Deng, A.; Taheri, A.; Mirzababaei, M. A sulphonated oil for stabilisation of expansive soils. Int. J. Pavement Eng. 2017, 20, 1285–1298. [Google Scholar] [CrossRef]

- Joshi, V.H.; Siavoshnia, M.; Ranjan, N.; Aterkar, S.; Pandya, A.A. Dynamic pullout resistance of soil reinforcements using stress control apparatus. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004; p. 14. [Google Scholar]

- Voottipruex, P.; Bergado, D.T.; Mairaeng, W.; Chucheepsakul, S.; Modmoltin, C. Soil reinforcement with combination roots system: A case study of vetiver grass and Acacia Mangium Willd. Lowl. Technol. Int. 2008, 10, 12. [Google Scholar]

- EN ISO. EN ISO 10318-1: 2015: Terms and Definitions; International Organization for Standardization: Geneva, Switzerland, 2015; p. 38. [Google Scholar]

- Chawla, K. Fibrous Materials; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar]

- Baillie, C. Green Composites: Polymer Composites and the Environment; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Asaduzzaman, M.; Islam, M.I. Soil Improvement by Using Bamboo Reinforcement. Am. J. Eng. Res. 2014, 3, 362–368. [Google Scholar]

- Kumar, S.; Solanki, C.; Wabhitkar, B.D. Study on embedded square footing resting on geotextile reinforced sand. Int. J. Civ. Struct. Eng. 2015, 5, 243–251. [Google Scholar]

- Lal, D.; Sankar, N.; Chandrakaran, S. Effect of reinforcement form on the behaviour of coir geotextile reinforced sand beds. Soils Found. 2017, 57, 227–236. [Google Scholar] [CrossRef]

- Mathew, A.; Sasikumar, A. Performance of Soft Soil Reinforced with Bamboo and Geonet. Int. Res. J. Eng. Technol. 2017, 4, 646–649. [Google Scholar]

- Rajagopal, K.; Ramakrishna, S. Coir Geotextiles as separation and filtration layer for low intensity road bases. In Proceedings of the Indian Geotechnical Conference (IGC-2009), Guntur, India, 17–19 December 2009; Allied Publishers: Guntur, India, 2009; pp. 941–946. [Google Scholar]

- Sridhar, R.; Prathapkumar, M.T. Behaviour of model footing resting on sand reinforced with number of layers of coir geotextile. Innov. Infrastruct. Solut. 2017, 2, 50. [Google Scholar] [CrossRef]

- Subaida, E.; Chandrakaran, S.; Sankar, N. Laboratory performance of unpaved roads reinforced with woven coir geotextiles. Geotext. Geomembr. 2009, 27, 204–210. [Google Scholar] [CrossRef]

- Vinod, P.; Bhaskar, A.B.; Sreehari, S. Behaviour of a square model footing on loose sand reinforced with braided coir rope. Geotext. Geomembr. 2009, 27, 464–474. [Google Scholar] [CrossRef]

- Chauhan, A.; Chauhan, P. Natural Fibers and Biopolymer. J. Biosens. Bioelectron. 2013, S6, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Georgopoulos, S.T.; Tarantili, P.; Avgerinos, E.; Andreopoulos, A.; Koukios, E. Thermoplastic polymers reinforced with fibrous agricultural residues. Polym. Degrad. Stab. 2005, 90, 303–312. [Google Scholar] [CrossRef]

- Luo, S.; Netravali, A.N. Mechanical and thermal properties of environment-friendly green composites made from pineapple leaf fibers and poly(hydroxybutyrate-co-valerate) resin. Polym. Compos. 1999, 20, 367–378. [Google Scholar] [CrossRef]

- Praveenkumara, J.; Sunder, R.N.; Chandan, H.R.; Marathe, S.; Madhu, P. Natural Fibers and Its Composites for Engineering Applications: An Overview. In Proceedings of the SARC International Conference, Chennai, India, 13 December 2017; p. 5. [Google Scholar]

- Pickering, K. Properties and performance of natural-fibre composites. In Properties and Performance of Natural-Fibre Composites; Woodhead Publishing: Cambridge, UK, 2008; pp. 67–126. [Google Scholar]

- Rowell, R.M.; Sanadi, A.R.; Caulfield, D.F.; Jacobson, R.E. Utilization of natural fibers in plastic composites: Problems and opportunities. In Lignocellulosic-Plastic Composites; Leao, A.L., Carvalho, F.X., Frollini, E., Eds.; University of São Paulo: Sao Paulo, Brazil, 1997; pp. 23–52. [Google Scholar]

- Satyanarayana, K.; Sukumaran, K.; Mukherjee, P.; Pavithran, C.; Pillai, S.G. Natural fibre-polymer composites. Cem. Concr. Compos. 1990, 12, 117–136. [Google Scholar] [CrossRef]

- Thomas, S.; Udo, G. Automotive applications of natural fiber composites. In Lignocellulosic-Plastics Composites, 1st ed.; University of São Paulo: Sao Paulo, Brazil, 1997; pp. 181–195. [Google Scholar]

- Yasodha, T. Sustainable Technology for Tribological Textiles. In Encyclopedia of Tribology; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2013; pp. 3519–3525. [Google Scholar]

- Ochi, S. Mechanical properties of kenaf fibers and kenaf/PLA composites. Mech. Mater. 2008, 40, 446–452. [Google Scholar] [CrossRef]

- Symington, M.C.; Banks, W.M.; West, O.D.; Pethrick, R. Tensile Testing of Cellulose Based Natural Fibers for Structural Composite Applications. J. Compos. Mater. 2009, 43, 1083–1108. [Google Scholar] [CrossRef] [Green Version]

- Amel, B.A.; Paridah, M.T.; Sudin, R.; Anwar, U.; Hussein, A.S. Effect of fiber extraction methods on some properties of kenaf bast fiber. Ind. Crop. Prod. 2013, 46, 117–123. [Google Scholar] [CrossRef]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Rassmann, S.; Paskaramoorthy, R.; Reid, R.G. Effect of resin system on the mechanical properties and water absorption of kenaf fibre reinforced laminates. Mater. Des. 2011, 32, 1399–1406. [Google Scholar] [CrossRef]

- Summerscales, J.; Dissanayake, N.P.J.; Virk, A.S.; Hall, W. A review of bast fibres and their composites. Part 1—Fibres as reinforcements. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1329–1335. [Google Scholar] [CrossRef] [Green Version]

- Zimmerman, J.M.; Losure, N.S. Mechanical properties of kenaf bast fiber reinforced epoxy matrix composite panels. J. Adv. Mater. 1998, 30, 32–38. [Google Scholar]

- Aziz, S.H.; Ansell, M.; Clarke, S.J.; Panteny, S.R. Modified polyester resins for natural fibre composites. Compos. Sci. Technol. 2005, 65, 525–535. [Google Scholar] [CrossRef]

- Virk, A.S.; Hall, W.; Summerscales, J. Failure strain as the key design criterion for fracture of natural fibre composites. Compos. Sci. Technol. 2010, 70, 995–999. [Google Scholar] [CrossRef]

- Cicala, G.; Cristaldi, G.; Recca, G.; Ziegmann, G.; El-Sabbagh, A.; Dickert, M. Properties and performances of various hybrid glass/natural fibre composites for curved pipes. Mater. Des. 2009, 30, 2538–2542. [Google Scholar] [CrossRef]

- Akil, H.M.; Omar, M.F.; Mazuki, A.; Safiee, S.; Ishak, Z.; Abu Bakar, A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

- Parikh, D.; Calamari, T.; Sawhney, A.; Blanchard, E.; Screen, F.; Warnock, M.; Stryjewski, D.; Muller, D. Improved Chemical Retting of Kenaf Fibers. Text. Res. J. 2002, 72, 618–624. [Google Scholar] [CrossRef]

- Cheung, H.-Y.; Ho, M.-P.; Lau, K.T.; Cardona, F.; Hui, D. Natural fibre-reinforced composites for bioengineering and environmental engineering applications. Compos. Part B Eng. 2009, 40, 655–663. [Google Scholar] [CrossRef]

- Ribot, N.; Ahmad, Z.; Mustaffa, N. Mechanical propertise of Kenaf fiber composite using co-cured in-line fiber joint. Int. J. Eng. Sci. Technol. 2011, 3, 3526–3534. [Google Scholar]

- Yousif, B.; Shalwan, A.; Chin, C.; Ming, K. Flexural properties of treated and untreated kenaf/epoxy composites. Mater. Des. 2012, 40, 378–385. [Google Scholar] [CrossRef]

- Malkapuram, R.; Kumar, V.; Negi, Y.S. Recent Development in Natural Fiber Reinforced Polypropylene Composites. J. Reinf. Plast. Compos. 2008, 28, 1169–1189. [Google Scholar] [CrossRef]

- Graupner, N.; Herrmann, A.S.; Müssig, J. Natural and man-made cellulose fibre-reinforced poly(lactic acid) (PLA) composites: An overview about mechanical characteristics and application areas. Compos. Part A Appl. Sci. Manuf. 2009, 40, 810–821. [Google Scholar] [CrossRef]

- Shibata, S.; Cao, Y.; Fukumoto, I. Press forming of short natural fiber-reinforced biodegradable resin: Effects of fiber volume and length on flexural properties. Polym. Test. 2005, 24, 1005–1011. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.A. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Sarsby, R. Use of ‘Limited Life Geotextiles’ (LLGs) for basal reinforcement of embankments built on soft clay. Geotext. Geomembr. 2007, 25, 302–310. [Google Scholar] [CrossRef]

- Kawahara, Y.; Tadokoro, K.; Endo, R.; Shioya, M.; Sugimura, Y.; Furusawa, T. Chemically Retted Kenaf Fibers. Sen’i Gakkaishi 2005, 61, 115–117. [Google Scholar] [CrossRef] [Green Version]

- Nitta, Y.; Noda, J.; Goda, K.; Lee, W. Effect of alkali-treatment on tensile properties of kenaf long fibers. In Proceedings of the 18th International Conference on Composite Materials: The Korean Society of Composite Materials, Jeju Island, Korea, 21–26 August 2011. [Google Scholar]

- Nosbi, N.; Akil, H.M.; Ishak, Z.A.M.; Bakar, A.A. Behavior of kenaf fibers after immersion in several water conditions. BioResources 2011, 6, 950–960. [Google Scholar]

- Meon, M.S.; Othman, M.F.; Husain, H.; Remeli, M.F.; Syawal, M.S.M. Improving Tensile Properties of Kenaf Fibers Treated with Sodium Hydroxide. Procedia Eng. 2012, 41, 1587–1592. [Google Scholar] [CrossRef] [Green Version]

- Rajappan, R.; Saravanan, P.; Paramadhayalan, P. Testing and Analysis of Kenaf Fibre Reinforced Polymer. In Proceedings of the International Conference on Recent Advancement on Mechanical Engineering Technology, Zhengzhou, China, 11–12 April 2015; special issue 9. pp. 153–156. Available online: https://www.jchps.com/specialissues/Special%20issue%209/29%20JCHPS%20149%20Paramadhayalan.P%20153-156.pdf (accessed on 23 May 2020).

- Ramesh, M. Kenaf (Hibiscus cannabinus L.) fibre based bio-materials: A review on processing and properties. Prog. Mater. Sci. 2016, 78–79, 1–92. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Sulong, A.B.; Radzi, M.K.F.M.; Ismail, N.; Raza, M.; Muhamad, N.; Khan, M.A. Influence of alkaline treatment and fiber loading on the physical and mechanical properties of kenaf/polypropylene composites for variety of applications. Prog. Nat. Sci. 2016, 26, 657–664. [Google Scholar] [CrossRef]

- Shirazi, M.G.; Rashid, A.S.A.; Bin Nazir, R.; Rashid, A.H.A.; Kassim, A.; Horpibulsuk, S. Investigation of tensile strength on alkaline treated and untreated kenaf geotextile under dry and wet conditions. Geotext. Geomembr. 2019, 47, 522–529. [Google Scholar] [CrossRef]

- ASTM D4595-17. Standard Test Method for Tensile Properties of Geotextiles by the Wide-Width Strip Method; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Rowell, R.M.; Sanadi, A.R.; Jacobson, R.E.; Caulfield, D.F. Properties of kenaf/polypropylene composites. In Kenaf Properties, Processing and Products; Mississippi State University: Starkville, MS, USA, 1999; pp. 381–392. [Google Scholar]

- Wambua, P.; Ivens, J.; Verpoest, I. Some mechanical properties of kenaf/polypropylene composites prepared using a film stacking technique. In Proceedings of the 13th International Conference on Composite Materials (ICCM-13), Beijing China, 25–29 June 2001; Society of Manufacturing Engineers: Dearborn, MI, USA, 2001. Available online: http://www.iccm-central.org/Proceedings/ICCM13proceedings/SITE/PAPERS/Paper-1125.pdf (accessed on 23 May 2020).

- Jeyanthi, S.; Rani, J.J. Improving mechanical properties by kenaf natural long fiber reinforced composite for automotive structures. J. Appl. Sci. Eng. 2012, 15, 275–280. [Google Scholar]

- Razak, N.I.A.; Ibrahim, N.A.; Zainudin, N.; Rayung, M.; Saad, W.Z. The Influence of Chemical Surface Modification of Kenaf Fiber using Hydrogen Peroxide on the Mechanical Properties of Biodegradable Kenaf Fiber/Poly(Lactic Acid) Composites. Molecules 2014, 19, 2957–2968. [Google Scholar] [CrossRef] [Green Version]

- Kumar, K.K.; Babu, P.R.; Reddy, K.R.N. Evaluation of flexural and tensile properties of short kenaf fiber reinforced green composites. Int. J. Adv. Mech. Eng. 2014, 4, 371–380. [Google Scholar]

- Hafizah, N.A.K.; Hussin, M.W.; Jamaludin, M.Y.; Bhutta, M.A.R.; Ismail, M.; Azman, M. Tensile Behaviour of Kenaf Fiber Reinforced Polymer Composites. J. Teknol. 2014, 69, 11–15. [Google Scholar] [CrossRef] [Green Version]

- Sardar, V.; Kotresh, K.; Gowda, M. Characterization and investigation of tensile test on kenaf fiber reinforced polyester composite material. Int. J. Recent Dev. Eng. Technol. 2014, 2, 104–112. [Google Scholar]

- Naveenkumar, R.; Sharun, V.; Dhanasakkaravarthi, P.; Rajakumar, I. Comparative study on jute and Kenaf fiber composite material. Int. J. Appl. Sci. Eng. Res. 2015, 4, 250–258. [Google Scholar]

- Huber, T.; Pang, S.; Staiger, M. All-cellulose composite laminates. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1738–1745. [Google Scholar] [CrossRef]

| Advantages | Disadvantages |

|---|---|

| Low density/light weight | Low strength properties, particularly its impact strength. |

| Low cost | Price can fluctuate, depending on the harvest amount or politics associated with agriculture |

| Fully biodegradable/Non-toxic | Low durability, this can be improved by flex treatments significantly. |

| Good insulation against electricity and noise | The low resistance to fire and moisture. |

| Source of income for rural/agricultural community | Different range of quality, influenced by weather |

| Fibre | Density (g/cm3) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Elongation at Break (%) |

|---|---|---|---|---|

| Jute | 1.3 | 393–773 | 26.5 | 1.5–1.8 |

| Sisal | 1.5 | 511–635 | 9.4–22 | 2.0–2.5 |

| Flax | 1.5 | 500–1500 | 27.6 | 2.7–3.2 |

| Hemp | 1.47 | 690 | 70 | 2.0–4.0 |

| Pineapple | 1.56 | 170–1672 | 60–82 | 2.4 |

| Cotton | 1.5–1.6 | 400 | 5.5–12.6 | 7.0–8.0 |

| knaf | 1.45 | 930 | 53 | 1.6 |

| E-glass | 2.55 | 3400 | 71 | 3.4 |

| Carbon | 1.4 | 4000 | 230–240 | 1.4–1.8 |

| Sources | Density (g/cm3) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Elongation at Break (%) |

|---|---|---|---|---|

| Cicala et al. [58] | N.A. | 692 | 10.94 | 4.3 |

| Akil et al. [59] | N.A. | 930 | 53 | 1.6 |

| Mohanty et al. [60] and Parikh et al. [61] | 1.4 | 284–800 | 21–60 | 1.6 |

| Cheung et al. [62] | N.A. | 295–1191 | 2.86 | 3.5 |

| Rassmann et al. [53] | 1.5 | 350–600 | 40 | 2.5–3.5 |

| Ribot et al. [63] | 0.75 | 400–550 | – | – |

| Yousif et al. [64] | 0.6 | – | – | – |

| Malkapuram et al. [65] Graupner et al. [66] and Shibata et al. [67] | 0.749 | 223–624 | 11–14.5 | 2.7–5.7 |

| Jawaid and Khalil [68] | 1.2 | 295 | – | 3–10 |

| Researchers | Soil Types | Reinforcement Material | Experimental Test | Purpose of The Study | Optimum Value of Important Parameter | |||

|---|---|---|---|---|---|---|---|---|

| L1 | N2 | d3 | S4: S1, S2, S3 … | |||||

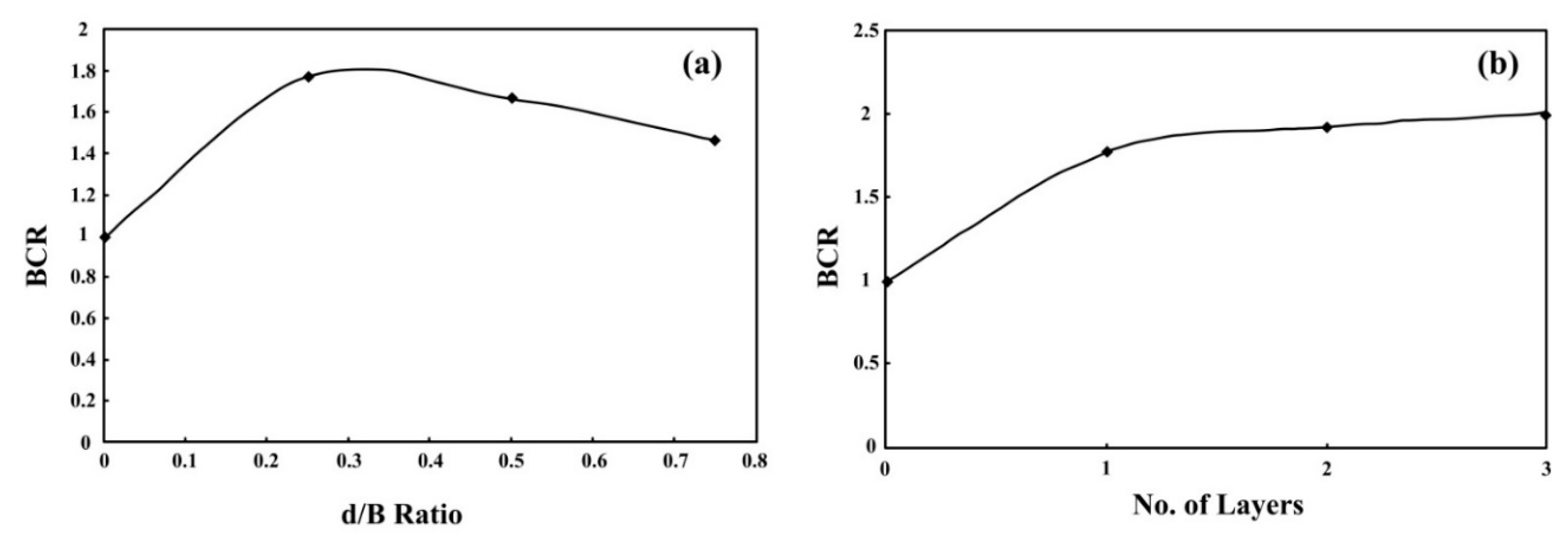

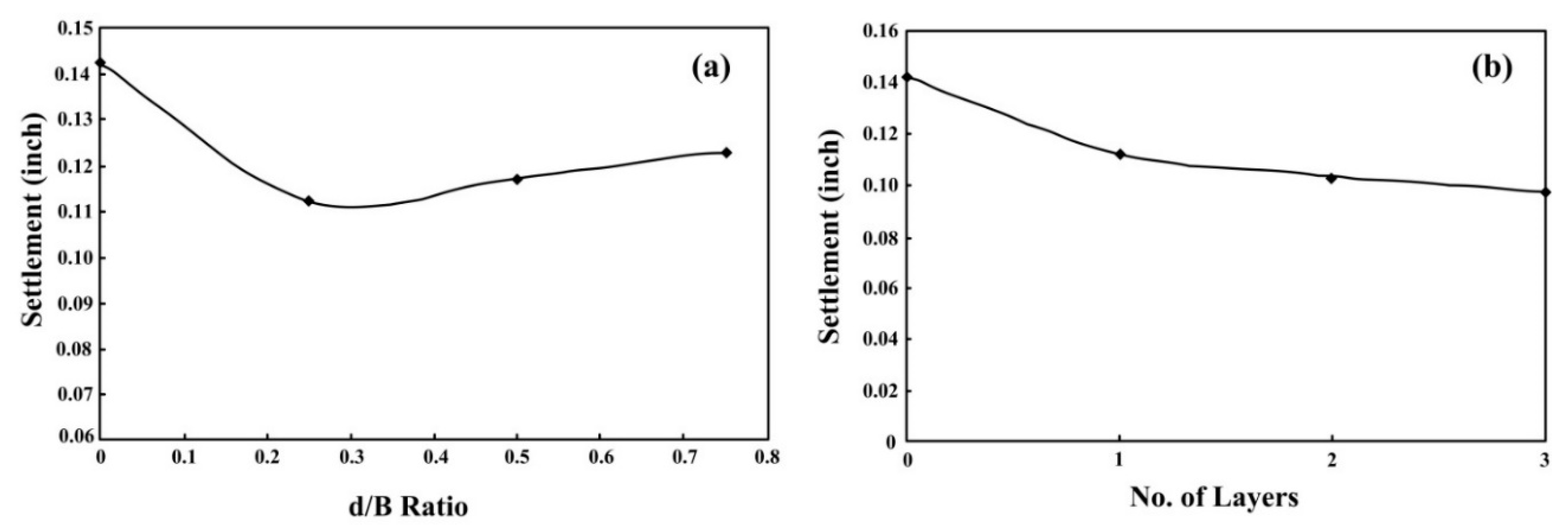

| Vinod et al. [39] | Loose Sand | Coir rope | Small scale vertical load tests | The most effective number of plies Bearing pressure-Settlement behaviour | 3B | 3 | 0.4B | 0.12B–0.2B |

| Results | Most efficient coir rope reinforcement depth on bearing capacity of soil = 0.4B5. Three-layer reinforced specimen (N = 3) was recommended as an optimum value of coir rope reinforcement layer. Because, the percentage increased in the Bearing Capacity Ratio (BCR) for N = 4 over BCR for N = 3 was very low. 9-ply braided coir rope instead of 7-ply coir rope demonstrated better performance in the form of soil strength improvement and settlement reduction | |||||||

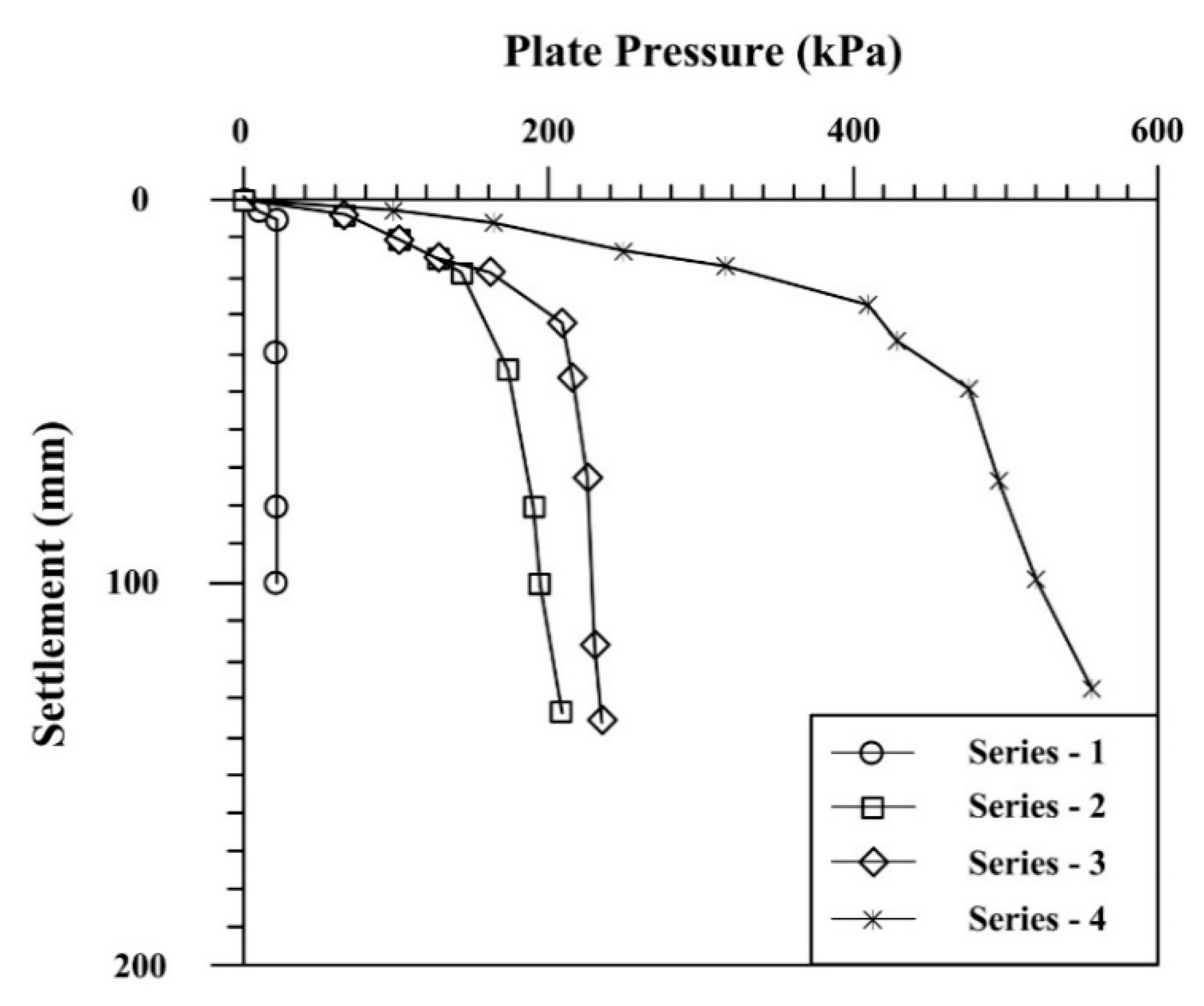

| Rajagopal and Ramakrishna [36] | Clay Gravel | Coir Geotextile | Large scale plate load tests | Soil Stiffness Bearing Capacity Ratio, BCR | 3B | 1 2 | 0.6B–1.2B | - |

| Results | Clearly indicated the capability of coir geotextiles in improving the stiffness and load-bearing capacity of soft subgrades. The coir geotextiles are suitable for cost-effective field applications. | |||||||

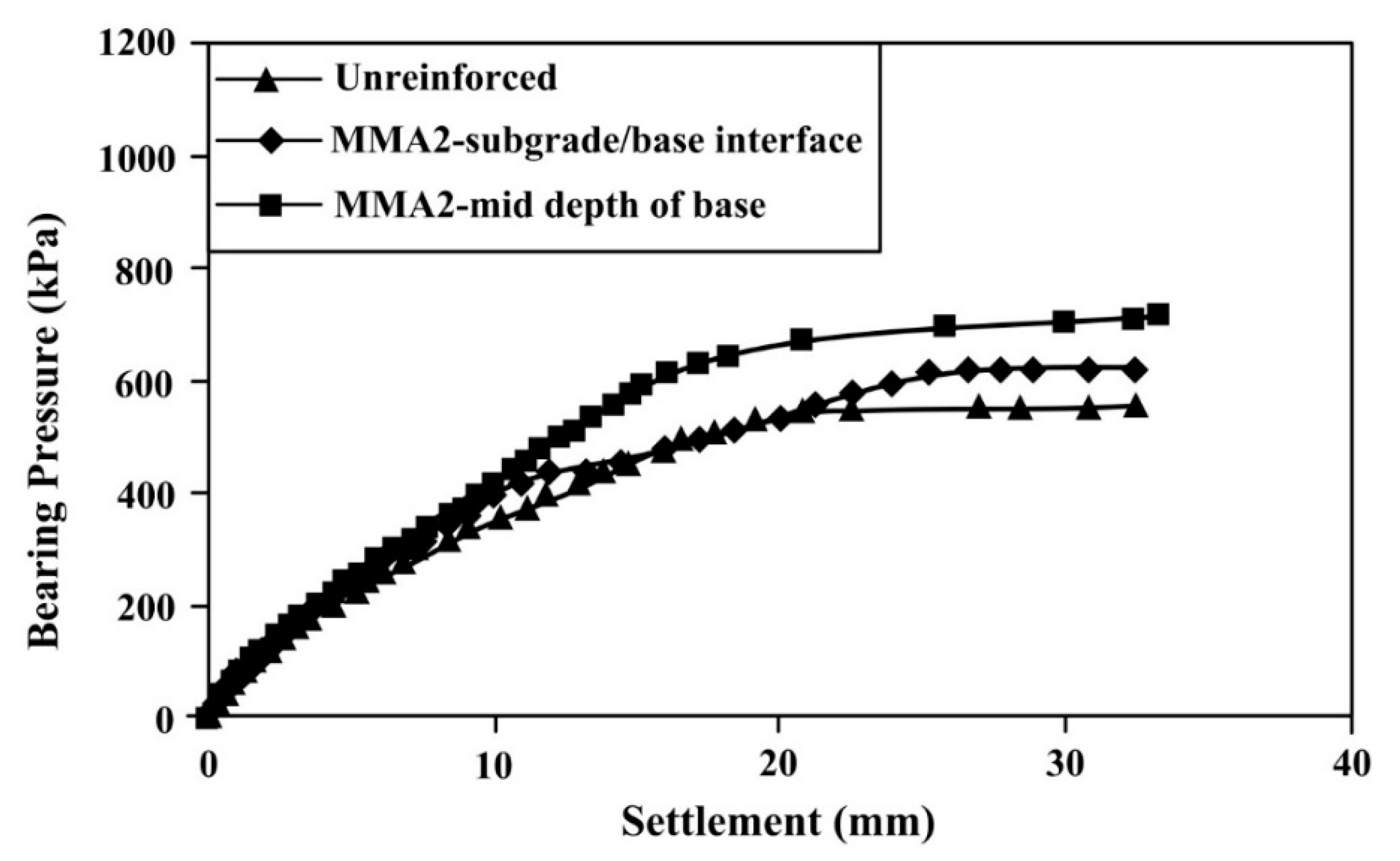

| Subaida et al. [38] | Clay | Coir Geotextile | Small scale vertical load tests | Bearing pressure-Settlement behaviour | - | - | one third of Plate diameter | - |

| Results | The coir reinforcement layer placed at the middle depth of the base layer caused the significant increases in bearing capacity of the specimen. The thin reinforced section shows more improvement in bearing capacity as compared to thicker sections with a reinforcement layer. | |||||||

| Asaduzzaman and Islam [32] | medium dense soil | bamboo reinforcement | Small scale vertical load tests | BCR and Settlement | - | 2–3 | 0.3B | - |

| Results | The improvement of soil bearing capacity only happened when the bamboo reinforcement layer placed within the deformation zone. Two-layer reinforced specimen (N = 2) was recommended as an optimum value of bamboo reinforcement layer. Because, the percentage increased in BCR for N = 3 over BCR for N = 2 was very low (4%). The settlement of footing decreased significantly with an increasing number of reinforcement layers up to N = 3. | |||||||

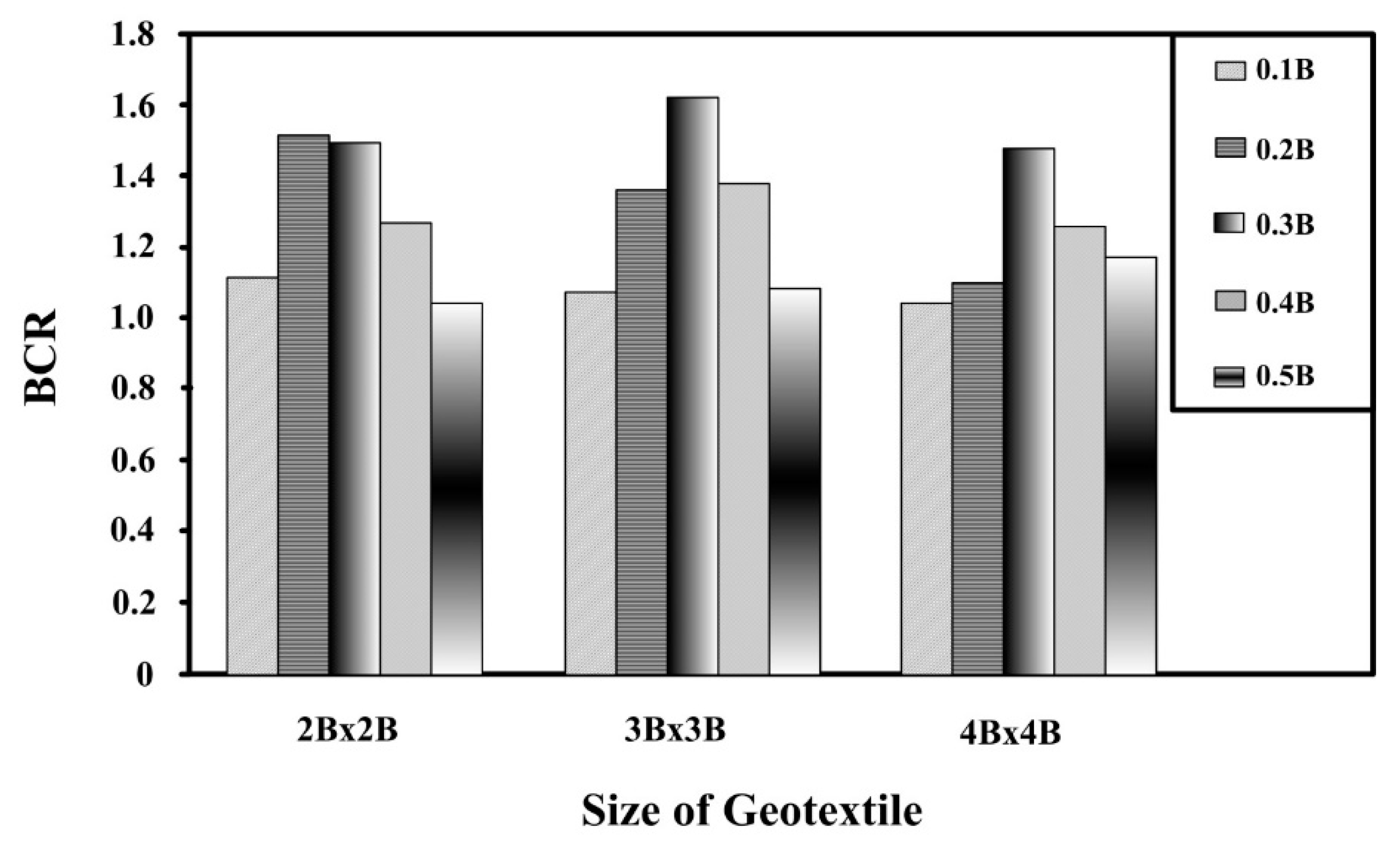

| Kumar et al. [33] | Fine Sand | N/A-Geotextiles | Small scale vertical load tests | BCR | 3B | 1 | 0.2B–0.3B | - |

| Results | The optimum reinforcement depth for 2Bx2B, 3Bx3B and 4Bx4B size of geotextile are 0.2B, 0.3B, 0.3B respectively. Geotextile with size equal to 4Bx4B shows maximum improvement in bearing capacity. | |||||||

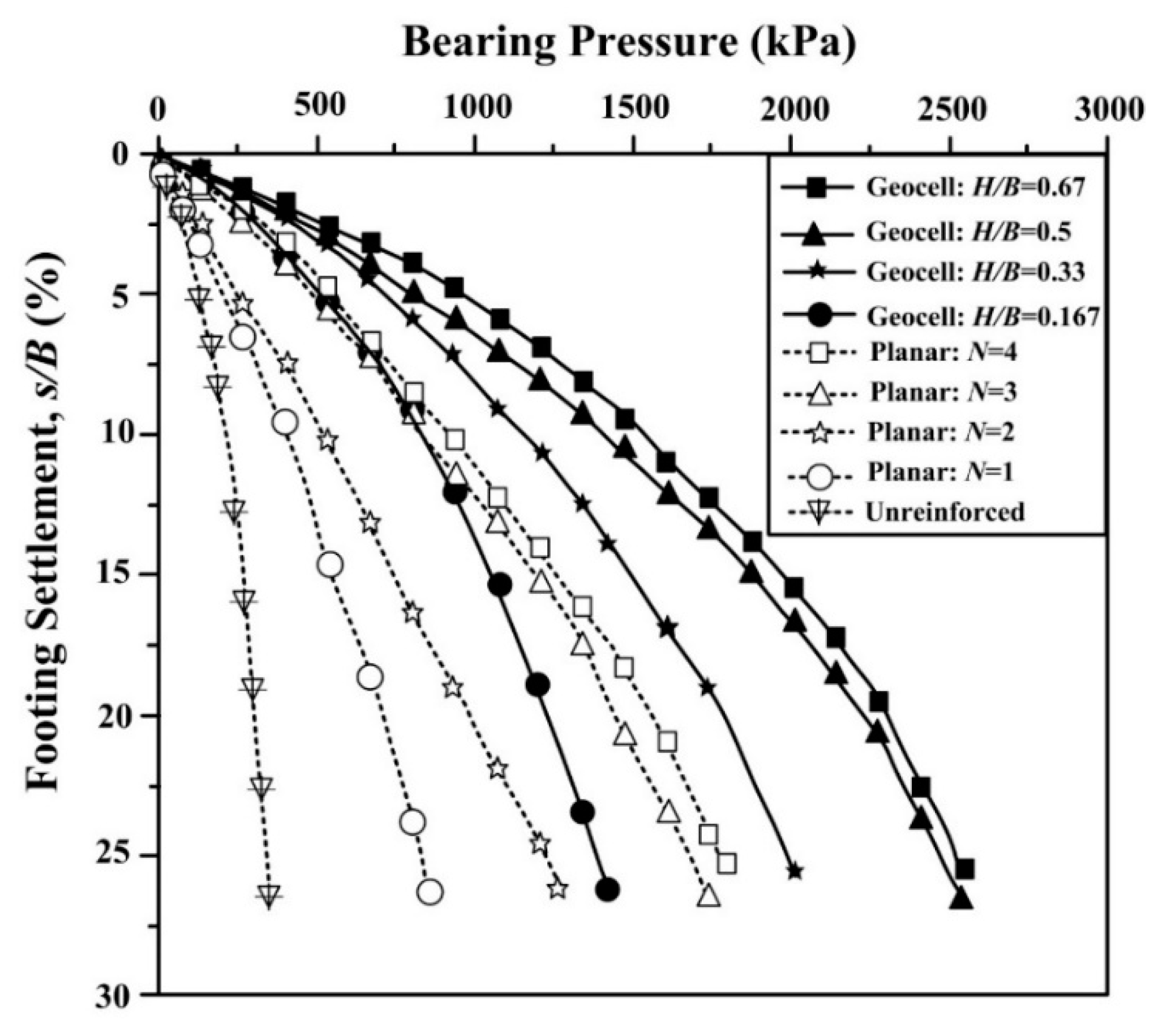

| Lal et al. [34] | Sand | Coir geotextile Coir geocell | Small scale vertical load tests | Bearing pressure-Settlement behaviour | - | - | 0.10B 0.25B | - |

| Results | For economic reasons, the suitable width of reinforcements was chosen to be medium size (bg/B = 3.2 and bp/B = 3.75). Most efficient coir geocell height on bearing capacity of soil= 0.5B d for planar reinforcement layer = 0.25B d for geocell reinforcement layer = 0.1B | |||||||

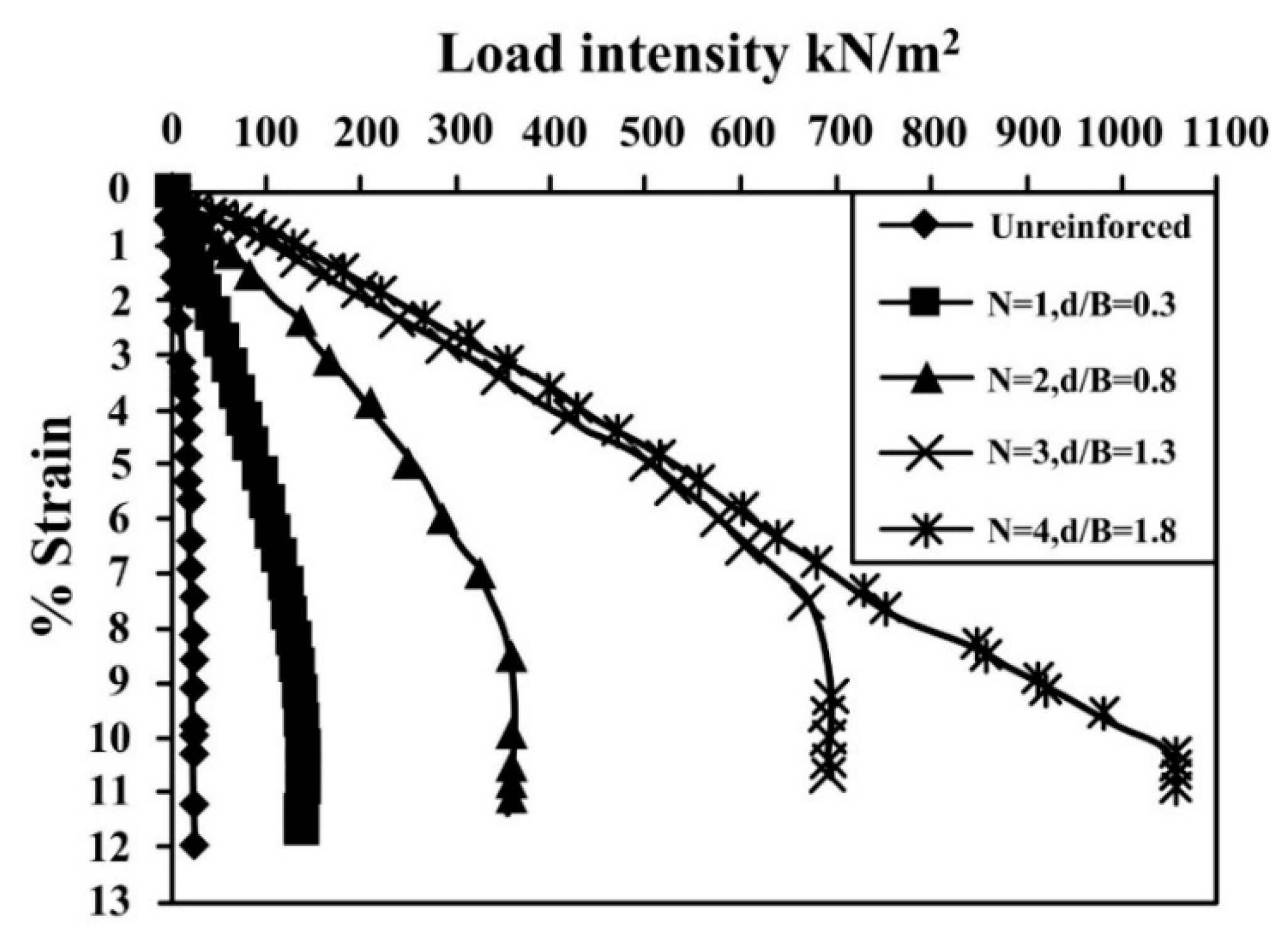

| Sridhar and Prathapkumar [37] | Sand | Coir Geotextiles | Direct shear tests Small scale vertical load tests | BCR Settlement reduction factor, SRF | - | 3–4 | 0.3B | Depth of each successive reinforcement layer = 0.5B |

| Results | From the direct shear test, the coir mat with opening size 20 × 20 mm provided maximum value of internal friction. BCR increases when the number of layers of reinforcement increases. When stress for coir geotextile increases, SRF increases as well. | |||||||

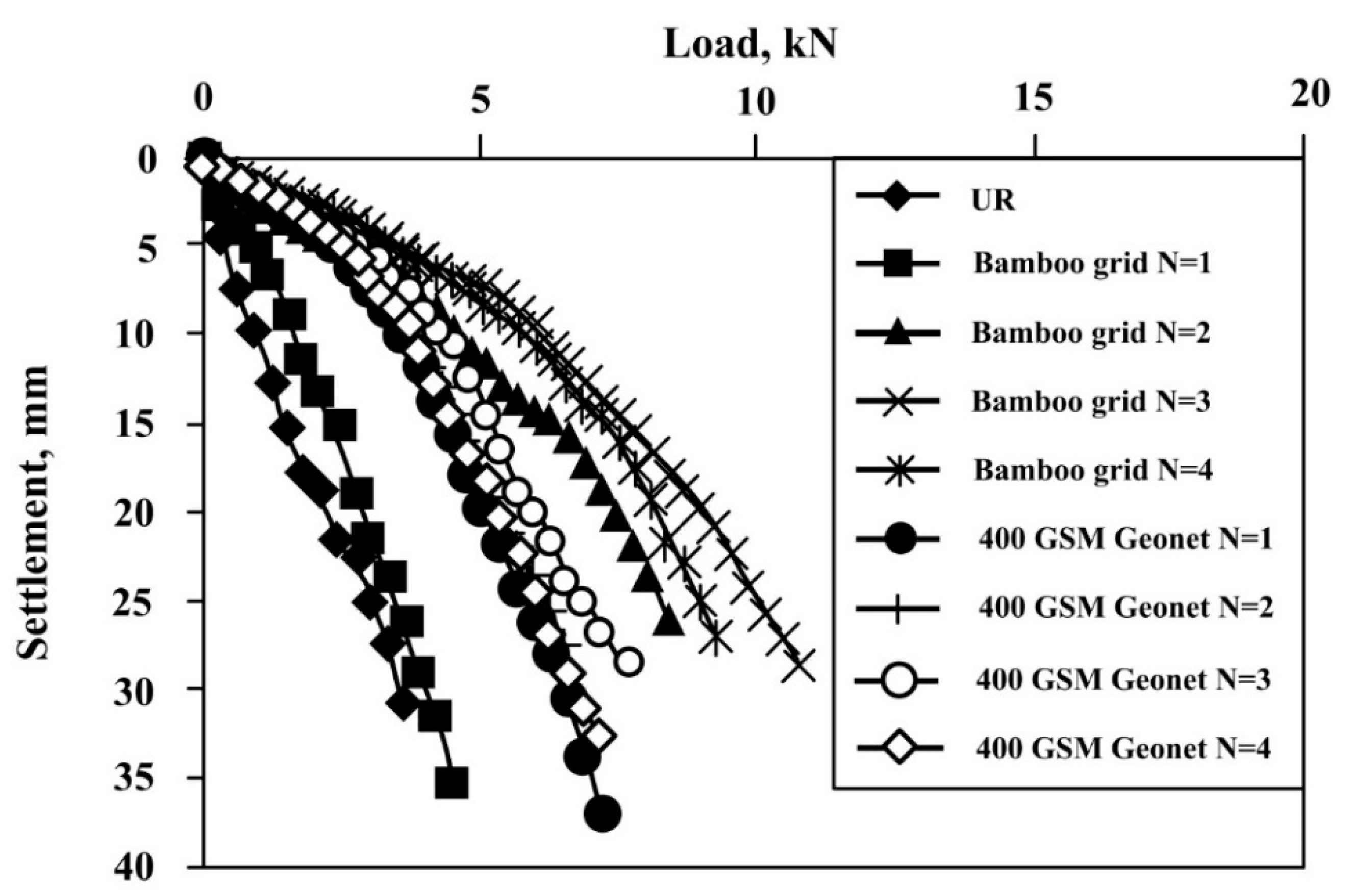

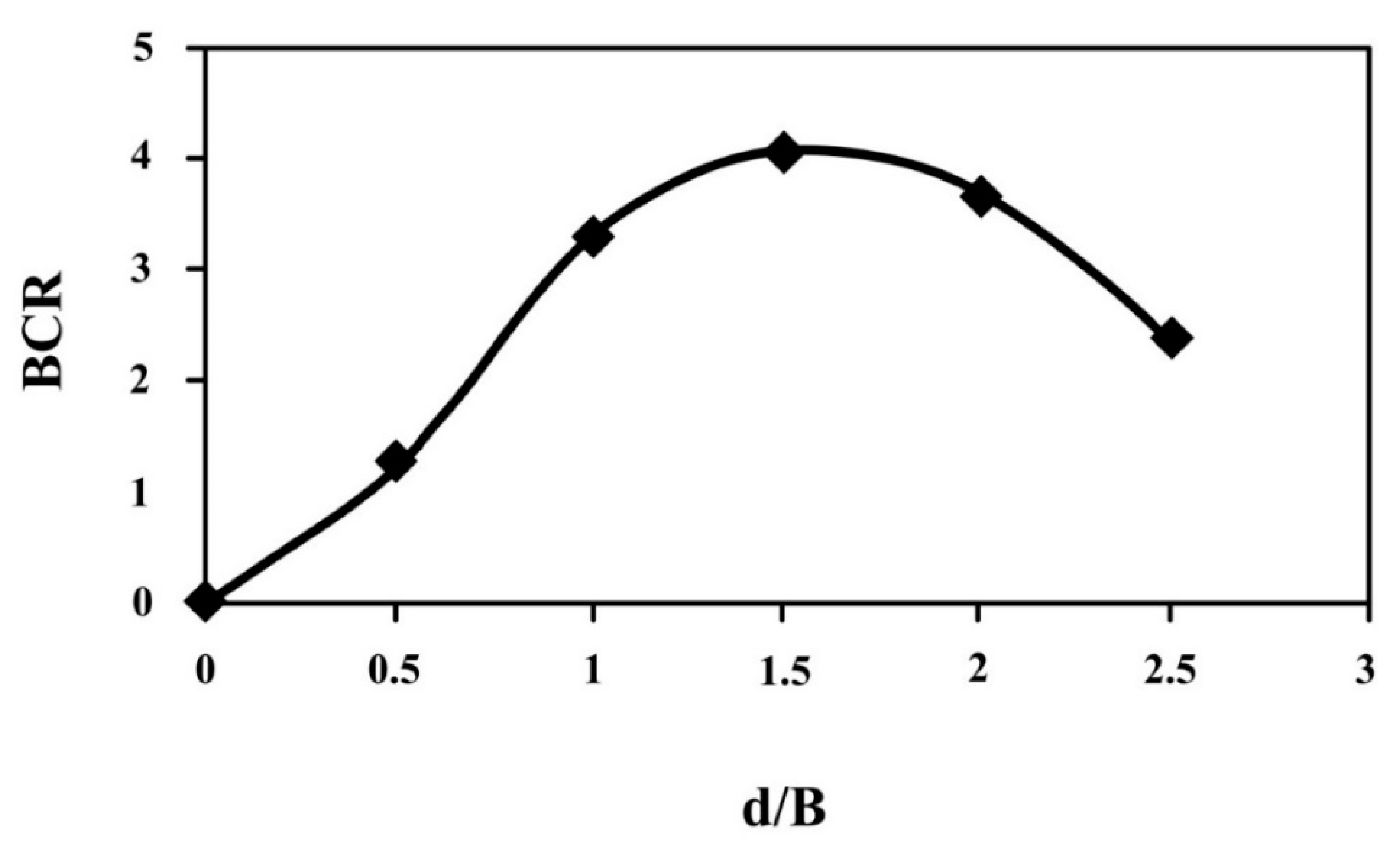

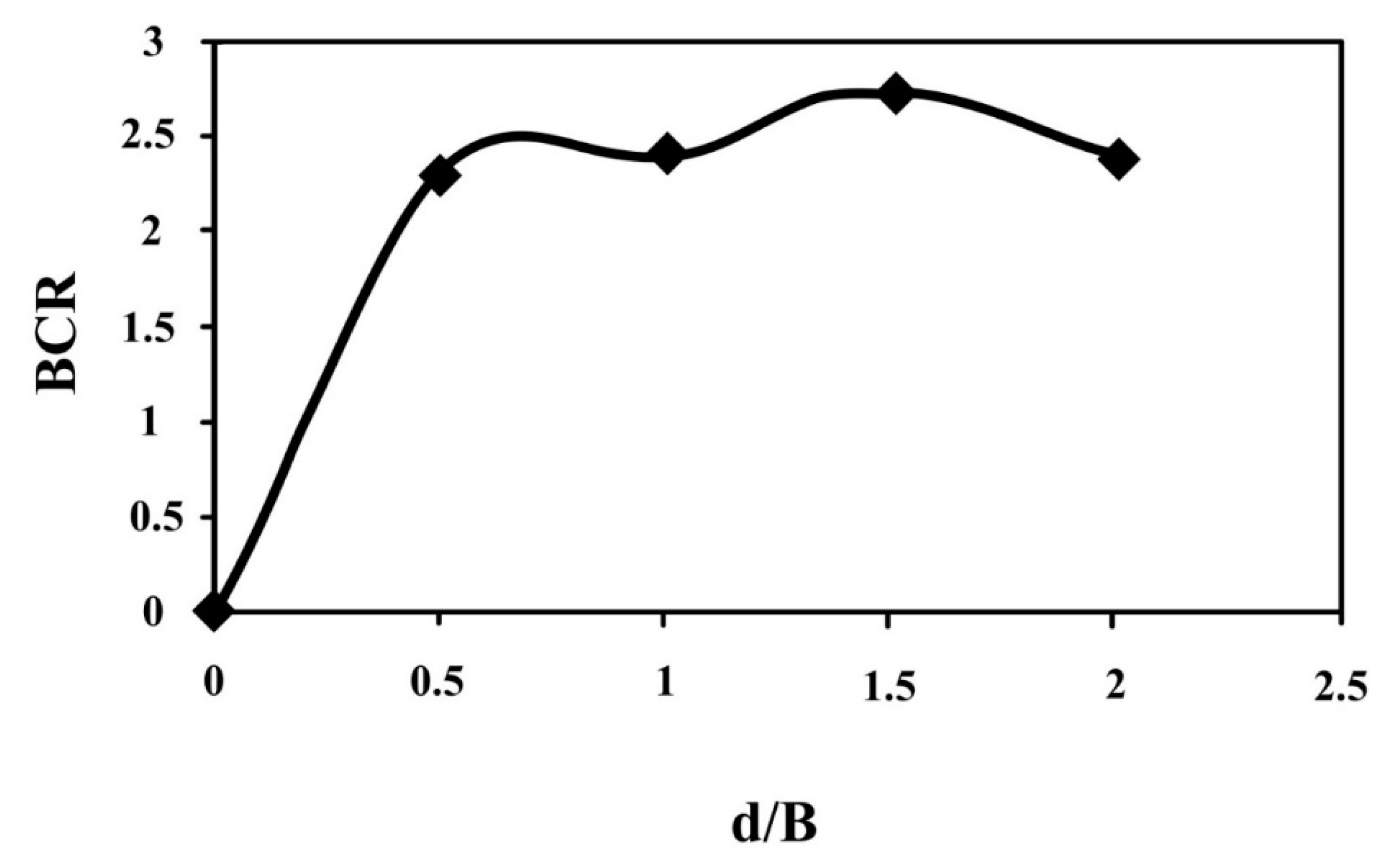

| Mathew and Sasikumar [28] | Soft soil | Bamboo gridCoir geonet | Small scale vertical load tests | BCR and Settlement | - | 3 | 1.5B | S1 = 0.5B |

| Results | The performance of bamboo-grid-reinforced soil is better than coir-geonet-reinforced soil. The bearing capacity becomes increased and the settlement gets reduced for reinforced soil. | |||||||

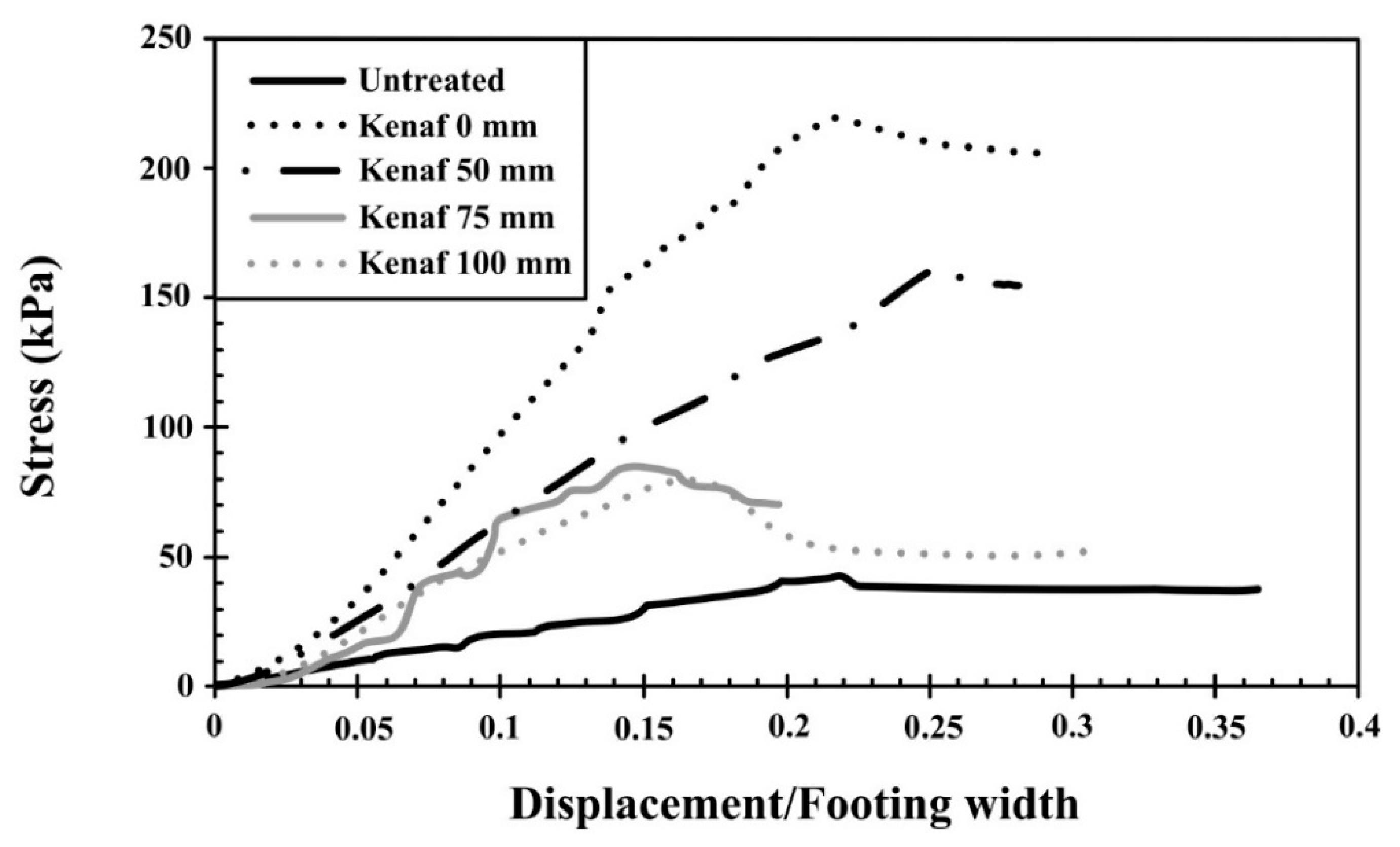

| Rashid et al. [15] | Sand | Woven knaf Geotextiles | Small scale vertical load tests | Influence of single reinforcement layer on Bearing capacity value (Nc) | - | 1 | 0B–0.25B | - |

| Results | In comparison with the untreated soil, the bearing capacity of sand soil model was improved up to 414.9% by the knaf fibre. The high bearing capacity value of the sand is caused by the short distance between knaf geotextile and the level of sand surface. | |||||||

| Parameters | Symbol | Typical Value | Recommended |

|---|---|---|---|

| Influence depth of Top layer spacing | d/B | 0–1 | 0.25 |

| Space between consecutive reinforcement layer | S/B | 0.2–0.7 | 0.25 |

| Number of geotextiles | N | 3–4 | 3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shirazi, M.G.; Rashid, A.S.B.A.; Nazir, R.B.; Rashid, A.H.B.A.; Moayedi, H.; Horpibulsuk, S.; Samingthong, W. Sustainable Soil Bearing Capacity Improvement Using Natural Limited Life Geotextile Reinforcement—A Review. Minerals 2020, 10, 479. https://doi.org/10.3390/min10050479

Shirazi MG, Rashid ASBA, Nazir RB, Rashid AHBA, Moayedi H, Horpibulsuk S, Samingthong W. Sustainable Soil Bearing Capacity Improvement Using Natural Limited Life Geotextile Reinforcement—A Review. Minerals. 2020; 10(5):479. https://doi.org/10.3390/min10050479

Chicago/Turabian StyleShirazi, Mohammad Gharehzadeh, Ahmad Safuan Bin A. Rashid, Ramli Bin Nazir, Azrin Hani Binti Abdul Rashid, Hossein Moayedi, Suksun Horpibulsuk, and Wisanukhorn Samingthong. 2020. "Sustainable Soil Bearing Capacity Improvement Using Natural Limited Life Geotextile Reinforcement—A Review" Minerals 10, no. 5: 479. https://doi.org/10.3390/min10050479

APA StyleShirazi, M. G., Rashid, A. S. B. A., Nazir, R. B., Rashid, A. H. B. A., Moayedi, H., Horpibulsuk, S., & Samingthong, W. (2020). Sustainable Soil Bearing Capacity Improvement Using Natural Limited Life Geotextile Reinforcement—A Review. Minerals, 10(5), 479. https://doi.org/10.3390/min10050479