Hybrid Failure of Cemented Paste Backfill

Abstract

:1. Introduction

2. Material and Methods

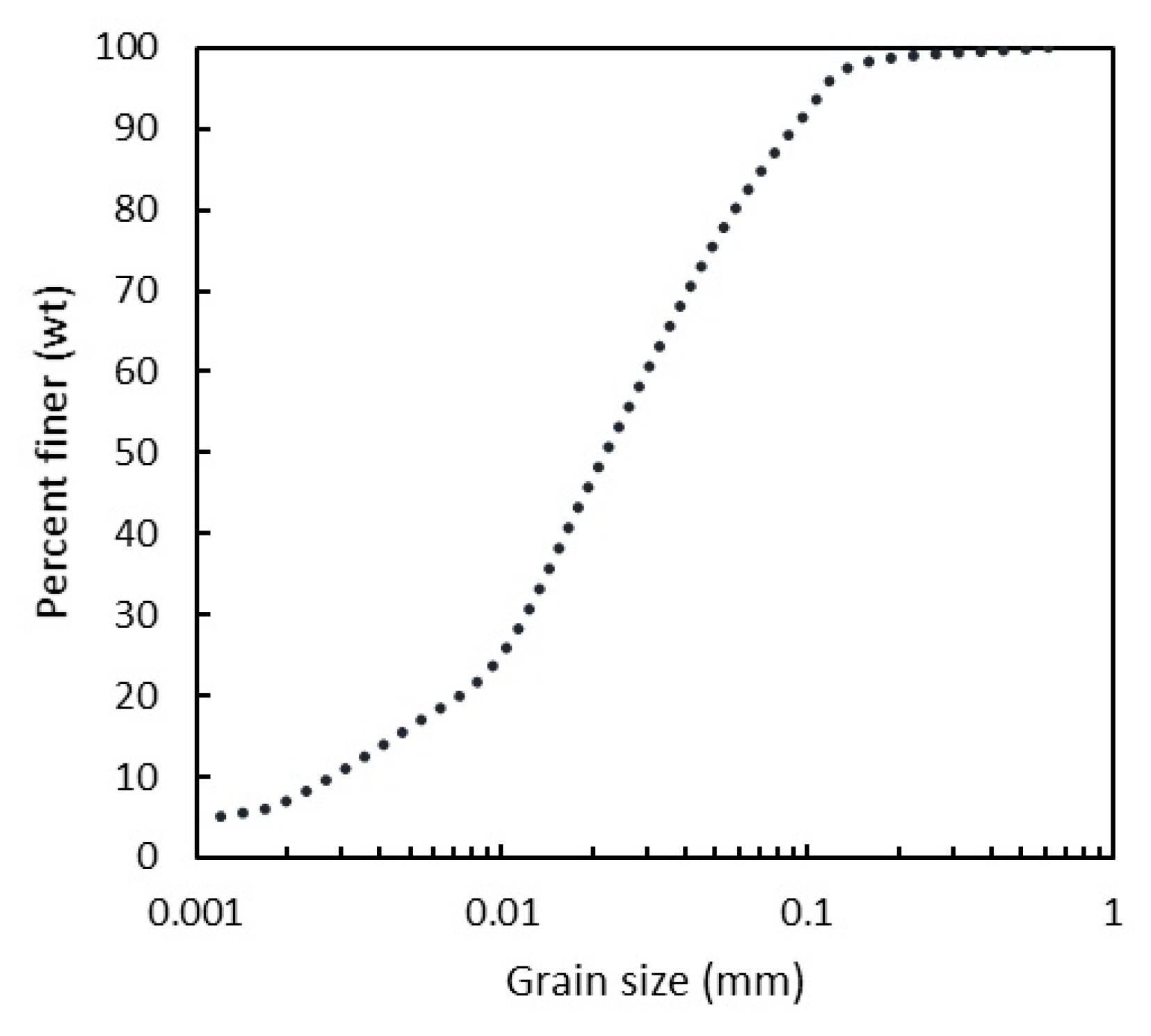

2.1. Sample Preparation

2.2. Testing Methods

2.3. Numerical Simulation

- The Mohr–Coulomb envelope for the strength parameter [24]τp = σ tanϕp + c,where τp is the peak shear stress, τr is the residual shear stress, σ is the normal stress, c is the cohesion, ϕp and ϕr are the peak and the residual angles of frictional resistance, respectively.τr = σ tanϕr,

- The modulus of elasticity E (material’s resistance to elastic deformation) [25]where σ is the stress and ε is the strain in the elastic region.E = σ/ε,

- The shear modulus (material’s resistance to shear deformation) [25]where G is the shear modulus, τxy is the shear stress, γxy is the engineering shear strain, and l is the gauge length of the shear, F is the total applied force, and A is the area of shear, and ∆x is the lateral displacement.G = τxy/γxy ≐ Fl/A∆x,

- The Poisson’s ratio v (ratio of longitudinal strain to transversal strain) [25]where E is the modulus of elasticity and G is the shear modulus.v = (E − 2G)/2G,

3. Results and Discussion

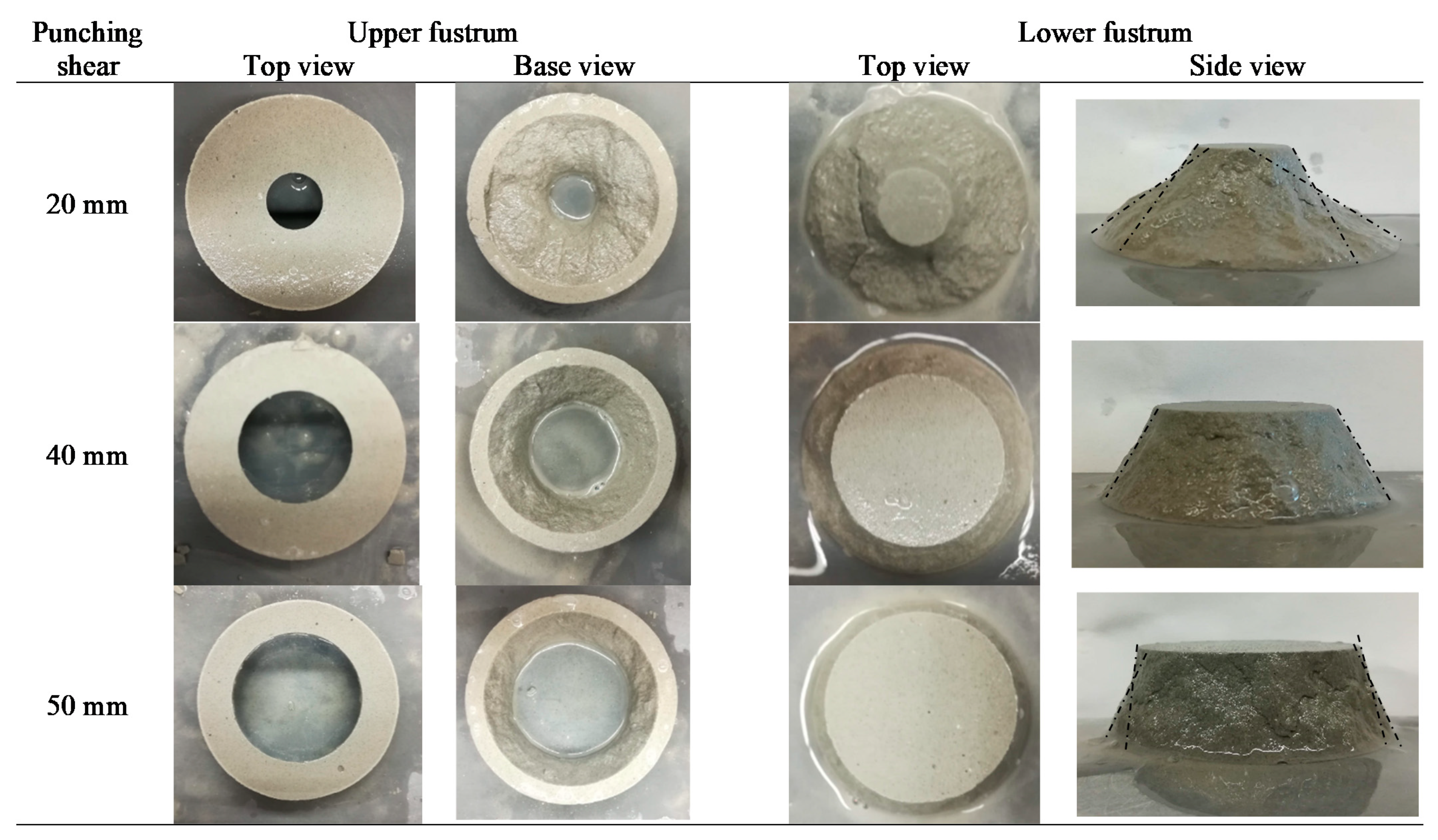

3.1. Fracture Morphology and Numerical Simulation

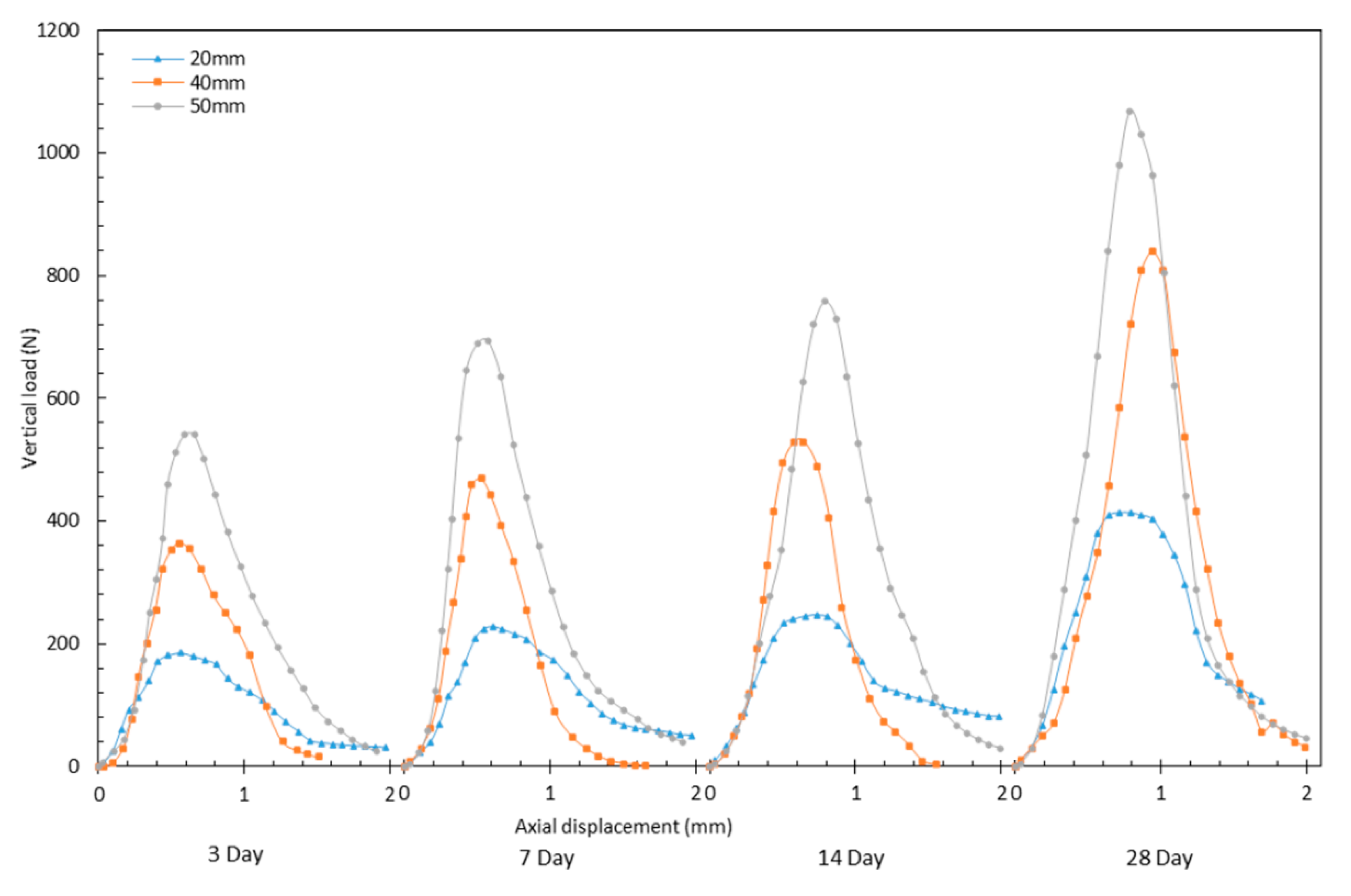

3.2. Strength Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hassani, F.; Archibald, J. Mine Backfill; Canadian Institute of Mining, Metallurgy and Petroleum: Montreal, QC, Canada, 1998. [Google Scholar]

- Grabinsky, M.W.F.; Simms, P. Self-Desiccation of Cemented Paste Backfill and Implications for Mine Design. In Proceedings of the Ninth International Seminar on Paste and Thickened Tailings, Perth, Australia, 3–7 April 2006; Australian Centre for Geomechanics: Perth, Australia, 2006; pp. 323–332. [Google Scholar] [CrossRef]

- Grabinsky, M.W.F.; Simms, P. Direct measurement of matric suction in triaxial tests on early age cemented. Can. Geotech. J. 2009, 46, 93–101. [Google Scholar] [CrossRef]

- Nasir, O.; Fall, M. Shear behaviour of cemented pastefill-rock interfaces. Eng. Geol. 2008, 101, 146–153. [Google Scholar] [CrossRef]

- Koupouli, N.J.; Belem, T.; Rivard, P.; Effenguet, H. Direct shear tests on cemented paste backfill–rock wall and cemented paste backfill–backfill interfaces. J. Rock Mech. Geotech. Eng. 2016, 8, 472–479. [Google Scholar] [CrossRef] [Green Version]

- Pan, A.N.; Grabinsky, M.W.F.; Guo, L. Shear Properties of Cemented Paste Backfill under Low Confining Stress. Adv. Civ. Eng. 2021, 2021, 1–11. [Google Scholar] [CrossRef]

- Fall, M.; Belem, T.; Samb, S.; Benzaazoua, M. Experimental characterization of the stress—strain behaviour. J. Mater. Sci. 2007, 42, 3914–3922. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, D.; Tian, Y.; Liu, X. Numerical simulation of stress-strain behaviour of cemented paste backfill in triaxial compression. Eng. Geol. 2017, 231, 165–175. [Google Scholar] [CrossRef]

- Zeng, B.; Huang, D.; Ye, S.; Chen, F.; Zhu, T.; Tu, Y. Triaxial extension tests on sandstone using a simple auxiliary apparatus. Int. J. Rock Mech. Min. Sci. Geomech. 2019, 120, 29–40. [Google Scholar] [CrossRef]

- Jafari, M.; Shahsavari, M.; Grabinsky, M. Drained Triaxial Compressive Shear Response of Cemented Paste Backfill (CPB). Rock Mech. Rock Eng. 2021, 54, 3309–3325. [Google Scholar] [CrossRef]

- Johnson, J.C.; Seymour, J.B.; Martin, L.A.; Stepan, M.; Arkoosh, A. Strength and Elastic Properties of Paste Backfill at the Lucky Friday Mine, Mullan, Idaho. In U.S. Rock Mechanics/Geomechanics Symposium; American Rock Mechanics Association: San Francisco, CA, USA, 2015. [Google Scholar]

- Pan, A.N.; Grabinsky, M. Tensile Strength of Cemented Paste Backfill. Geotech. Test. J. 2021, 44, 1886–1897. [Google Scholar] [CrossRef]

- Komurlu, E.; Kesimal, A.; Demir, S. Experimental and numerical analyses on determination of indirect (splitting) tensile strength of cemented paste backfill materials under different loading apparatus. Geomech. Eng. 2016, 10, 775–791. [Google Scholar] [CrossRef]

- Boulifa, R.; Samai, L.M.; Benhassine, T.M. A new technique for studying the behaviour of concrete in shear. J. King Saud Univ. Sci. 2013, 25, 149–159. [Google Scholar] [CrossRef] [Green Version]

- Francesconi, L.; Pani, L.; Stochino, F. Punching shear strength of reinforced recycled concrete slabs. Constr. Build Mater. 2016, 127, 248–263. [Google Scholar] [CrossRef]

- Genikomsou, A.S.; Polak, A.M. Finite element analysis of punching shear of concrete slabs using damaged plasticity model in ABAQUS. Eng. Struct. 2015, 98, 38–48. [Google Scholar] [CrossRef]

- Grabinsky, M.W.F. In situ monitoring for ground truthing paste backfill designs. In Proceedings of the Thirteenth International Seminar on Paste and Thickened Tailings, Toronto, ON, Canada, 3–6 May 2010; Australian Centre for Geomechanics: Toronto, ON, Canada, 2010; pp. 85–98. [Google Scholar] [CrossRef] [Green Version]

- Jafari, M.; Shahsavari, M.; Grabinsky, M.W.F. Cemented Paste Backfill 1-D Consolidation Results Interpreted in the Context of Ground Reaction Curves. Rock Mech. Rock Eng. 2020, 53, 4299–4308. [Google Scholar] [CrossRef]

- Thompson, B.D.; Bawden, W.F.; Grabinsky, M.W.F. In situ measurements of cemented paste backfill at the Cayeli Mine. Can. Geotech. J. 2012, 49, 755–772. [Google Scholar] [CrossRef]

- Jafari, M.; Shahsavari, M.; Grabinsky, M.W.F. Hydration Effects on Specific Gravity and Void Ratio of Cemented Paste Backfill. Geotech. Test. J. 2020, 43, 1300–1316. [Google Scholar] [CrossRef]

- Barrick Gold Corporation. Roscoe Postle Associates, Technical Report on the Hemlo Mine; Barrick Gold Corporation: Marathon, ON, Canada, 2017. [Google Scholar]

- Ercikdi, B.; Kesimal, A.; Cihangir, F.; Deveci, H.; Alp, I. Cemented paste backfill of sulphide-rich tailings: Importance of binder type and dosage. Cem. Concr. Compos. 2009, 31, 268–274. [Google Scholar] [CrossRef]

- Grabinsky, M.W.F.; Pan, A.N. Cemented paste backfill failure envelope at low confining stress. In Proceedings of the Minefill 2021, The 13th International Symposium on Mining with Backfill, Katowice, Poland, 25–28 May 2021; Society for Mining, Metallurgy and Exploration Minefill: Katowice, Poland, 2021. [Google Scholar]

- Terzaghi, K. Theoretical Soil Mechanics; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1943. [Google Scholar]

- Beer, F.P.; Johnston, E.R.; DeWolf, J.T.; Mazurek, D.F. Mechanics of Materials, 6th ed.; McGraw Hill: New York, NY, USA, 2012. [Google Scholar]

| Tailing Composition | ||||||||||||||||||

| Composition | CaO | SiO2 | SO3 | Al2O3 | MgO | Fe2O3 | K2O | Na2O | ||||||||||

| Content (wt %) | 64.2 | 20.0 | 4.1 | 3.9 | 3.1 | 3.0 | 0.5 | 0.2 | ||||||||||

| Binder Composition | ||||||||||||||||||

| Composition | SiO2 | Al2O3 | CaO | MgO | K2O | Na2O | Fe2O3 | S | TiO2 | P2O5 | ||||||||

| Content (wt %) | 59.8 | 12.2 | 3.6 | 3.5 | 3.4 | 3.2 | 2.4 | 0.6 | 0.4 | 0.2 | ||||||||

| Cement Content (%) | Binder Type | Curing Time (Days) | Trial Per Mix | Number of Samples |

|---|---|---|---|---|

| 4.2 | 100% GPC | 3, 7, 14 and 28 | 3 | 12 |

| 6.9 | 100% GPC | 3, 7, 14 and 28 | 3 | 12 |

| 9.7 | 100% GPC | 3, 7, 14 and 28 | 3 | 12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, A.; Jafari, M.; Guo, L.; Grabinsky, M. Hybrid Failure of Cemented Paste Backfill. Minerals 2021, 11, 1141. https://doi.org/10.3390/min11101141

Pan A, Jafari M, Guo L, Grabinsky M. Hybrid Failure of Cemented Paste Backfill. Minerals. 2021; 11(10):1141. https://doi.org/10.3390/min11101141

Chicago/Turabian StylePan, Andrew, Mohammadamin Jafari, Lijie Guo, and Murray Grabinsky. 2021. "Hybrid Failure of Cemented Paste Backfill" Minerals 11, no. 10: 1141. https://doi.org/10.3390/min11101141

APA StylePan, A., Jafari, M., Guo, L., & Grabinsky, M. (2021). Hybrid Failure of Cemented Paste Backfill. Minerals, 11(10), 1141. https://doi.org/10.3390/min11101141