Borehole-Based Monitoring of Mining-Induced Movement in Ultrathick-and-Hard Sandstone Strata of the Luohe Formation

Abstract

:1. Introduction

2. Materials: Mining Conditions of Panel #2 in the Tingnan Coal Mine

2.1. Hydrogeographic Conditions

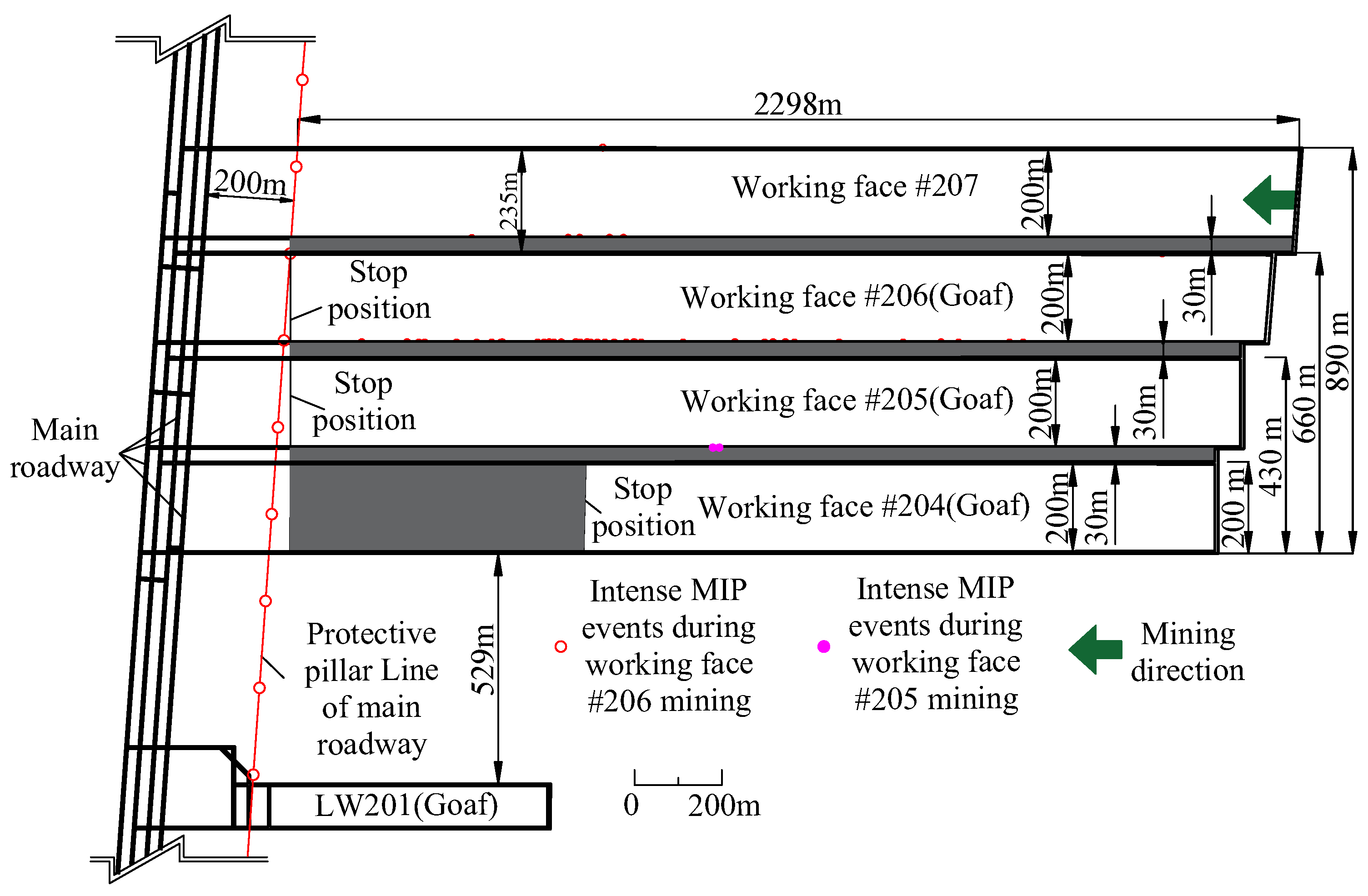

2.2. Mining Conditions of the Working Face

2.3. Intense MIP Events in the Working Face Roadways

2.4. Surface Subsidence

3. Methods and Design of Monitoring the Movement of the UTHS

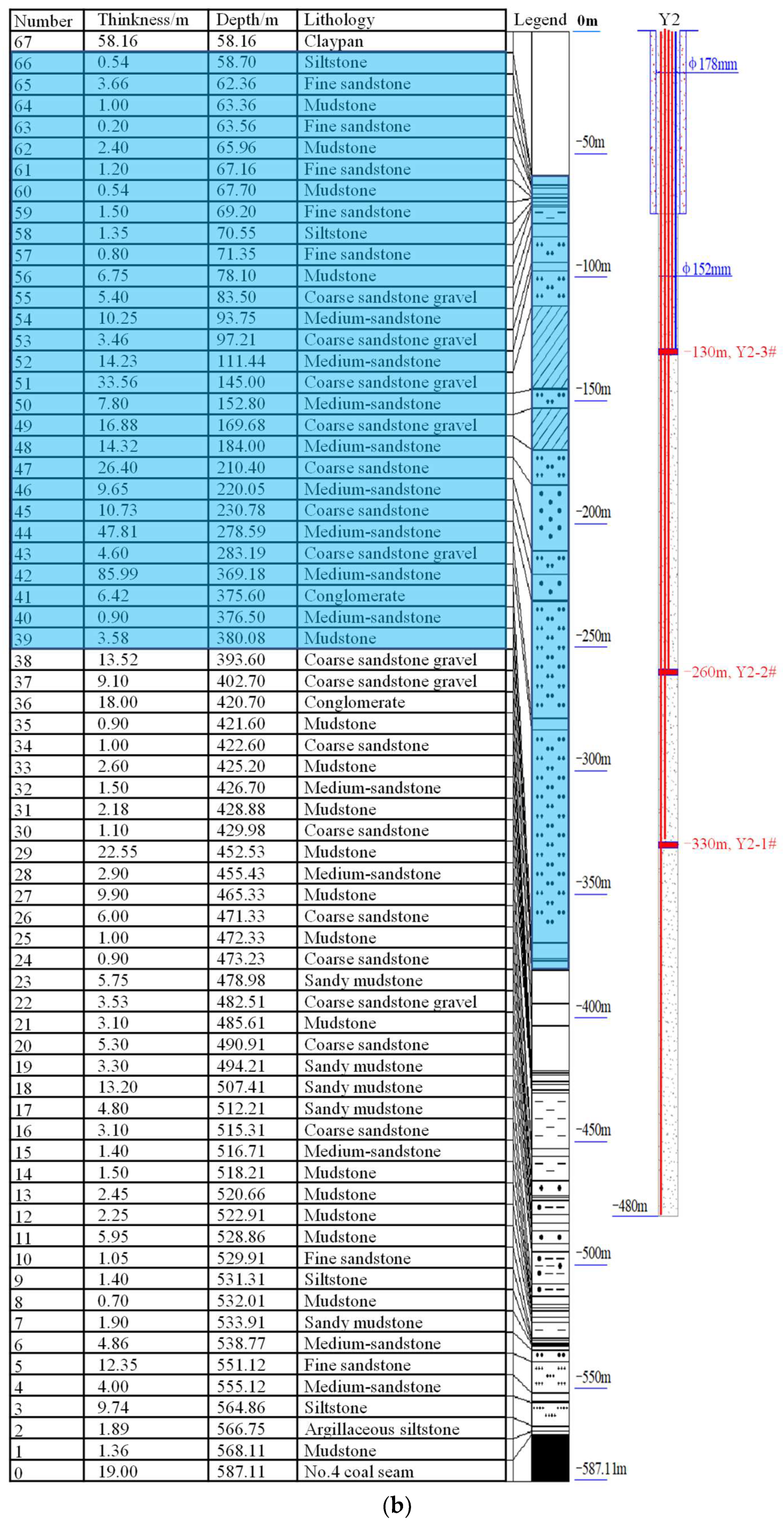

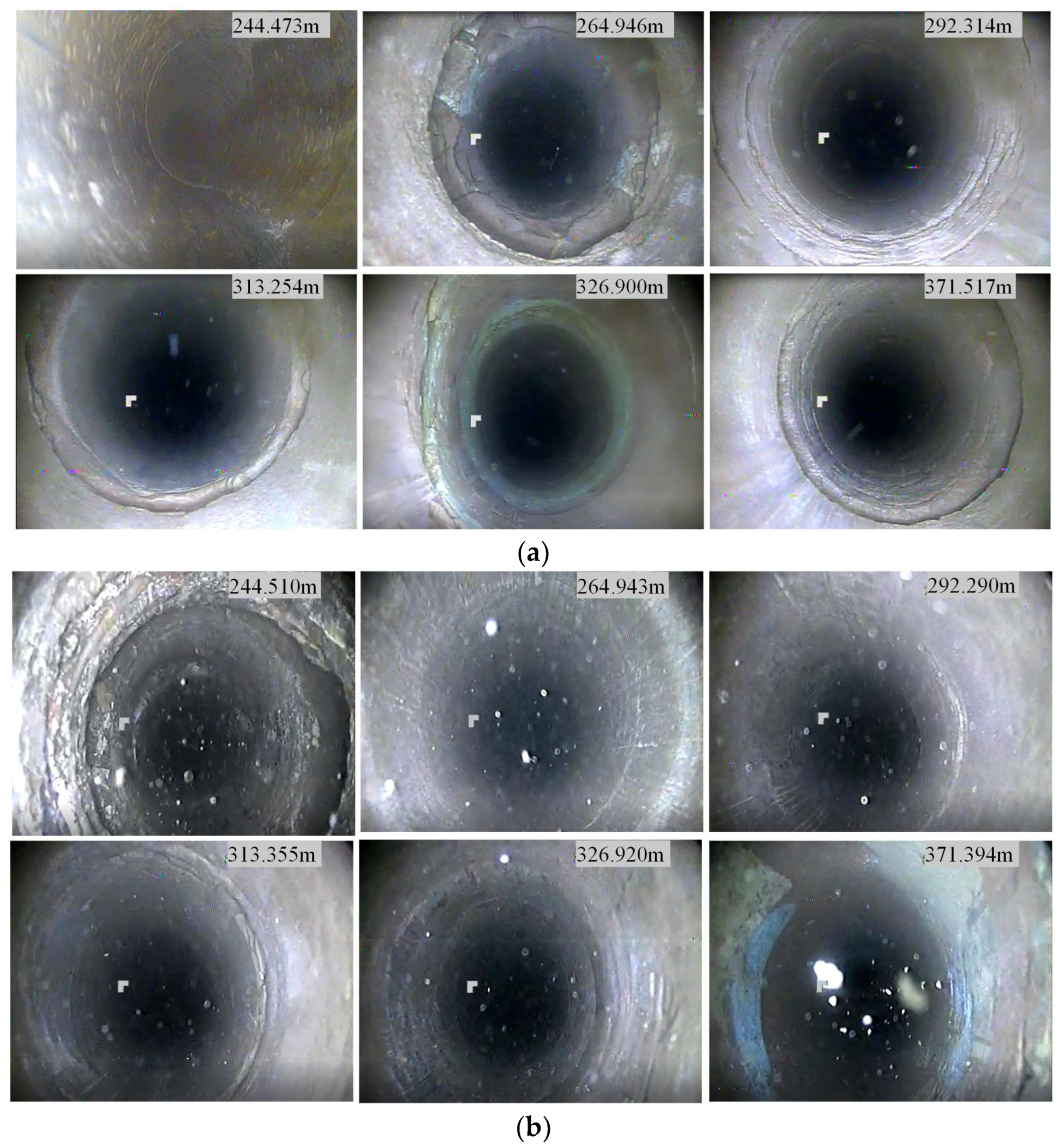

3.1. Method of Fracture Detection

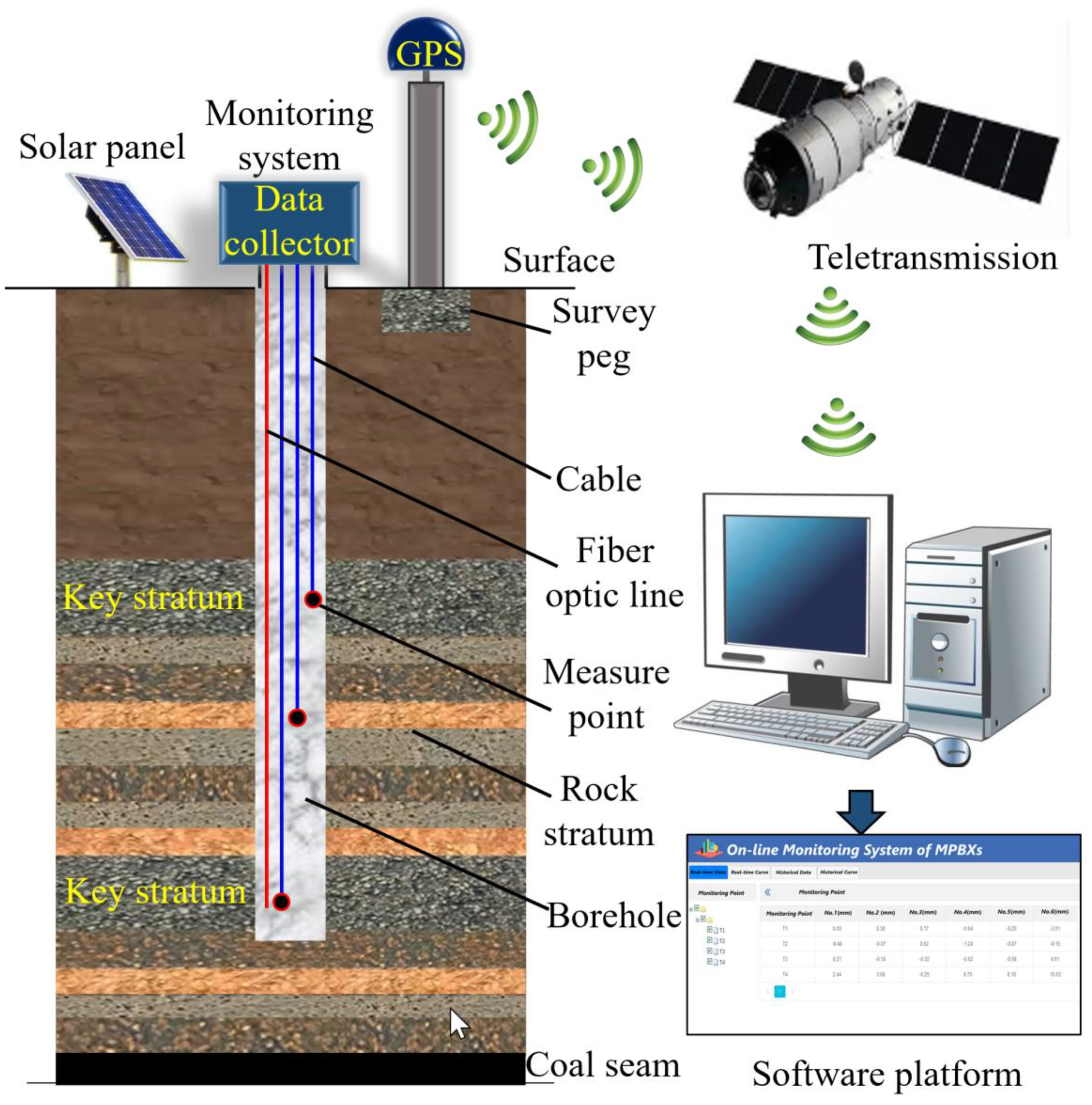

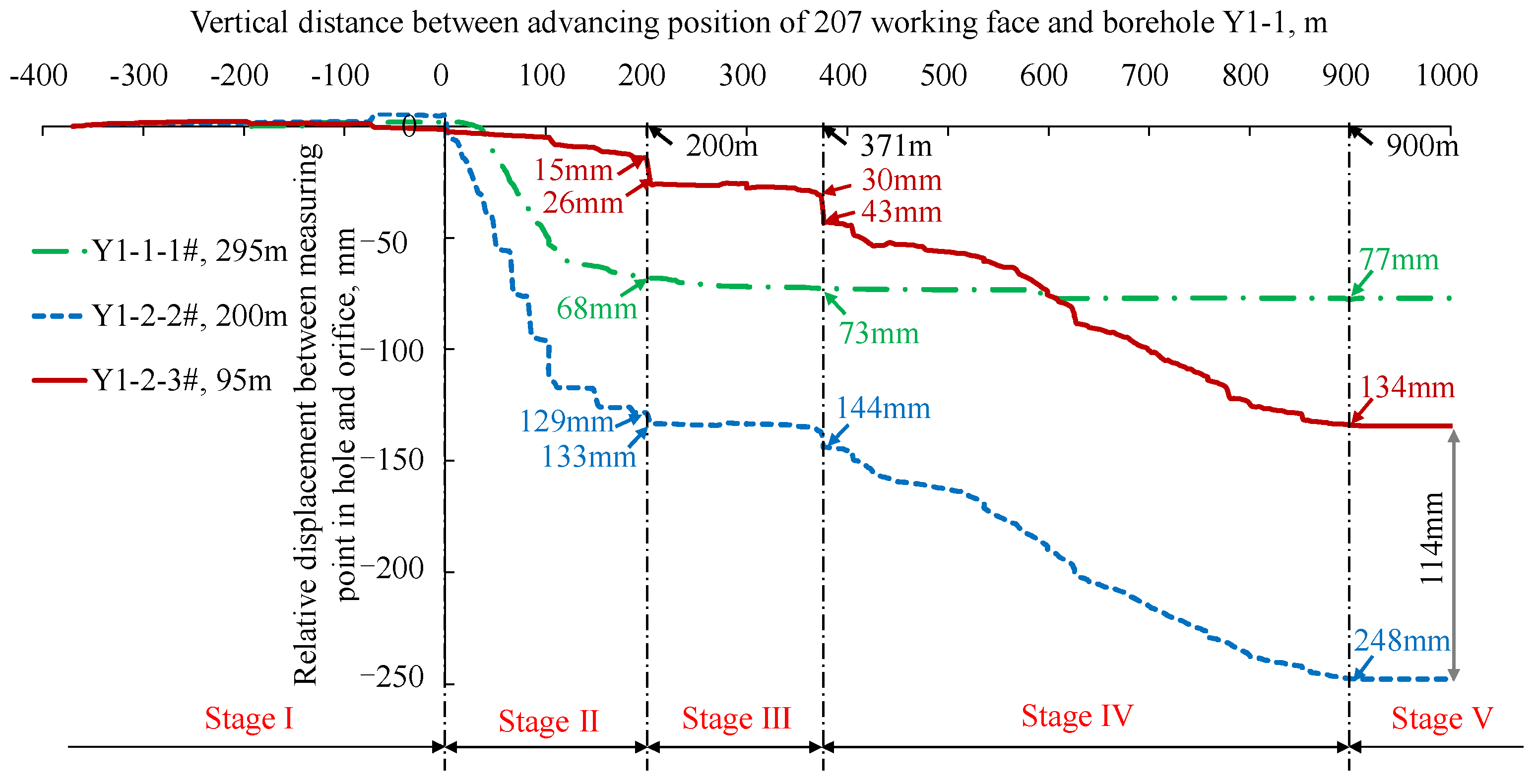

3.2. Method of Strata Movement Monitoring

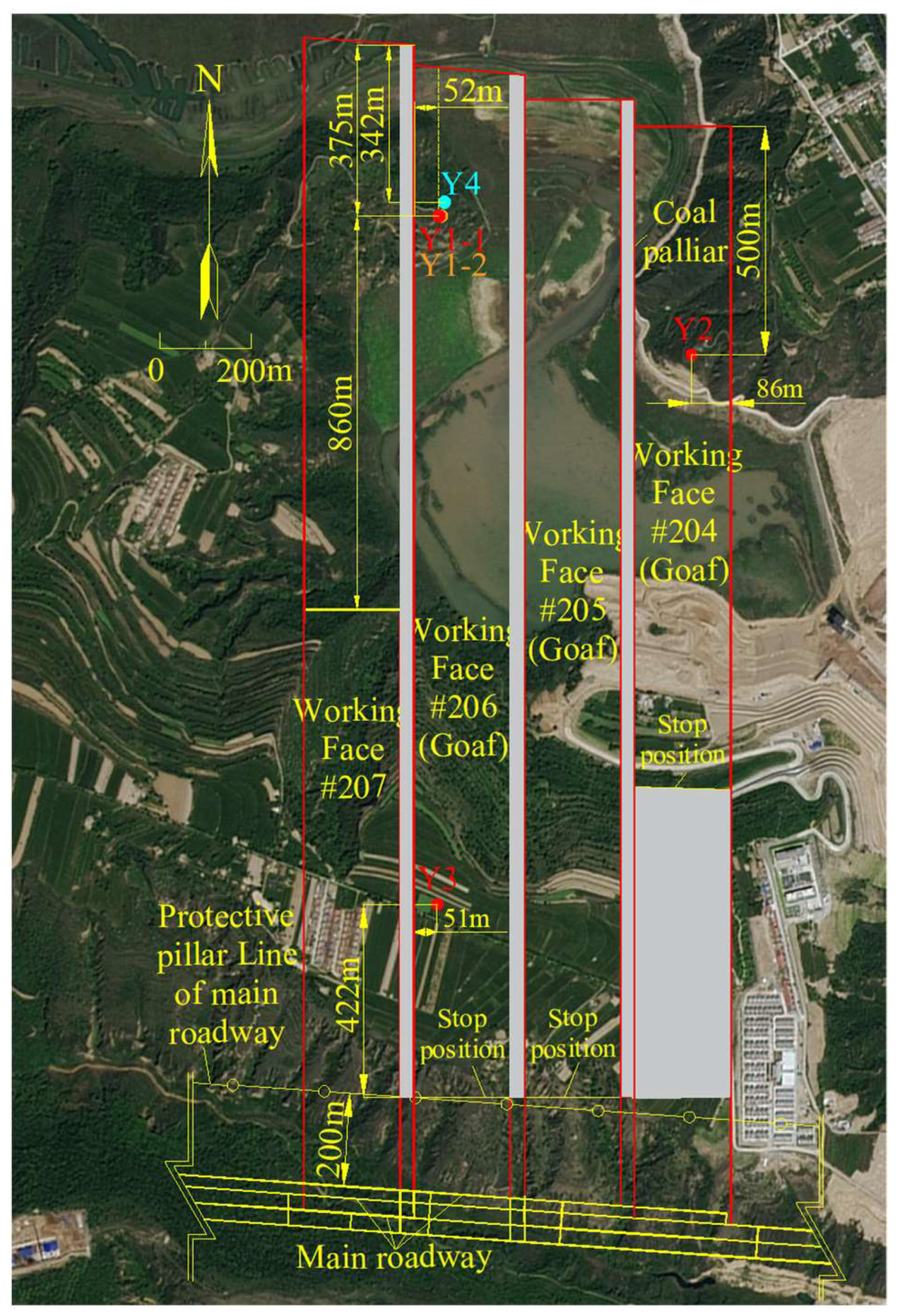

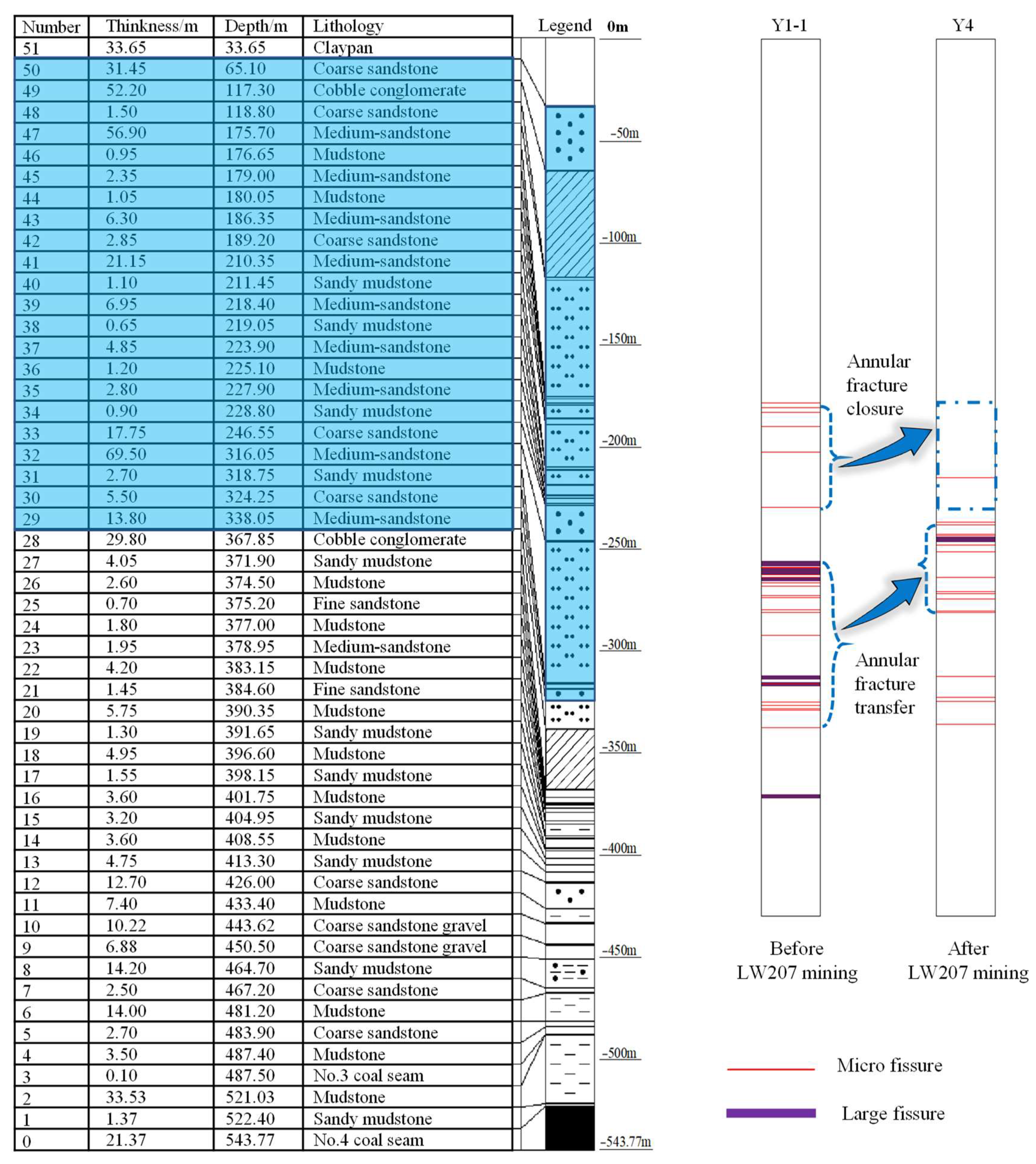

3.3. Borehole Layout

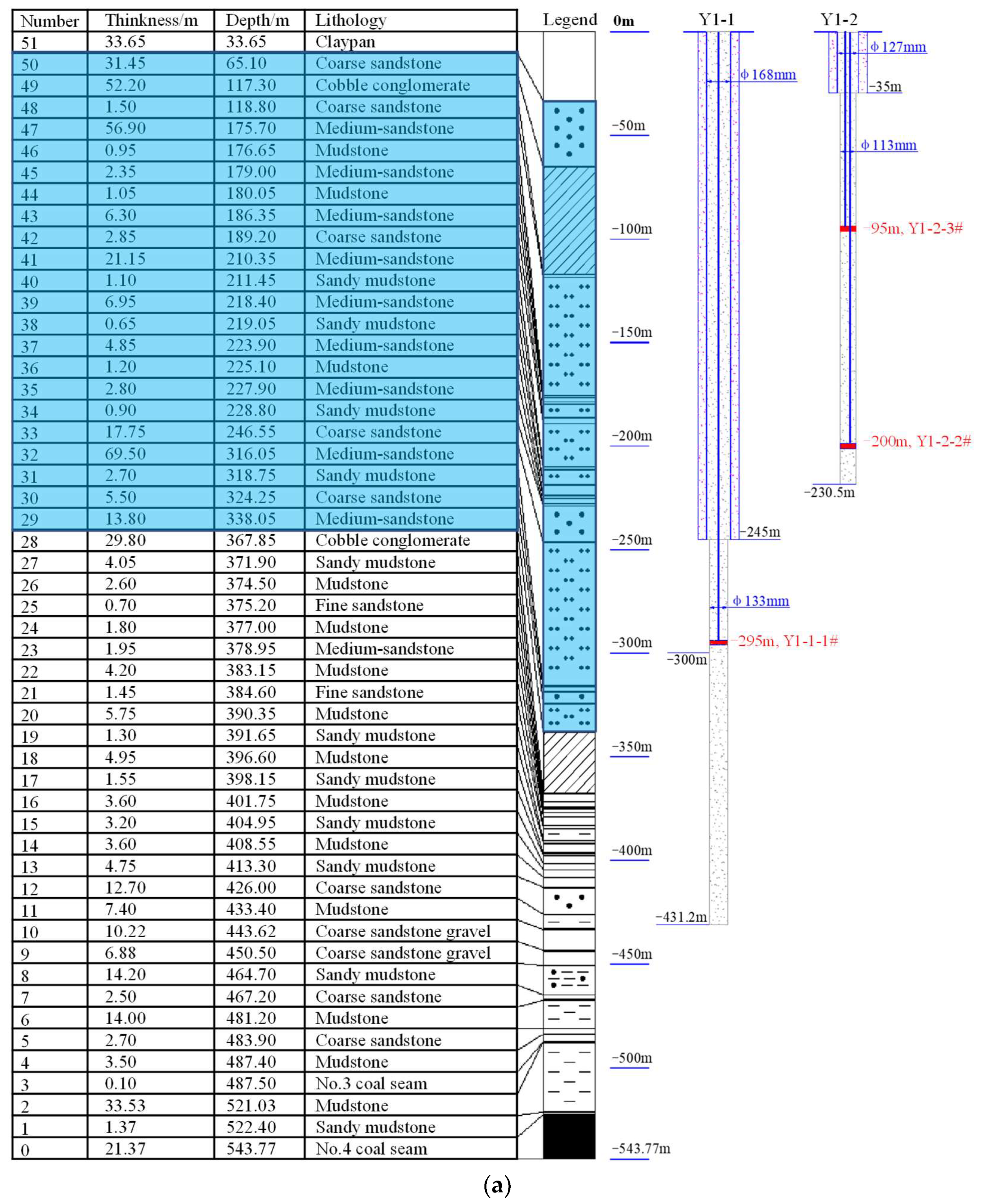

3.4. Monitoring Position in the Borehole

4. Results: Distribution of Internal Fractures in the UTHS

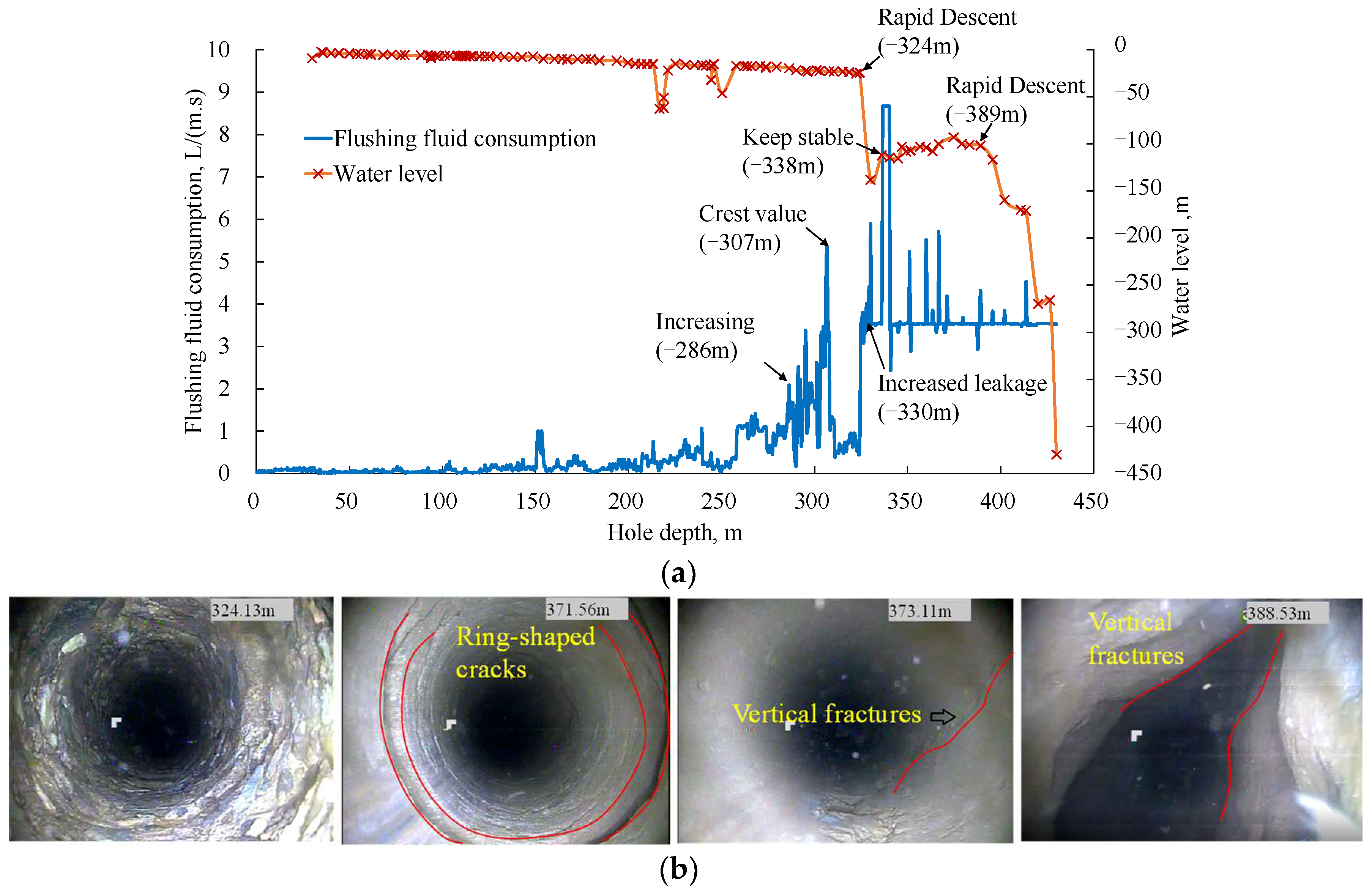

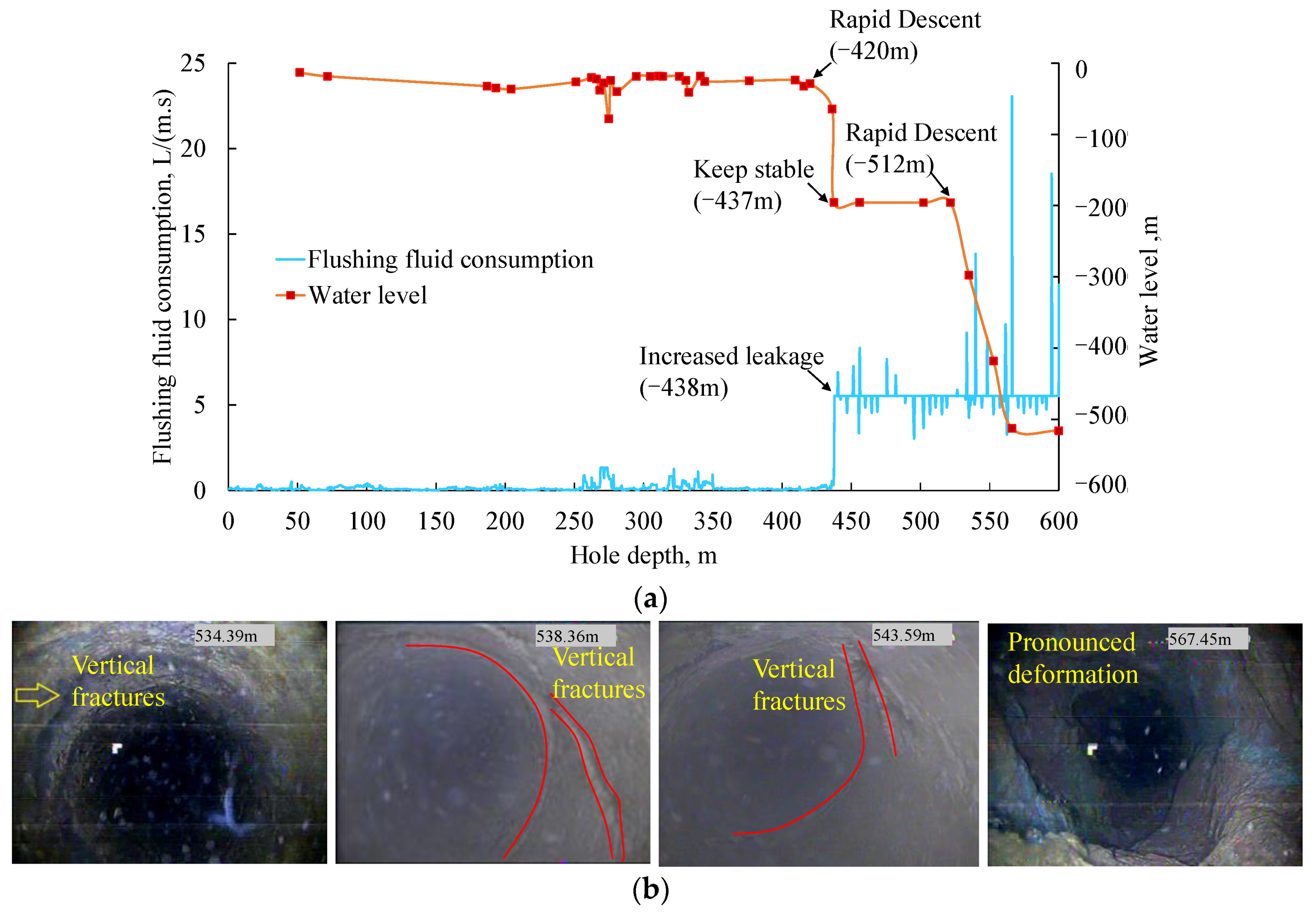

4.1. Development of Water-Conducting Fractures

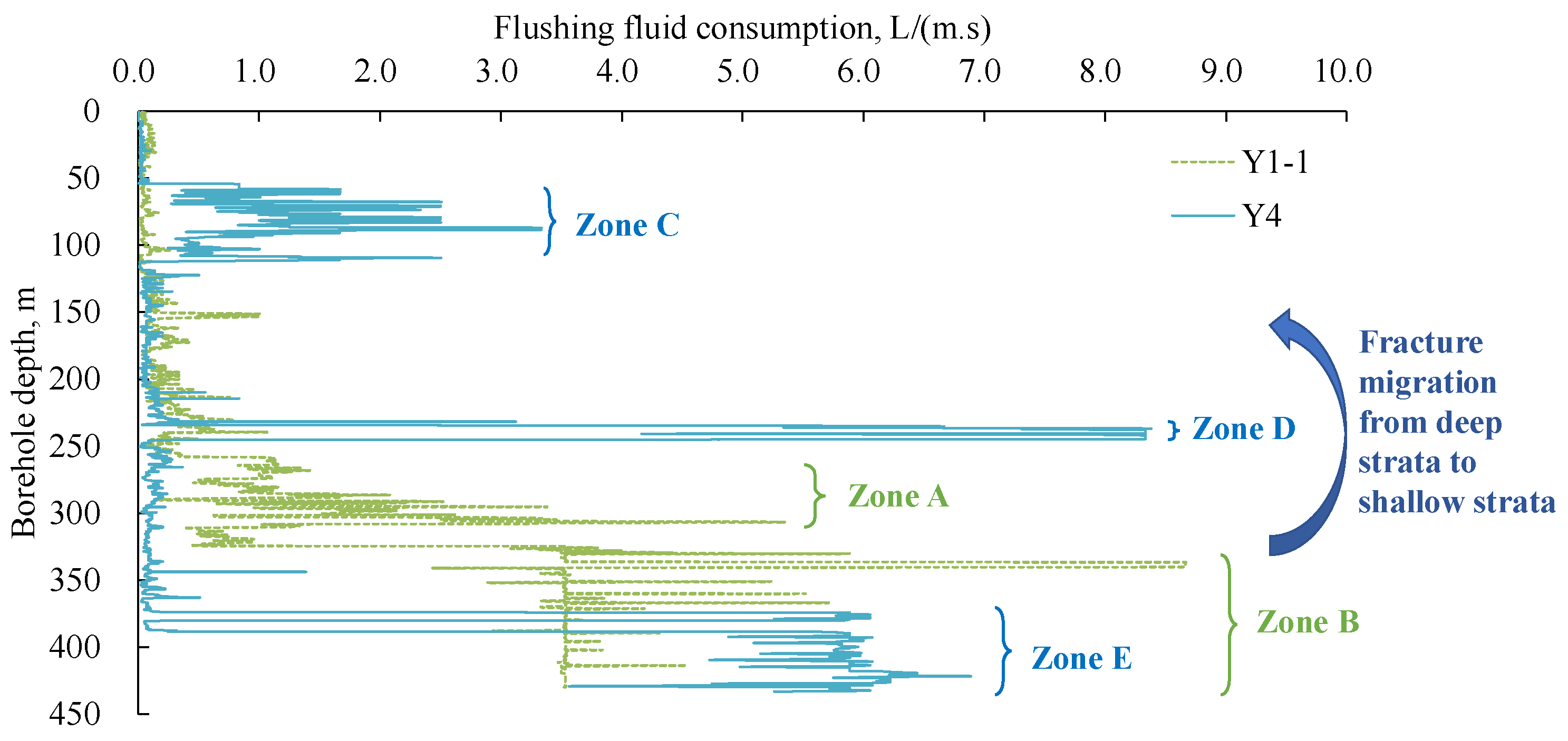

4.2. Mining-Induced Crack Closure and Migration

5. Discussion: Behavior of Internal Strata Movement

5.1. Data from Boreholes above the Goaf of Working Face #206

5.2. Data from the Borehole above the Goaf of Working Face #204

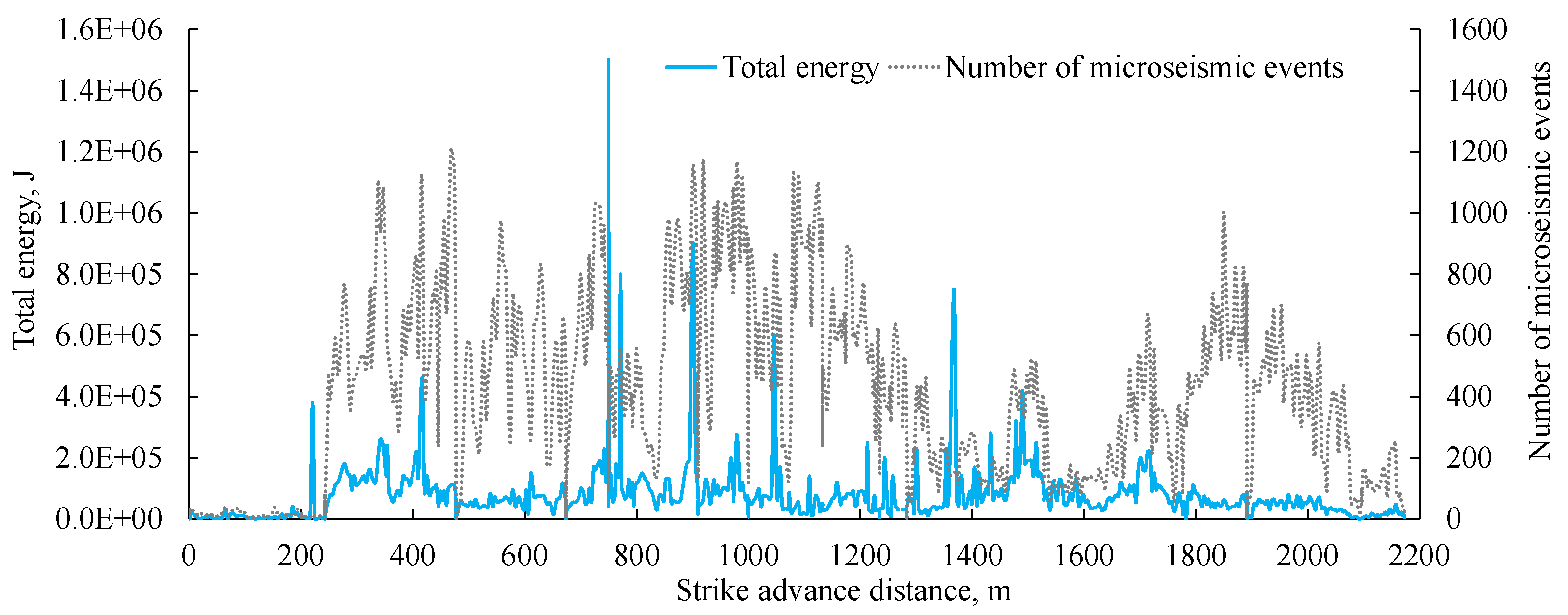

6. Microseismic Monitoring at Working Face #207

7. Conclusions

- (1)

- Armored cables with MPBXs and fiber optic lines were used together for the first time over a panel-wide area and at great depths in the Luohe Formation UTHS of the Binchang Mining Area to monitor the evolution of mining-induced cracks in Panel #2 in the Tingnan Coal Mine, which serves as a reference for future endeavors to measure overburden movement.

- (2)

- The Luohe Formation UTHS had already fractured before Working Face #207 was mined, as ring-shaped lateral fractures were observed 24.8–81 m above the lower boundary of the Luohe Formation. However, no vertical penetrating fractures were observed. The height of the WCFZ in Working Face #206 was 140.2 m and 148.3 m, with a mining height of 7.5 m and 9.0 m. Based on the monitoring of the internal strata movement, the peephole-based crack surveys, and the comparison of drilling fluid losses in each borehole, it was determined that crack closure occurred in the middle and lower parts of the Luohe Formation during the mining of Working Face #207. These fractures also migrated towards shallower strata. As the Luohe Formation continuously subsided during the mining of Working Face #207, there was no risk that a large and sudden break would occur in some “dangling” part of the Luohe Formation UTHS.

- (3)

- The results and conclusions drawn from the monitoring of internal strata movement in the Luohe Formation UTHS serve as important references for assessing the risk of mining Working Face #207. The final displacements of Y1-1-1#, Y1-2-2#, and Y1-2-3# relative to the surface were 77, 248, and 134 mm, which were very small relative to the surface subsidence. The Luohe Formation UTHS was not poised in a suspended and unmoving state during the mining of Working Face #207. Therefore, it was unlikely that a large and sudden break would occur in the UTHS during the mining of Working Face #207. The conclusions of this paper have also been validated by the microseismic monitoring that was performed during the mining of Working Face #207.

8. Highlights

- (1)

- This paper focused on Panel #2 at the Tingnan Coal Mine in the Binchang mining area.

- (2)

- The internal strata motion of the overburden and its fractures were monitored in situ.

- (3)

- Fiber optics with multipoint borehole extensometers were installed in the boreholes.

- (4)

- The paper provides important data for safer mining operations at Working Face #207.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fan, K.F.; Li, W.P.; Wang, Q.Q.; Liu, S.L.; Xue, S.; Xie, C.Y.; Wang, Z.K. Formation mechanism and prediction method of water inrush from separated layers within coal seam mining: A case study in the Shilawusu mining area, China. Eng. Fail. Anal. 2019, 103, 158–172. [Google Scholar] [CrossRef]

- He, J.H.; Li, W.P.; Qiao, W.; Yang, Z.; Wang, Q.Q. Analysis of key factors affecting water disaster in deep mining and establishment of a water disaster evaluation method suitable for different mining depths. Geofluids 2021, 2021, 9948763. [Google Scholar] [CrossRef]

- Jiang, Y.D.; Zhao, Y.X.; Wang, H.W.; Zhu, J. A review of mechanism and prevention technologies of coal bumps in China. J. Rock Mech. Geotech. 2017, 9, 180–194. [Google Scholar] [CrossRef]

- Shi, X.C.; Zhang, Y.; Lv, G.L. Water-preserved mining and exploitation of groundwater resources in yonglong-binchang mining area. J. Min. Safe Eng. 2018, 35, 1241–1247. (In Chinese) [Google Scholar]

- Wang, G.F.; Gong, S.Y.; Dou, L.M.; Cai, W.; Yuan, X.Y.; Fan, C.J. Rockburst mechanism and control in coal seam with both syncline and hard strata. Saf. Sci. 2019, 115, 320–328. [Google Scholar] [CrossRef]

- Lv, Y.G.; Xiao, Q.H.; Cheng, J.L. Mechanism and prevention of water-sand inrush in soft rock with weakly abundant water: A case study in shanghai temple mining area. J. Chin. Coal Soc. 2019, 44, 3154–3163. (In Chinese) [Google Scholar]

- Qiao, W.; Wang, Z.W.; Li, W.P.; Lv, Y.G.; Li, L.G.; Huang, Y.; He, J.H.; Li, X.Q.; Zhao, S.L.; Liu, M.N. Formation mechanism, disaster-causing mechanism and prevention technology of roof bed separation water disaster in coal mine. J. Chin. Coal Soc. 2021, 46, 507–522. (In Chinese) [Google Scholar]

- Mondal, D.; Roy, P.N.S.; Behera, P.K. Use of correlation fractal dimension signatures for understanding the overlying strata dynamics in longwall coal mines. Int. J. Rock Mech. Min. 2017, 91, 210–221. [Google Scholar] [CrossRef]

- Mondal, D.; Roy, P.N.S.; Kumar, M. Monitoring the strata behavior in the destressed zone of a shallow Indian longwall panel with hard sandstone cover using mine-microseismicity and borehole televiewer data. Eng Geol. 2020, 271, 105593. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, F.X.; Li, K.Q.; Wang, C.W.; Wu, X.G.; Gao, H.J.; Ji, S.H. Study of the compatible deformation and stability of the system of super thick strata and coal pillars. Chin. J. Rock Mech. Eng. 2017, 36, 326–334. (In Chinese) [Google Scholar]

- Wang, J.A.; Liu, H.; Ji, H.G. Study on fracture mechanism of overlying super-thick rock stratum in underground mining. Chin. J. Rock Mech. Eng. 2009, 28, 2815–2823. (In Chinese) [Google Scholar]

- Xuan, D.Y.; Xu, J.L.; Zhu, W.B. Dynamic disaster control under a massive igneous sill by grouting from surface boreholes. Int. J. Rock Mech. Min. 2014, 71, 176–187. [Google Scholar] [CrossRef]

- Xuan, D.Y.; Wang, B.L.; Xu, J.L. A shared borehole approach for coal-bed methane drainage and ground stabilization with grouting. Int. J. Rock Mech. Min. 2016, 86, 235–244. [Google Scholar] [CrossRef]

- Han, H.; Xu, J.; Wang, X.; Xie, J.; Xing, Y. Surface subsidence prediction method for coal mines with ultrathick and hard stratum. Adv. Civ. Eng. 2019, 2019, 3714381. [Google Scholar] [CrossRef]

- Ning, J.G.; Wang, J.; Jiang, L.S.; Jiang, N.; Liu, X.S.; Jiang, J.Q. Fracture analysis of double-layer hard and thick roof and the controlling effect on strata behavior: A case study. Eng. Fail Anal. 2017, 81, 117–134. [Google Scholar] [CrossRef]

- Scott, A.A.; Nicholas, J.L. Rockfill embankment settlement: Sugarloaf Mountain bridge abutment and hoover dam bypass (US-93). Transport. Res. Rec. 2016, 1, 3–12. [Google Scholar]

- Avramov, I.; Velkov, T.; Garko, I.; Stefanov, D.; Georgakiev, I. Using large-scale geotechnical modelling to solve mining tasks at a gold-copper mine. In Proceedings of the International European Rock Mechanics Symposium (EUROCK), Saint Petersburg, Russia, 22–26 May 2018; pp. 465–470. [Google Scholar]

- Barton, N.; Pandey, S.K. Numerical modelling of two stopping methods in two Indian mines using degradation of C and mobilization of Φ based on Q-parameters. Int. J. Rock Mech. Min. 2011, 48, 1095–1112. [Google Scholar] [CrossRef]

- Yeung, M.R.; Blair, S.C. Analysis of large block test data using the DDA method. In Proceedings of the 3rd International Conference on Analysis of Discontinuous Deformation, Vail, CO, USA, 3–4 June 1999; pp. 141–150. [Google Scholar]

- Sinha, S.; Walton, G. Integration of three-dimensional continuum model and two-dimensional bonded block model for studying the damage process in a granite pillar at the Creighton Mine, Sudbury, Canada. J. Rock. Mech. Geotech. 2021, 13, 275–288. [Google Scholar] [CrossRef]

- Abdellah, W.; Raju, G.D.; Mitri, H.S.; Thibodeau, D. Stability of underground mine development intersections during the life of a mine plan. Int. J. Rock Mech. Min. 2014, 72, 173–181. [Google Scholar] [CrossRef]

- Ingram, D.K.; Trevits, M.A.; Jeran, P.W. Overburden failure due to longwall mining. In Proceedings of the 1st North American Rock Mechanics Symposium, Austin, TX, USA, 1–3 June 1994; pp. 1025–1032. [Google Scholar]

- Zhu, W.B.; Xu, J.L.; Shi, X.S.; Wang, X.Z.; Liu, W.T. Research on influence of overburden primary key stratum movement on surface subsidence with in-situ drilling test. Chin. J. Rock Mech. Eng. 2009, 28, 403–409. (In Chinese) [Google Scholar]

- Yang, J.Z.; Hu, B.W.; Wang, Z.R. Study on distribution characteristics of collapse zone, fissure zone and curved subsidence zone and layered settlement of overburden on 8.8 m super-large mining height coal mining face. Coal Sci. Tech. 2020, 48, 42–48. (In Chinese) [Google Scholar]

- Holla, L.; Buizen, M. The ground movement, strata fracturing and changes in permeability due to deep longwall mining. Int. J. Rock Mech. Min. 1991, 28, 207–217. [Google Scholar] [CrossRef]

- Kuang, T.J.; Li, Z.; Zhu, W.B.; Xie, J.L.; Ju, J.F.; Liu, J.R.; Xu, J.M. The impact of key strata movement on ground pressure behaviour in the Datong coalfield. Int. J. Rock Mech. Min. 2019, 119, 193–204. [Google Scholar] [CrossRef]

- Yu, B.; Gao, R.; Kuang, T.J.; Huo, B.J.; Meng, X.B. Engineering study on fracturing high-level hard rock strata by ground hydraulic action. Tunn. Undergr. Sp. Tech. 2019, 86, 156–164. [Google Scholar] [CrossRef]

- Yu, B.; Zhao, J.; Kuang, T.J.; Meng, X.B. In situ investigations into overburden failures of a super-thick coal seam for longwall top coal caving. Int. J. Rock Mech. Min. 2015, 78, 155–162. [Google Scholar] [CrossRef]

- Yu, B.; Zhao, J.; Xiao, H.T. Case study on overburden fracturing during longwall top coal caving using microseismic monitoring. Rock Mech. Rock Eng. 2017, 50, 507–511. [Google Scholar] [CrossRef]

- Cheng, G.W.; Ma, T.H.; Tang, C.A.; Liu, H.Y.; Wang, S.J. A zoning model for coal mining induced strata movement based on micro seismic monitoring. Int. J. Rock Mech. Min. 2017, 94, 123–138. [Google Scholar] [CrossRef]

- Liu, Y.; Li, W.P.; He, J.H.; Liu, S.W.; Cai, L.Y.; Cheng, G. Application of brillouin optical time domain reflectometry to dynamic monitoring of overburden deformation and failure caused by underground mining. Int. J. Rock Mech. Min. 2018, 106, 133–143. [Google Scholar] [CrossRef]

- Cappa, F.; Guglielmi, Y.; Gaffet, S.; Lançon, H.; Lamarque, I. Use of in situ fiber optic sensors to characterize highly heterogeneous elastic displacement fields in fractured rocks. Int. J. Rock Mech. Min. 2006, 43, 647–654. [Google Scholar] [CrossRef]

- Xie, J.L.; Xu, J.L. Effect of key stratum on the mining abutment pressure of a coal seam. Geosci. J. 2017, 21, 267–276. [Google Scholar] [CrossRef]

- Han, H.K.; Xu, J.L.; Wang, X.Z.; Xie, J.L.; Xing, Y.T. Method to calculate working surface abutment pressure based on key strata theory. Adv. Civ. Eng. 2019, 2019, 767832. [Google Scholar] [CrossRef] [Green Version]

- Guo, G.L.; Zha, J.F. Mining Subsidence; China University of Mining & Technology Press: Xuzhou, China, 2020. [Google Scholar]

- Xu, J.L.; Zhu, W.B.; Wang, X.Z. New method to predict the height of fractured water-conducting zone by location of key strata. J. Chin. Coal Soc. 2012, 37, 762–769. (In Chinese) [Google Scholar]

- He, C.C.; Lu, W.Y.; Zha, W.H. Evolution mechanism of interconnected vertical fractures in the overburden of longwall coal mining. Geofluids 2020, 2020, 8862517. [Google Scholar] [CrossRef]

| Borehole No. | Y1-1 | Y1-2 | Y2 | Y3 | Y4 |

|---|---|---|---|---|---|

| Vertical distance between orifice and 207 cut/m | 375.0 | 380.0 | 676.6 | 1883.2 | 342.0 |

| Orifice elevation/m | +891.7 | +891.6 | +927.6 | +1069.6 | +891.5 |

| Depth/m | 431.2 | 230.5 | 480.0 | 600.0 | 430.0 |

| Thickness of loess layer/m | 33.7 | 33.7 | 51.0 | 187.0 | 30.0 |

| Buried depth of bottom boundary of the Luohe Formation/m | 338.1 | 338.1 | 376.6 | 509.0 | 338.1 |

| The depth of hole bottom exceeding the bottom boundary of the Luohe Formation/m | 93.1 | −107.6 | 103.4 | 91.0 | 91.9 |

| Buried depth of coal seam roof/m | 511.8 | 511.8 | 557.6 | 682.7 | 510.1 |

| Distance between bottom boundary of the Luohe Formation and roof of coal seam/m | 173.7 | 173.7 | 181.0 | 173.7 | 172.0 |

| Distance between hole bottom and coal seam roof/m | 80.6 | 281.2 | 77.6 | 82.7 | 80.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Zhu, W.; Xie, J.; Han, H.; Xu, J.; Tang, Z.; Xu, J. Borehole-Based Monitoring of Mining-Induced Movement in Ultrathick-and-Hard Sandstone Strata of the Luohe Formation. Minerals 2021, 11, 1157. https://doi.org/10.3390/min11111157

Wang X, Zhu W, Xie J, Han H, Xu J, Tang Z, Xu J. Borehole-Based Monitoring of Mining-Induced Movement in Ultrathick-and-Hard Sandstone Strata of the Luohe Formation. Minerals. 2021; 11(11):1157. https://doi.org/10.3390/min11111157

Chicago/Turabian StyleWang, Xiaozhen, Weibing Zhu, Jianlin Xie, Hongkai Han, Jingmin Xu, Zhongyi Tang, and Jialin Xu. 2021. "Borehole-Based Monitoring of Mining-Induced Movement in Ultrathick-and-Hard Sandstone Strata of the Luohe Formation" Minerals 11, no. 11: 1157. https://doi.org/10.3390/min11111157

APA StyleWang, X., Zhu, W., Xie, J., Han, H., Xu, J., Tang, Z., & Xu, J. (2021). Borehole-Based Monitoring of Mining-Induced Movement in Ultrathick-and-Hard Sandstone Strata of the Luohe Formation. Minerals, 11(11), 1157. https://doi.org/10.3390/min11111157