The Effect of Finely-Grinded Crushed Brick Powder on Physical and Microstructural Characteristics of Lightweight Concrete

Abstract

:1. Introduction

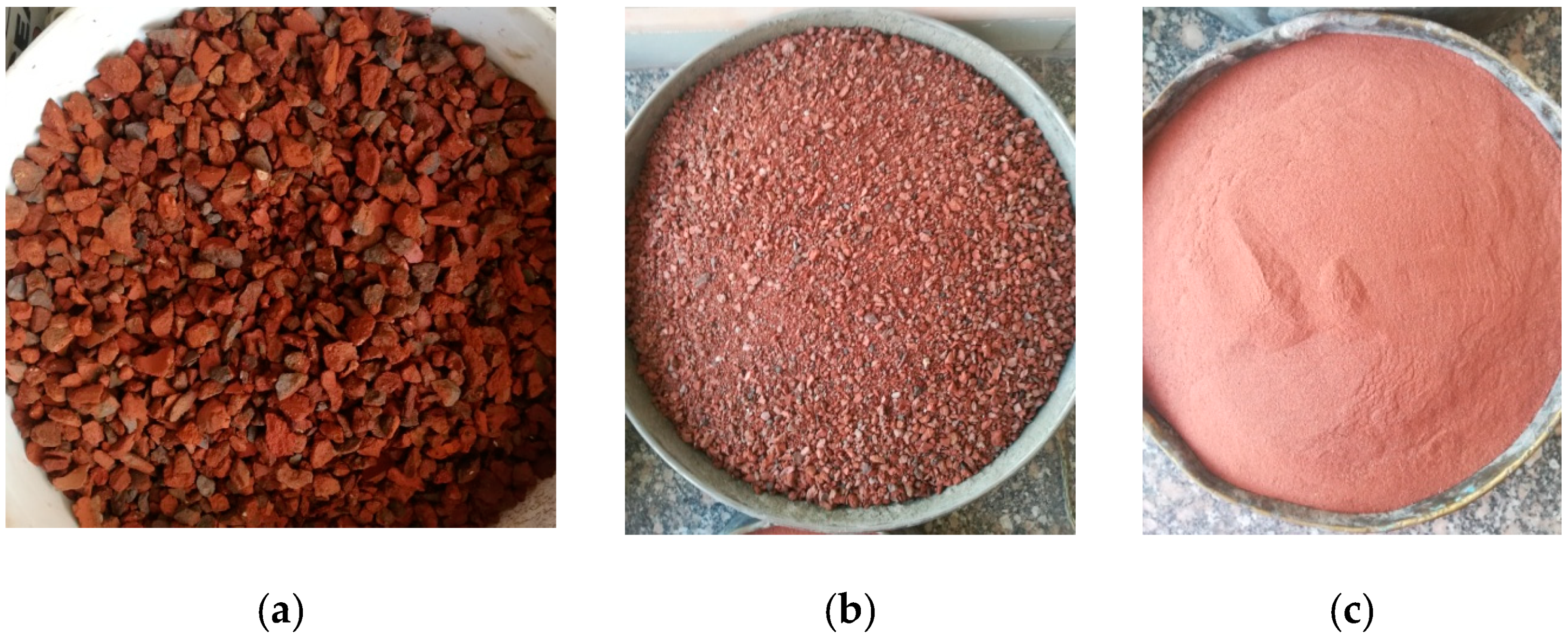

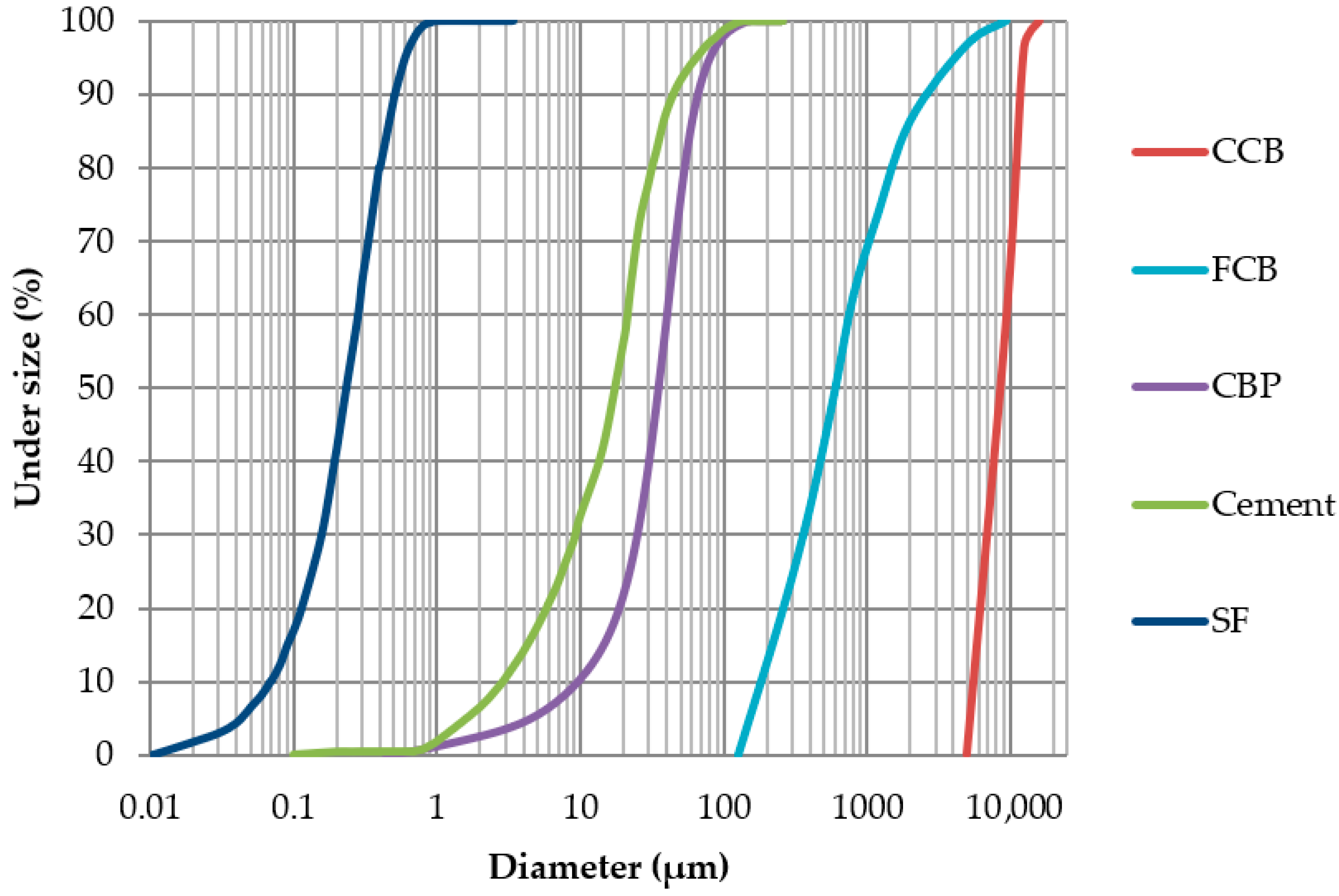

2. Materials

3. Mix Proportioning

4. Experimental Work

- : Total porosity of the concrete (%),

- : Specific density (gm/cm3),

- : Dry density (gm/cm3).

5. Results and Discussion

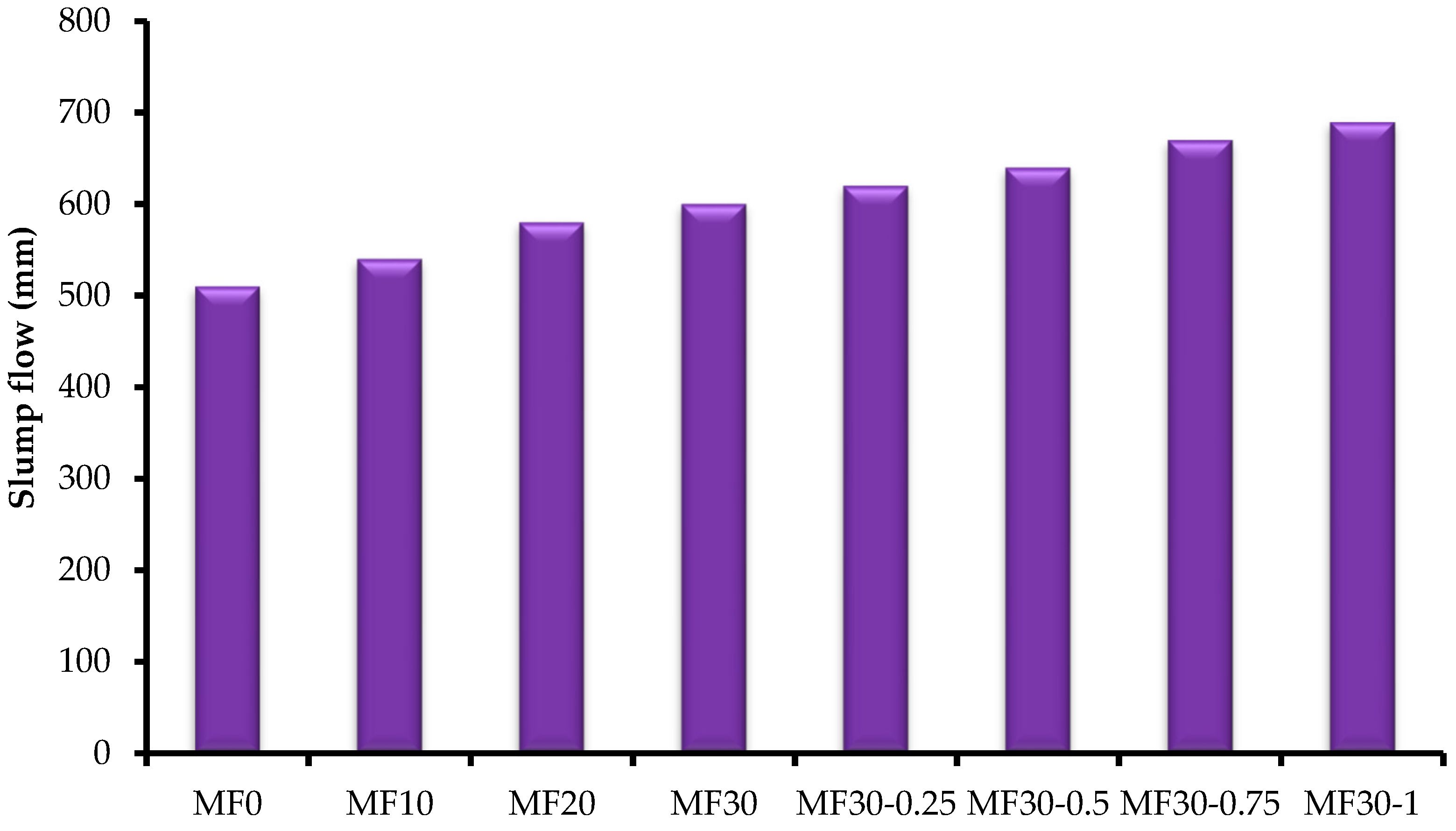

5.1. Fresh Properties (Flowability)

5.2. Hardened Properties

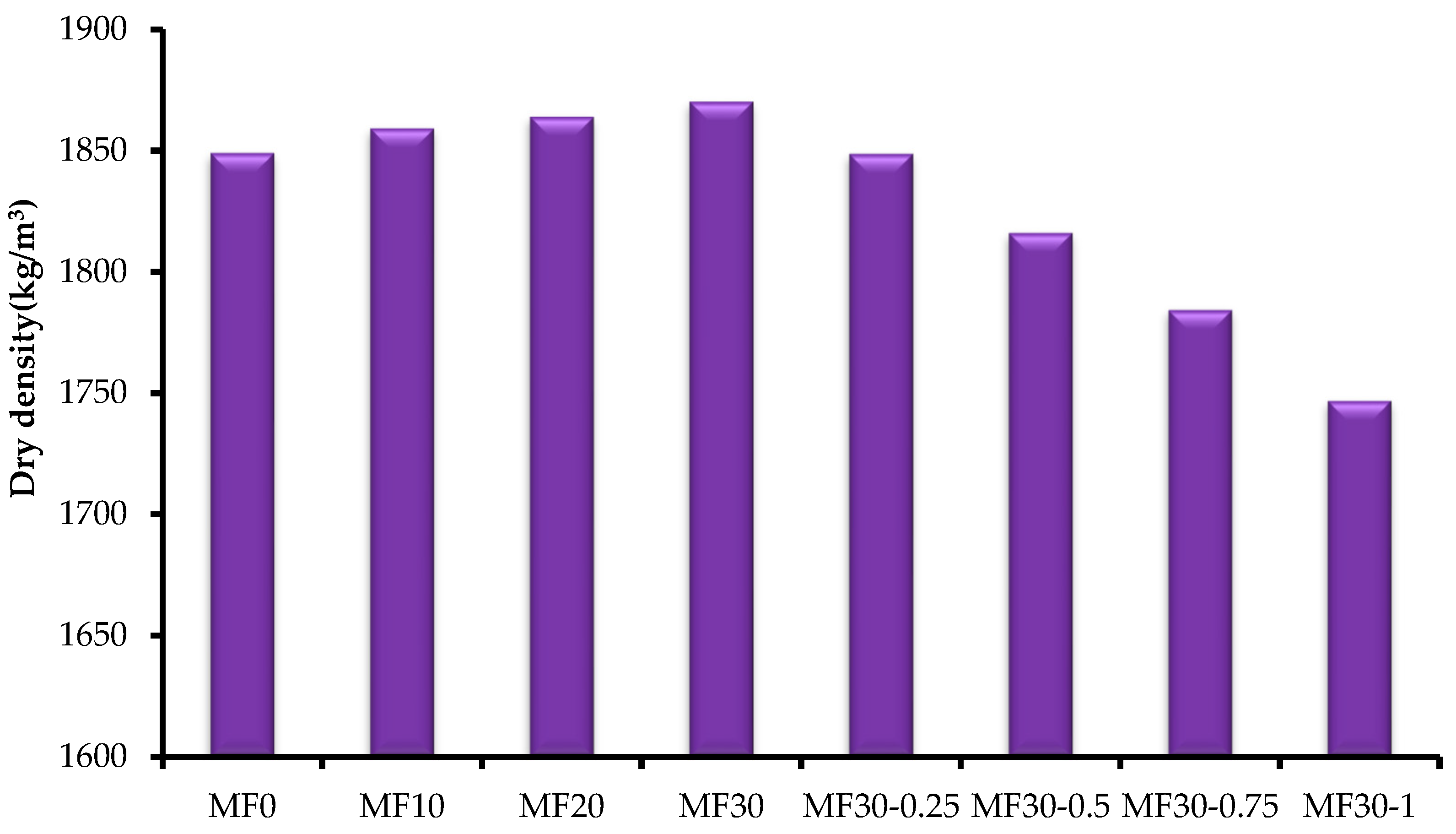

5.2.1. Dry Density

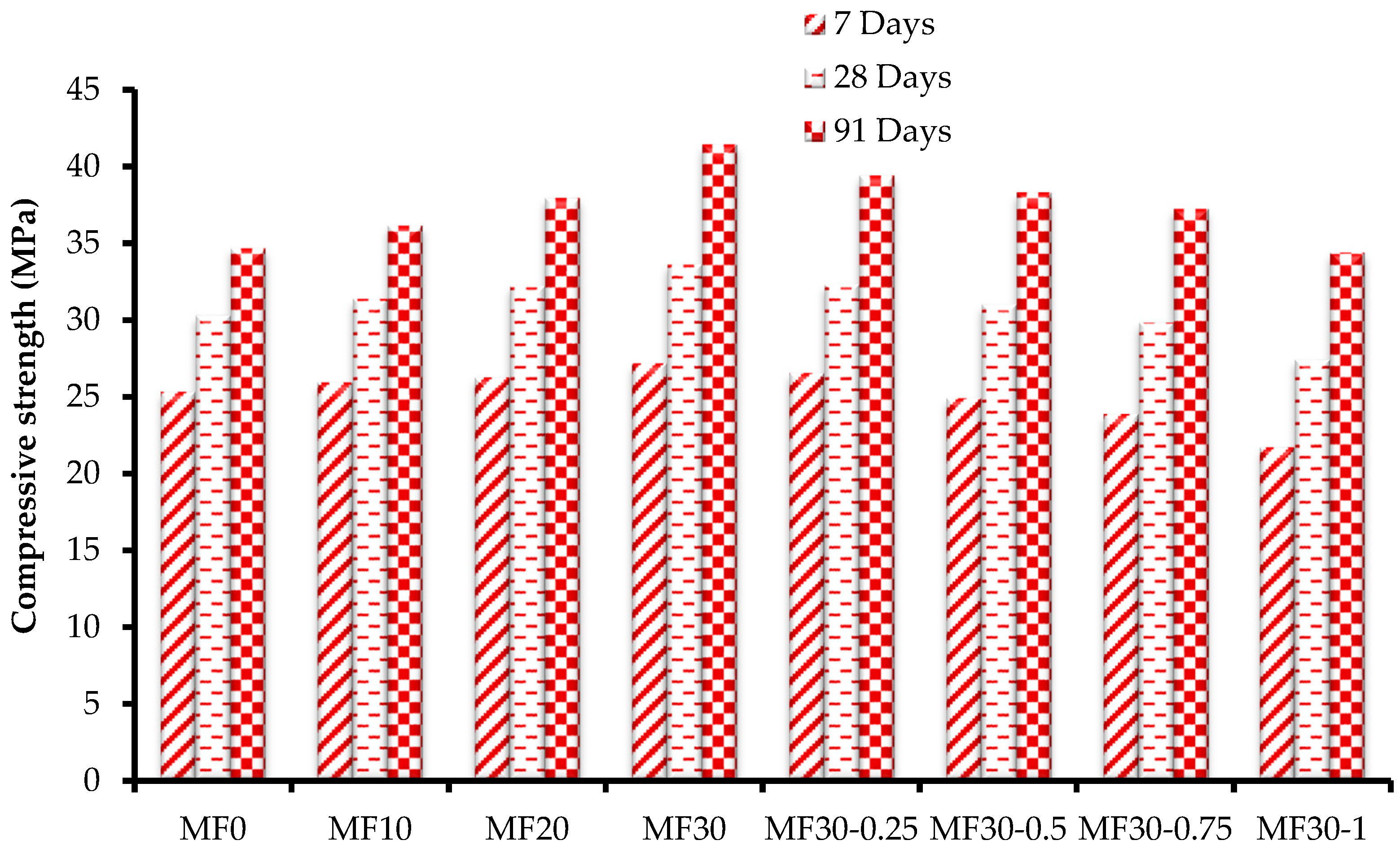

5.2.2. Compressive Strength

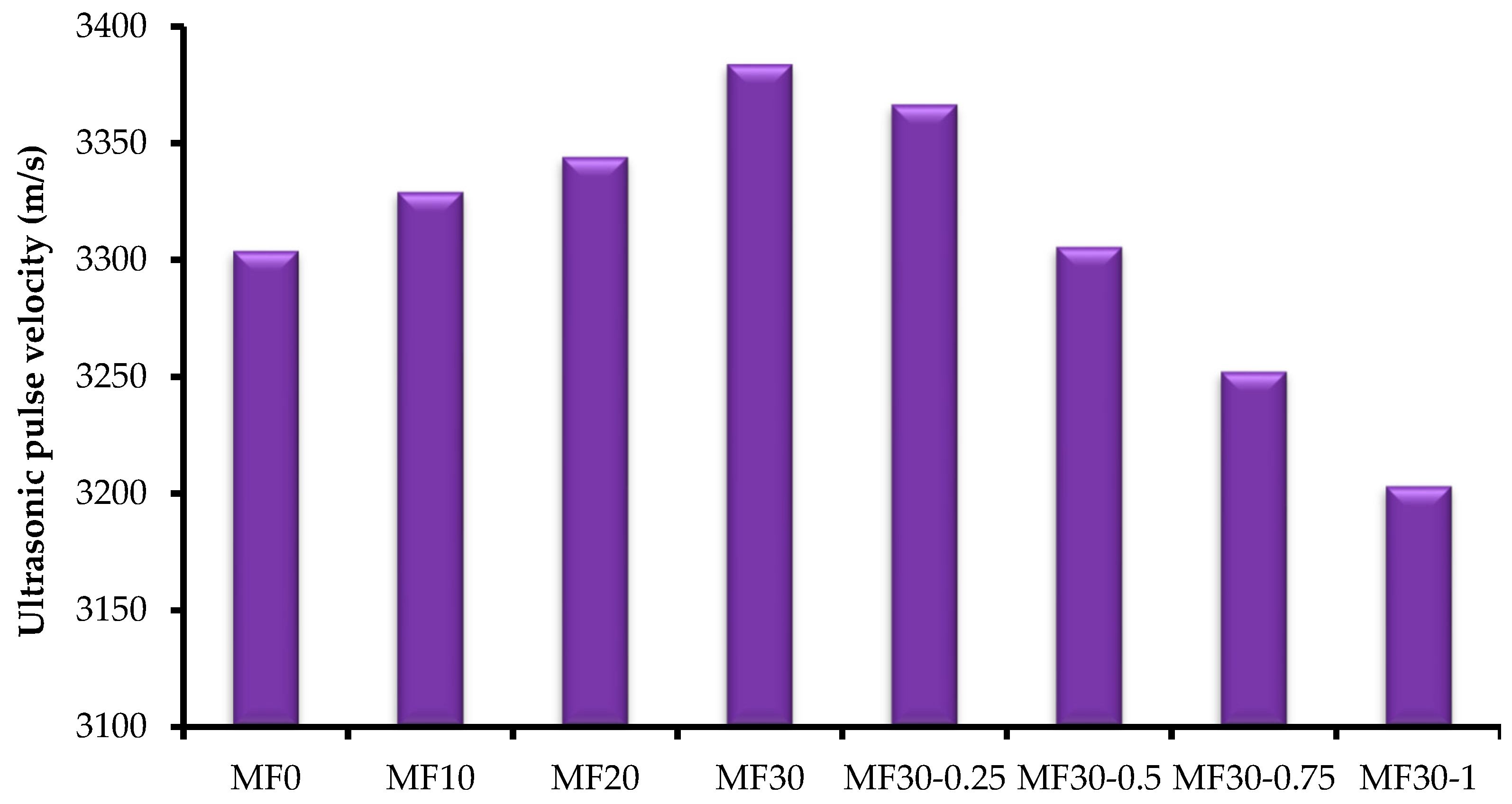

5.2.3. Ultrasonic Pulse Velocity

5.2.4. Thermal Conductivity Coefficient

5.2.5. Sorptivity

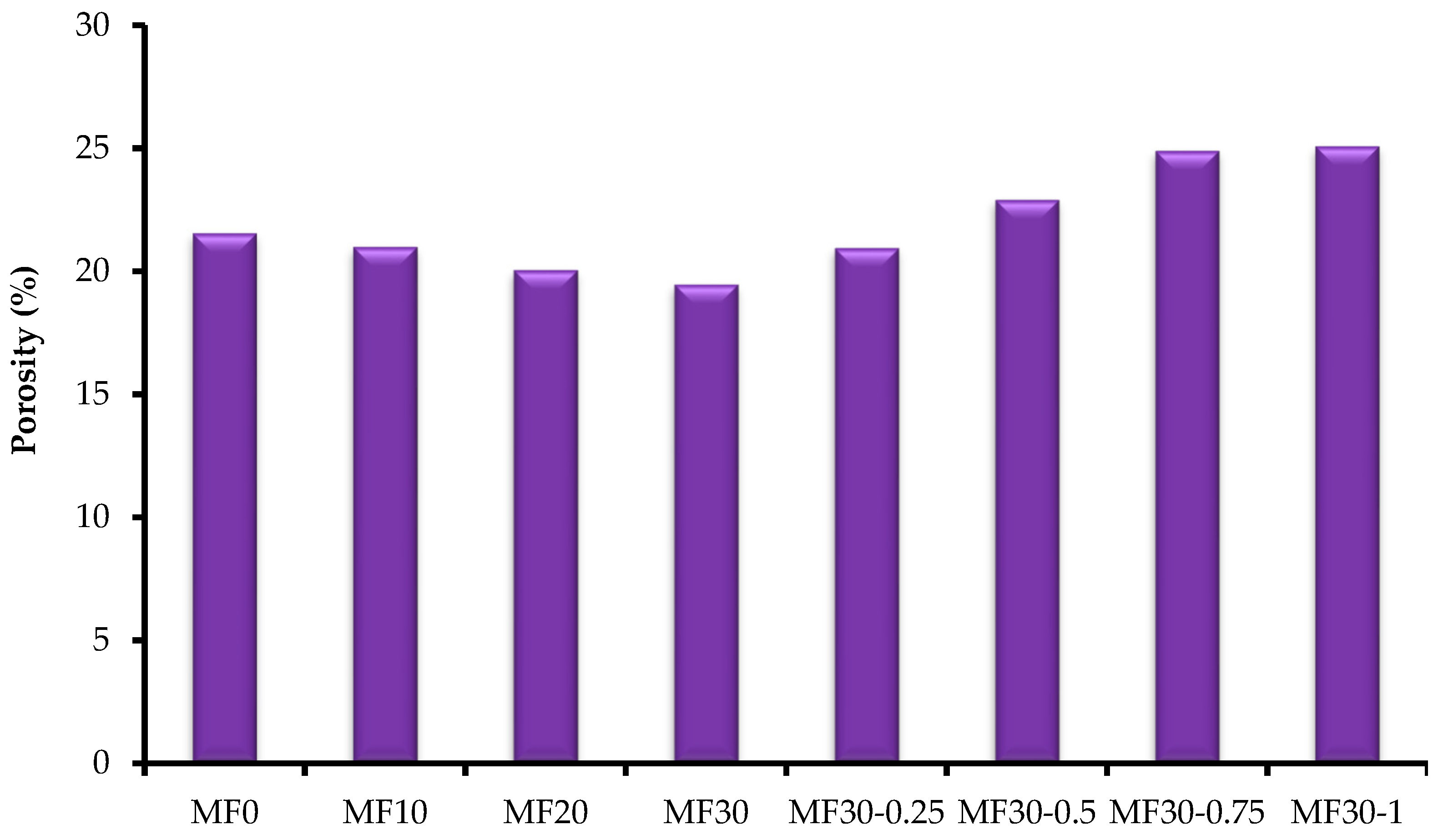

5.2.6. Porosity

5.3. Microstructural Investigations

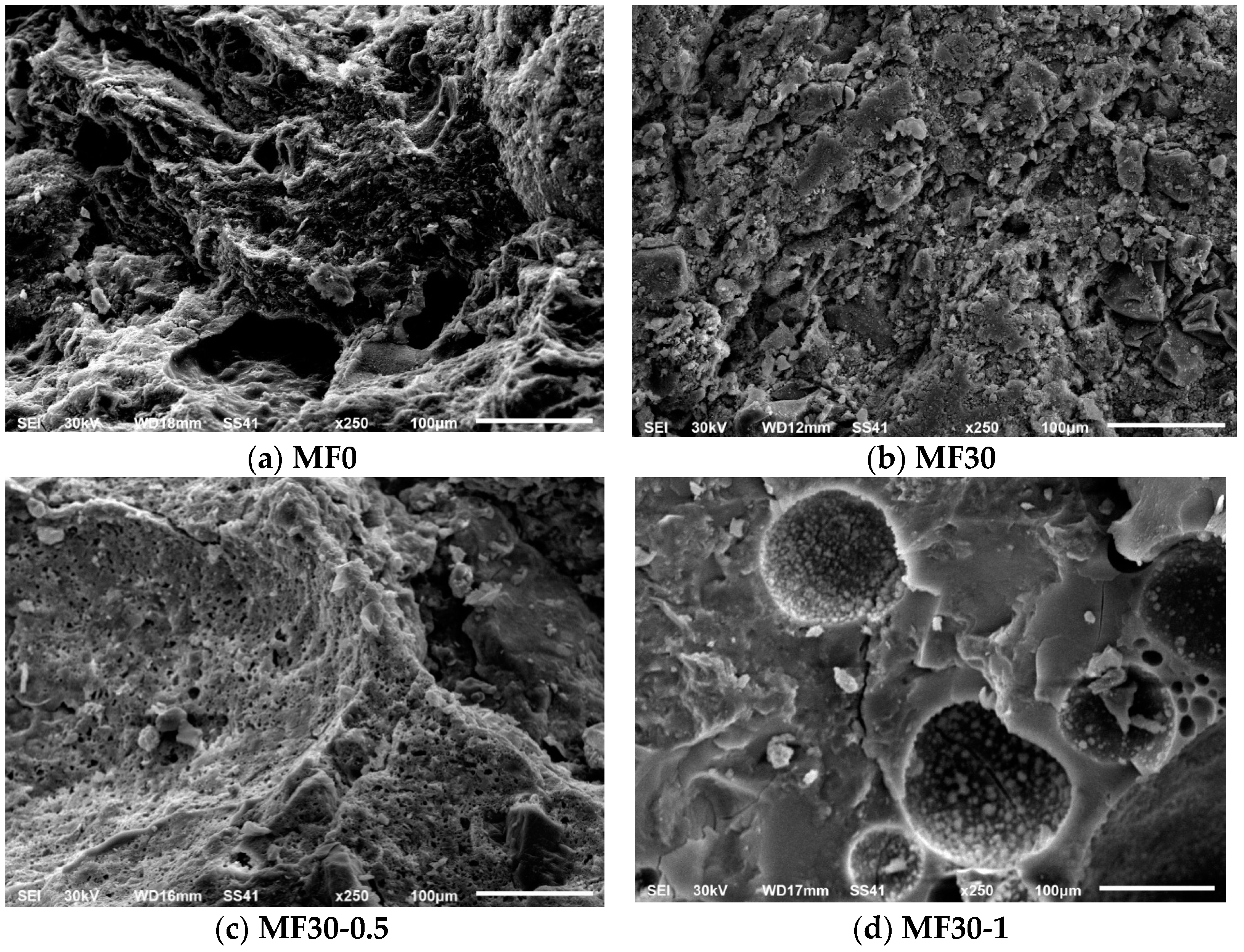

5.3.1. Scanning Electron Microscopy (SEM)

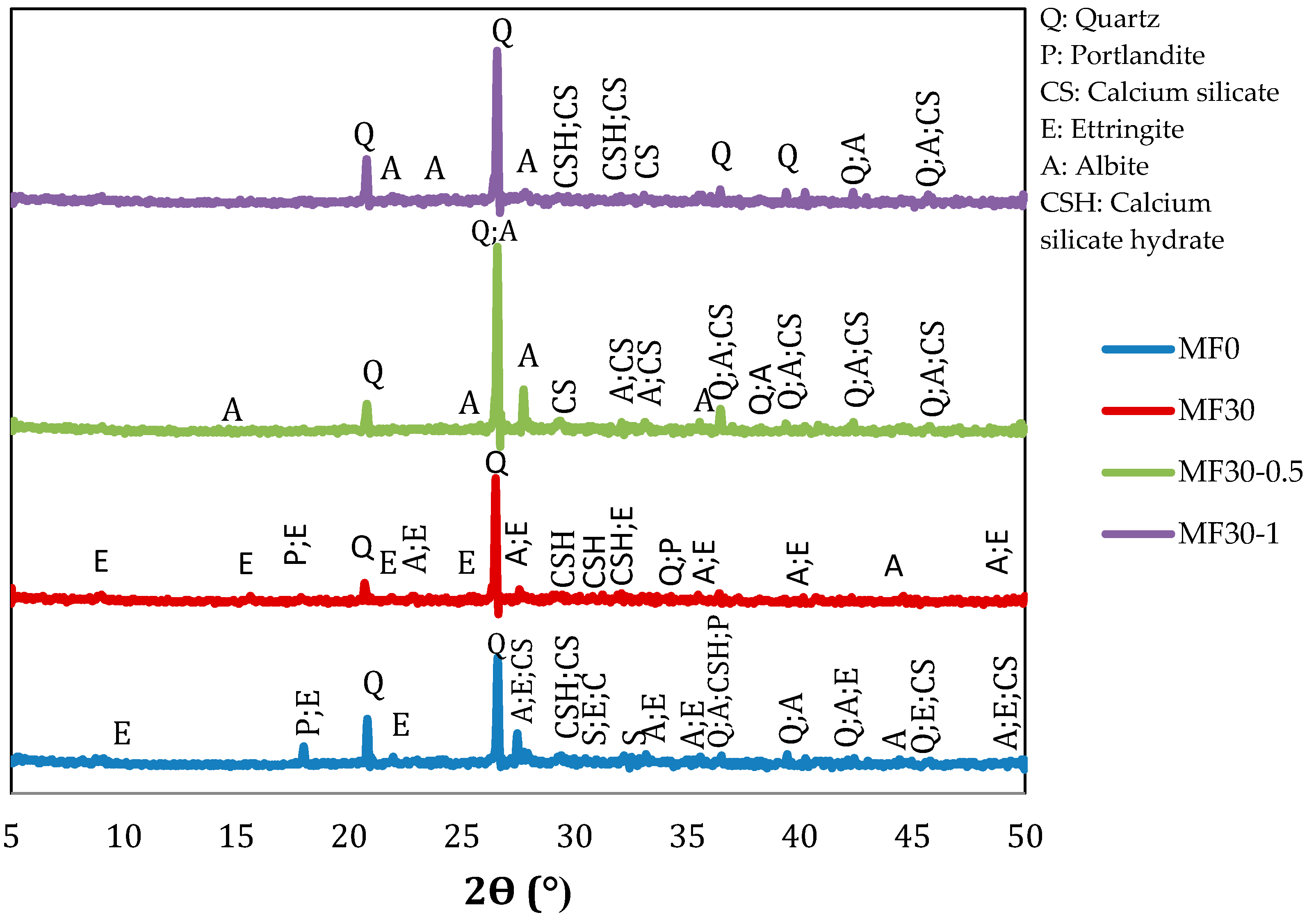

5.3.2. X-ray Diffraction (XRD)

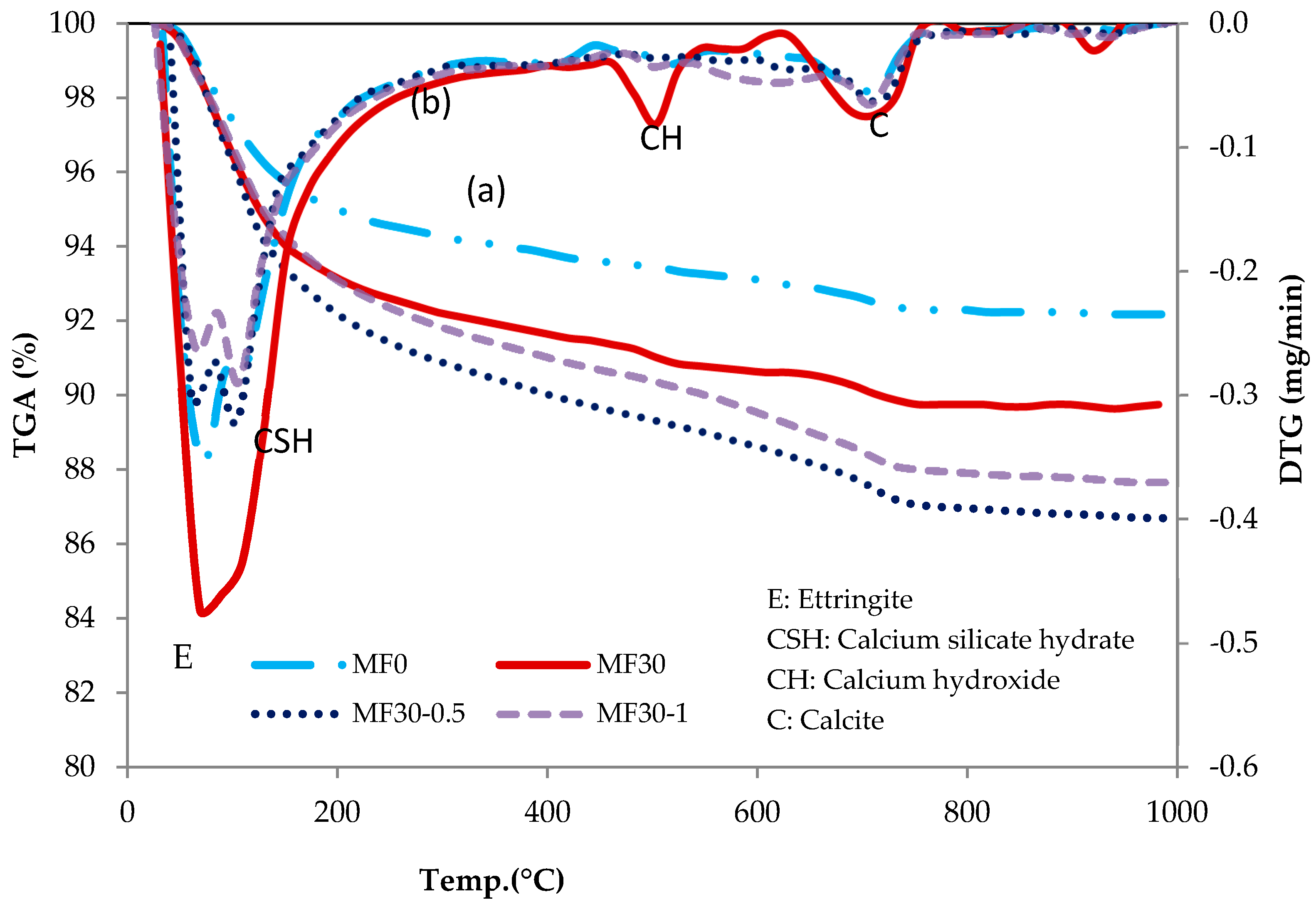

5.3.3. Thermo-Gravimetric Analysis (TGA)

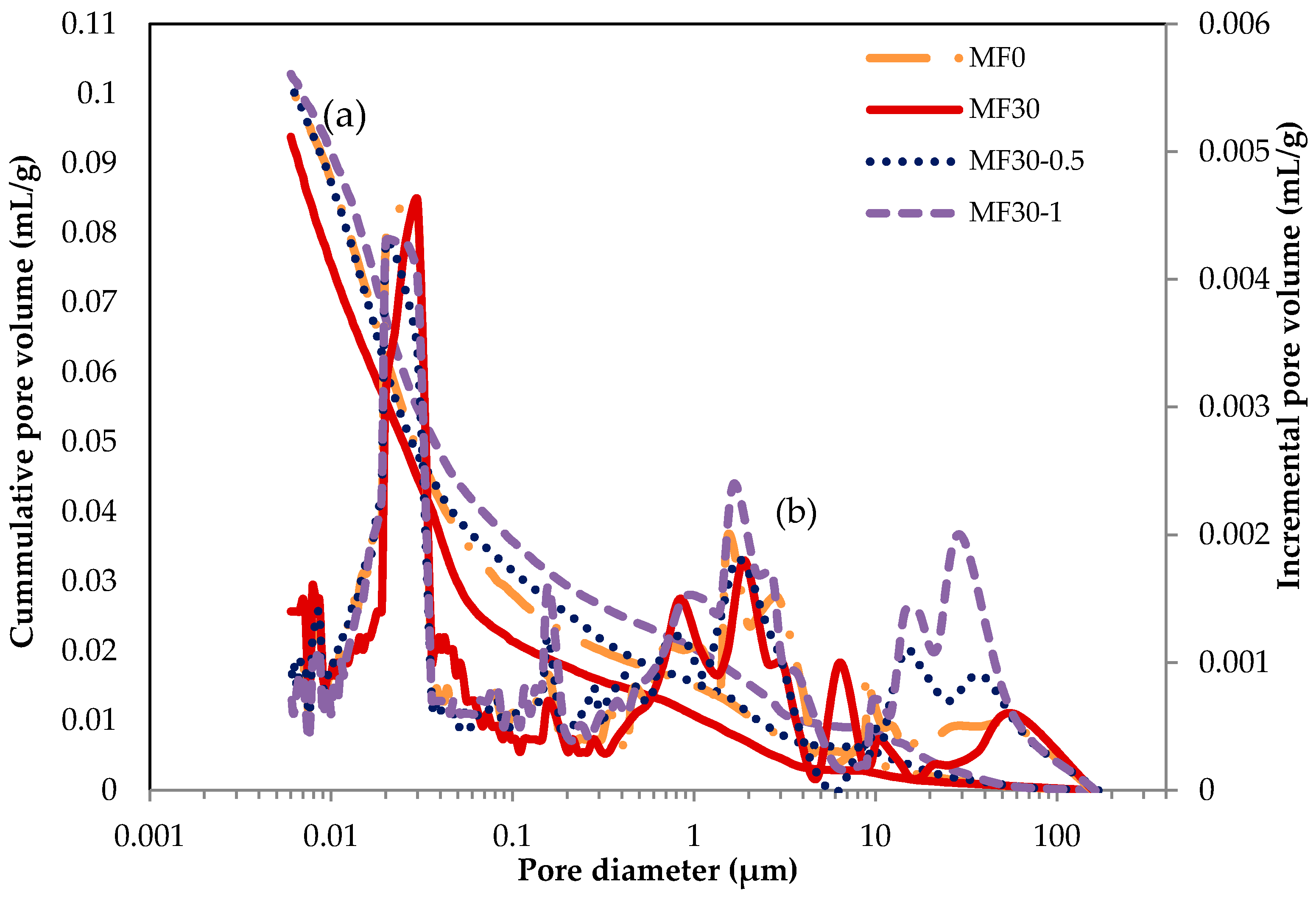

5.3.4. Mercury Intrusion Porosimetry (MIP)

6. Conclusions

- The use of CBP as a filler material increases the concrete workability. It also caused an increase in the concrete dry density, compressive strength, UPV values, and thermal conductivity with the increase in the CBP content as it filled the pores and therefore enhanced the mechanical and durability properties of the concrete. There was an observed decrease in the concrete porosity when the CBP was used as filler material. Microstructural investigations (SEM, XRD, TGA, and MIP) proved that using CBP as a filler material decreases the capillary pores and air voids in the concrete; this is due to its filling ability and pozzolanic activity, which caused an increase in the CSH content.

- Adding an AEA in concrete increases its workability. However, it decreases the concrete dry density, compressive strength, UPV values, and thermal conductivity when the AEA content is increased in the concrete due to the created voids. These voids negatively affect the mechanical and durability properties of concrete but improve its thermal properties. An increase was also found in the concrete porosity while increasing the AEA content. Microstructural investigations (SEM, XRD, TGA, and MIP) proved that adding an AEA in concrete decreases the formation of CSH and increases the capillary pores and air voids, and this is related to the amount of the AEA.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Debieb, F.; Kenai, S. The use of coarse and fine crushed bricks as aggregate in concrete. Constr. Build. Mater. 2008, 22, 886–893. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, J.; Chen, F.; Liu, C.; Chen, X. Utilization of waste clay bricks as coarse and fine aggregates for the preparation of lightweight aggregate concrete. J. Clean. Prod. 2018, 201, 706–715. [Google Scholar] [CrossRef]

- Duan, Z.; Hou, S.; Xiao, J.; Singh, A. Rheological properties of mortar containing recycled powders from construction and demolition wastes. Constr. Build. Mater. 2020, 237, 117622. [Google Scholar] [CrossRef]

- Atyia, M.M.; Mahdy, M.G.; Abd Elrahman, M. Production and properties of lightweight concrete incorporating recycled waste crushed clay bricks. Constr. Build. Mater. 2021, 304, 124655. [Google Scholar] [CrossRef]

- Wong, C.L.; Mo, K.H.; Yap, S.P.; Alengaram, U.; Ling, T.C. Potential use of brick waste as alternate concrete-making materials: A review. J. Clean. Prod. 2018, 195, 226–239. [Google Scholar] [CrossRef]

- Zhu, L.; Zhu, Z. Reuse of clay brick waste in mortar and concrete. Adv. Mater. Sci. Eng. 2020, 2020. [Google Scholar] [CrossRef]

- Hansen, T.C. (Ed.) Recycling of Demolished Concrete and Masonry; CRC Press: Boca Raton, FL, USA, 1992. [Google Scholar]

- Janotka, I.; Martauz, P.; Bačuvčík, M. Design of Concrete Made with Recycled Brick Waste and Its Environmental Performance. Minerals 2021, 11, 463. [Google Scholar] [CrossRef]

- Cachim, P.B. Mechanical properties of brick aggregate concrete. Constr. Build. Mater. 2009, 23, 1292–1297. [Google Scholar] [CrossRef]

- Ibrahim, N.M.; Salehuddin, S.; Amat, R.C.; Rahim, N.L.; Izhar, T.N.T. Performance of lightweight foamed concrete with waste clay brick as coarse aggregate. Apcbee Procedia 2013, 5, 497–501. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Du, Q.; Bao, Y. Concrete with recycled concrete aggregate and crushed clay bricks. Constr. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Zong, L.; Fei, Z.; Zhang, S. Permeability of recycled aggregate concrete containing fly ash and clay brick waste. J. Clean. Prod. 2014, 70, 175–182. [Google Scholar] [CrossRef]

- Zheng, C.; Lou, C.; Du, G.; Li, X.; Liu, Z.; Li, L. Mechanical properties of recycled concrete with demolished waste concrete aggregate and clay brick aggregate. Results Phys. 2018, 9, 1317–1322. [Google Scholar] [CrossRef]

- Bektas, F.; Wang, K.; Ceylan, H. Effects of crushed clay brick aggregate on mortar durability. Constr. Build. Mater. 2009, 23, 1909–1914. [Google Scholar] [CrossRef]

- Dang, J.; Zhao, J.; Hu, W.; Du, Z.; Gao, D. Properties of mortar with waste clay bricks as fine aggregate. Constr. Build. Mater. 2018, 166, 898–907. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Mobili, A.; Giosuè, C.; Corinaldesi, V.; Tittarelli, F. Bricks and concrete wastes as coarse and fine aggregates in sustainable mortars. Adv. Mater. Sci. Eng. 2018, 2018. [Google Scholar] [CrossRef] [Green Version]

- Aliabdo, A.A.; Abd-Elmoaty, A.E.M.; Hassan, H.H. Utilization of crushed clay brick in cellular concrete production. Alex. Eng. J. 2014, 53, 119–130. [Google Scholar] [CrossRef] [Green Version]

- Sikora, P.; Rucinska, T.; Stephan, D.; Chung, S.Y.; Abd Elrahman, M. Evaluating the effects of nanosilica on the material properties of lightweight and ultra-lightweight concrete using image-based approaches. Constr. Build. Mater. 2020, 264, 120241. [Google Scholar] [CrossRef]

- Kim, H.K.; Jeon, J.H.; Lee, H.K. Workability, and mechanical, acoustic and thermal properties of lightweight aggregate concrete with a high volume of entrained air. Constr. Build. Mater. 2012, 29, 193–200. [Google Scholar] [CrossRef]

- Abd Elrahman, M.; Chung, S.Y.; Sikora, P.; Rucinska, T.; Stephan, D. Influence of nanosilica on mechanical properties, sorptivity, and microstructure of lightweight concrete. Materials 2019, 12, 3078. [Google Scholar] [CrossRef] [Green Version]

- Wongsa, A.; Sata, V.; Nuaklong, P.; Chindaprasirt, P. Use of crushed clay brick and pumice aggregates in lightweight geopolymer concrete. Constr. Build. Mater. 2018, 188, 1025–1034. [Google Scholar] [CrossRef]

- Noaman, A.T.; Jameel, G.S.; Ahmed, S.K. Producing of workable structural lightweight concrete by partial replacement of aggregate with yellow and/or red crushed clay brick (CCB) aggregate. J. King Saud Univ.-Eng. Sci. 2021, 33, 240–247. [Google Scholar]

- Dolch, W.L. Air-entraining admixtures. In Concrete Admixtures Handbook; William Andrew Publishing: Norwich, NY, USA, 1996; pp. 518–557. [Google Scholar]

- Kosmatka, S.H.; Wilson, M.L. Design and Control of Concrete Mixtures, 15th ed.; Portland Cement Association: Skokie, IL, USA, 2011. [Google Scholar]

- Deng, X.; Gao, X.; Wang, R.; Gao, M.; Yan, X.; Cao, W.; Liu, J. Investigation of microstructural damage in air-entrained recycled concrete under a freeze–thaw environment. Constr. Build. Mater. 2021, 268, 121219. [Google Scholar] [CrossRef]

- Chung, S.Y.; Sikora, P.; Rucinska, T.; Stephan, D.; Abd Elrahman, M. Comparison of the pore size distributions of concretes with different air-entraining admixture dosages using 2D and 3D imaging approaches. Mater. Charact. 2020, 162, 110182. [Google Scholar] [CrossRef]

- Schackow, A.; Effting, C.; Folgueras, M.V.; Güths, S.; Mendes, G.A. Mechanical and thermal properties of lightweight concretes with vermiculite and EPS using air-entraining agent. Constr. Build. Mater. 2014, 57, 190–197. [Google Scholar] [CrossRef]

- Kubissa, W.; Jaskulski, R.; Grzelak, M. Torrent air permeability and sorptivity of concrete made with the use of air entraining agent and citric acid as setting retardant. Constr. Build. Mater. 2021, 268, 121703. [Google Scholar] [CrossRef]

- Tarhan, Y.; Şahin, R. Fresh and Rheological Performances of Air-Entrained 3D Printable Mortars. Materials 2021, 14, 2409. [Google Scholar] [CrossRef] [PubMed]

- EN ISO 19595:2017; Aggregates for Concrete. ISO: Geneva, Switzerland, 2017.

- ES 4756-1; Egyptian Standard Specifications (ES) 4576-1. Cement Part 1: Composition, Specifications and Conformity Criteria for Common Cements. Egyptian Organization for Standardization and Quality (EOS). EOS Egypt: Cairo, Egypt, 2013.

- ASTM C1240-01; Standard Specification for Use of Silica Fume for Use as a Mineral Admixture in Hydraulic-Cement Concrete, Mortar, and Grout. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C494/C494M-08; Standard Specification for Chemical Admixtures for Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C260 C260M-10a; Standard Specification for Air-Entraining Admixtures for Concrete. ASTM International: West Conshohocken, PA, USA, 2016.

- EN 12350: 2019: EN 12350; Testing fresh Concrete, Part 8: Slump-Flow Test. Swedish Institute for Standards: Stockholm, Sweden, 2019.

- EN 12390-7: DIN EN 12390-7; Prüfung von Festbeton–Teil 7: Dichte von Festbeton. Beuth Verlag GmbH : Berlin, Germany, 2009. Available online: https://dx.doi.org/10.31030/1511392 (accessed on 1 December 2021).

- BS EN 12390; Testing Hardened Concrete-Part 3: Compressive Strength of Test Specimens. European Standards Institution: Brussels, Belgium, 2019.

- ASTM C 597-16: ASTM C 597; Standard Test Method for Pulse Velocity through Concrete. ASTM International: West Conshohocken, PA, USA, 2016.

- EN ISO 15148: DIN EN ISO 15148; Bestimmung des Wasseraufnahmekoeffizienten bei Teilweisem Eintauchen. ISO: Geneva, Switzerland, 2002. Available online: https://dx.doi.org/10.31030/3002895 (accessed on 1 December 2021).

- Tragwerke aus Beton, Stahlbeton und Spannbeton-Teil 1, “Bemessung und Konstruktion”. DIN 1045-1. Available online: https://www.baunormenlexikon.de/norm/din-1045-1/1ce039fc-a3e6-4f97-a670-38950b599945 (accessed on 1 December 2021).

- Scrivener, K.; Snellings, R.; Lothenbach, B. (Eds.) A Practical Guide to Microstructural Analysis of Cementitious Materials; Boca CRC Press: Raton, FL, USA, 2016; Volume 540. [Google Scholar]

- Aligizaki, K.K. Pore Structure of Cement-Based Materials: Testing, Interpretation and Requirements; CRC Press, Taylor & Francis Group: London, UK, 2005. [Google Scholar]

| References | Production | Compressive Strength (Mpa) | Dry Density (kg/m3) |

|---|---|---|---|

| Zhao et al., 2018 [2] | Lightweight aggregate concrete | 32.6–40.2 | 1729–1850 |

| Atyia et al., 2021 [4] | Structural lightweight aggregate concrete | ≥27 | ≤1860 |

| Wongsa et al., 2018 [22] | Lightweight geopolymer concrete | 8.2–18.3 | 1685–1749 |

| Noaman et al., 2021 [23] | Structural lightweight aggregate concrete | 27.2–27.8 | 1926–1960 |

| Oxide Composition (%) | Cement | SF | CBP |

|---|---|---|---|

| SiO2 | 20.15 | 90.18 | 51.6 |

| Fe2O3 | 3.25 | 0.35 | 10.40 |

| Al2O3 | 6.1 | 0.47 | 14.0 |

| CaO | 62.6 | 0.56 | 7.15 |

| MgO | 1.9 | 4.32 | 1.67 |

| SO3 | 2.4 | 0.26 | 7.66 |

| TiO2 | 0.3 | 0.22 | 1.82 |

| Loss on Ignition | 1.7 | 2.9 | 1.74 |

| Mix Label | Components (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|

| CCB | FCB | CBP | Cement | SF | water | SP | AEA | |

| MF0 | 700 | 700 | ـ | 432 | 48 | 168 | 7.2 | ـ |

| MF10 | 700 | 630 | 70 | 432 | 48 | 168 | 7.2 | - |

| MF20 | 700 | 560 | 140 | 432 | 48 | 168 | 7.2 | ـ |

| MF30 | 700 | 490 | 210 | 432 | 48 | 168 | 7.2 | ـ |

| MF30-0.25 | 700 | 490 | 210 | 432 | 48 | 168 | 7.2 | 1.2 |

| MF30-0.5 | 700 | 490 | 210 | 432 | 48 | 168 | 7.2 | 2.4 |

| MF30-0.75 | 700 | 490 | 210 | 432 | 48 | 168 | 7.2 | 3.6 |

| MF30-1 | 700 | 490 | 210 | 432 | 48 | 168 | 7.2 | 4.8 |

| Compound Name | Chemical Formula | ICCD Code * |

|---|---|---|

| Albite (A) | NaAlSi3O8 | 1616-083-01 |

| Quartz (Q) | SiO2 | 0539-083-01 |

| Ettringite, syn (E) | Ca6Al2(SO4)3(OH)12·26H2O | 1451-041-00 |

| Portlandite, syn (P) | Ca(OH)2 | 1481-044-00 |

| Calcium silicate (CS) | Ca3SiO5 | 0739-055-00 |

| Calcium silicate hydrate (CSH) | Ca2SiO4·0.35H2O | 0306-033-00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-kroom, H.; Atyia, M.M.; Mahdy, M.G.; Abd Elrahman, M. The Effect of Finely-Grinded Crushed Brick Powder on Physical and Microstructural Characteristics of Lightweight Concrete. Minerals 2022, 12, 159. https://doi.org/10.3390/min12020159

Al-kroom H, Atyia MM, Mahdy MG, Abd Elrahman M. The Effect of Finely-Grinded Crushed Brick Powder on Physical and Microstructural Characteristics of Lightweight Concrete. Minerals. 2022; 12(2):159. https://doi.org/10.3390/min12020159

Chicago/Turabian StyleAl-kroom, Hussein, May M. Atyia, Mohamed G. Mahdy, and Mohamed Abd Elrahman. 2022. "The Effect of Finely-Grinded Crushed Brick Powder on Physical and Microstructural Characteristics of Lightweight Concrete" Minerals 12, no. 2: 159. https://doi.org/10.3390/min12020159

APA StyleAl-kroom, H., Atyia, M. M., Mahdy, M. G., & Abd Elrahman, M. (2022). The Effect of Finely-Grinded Crushed Brick Powder on Physical and Microstructural Characteristics of Lightweight Concrete. Minerals, 12(2), 159. https://doi.org/10.3390/min12020159