1. Introduction

Additive manufacturing in the form of 3D printing is becoming more and more accessible and affordable. It is being used by an ever-increasing number of people, even in the comfort of their own homes [

1]. Although fused-deposition modeling (FDM) is still the predominant 3D printing method, other technologies, including powder bed fusion (PBF) ones, are becoming more and more popular. Three-dimensional prints can be analyzed in a number of ways—for example, from the point of view of their watertightness [

2], strength [

3], roughness [

4], or their general dimensional accuracy [

5]. Both the material and the technology used can definitely influence the quality of the final product, and that also includes its surface quality.

Even though thermoplastics are still the most commonly used materials in the field of 3D printing, they are not the only ones that can be used for that purpose. Other materials are used, as well, including such materials that no one would have thought of a decade ago. Printing in metal, despite being a relatively old technology, is currently gaining momentum and has the potential of manufacturing parts that are much stronger than those made of plastic [

6]. With recent developments in biomedicine, 3D printing of tissues is already possible, and it may also be feasible to print entire organs in the future [

7]. Three-dimensional printing also has its place in the world of electronics, where it can be used to manufacture electronic objects such as circuit boards [

8]. A class of much larger 3D printers includes those capable of printing in concrete, which makes it possible to obtain building-like structures [

9]. Finally, there are also 3D printers that can manufacture food items, not only for visual effect, but for nutritional value [

10].

Selective laser sintering (SLS) is a 3D printing method that involves sintering, (i.e., coalescing into a solid or porous mass by means of heating without melting) powdered thermoplastic materials by using a heat source, such as CO

2, diode, or optical fiber lasers. Materials that are commonly used in SLS include mainly polyamides (nylons), especially PA11 and PA12. It is significantly older than the Multi Jet Fusion technology, as it was initially developed as early as 1986 [

11]. It belongs to the same family as MJF (powder bed fusion); hence it is listed here for comparison.

Multi Jet Fusion (MJF) is a relatively new and promising technology developed by Hewlett-Packard (HP) and introduced in 2017 [

12]. Just like SLS, it uses powdered materials; however, instead of sintering the particles by means of a laser heat source, an inkjet printhead forms 3D components by applying two different binder fluids (fusing and detailing agents) to the surface of the powder bed. The fusing agent is applied inside the model boundaries, while the detailing agent is applied at the edges of the model [

13]. Additionally, the CMYK (cyan, magenta, yellow, key) coloring agent gives a hue to selected regions of the print, which makes it possible to obtain a specific surface color, as in the case of traditional color printers. MJF is more predictable than SLS, since it takes the same amount of time for each layer to be printed, regardless of the shape or the size of the model. In general, it is also at least two times faster than SLS. Moreover, it offers high reusability, as printing materials are designed to minimize powder waste and can be reused in a later build [

14]. It has also been reported that, being capable of printing 30 million drops per second across the width of the printing area, it can achieve very accurate dimensional precision (±0.2%) in comparison with other technologies [

15].

Some of the unconventional applications of 3D printing include biomedical ones, such as for orthoses that are tailor-made for individual patients [

16,

17]. Achieving the optimal surface quality can definitely improve the overall comfort of using an orthosis and also reduce the wearing out of clothes that come in contact with it. Therefore, it is desirable to make the roughness of those surfaces as low as possible. MJF is much better than FDM in terms of surface quality and even better than SLS in terms of dimensional accuracy. Moreover, MJF-printed objects are not as brittle as those made using SLS when it comes to breaking [

13].

The present study aimed to verify whether the placement and orientation inside the print chamber can increase or decrease the overall surface roughness of MJF-printed parts. At the same time, the surface roughness of the three different materials—polypropylene (PP), thermoplastic polyurethane (TPU), and polyamide 11 (PA11)—was tested. Those materials are not the most common when it comes to MJF printing [

18], which is why they seem to provide an interesting area of research. The following paragraphs contain some background information concerning the materials themselves.

Polypropylene is the second-most-common petroleum-based plastic material next to polyethylene, to which it is similar, although it exhibits a much higher resistance to stress cracking [

19].

Thermoplastic polyurethane is a versatile polymeric material exhibiting excellent physical properties [

20]. It has high elasticity as well as impact strength, and it retains flexibility over a wide temperature range while also displaying high-energy radiation resistance [

21].

Polyamide 11, being a bioplastic that belongs to the nylon family, is unique among other polyamides in that it is non-petroleum sourced [

22] and is derived from castor plants [

23]. It is also less common than, e.g., PA12 in the field of 3D printing.

There have been surface quality and dimensional accuracy tests performed, for example, on MJF-printed cubes; however, the number of samples was rather low, and the polymer used was PA12 [

24]. It is therefore worth verifying whether the other polymers perform better in terms of the resulting surface quality, which is also one of the goals of this study.

3. Results and Discussion

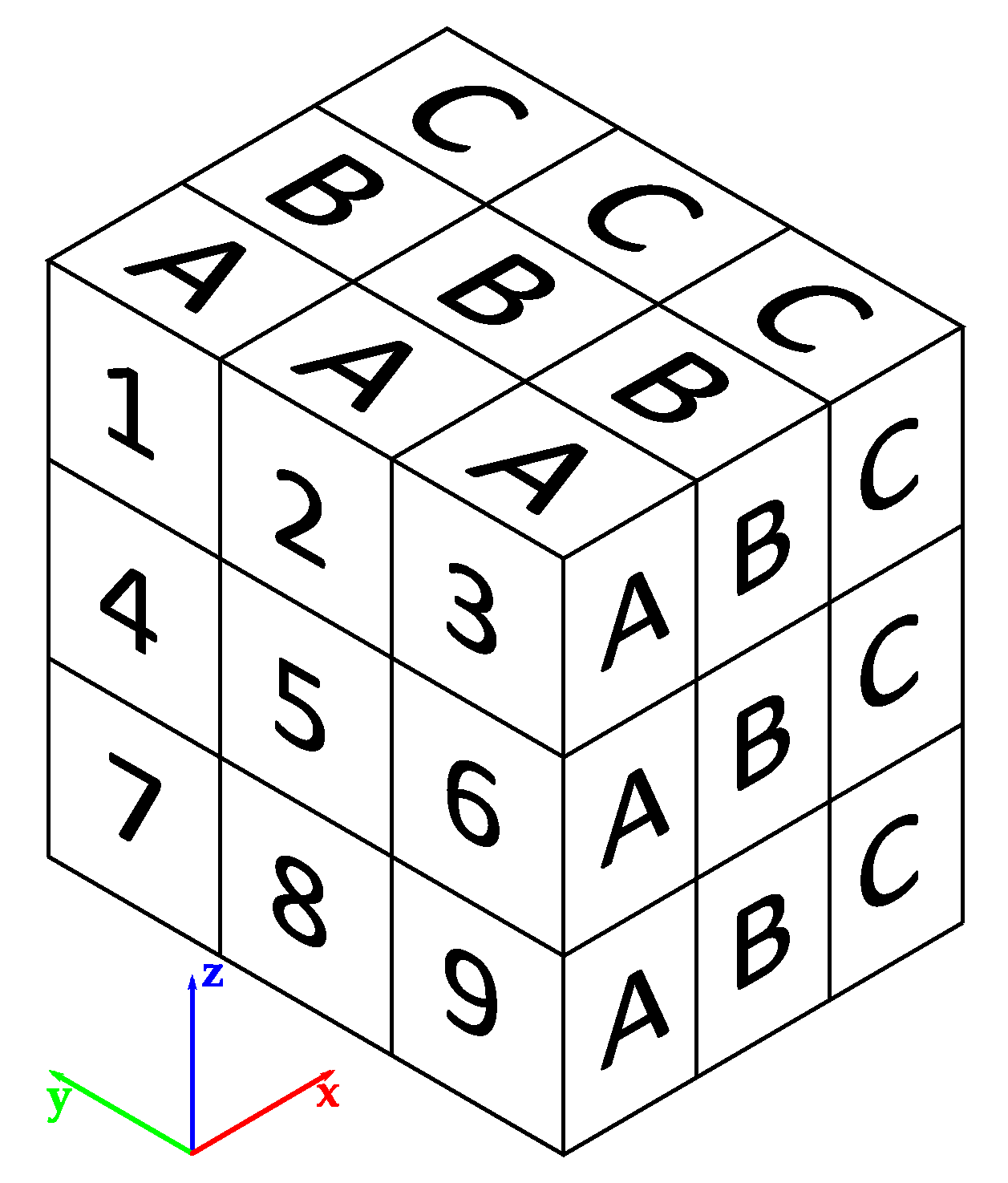

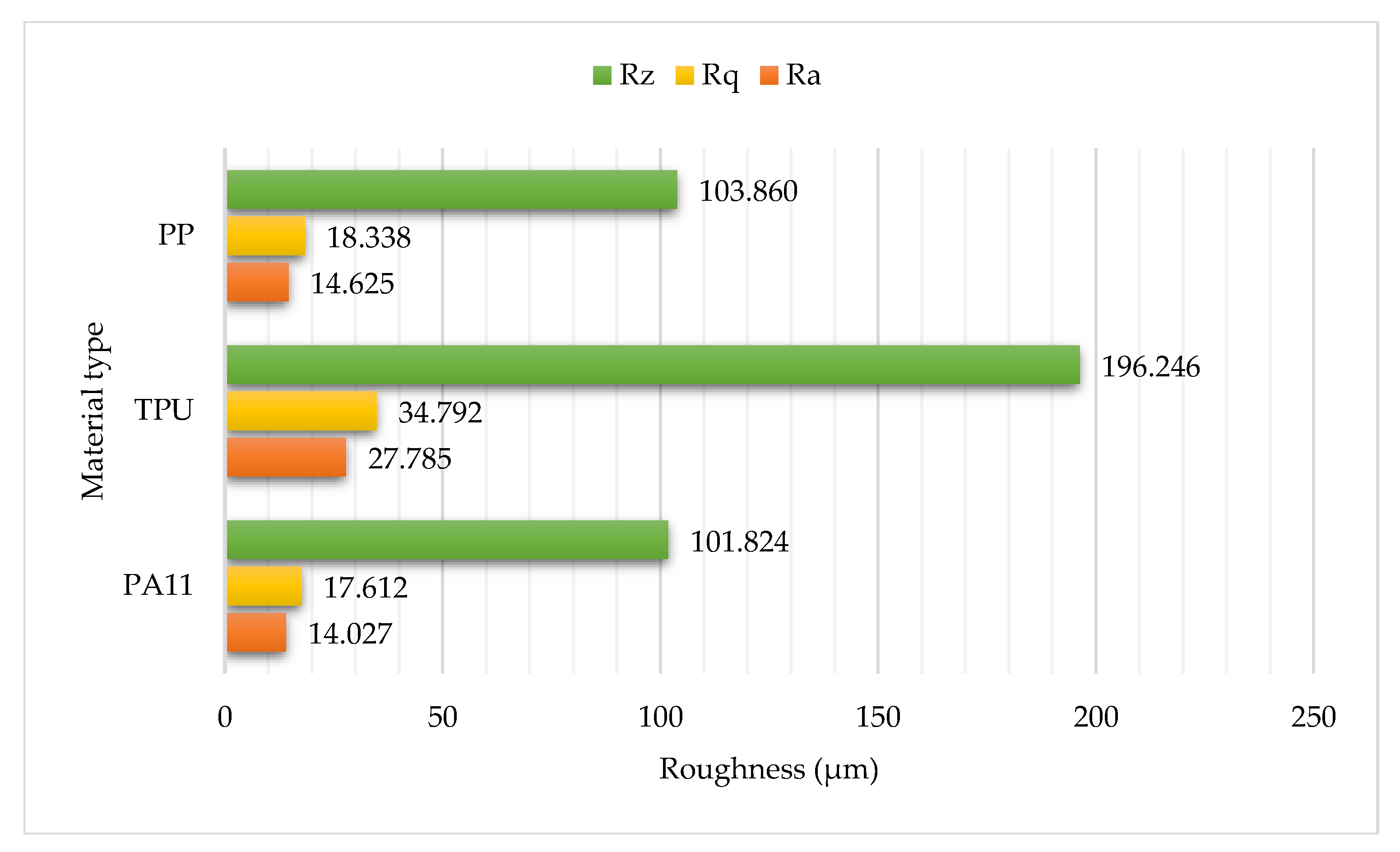

After measuring all of the samples, the computer-calculated values of the selected parameters were exported and analyzed. The obtained results have been grouped and presented graphically both for the respective materials and the print chamber zones along with the orientation. This should make it easier to analyze and interpret them. In

Figure 9, we can see the arithmetic mean values of the three typical roughness parameters obtained for the respective material types. All of the parameters employed are expressed in micrometers.

On the next plot, shown in

Figure 10, the standard deviations for the three computed roughness parameters have been presented in order to see how much, on average, the results diverge from the determined mean values.

Based on the averaged-out values for the respective materials, it can be observed that the samples made of flexible thermoplastic polyurethane (TPU) display a roughness level that is nearly twice as high as that for the other two materials, and their average comes up almost to 28 µm. The surface roughness of the polypropylene (PP) samples is similar to that of the polyamide 11 (PA11) samples, with the average falling within the interval from 14 to 15 µm.

The mean value of the

parameter for the material PP was 14.625 μm; for TPU, it was 27.785 μm, and for PA11—14.027 μm. For comparison,

Table 4 lists the typical

values obtained in some other manufacturing technologies for selected materials.

Next, we can observe how the

values for each material are correlated if we look at

Figure 11, where the samples are ordered by their respective zones and orientations, from A1XY to C9ZY. Even visually, one can see that the results for PP and PA11 are more closely correlated than those for PP and TPU. For PP and PA11, the calculated value of the Pearson correlation coefficient was 0.415, which suggests a moderate correlation, whereas for PP and TPU, the calculated correlation was only 0.037. The two-tailed

p-value for PP and PA11, under the assumption that both datasets were normally distributed (which they roughly were), was as low as 0.00000004041. This indicates that the probability of uncorrelated datasets yielding a similar value of the Pearson coefficient was extremely low. As could be expected, the

p-value obtained for PP and TPU was significantly higher and reached 0.6408.

Figure 12 shows the averaged-out values of

for the respective print chambers (including all six orientations). The highest nine values in the print chamber are marked in red, and the lowest nine values are marked in green. The intermediate values are highlighted in yellow.

A brief analysis of the averaged-out results does not suggest any significant relationship between the roughness of a sample and its location when considering all 27 subzones for PP and PA11. Nonetheless, particularly for TPU, we can see that most of the maximum values are found in zone B treated as a whole.

For the samples made of PP, the highest value was registered for zone B4 in the ZX orientation (18.784 μm). For the same zone and the same material, the highest values of (23.613 μm) and (138.538 μm) were also recorded. In the case of TPU, it was mainly zone B9 in the XY orientation, where was 36.885 μm and was 45.333 μm. On the other hand, was the highest in zone B7 and the YX orientation, and it reached 250.839 μm. For the last material, PA11, reached 18.371 μm in zone B4 and the ZX orientation, was 23.227 μm there, and the maximum was 133.205 μm, but in zone C3 and the ZY orientation. The values were noticeably higher in most of the subzones of zone B, especially the outlying ones (1, 4, 7 and 3, 6, 9).

For PP, the mean value in zone B was 14.69 μm. For TPU, it was 29.067 μm in the same zone. For PA11, it was 14.293 μm, also for zone B. The relative difference was the lowest in the case of PP, where the averaged-out parameter value for zone A reached 14.687 μm. In the remaining cases, the differences were much more noticeable.

Additionally, one-way and two-way ANOVA (analysis of variance) tests were performed on the datasets for each material, with the null hypothesis (

) stating that neither the location nor the print orientation had any impact on the surface roughness. Seeing that the 27 subzones were too many for a statistically meaningful conclusion, that number was reduced to 3, each encompassing 9 of the previous subzones. The results of the one-way test can be viewed in

Table 5, whereas the values obtained in the two-way test are listed in

Table 6.

Based on those tests, we can see that it is the orientation that has the greater statistical significance, especially in the case of polypropylene, for which the p-value was calculated as less than 2 × 10−16 (0.0000000000000002), while the F-value was fairly high. For both PP and PA11, the location of the sample in the print chamber appears to be statistically insignificant. Only in the case of TPU, the p-value for that category could be spoken of as being statistically significant (less than 0.001). This seems to harmonize with the rest of the observations.

Let us also juxtapose the results in terms of the sample orientation for each material, which is shown on the plots in

Figure 13,

Figure 14 and

Figure 15. The standard deviation for each parameter and orientation is also included in the form of an error bar, from its negative value to its positive value.

The plots of the mean roughness values for the different orientations suggest that a surface printed in a vertical orientation (ZX or ZY) coincident with the measurement direction tends to have a higher surface roughness compared with the other possible orientations (XY, XZ, YX, YZ). A similar trend was also noticed in the study conducted by Sagbas B. et al. [

19], who reported higher dimensional deviations and roughness values for the Z surfaces in their cube-shaped samples (with

reaching 23.46 μm for PA12).

4. Conclusions

While the mean roughness of the TPU samples is almost twice as high as that of the PP or PA11 ones, the latter two exhibit roughness levels that are very similar to each other. For that reason, it is difficult to declare the winner between those two materials—at least without applying any post-processing—even after taking the standard deviation into account.

The correlation between how the roughness levels are spread across the corresponding zones and orientations is drastically higher for PP and PA11 than for PP and TPU. This may indicate that such common trends are much more likely to occur for materials whose surface roughness values fall within similar intervals.

Most of the maximum values of the arithmetic mean profile deviation occurred in zone B considered as a whole, that is, without it being split into nine smaller subzones. This was especially true for the TPU samples, where the values were significantly higher in most of the subzones of zone B, especially the outlying ones. A similar relationship was observed for the averaged-out values for the three main zones (A, B, C), with zone B characterized by the highest mean roughness, even though not in every case were there considerable relative differences among the main zones.

It appears that the possible increase in roughness is not dependent on the shape of the object so much as on its spatial orientation. The relationship between roughness and orientation is particularly apparent for the harder materials (PP and PA11). In the case of the most flexible material of all three, TPU, this trend appears to be broken, which may have to do with its flexibility and surface structure.

Apart from the case of the TPU samples, as confirmed by the two-way ANOVA test, no clear relationship has been established between the print chamber zone in which the object being printed was located and the resulting mean roughness. The statistical significance of the print chamber zone for PP and PA11 turned out to be very low. What had a more noticeable impact on the surface quality was the orientation of the sample in the print chamber, although the computed standard deviation values indicate that those results may to some extent diverge from the mean value for the given orientation and could also potentially overlap. Nonetheless, the statistics indicate that there exists a certain relationship between the sample orientation and the obtained surface roughness, and its values are usually higher in the Z direction. Finally, as expected, the type of material used to produce the samples is bound to have the greatest impact on their surface quality.

It is also necessary to add that, despite some differences in the roughness of the samples printed in the ZX and ZY planes for the two examined materials, it is not something as significant as in the case of the popular FDM technology, where the roughness is usually much higher when measured across the layers, by possibly even two or three times for certain materials [

30]. Therefore, we can expect greater isotropy for 3D prints based on the Multi Jet Fusion technology, as well as a more predictable and regular surface structure regardless of the direction. However, this does not mean that the angle at which an object is printed will not affect its tensile strength, and printing at 45° may actually improve its tensile properties, as shown by Lee K. P. M. et al. in their work [

31]. Another factor to consider in the future may be how much the roughness of a surface is influenced by whether it faces up or down. Research findings indicate that the bottom surface tends to be the least smooth of all. When it comes to tensile strength, the same authors have reported that MJF samples deform more than SLS specimens before they break, and they also exhibit a ductile fracture mechanism [

13].

Since there exist some surface characteristics inherent to Multi Jet Fusion that cannot necessarily be adjusted or influenced during the process itself, additional post-processing may be required to produce a positive effect on the smoothness of the obtained surface, which should also constitute the next step in this ongoing research.