Influence of Processing Conditions on the Mechanical Properties of 17-4PH Specimens Produced by Additive Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

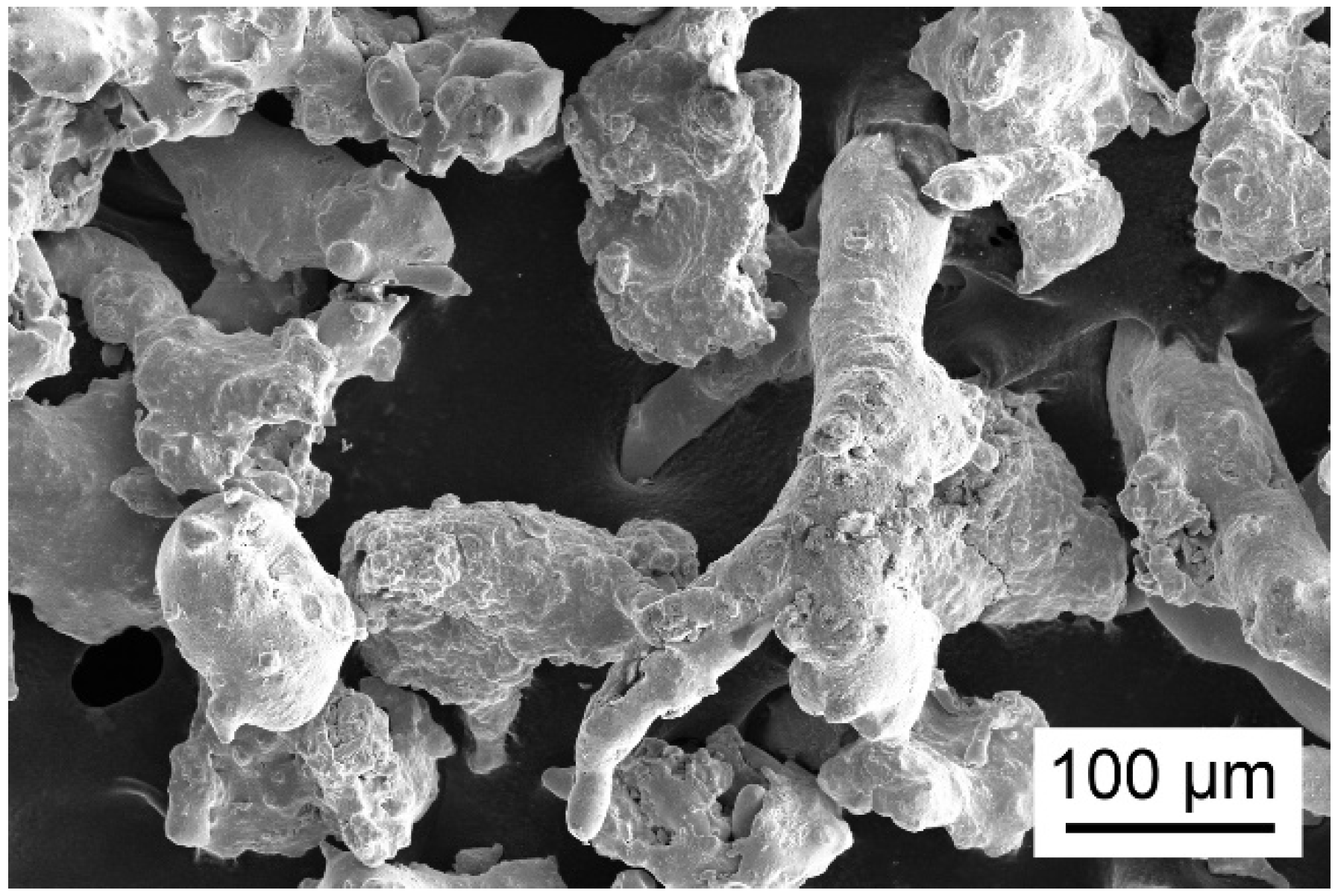

2.1. Materials

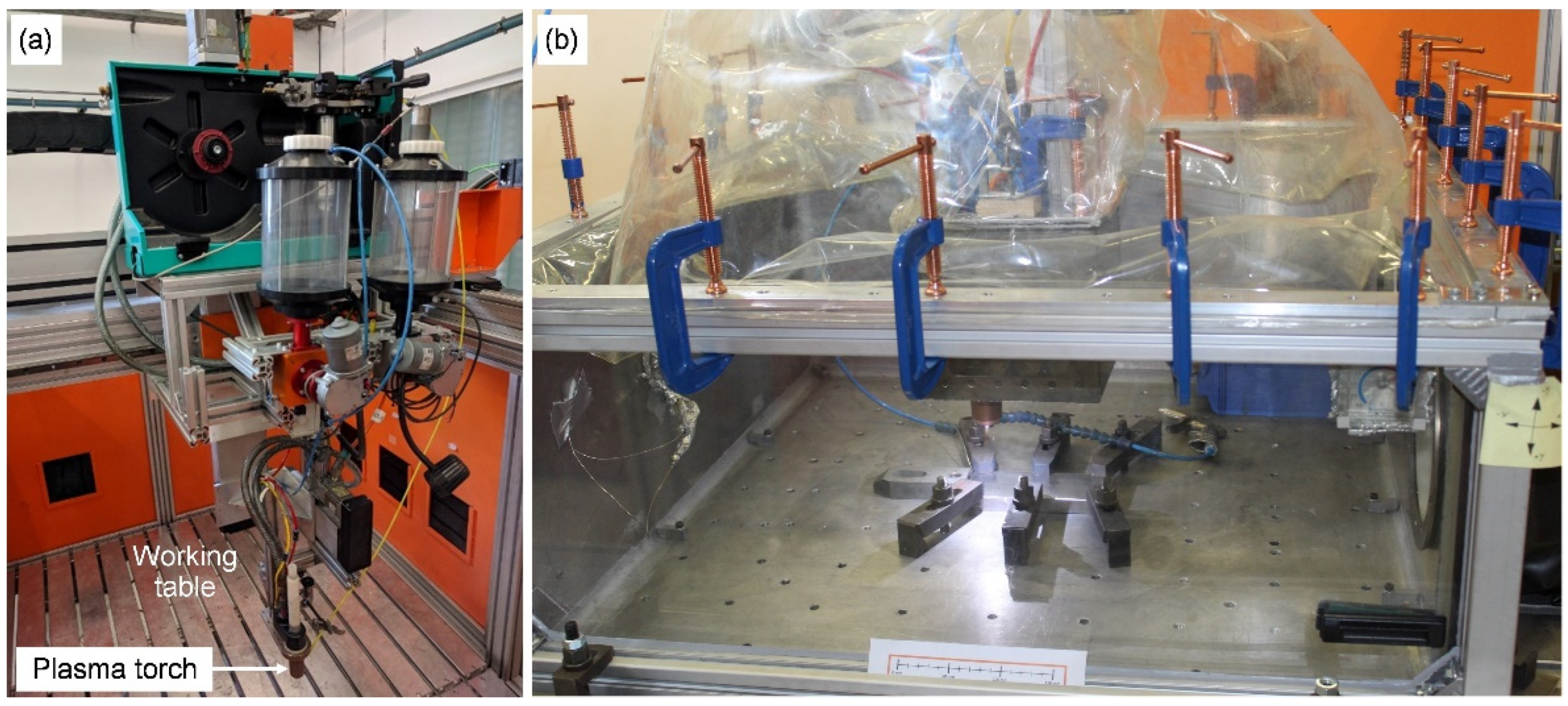

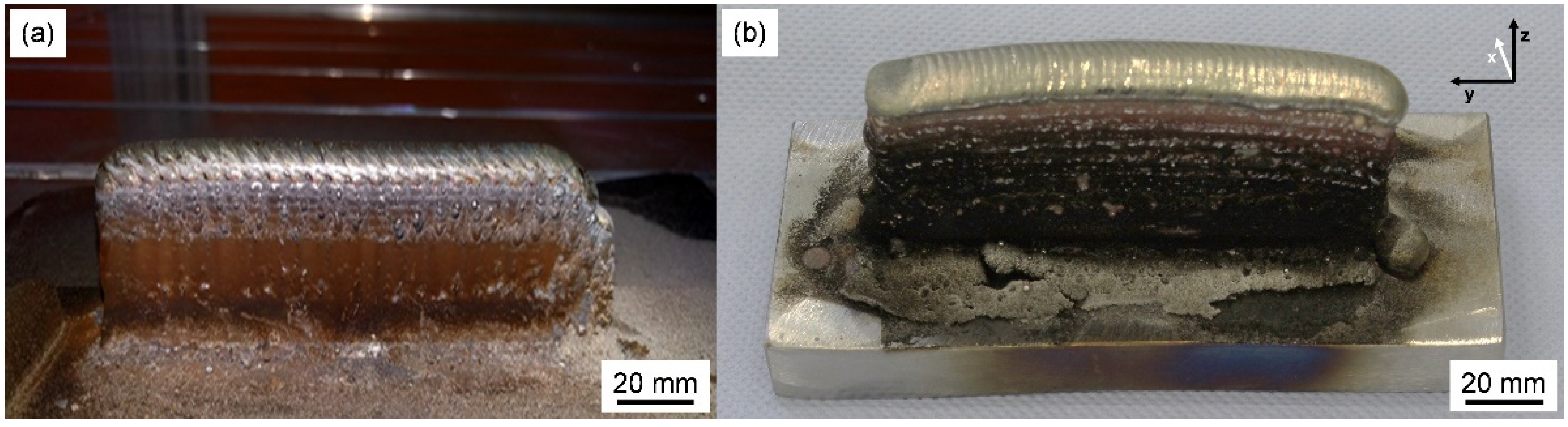

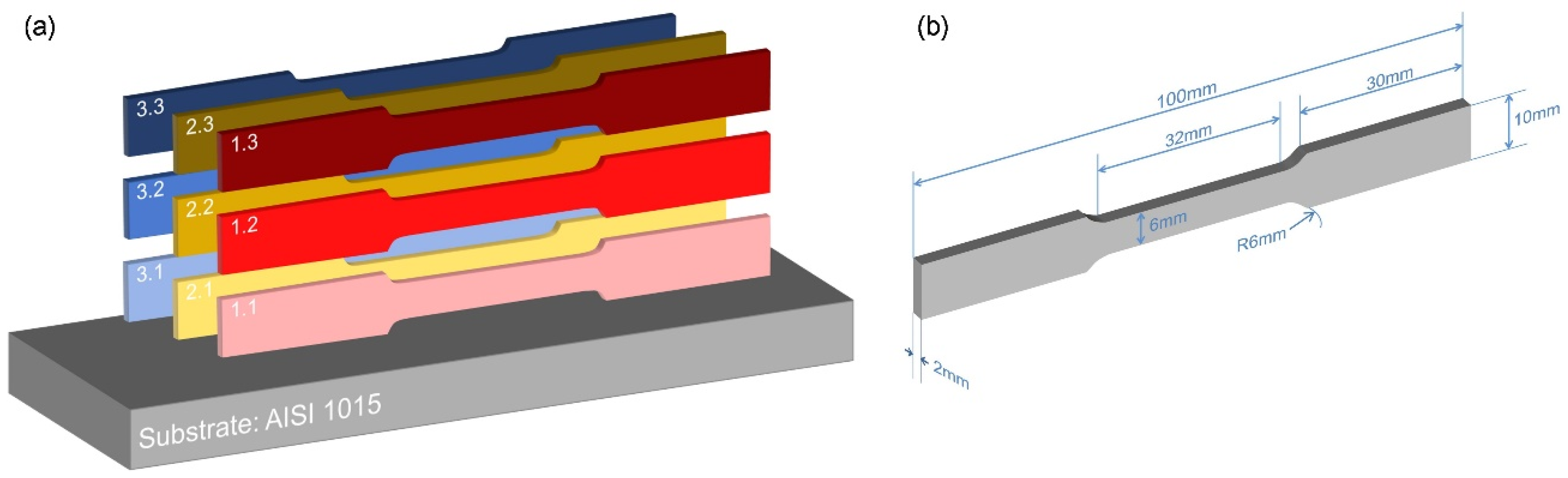

2.2. Manufacturing

2.3. Thermal Treatments

2.4. Properties and Microstructural Characterization

3. Results

3.1. Mechanical and Physical Properties

3.2. Tribological Behaviour

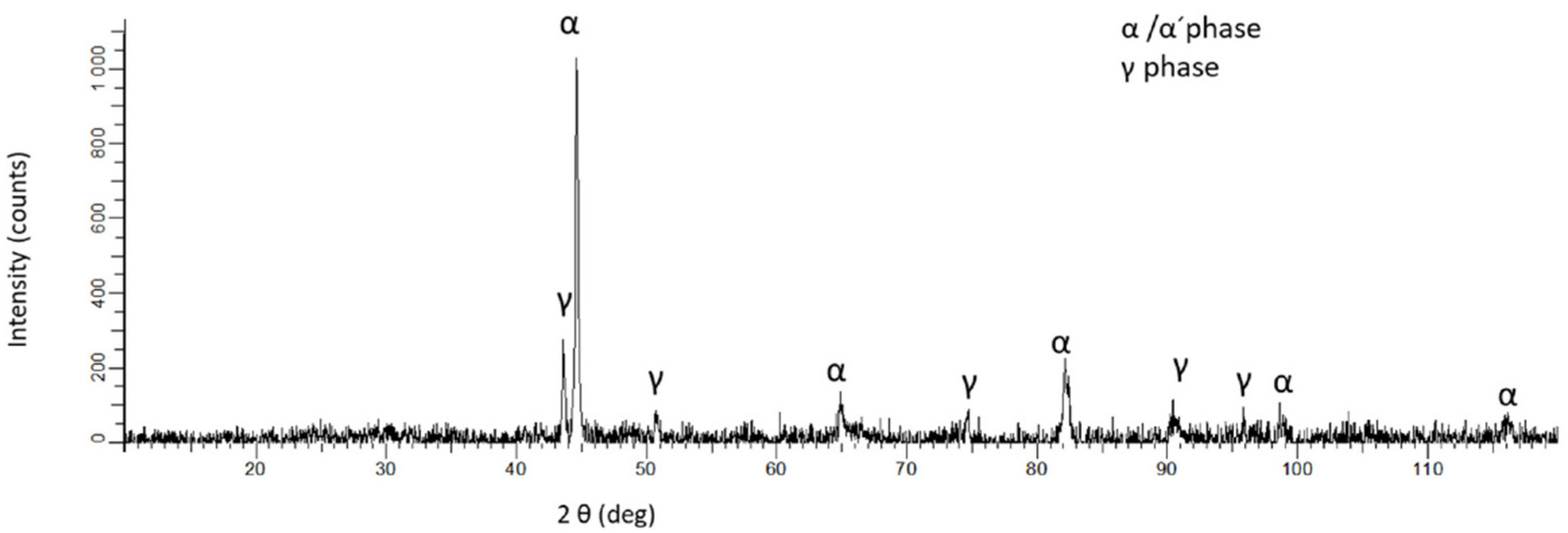

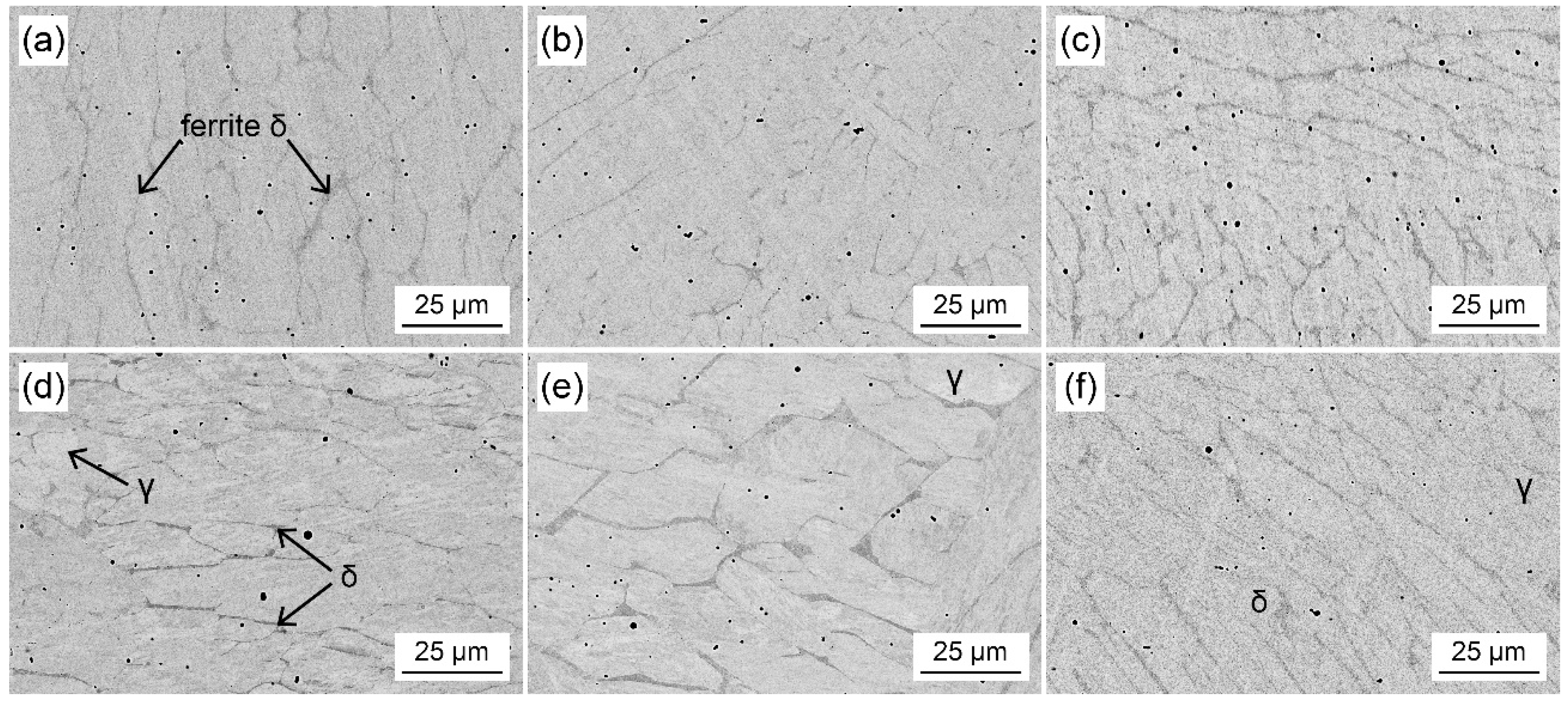

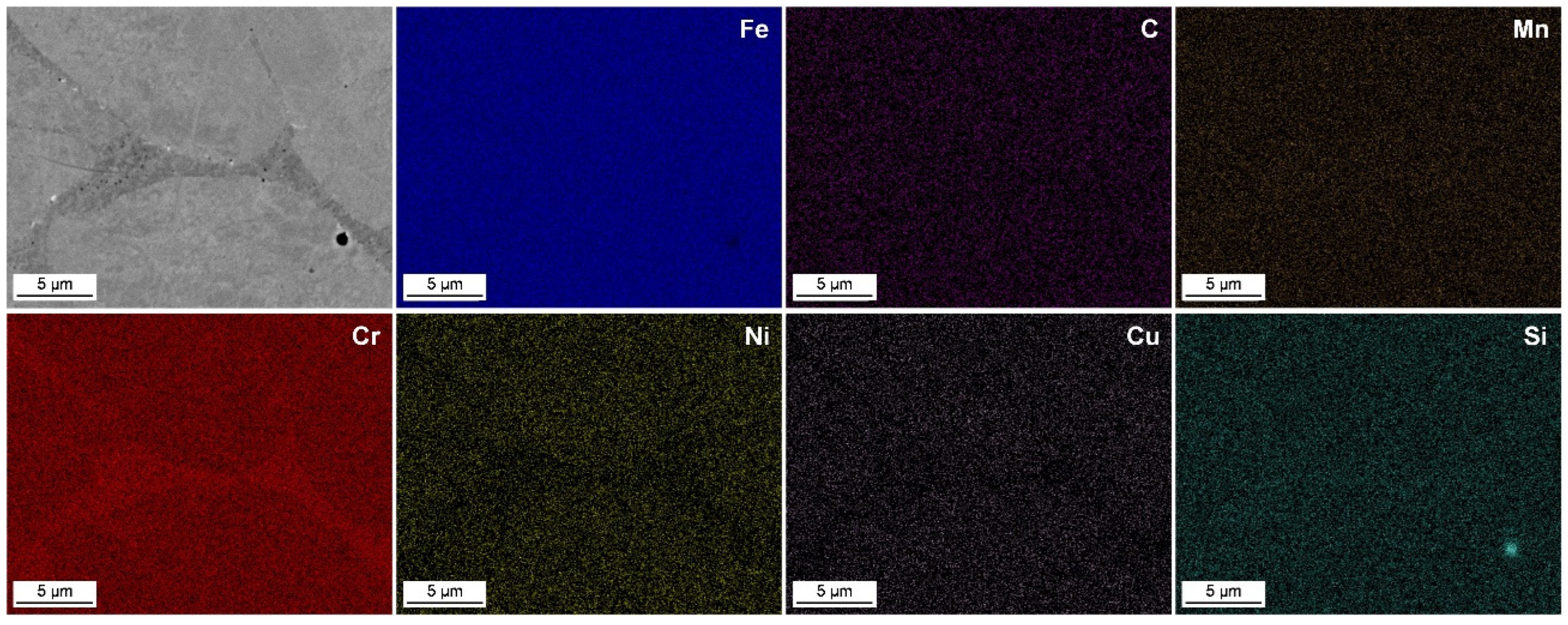

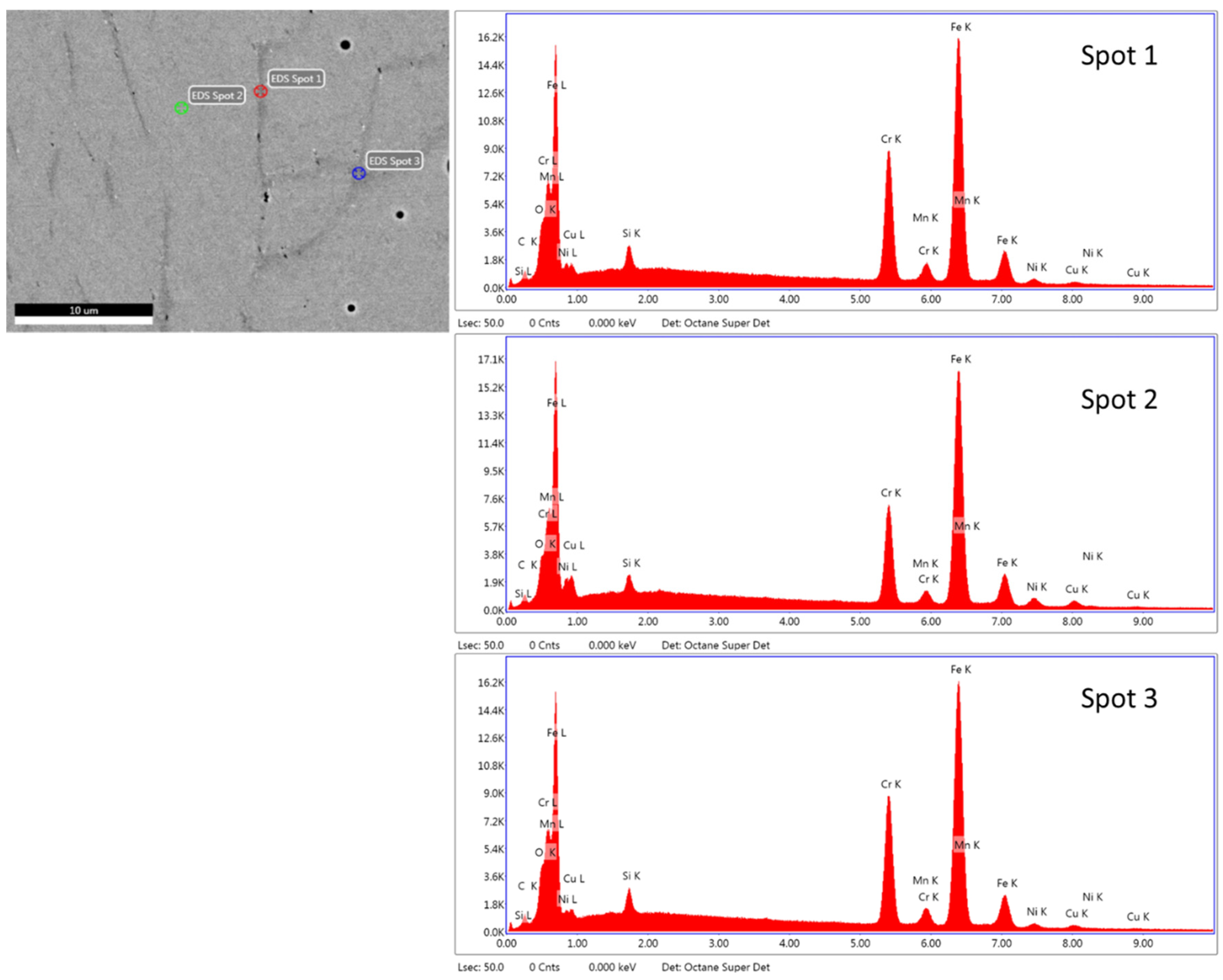

3.3. Microstructure and XRD Analysis

4. Discussion

5. Conclusions

- The specimens processed in air showed less content of the retained austenitic phase, resulting in improved mechanical properties relative to those of the specimens produced in argon. Furthermore, an embrittlement effect of interdendritic δ ferrite was detected in specimens treated with TT1.

- Due to variations in phases during processing and thermal treatments, the mechanical properties of the specimens were subject to treatment effects as follows: (i) TT1 improved the Young’s modulus and yield strength values of the specimens at the cost of the elongation decrement, and (ii) TT2 improved the elongation, contributing to the maintenance of acceptable UTS values.

- Consistent with the mechanical and physical properties, the tribological behaviour of TT1-treated samples was in agreement with the obtained hardness values.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Giganto, S.; Martínez-Pellitero, S.; Barreiro, J.; Zapico, P. Influence of 17-4 PH stainless steel powder recycling on properties of SLM additive manufactured parts. J. Mater. Sci. Technol. 2022, 16, 1647–1658. [Google Scholar] [CrossRef]

- Ding, H.; Bao, X.; Jamili-Shirvan, J.; Jin, J.; Deng, L.; Yao, K.; Gong, P.; Wang, X. Enhancing strength-ductility synergy in an ex situ Zr-based metallic glass composite via nanocrystal formation within high-entropy alloy particles. Mater. Des. 2021, 210, 110108. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Paris, H.; Mokhtarian, H.; Coatanéa, E.; Museau, M.; Flores Ituarte, I. Comparative environmental impacts of additive and substractive manufacturing technologies. CIRP Ann. Manuf. Technol. 2015, 65, 29–32. [Google Scholar] [CrossRef]

- Thawon, I.; Fongsamootr, T.; Mona, Y.; Suttakul, P. Investigation of the Mechanical Properties of Additively Manufactured Metal Parts with Different Relative Densities. Appl. Sci. 2022, 12, 9915. [Google Scholar] [CrossRef]

- Lou, N.; Scheitler, C.; Ciftci, N.; Galgon, F.; Fu, Z.; Uhlenwinkel, V.; Schmidt, M.; Körner, C. Preparation of Fe-Co-B-Si-Nb bulk metallic glasses by laser powder bed fusion: Microstructure and properties. Mater. Charact. 2020, 162, 110206. [Google Scholar] [CrossRef]

- Ronneberg, T.; Davies, C.M.; Hooper, P.A. Revealing relationships between porosity, microstructure and mechanical properties of laser powder bed fusion 316L stainless steel through heat treatment. Mater. Des. 2020, 189, 108481. [Google Scholar] [CrossRef]

- Reijonen, J.; Revuelta, A.; Riipinen, T.; Ruusuvuori, K.; Puukko, P. On the effect of shielding gas flow on porosity and melt pool geometry in laser powder bed fusion additive manufacturing. Addit. Manuf. 2020, 32, 101030. [Google Scholar] [CrossRef]

- Jessy Michla, J.R.; Ravikumar, B.; Ram Prabhu, T.; Siengchin, S.; Arul Kumar, M.; Rajini, N. Effect of nitriding on mechanical and microstructural properties of Direct Metal Laser Sintered 17-4PH stainless steel. J. Mater. Res. Technol. 2022, 19, 2810–2821. [Google Scholar] [CrossRef]

- Yang, K.T.; Kim, M.K.; Kim, D.; Suhr, J. Investigation of laser powder bed fusion manufacturing and post-processing for surface quality of as-built 17-4PH stainless steel. Surf. Coat. Technol. 2021, 422, 127492. [Google Scholar] [CrossRef]

- Guennouni, N.; Maisonnette, D.; Grosjean, C.; Poquillon, D.; Blanc, C. Susceptibility to Pitting and Environmentally Assisted Cracking of 17-4PH Martensitic Stainless Steel Produced by Laser Beam Melting. Materials 2022, 15, 7121. [Google Scholar] [CrossRef]

- Hayes, B.J.; Martin, B.W.; Welk, B.; Kuhr, S.J.; Ales, T.K.; Brice, D.A.; Ghamarian, I.; Baker, A.H.; Haden, C.V.; Harlow, D.G.; et al. Predicting tensile properties of Ti-6Al-4V produced via directed energy deposition. Acta Mater. 2017, 133, 120–133. [Google Scholar] [CrossRef]

- Edwards, P.; Ramulu, M.; O’Conner, A. Electron Beam Additive Manufacturing of Titanium Components, Properties and Performance. J. Manuf. Sci. Eng. 2013, 135, 061016-1. [Google Scholar] [CrossRef]

- McAndrew, A.R.; Alvarez Rosales, M.; Colegrove, P.A.; Hönnige, J.R.; Ho, A.; Fayolle, R.; Eyitayo, K.; Stan, I.; Sukrongpang, P.; Crochemore, A.; et al. Interpass rolling of Ti-6Al-4V wire + arc additively manufacturing features for microstructural refinement. Addit. Manuf. 2018, 21, 340–349. [Google Scholar] [CrossRef]

- Hönnige, J.R.; Colegrove, P.A.; Ahmed, B.; Fitzpatrick, M.E.; Ganguly, S.; Lee, T.L.; Williams, S.W. Residual stress and texture control in Ti-6Al-4V wire+arc additively manufactured intersections by stress relief and rolling. Mater. Des. 2018, 150, 193–205. [Google Scholar] [CrossRef] [Green Version]

- Pérez-Soriano, E.M.; Ariza, E.; Arévalo, C.; Montealegre-Melendez, I.; Kitzmantel, M.; Neubauer, E. Processing by Additive Manufacturing Based on Plasma Transferred Arc of Hastelloy in Air and Argon Atmosphere. Metals 2020, 10, 200. [Google Scholar] [CrossRef] [Green Version]

- Bouaziz, M.A.; Djouda, J.M.; Chemkhi, M.; Rambaudon, M.; Kauffmann, J.; Hild, F. Heat treatment effect on 17-4PH stainless steel manufactured by Atomic Diffusion Additive Manufacturing (ADAM). Procedia CIRP 2021, 104, 935–938. [Google Scholar] [CrossRef]

- Pragana, J.P.M.; Braganca, I.M.F.; Silva, C.M.A.; Martins, P.A.F. Hybrid Wire-Arc Additive Manufacturing od Conformal Cooling Channels: A Feasibility Study. Int. J. Precis. Eng. Manuf.-Green Technol. 2022, 1–13. [Google Scholar] [CrossRef]

- ASTM A693-16; Standard Specification for Precipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and Strip. ASTM International: West Conshohocken, PA, USA, 2016.

- Meredith, S.D.; Zuback, J.S.; Keist, J.S.; Palmer, T.A. Impact of Composition on the Heat Treatment Response of Additively Manufactured 17-4 PH Grade Stainless Steel. Mater. Sci. Eng. A 2018, 738, 44–56. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Elwany, A.; Bian, L. Effects of building orientation and heat treatment on fatigue behavior of selective laser melted 17-4PH stainless steel. Int. J. Fatigue 2017, 94, 218–235. [Google Scholar] [CrossRef]

- Zapico, P.; Giganto, S.; Barreiro, J.; Martínez-Pellitero, S. Characterization of 17-4PH metallic powder recycling to optimize the performance of the selective laser melting process. J. Mater. Res. Technol. 2020, 9, 1273–1285. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Hernandez, J.; Collins, S.; Amato, K.N.; Gaytan, S.M.; Shindo, P.W. Microstructures and Properties of 17-4 PH Stainless Steel Fabricated by Selective Laser Melting. J. Mater. Res. Technol. 2012, 1, 167–177. [Google Scholar] [CrossRef] [Green Version]

- Ariza-Galván, E.; Montealegre-Meléndez, I.; Pérez-Soriano, E.M.; Arévalo Mora, C.; Meuthen, J.; Neubauer, E.; Kitzmantel, M. Processing Of 17-4PH By Additive Manufacturing Using A Plasma Metal Deposition (PMD) Technique. In Proceedings of the Euro PM2019, Maastricht, The Netherlands, 13–16 October 2019; European Powder Metallurgy Association (EPMA): Shrewsbury, UK, 2019. 4348497. [Google Scholar]

- Chen, X.; Li, J.; Cheng, X.; Wang, H.; Huang, Z. Effect of heat treatment on microstructure, mechanical and corrosion properties of austenitic stainless steel 316L using arc additive manufacturing. Mater. Sci. Eng. A 2018, 715, 307–314. [Google Scholar] [CrossRef]

- ASTM E-8; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C373-88; Standard Test Method for Water Absorption, Bulk Density, Apparent Porosity, and Apparent Specific Gravity of Fired Whiteware Products. ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM A 564/A 564M-02a; Standard Specification for Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapes. ASTM International: West Conshohocken, PA, USA, 2017.

- Yoo, W.D.; Lee, J.H.; Youn, K.T.; Rhyim, Y.M. Study on the Microstructure and Mechanical Properties of 17-4 PH Stainless Steel Depending on Heat Treatment and Aging Time. Solid State Phenom. 2006, 118, 15–20. [Google Scholar] [CrossRef]

- Sun, Y.; Hebert, R.J.; Aindow, M. Effect of heat treatments on microstructural evolution of additively manufactured and wrought 17-4PH stainless steel. Mater. Des. 2018, 156, 429–440. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Caballero, A.; Ding, J.; Ganguly, S.; Williams, S. Wire + Arc Additive Manufacture of 17-4 PH stainless steel: Effect of different processing conditions on microstructure, hardness, and tensile strength. J. Mater. Process. Technol. 2019, 268, 54–62. [Google Scholar] [CrossRef]

- Bahrami Balajaddeh, M.; Naffakh-Moosavy, H. Pulsed Nd:YAG laser welding of 17-4 PH stainless steel: Microstructure, mechanical properties, and weldability investigation. Opt. Laser Technol. 2019, 119, 105651. [Google Scholar] [CrossRef]

- Ziewiec, A.; ZieliŃska-Lipiec, A.; Tasak, E. Microstructure of Welded Joints of X5CrNiCuNb16-4 (17-4PH) Martensitic Stainless Steel After Heat Treatment. Arch. Metall. Mater. 2014, 59, 965–970. [Google Scholar] [CrossRef]

- Cheruvathur, S.; Lass, E.A.; Campbell, C.E. Additive Manufacturing of 17-4 PH Stainless Steel: Post-processing Heat Treatment to Achieve Uniform Reproducible Microstructure. JOM 2016, 68, 930–942. [Google Scholar] [CrossRef]

| Composition in Mass% | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Feedstock | Fe | Cr | Ni | Cu | Si | P | C | Mn | S | Nb |

| Hoeganaes Corporation | Bal. | 16.7 | 4.1 | 3.9 | 0.9 | - | 0.02 | - | 0.01 | 0.3 |

| Standard | Bal. | 15–17.5 | 3-5 | 3-5 | 1 | 0.04 | 0.07 | 1 | 0.03 | 0.15–0.45 |

| W1 (Built in Air) | W2 (Built in Ar) | |||

|---|---|---|---|---|

| Sample | UTS (MPa) | Elongation (%) | UTS (MPa) | Elongation (%) |

| 1.1 As built | 1107.12 | 1.58 | 1007.53 | 1.37 |

| 1.2 As built | 1161.59 | 3.31 | 1108.64 | 5.14 |

| 1.3 As built | 1144.61 | 7.29 | 1070.99 | 5.04 |

| As-built Average | 1137.77 ± 22.76 | 4.06 ± 2.92 | 1062.39 ± 51.10 | 3.85 ± 2.15 |

| 2.1 TT1 | 1421.71 | 2.09 | 1074.51 | 3.47 |

| 2.2 TT1 | 1364.69 | 1.18 | 899.18 | 0.54 |

| 2.3 TT1 | 1353.07 | 1.17 | 614.53 | 0.35 |

| TT1 Average | 1379.82 ± 29.99 | 1.48 ± 0.53 | * NR1 | 1.45 ± 1.74 |

| 3.1 TT2 | 1140.97 | 8.65 | 1001.89 | 12.35 |

| 3.2 TT2 | 1126.93 | 10.03 | 938.32 | 10.40 |

| 3.3 TT2 | 1078.50 | 12.27 | 928.84 | 10.93 |

| TT2 Average | 1115.47 ± 26.76 | 10.32 ± 1.83 | 956.35 ± 39.73 | 11.23 ± 1.01 |

| W1 (Built in Air) | W2 (Built in Ar) | |||

| Sample | Young’s modulus (GPa) | Yield strength (MPa) | Young’s modulus (GPa) | Yield strength (MPa) |

| 1.1 As built | 198.02 | 935.29 | 161.34 | 806.18 |

| 1.2 As built | - | 758.23 | 133.68 | 853.09 |

| 1.3 As built | 196.5 | 912.45 | 183.53 | 743.42 |

| As-built Average | 197.04 ± 0.99 | 868.66 ± 78.64 | 159.52 ± 24.98 | 800.90 ± 55.03 |

| 2.1 TT1 | 199.51 | 1187.08 | 163.29 | 903.29 |

| 2.2 TT1 | 214.14 | 1230.66 | 215.14 | 899.18 |

| 2.3 TT1 | 203.56 | 1248.50 | 183.56 | 614.53 |

| TT1 Average | 205.74 ± 6.19 | 1222.08 ± 25.79 | 187.33 ± 26.13 | * NR1 |

| 3.1 TT2 | 158.79 | 1071.29 | 166.23 | 678.21 |

| 3.2 TT2 | 226.50 | 1023.02 | 152.35 | 854.70 |

| 3.3 TT2 | 186.73 | 995.93 | 162.79 | 855.11 |

| TT2 Average | 190.67 ± 27.78 | 1030.08 ± 31.08 | 160.46 ± 7.23 | 796.01 ± 102.02 |

| Hardness HV1 | ||

|---|---|---|

| Sample | W1 (Built in Air) | W2 (Built in Ar) |

| 1.1 As built | 414.20 ± 4.55 | 367.00 ± 2.83 |

| 1.2 As built | 414.60 ± 7.67 | 361.50 ± 3.58 |

| 1.3 As built | 408.00 ± 4.90 | 368.70 ± 6.59 |

| As-built Average | 412.27 ± 6.27 | 365.73 ± 4.33 |

| 2.1 TT1 | 525.20 ± 11.46 | 482.60 ± 6.58 |

| 2.2 TT1 | 523.80 ± 11.54 | 481.20 ± 7.85 |

| 2.3 TT1 | 530.60 ± 15.66 | 475.30 ± 8.49 |

| TT1 Average | 526.60 ± 12.44 | 479.70 ± 7.64 |

| 3.1 TT2 | 405.20 ± 2.95 | 370.60 ± 6.11 |

| 3.2 TT2 | 416.00 ± 4.69 | 373.80 ± 3.18 |

| 3.3 TT2 | 406.20 ± 6.53 | 368.20 ± 5.29 |

| TT2 Average | 409.13 ± 6.81 | 370.87 ± 4.86 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ariza-Galván, E.; Montealegre-Meléndez, I.; Pérez-Soriano, E.M.; Neubauer, E.; Kitzmantel, M.; Arévalo, C. Influence of Processing Conditions on the Mechanical Properties of 17-4PH Specimens Produced by Additive Manufacturing. Machines 2022, 10, 976. https://doi.org/10.3390/machines10110976

Ariza-Galván E, Montealegre-Meléndez I, Pérez-Soriano EM, Neubauer E, Kitzmantel M, Arévalo C. Influence of Processing Conditions on the Mechanical Properties of 17-4PH Specimens Produced by Additive Manufacturing. Machines. 2022; 10(11):976. https://doi.org/10.3390/machines10110976

Chicago/Turabian StyleAriza-Galván, Enrique, Isabel Montealegre-Meléndez, Eva María Pérez-Soriano, Erich Neubauer, Michael Kitzmantel, and Cristina Arévalo. 2022. "Influence of Processing Conditions on the Mechanical Properties of 17-4PH Specimens Produced by Additive Manufacturing" Machines 10, no. 11: 976. https://doi.org/10.3390/machines10110976

APA StyleAriza-Galván, E., Montealegre-Meléndez, I., Pérez-Soriano, E. M., Neubauer, E., Kitzmantel, M., & Arévalo, C. (2022). Influence of Processing Conditions on the Mechanical Properties of 17-4PH Specimens Produced by Additive Manufacturing. Machines, 10(11), 976. https://doi.org/10.3390/machines10110976