Minimizing Misalignment and Frame Protrusion of Shoulder Exoskeleton via Optimization for Reducing Interaction Force and Minimizing Volume

Abstract

1. Introduction

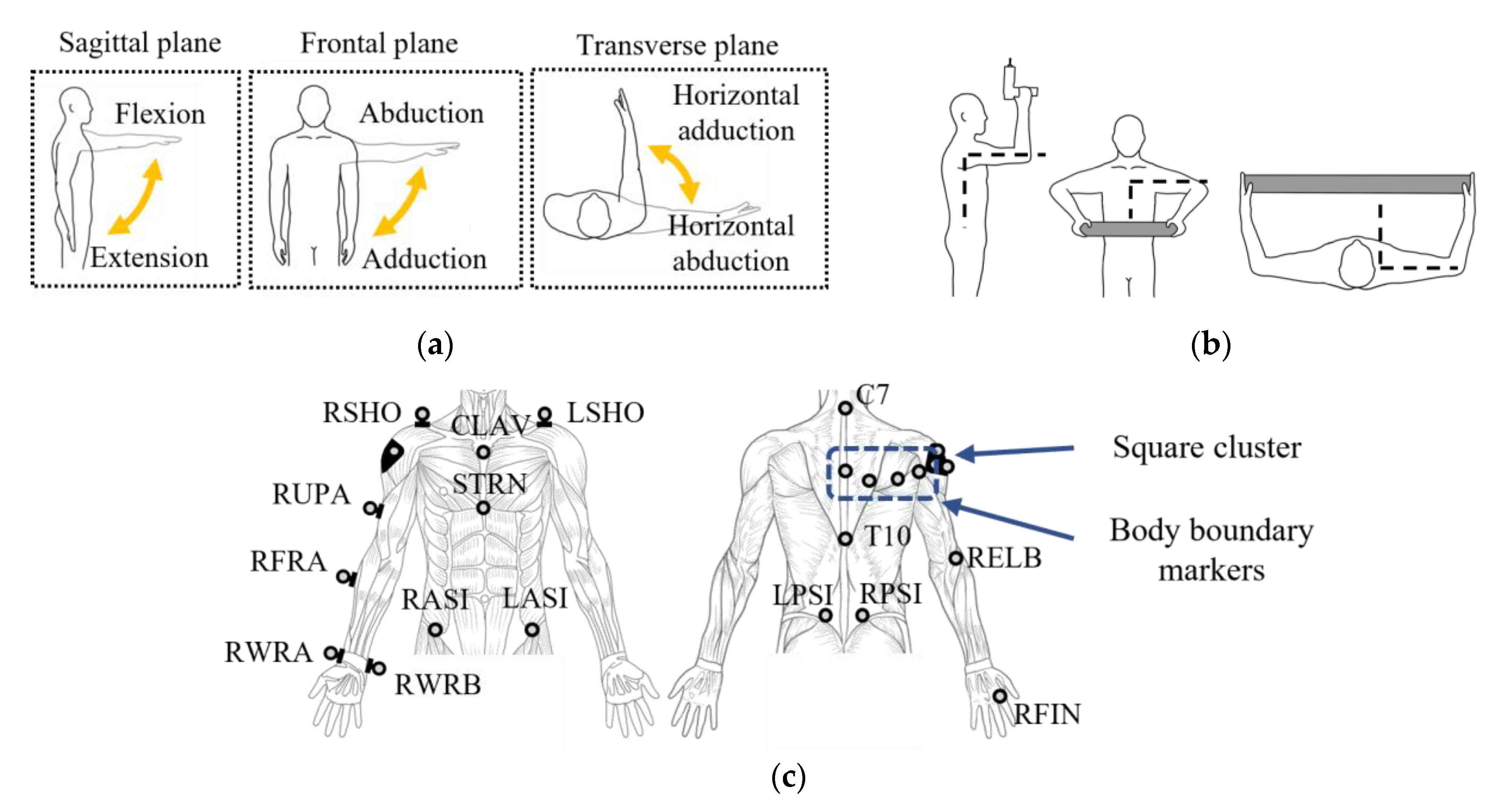

2. Motion Capture to Extract the Target Exoskeleton Trajectory and Orientation

2.1. Experimental Setup

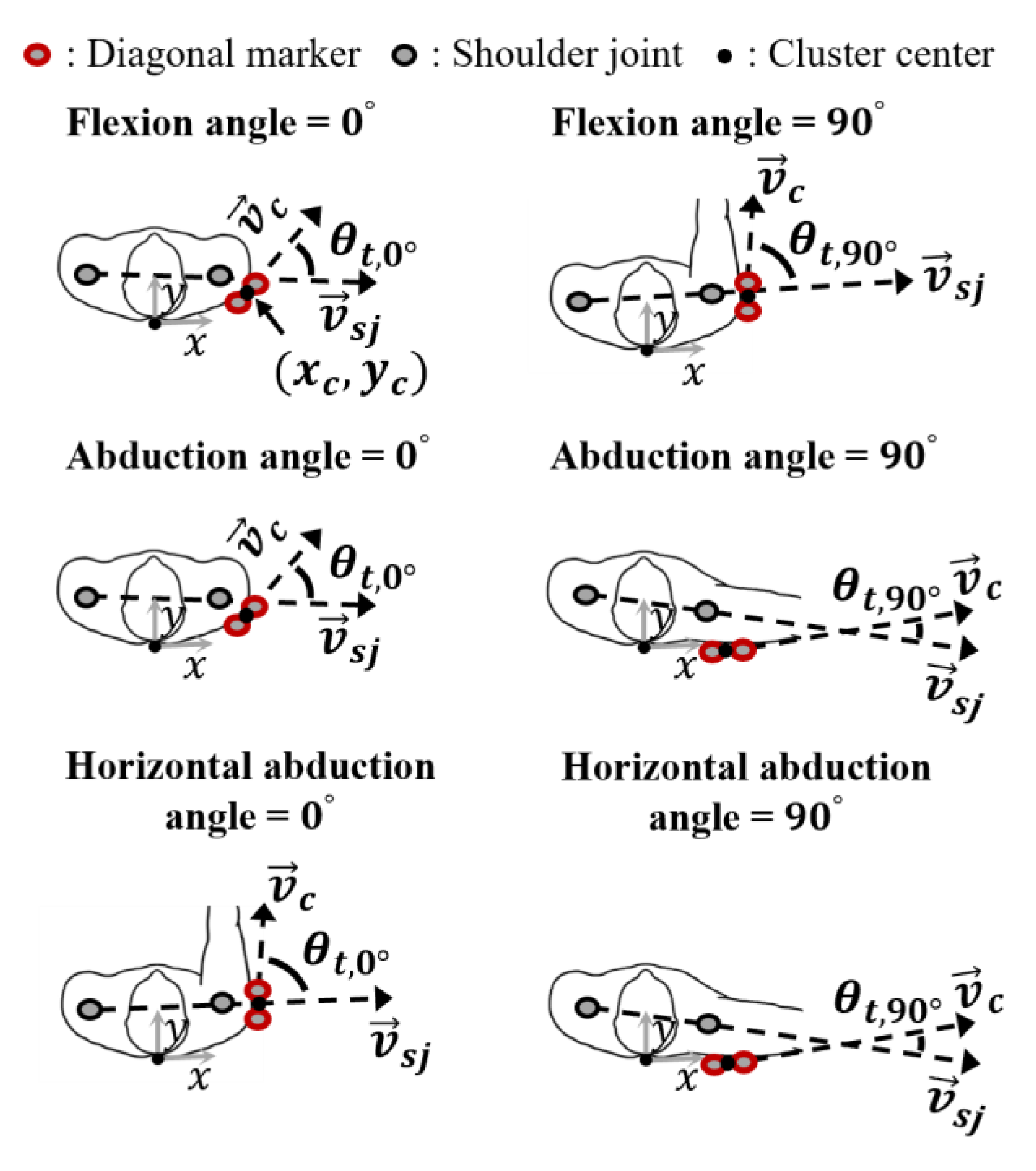

2.2. Required Trajectory and Orientation Information of the Exoskeleton in 2-D

2.3. Acquisition of the Target Trajectory and Orientation Using a Cluster

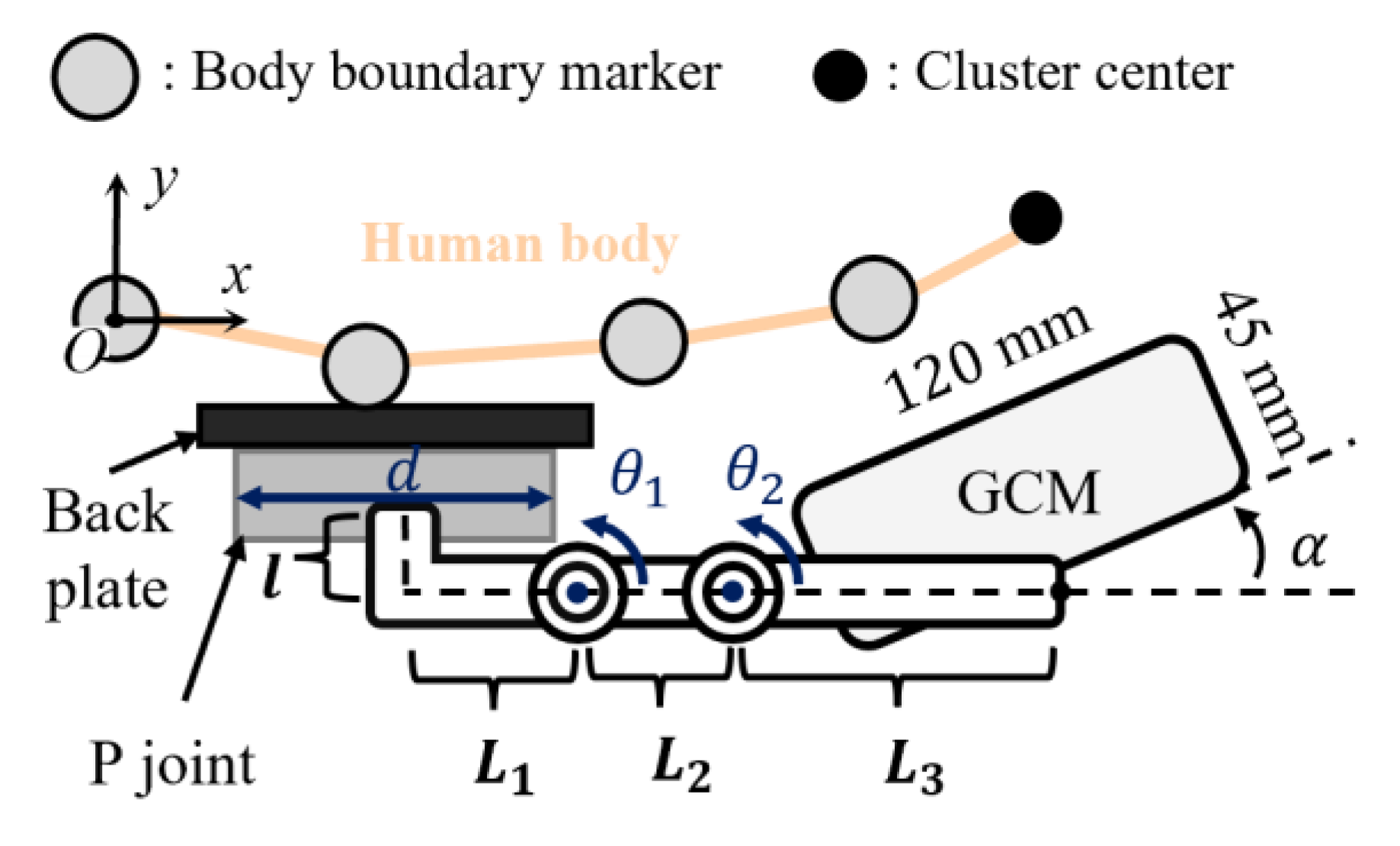

3. Kinematic Optimization of 3-DOF Joint Configuration

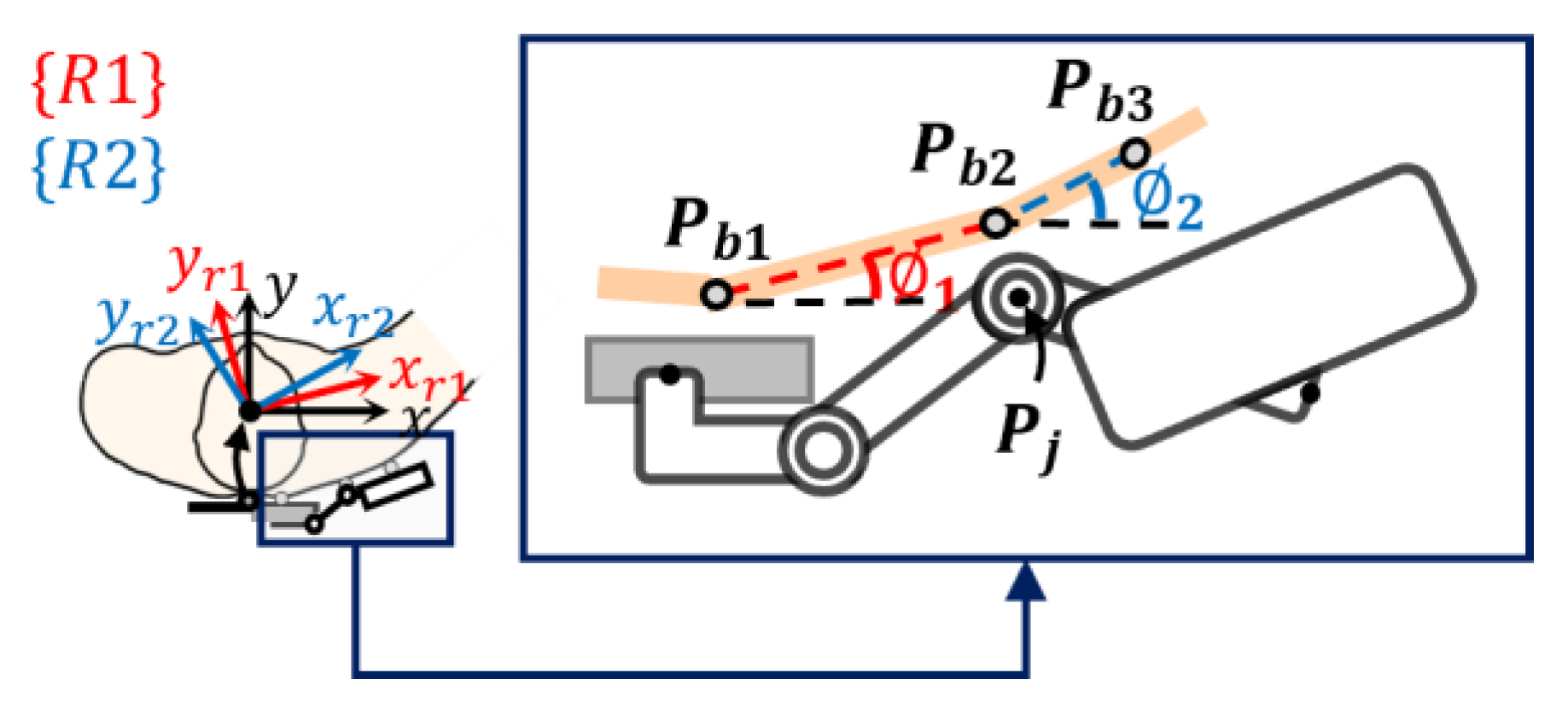

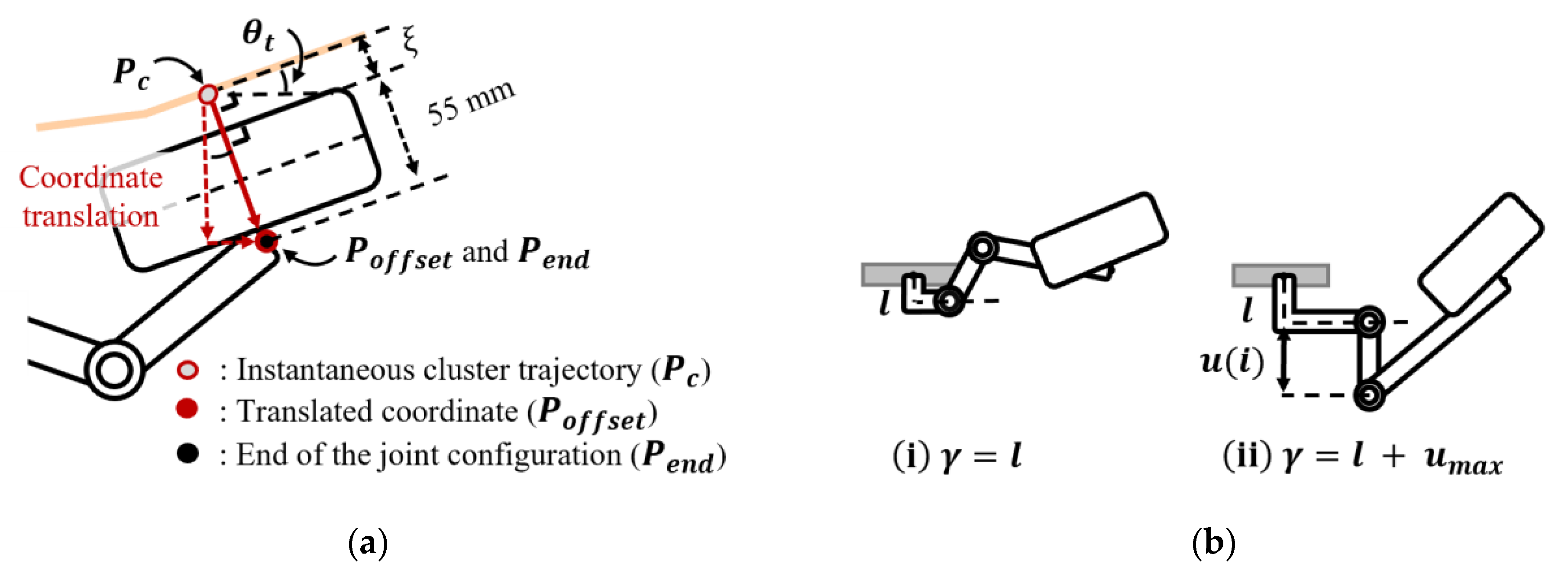

3.1. Kinematic Model and Design Variables

3.2. Design Constraints

3.2.1. Interference with Human Body

3.2.2. Interference with GCM

3.3. Objective Functions

3.3.1. Reducing Misalignment by Tracking Target Data

3.3.2. Minimizing Frame Protrusion

3.4. Optimization Process

3.5. Optimization Result

4. Simulation and Experiment Based Verification

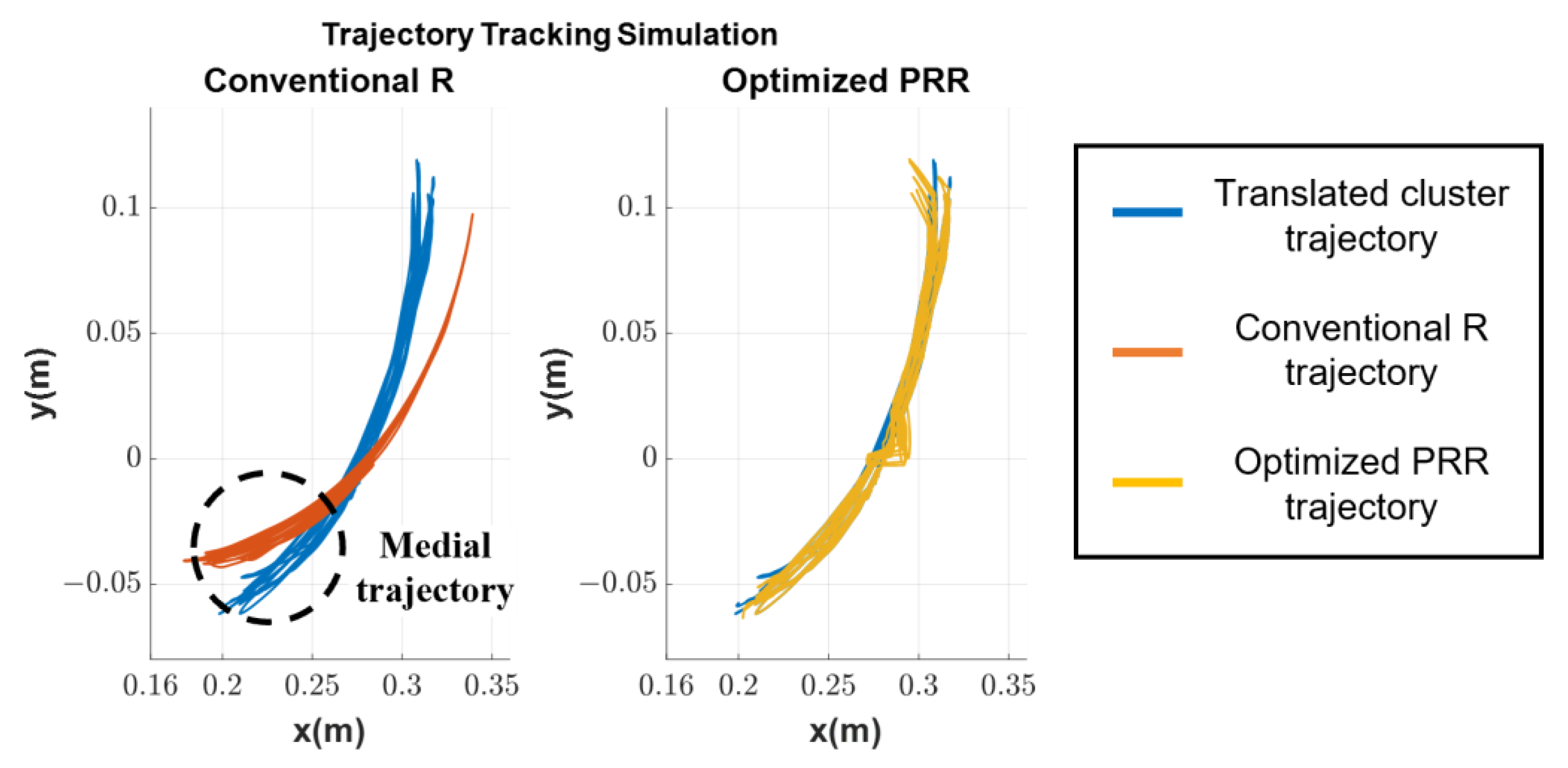

4.1. Simulation Result

4.2. Experiment Setup and Protocol

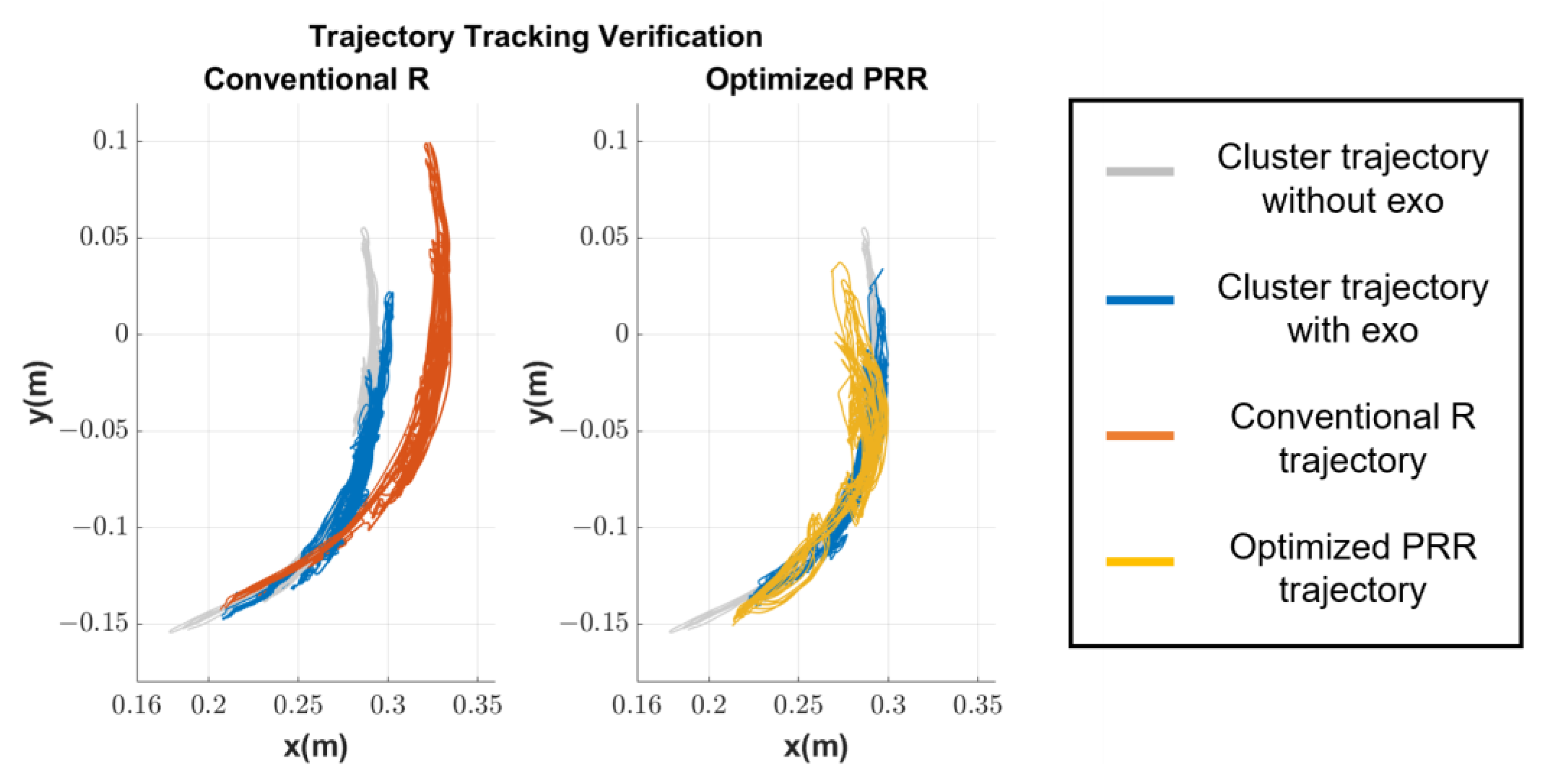

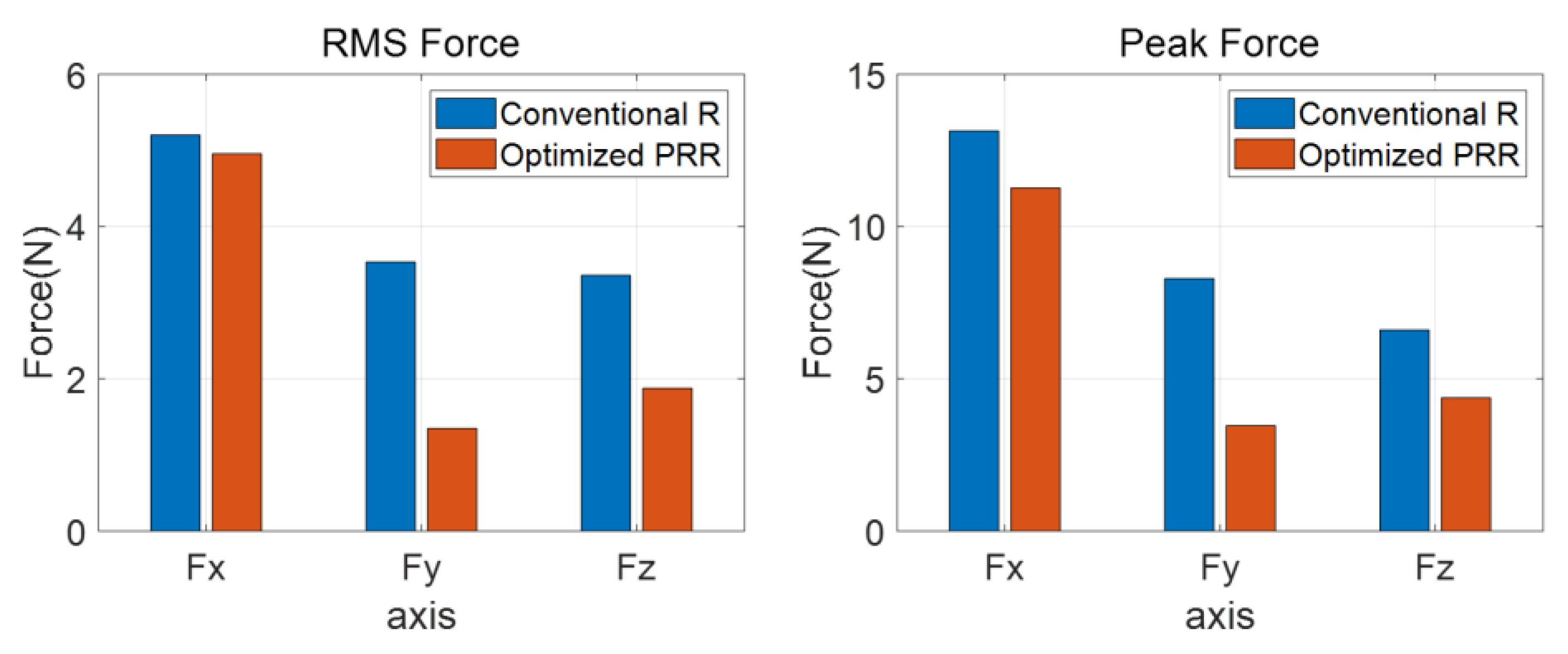

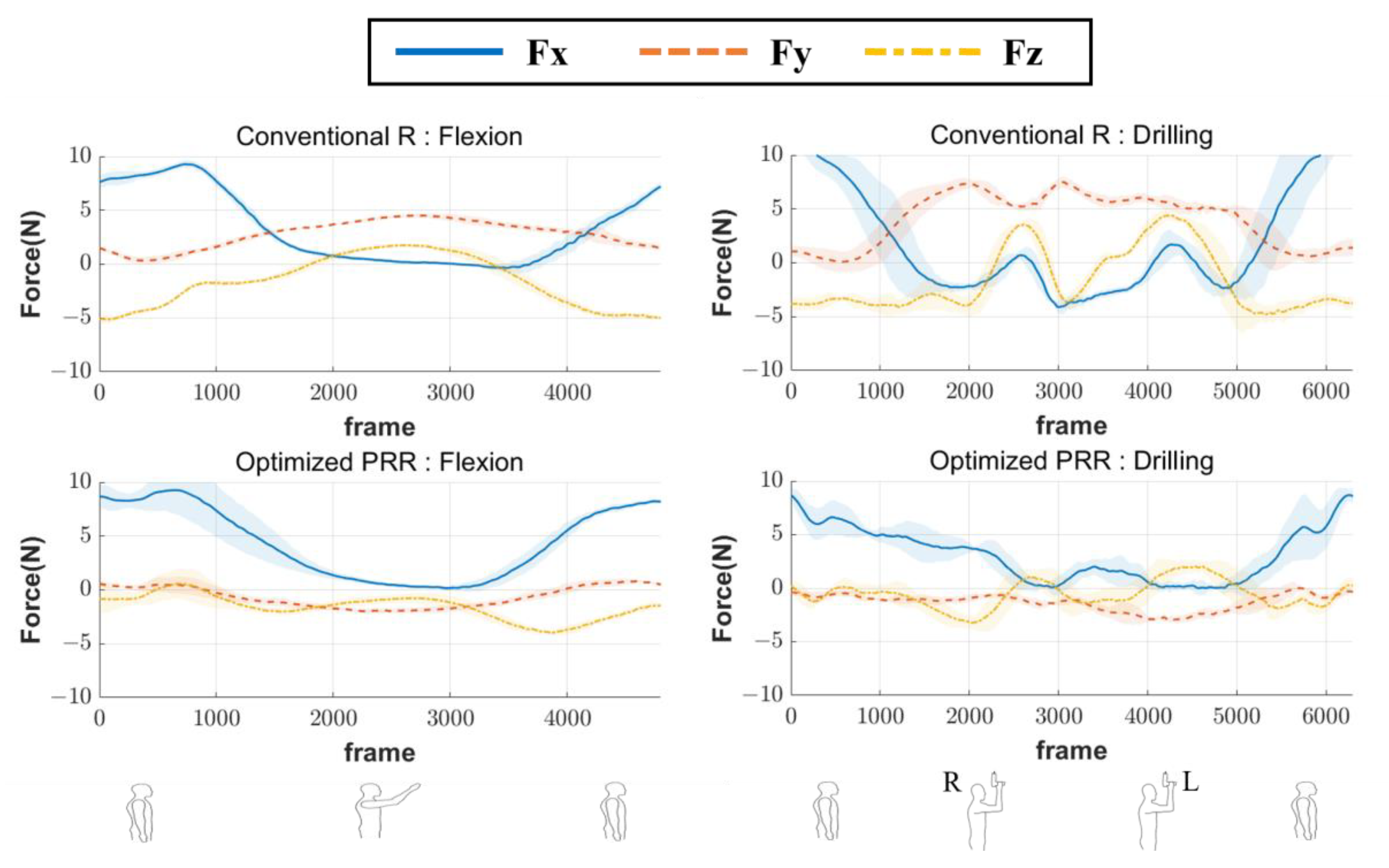

4.3. Experiment Result

5. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Coenen, P.; Gouttebarge, V.; van der Burght, A.S.; van Dieën, J.H.; Frings-Dresen, M.H.; van der Beek, A.J.; Burdorf, A. The effect of lifting during work on low back pain: A health impact assessment based on a meta-analysis. J. Occup. Environ. Med. 2014, 71, 871–877. [Google Scholar] [CrossRef] [PubMed]

- Nordander, C.; Hansson, G.Å.; Ohlsson, K.; Arvidsson, I.; Balogh, I.; Strömberg, U.; Skerfving, S. Exposure-response relationships for work-related neck and shoulder musculoskeletal disorders—Analyses of pooled uniform data sets. Appl. Ergon. 2016, 55, 70–84. [Google Scholar] [CrossRef] [PubMed]

- De Looze, M.P.; Bosch, T.; Krause, F.; Stadler, K.S.; O’sullivan, L.W. Exoskeletons for industrial application and their potential effects on physical work load. Ergonomics 2016, 59, 671–681. [Google Scholar] [CrossRef]

- Kim, S.; Nussbaum, M.A.; Esfahani, M.I.M.; Alemi, M.M.; Alabdulkarim, S.; Rashedi, E. Assessing the influence of a passive, upper extremity exoskeletal vest for tasks requiring arm elevation: Part I—“Expected” effects on discomfort, shoulder muscle activity, and work task performance. Appl. Ergon. 2018, 70, 315–322. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Hemming, D.; Luo, R.B.; Reynolds, J.; Delong, J.C.; Sandler, B.J.; Horgan, S. Solving the surgeon ergonomic crisis with surgical exosuit. Surg. Endosc. 2018, 32, 236–244. [Google Scholar] [CrossRef]

- Yan, H.; Yang, C.; Zhang, Y.; Wang, Y. Design and validation of a compatible 3-degrees of freedom shoulder exoskeleton with an adaptive center of rotation. J. Mech. Des. 2014, 136, 071006. [Google Scholar] [CrossRef]

- Zanotto, D.; Akiyama, Y.; Stegall, P.; Agrawal, S.K. Knee joint misalignment in exoskeletons for the lower extremities: Effects on userćs gait. IEEE Trans. Robot. 2015, 31, 978–987. [Google Scholar] [CrossRef]

- Schiele, A.; Van Der Helm, F.C. Kinematic design to improve ergonomics in human machine interaction. IEEE Trans. Neural Syst. Rehabil. Eng. 2006, 14, 456–469. [Google Scholar] [CrossRef]

- Wang, T.; Olivoni, E.; Spyrakos-Papastavridis, E.; O’Connor, R.J.; Dai, J.S. Novel design of a rotation center auto-matched ankle rehabilitation exoskeleton with decoupled control capacity. J. Mech. Des. 2022, 144, 053301. [Google Scholar] [CrossRef]

- Iranzo, S.; Piedrabuena, A.; Iordanov, D.; Martinez-Iranzo, U.; Belda-Lois, J.M. Ergonomics assessment of passive upper-limb exoskeletons in an automotive assembly plant. Appl. Ergon. 2020, 87, 103120. [Google Scholar] [CrossRef]

- Van Engelhoven, L.; Poon, N.; Kazerooni, H.; Rempel, D.; Barr, A.; Harris-Adamson, C. Experimental evaluation of a shoulder-support exoskeleton for overhead work: Influences of peak torque amplitude, task, and tool mass. IISE Trans. Occup. Ergon. Hum. Factors. 2019, 7, 250–263. [Google Scholar] [CrossRef]

- De Vries, A.; Murphy, M.; Könemann, R.; Kingma, I.; de Looze, M. The amount of support provided by a passive arm support exoskeleton in a range of elevated arm postures. IISE Trans. Occup. Ergon. Hum. Factors 2019, 7, 311–321. [Google Scholar] [CrossRef]

- Otten, B.M.; Weidner, R.; Argubi-Wollesen, A. Evaluation of a novel active exoskeleton for tasks at or above head level. IEEE Robot. Autom. Lett. 2018, 3, 2408–2415. [Google Scholar] [CrossRef]

- Nef, T.; Guidali, M.; Riener, R. ARMin III—Arm therapy exoskeleton with an ergonomic shoulder actuation. Appl. Bionics Biomech. 2009, 6, 127–142. [Google Scholar] [CrossRef]

- Hsieh, H.C.; Chen, D.F.; Chien, L.; Lan, C.C. Design of a parallel actuated exoskeleton for adaptive and safe robotic shoulder rehabilitation. IEEE ASME Trans. Mechatron. 2017, 22, 2034–2045. [Google Scholar] [CrossRef]

- Ergin, M.A.; Patoglu, V. ASSISTON-SE: A self-aligning shoulder-elbow exoskeleton. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–18 May 2012. [Google Scholar]

- Kim, B.; Deshpande, A.D. An upper-body rehabilitation exoskeleton harmony with an anatomical shoulder mechanism: Design, modeling, control, and performance evaluation. Int. J. Rob. Res. 2017, 36, 414–435. [Google Scholar] [CrossRef]

- Stienen, A.H.; Hekman, E.E.; Prange, G.B.; Jannink, M.J.; Aalsma, A.M.; van der Helm, F.C.; van der Kooij, H. Dampace: Design of an exoskeleton for force-coordination training in upper-extremity rehabilitation. J. Med. Dev. Trans. ASME 2009, 3, 031003. [Google Scholar] [CrossRef]

- Hyun, D.J.; Bae, K.; Kim, K.; Nam, S.; Lee, D.H. A light-weight passive upper arm assistive exoskeleton based on multi-linkage spring-energy dissipation mechanism for overhead tasks. Rob. Auton. Syst. 2019, 122, 103309. [Google Scholar] [CrossRef]

- Park, D.; Toxiri, S.; Chini, G.; Di Natali, C.; Caldwell, D.G.; Ortiz, J. Shoulder-sidewinder (shoulder-side wearable industrial ergonomic robot): Design and evaluation of shoulder wearable robot with mechanisms to compensate for joint misalignment. IEEE Trans. Robot. 2021, 38, 1460–1471. [Google Scholar] [CrossRef]

- Christensen, S.; Bai, S. Kinematic analysis and design of a novel shoulder exoskeleton using a double parallelogram linkage. J. Mech. Robot. 2018, 10, 041008. [Google Scholar] [CrossRef]

- Castro, M.N.; Rasmussen, J.; Andersen, M.S.; Bai, S. A compact 3-DOF shoulder mechanism constructed with scissors linkages for exoskeleton applications. Mech. Mach. Theory 2019, 132, 264–278. [Google Scholar] [CrossRef]

- Sarkisian, S.V.; Ishmael, M.K.; Lenzi, T. Self-aligning mechanism improves comfort and performance with a powered knee exoskeleton. IEEE Trans. Neural Syst. Rehabil. Eng. 2021, 29, 629–640. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Moon, J.; Ryu, J.; Lee, G. CVGC-II: A new version of a compact variable gravity compensator with a wider range of variable torque and energy-free variable mechanism. IEEE ASME Trans. Mechatron. 2021, 27, 678–689. [Google Scholar] [CrossRef]

- Näf, M.B.; Junius, K.; Rossini, M.; Rodriguez-Guerrero, C.; Vanderborght, B.; Lefeber, D. Misalignment compensation for full human-exoskeleton kinematic compatibility: State of the art and evaluation. Appl. Mech. Rev. 2018, 70, 050802. [Google Scholar] [CrossRef]

- Huysamen, K.; Power, V.; O’Sullivan, L. Kinematic and kinetic functional requirements for industrial exoskeletons for lifting tasks and overhead lifting. Ergonomics 2020, 63, 818–830. [Google Scholar] [CrossRef] [PubMed]

| Optimized Variables | |

|---|---|

| (m) | 0.040 |

| (m) | 0.080 |

| (m) | 0.0679 |

| (m) | 0.1678 |

| 5 | |

| Conventional R | Optimized PRR | |

|---|---|---|

| Mechanism | Over shoulder | Under shoulder |

| (mm) | 21.9039 | 3.1584 |

| 1 | 2.6718 |

| Conventional R | Optimized PRR | |

|---|---|---|

| RMSE of trajectory (mm) | 42.9561 | 16.3124 |

| PE of trajectory (mm) | 76.2605 | 33.8092 |

| 18.9 | 12.2 | |

| 50.0 | 25.7 |

| Conventional R | Optimized PRR | |

|---|---|---|

| RMSE of trajectory (mm) | 60.8039 | 19.1988 |

| PE of trajectory (mm) | 82.5807 | 31.2178 |

| 25.0 | 13.6 | |

| 35.9 | 28.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, J.; Kim, S.; Moon, J.; Kim, J.; Lee, G. Minimizing Misalignment and Frame Protrusion of Shoulder Exoskeleton via Optimization for Reducing Interaction Force and Minimizing Volume. Machines 2022, 10, 1223. https://doi.org/10.3390/machines10121223

Yoon J, Kim S, Moon J, Kim J, Lee G. Minimizing Misalignment and Frame Protrusion of Shoulder Exoskeleton via Optimization for Reducing Interaction Force and Minimizing Volume. Machines. 2022; 10(12):1223. https://doi.org/10.3390/machines10121223

Chicago/Turabian StyleYoon, Jihwan, Sumin Kim, Junyoung Moon, Jehyeok Kim, and Giuk Lee. 2022. "Minimizing Misalignment and Frame Protrusion of Shoulder Exoskeleton via Optimization for Reducing Interaction Force and Minimizing Volume" Machines 10, no. 12: 1223. https://doi.org/10.3390/machines10121223

APA StyleYoon, J., Kim, S., Moon, J., Kim, J., & Lee, G. (2022). Minimizing Misalignment and Frame Protrusion of Shoulder Exoskeleton via Optimization for Reducing Interaction Force and Minimizing Volume. Machines, 10(12), 1223. https://doi.org/10.3390/machines10121223