A 3D-Printed Continuously Variable Transmission for an Electric Vehicle Prototype †

Abstract

1. Introduction

2. Materials and Methods

2.1. The Competition Circuit and Basic Rules

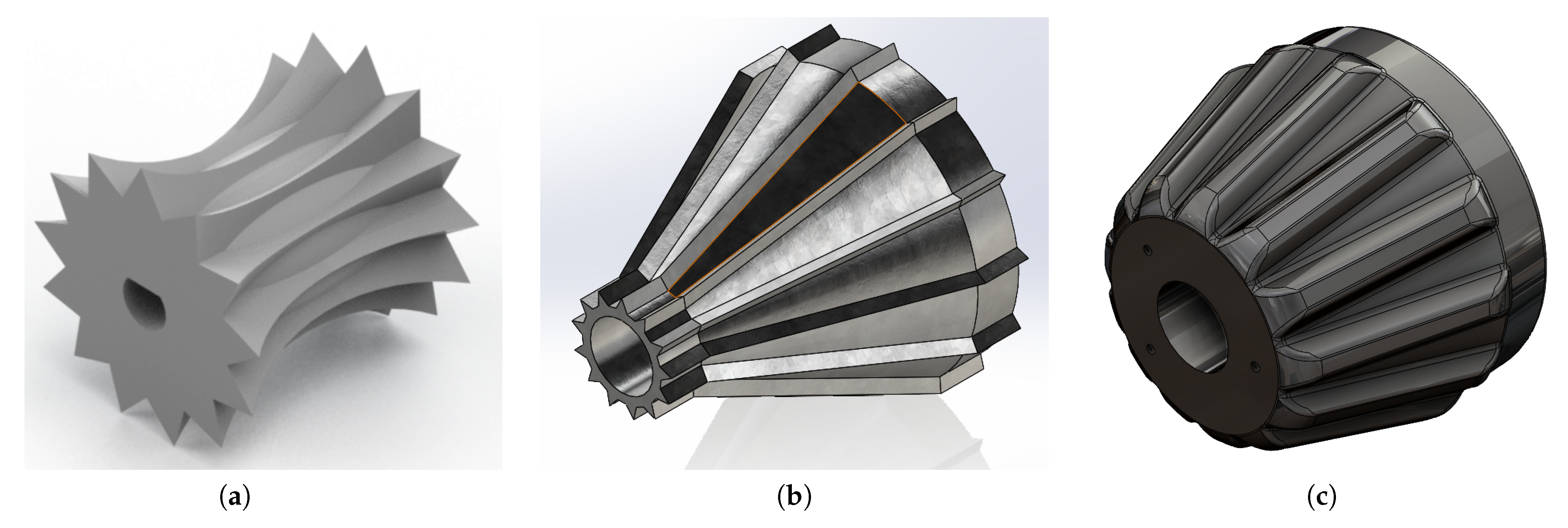

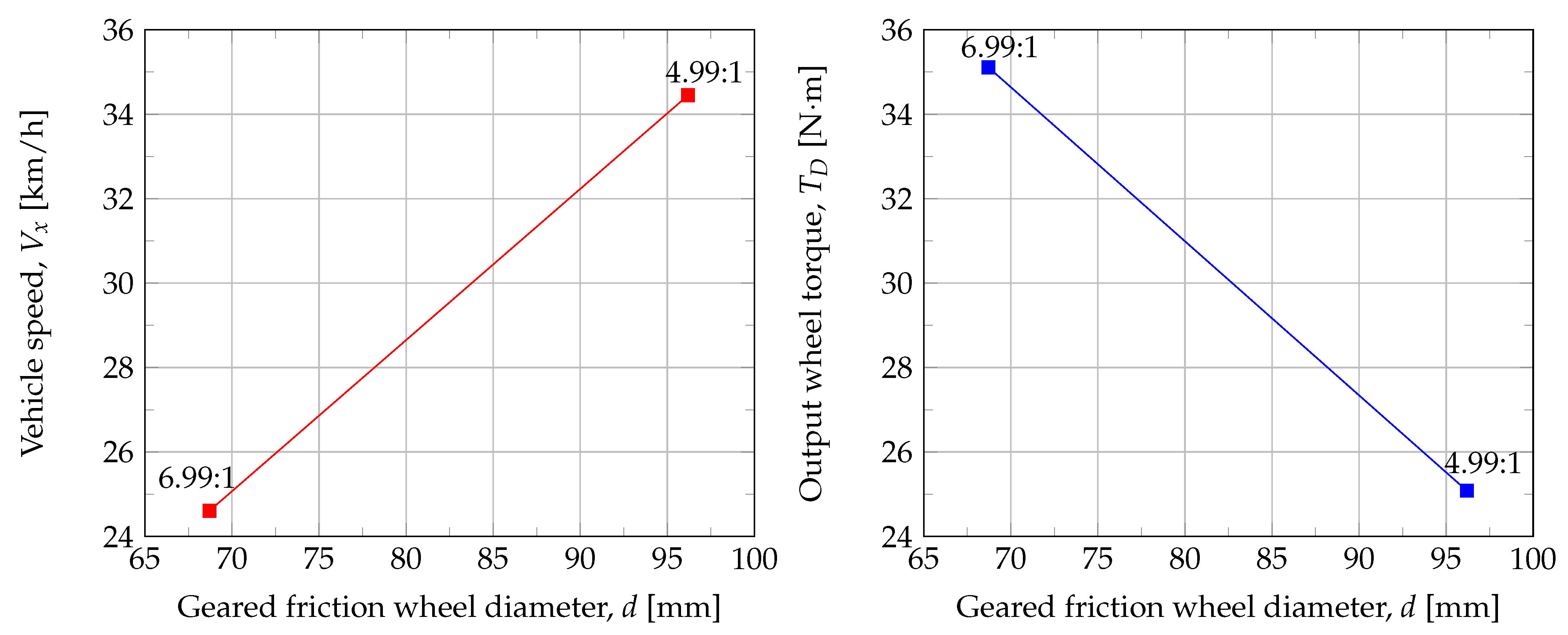

2.2. Transmission Concepts and Design

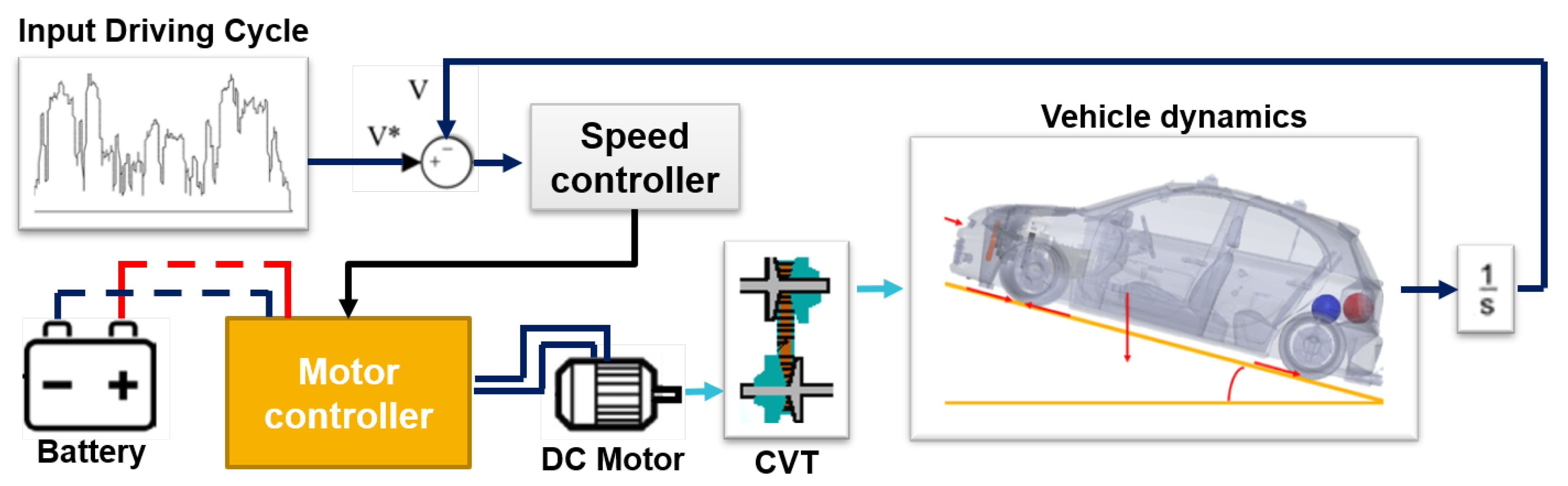

2.3. Vehicle Dynamic Model and Performance

2.4. 3D Printing Concepts and Methods

3. Results

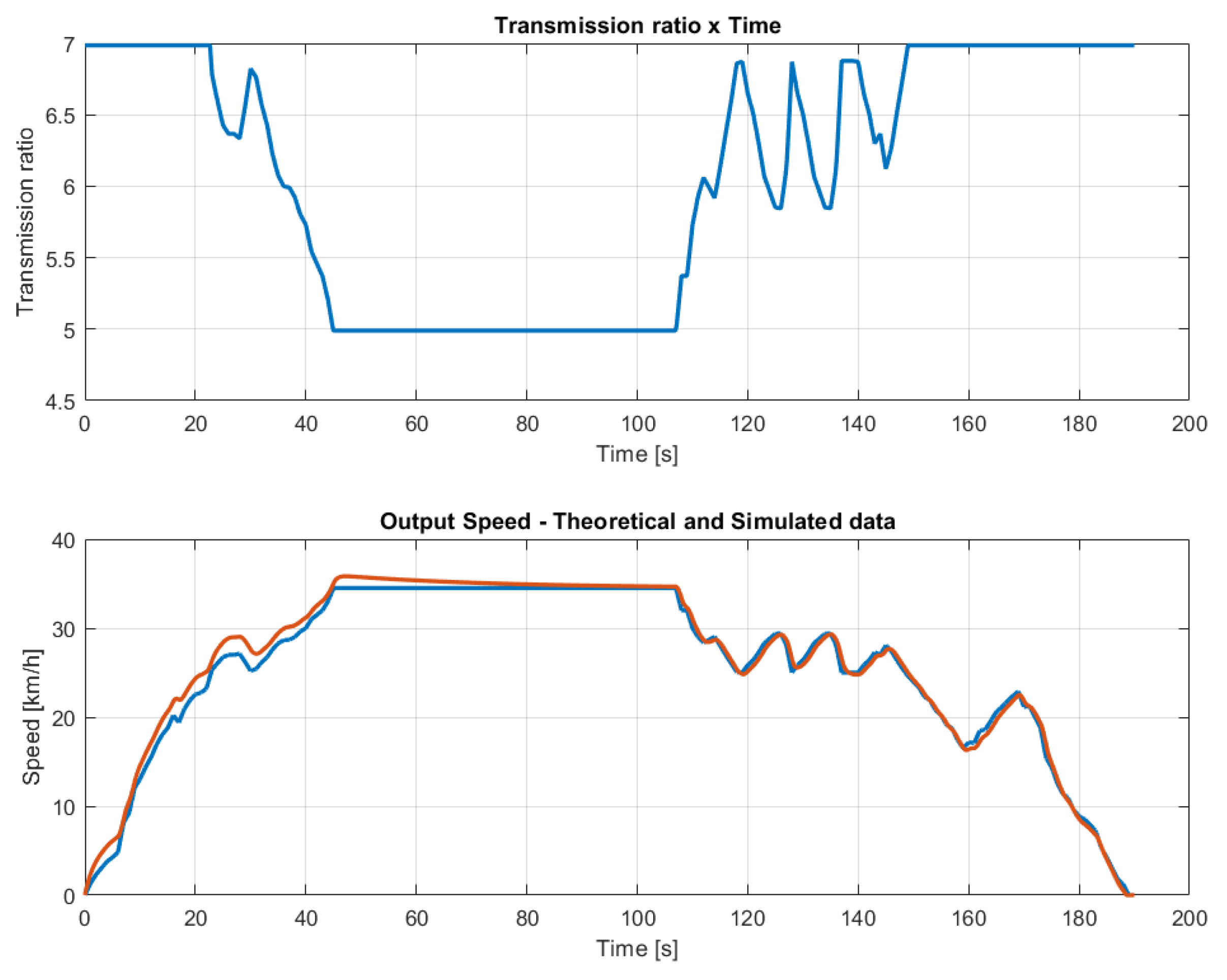

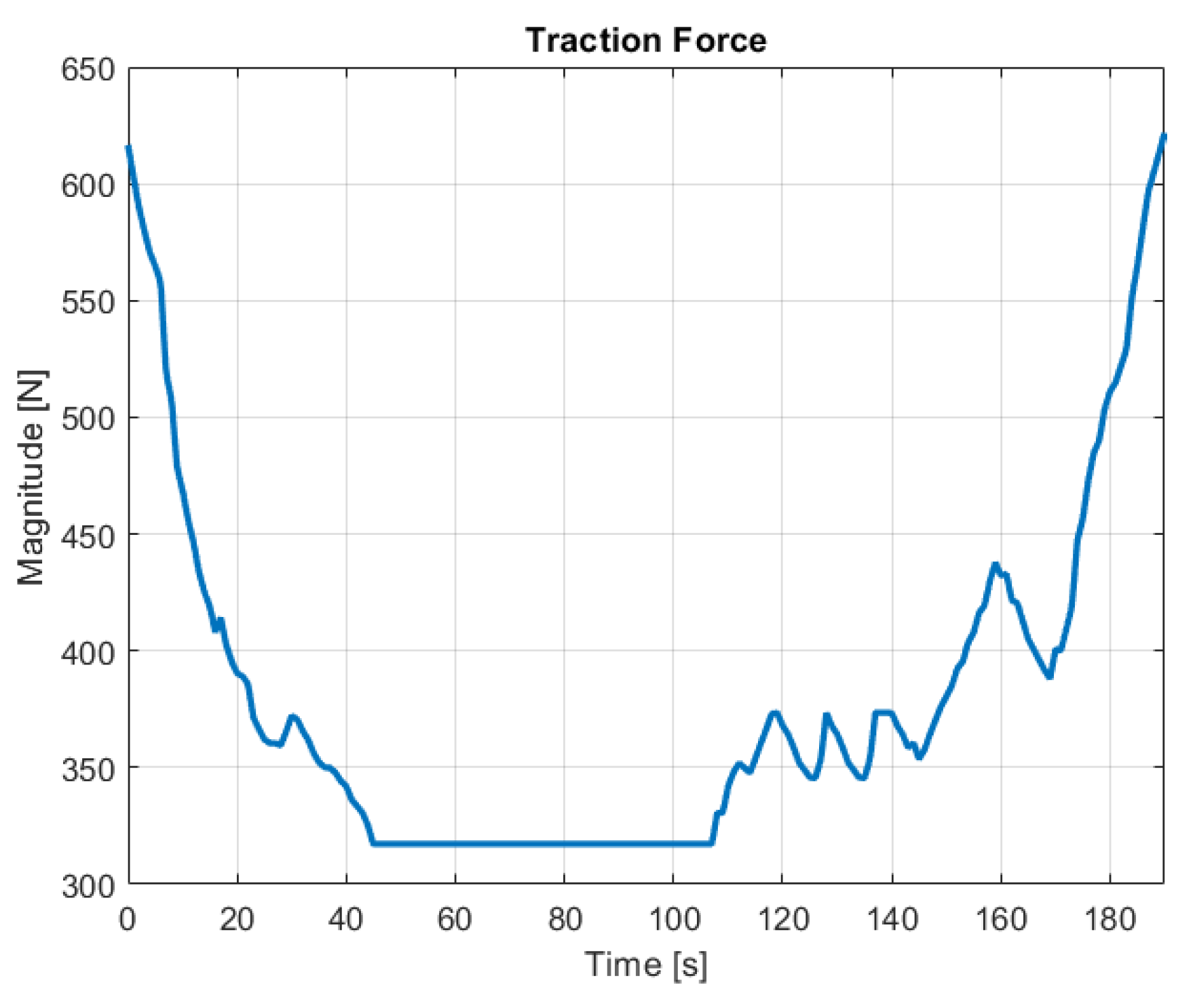

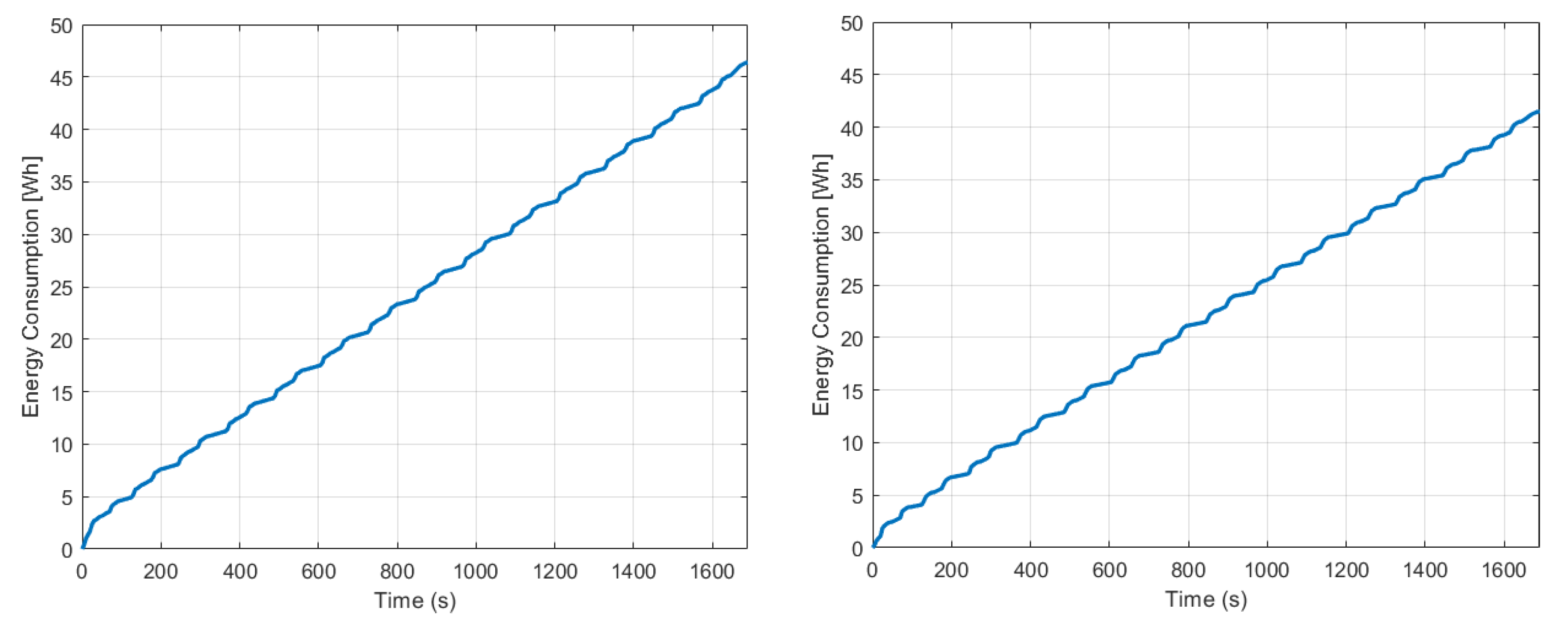

3.1. General Driving Cycle Simulation

3.2. Shell Eco-Marathon Circuit Driving Cycle Simulation

3.3. 3D Printing Optimization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reddy, K.J.; Natarajan, S. Energy sources and multi-input DC-DC converters used in hybrid electric vehicle applications—A review. Int. J. Hydrogen Energy 2018, 43, 17387–17408. [Google Scholar] [CrossRef]

- Miyamoto, M.; Takeuchi, K. Climate agreement and technology diffusion: Impact of the Kyoto Protocol on international patent applications for renewable energy technologies. Energy Policy 2019, 129, 1331–1338. [Google Scholar] [CrossRef]

- Alnunu, N.; Said, S.; Al-Sharman, S.; Al-Ibrahimi, A.; AbdulAziz, A.; Hellabi, M.A.; Touati, F.; Ghani, S.; Mahdi, E.S.; Benammar, M. Design of Qatar University’s first solar car for Shell Eco-Marathon competition. In Proceedings of the 2012 First International Conference on Renewable Energies and Vehicular Technology, Nabeul, TN, USA, 26–28 March 2012; pp. 49–54. [Google Scholar] [CrossRef]

- Baldissera, P.; Delprete, C. Human powered vehicle design: A challenge for engineering Education. ASME ESDA2014-20549. In Proceedings of the ASME 2014 12th Biennial Conference on Engineering Systems Design and Analysis, Copenhagen, Denmark, 25–27 July 2014. [Google Scholar] [CrossRef]

- Buck, L.; Mclening, C.; Burgess, J. Eco-car: A perfect vehicle for technical design teaching? In Proceedings of the 16th International Conference on Engineering and Product Design Education (E&PDE14), Design Education and Human Technology Relations, University of Twente, Enschede, The Netherlands, 4–5 September 2014. [Google Scholar]

- Abdulwahed, M.; Ahmad, S.; Hasna, M.O.; Ghani, S.; Benammar, M. Contribution of Shell Eco-Marathon engineering design experience to soft skills development: A qualitative analysis in the Asian context. In Proceedings of the 2014 International Conference on Interactive Collaborative Learning (ICL), Dubai, United Arab Emirates, 3–6 December 2014. [Google Scholar] [CrossRef]

- von Solms, S.; Nel, H. Reflective learning in engineering education: A case study of shell Eco-Marathon. In Proceedings of the 2017 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 10–13 December 2017. [Google Scholar] [CrossRef]

- Verma, A.R.; Chaurasia, A.; Jaiswal, S.S.; Bhonde, L.; Guha, R.; Sahu, H.; Patel, S.; Banthiya, S.; Maddeshiya, S.; Mirzapure, S.; et al. Team AVERERA’s Alterno V4.0–A Hyper Energy-Efficient Electric Prototype Vehicle for Shell Eco-Marathon; SAE Technical Paper 2021-01-0792; SAE International: Warrendale, PA, USA, 2021. [Google Scholar] [CrossRef]

- Fabian, M.; Puškár, M.; Boslai, R.; Kopas, M.; Kender, Š.; Huňady, R. Design of experimental vehicle specified for competition Shell Eco-marathon 2017 according to principles of car body digitisation based on views in 2D using the intuitive tool Imagine&Shape CATIA V5. Adv. Eng. Softw. 2018, 115, 413–428. [Google Scholar] [CrossRef]

- Gunadi; Fergianto, F. Designing Shell Eco-Marathon car bodies with SolidWorks. J. Physics Conf. Ser. 2020, 1700, 012072. [Google Scholar] [CrossRef]

- Ary, A.K.; Sanjaya, Y.; Prabowo, A.R.; Imaduddin, F.; Nordin, N.A.B.; Istanto, I.; Cho, J.H. Numerical estimation of the torsional stiffness characteristics on urban Shell Eco-Marathon (SEM) vehicle design. Curved Layer. Struct. 2021, 8, 167–180. [Google Scholar] [CrossRef]

- Brusaglino, G.; Buja, G.; Carello, M.; Carlucci, A.; Onder, C.; Razzetti, M. New technologies demonstrated at Formula Electric and Hybrid Italy 2008. World Electr. Veh. J. 2009, 3, 160–171. [Google Scholar] [CrossRef]

- Carello, M.; Bertipaglia, A.; Messana, A.; Airale, A.G.; Sisca, L. Modeling and Optimization of the Consumption of a Three-Wheeled Vehicle; SAE Technical Pape 2019-01-0164; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Gechev, T.; Punov, P. Driving strategy for minimal energy consumption of an ultra-energy-efficient vehicle in Shell Eco-Marathon competition. IOP Conf. Ser. Mater. Sci. Eng. 2020, 1002, 012018. [Google Scholar] [CrossRef]

- Punov, P.; Gechev, T. Energy management of a fuel cell hybrid ultra-energy efficient vehicle. Int. J. Hydrogen Energy 2021, 46, 20291–20302. [Google Scholar] [CrossRef]

- Stabile, P.; Ballo, F.; Mastinu, G.; Gobbi, M. An ultra-efficient lightweight electric vehicle—Power demand analysis to enable lightweight construction. Energies 2021, 14, 766. [Google Scholar] [CrossRef]

- Wasselynck, G.; Auvity, B.; Olivier, J.C.; Trichet, D.; Josset, C.; Maindru, P. Design and testing of a fuel cell powertrain with energy constraints. Energy 2012, 38, 414–424. [Google Scholar] [CrossRef]

- Cichoński, K.; Jezierska-Krupa, K.; Gleń, M.; Skarka, W. The comparative study of drivetrain of high-performance electric vehicle. Diagnostyka 2014, 15, 65–70. [Google Scholar]

- Nassif, G.G.; de Almeida, S.C. Impact of powertrain hybridization on the performance and costs of a fuel cell electric vehicle. Int. J. Hydrogen Energy 2020, 45, 21722–21737. [Google Scholar] [CrossRef]

- Carello, M.; Pinheiro, H.C.; Longega, L.; Di Napoli, L. Design and Modelling of the Powertrain of a Hybrid Fuel Cell Electric Vehicle; SAE Technical Pape 2021-01-0734; SAE International: Warrendale, PA, USA, 2021. [Google Scholar] [CrossRef]

- Messana, A.; Sisca, L.; Ferraris, A.; Airale, A.; de Carvalho Pinheiro, H.; Sanfilippo, P.; Carello, M. From Design to Manufacture of a Carbon Fiber Monocoque for a Three-Wheeler Vehicle Prototype. Materials 2019, 12, 332. [Google Scholar] [CrossRef]

- Sethi, N.; Chauhan, P.; Bansal, S.; Singari, R.M. Robust vehicle development for student competitions using fiber-reinforced composites. In Lecture Notes in Mechanical Engineering; Springer: Singapore, 2021; pp. 61–76. [Google Scholar] [CrossRef]

- Ferraris, A.; Messana, A.; Multari, D.; Sisca, L.; Airale, A.G.; Carello, M. Steering System of a Low-Consumption Vehicle: From the Dynamics Analysis to the Design of the Wheel Assembly. In Advances in Italian Mechanism Science. IFToMM ITALY 2018. Mechanisms and Machine Science; Carbone, G., Gasparetto, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; Volume 68, pp. 91–99. [Google Scholar] [CrossRef]

- Zhai, G.; Liang, Z.; Li, M. Study on the Optimization Model of a Flexible Transmission. Math. Probl. Eng. 2019, 2019, 1–12. [Google Scholar] [CrossRef]

- Iliev, S.; Gunev, D.; Mitev, E. Design and Development of a Steering Wheel for an Energy Efficient Vehicle. In Proceedings of the International Symposium on Intelligent Manufacturing and Automation, Vienna, Austria, 23–26 November 2019; pp. 0405–0414. [Google Scholar] [CrossRef]

- Kral, J.; Palko, M.; Palko, M.; Pavlikova, L. Design and development of ultra-light front and rear axle of experimental vehicle. Open Eng. 2020, 10, 232–237. [Google Scholar] [CrossRef]

- Gilewski, M.; Czarnigowski, J.; Górski, W.; Mitrus, K.; Różyło, P.; Trocha, S.; Wypychowski, M. Strength analysis of the drive wheel hub of a hydrogen-powered prototype hyper-light vehicle. J. Phys. Conf. Ser. 2021, 1736, 012056. [Google Scholar] [CrossRef]

- Soto, P.A.; Collet, M.; Bauduin, S.; Fernandez Sanchez, E.F.; Aguilera, A.M.; Duysinx, P. Topology optimization of mechanical components fabricated by additive manufacturing for a Shell Eco-Marathon vehicle. In Proceedings of the 12th World Congress of Structural and Multidisciplinary Optimisation, Braunschweig, Germany, 5–9 June 2017. [Google Scholar]

- Hands, C.H.; du Plessis, A.; Minnaar, N.; Blakey-Milner, B.A.; Burger, E. Can Additive Manufacturing Help Win the Race? Preprints 2018, 2018110040. [Google Scholar] [CrossRef]

- Sosnowski, M.; Skarka, W. Optimization of a Composite Beam-Based Load Bearing Structure, for an Ultra-Efficient Electric Vehicle. In EngOpt 2018 Proceedings of the 6th International Conference on Engineering Optimization; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1073–1082. [Google Scholar] [CrossRef]

- Yankov, E.; Kamarinchev, D.; Minev, R.; Minev, E. Optimal Build Inclination in 3d Printing–Shell Eco–Marathon Rapid Prototyping Car Parts Case7. Proc. Univ. Ruse 2019, 58, 51–58. [Google Scholar]

- Junk, S.; Dorner, M.; Fleig, C. Additive Manufacturing of Continuous Carbon Fiber-Reinforced Plastic Components. In Sustainable Design and Manufacturing 2020; Scholz, S.G., Howlett, R.J., Setchi, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 149–159. [Google Scholar] [CrossRef]

- Kılıç, A.E. Redesign of Drivetrain Component of a Shell Eco-Marathon Vehicle for Additive Manufacturing via Topology Optimization. Master’s Thesis, Piri Reis Üniversitesi, Tuzla/Istanbul, Turkey, 2020. [Google Scholar]

- Pagerit, S.; Sharer, P.; Rousseau, A. Fuel Economy Sensitivity to Vehicle Mass for Advanced Vehicle Powertrains; SAE Technical Paper 2006-01-0665; SAE International: Warrendale, PA, USA, 2006. [Google Scholar] [CrossRef]

- Merschak, S.; Hehenberger, P.; Schmidt, S.; Kirchberger, R. Considerations of Life Cycle Assessment and the Estimate of Carbon Footprint of Powertrains; SAE Technical Paper 2020-32-2314; SAE International: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Vaughan, N. Transmission and Driveline: Introduction. In Encyclopedia of Automotive Engineering; Crolla, D., Foster, D., Kobayashi, T., Vaughan, N., Eds.; Wiley: Hoboken, NJ, USA, 2014; p. 11. [Google Scholar] [CrossRef]

- Srivastava, N.; Haque, I. A review on belt and chain continuously variable transmissions (CVT): Dynamics and control. Mech. Mach. Theory 2009, 44, 19–41. [Google Scholar] [CrossRef]

- van Spijk, J.; Englisch, A. The Variable Pulley CVT. In Encyclopedia of Automotive Engineering; Crolla, D., Foster, D., Kobayashi, T., Vaughan, N., Eds.; Wiley: Hoboken, NJ, USA, 2014; p. 17. [Google Scholar] [CrossRef]

- Tanaka, H. Traction Drive CVT. In Encyclopedia of Automotive Engineering; Crolla, D., Foster, D., Kobayashi, T., Vaughan, N., Eds.; Wiley: Hoboken, NJ, USA, 2014; p. 10. [Google Scholar] [CrossRef]

- Wikipedia. Continuously Variable Transmission—Wikipedia, The Free Encyclopedia. 2021. Available online: http://en.wikipedia.org/w/index.php?title=Continuously%20variable%20transmission&oldid=1035194623 (accessed on 3 August 2021).

- Setlur, P.; Wagner, J.; Dawson, D.; Samuels, B. Nonlinear control of a continuously variable transmission (CVT). IEEE Trans. Control. Syst. Technol. 2003, 11, 101–108. [Google Scholar] [CrossRef]

- Shibayama, T. CVT Control–System Integration, Ratio Choice, Shift Strategy and Dynamics, Adaptive Features, Engine Calibration, Electric Motor Assist. In Encyclopedia of Automotive Engineering; Crolla, D., Foster, D., Kobayashi, T., Vaughan, N., Eds.; Wiley: Hoboken, NJ, USA, 2014; p. 19. [Google Scholar] [CrossRef]

- Lazarek, M.; Brzeski, P.; Perlikowski, P. Design and modeling of the CVT for adjustable inerter. J. Frankl. Inst. 2019, 356, 7611–7625. [Google Scholar] [CrossRef]

- Yao, M.; Qin, D.; Zhou, X.; Zhan, S.; Zeng, Y. Integrated optimal control of transmission ratio and power split ratio for a CVT-based plug-in hybrid electric vehicle. Mech. Mach. Theory 2019, 136, 52–71. [Google Scholar] [CrossRef]

- Nihari, Y.; Gonzalez, V.L.; Rodrigues, G.S.; Lopes, E.D.R. Performance Comparison between Passenger’s Vehicles Using Manual Transmission and CVT Systems; SAE Technical Pape 2020-36-0171; SAE International: Warrendale, PA, USA, 2021. [Google Scholar] [CrossRef]

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Hor. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Agapovichev, A.V.; Balaykin, A.V.; Smelov, V.G. Production technology of the internal combustion engine crankcase using additive technologies. Mod. Appl. Sci. 2015, 9, 335–343. [Google Scholar] [CrossRef]

- Gray, J.; Depcik, C. Review of additive manufacturing for internal combustion engine components. SAE Int. J. Engines 2020, 13, 617–632. [Google Scholar] [CrossRef]

- Ehsani, M.; Gao, Y.; Longo, S.; Ebrahimi, K.M. Modern Electric, Hybrid Electric, and Fuel Cell Vehicles, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar] [CrossRef]

- Minaker, B.P. Fundamentals of Vehicle Dynamics and Modelling: A Textbook for Engineers With Illustrations and Examples; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Gillespie, T.D. Fundamentals of Vehicle Dynamics; Society of Automotive Engineers: Warrendale, PA, USA, 1992. [Google Scholar]

- Faria, J.B.; Toledo, J.A.; Barbosa, T.P. Modelagem Computacional de um Veículo Elétrico para Competição de Eficiência Energética. Anais do XXIII Congresso Brasileiro de Automática. Soc. Bras. Autom. 2020, 2, 1. [Google Scholar] [CrossRef]

- Barbosa, T.P.; da Silva, L.A.R.; Pujatti, F.J.P.; Gutiérrez, J.C.H. Hydraulic hybrid passenger vehicle: Fuel savings possibilities. Mech. Based Des. Struct. Mach. 2020, 1–19. [Google Scholar] [CrossRef]

| Output wheel diameter, D [mm] | 480 |

| Vehicle + pilot mass, m [kg] | 100 |

| Frontal area, [m] | 0.49 |

| Drag coefficient, | 0.3 |

| Rolling resistance coefficient, | 0.0015 |

| Air density, [kg/m] | 1.2 |

| Gravity, g [m/s] | 9.81 |

| Properties | ABS | PLA | PETG |

|---|---|---|---|

| Tensile modulus [MPa] | 1335 | 1896 | 1067 |

| Yield strength [MPa] | 14.7 | 24.8 | 18.6 |

| Ultimate strength [MPa] | 29 | 46 | 32.6 |

| Strain at break [%] | 7.08 | 3.69 | 7.74 |

| Specific weight [g/cm] | 1.04 | 1.24 | 1.27 |

| Build plate temperature [°C] | 100–110 | 60–80 | 60–80 |

| Printing temperature [°C] | 220–245 | 190–210 | 220–245 |

| Printing speed [mm/s] | 60–100 | 60–100 | 40–60 |

| Parameters | Initial Settings | Optimized Settings | ||

|---|---|---|---|---|

| Extruder | Local Reinforcements | Extruder | Local Reinforcements | |

| Top and bottom layers | 3 | - | 4 | 3 |

| Infill density [%] | 100 | - | 35 | 85 |

| Wall thickness [mm] | 0.6 | - | 0.6 | 0.6 |

| Wall line counting | 3 | - | 2 | 3 |

| Results | ||||

| Mass [g] | 437.2 | 386.7 | ||

| Max displacement [mm] | 0.24 | 0.28 | ||

| Printing time | 22 h 57 min | 23 h 36 min | ||

| Factor of safety | 3.92 | 3.24 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coimbra, M.R.C.; Barbosa, T.P.; Vasques, C.M.A. A 3D-Printed Continuously Variable Transmission for an Electric Vehicle Prototype. Machines 2022, 10, 84. https://doi.org/10.3390/machines10020084

Coimbra MRC, Barbosa TP, Vasques CMA. A 3D-Printed Continuously Variable Transmission for an Electric Vehicle Prototype. Machines. 2022; 10(2):84. https://doi.org/10.3390/machines10020084

Chicago/Turabian StyleCoimbra, Marcos R. C., Társis P. Barbosa, and César M. A. Vasques. 2022. "A 3D-Printed Continuously Variable Transmission for an Electric Vehicle Prototype" Machines 10, no. 2: 84. https://doi.org/10.3390/machines10020084

APA StyleCoimbra, M. R. C., Barbosa, T. P., & Vasques, C. M. A. (2022). A 3D-Printed Continuously Variable Transmission for an Electric Vehicle Prototype. Machines, 10(2), 84. https://doi.org/10.3390/machines10020084