Abstract

Flexible joints are widely used in ‘soft’ touching and holding, and they represent the main component of ultra-short radius drilling tools. The analysis of contact and motion characteristics is an essential issue in the design and development stage of flexible joints. In this study, a collision dynamics model of a ball cage flexible joint (BCFJ), which is suitable for the characteristics of small clearance and large load, is established. The model contains a nonlinear stiffness coefficient and can describe the contact force between the ball key and the raceways. Moreover, the computational procedure for the dynamic analysis of BCFJ with clearance is established, and the dynamic simulation for collision and contact between ball, cage, outer race, and inner race was carried out. By numerical calculation, the variation of contact force on the five contact points of the ball key and ball cage is discussed, and the influence of ball cage clearance on contact force between ball key, ball seat, and ball cage is obtained. The results indicate that the effects of the ball cage clearance on the contact force cannot be ignored, which is the main cause for the vibration of the flexible joint system, and the amplitude of the contact force will gradually increase with the increase of the clearance. The proposed model and procedure can analyze the dynamic behavior of flexible joints with small clearance and large load, providing a basis for further research on wear prediction and safety evaluation of the BCFJ with clearance.

1. Introduction

Ultra-short radius drilling technology is an effective means to develop special oil and gas reservoirs and remaining oil reservoirs [1]. It is widely used in oilfield production due to its many advantages, such as small radius of curvature (the curvature radius is usually 1–4 m), low drilling cost, and short construction period. Flexible drilling pipe is the main tool used in ultra-short radius wellbores, and different from the conventional drill pipe structure, it is a multi-body mechanism and mainly composed of multiple hinged flexible joints. The motion process of the flexible joint is mainly the rotational collision of the multi-body mechanism, and its motion characteristics are closely related to the clearance and nonlinear contact. Therefore, it is very important to establish a collision dynamics model of flexible joint that considers the clearance, which is the basis for analyzing the stability and reliability of the system.

The ball cage flexible drill pipe is the key to realize ultra-short radius drilling technology. The articulated structure between multiple flexible joints can form a very small radius of curvature during drilling. Based on this feature, ultra-short radius drilling technology can achieve accurate directional production in the process of oil and gas reservoir exploitation, and has higher efficiency than conventional drilling technology. In addition, the ball-cage flexible sub is designed based on the principle of a ball-cage constant speed universal joint. Firstly, the ball-cage flexible sub can realize complete constant speed transmission and can restrain the vibration and impact of a multi-body structure caused by the change of speed and torque. Secondly, the ball cage type flexible sub has high transmission efficiency, small power loss, compact structure, and small occupation space. Furthermore, the ball cage type flexible sub has a large swing angle, up to 70 degrees, which is suitable for the small radius of curvature drilling. Therefore, the study of ball cage flexible drill pipe has important theoretical and practical significance.

When the mechanism is in contact with fluids, such as oil and gas, in addition to the effect of the fluid itself on the mechanism [2,3,4], the clearance inside the mechanism will also affect the stability of the mechanism. The existence of clearance in the mechanism is inevitable, and that will lead to collision and contact in the process of mechanism movement, resulting in vibration and impact, which will cause the failure and wear of the mechanism [5,6]. To solve this problem, scholars have conducted many studies on the collision dynamics of multi-body mechanisms with clearance.

The difficulty in establishing the dynamics model of a multi-body mechanism with clearance lies in how to describe the clearance reasonably and introduce it into the model. Flores et al. [7] and Bing and Ye [8] introduced the clearance vector into the hinge with clearance to describe the precise position between the component of mechanisms. The method is widely used in many models. Based on the improved contact force model and the modified Coulomb friction model, Wang et al. [9] developed a dynamics model of the crank-slider mechanism considering the clearance, and further studied the effects of clearance size, crank speed, and hinge material on the dynamic response of the system. Sun et al. [10] used the Lankarani–Nikravesh contact force model to describe the clearance hinge and analyzed the motion accuracy of the crank-slider system with hinge clearance. Qu et al. [11] described the contact force of the hinge with clearance by using the Flores contact force model and the Lucre friction force model, and studied the influence of the position, size, and number of the hinge gap on the dynamic characteristics of the deployable planar X-shaped structure. Chen et al. [12] developed a nonlinear dynamics model of a nine-link mechanical system considering the hinge clearance and connecting rod flexibility by using the Lagrangian method and studied the influence of crank clearance value and driving speed on the dynamic characteristics of system. By using the floating coordinate method and the assumed mode method, Salahshoor et al. [13] established a dynamics model of the crank-slider mechanism considering the flexibility of the components and the hinge clearance and studied the influence of hinge clearance on its vibration characteristics. Hou et al. [14] drew a bifurcation diagram of the system corresponding to different clearance sizes and friction coefficients.

Based on the above dynamic models of the mechanism with clearance, scholars further conducted a comparative study on the collision force model and friction model caused by the clearance. The continuous contact force model, which equals the collision between multi-body systems in a spring damping model, is the most commonly used collision contact model. Moreover, the objects in contact collision can invade each other by setting stiffness and penetration depth [15]. Hunt and Crossley [16] proposed a contact force model with a nonlinear spring damping term by combining Hertz contact theory with the momentum theorem and introducing a collision recovery coefficient. Lankarani and Nikravesh [17] improved Hunt’s contact force model and developed a more accurate model (Lankarani–Nikravesh collision contact model), but the collision recovery coefficient in this model is high. Therefore, Flores et al. [18] proposed a new model with low coefficient of restitution. Considering the hinge clearance between multi-body mechanisms, Luka et al. [19] and Gummer and Sauer [20] presented a contact impact force model with pin slot clearance on the basis of L-N contact model. The above collision force model was based on the point contact theory, and these models are only suitable for conditions where the contact area is small and the recovery coefficient is close to 1. Therefore, Bai and Zhao [21] and Wang et al. [22] studied the improved contact force model, respectively, and proposed the models suitable for large gap, small load, and small recovery coefficient. The mechanism with clearance has also been applied in ultra-short radius drilling tools. Luo et al. [1,23] designed the cross-shaft flexible joint and studied the contact force of flexible drilling tools based on the Lankarani–Nikravesh model.

In this work, aiming at a new ultra-short radius drilling tool, the ball-cage flexible sub proposed by the working group, a collision dynamic model and analysis program are established. The program is suitable for solving the collision problem of a multi-body mechanism with small clearance in flexible sub under the action of large load (bit weight and rotational speed) in the ultra-short radius drilling process. In addition, the model and program provide a foundation for further research concerning the wear prediction and safety evaluation of ball cage flexible joints. This study provides a good method for improving the applicability of ball cage flexible sub.

The BCFJ is designed based on the previous research [24,25]. Due to the influence of ultra-short radius wellbore and weight on bit, the rotating mechanism of the BCFJ has the characteristics of small clearance and large load. In order to solve this problem, the nonlinear stiffness coefficient is introduced in the Lankarani–Nikravesh model to establish a collision dynamic model suitable for small clearance and large load. Based on the new model, the variation of multi-body contact force during ultra-short radius drilling is analyzed and the results are helpful for the stability and reliability analysis of flexible drilling tools. The remainder of this paper is organized as follows. In Section 2, we introduce the structure of the BCFJ. In Section 3, the collision dynamics model considering ball cage clearance is established. In Section 4, the variation of contact force on different positions of BCFJ is studied. In Section 5, some conclusions about this work are summarized.

2. Structure of BCFJ

A new type of BCFJ is proposed based on the working principle of the ball cage universal joint. Compared with the cross shaft universal joint commonly used for flexible drilling pipe, the advantages of ball cage flexible drilling pipe are high transmission efficiency, large swing angle amplitude, low wear degree, and low energy loss [23].

Table 1 shows the structural components of the ball cage flexible drilling pipe. The structure is composed of three parts: upper three connections, lower three connections, and flexible joints. Moreover, there are flexible joints in the middle of the structure, which are identical. Each part is connected by a constant velocity universal joint that contains ball cage and ball keys. The length of the flexible joint is designed according to the curvature radius of the hole and the size of flexible drilling pipe, and it can be described as [24,26].

where l is the length of flexible joint, R is the curvature radius of wellbore, C is the minimum clearance between flexible drilling pipe and wellbore, and d is the outer radius of the flexible joint.

Table 1.

Structure components of ball cage flexible drilling pipe.

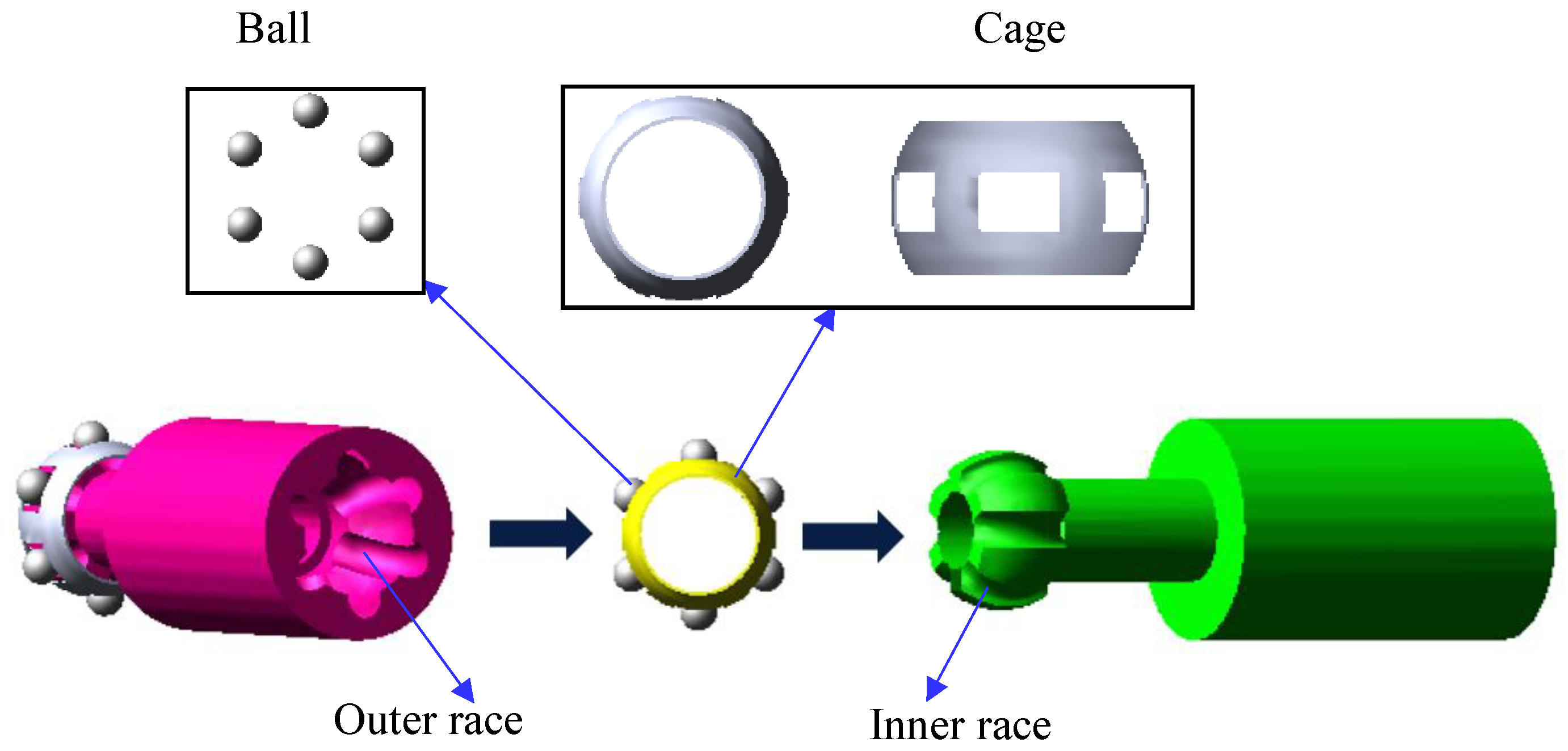

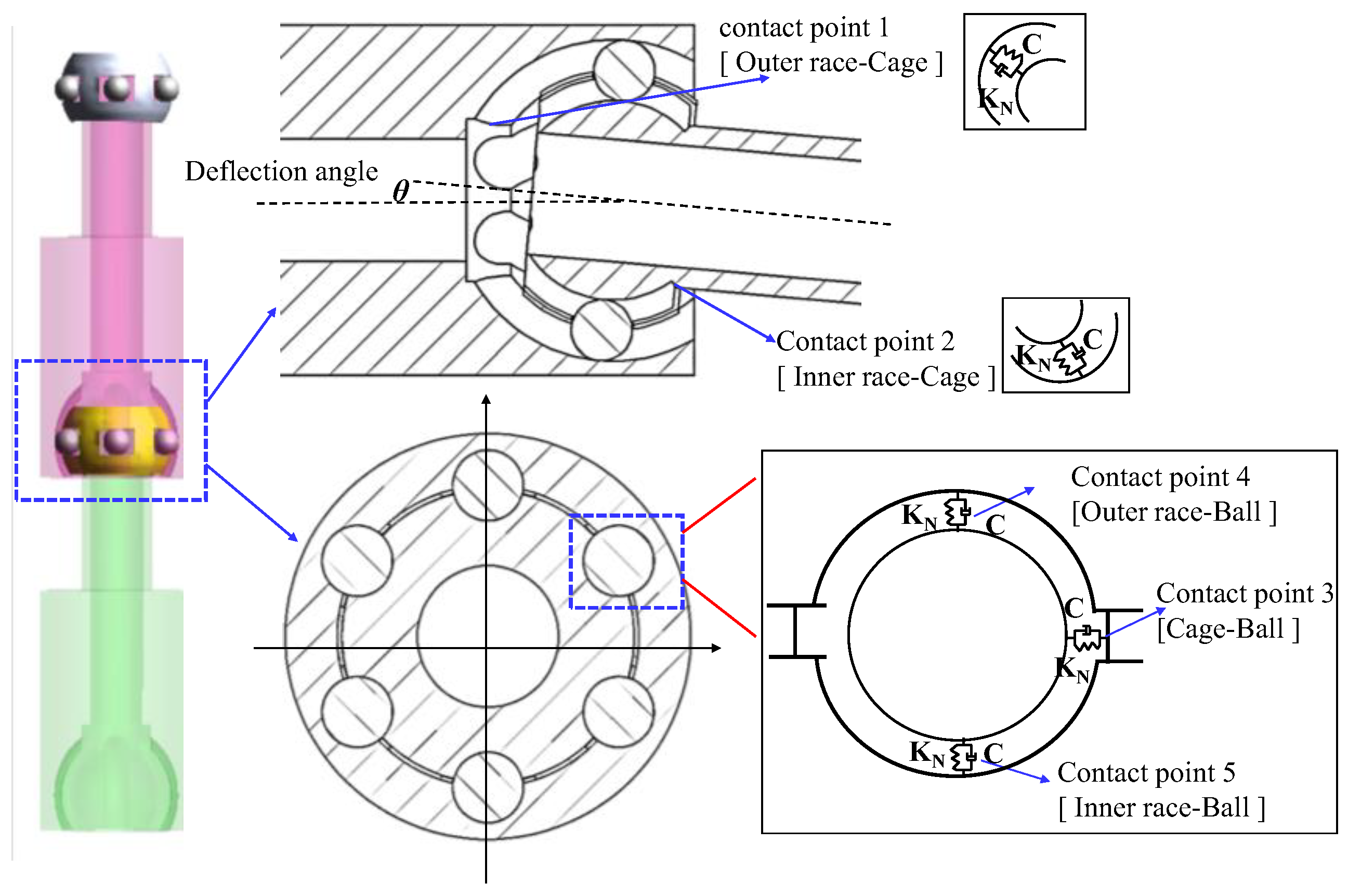

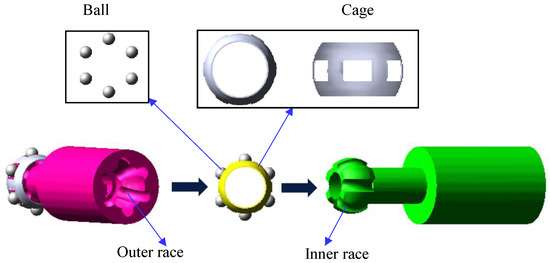

The upper three connections can not only bear the axial load and torsional load, but also transmit the above loads respectively. Thus, it plays an important role regarding the stability of the drilling pipe. The lower three connections are mainly used to connect various drill bits to guide the drilling direction. Figure 1 shows the structure components of the BCFJ, which consist of the ball head, the ball seat, the ball key, and the ball cage. There are six ball keys whose movements are constrained by the six windows of the ball cage. The ball head and ball seat have six arc-shaped outer grooves and inner grooves, respectively, which are mutually restrained with ball keys and transmit the drilling torque.

Figure 1.

The structure components of BCFJ.

3. Methodology

Assumptions: Within a cycle, the relative motion relationship between the ball and the cage includes three states: “contact-collision-separation”. The collision force is generated by the local contact deformation of the collision body, and a spring damping system is used to replace the complex deformation of the contact area. The energy loss during contact collision can be simulated using dampers. The simulation assumed the room temperature, atmospheric pressure, absence of vibrations, and air as ball contact surroundings. These assumptions would cause computational errors.

3.1. Contact Force Model Considering Ball Cage Clearance

The dynamic responses of the flexible joint show obvious nonlinear characteristics because of the clearance between multi-body mechanisms. Therefore, the contact force model considering ball cage clearance is the basis for the multi-body collision dynamics analysis of flexible joint. The ball head, ball seat, and ball cage are regarded as elastic collision bodies. During the process of collision, the motion constraint between two objects can be replaced by contact force, including normal contact force and tangential contact force.

3.1.1. Normal Contact Force Model

At present, the Lankarani–Nikravesh model is wildly used to describe the normal contact force between multi-body mechanisms [17,22]. The model can be described as

where is the normal contact force of collision point, K is the equivalent contact stiffness, δ is the compressive elastic deformation caused by collision, n is the material nonlinear coefficient, and the nonlinear rheological model for the material (42CrMo) can be presented as Equation (3). is the relative collision velocity of the collision point in BCFJ, Cr is the recovery coefficient of the material, and is the initial collision velocity of collision point in BCFJ.

where is rheological stress, is strain, is the strain rate, T is material temperature, is the reference temperature, and is the melting point.

The model considers the effects of material properties, geometry, elastic deformation, and collision velocity on the motion characteristics when describing the energy loss and transfer during the collision process. Therefore, many researchers studied the collision dynamics of hinged mechanisms with clearance based on the model. Especially, the model is also applied in the famous multi-body dynamics analysis software ADAMS 2019 (MSC Software, Newport Beach, CA, USA).

In this model, the contact stiffness K represents the key parameters for the normal contact force, and K is only related to the shape and material of the contact body [22]. However, K will change with elastic deformation, which will cause calculation errors. In order to reduce the errors, we conduct the following work.

According to the relationship between the contact force and the elastic displacement of the collision body clearance proposed by Liu et al. [27], we can obtain that

where L is the axial length of the bearing, is the equivalent elastic modulus of the material, and is the radial radius clearance of the contact body.

Taking the derivative of Equation (3), the nonlinear stiffness coefficient , which considers the ball cage clearance, ball cage length, and collision elastic deformation, can be obtained as

Using the nonlinear stiffness coefficient shown in Equation (4) to replace the contact stiffness K in Equation (2), the normal contact force can be rewritten as

According to Equation (5), the elastic deformation δ, cage clearance , and recovery coefficient are all key parameters affecting the nonlinear stiffness coefficient . Therefore, the influence of three parameters on the normal contact force is studied in this work.

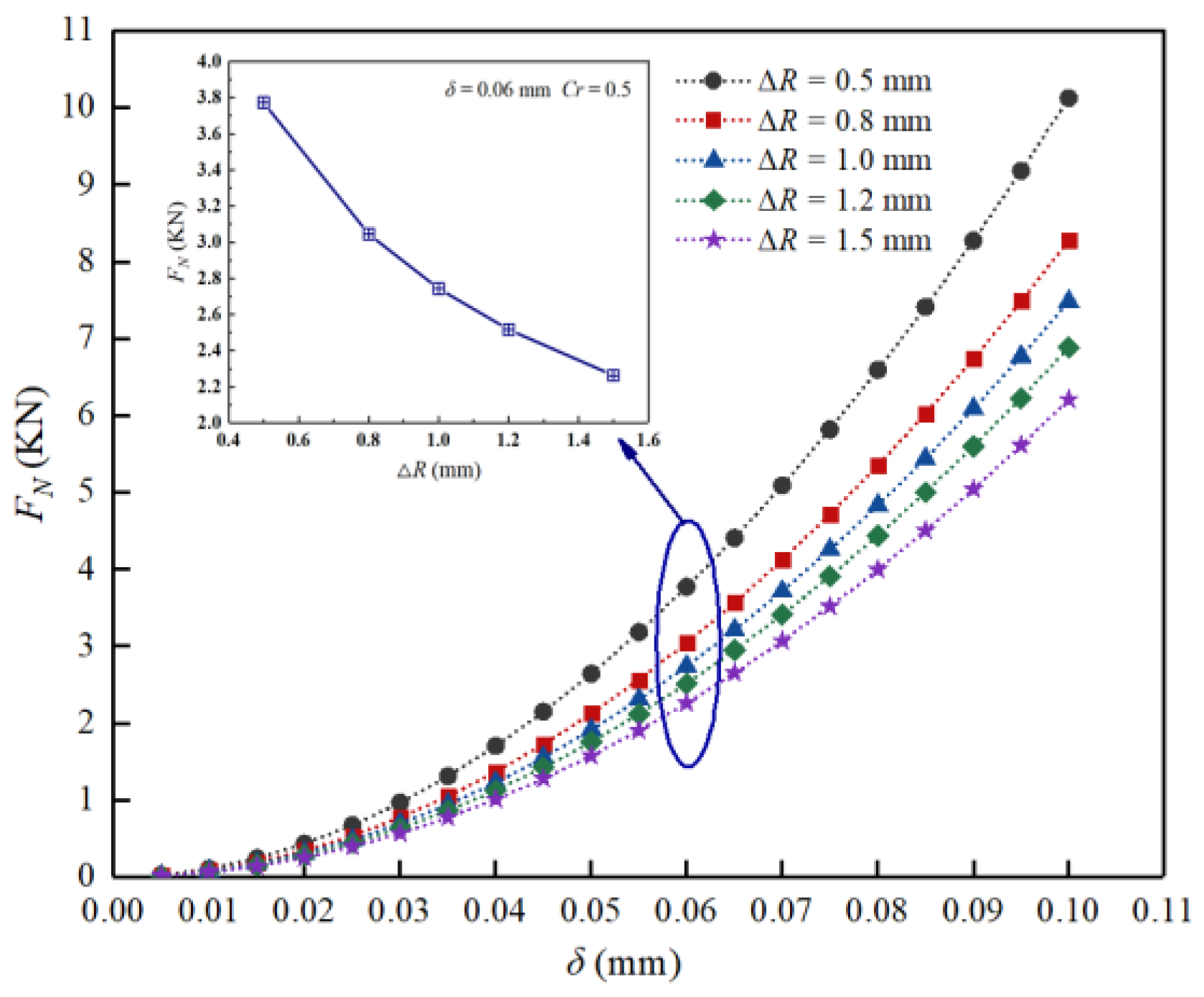

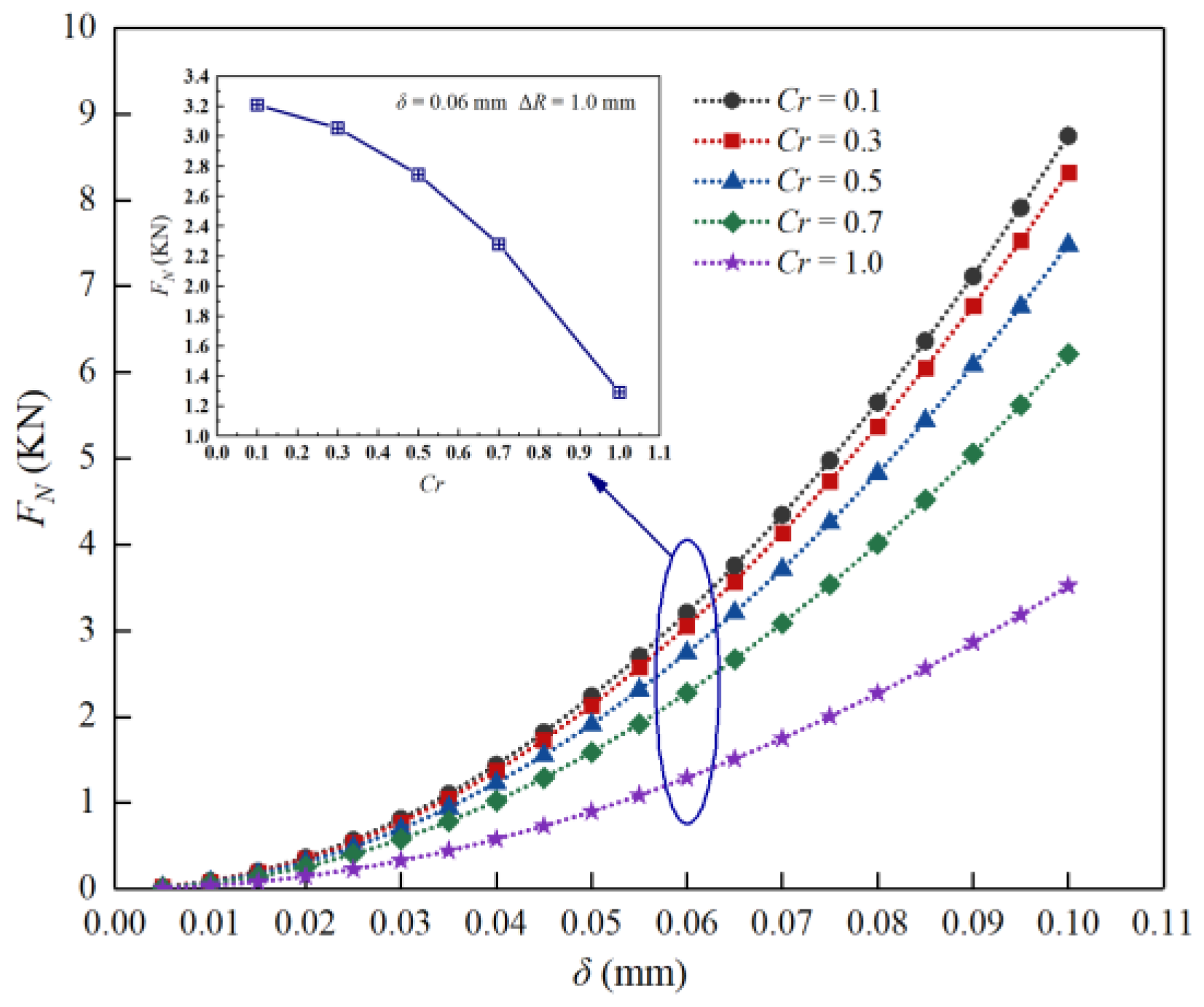

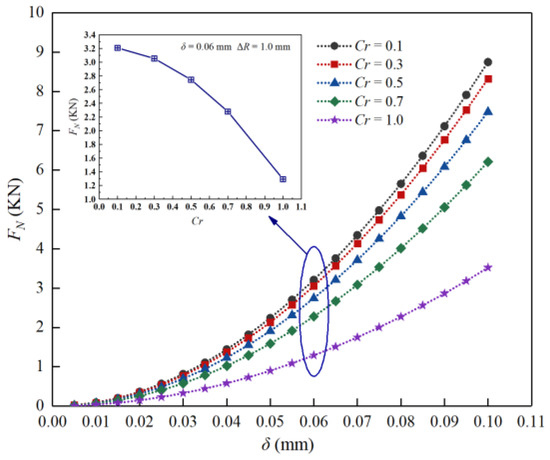

Taking the material parameters and dimension of flexible joint shown in Table 2 as an example, the influence of ball cage clearance and recovery coefficient on normal contact force is studied, and the results are shown in Figure 2 and Figure 3.

Table 2.

The material parameters and dimensions of flexible joint.

Figure 2.

The influence of clearance and elastic deformation δ on the normal contact force .

Figure 3.

The influence of recovery coefficient and elastic deformation δ on the normal contact force .

Figure 2 shows the distribution law of normal contact force under different radial clearance sizes, when the recovery coefficient is 0.5 and the initial collision velocity is 1.5 m/s. It can be seen that the value of contact force during collision increases with the elastic deformation and the peak value of contact force during the collision process gradually decreases with the increasing ball cage radial clearance. Meanwhile, under the same elastic deformation, the contact force decreases slower with the increase of ball cage radial clearance, which is obtained from the variation of contact force when elastic deformation δ is 0.06 mm. The results indicate that with the increase of elastic deformation or the decrease of ball cage radial clearance, the influence of clearance on contact force is more obvious.

Figure 3 shows the distribution law of normal contact force under different recovery coefficients, when the radial clearance is 1.0 mm and the initial collision velocity is 1.5 m/s. It can be seen that the peak value of contact force is inversely proportional to the recovery coefficient and under the same elastic deformation, the normal contact force decreases faster with the increase of recovery coefficient, which is obtained from the variation of contact force when elastic deformation δ is 0.06 mm. The results show that with the decrease of recovery coefficient, the influence of the recovery coefficient on contact force is more obvious.

3.1.2. Tangential Contact Force Model

During the collision process of a multi-body mechanism, friction is unavoidable. Considering the friction between collision contacts, the tangential contact force model, which is established by introducing the dynamic friction coefficient into ADAMS software, can be expressed as [21]

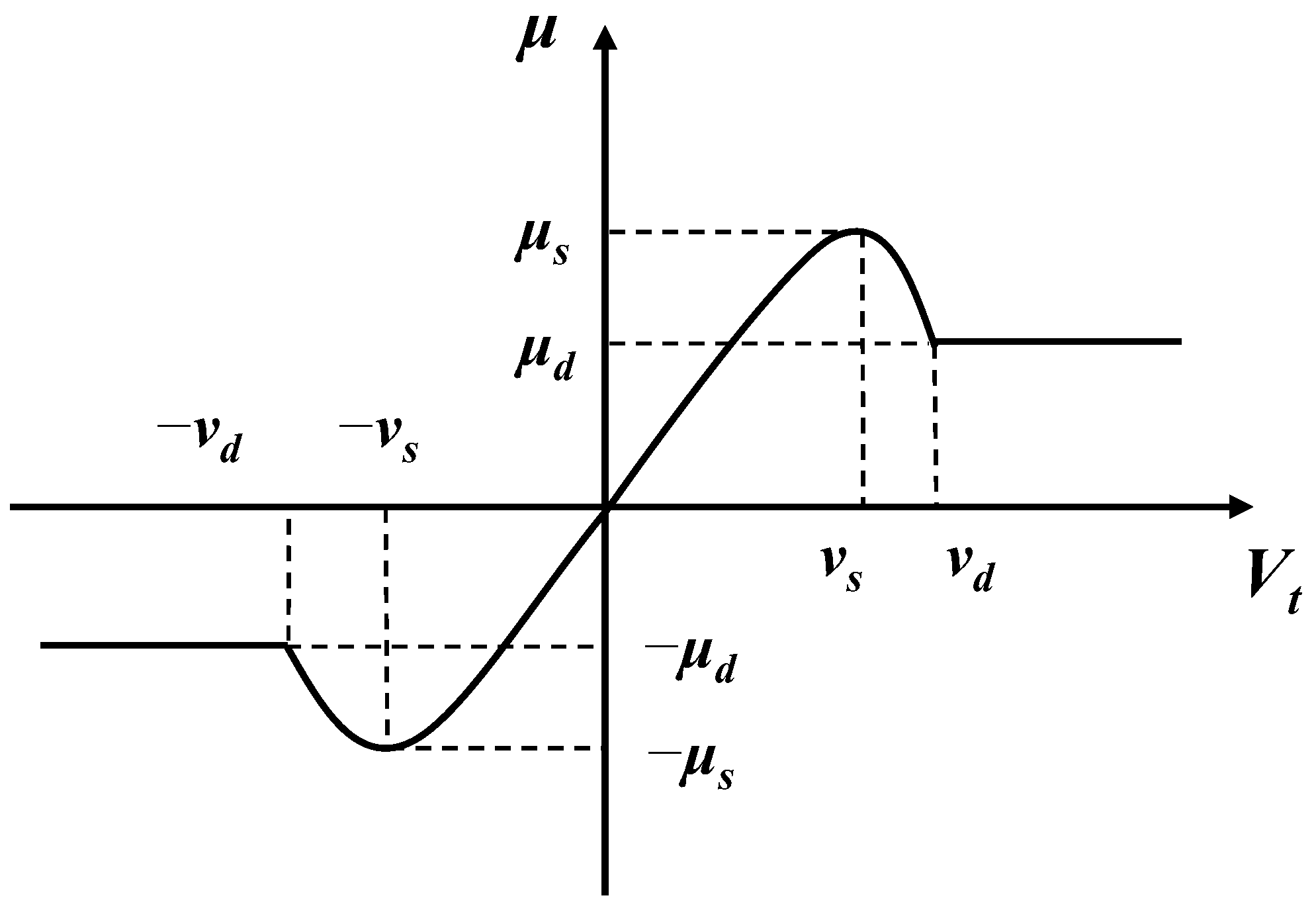

where is tangential friction, is the friction coefficient, and is the normal contact force. According to the evolution of the tangential friction coefficient with relative velocity, which is shown in Figure 4, the friction coefficient can be described as [22]

where is the tangential relative velocity of the collision body, is the critical speed of sliding friction, is the coefficient of sliding friction, and is the coefficient of static friction.

Figure 4.

The evolution of tangential friction coefficient with relative velocity.

3.2. Collision Dynamics Model

The contact force constraint matrix of the flexible joint with clearance includes the normal collision force matrix and tangential friction force matrix on the contact point and it can be described as

where is the contact force matrix, is the normal collision force matrix, is the tangential friction matrix, and is the friction coefficient which can be obtained by the step function:

The collision dynamics model of the flexible joint is developed by introducing the contact force constraint matrix and is expressed as

where x is the coordinate matrix, M is the mass matrix, C is the damping matrix, K is the stiffness matrix, Φ is the Jacobian matrix of the constraint equation, λ is the Lagrange multiplier matrix, and F is the force matrix.

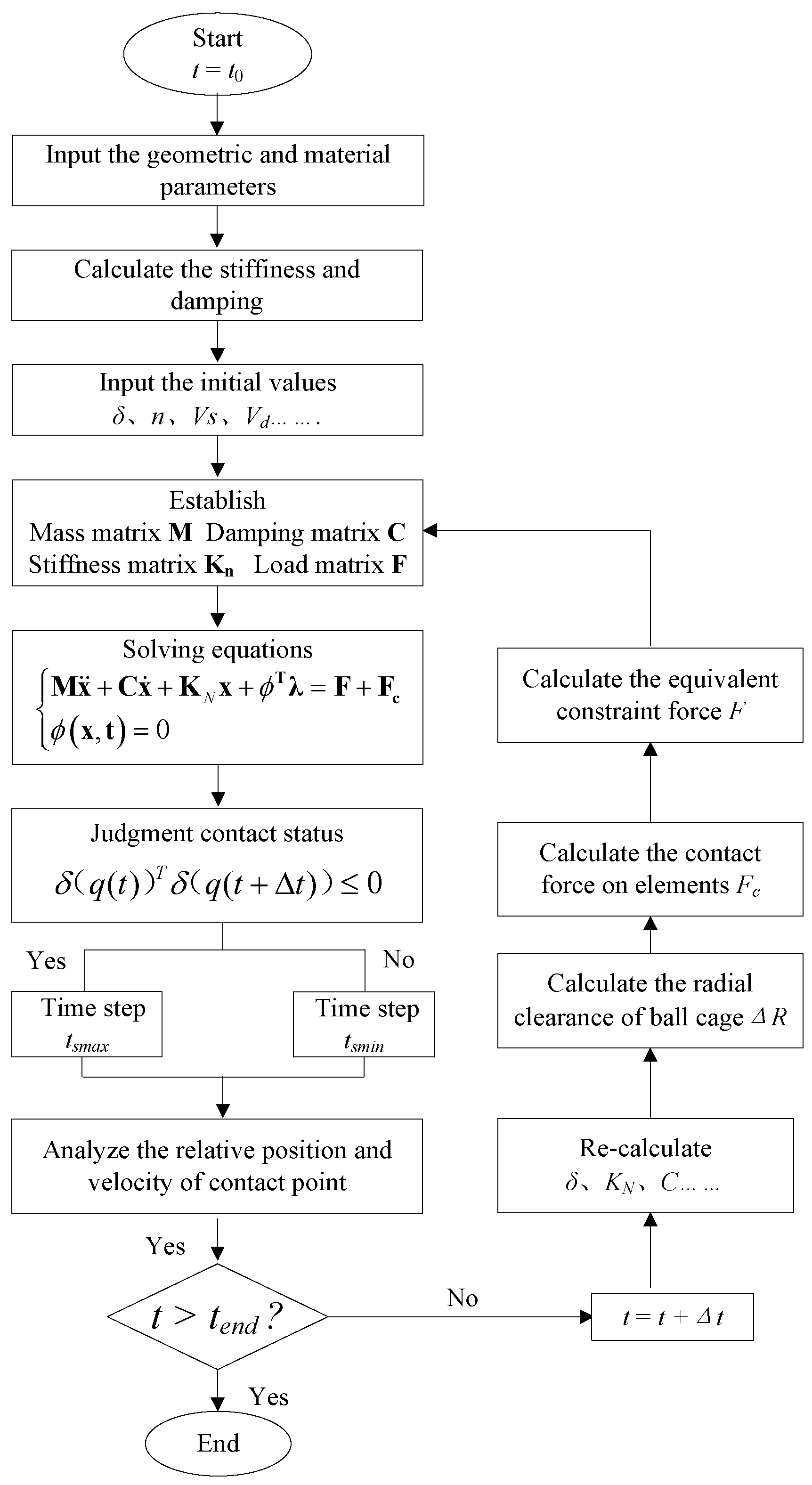

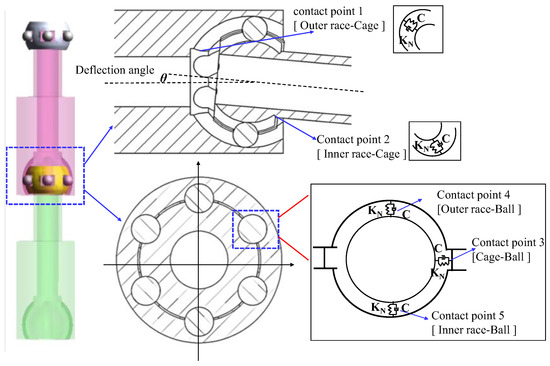

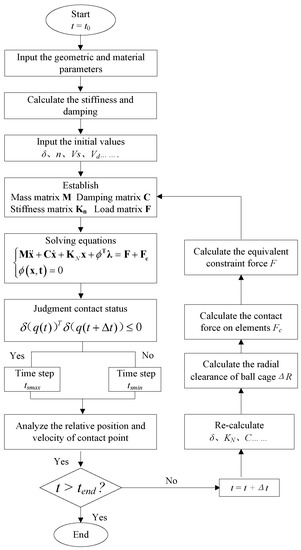

As shown in Figure 5, there are five types of contact points in flexible joints as they are in motion: contact between the outer race and the cage, contact between the inner race and the cage, contact between the cage and the ball, contact between the outer race and the ball, and contact between the inner race and the ball. These contact points are one-point contacts. The multi-body motion characteristics of the flexible joint are studied by analyzing the collision dynamics of five contact points. Figure 6 shows the flowchart of the computational procedure for the dynamic analysis of BCFJ with clearance.

Figure 5.

Position view of contact point on flexible joint (five points).

Figure 6.

Flowchart of computational procedure for dynamic analysis of BCFJ with clearance.

4. Results and Discussion

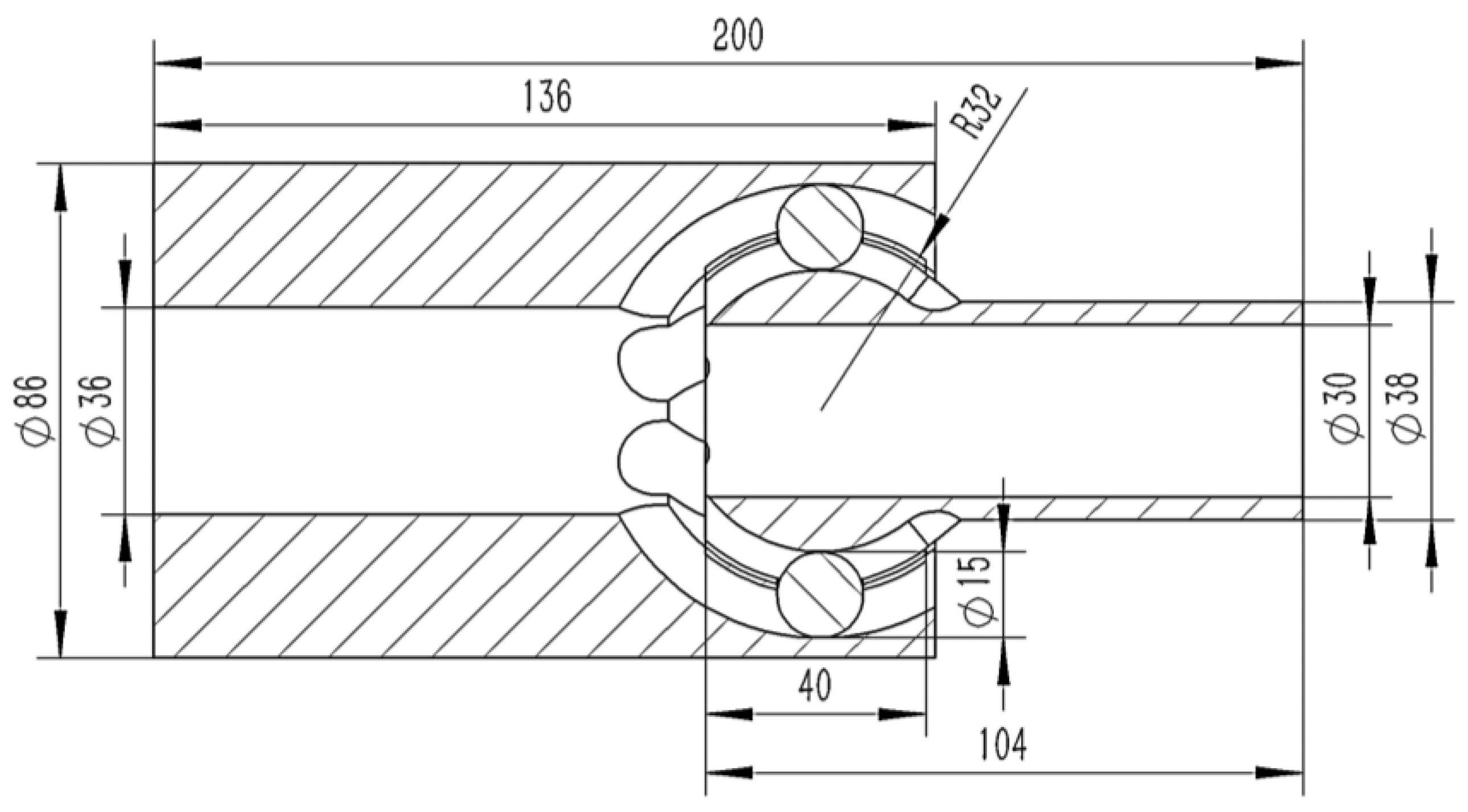

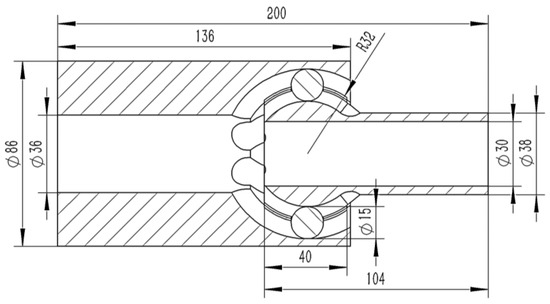

In the process of ultra-short radius drilling, the state of the ball cage universal joint is constantly changing between separation and connection. The ball key, cage, ball head, ball seat, and other mechanisms collide with each other, resulting in contact constraints. Figure 7 shows the geometric parameters of the BCFJ. The variation of contact force is studied by using the structure model of ball cage flexible drilling tools (as shown in Figure 1). The wellbore curvature radius is 1 mm, the computation time is 3 s, and the time step is 0.001 s.

Figure 7.

Geometric parameters of BCFJ (mm).

The material parameters of the flexible joint are as follows. The density ρ is 7.801 kg/cm3, the elastic modulus E* is 207 GPa, the Poisson’s ratio υ is 0.29, static friction coefficient between components is 0.12, dynamic friction coefficient is 0.03, the maximum elastic deformation δ is 0.1 mm, the initial collision velocity is 1.5 m/s [28], the nonlinear index n is 1.5, and the included angle between ball head and ball seat θ is 157°.

The motion process of the flexible joint is simulated. Rotating speed (100 r/min) is applied on the upper three connections, and the positive direction of rotation is along the axis of the wellbore toward the bottom of the well. The rotational resistance torque (1.8 kN × m) is applied on the lower three connections, and the positive direction is toward the wellhead. When the upper three connection of the flexible joint is rotating, the torque is transmitted to the ball head through the six ball keys in the outer raceway, and it is transmitted along the well depth in turn. The results of the contact force in the process of the motion are as follows.

4.1. Contact Forces Analysis of BCFJ

It can be seen from Figure 5 that there are three types of contact force on the cage: the outer race and the cage (contact point 1), the inner race and the cage (contact point 2), and the cage and the ball (contact point 3). There are two types of contact force on the ball keys: the outer race and the ball (contact point 4), and the inner race and the ball (contact point 5).

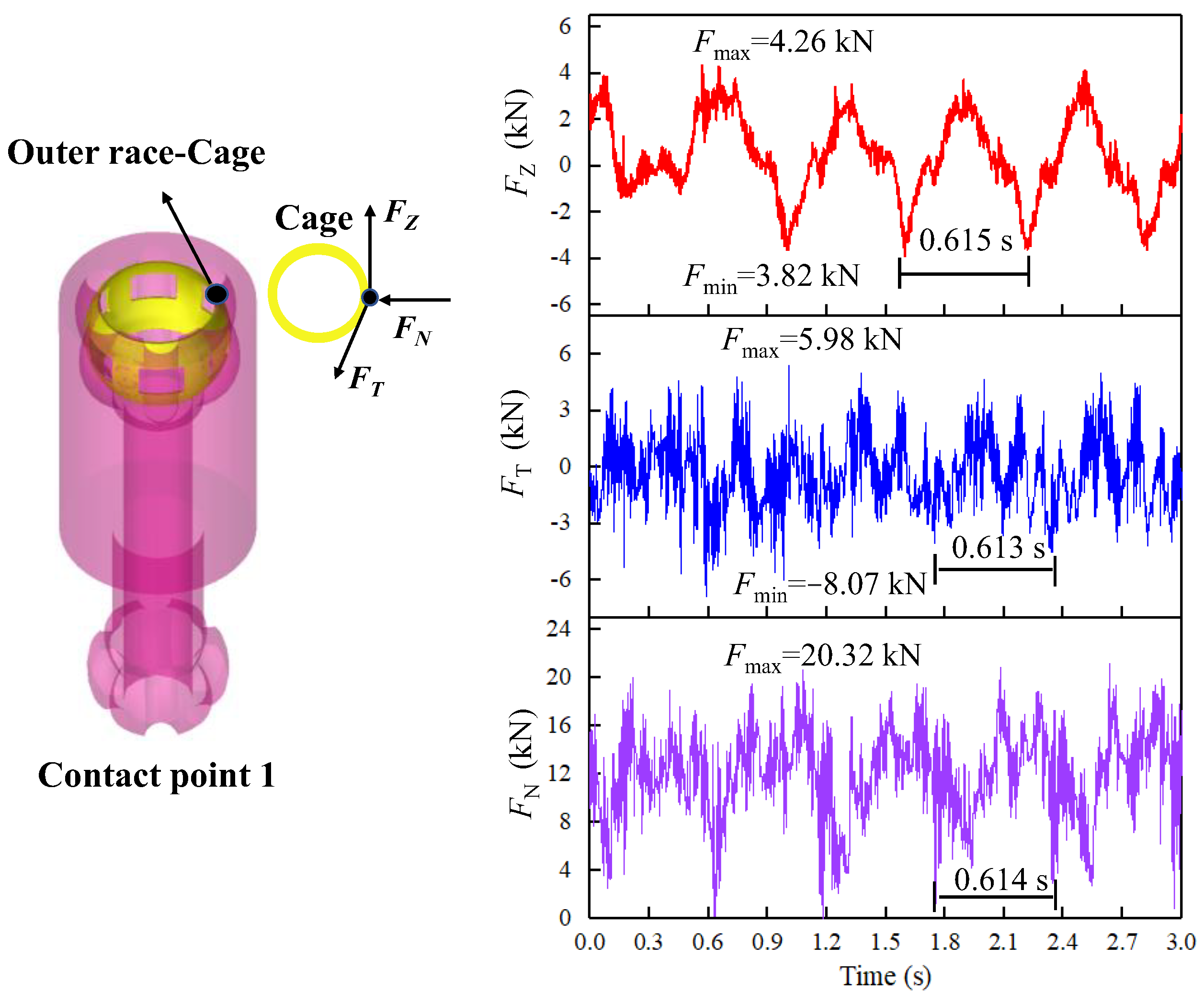

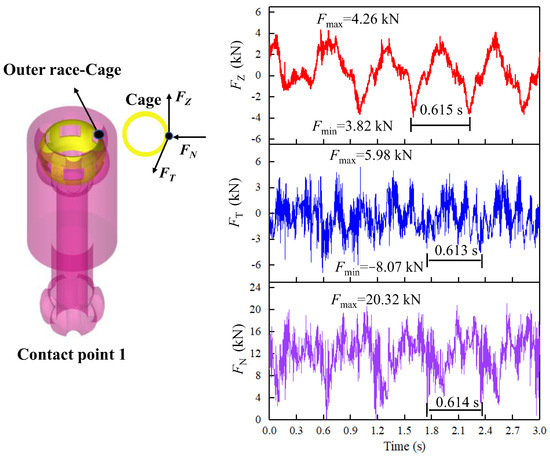

4.1.1. Contact Forces of Point 1

As the flexible joint begins to operate, the arc-shaped inner race of the ball seat collides with the cage, and the contact point changes constantly. The contact forces on the cage are combined into three types: normal contact force (the normal direction of the cage), axial contact force (the axial direction of the cage), and tangential contact (the tangential direction of the cage). Figure 8 shows the variation of contact force between outer race and cage (contact point 1). The periods of contact forces are 0.615 s (), 0.613 s (), and 0.614 s (), respectively. Theoretically, the periods are equal, but there is a maximum error of 0.002 s due to the influence of the calculation error. The frequency of the collision force is 1.63 Hz, which is consistent with the input rotation frequency. The peak value of normal contact force is 20.32 kN, which is the maximum value of the three.

Figure 8.

The variation of contact force between outer race and cage.

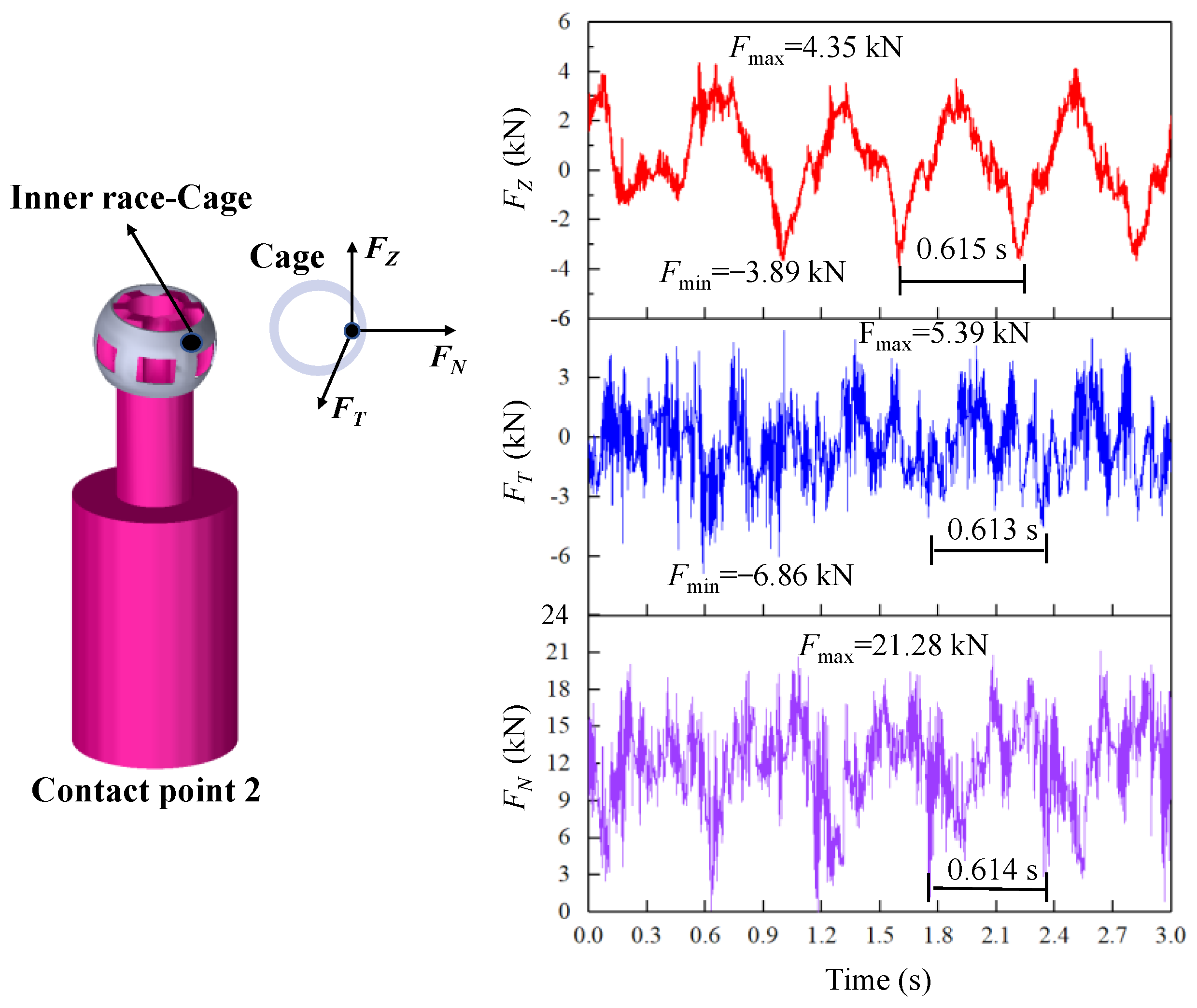

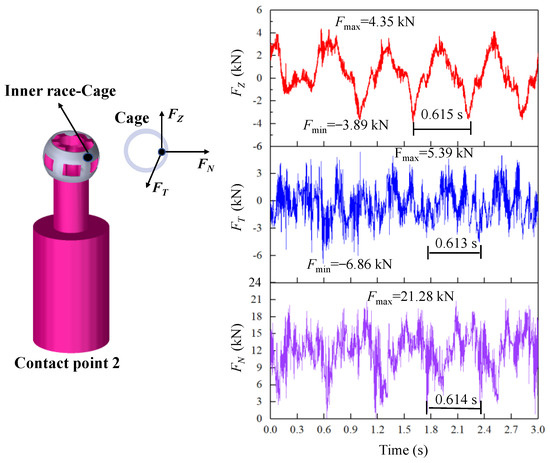

4.1.2. Contact Forces of Point 2

Figure 9 shows the variation of contact force between inner race and cage (contact point 2). Comparing the result with that in Figure 8, we can obtain that the variation cycle and trend of contact forces are similar, and this is because the shape of outer race (ball seat) and inner race (ball head) is the same. Furthermore, due to the influence of the cage clearance, there is a 0.22 s time difference between the collision time of contact point 1 and contact point 2. The contact forces of contact point 2 are still dominated by the normal contact force, and the maximum value is 21.28 kN.

Figure 9.

The variation of contact force between inner race and cage.

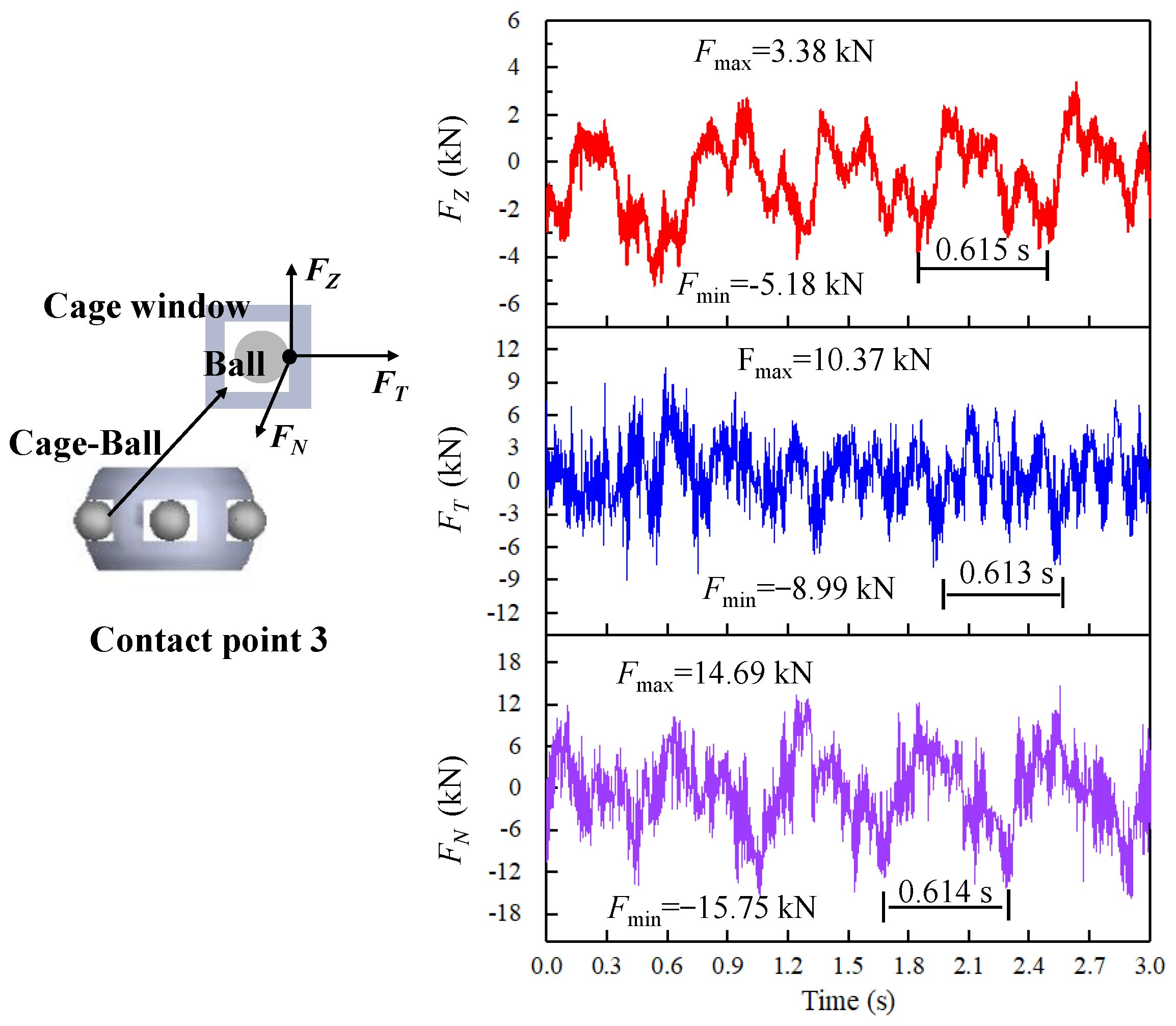

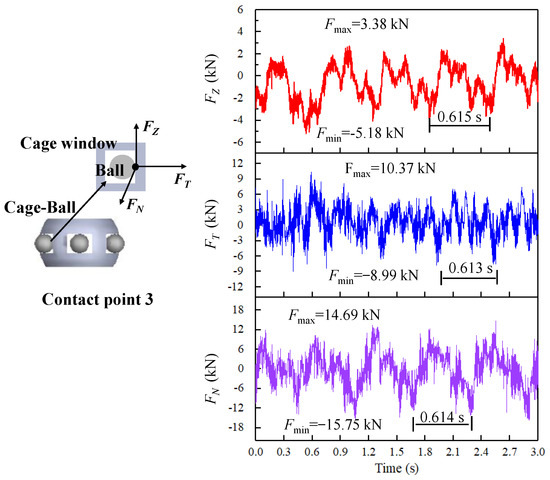

4.1.3. Contact Forces of Point 3

Figure 10 shows the variation of contact force between cage and ball (contact point 3). During the rotation, six ball keys are in contact with the inside and outside of the cage window, so the normal contact force fluctuates between positive and negative values (from −15.75 kN to 14.69 kN). Without considering gravity, in order to make sure that the cage can keep oscillating at the equilibrium position under different rotation angles, the cage should meet the equilibrium condition under the action of contact forces. To verify that, the contact force of contact points on the cage are analyzed at the time t = 1.51 s, and the results are listed in Table 3. It can be seen from the table that the ball cage satisfies the equilibrium condition in three directions, which verifies the reliability of the calculation model.

Figure 10.

The variation of contact force between cage and ball.

Table 3.

Contact forces of cage at the time 1.51 s.

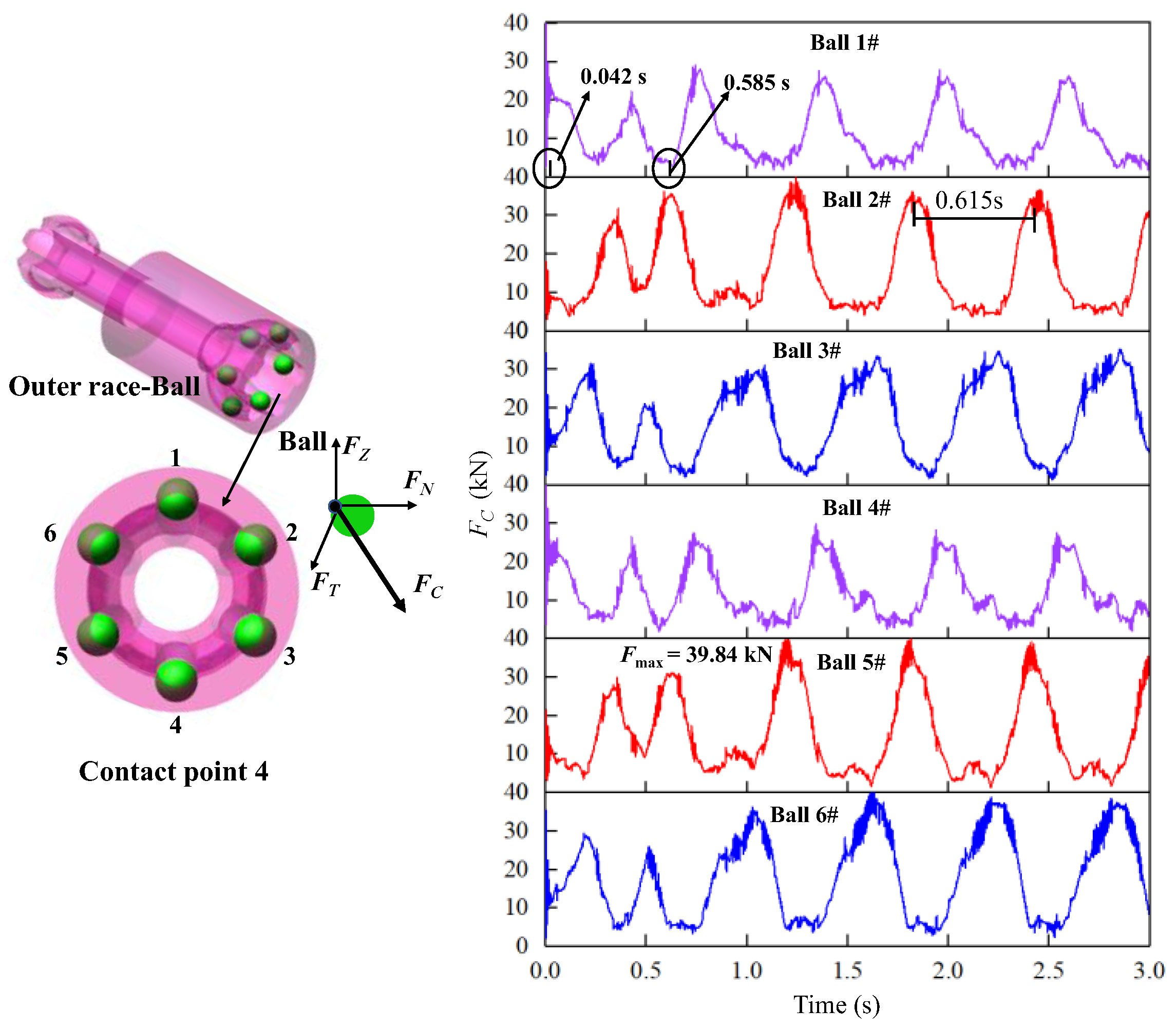

4.1.4. Contact Forces of Point 4

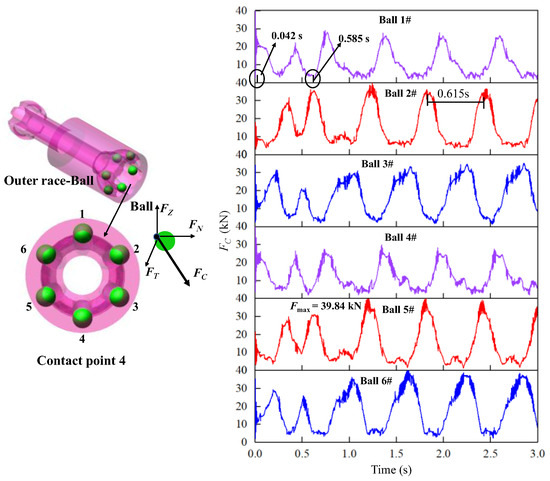

Figure 11 shows the variation of contact force between the groove of the outer race and the six ball keys (contact point 4). The contact force between the outer race and ball keys shown in the Figure 11 is the result of the normal contact force , axial contact force , and tangential contact force . The collision contact force shows obvious periodicity, and its motion period is 0.61 s (frequency is 1.63 Hz). The peak value of contact force on 2# ball key and its symmetrical 5# ball key at the inner side of the deflection is the largest, which is 39.84 kN.

Figure 11.

The variation of contact force between outer race and ball keys.

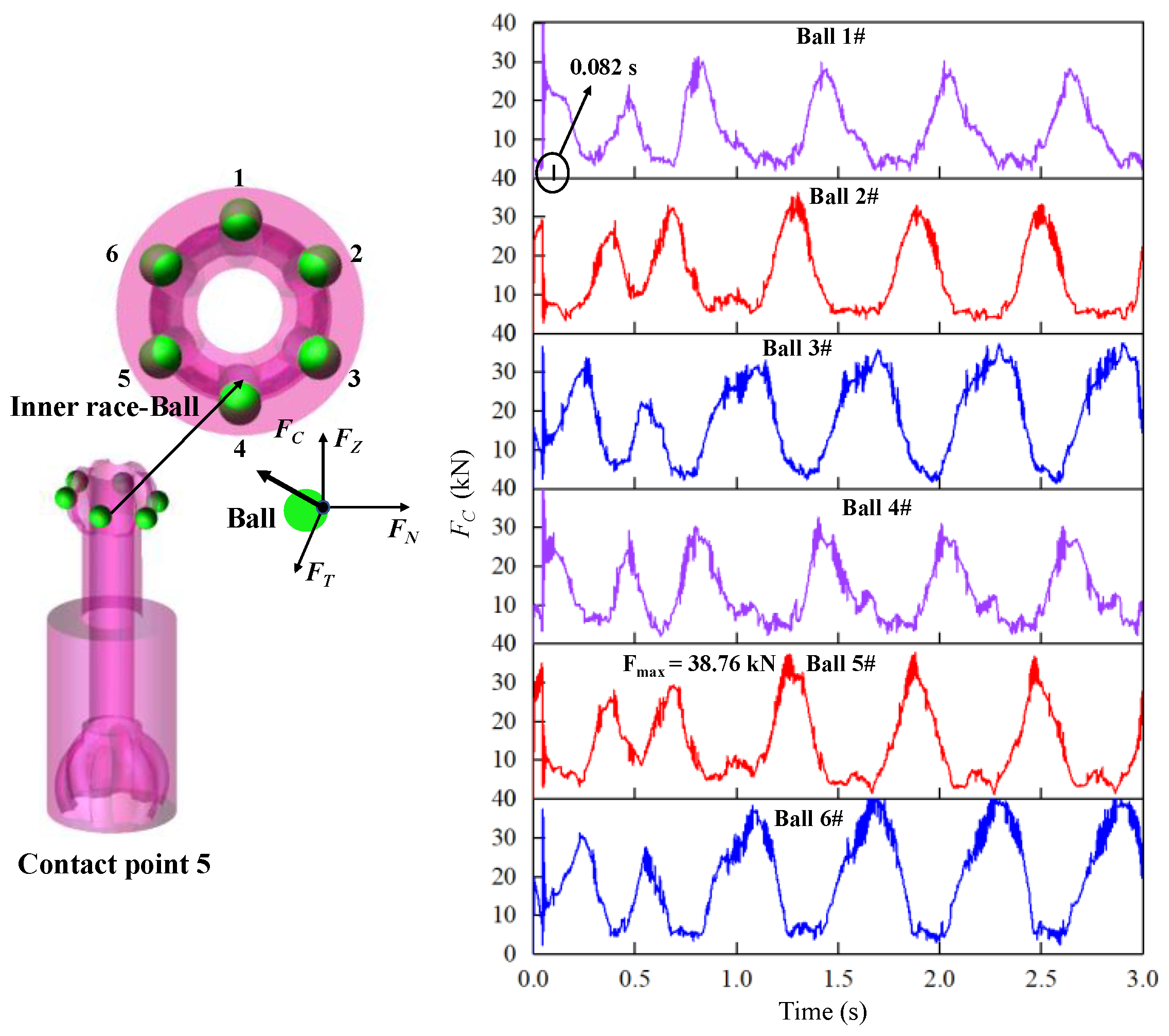

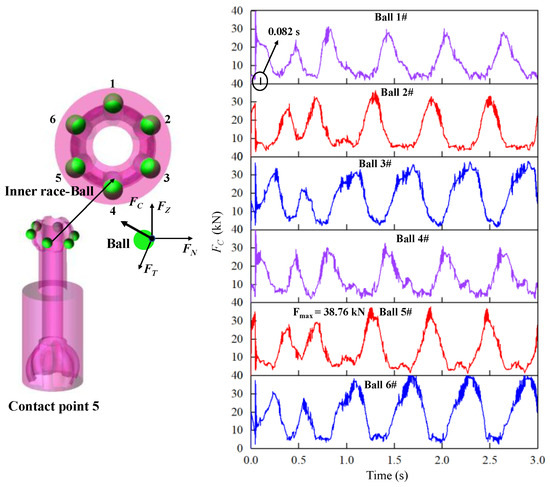

4.1.5. Contact Forces of Point 5

Figure 12 shows the variation of contact force between the groove of the inner race and the ball keys (contact point 5). Because the groove shape of ball seat corresponds to that of ball head, the variation of contact force is basically the same as that shown in Figure 11. However, due to the impact of clearance, there is a time loss in the transferring process of torque load from ball seat to ball head. Therefore, the contact force curve shown in Figure 12 has a delay time of 0.04s (0.042 s–0.082 s) compared with that shown in Figure 11. Comparing Figure 12 and Figure 11, it can be seen that the peak value of contact force on 5 # ball key, which is in contact with the ball head, is 38.76 kN.and the peak value of contact force on 5 # ball key in contact with the ball seat is 39.84 kN. The results indicate that 2.71% loss exists in the load transfer process.

Figure 12.

The variation of contact force between inner race and ball keys.

4.2. Discussion

4.2.1. Variation of Contact Forces

When the rotary motion is stabilized, the direction of contact force between outer race and cage which periodically varies with each revolution causes the oscillation movement. Meanwhile, the amplitude of the normal contact force is obviously greater than the tangential friction and axial friction, which indicates that the collision contact between ball seat and cage mainly occurs in the normal direction. Comparing the contact force curves shown in Figure 8 and Figure 9, the peak values and amplitudes of contact force are different, and the difference between them represents the vector values of contact force between cage and ball. This is because according to the force equilibrium condition, the sum of the contact force vector between the cage and ball seat, ball head, and ball key need to be zero to ensure the balance of the cage.

At the initial stage of collision (0–0.042 s), the rotating speed of the ball seat is high and the momentum is large because of the starting torque, and the impact force increases sharply in a short time. The collision stabilization time of ball keys is 0.585 s. After that, the contact force changes stability and periodically. The torque load is transmitted to six ball keys through the ball seat, but the contact force of each ball key is different due to the influence of clearance and deflection angle. Due to the impact of clearance, there is a time loss in the transferring process of torque load from ball seat to ball head. Therefore, the contact force curve shown in Figure 12 has a delay time of 0.04 s (0.042 s–0.082 s) compared with that shown in Figure 11.

According to the change rule of the contact force of the five contact points over time, the collision contact force has a movement period, and the collision contact will have repeated movement of “contact-collision-separation”. Influenced by this phenomenon, unequal speed transmission occurs in the movement process of the ball-cage flexible sub. In addition, tangential friction also reduces the torque in the process of flexible subtraction. Under the combined action of the two, the flexible sub will vibrate and impact.

As shown in Figure 5, there are five types of contact points in the ball cage flexible joint as they are in motion: between the outer race and the cage, the inner race and the cage, the cage and the ball, the outer race and the ball, and the inner race and the ball. These contact points are one-point contacts. The contact point at which wear begins first and which usually fails first is between the inner race and the ball set, so this is the main factor affecting the life of ball cage flexible joint. The variation of contact force and the peak collision load on the five contact points provides a foundation for further research on the wear analysis and life evaluation of ball cage flexible joints.

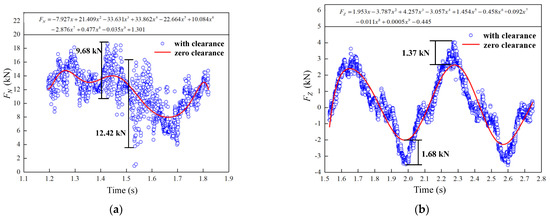

4.2.2. Effect of Clearance

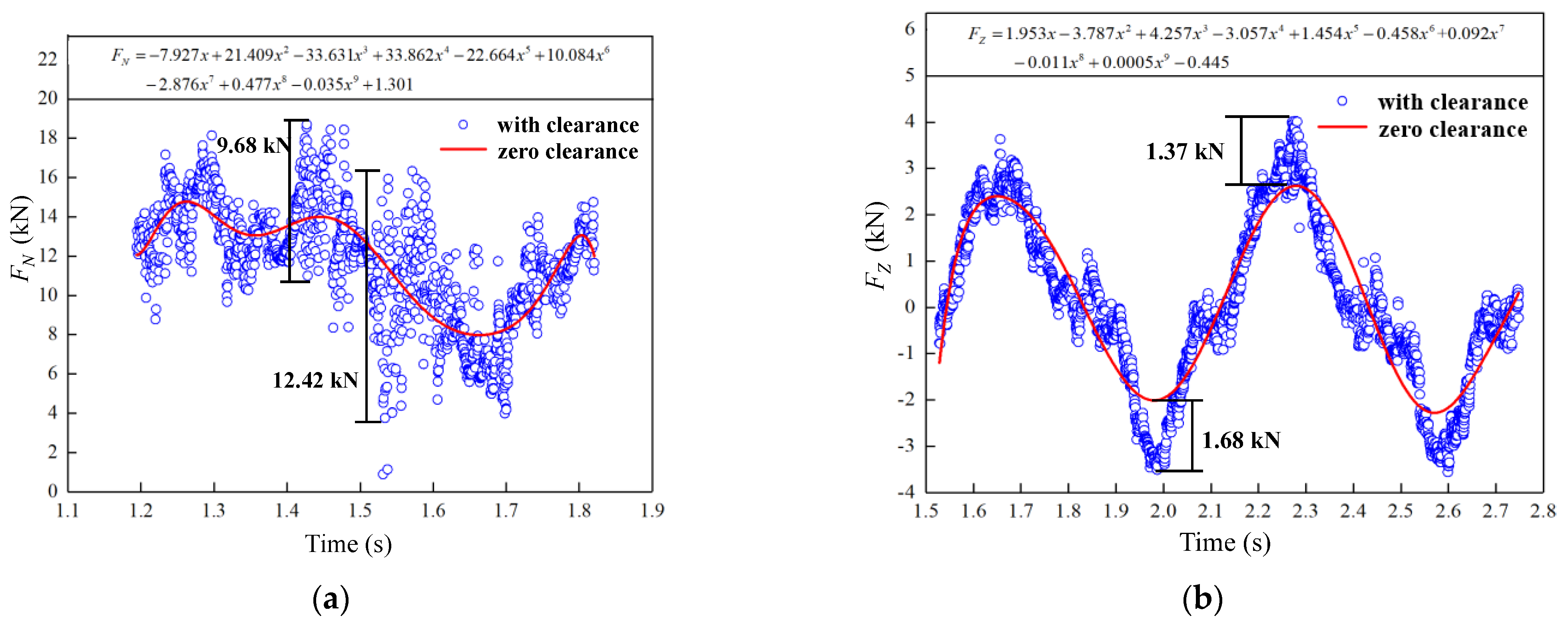

Researchers [29,30] believe that the oscillation of the collision contact force is mainly caused by the hinge clearance, and large clearance can lead to fewer collisions at the hinge, which can make the peak value of contact force higher. When the collision is stabilized, the contact force shape function can be obtained by fitting the normal contact force and axial contact force at the ball cage by using ninth-order polynomials during a certain time period. The fitting function is shown in Figure 13, and the selected time periods are from 1.18 s to 1.82 s (normal contact force) and from 1.52 s to 2.75 s (normal contact force), respectively. The force obtained by fitting can be regarded as the contact force on the cage without clearance and then comparing with the discrete point shown in Figure 13, the influence of clearance on contact force oscillation can be studied.

Figure 13.

The influence of clearance on contact force between cage and ball seat. (a) The normal contact force (1.18 s–1.82 s); (b) The axial contact force (1.52 s–2.75 s).

As shown in Figure 13, the effects of clearance on the contact force cannot be ignored. There will be repeated “contact-collision-separation” motion between the ball cage and groove, which is the main cause for the vibration of contact force. As shown in Figure 13a, the normal contact force amplitude between cage and ball seat is large, and the maximum value is 12.42 kN. There are many discrete points near the fitting curve and they are messy, which indicates that the clearance has a greater influence on the normal contact force. However, the discrete points near the fitting curve of the axial contact force of the cage are relatively concentrated, and the maximum amplitude of contact force is 1.68 kN, as shown in Figure 13b, which indicates that the clearance has little influence on the axial contact force.

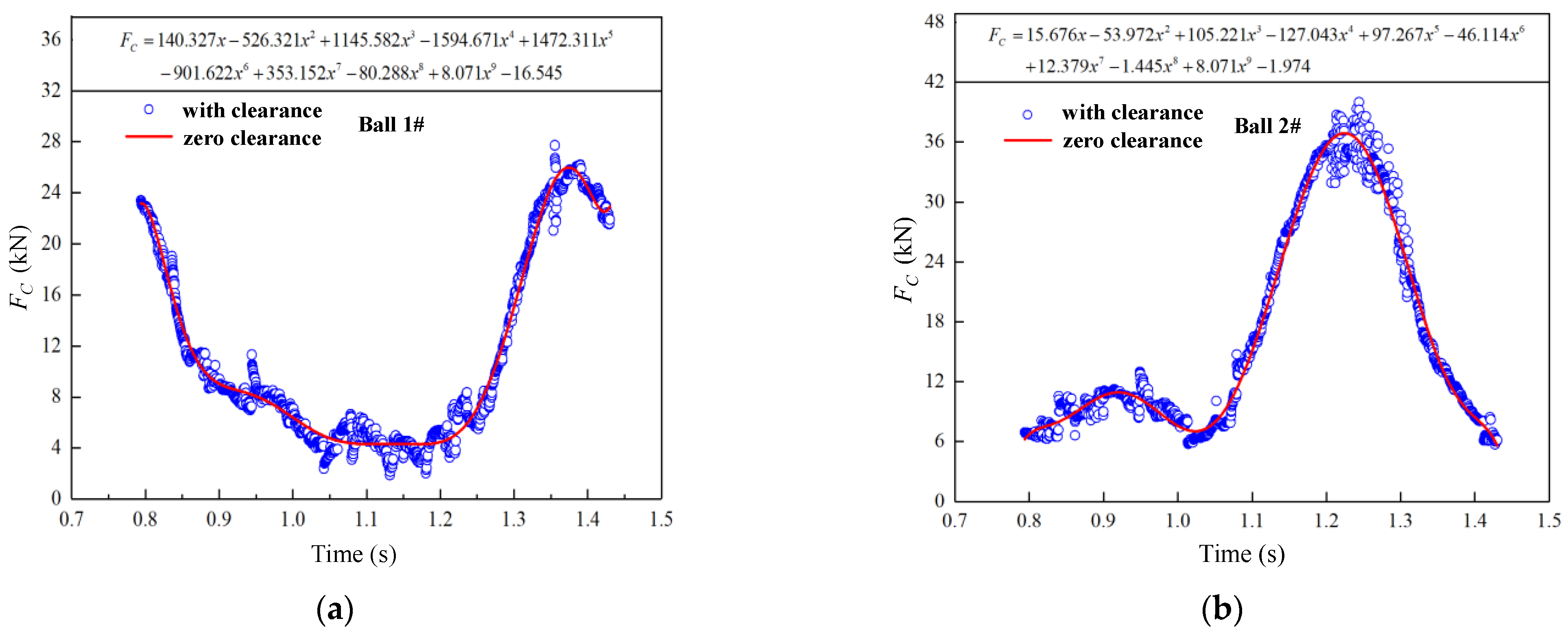

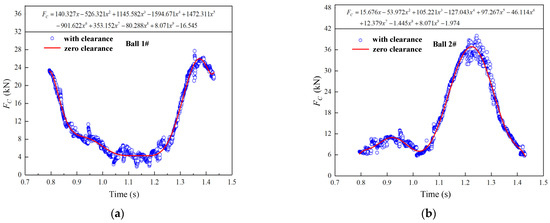

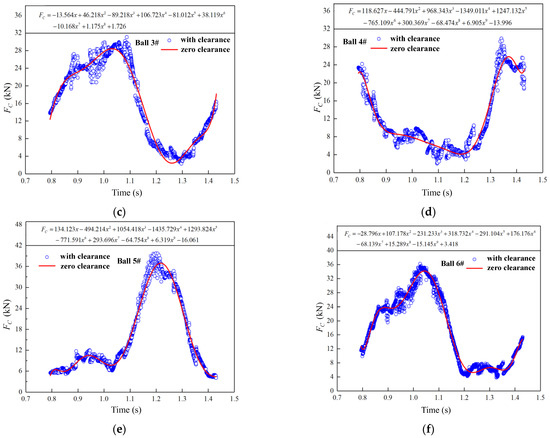

Figure 14 shows the variation of contact force between six ball keys and the ball seat with or without clearance. Due to the high coincidence between the ball seat groove and the ball key in geometry, the clearance between them is smaller than that between cage and ball seat. Compared with the results shown in Figure 13, the oscillation amplitude of contact force is smaller, and contact force error between the fitting curve and discrete point is also smaller. The results shown in Figure 13 and Figure 14 indicate that the large clearance leads to the large amplitude vibration of contact force and causes large error of contact force.

Figure 14.

The influence of clearance on contact force between ball keys and ball seat (0.79 s–1.43 s). (a) Contact force of ball key 1; (b) Contact force of ball key 2; (c) Contact force of ball key 3; (d) Contact force of ball key 4; (e) Contact force of ball key 5; (f) Contact force of ball key 6.

According to the results and discussion, it can be found that the proposed model and computational procedure can not only be used to analyze the overall dynamic behavior of multibody systems containing ball cage flexible joints, but also to obtain the collision load on each element in motion. The simulation of the dynamic loads on each contact point can be used for the strength checking, fatigue life prediction, and wear analysis of ball cage flexible joints with clearance in multibody systems.

At present, the model has some limitations. In the simulation, we assume that the contact environment of the ball is room temperature, with atmospheric pressure, no vibration, and air. These assumptions lead to miscalculations. In addition, there is a lack of laboratory tests (and field tests) to verify the model and its coefficients. So, future research requires laboratory experiments (and field tests). The simulation results are compared with those obtained using different multi-body dynamics software. A comparison of the mechanism with more traditional flexible joint mechanisms used in the oil/gas industry demonstrates the advantages of the ball-cage flexible joint.

5. Conclusions

In this paper, a collision dynamics model and computational procedure for the dynamic analysis of BCFJ with clearance is proposed. The dynamic simulation for collision and contact in the process of rotation was carried out, and the variation of contact force on five contact points of ball keys and ball cage was studied. The main conclusions are summarized as follows:

- The effects of the ball cage clearance on the contact force of the flexible joint cannot be ignored. There will be repeated “contact-collision-separation” motion between the ball cage and groove, which is the main cause for the vibration of flexible joint multi-body systems. The influence of the clearance on the contact force of the ball cage is greater than that of the ball key contact force.

- When the flexible joint rotates stably, the collision contact force on the five contact points changes periodically. The frequency of contact force is 1.63 Hz, which is basically the same as the rotation speed of the flexible joint. The data indicate that the calculation model is reliable.

- The peak value and amplitude of the normal contact force of the ball cage are obviously larger than those of the tangential friction force and the axial friction force. For ball keys, the contact force value on the inside of the deflection is the maximum, and the variation of contact force is close in symmetrical position. The torque load is transmitted from the ball seat to the ball key and the ball cage, and then to the ball head. There is a time difference and loss in the process of torque load transfer.

The proposed model and procedure in this paper can be used to optimize the structure of BCFJ, reduce collision energy loss, and improve the transmission efficiency. The results will be helpful to ensure better application of ball cage type flexible short joints in oilfield production. Furthermore, the simulation of the collision contact force can be used for the wear analysis and safety evaluation of ball cage universal joints.

Author Contributions

X.Z., paper method design and draft writing; F.Z., chart making and revision and revision of the first draft of the paper; X.Y., software programming and programming; Y.X., numerical simulation study; P.J., literature search and data analysis; B.Z., the idea of specific research ideas and the final revision and finalization of the paper; S.X., the guidance of paper writing and the determination of specific research direction. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Luo, M.; Xu, T.; Jiang, J.; Chi, X.; Wang, J.; Xue, S. Two-layer contact nonlinear mechanical analysis of flexible drilling tool in the wellbore. CMES-Comp. Model Eng. 2020, 1, 75–100. [Google Scholar] [CrossRef]

- El-Sapa, S.; Almoneef, A.A. The Axisymmetric Migration of an Aerosol Particle Embedded in a Brinkmann Medium of a Couple Stress Fluid with Slip Regime. Eur. J. Pure Appl. Math. 2022, 15, 1566–1592. [Google Scholar] [CrossRef]

- El-Sapa, S. The Force on a Magneto-spherical Particle Oscillating in a viscous Fluid Perpendicular to an Impermeable Planar Wall with Slippage. Eur. J. Pure Appl. Math. 2022, 15, 1376–1401. [Google Scholar] [CrossRef]

- Sherief, H.; Faltas, M.; Ragab, K. Motion of a slip spherical particle near a planar micropolar-viscous interface. Eur. J. Mech. B-Fluid. 2021, 89, 274–288. [Google Scholar] [CrossRef]

- Varedi-Koulaei, S.M.; Daniali, H.M.; Farajtabar, M.; Fathi, B.; Shafiee-Ashtiani, M. Reducing the undesirable effects of joints clearance on the behavior of the planar 3-RRR parallel manipulators. Nonlinear Dyn. 2016, 86, 1007–1022. [Google Scholar] [CrossRef]

- Marques, F.; Isaac, F.; Dourado, N.; Souto, A.; Flores, P.; Lankarani, H. A study on the dynamics of spatial mechanisms with frictional spherical clearance joints. J. Comput. Nonlinear Dyn. 2017, 12, 051013. [Google Scholar] [CrossRef]

- Flores, P.; Ambrosio, J.; Claro, J.; Lankarani, M.H.; Koshy, C.S. A study on dynamics of mechanical systems including joints with clearance and lubrication. Mech. Mach. Theory 2006, 41, 247–261. [Google Scholar] [CrossRef]

- Bing, S.; Ye, J. Dynamic analysis of the reheat-stop-valve mechanism with revolute clearance joint in consideration of thermal effect. Mech. Mach. Theory 2008, 43, 1625–1638. [Google Scholar] [CrossRef]

- Wang, X.; Liu, G.; Ma, S.; Tong, R. Study on dynamic responses of planar multibody systems with dry revolute clearance joint, numerical and experimental approaches. J. Sound Vib. 2019, 438, 116–138. [Google Scholar] [CrossRef]

- Sun, D.; Shi, Y.; Zhang, B. Robust optimization of constrained mechanical system with joint clearance and random parameters using multi-objective particle swarm optimization. Struct. Multidiscip. Optim. 2018, 58, 2073–2084. [Google Scholar] [CrossRef]

- Qu, S.; Li, R.; Bai, S.; Liang, S. Unified model for the output accuracy of open-chain manipulators that considers joint clearance and structural parameters. J. Mech. Sci. Technol. 2018, 32, 4925–4931. [Google Scholar] [CrossRef]

- Chen, X.; Jiang, S.; Deng, Y.; Wang, Q. Dynamics analysis of 2-DOF complex planar mechanical system with joint clearance and flexible links. Nonlinear Dyn. 2018, 93, 1009–1034. [Google Scholar] [CrossRef]

- Salahshoor, E.; Ebrahimi, S.; Zhang, Y. Frequency analysis of a typical planar flexible multibody system with joint clearances. Mech. Mach. Theory 2018, 126, 429–456. [Google Scholar] [CrossRef]

- Hou, Y.; Wang, Y.; Jing, G.; Deng, Y.; Zeng, D.; Qiu, X. Chaos phenomenon and stability analysis of RU-RPR parallel mechanism with clearance and friction. Adv. Mech. Eng. 2018, 10, 1–11. [Google Scholar] [CrossRef]

- Bai, Z.Z. Research on Dynamic Characteristic of Mechanism with Joint Clearance. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2011. [Google Scholar]

- Hunt, K.H.; Crossley, F.R. Coefficient of restitution interpreted as damping in vibroimpact. J. Appl. Mech. 1975, 42, 440–445. [Google Scholar] [CrossRef]

- Lankarani, H.M.; Nikravesh, P.E. A contact force Model With Hysteresis Damping for Impact Analysis of Multibody Systems. J. Mech. Des. 1990, 112, 369–376. [Google Scholar] [CrossRef]

- Flores, P.; Machado, M.; Silva, M.T.; Martins, J.M. On the continuous contact force models for soft materials in multibody dynamics. Multibody Syst. Dyn. 2011, 25, 357–375. [Google Scholar] [CrossRef]

- Luka, S.; Janko, S.; Miha, B. A validated model for a pin-slot clearance joint. Nonlinear Dyn. 2017, 88, 131–143. [Google Scholar]

- Gummer, A.; Sauer, B. Modeling planar slider-crank mechanisms with clearance joints in recurdyn. Multibody Syst. Dyn. 2014, 31, 127–145. [Google Scholar] [CrossRef]

- Bai, Z.F.; Zhao, Y. Dynamics modeling and quantification analysis of multibody systems including revolute clearance joints. Precis. Eng. 2012, 36, 554–567. [Google Scholar] [CrossRef]

- Wang, X.P.; Liu, G.; Ma, S.J. Dynamic analysis of planar mechanical systems with clearance joints using a new nonlinear contact force model. J. Mech. Sci. Technol. 2016, 30, 1537–1545. [Google Scholar] [CrossRef]

- Luo, M.; Xu, T.; Wang, J.; Li, Q.; Zhang, J. Contact nonlinear finite element analysis of controllable universal joint flexible slender in tube. J. China Univ. Pet. (Ed. Nat. Sci.) 2019, 43, 75–81. [Google Scholar]

- Zhu, X.; Xu, Y.; Zhou, W.; Ye, G.; Zhou, B. Research on Parameter Design Method and Motion Characteristics of a Ball Cage Flexible Joint. Energies 2022, 15, 7591. [Google Scholar] [CrossRef]

- Zhu, X.; Xu, Y.; Mao, C.; Zhou, W.; Xia, Y.; Ye, G.; Zhou, B. Research on Multi-Body Collision Dynamics of Ball Cage Flexible Drill Pipe Considering Borehole Curvature. Machines 2023, 11, 357. [Google Scholar] [CrossRef]

- Xu, T.; Luo, T.; Wang, J.; Zhang, J.; Dong, X. Optimization design of flexible drill pipe and study on its carrying capacity. Chem. Eng. Mach. 2018, 45, 768–772. [Google Scholar]

- Liu, C.S.; Zhang, K.; Yang, R. The FEM analysis and approximate model for cylindrical joints with clearances. Mech. Mach. Theory 2007, 42, 183–197. [Google Scholar] [CrossRef]

- Flores, P. Dynamic analysis of mechanical systems with imperfect kinematic joints. Ph.D. Thesis, Universidade Do Minho, Braga, Portugal, 2004. [Google Scholar]

- Lim, Y.H.; Song, M.E.; Lee, W.H.; Cho, H.J.; Bae, D.S. Multibody dynamics analysis of the driveshaft coupling of the ball and tripod types of constant velocity joints. Multibody Syst. Dyn. 2009, 22, 145–162. [Google Scholar] [CrossRef]

- Wang, X.P.; Liu, G. Modeling and simulation of revolute joint with clearance in planar multi-body systems. J. Mech. Sci. Technol. 2015, 29, 4113–4120. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).