Effect of Variable-Nozzle-Turbocharger-Coupled Exhaust Gas Recirculation on Natural Gas Engine Emissions and Collaborative Optimization

Abstract

:1. Introduction

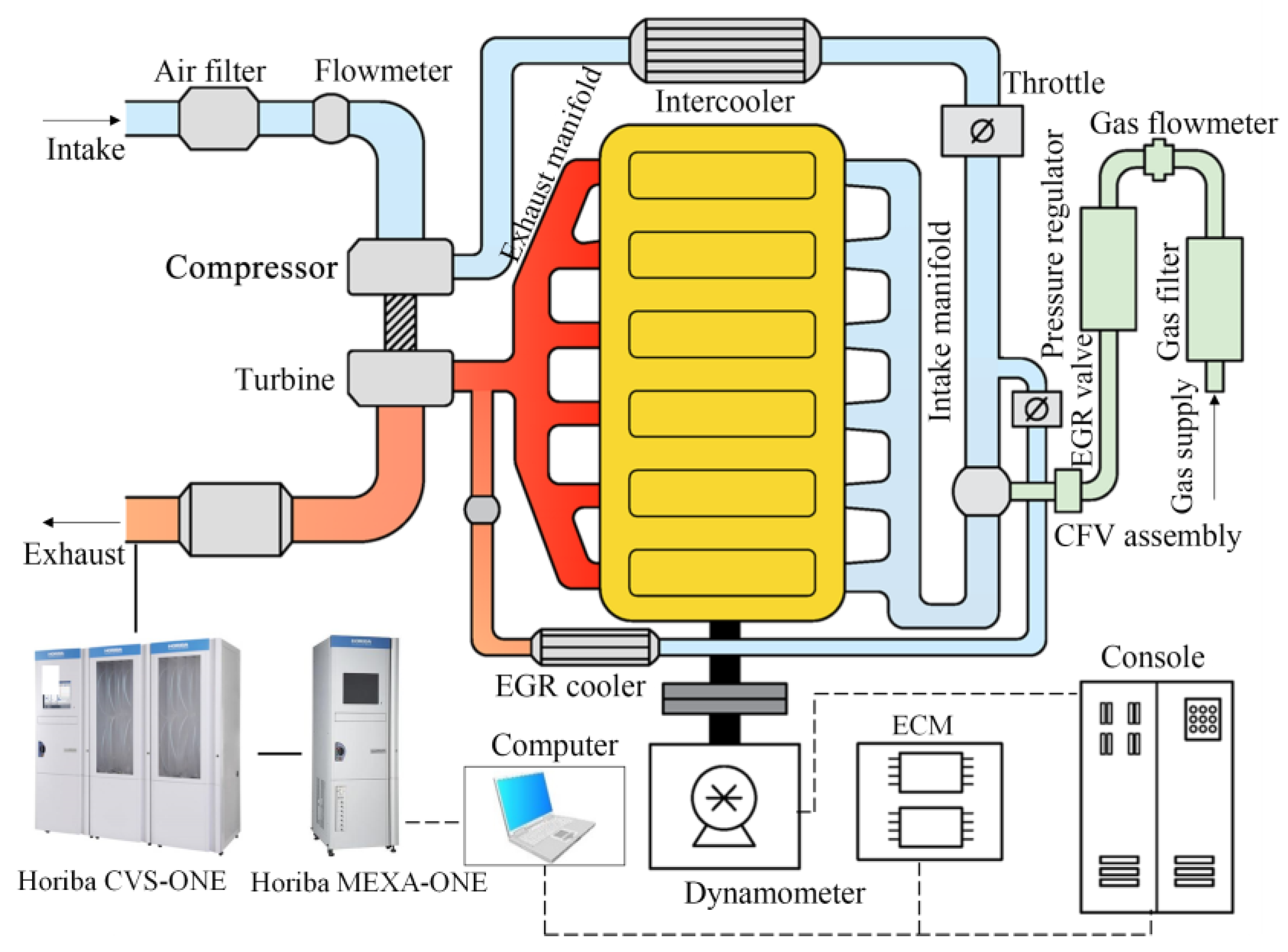

2. Materials and Methods

3. Results and Discussion

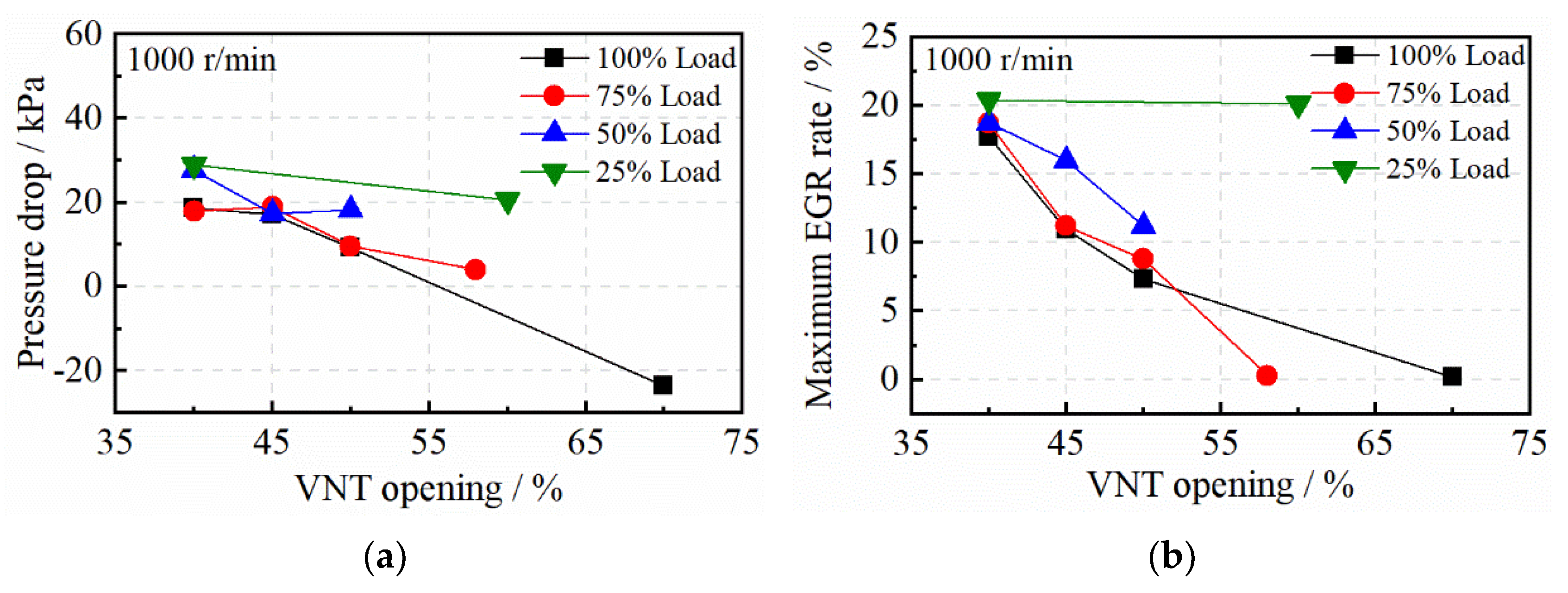

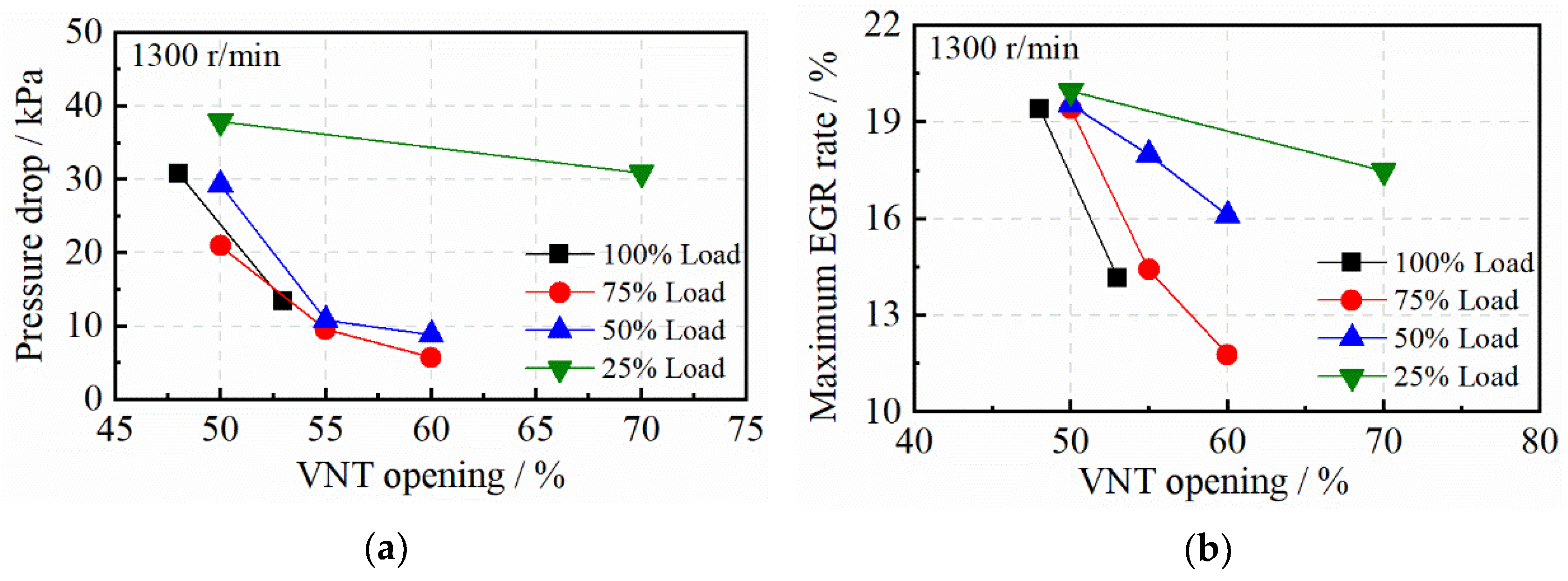

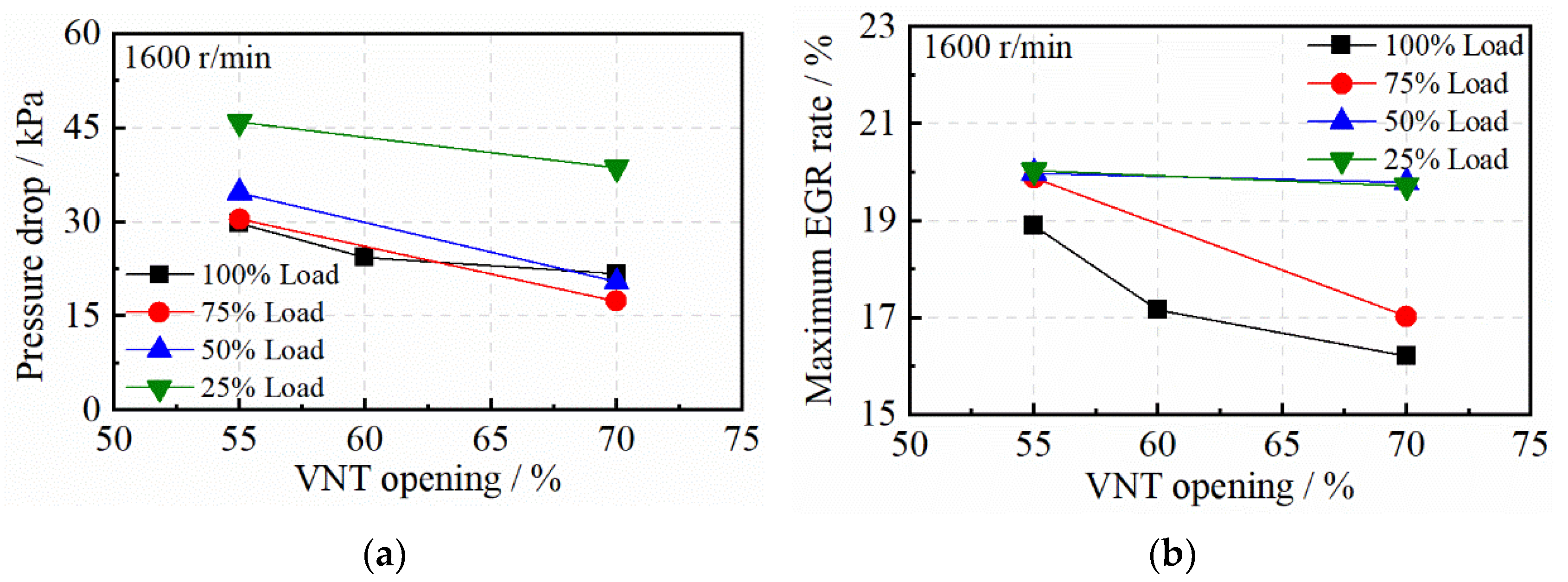

3.1. Impact of VNT on EGR Introduction Ability

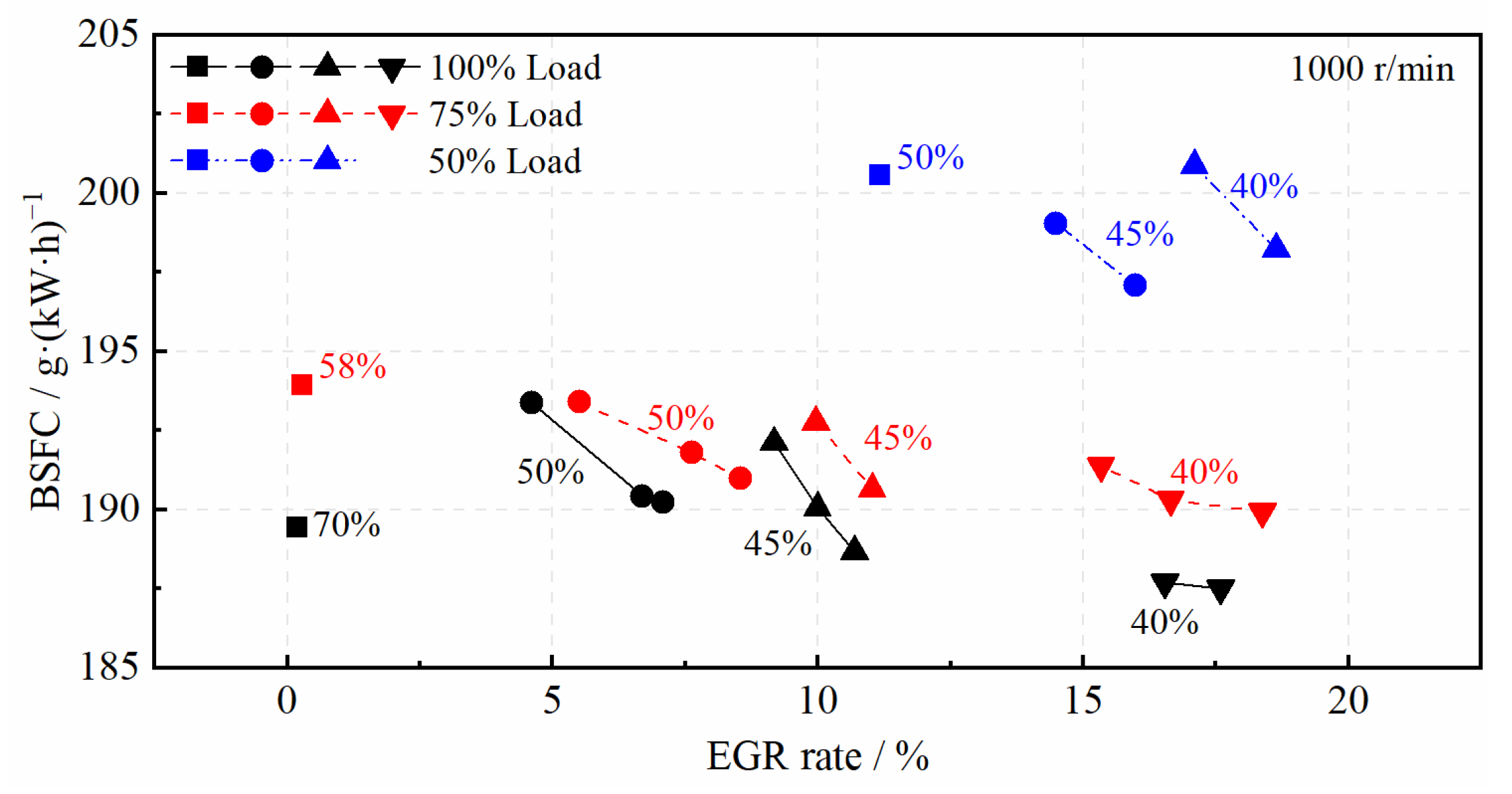

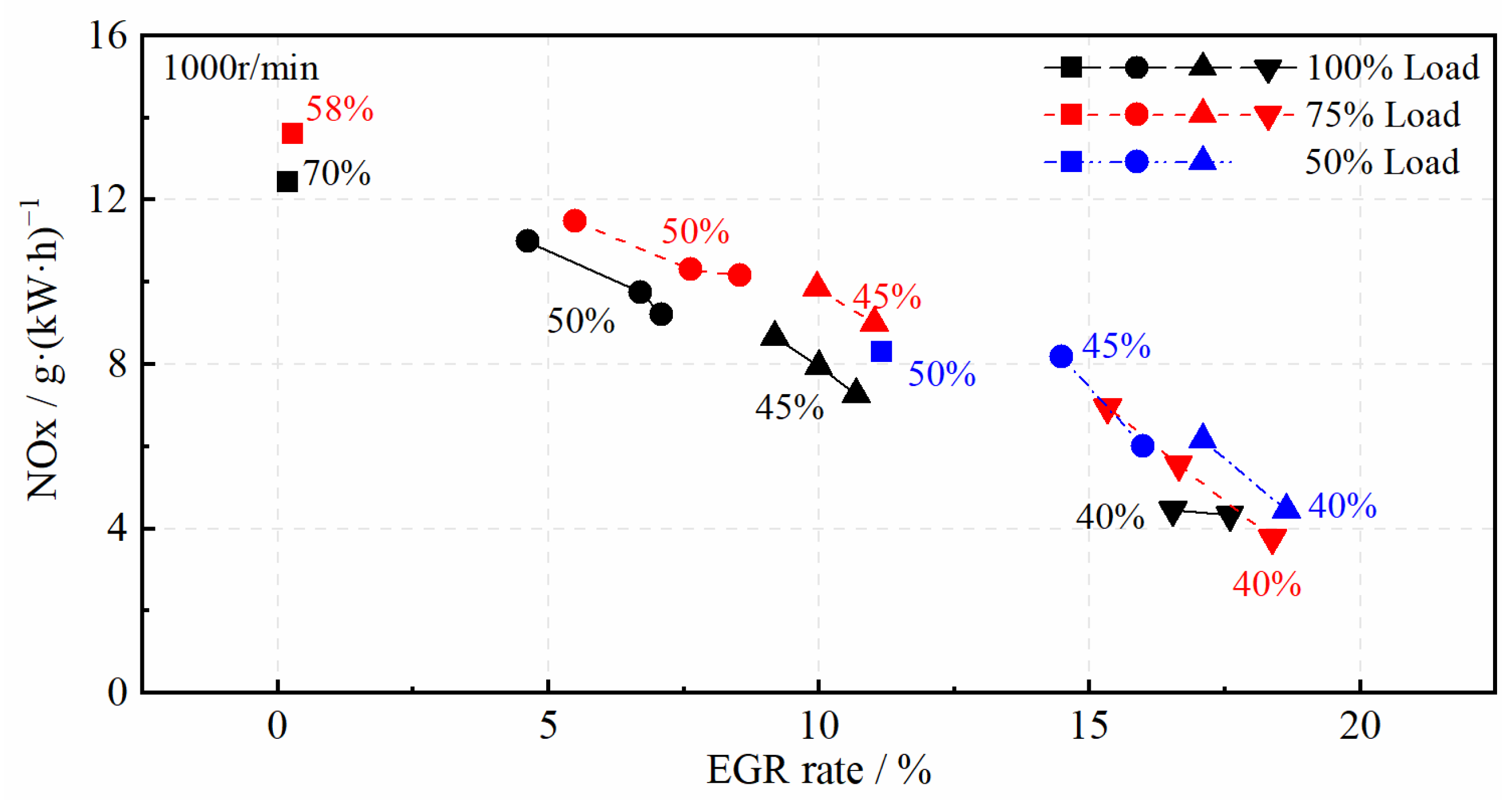

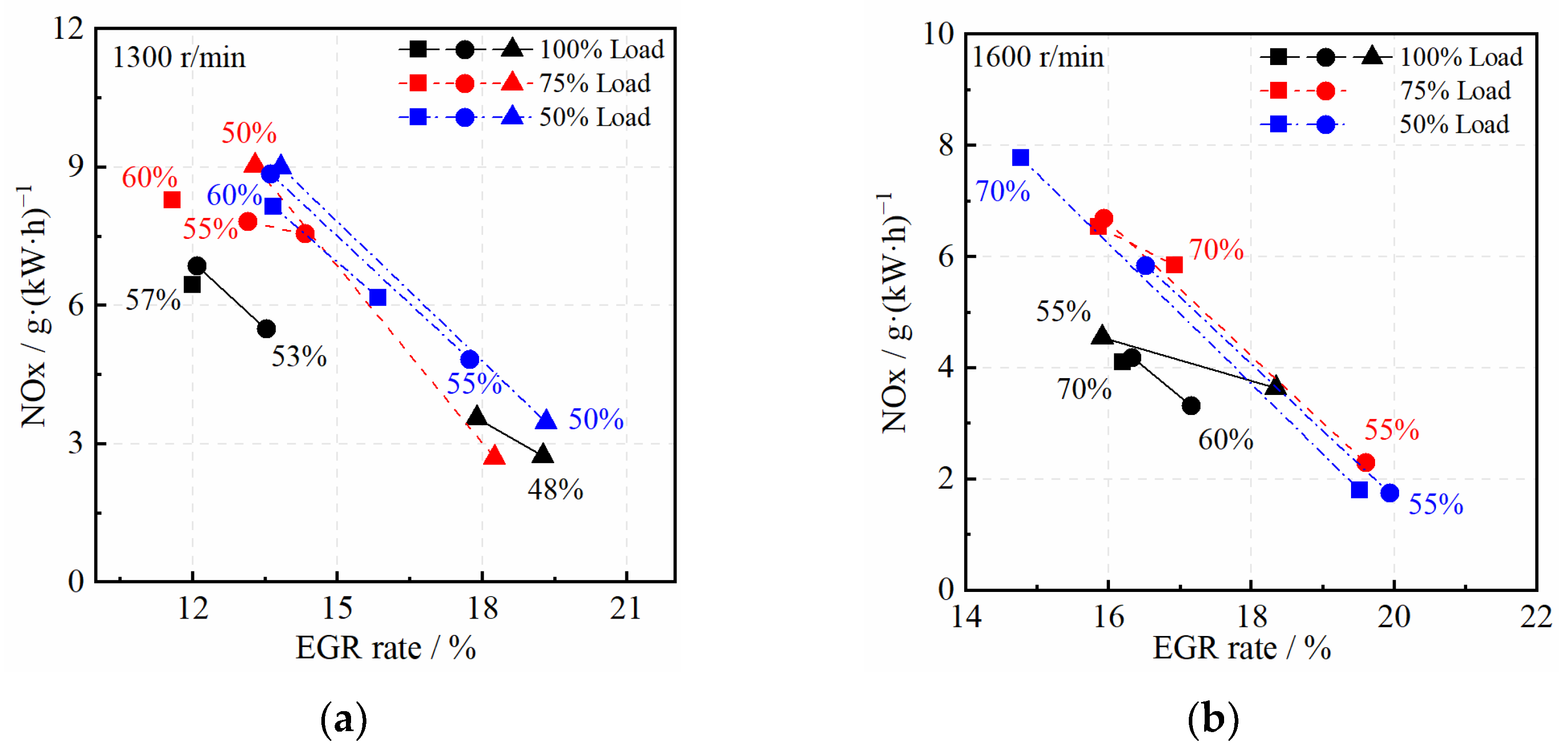

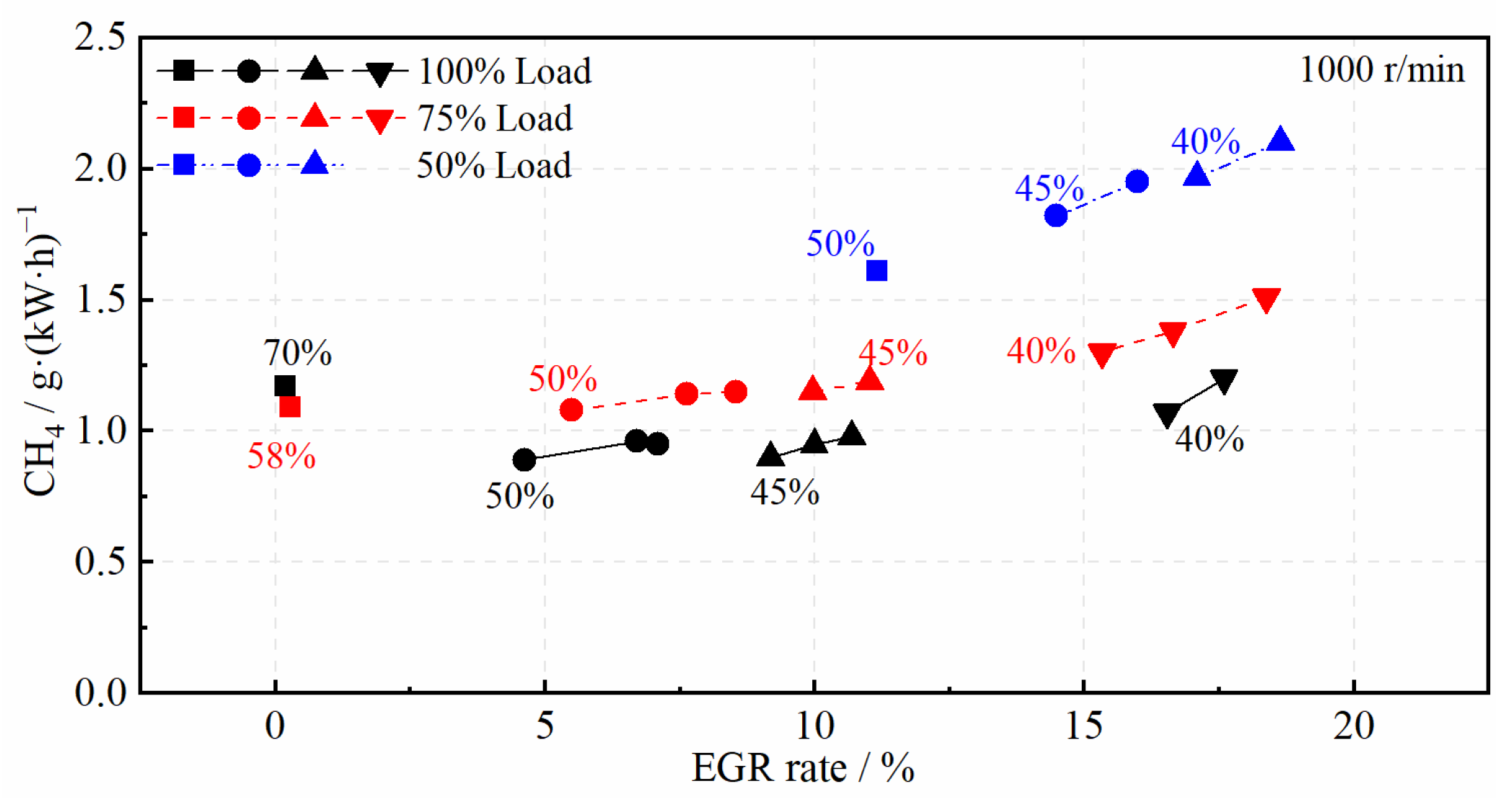

3.2. Impact of VNT-Coupled EGR on Engine Economy and Emissions

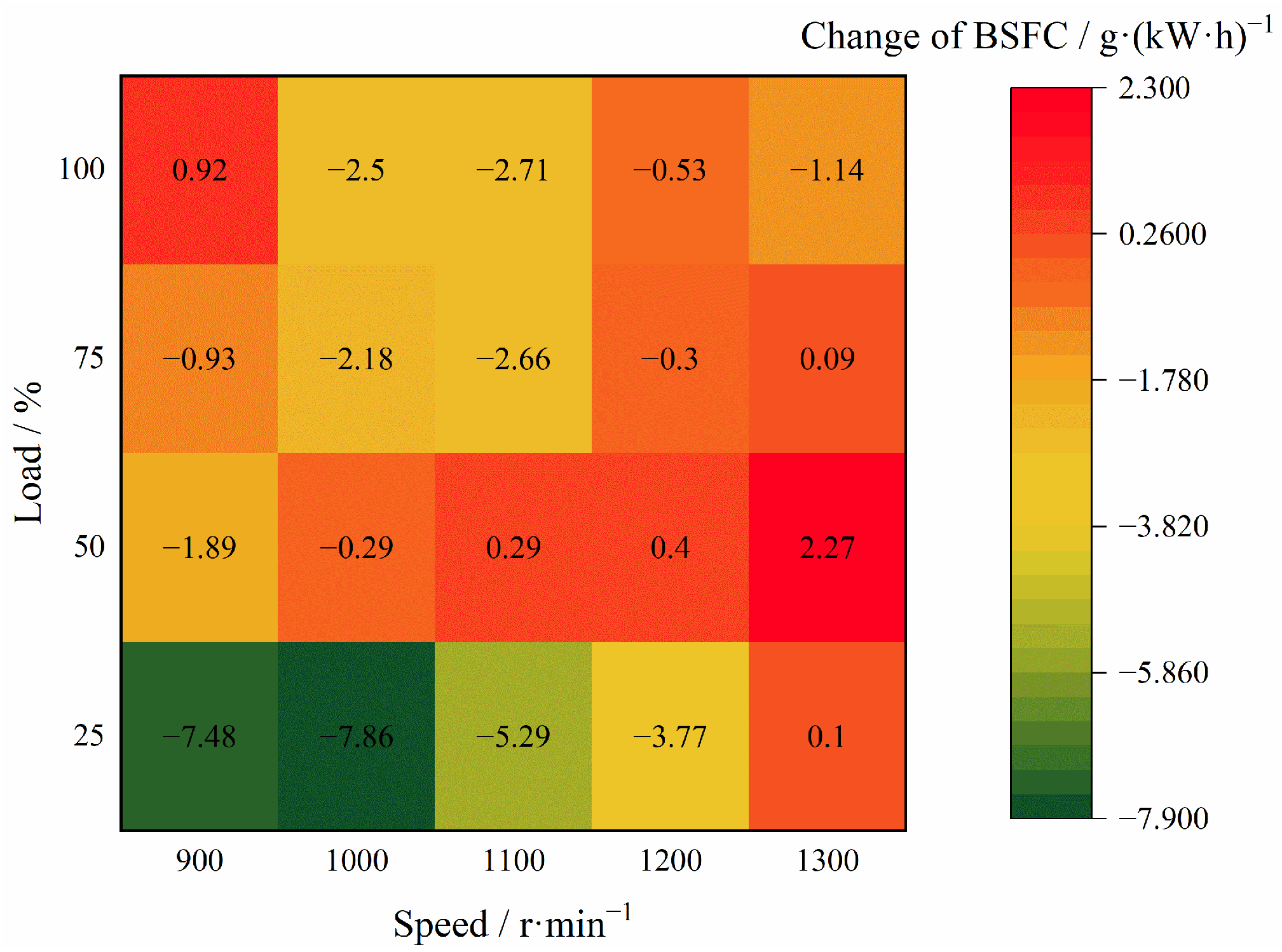

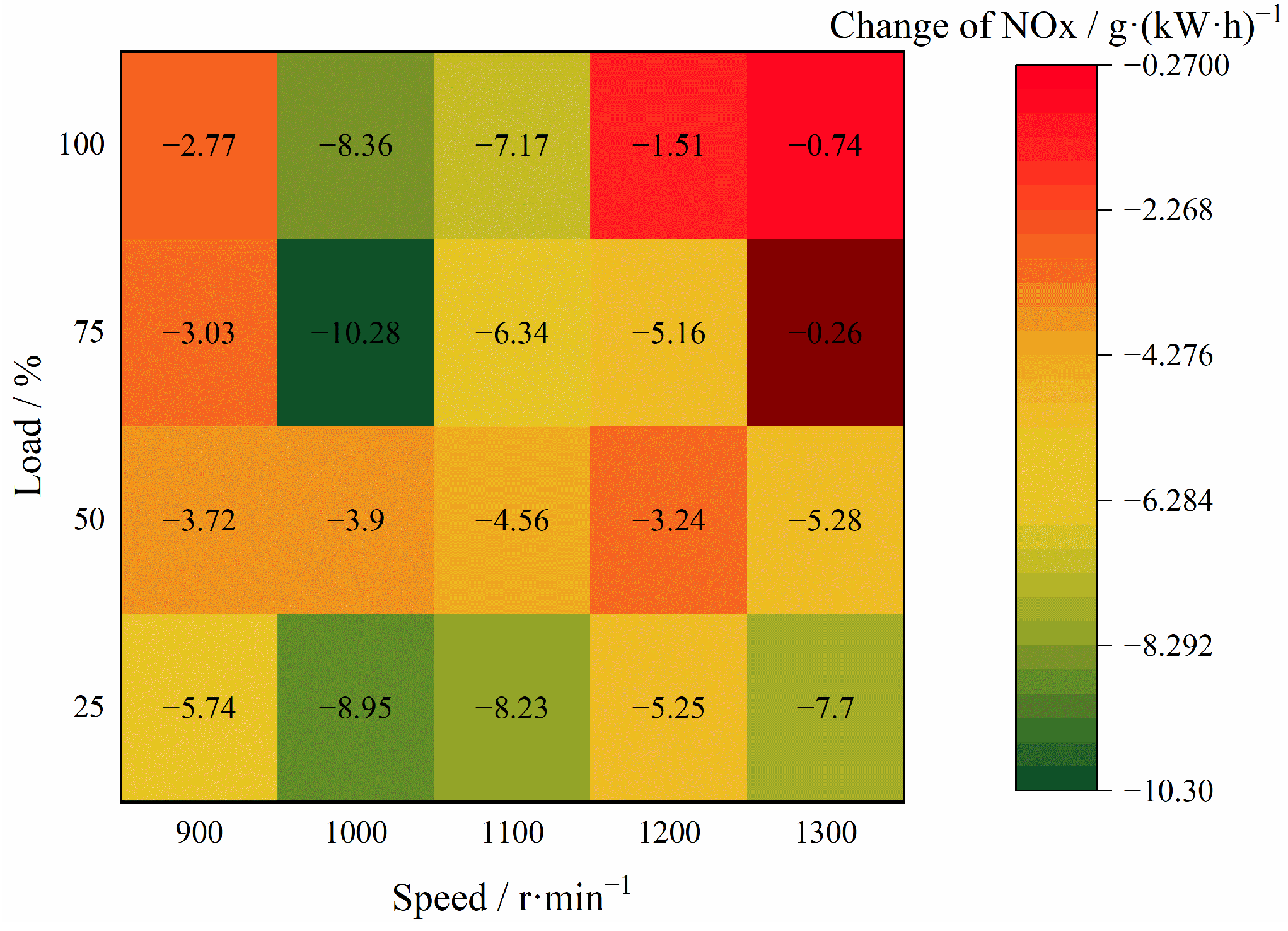

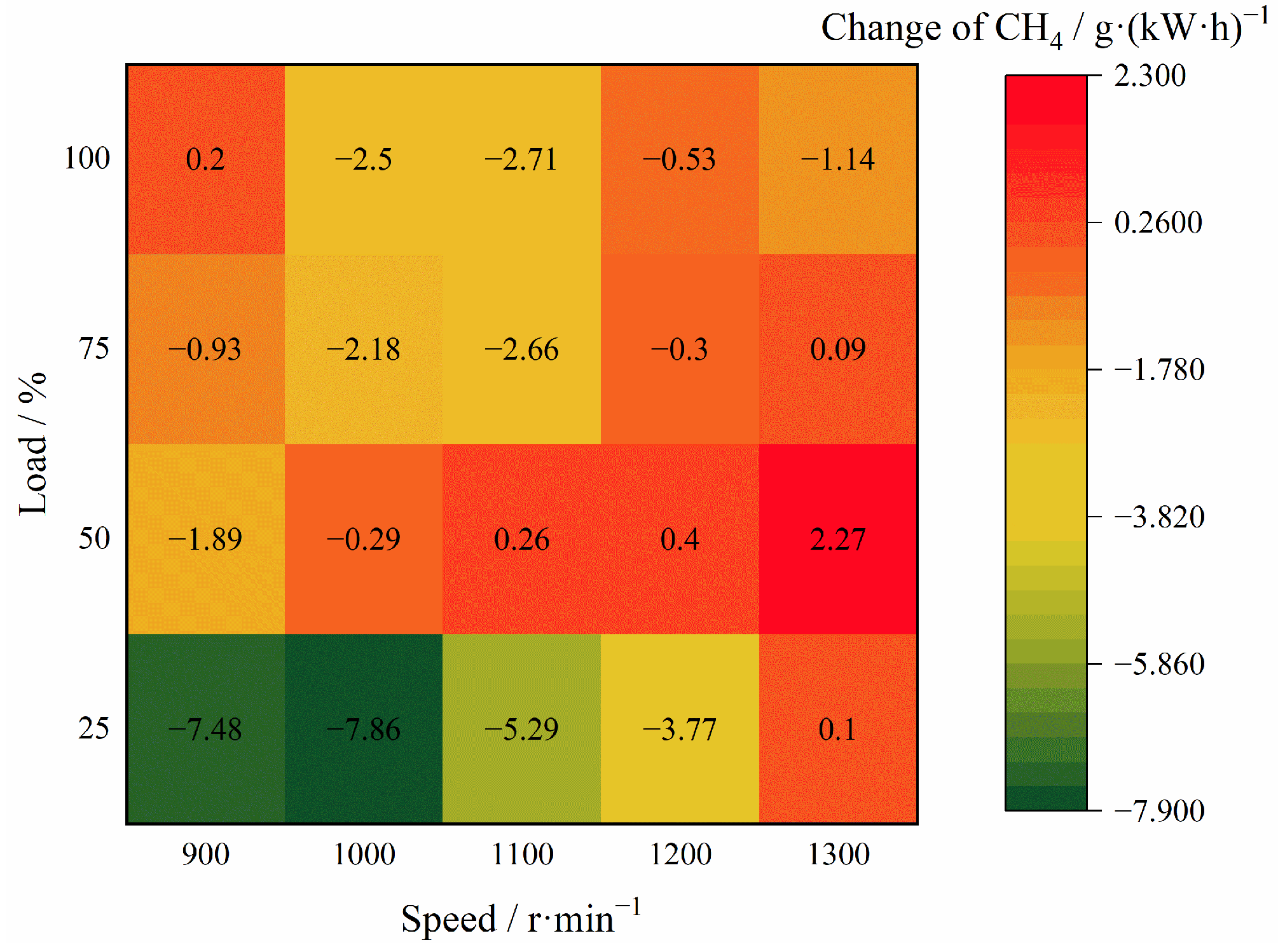

3.3. Validation and Analysis of Multi-Objective Optimization Results

4. Conclusions

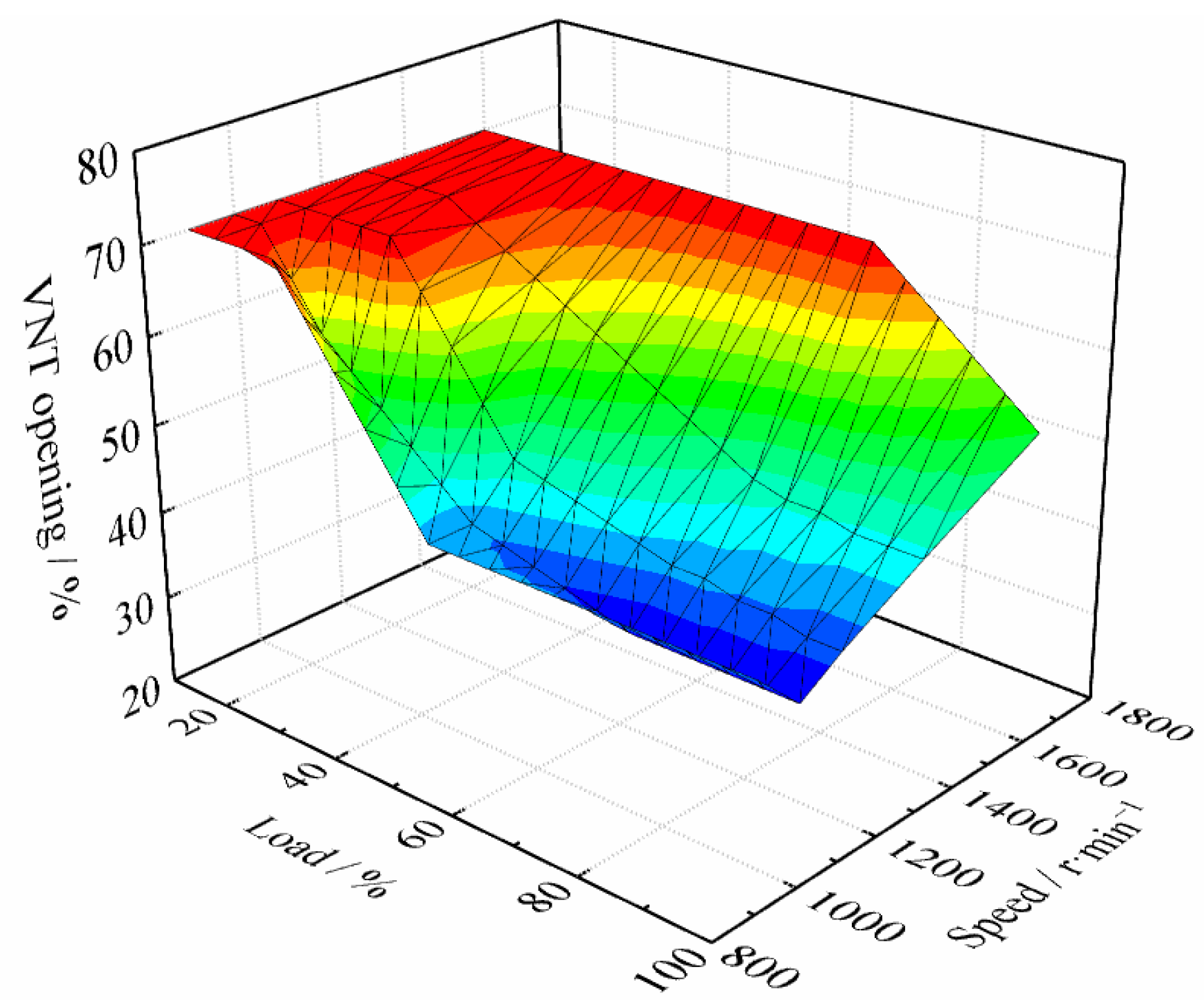

- The use of VNTs in equivalent combustion natural gas engines can enhance the ability to introduce EGR under multiple operating conditions and expand the range of EGR regulation, thereby reducing the engine thermal load, improving fuel efficiency, and reducing emissions. As the VNT opening decreased, the maximum EGR rate achievable under various operating conditions also significantly increased. By adjusting the VNT opening, maximum EGR rates of 17.7% and 18.4% could be achieved under the 1000 r/min external characteristic and 75% load conditions, respectively; it should be noted that previously, under these conditions, EGR could not be introduced.

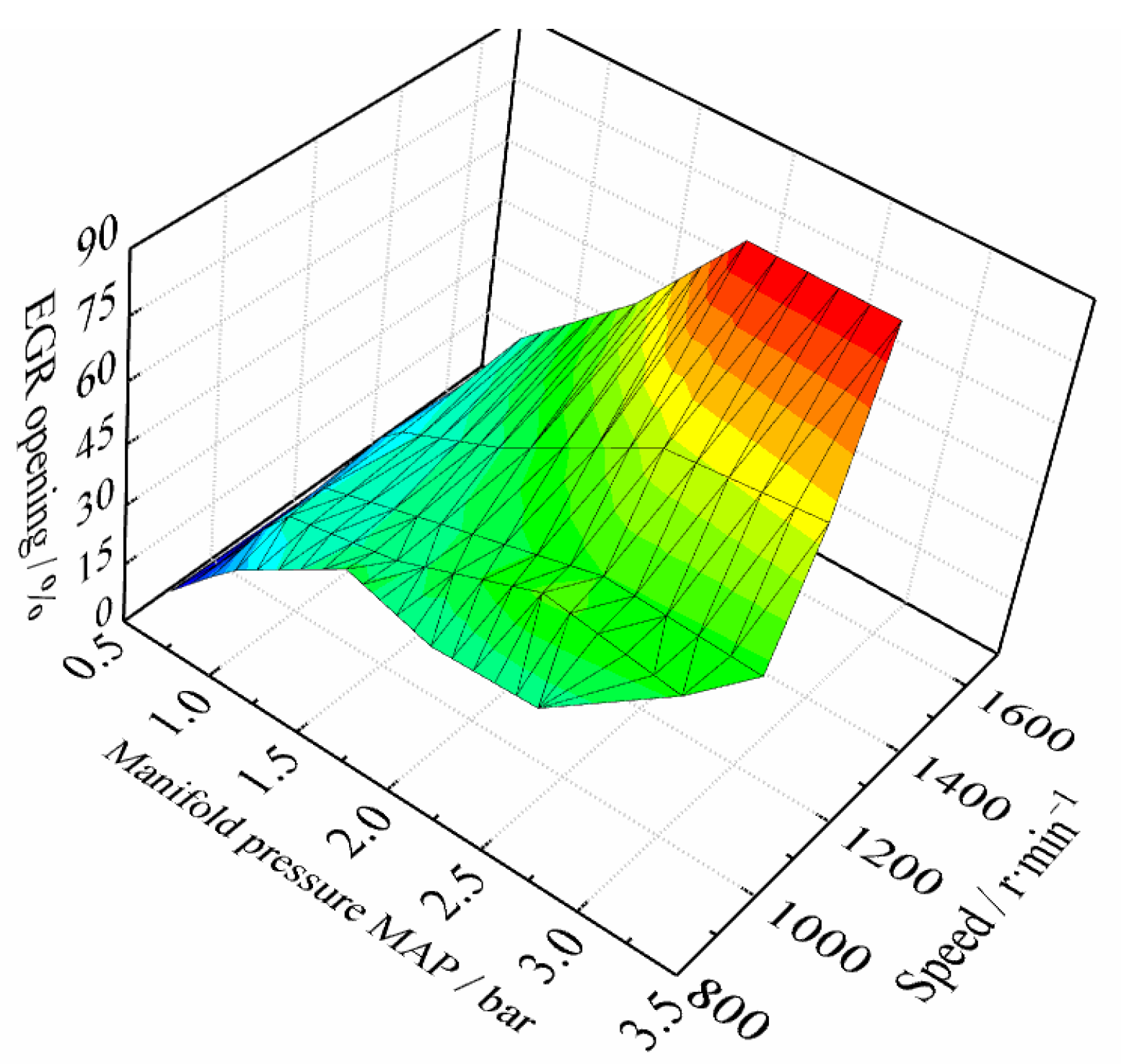

- Under medium to high speed operating conditions, owing to the higher engine thermal burden, the range of VNT opening adjustment became narrower. Although reducing the VNT opening could still improve the maximum EGR rate, it did not optimize the economic performance. Thus, adopting a medium VNT opening resulted in better thermal efficiency. Compared to 1300 r/min, a higher speed brought more intake flow; hence, the turbocharger could achieve a maximum EGR rate of 20% at 55% opening.

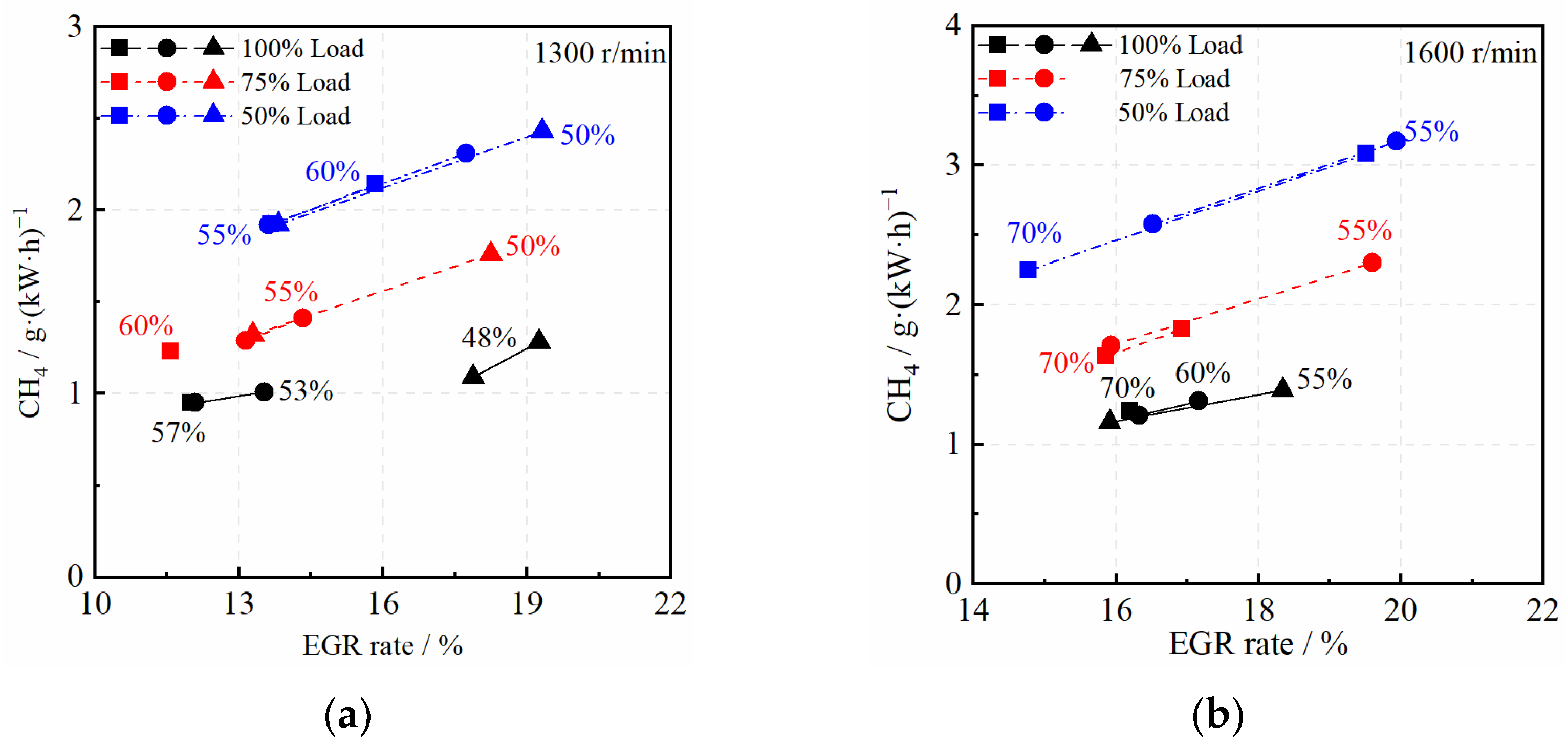

- The regularity of CH4 emissions was more obvious, exhibiting a nearly linear increase with the EGR rate. Under the same operating conditions, CH4 emissions were almost unaffected by changes in the VNT opening and only varied with changes in the EGR rate.

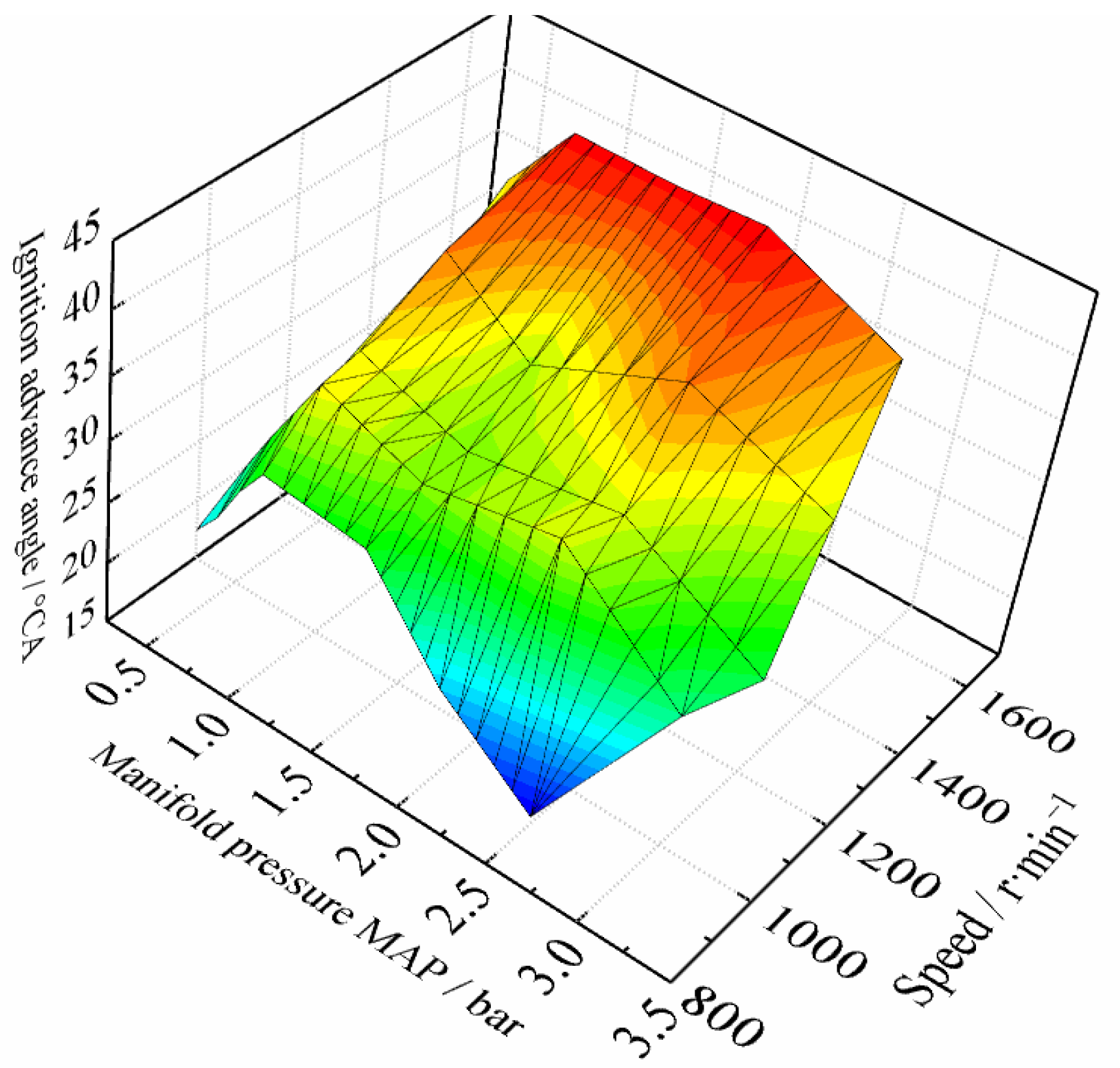

- The multi-objective optimization method based on a support vector regression model and NSGA-II genetic algorithm effectively optimized VNT and EGR control parameters, thus slightly improving the economy and significantly reducing NOx emissions, while maintaining the original engine power performance. At 20 optimized validation operating points, the average decrease in BSFC was 0.94%, the average decrease in NOx was 47.0%, and the average increase in CH4 was 3.7%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, H.; He, J.; Zhong, X. Engine combustion and emission fuelled with natural gas: A review. J. Energy Inst. 2018, 92, 1123–1136. [Google Scholar] [CrossRef]

- Thiruvengadam, A.; Besch, M.; Carder, D.; Oshinuga, A.; Pasek, R.; Hogo, H.; Gautam, M. Unregulated greenhouse gas and ammonia emissions from current technology heavy-duty vehicles. J. Air Waste Manag. Assoc. 2016, 66, 1045–1060. [Google Scholar] [CrossRef] [PubMed]

- Schröder, A.; Eicheldinger, S.; Prager, M.; Jaensch, M. Experimental mild conversion of a lean burn natural gas engine with SCR to a hydrogen engine: NOx and GWP potential for marine applications. Int. J. Engine Res. 2023, 24, 2369–2387. [Google Scholar] [CrossRef]

- Xin, M.; Gan, H.; Cong, Y.; Wang, H. Numerical simulation of methane slip from marine dual-fuel engine based on hydrogen-blended natural gas strategy. Fuel 2024, 358, 130132. [Google Scholar] [CrossRef]

- Wei, L.; Geng, P. A review on natural gas/diesel dual fuel combustion, emissions and performance. Fuel Process. Technol. 2016, 142, 264–278. [Google Scholar] [CrossRef]

- Kim, S.; Park, C.; Jang, H.; Kim, C.; Kim, Y. Effect of boosting on a performance and emissions in a port fuel injection natural gas engine with variable intake and exhaust valve timing. Energy Rep. 2021, 7, 4941–4950. [Google Scholar] [CrossRef]

- Shu, J.; Fu, J.; Liu, J.; Ma, Y.; Wang, S.; Deng, B.; Zeng, D. Effects of injector spray angle on combustion and emissions characteristics of a natural gas (NG)-diesel dual fuel engine based on CFD coupled with reduced chemical kinetic model. Appl. Energy 2019, 233–234, 182–195. [Google Scholar] [CrossRef]

- Li, Y.; Li, H.; Guo, H.; Li, Y.; Yao, M. A numerical investigation on methane combustion and emissions from a natural gas-diesel dual fuel engine using CFD model. Appl. Energy 2017, 205, 153–162. [Google Scholar] [CrossRef]

- Gong, J.; Wang, D.; Li, J.; Currier, N.; Yezerets, A. Dynamic oxygen storage modeling in a three-way catalyst for natural gas engines: A dual-site and shrinking-core diffusion approach. Appl. Catal. B Environ. 2017, 203, 936–945. [Google Scholar] [CrossRef]

- Lehtoranta, K.; Koponen, P.; Vesala, H.; Kallinen, K.; Maunula, T. Performance and Regeneration of Methane Oxidation Catalyst for LNG Ships. J. Mar. Sci. Eng. 2021, 9, 111. [Google Scholar] [CrossRef]

- Lu, X.; Wei, L.; Zhong, J. Effects of Injection Overlap and EGR on Performance and Emissions of Natural Gas HPDI Marine Engine. Combust. Sci. Technol. 2024, 196, 37–54. [Google Scholar] [CrossRef]

- Wu, B.; Luo, Y.; Feng, Y.; Zhu, C.; Yang, P. Design and thermodynamic analysis of solid oxide fuel cells–internal combustion engine combined cycle system based on Two-Stage waste heat preheating and EGR. Fuel 2023, 342, 127817. [Google Scholar] [CrossRef]

- Li, Y.; Wang, P.; Wang, S.; Liu, J.; Xie, Y.; Li, W. Quantitative investigation of the effects of CR, EGR and spark timing strategies on performance, combustion and NOx emissions characteristics of a heavy-duty natural gas engine fueled with 99% methane content. Fuel 2019, 255, 115803.115801–115803.115810. [Google Scholar] [CrossRef]

- Zheng, M.; Irick, D.K.; Hodgson, J. Stabilizing Excessive EGR With an Oxidation Catalyst on a Modern Diesel Engine. In Proceedings of the ASME 2002 Internal Combustion Engine Division Spring Technical Conference, Rockford, IL, USA, 14–17 April 2002. [Google Scholar]

- Li, W.; Liu, Z.; Wang, Z.; Xu, Y. Experimental investigation of the thermal and diluent effects of EGR components on combustion and NOx emissions of a turbocharged natural gas SI engine. Energy Convers. Manag. 2014, 88, 1041–1050. [Google Scholar] [CrossRef]

- Reynolds, C.C.O.B.; Evans, R.L. Improving emissions and performance characteristics of lean burn natural gas engines through partial stratification. Int. J. Engine Res. 2005, 5, 105–114. [Google Scholar] [CrossRef]

- Wijetunge, R.S.; Hawley, J.G.; Vaughan, N.D. An exhaust pressure control strategy for a diesel engine. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2004, 218, 449–464. [Google Scholar] [CrossRef]

- Yu, S.; Wei, L.; Zhou, S.; Lu, X.; Huang, W. Numerical Study on the Effects of Pilot Diesel Quantity Coupling EGR in a High Pressure Direct Injected Natural Gas Engine. Combust. Sci. Technol. 2024, 196, 1–18. [Google Scholar] [CrossRef]

- Vapnik, V.; Vapnik, V. The Natural of Statistical Learning Theory; Springer: New York, NY, USA, 1995. [Google Scholar]

- Li, Y.; Gong, S.; Sherrah, J.; Liddell, H. Support vector machine based multi-view face detection and recognition. Image Vis. Comput. 2004, 22, 413–427. [Google Scholar] [CrossRef]

- Shih, P.; Liu, C. Face detection using discriminating feature analysis and Support Vector Machine. Pattern Recognit. 2004, 39, 260–276. [Google Scholar] [CrossRef]

- Dong, J.X.; Krzyżak, A.; Suen, C.Y. An improved handwritten Chinese character recognition system using support vector machine. Pattern Recognit. Lett. 2005, 26, 1849–1856. [Google Scholar] [CrossRef]

- Campbell, W.M.; Campbell, J.P.; Gleason, T.P.; Reynolds, D.A.; Shen, W. Speaker Verification Using Support Vector Machines and High-Level Features. IEEE Trans. Audio Speech Lang. Process. 2007, 15, 2085–2094. [Google Scholar] [CrossRef]

- Peng, G.; Wang, W.S.Y. Tone recognition of continuous Cantonese speech based on support vector machines. Speech Commun. 2005, 45, 49–62. [Google Scholar] [CrossRef]

- Melgani, F.; Bruzzone, L. Classification of hyperspectral remote sensing images with support vector machines. IEEE Trans. Geosci. Remote Sens. 2004, 42, 1778–1790. [Google Scholar] [CrossRef]

- Chi, M.; Bruzzone, L. Semisupervised Classification of Hyperspectral Images by SVMs Optimized in the Primal. IEEE Trans. Geosci. Remote Sens. 2007, 45, 1870–1880. [Google Scholar] [CrossRef]

- Chi, M.; Feng, R.; Bruzzone, L. Classification of hyperspectral remote-sensing data with primal SVM for small-sized training dataset problem. Adv. Space Res. 2008, 41, 1793–1799. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, R.S.; Ye, Z.B. Combination of particle-swarm optimization with least-squares support vector machine for FDTD time series forecasting. Microw. Opt. Technol. Lett. 2006, 48, 141–144. [Google Scholar] [CrossRef]

- Osowski, S.; Hoai, L.T.; Markiewicz, T. Support vector machine-based expert system for reliable heartbeat recognition. IEEE Trans. Biomed. Eng. 2004, 51, 582–589. [Google Scholar] [CrossRef]

- Wong, K.I.; Wong, P.K.; Cheung, C.S.; Vong, C.M. Modeling and optimization of biodiesel engine performance using advanced machine learning methods. Energy 2013, 55, 519–528. [Google Scholar] [CrossRef]

- Keerthi, S.S.; Lin, C.J. Asymptotic Behaviors of Support Vector Machines with Gaussian Kernel. Neural Comput. 2003, 15, 1667–1689. [Google Scholar] [CrossRef] [PubMed]

- Zitzler, E.; Thiele, L. Multiobjective evolutionary algorithms: A comparative case study and the strength Pareto approach. IEEE Trans. Evol. Comput. 1999, 3, 257–271. [Google Scholar] [CrossRef]

- Edupuganti, V.; Prasad, M.; Ravi, V. A fast and elitist multiobjective genetic algorithm: NSGA-II. Int. J. Comput. Inf. Syst. Ind. Manag. Appl. IJCISIM 2010, 2, 121–136. [Google Scholar]

| Items | Parameters |

|---|---|

| Bore/mm | 126 |

| Stroke/mm | 166 |

| Compression Ratio | 11.5 |

| Maximum Torque/N·m | 2100 |

| Speed at Maximum Torque/r·min−1 | 1300 |

| Rated Power/kW | 330 |

| Speed at Rated Power/r·min−1 | 1800 |

| Device or System | Type | Accuracy/Resolution |

|---|---|---|

| Dynamometer | INDY S66-4/4400-1BS-1 | ±0.2% N·m; ±2 r/m |

| Gas flow meter | Toceil CMF025 | ±2.5% |

| Combustion Analyzer | Kistler Ki-box 2893B | / |

| Cylinder pressure sensor | Kistler 6052Cu20 | ±0.5% |

| Goniometer | Kistler CA adapter 2619 | 0.1 CA |

| Signal amplifier | Kistler 5064C | ±0.1V |

| Sample | Parameter | Torque (N·m) | BSFC (g/kW·h) | Temperature (°C) | NOx (g/kW·h) | CH4 (g/kW·h) | EGR Rate (%) | Kpeak (-) |

|---|---|---|---|---|---|---|---|---|

| Training set | R2 | 0.998 | 0.991 | 0.997 | 0.980 | 0.997 | 0.999 | 0.933 |

| MSE | 164.1 | 0.53 | 2.09 | 0.066 | 0.001 | 0.006 | 0.008 | |

| MAPE (%) | 0.43 | 0.08 | 0.11 | 1.85 | 0.50 | 0.24 | 4.86 | |

| Testing set | R2 | 0.995 | 0.965 | 0.993 | 0.955 | 0.991 | 0.975 | 0.909 |

| MSE | 1211.1 | 3.91 | 18.87 | 0.385 | 0.005 | 0.493 | 0.025 | |

| MAPE (%) | 1.53 | 0.56 | 0.43 | 4.93 | 2.30 | 3.67 | 9.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, K.; Lou, D.; Zhang, Y.; Ren, Y.; Fan, L. Effect of Variable-Nozzle-Turbocharger-Coupled Exhaust Gas Recirculation on Natural Gas Engine Emissions and Collaborative Optimization. Machines 2024, 12, 260. https://doi.org/10.3390/machines12040260

Zhu K, Lou D, Zhang Y, Ren Y, Fan L. Effect of Variable-Nozzle-Turbocharger-Coupled Exhaust Gas Recirculation on Natural Gas Engine Emissions and Collaborative Optimization. Machines. 2024; 12(4):260. https://doi.org/10.3390/machines12040260

Chicago/Turabian StyleZhu, Kan, Diming Lou, Yunhua Zhang, Yedi Ren, and Lanlan Fan. 2024. "Effect of Variable-Nozzle-Turbocharger-Coupled Exhaust Gas Recirculation on Natural Gas Engine Emissions and Collaborative Optimization" Machines 12, no. 4: 260. https://doi.org/10.3390/machines12040260

APA StyleZhu, K., Lou, D., Zhang, Y., Ren, Y., & Fan, L. (2024). Effect of Variable-Nozzle-Turbocharger-Coupled Exhaust Gas Recirculation on Natural Gas Engine Emissions and Collaborative Optimization. Machines, 12(4), 260. https://doi.org/10.3390/machines12040260