Failure Inducement Factor Analysis and Optimal Design Method of Ball Bearing Cage for Aviation Motor

Abstract

:1. Introduction

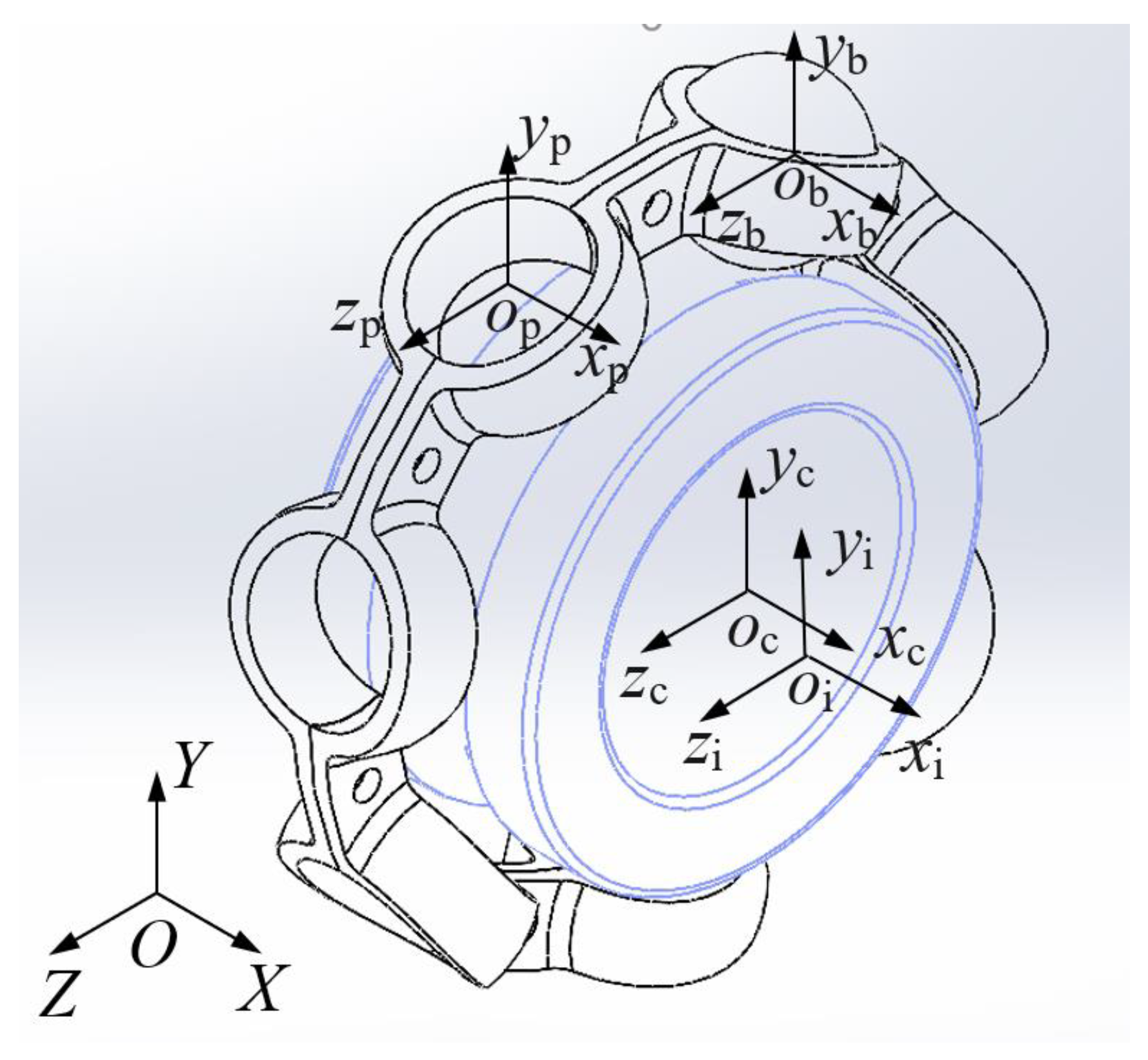

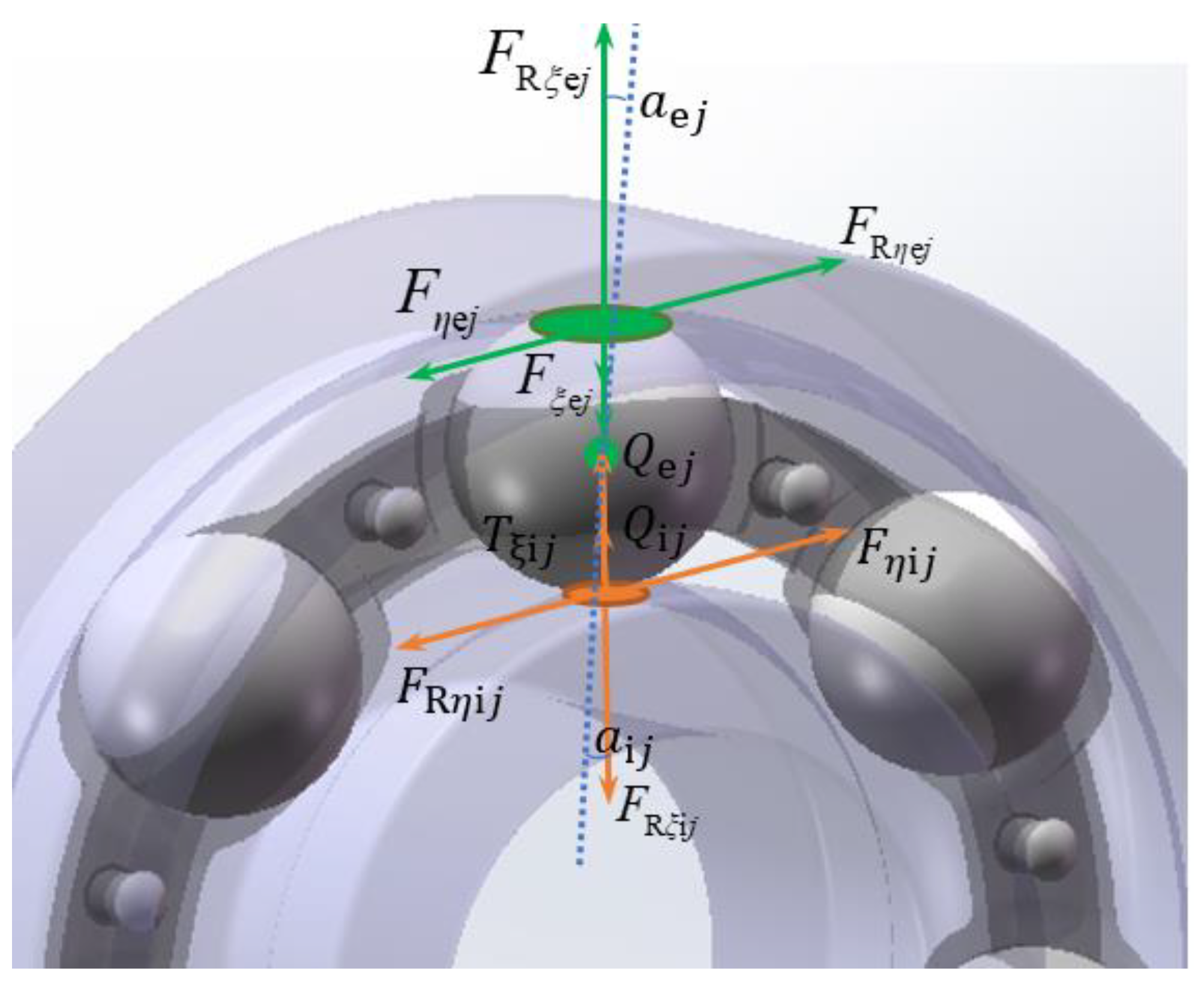

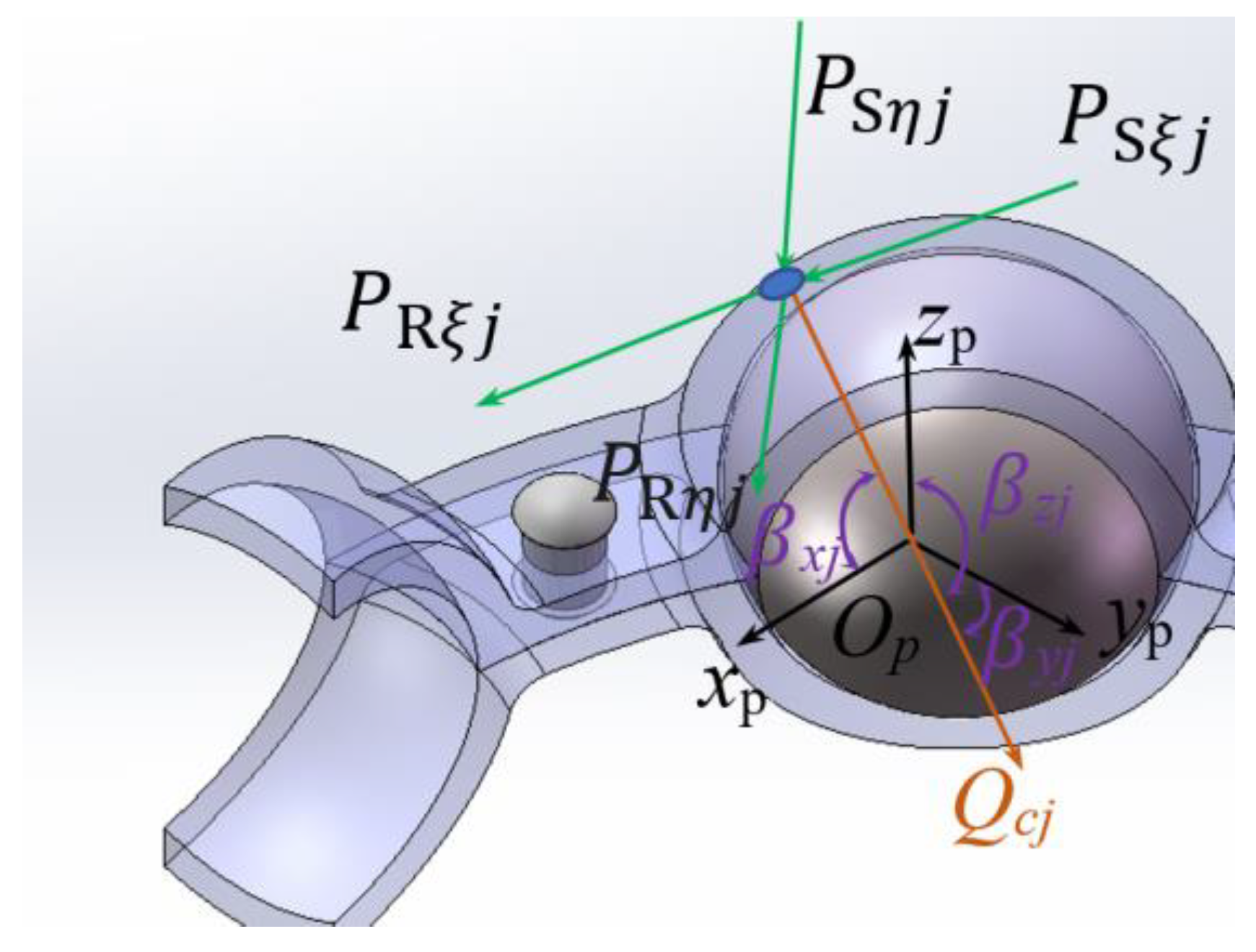

2. Dynamic Analysis Model of a Ball Bearing

3. Results and Analysis

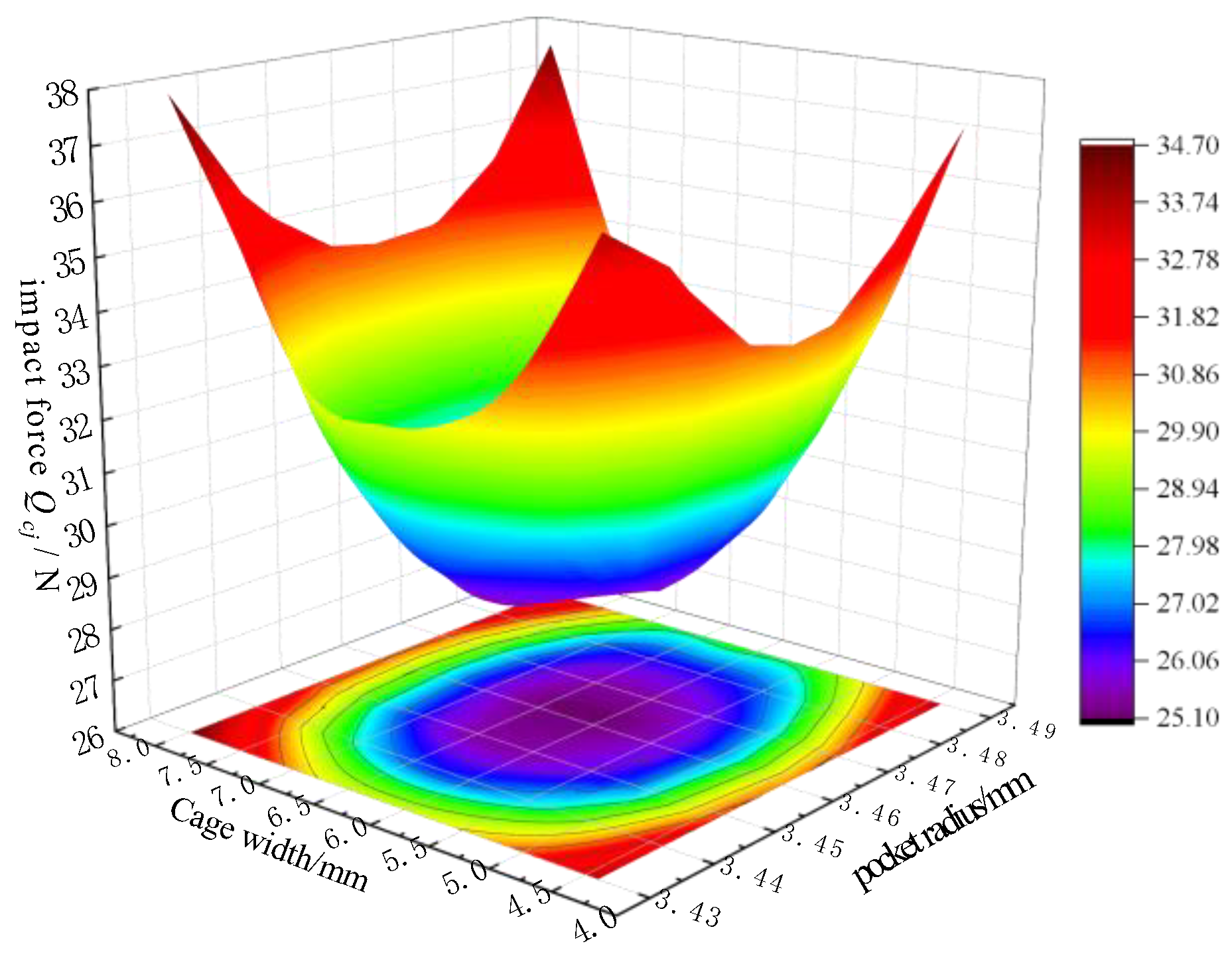

3.1. Influence of Cage Structure Parameters on Dynamic Contact Characteristics of Ball and Cage

3.1.1. Influence of Pocket Radius on Dynamic Contact Characteristics of Ball and Cage

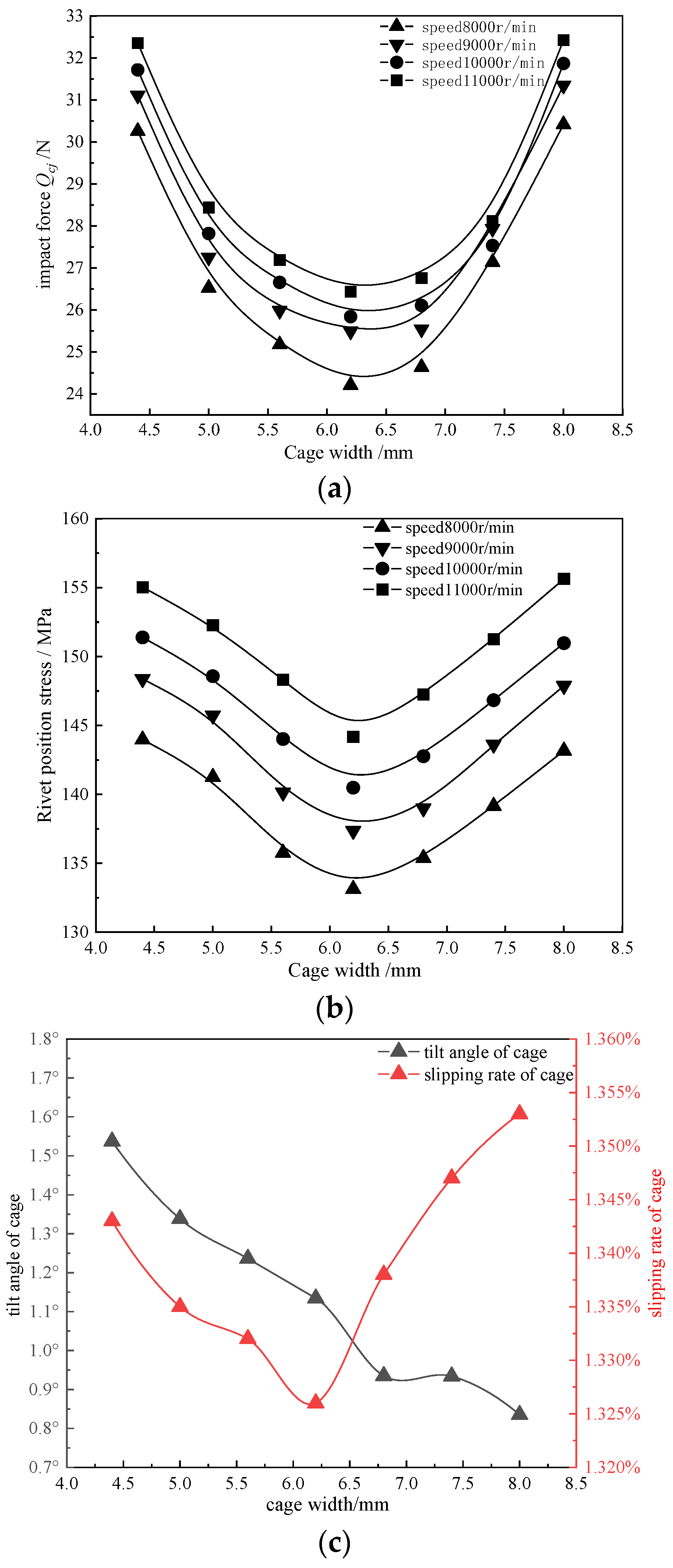

3.1.2. Influence of Cage Width on Dynamic Contact Characteristics between Ball and Cage

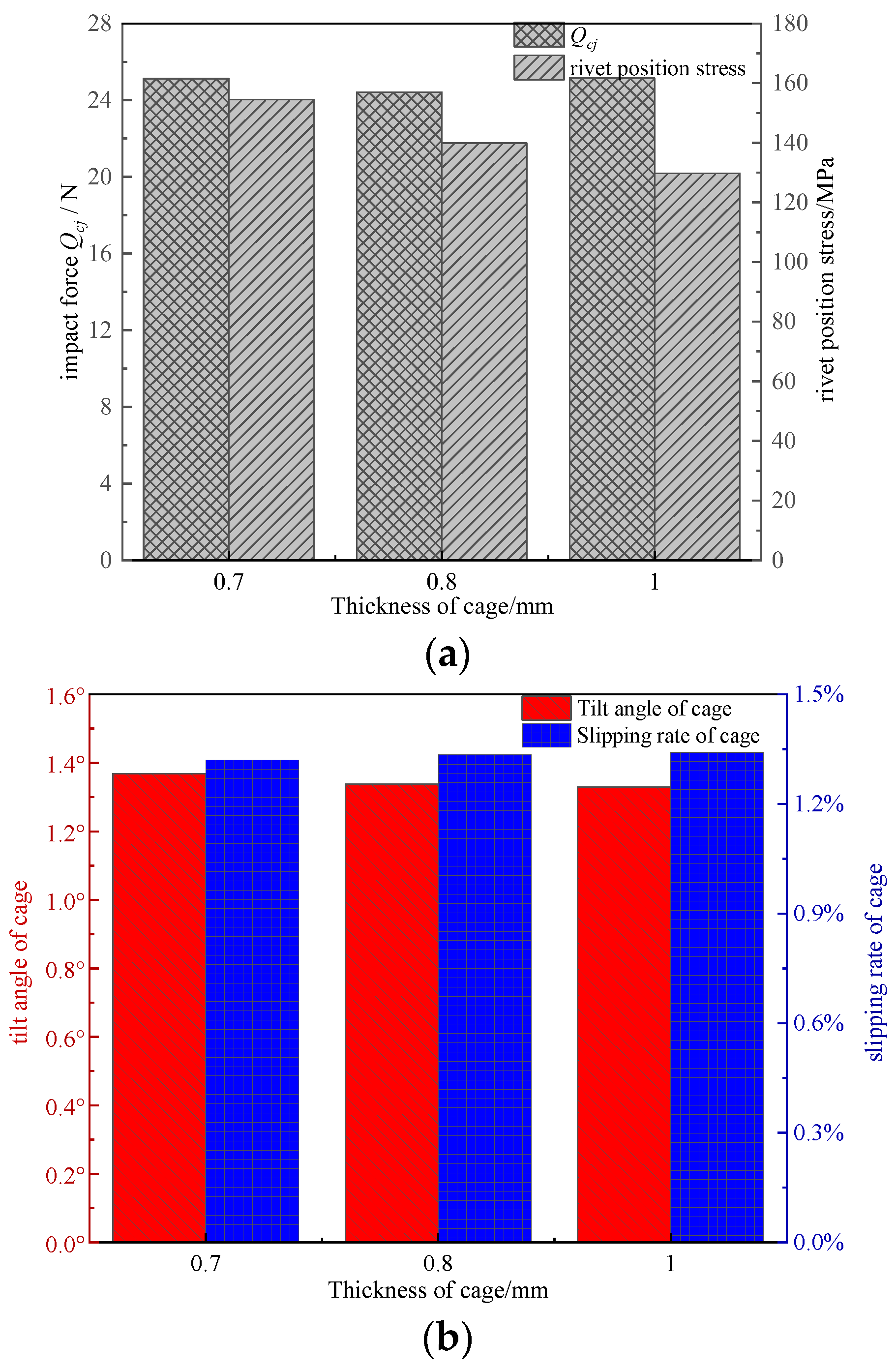

3.1.3. Influence of Cage Thickness on Contact Characteristics of Steel Ball and Pocket Hole

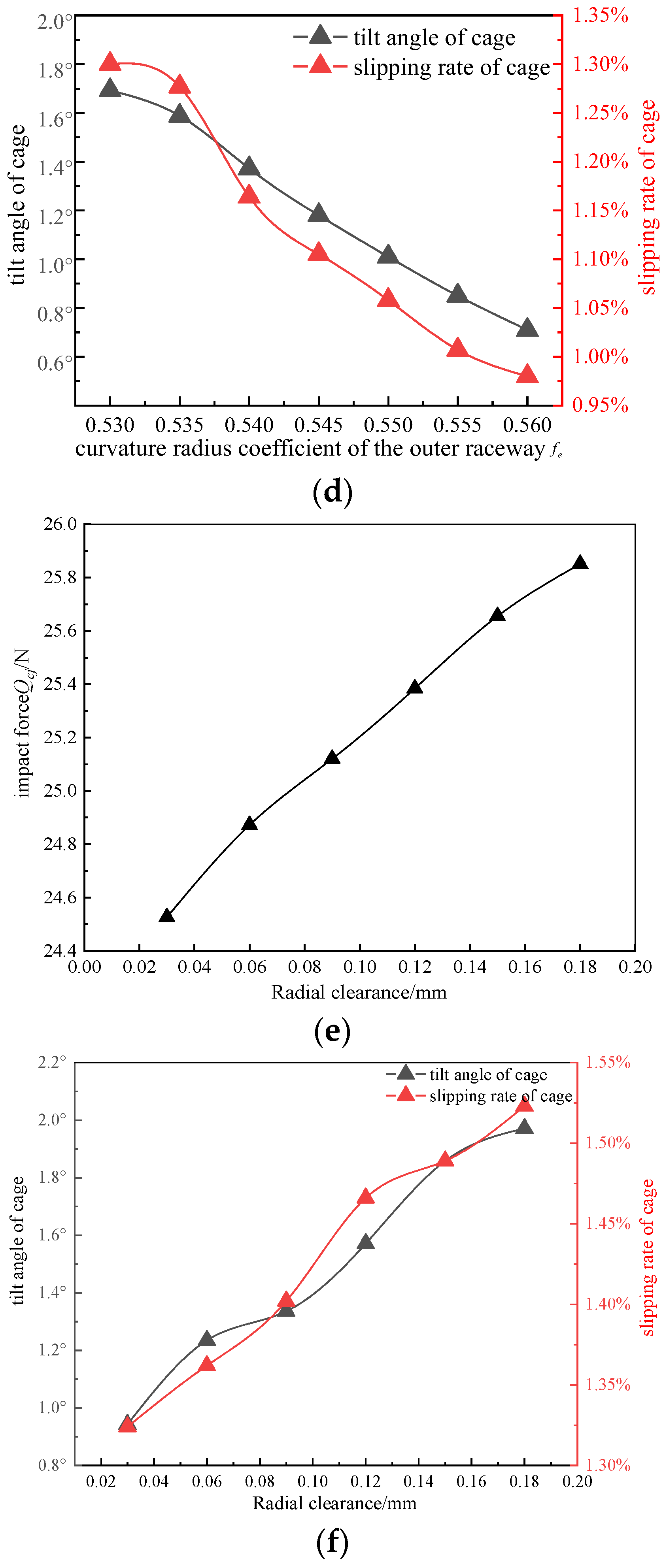

3.2. Influence of Channel Structure Parameters on Contact Characteristics between Ball and Cage

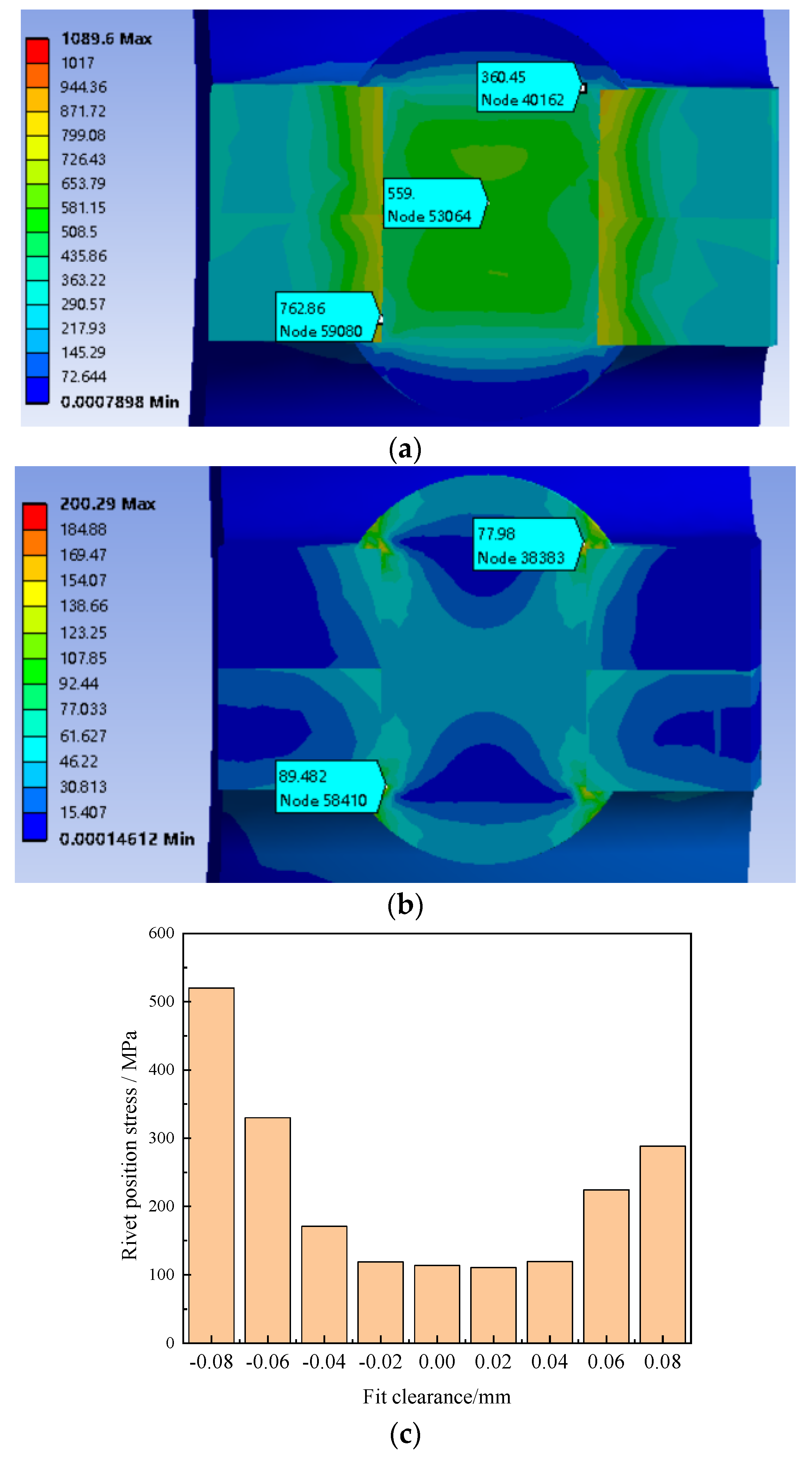

3.3. Influence of Rivet Mating Relationship on Contact Characteristics between Steel Ball and Cage

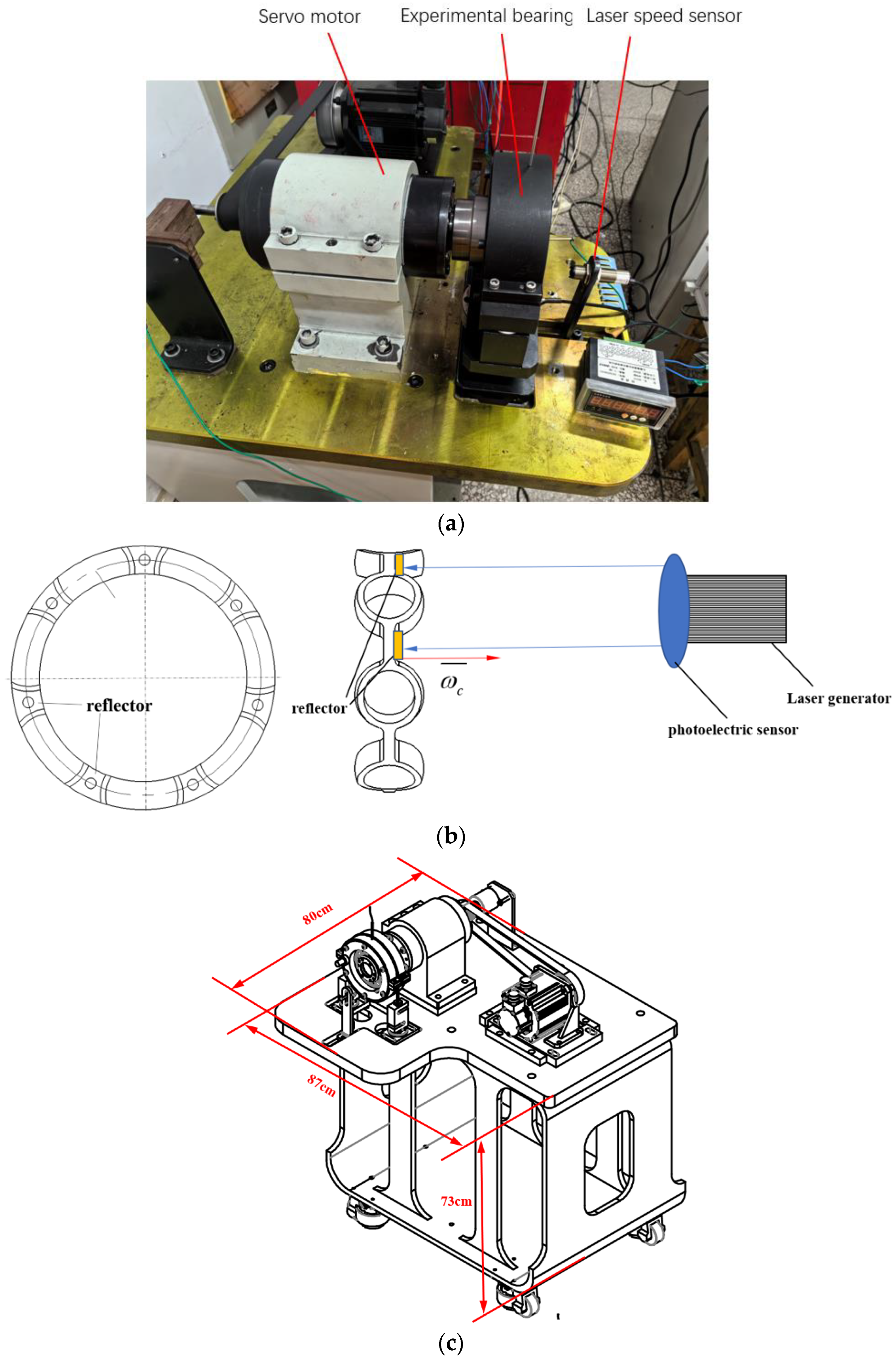

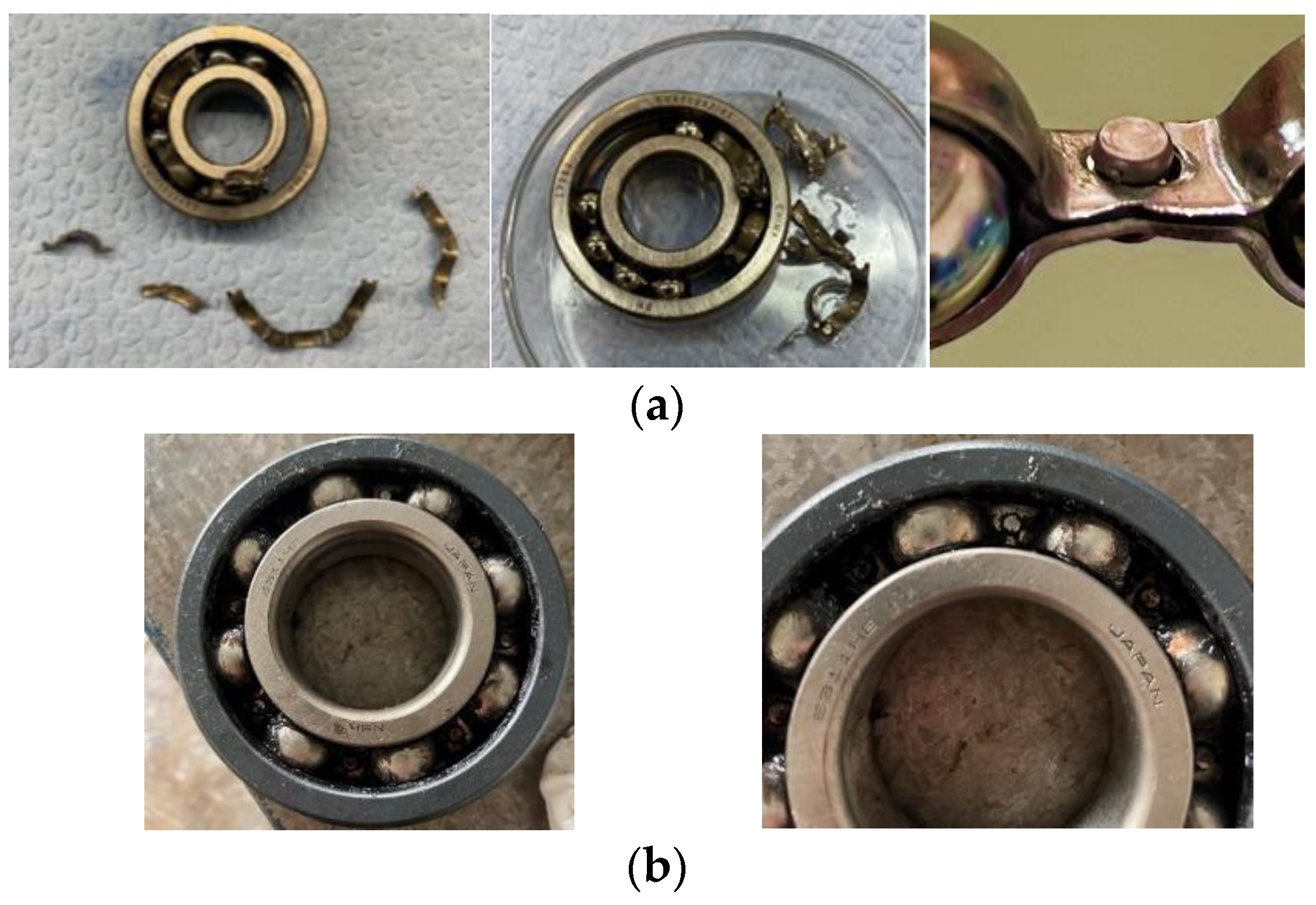

4. Test Verification

5. Conclusions

- (1)

- A suitable cage hole radius can significantly reduce the impact force between the steel ball and cage and the stress on the rivet part as well as improve the operational stability of the cage, thus enhancing the adaptability of the working conditions of the bearing cage. The recommended pocket radius of the bearing in this study is approximately 3.46 mm (after normalization, the radius of the pocket is 13.3% of the pitch diameter). A larger coefficient of the groove curvature radius and a smaller radial clearance must be selected within the design range.

- (2)

- In the wave-pattern holding erection time, the cage wall thickness must be increased within the allowable weight range. This will not have a significant impact on the slip rate of the cage and can improve the strength margin of the cage.

- (3)

- In the contact to ensure the grease lubrication effect, the cage width is selected near 6 mm (after normalization, the width of cage is 23.1% of the pitch diameter), which can make sure that the impact force between the steel ball and the cage and the stress at the rivet are in the lowest state within the selection range of the cage width.

- (4)

- The double-half-wave cage rivet and rivet hole in a small-gap matching state are conducive to extending the life of the rivet and preventing its premature fatigue failure.

- (5)

- Due to the limitation of the space inside the experiment, the impact force between the cage and the ball and the tilt angle of the cage cannot be directly measured. At present, only the slip rate is used to verify the accuracy of the simulation and evaluate the rationality of the bearing design. In future work, more accurate experimental instruments should be used to carry out deeper research.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Deng, S.E.; Jia, Q.Y.; Xue, J.X. Design Theory of Rolling Bearings, 2nd ed.; Standards Press of China: Beijing, China, 2014; pp. 258–260. (In Chinese) [Google Scholar]

- Gupta, P.K.; Paul, B. Advanced Dynamics of Rolling Elements. J. Appl. Mech. 1986, 53, 731–732. [Google Scholar] [CrossRef]

- Rivera, M.P. Bearing-Cage Frictional Instability—A Mechanical Model. Tribol. Trans. 1991, 34, 117–121. [Google Scholar] [CrossRef]

- Donley, A.D.; Boesiger, E.A.; Loewenthal, S. An Analytical and Experimental Investigation of Ball Bearing Retainer Instabilities. J. Tribol. 2008, 114, 530–538. [Google Scholar]

- Salam, I.; Tauqir, A.; Haq, A.U.; Khan, A.Q. An aircrash due to fatigue failure of a ball bearing. Eng. Fail. Anal. 1998, 5, 261–269. [Google Scholar] [CrossRef]

- Ejaz, N.; Salam, I.; Tauqir, A. Failure analysis of an aero engine ball bearing. J. Fail. Anal. Prev. 2006, 6, 25–31. [Google Scholar] [CrossRef]

- Ejaz, N.; Ali, L.; Rizvi, S.A. Failure of an aero engine ball bearing due to axial loading. J. Fail. Anal. Prev. 2015, 15, 15–24. [Google Scholar] [CrossRef]

- Wei, M.; Dyson, J.; Darvell, B. Failure analysis of the ball bearings of dental air turbine handpieces. Aust. Dent. J. 2013, 58, 514–521. [Google Scholar] [CrossRef]

- Mishra, R.K.; Muduli, S.K.; Srinivasan, K.; Ahmed, S.I. Failure analysis of an inter-shaft bearing of an aero gas turbine engine. J. Fail. Anal. Prev. 2015, 15, 205–210. [Google Scholar] [CrossRef]

- Kishore, K.; Mukhopadhyay, G. Root cause failure analysis of pinch roll bearing at hot strip mill. J. Fail. Anal. Prev. 2019, 19, 219–229. [Google Scholar] [CrossRef]

- Xing, C.; Sun, M. Fatigue fracture mechanism of cage of aero-engine spindle bearing. Aero Engines 2002, 2, 32–34. (In Chinese) [Google Scholar]

- Chen, L.; Zhang, Y.; Zhao, Y.; Yang, W. Failure analysis of aero-engine bearings. Aviat. Manuf. Technol. 2015, 128, 120–123. (In Chinese) [Google Scholar]

- Niu, R.; Luo, R.; Wang, Y.; Li, H.; Deng, S. Dynamic characteristics of angular contact ball bearings considering wear effects. J. Vib. Shock 2022, 41, 84–93. [Google Scholar]

- Tu, W.; Liang, J.; Yang, J.; Yang, B.; Zhang, G.; Yuan, X. Dynamic analysis of impact contact characteristics of the cage of a rolling bearing under variable working conditions. J. Vib. Shock 2022, 41, 278–286. [Google Scholar]

- Lu, L.; Shuai, H.; Kai, Z. Analysis of roller bearing cage broken under high DN value. J. Aerosp. Power 2020, 35, 2115–2122. [Google Scholar]

- Pang, B.; Qiao, S.; Deng, S. Improved design of cage and strength analysis based on ANSYS. J. Mech. Transm. 2010, 34, 76–78. [Google Scholar]

- Cui, Y.C.; Deng, S.E.; Zhang, W.H.; Chen, G. The impact of roller dynamic unbalance of high-speed cylindrical roller bearing on the cage nonlinear dynamic characteristics. Mech. Mach. Theory 2017, 118, 65–83. [Google Scholar]

- Cui, Y.C.; Deng, S.E.; Deng, K.W.; Liao, H.; Zhang, W. Experimental study on impact of roller imbalance on cage stability. Chin. J. Aeronaut. 2021, 34, 248–264. [Google Scholar] [CrossRef]

- Cui, Y.; Cai, L.; Zhang, S.; Cui, Y.; Deng, S. Study on Fatigue Characteristics of Rivets in Bearing Cage for an Aeroengine Transmission System. Machines 2023, 11, 700. [Google Scholar] [CrossRef]

- Zhang, W.; Hu, Y.; Deng, S.; Xu, J.; Li, F. Collision Behavior between Ball and Cage in Ball Bearing during Oscillating. Acta Armamentrii 2022, 43, 207–217. [Google Scholar]

- Jia, X.; Zhang, W.; Zhao, B.; Cui, C.; Deng, S. Influence of Structural Parameters of Deep Groove Ball Bearing Crown Cage on Its Performance. Bearing 2021, 13–19. [Google Scholar] [CrossRef]

- Arya, U.; Sadeghi, F.; Conley, B.; Russell, T.; Peterson, W.; Meinel, A. Experimental Investigation of Cage Dynamics and Ball-Cage Contact Forces in an Angular Contact Ball Bearing. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 2522–2534. [Google Scholar] [CrossRef]

- Yuan, D.; Wang, R.; Chen, S.; Chen, X. Experimental research on cage motion with different pocket shapes in angular contact ball bearing. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 1325–1335. [Google Scholar] [CrossRef]

- Chen, S.; Chen, X.; Shuai, Q.; Gu, J. Effects of Cage Pocket Shapes on Dynamics of Angular Contact Ball Bearings. Tribol. Online 2020, 15, 343–355. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Bearing outer diameter/mm | 37 |

| Bearing inner diameter/mm | 15 |

| Pitch diameter of the ball/mm | 26 |

| Ball diameter/mm | 6.47 |

| Pitch diameter/mm | 26 |

| Bearing width/mm | 10 |

| Cage width/mm | 6.5 |

| Pocket radius/mm | 3.45 |

| Speed/r/min | 9000 |

| Overturning moment/N·mm | 82,500 |

| Component Name | Material | Density/(g/cm3) | Elastic Modulus/GPa | Poisson Ratio |

|---|---|---|---|---|

| Inner(Outer) ring and ball | GCr15 | 7.85 | 205 | 0.291 |

| cage | ML15 | 7.82 | 192 | 0.3 |

| No. | Pocket Radius/mm | Cage Width/mm | Qcj/N | No. | Pocket Radius/mm | Cage Width/mm | Qcj/N |

|---|---|---|---|---|---|---|---|

| 1 | 3.43 | 8 | 34.67 | 26 | 3.46 | 5.6 | 25.47 |

| 2 | 3.43 | 7.4 | 32.373 | 27 | 3.46 | 5 | 27.07 |

| 3 | 3.43 | 6.8 | 29.837 | 28 | 3.46 | 4.4 | 30.841 |

| 4 | 3.43 | 6.2 | 29.657 | 29 | 3.47 | 8 | 31.24 |

| 5 | 3.43 | 5.6 | 29.932 | 30 | 3.47 | 7.4 | 27.85 |

| 6 | 3.43 | 5 | 31.1 | 31 | 3.47 | 6.8 | 25.87 |

| 7 | 3.43 | 4.4 | 33.582 | 32 | 3.47 | 6.2 | 25.51 |

| 8 | 3.44 | 8 | 32.667 | 33 | 3.47 | 5.6 | 25.86 |

| 9 | 3.44 | 7.4 | 28.821 | 34 | 3.47 | 5 | 27.28 |

| 10 | 3.44 | 6.8 | 27.24 | 35 | 3.47 | 4.4 | 30.977 |

| 11 | 3.44 | 6.2 | 26.27 | 36 | 3.48 | 8 | 32.27 |

| 12 | 3.44 | 5.6 | 27.23 | 37 | 3.48 | 7.4 | 28.61 |

| 13 | 3.44 | 5 | 28.74 | 38 | 3.48 | 6.8 | 26.57 |

| 14 | 3.44 | 4.4 | 32.85 | 39 | 3.48 | 6.2 | 26.33 |

| 15 | 3.45 | 8 | 31.345 | 40 | 3.48 | 5.6 | 26.68 |

| 16 | 3.45 | 7.4 | 27.934 | 41 | 3.48 | 5 | 28.46 |

| 17 | 3.45 | 6.8 | 25.83 | 42 | 3.48 | 4.4 | 32.53 |

| 18 | 3.45 | 6.2 | 25.49 | 43 | 3.49 | 8 | 34.42 |

| 19 | 3.45 | 5.6 | 25.98 | 44 | 3.49 | 7.4 | 30.538 |

| 20 | 3.45 | 5 | 27.251 | 45 | 3.49 | 6.8 | 27.93 |

| 21 | 3.45 | 4.4 | 31.107 | 46 | 3.49 | 6.2 | 28.734 |

| 22 | 3.46 | 8 | 31.162 | 47 | 3.49 | 5.6 | 27.96 |

| 23 | 3.46 | 7.4 | 27.61 | 48 | 3.49 | 5 | 30.071 |

| 24 | 3.46 | 6.8 | 25.48 | 49 | 3.49 | 4.4 | 33.9 |

| 25 | 3.46 | 6.2 | 25.12 |

| Bearing Load and Speed | Modified Bearing | Original Bearing | ||

|---|---|---|---|---|

| Experimental Value | Artificial Value | Experimental Value | Artificial Value | |

| 82,500 N·mm 9000 rpm | 1.13% | 1.04% | 1.84% | 1.67% |

| 82,500 N·mm 8000 rpm | 1.07% | 0.94% | 1.35% | 1.27% |

| 82,500 N·mm 7000 rpm | 0.97% | 0.92% | 1.14% | 1.05% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Y.; Cai, L.; Wang, J.; Gao, X. Failure Inducement Factor Analysis and Optimal Design Method of Ball Bearing Cage for Aviation Motor. Machines 2024, 12, 466. https://doi.org/10.3390/machines12070466

Cui Y, Cai L, Wang J, Gao X. Failure Inducement Factor Analysis and Optimal Design Method of Ball Bearing Cage for Aviation Motor. Machines. 2024; 12(7):466. https://doi.org/10.3390/machines12070466

Chicago/Turabian StyleCui, Yongcun, Linshen Cai, Jingjing Wang, and Xiaoguo Gao. 2024. "Failure Inducement Factor Analysis and Optimal Design Method of Ball Bearing Cage for Aviation Motor" Machines 12, no. 7: 466. https://doi.org/10.3390/machines12070466

APA StyleCui, Y., Cai, L., Wang, J., & Gao, X. (2024). Failure Inducement Factor Analysis and Optimal Design Method of Ball Bearing Cage for Aviation Motor. Machines, 12(7), 466. https://doi.org/10.3390/machines12070466