A Novel Algorithm to Detect Broken Bars in Induction Motors

Abstract

:1. Introduction

- The speed of the machine must be constant and known;

- The stator fundamental frequency must be constant;

- The load must be constant;

- The load should be as high as possible in order to separate the broken bar frequency from the fundamental one.

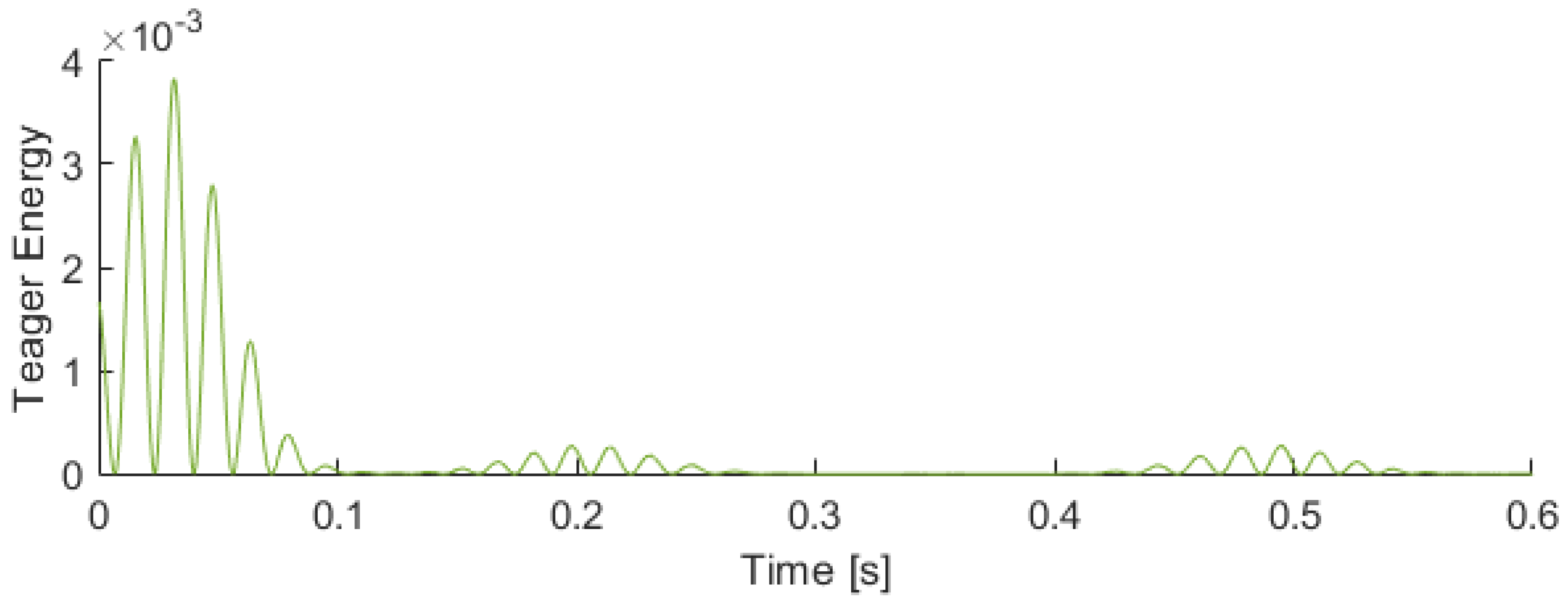

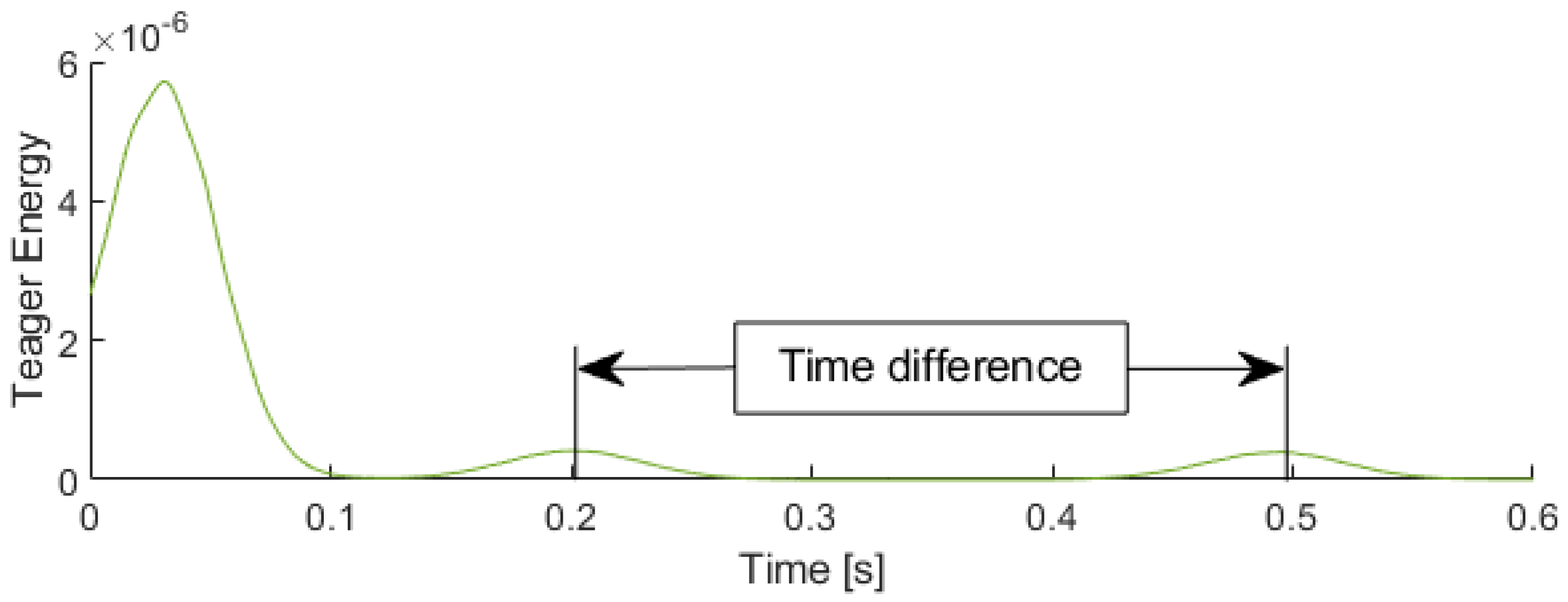

2. Teager Energy Operator

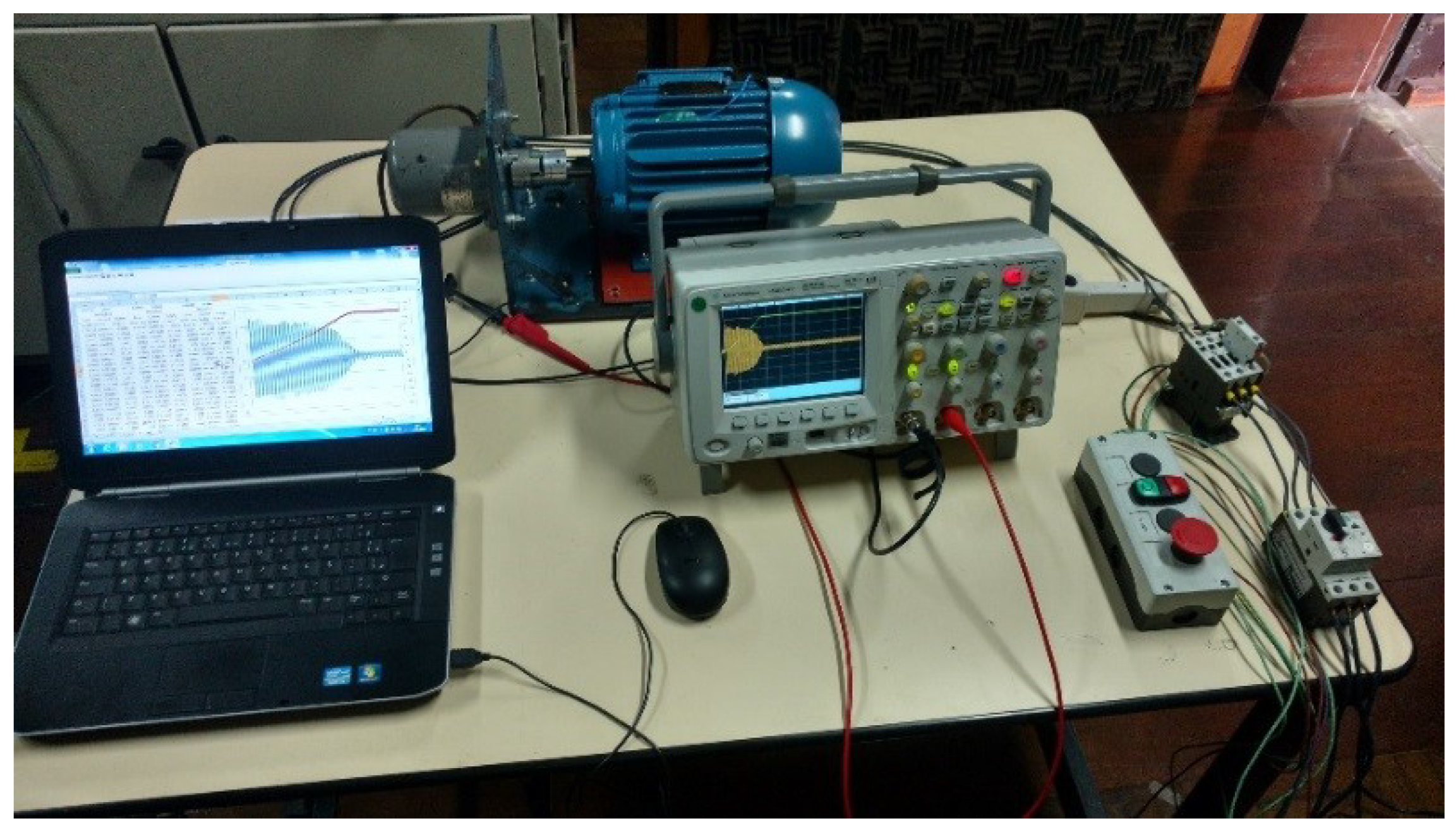

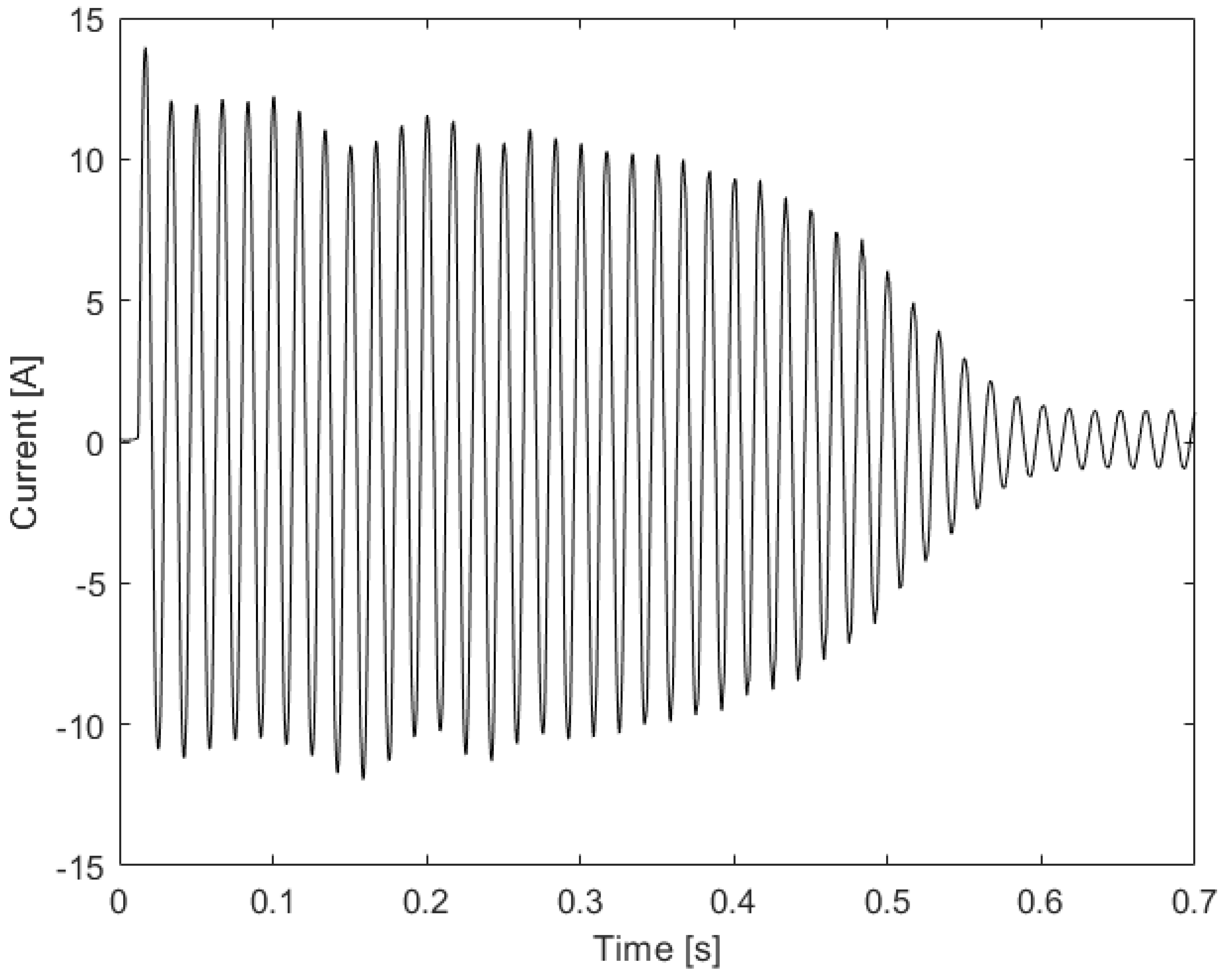

3. Experimental Setup

- Rotor without failure (HEALTHY);

- Rotor with one bar partially broken (½ BAR);

- Rotor with one bar completely failed (1 BAR);

- Rotor with 2 bars totally failed, geometrically separated by (2 BAR 180);

- Rotor with 2 bars totally failed, geometrically separated by (2 BAR 90);

- Rotor with 2 adjacent bars totally failed (2 BAR).

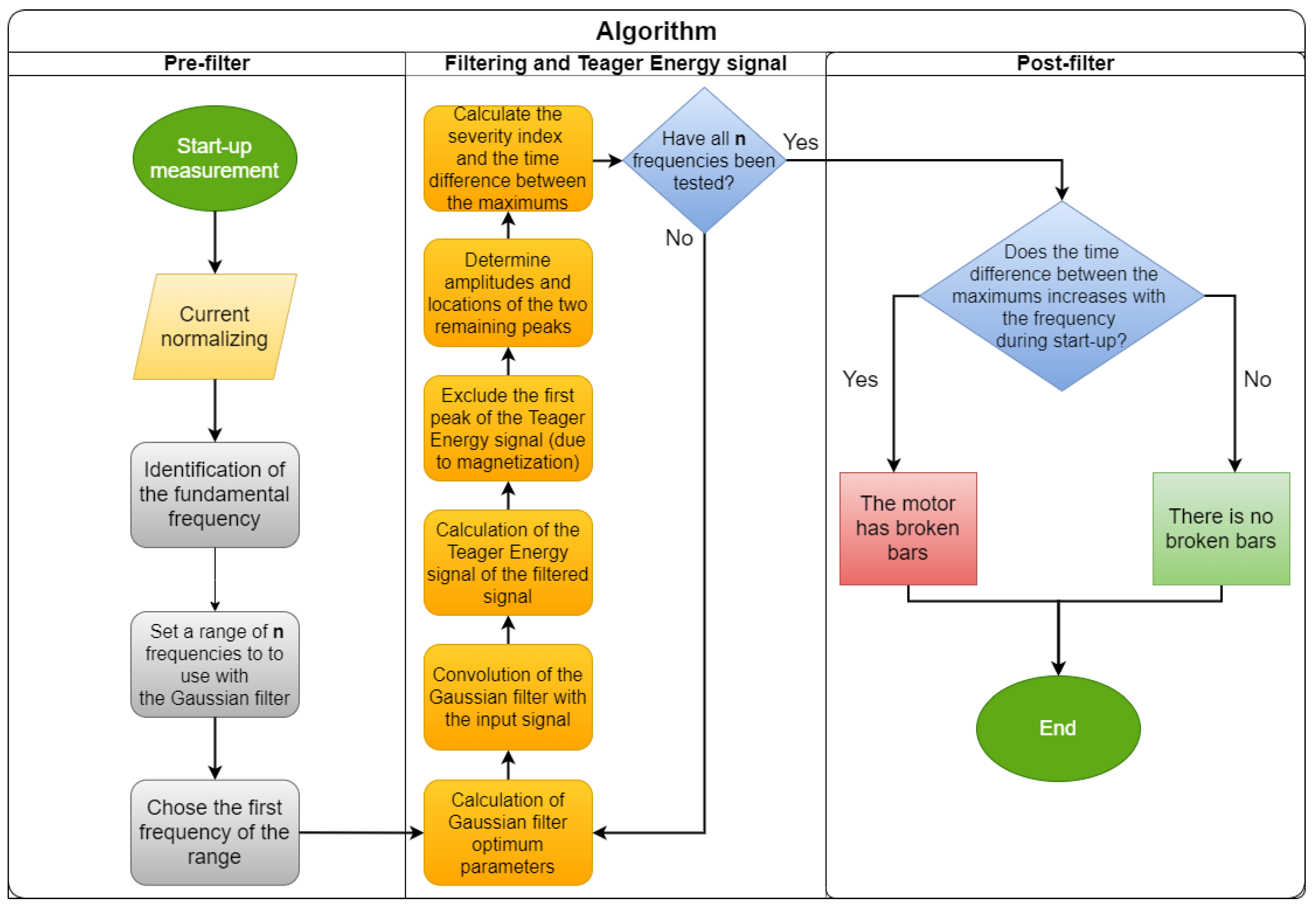

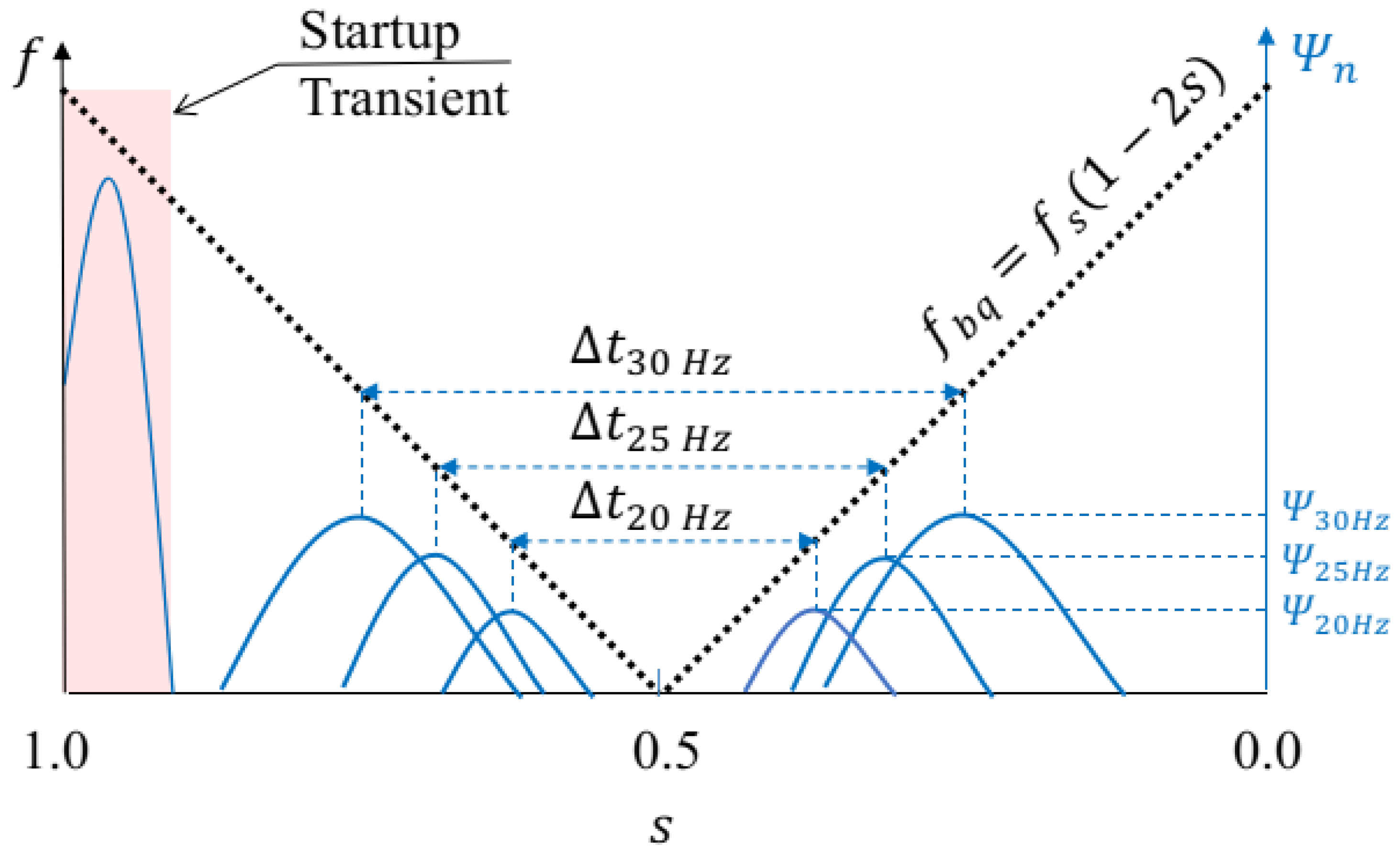

4. Algorithm Development

5. Results

5.1. Qualification

5.2. Quantification

5.2.1. Benchmarking

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Penman, J.; Stavrou, A. Broken rotor bars: Their effect on the transient performance of induction machines. IEE Proc. Electr. Power Appl. 1996, 143, 449–457. [Google Scholar] [CrossRef]

- Thomson, W.T.; Fenger, M. Current signature analysis to detect induction motor faults. IEEE Ind. Appl. Mag. 2001, 7, 26–34. [Google Scholar] [CrossRef]

- Bellini, A.; Filippetti, F.; Franceschini, G.; Tassoni, C.; Kliman, G.B. Quantitative evaluation of induction motor broken bars by means of electrical signature analysis. IEEE Trans. Ind. Appl. 2001, 37, 1248–1255. [Google Scholar] [CrossRef]

- Deleroi, W. Der Stabbruch im Käfiǵläufer eines Asynchronmotors. Arch. Für Elektrotechnik 1984, 67, 91. [Google Scholar] [CrossRef]

- Riera-Guasp, M.; Antonino-Daviu, J.A.; Roger-Folch, J.; Molina Palomares, P.M. The use of the wavelet approximation signal as a tool for the diagnosis of rotor bar failures. IEEE Trans. Ind. Appl. 2008, 44, 716–726. [Google Scholar] [CrossRef] [Green Version]

- Baranov, G.D.; Nepomuceno, E.G.; Vaganov, M.A.; Ostrovskii, V.Y.; Butusov, D.N. New spectral markers for broken bars diagnostics in induction motors. Machines 2020, 8, 6. [Google Scholar] [CrossRef] [Green Version]

- Douglas, H.; Pillay, P.; Ziarani, A.K. Broken rotor bar detection in induction machines with transient operating speeds. IEEE Trans. Energy Convers. 2005, 20, 135–141. [Google Scholar] [CrossRef]

- Watson, J.F.; Paterson, N.C. Improved techniques for rotor fault detection in three-phase induction motors. In Proceedings of the Conference Record of 1998 IEEE Industry Applications Conference, Thirty-Third IAS Annual Meeting (Cat. No. 98CH36242), St. Louis, MO, USA, 12–15 October 1998; Volume 1, pp. 271–277. [Google Scholar]

- Burriel-Valencia, J.; Puche-Panadero, R.; Martinez-Roman, J.; Sapena-Bano, A.; Pineda-Sanchez, M. Short-Frequency Fourier Transform for Fault Diagnosis of Induction Machines Working in Transient Regime. IEEE Trans. Instrum. Meas. 2017, 66, 432–440. [Google Scholar] [CrossRef] [Green Version]

- Gyftakis, K.N.; Spyropoulos, D.V.; Arvanitakis, I.; Panagiotou, P.A.; Mitronikas, E.D. Induction motors torque analysis via frequency extraction for reliable broken rotor bar detection. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; pp. 1468–1474. [Google Scholar] [CrossRef]

- Sinha, A.K.; Hati, A.S.; Benbouzid, M.; Chakrabarti, P. Ann-based pattern recognition for induction motor broken rotor bar monitoring under supply frequency regulation. Machines 2021, 9, 87. [Google Scholar] [CrossRef]

- Morinigo-Sotelo, D.; Romero-Troncoso, R.D.J.; Panagiotou, P.A.; Antonino-Daviu, J.A.; Gyftakis, K.N. Reliable Detection of Rotor Bars Breakage in Induction Motors via MUSIC and ZSC. IEEE Trans. Ind. Appl. 2018, 54, 1224–1234. [Google Scholar] [CrossRef]

- Pons-Llinares, J.; Riera-Guasp, M.; Antonino-Daviu, J.A.; Habetler, T.G. Pursuing optimal electric machines transient diagnosis: The adaptive slope transform. Mech. Syst. Signal Process. 2016, 80, 553–569. [Google Scholar] [CrossRef]

- Fernandez-Cavero, V.; Pons-Llinares, J.; Duque-Perez, O.; Morinigo-Sotelo, D. Detection of Broken Rotor Bars in Nonlinear Startups of Inverter-Fed Induction Motors. IEEE Trans. Ind. Appl. 2021, 57, 2559–2568. [Google Scholar] [CrossRef]

- Lizarraga-Morales, R.A.; Rodriguez-Donate, C.; Cabal-Yepez, E.; Lopez-Ramirez, M.; Ledesma-Carrillo, L.M.; Ferrucho-Alvarez, E.R. Novel FPGA-based methodology for early broken rotor bar detection and classification through homogeneity estimation. IEEE Trans. Instrum. Meas. 2017, 66, 1760–1769. [Google Scholar] [CrossRef]

- Abid, A.; Khan, M.T.; Lang, H.; De Silva, C.W. Adaptive system identification and severity index-based fault diagnosis in motors. IEEE/ASME Trans. Mechatronics 2020, 24, 1628–1639. [Google Scholar] [CrossRef]

- Valtierra-Rodriguez, M.; Rivera-Guillen, J.R.; Basurto-Hurtado, J.A.; Jesus De-Santiago-Perez, J.; Granados-Lieberman, D.; Amezquita-Sanchez, J.P. Convolutional neural network and motor current signature analysis during the transient state for detection of broken rotor bars in induction motors. Sensors 2020, 20, 3721. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Ramirez, M.; Ledesma-Carrillo, L.M.; Garcia-Guevara, F.M.; Munoz-Minjares, J.; Cabal-Yepez, E.; Villalobos-Pina, F.J. Automatic Early Broken-Rotor-Bar Detection and Classification Using Otsu Segmentation. IEEE Access 2020, 8, 112624–112632. [Google Scholar] [CrossRef]

- Concari, C.; Franceschini, G.; Tassoni, C. Monitoring of rotor cage conditions in induction machines by instantaneous reactive power and current space vector’s reactive component. In Proceedings of the 2009 IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Cargese, France, 31 August–3 September 2009; pp. 1–7. [Google Scholar] [CrossRef]

- Didier, G.; Ternisien, E.; Caspary, O.; Razik, H. Fault detection of broken rotor bars in induction motor using a global fault index. IEEE Trans. Ind. Appl. 2006, 42, 79–88. [Google Scholar] [CrossRef] [Green Version]

- Janeiro, F.M.; Martins, J.F.; Pires, V.F.; Ramos, P.M.; Pires, A.J. Induction Motor Broken Bars Online Detection. In Proceedings of the 2008 IEEE Instrumentation and Measurement Technology Conference, Victoria, BC, Canada, 12–15 May 2008; Volume 2, pp. 2137–2140. [Google Scholar] [CrossRef]

- El-Dine Atta, M.E.; Ibrahim, D.K.; Gilany, M.I. Broken Bar Faults Detection under Induction Motor Starting Conditions Using the Optimized Stockwell Transform and Adaptive Time-Frequency Filter. IEEE Trans. Instrum. Meas. 2021, 70, 3518110. [Google Scholar] [CrossRef]

- Lee, S.B.; Stone, G.C.; Antonino-Daviu, J.; Gyftakis, K.N.; Strangas, E.G.; Maussion, P.; Platero, C.A. Condition Monitoring of Industrial Electric Machines: State of the Art and Future Challenges. IEEE Ind. Electron. Mag. 2020, 14, 158–167. [Google Scholar] [CrossRef]

- Didier, G.; Ternisien, E.; Caspary, O.; Razik, H. A new approach to detect broken rotor bars in induction machines by current spectrum analysis. Mech. Syst. Signal Process. 2007, 21, 1127–1142. [Google Scholar] [CrossRef] [Green Version]

- Kaiser, J.F. On a simple algorithm to calculate the ‘energy’ of a signal. In Proceedings of the International Conference on Acoustics, Speech, and Signal Processing, Albuquerque, NM, USA, 3–6 April 1990; Volume 1, pp. 381–384. [Google Scholar] [CrossRef]

- Bellini, A.; Filippetti, F.; Franceschini, F.; Sobczyk, T.J.; Tassoni, C. Diagnosis of induction machines by d-q and i.s.c. rotor models. In Proceedings of the 2005 5th IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Vienna, Austria, 7–9 September 2005; pp. 7–9. [Google Scholar] [CrossRef]

| Rotor | (s) | (s) | (s) | |

|---|---|---|---|---|

| HEALTHY | 20 | 0.250 | 0.690 | 0.439 |

| HEALTHY | 25 | 0.220 | 0.280 | 0.064 |

| HEALTHY | 30 | 0.280 | 0.460 | 0.186 |

| ½ BAR | 20 | 0.270 | 0.420 | 0.158 |

| ½ BAR | 25 | 0.250 | 0.450 | 0.197 |

| ½ BAR | 30 | 0.180 | 0.470 | 0.284 |

| 1 BAR | 20 | 0.280 | 0.450 | 0.178 |

| 1 BAR | 25 | 0.230 | 0.480 | 0.247 |

| 1 BAR | 30 | 0.200 | 0.500 | 0.296 |

| 2 BAR 180 | 20 | 0.240 | 0.480 | 0.244 |

| 2 BAR 180 | 25 | 0.230 | 0.500 | 0.271 |

| 2 BAR 180 | 30 | 0.200 | 0.520 | 0.324 |

| 2 BAR 90 | 20 | 0.260 | 0.480 | 0.226 |

| 2 BAR 90 | 25 | 0.230 | 0.500 | 0.274 |

| 2 BAR 90 | 30 | 0.210 | 0.530 | 0.316 |

| 2 BAR | 20 | 0.270 | 0.490 | 0.219 |

| 2 BAR | 25 | 0.230 | 0.510 | 0.277 |

| 2 BAR | 30 | 0.210 | 0.540 | 0.330 |

| Rotor | |||

|---|---|---|---|

| HEALTHY | 8.249 × 10−10 | 9.424 × 10−10 | 8.837 × 10−10 |

| ½ BAR | 5.835 × 10−9 | 4.523 × 10−8 | 2.553 × 10−8 |

| 1 BAR | 4.169 × 10−7 | 3.948 × 10−7 | 4.058 × 10−7 |

| 2 BAR 180 | 1.515 × 10−6 | 1.413 × 10−6 | 1.464 × 10−6 |

| 2 BAR 90 | 1.625 × 10−6 | 1.402 × 10−6 | 1.514 × 10−6 |

| 2 BAR | 2.572 × 10−6 | 2.369 × 10−6 | 2.471 × 10−6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Souza, M.V.; Lima, J.C.O.; Roque, A.M.P.; Riffel, D.B. A Novel Algorithm to Detect Broken Bars in Induction Motors. Machines 2021, 9, 250. https://doi.org/10.3390/machines9110250

Souza MV, Lima JCO, Roque AMP, Riffel DB. A Novel Algorithm to Detect Broken Bars in Induction Motors. Machines. 2021; 9(11):250. https://doi.org/10.3390/machines9110250

Chicago/Turabian StyleSouza, Mateus Ventura, José Claudeni Oliveira Lima, Alexandre Magno Pinto Roque, and Douglas Bressan Riffel. 2021. "A Novel Algorithm to Detect Broken Bars in Induction Motors" Machines 9, no. 11: 250. https://doi.org/10.3390/machines9110250

APA StyleSouza, M. V., Lima, J. C. O., Roque, A. M. P., & Riffel, D. B. (2021). A Novel Algorithm to Detect Broken Bars in Induction Motors. Machines, 9(11), 250. https://doi.org/10.3390/machines9110250